Non-Destructive Testing Applications for Steel Bridges

Abstract

:1. Introduction

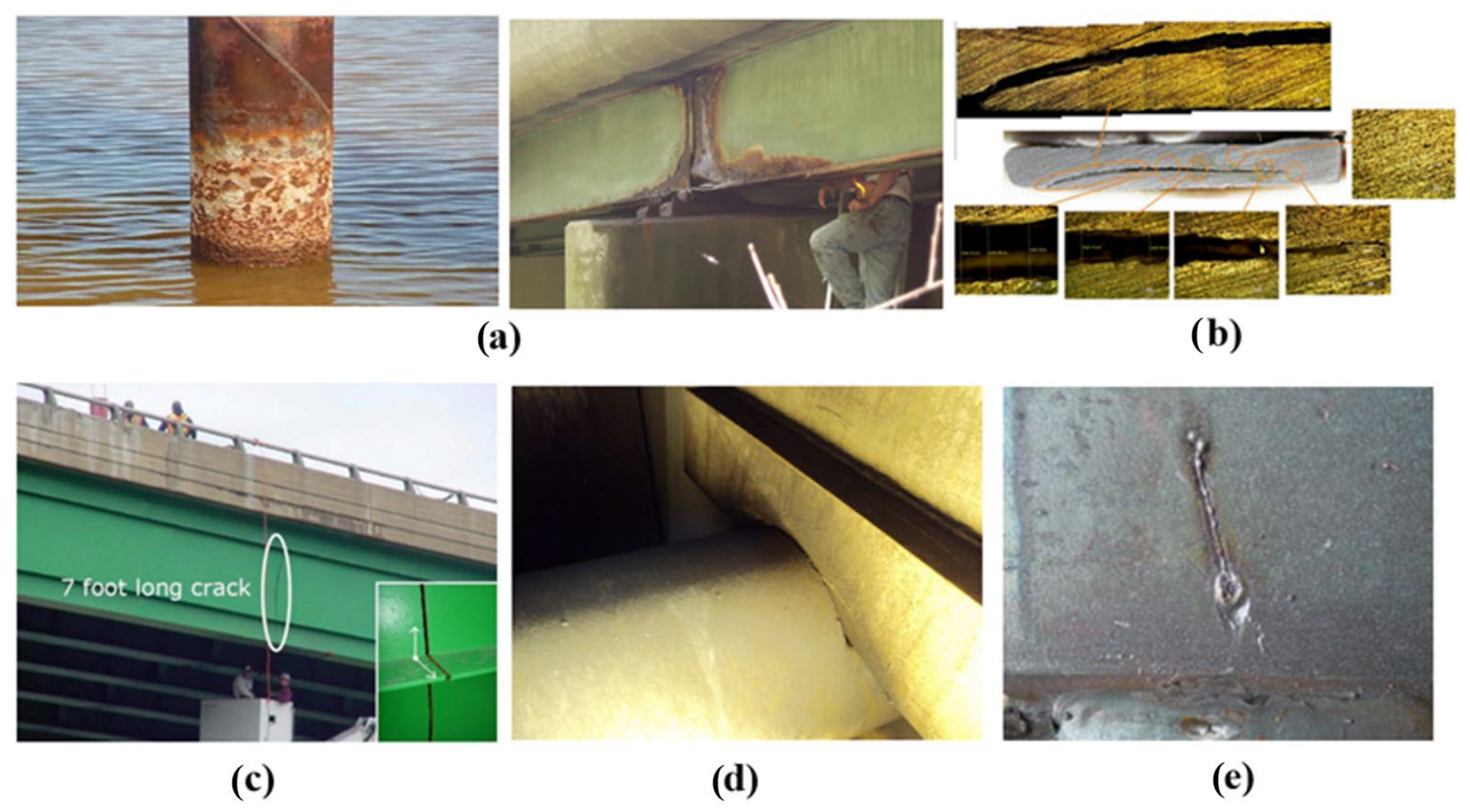

2. Need for Inspection of Steel Bridges

3. NDT Methods with Potential Application to Steel Bridges

3.1. Test Methods Applicable Only to External/Surface Defects

3.1.1. Visual Testing (VT)

3.1.2. Dye Penetrant Testing (PT)

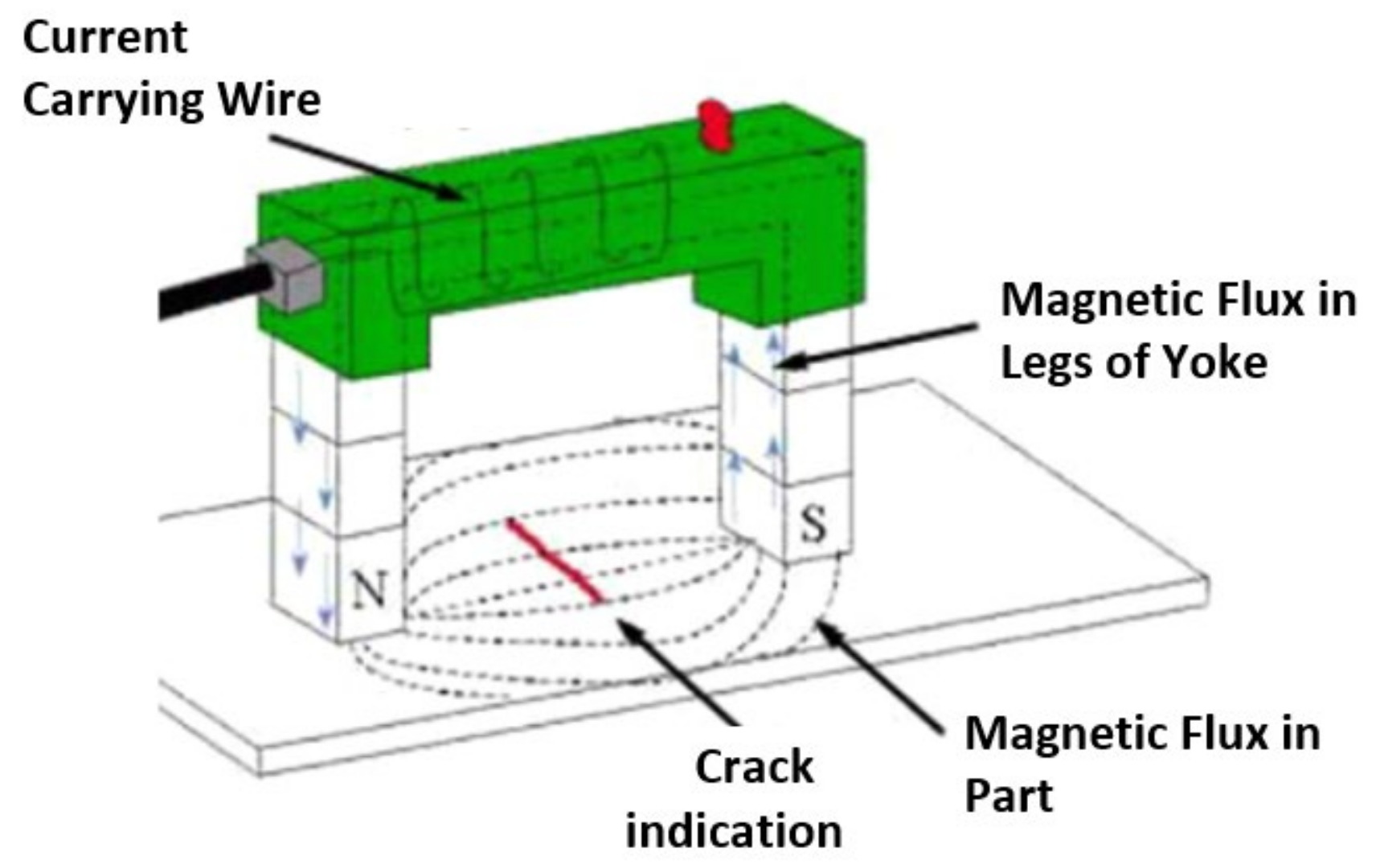

3.1.3. Magnetic Particle Testing (MT)

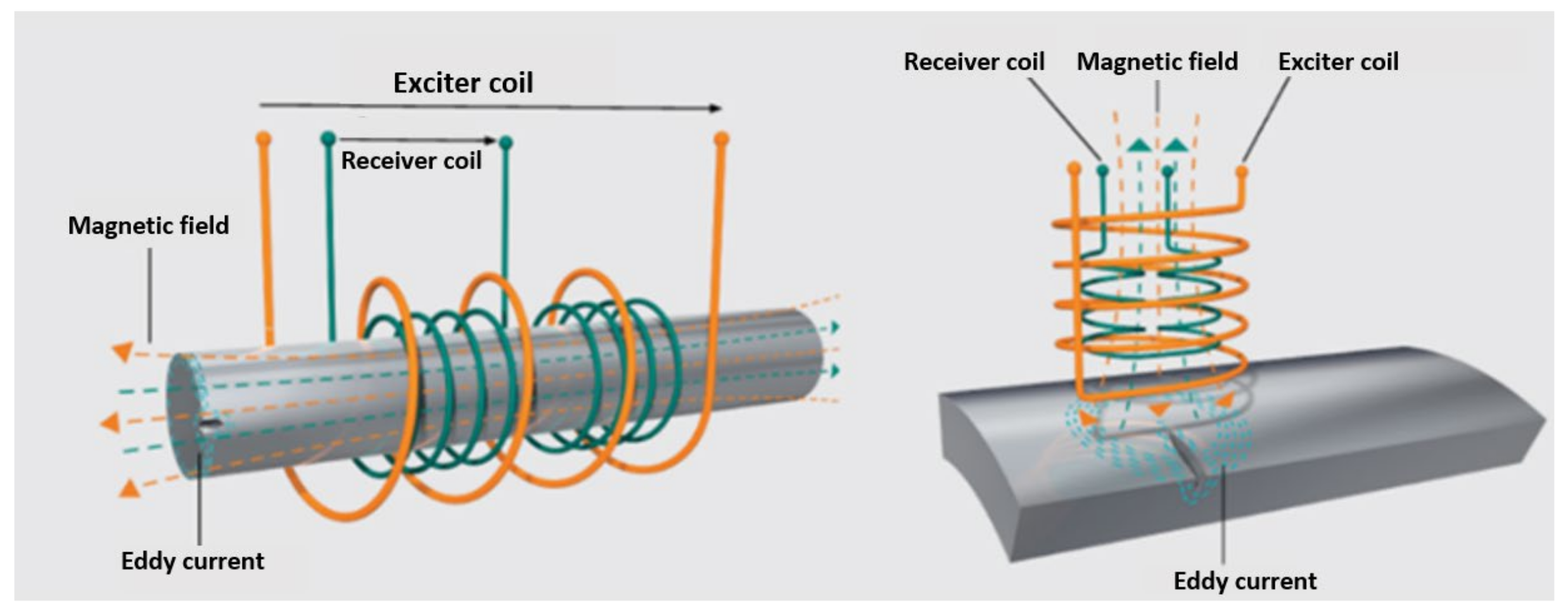

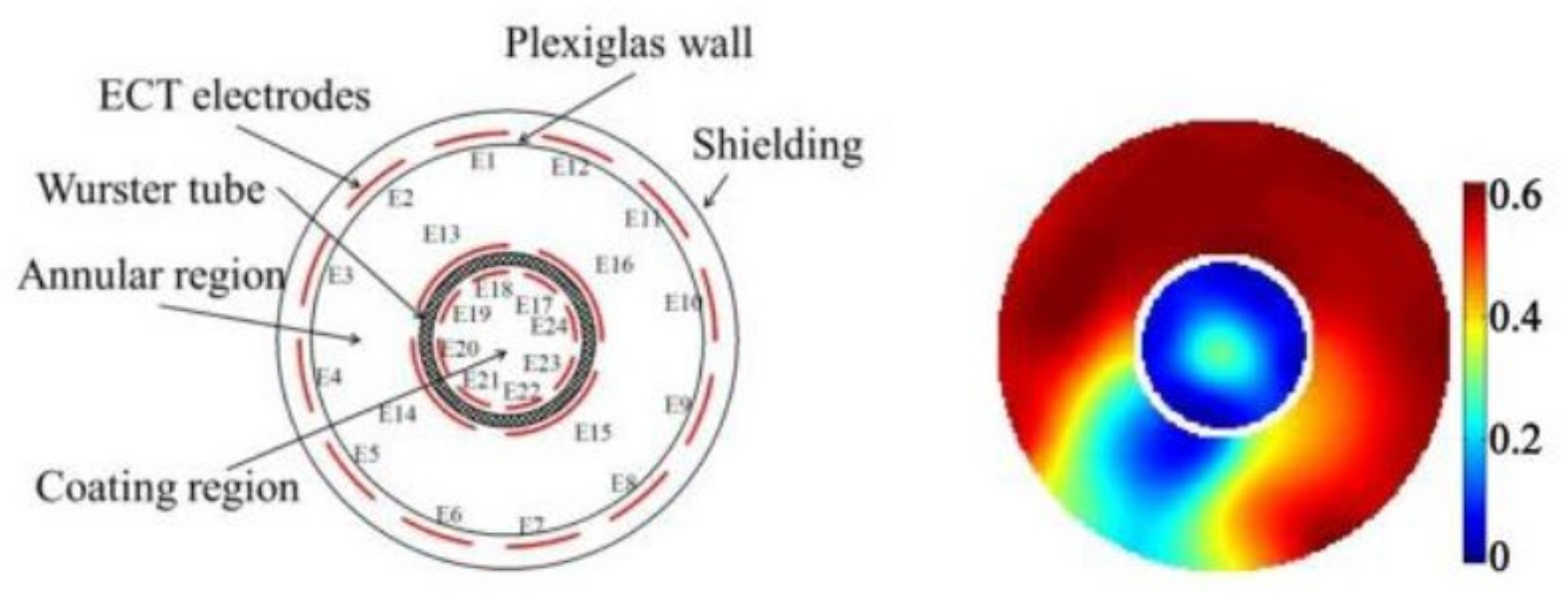

3.1.4. Eddy Current Method (EC)

3.2. Test Methods Applicable to Internal/Subsurface Defects

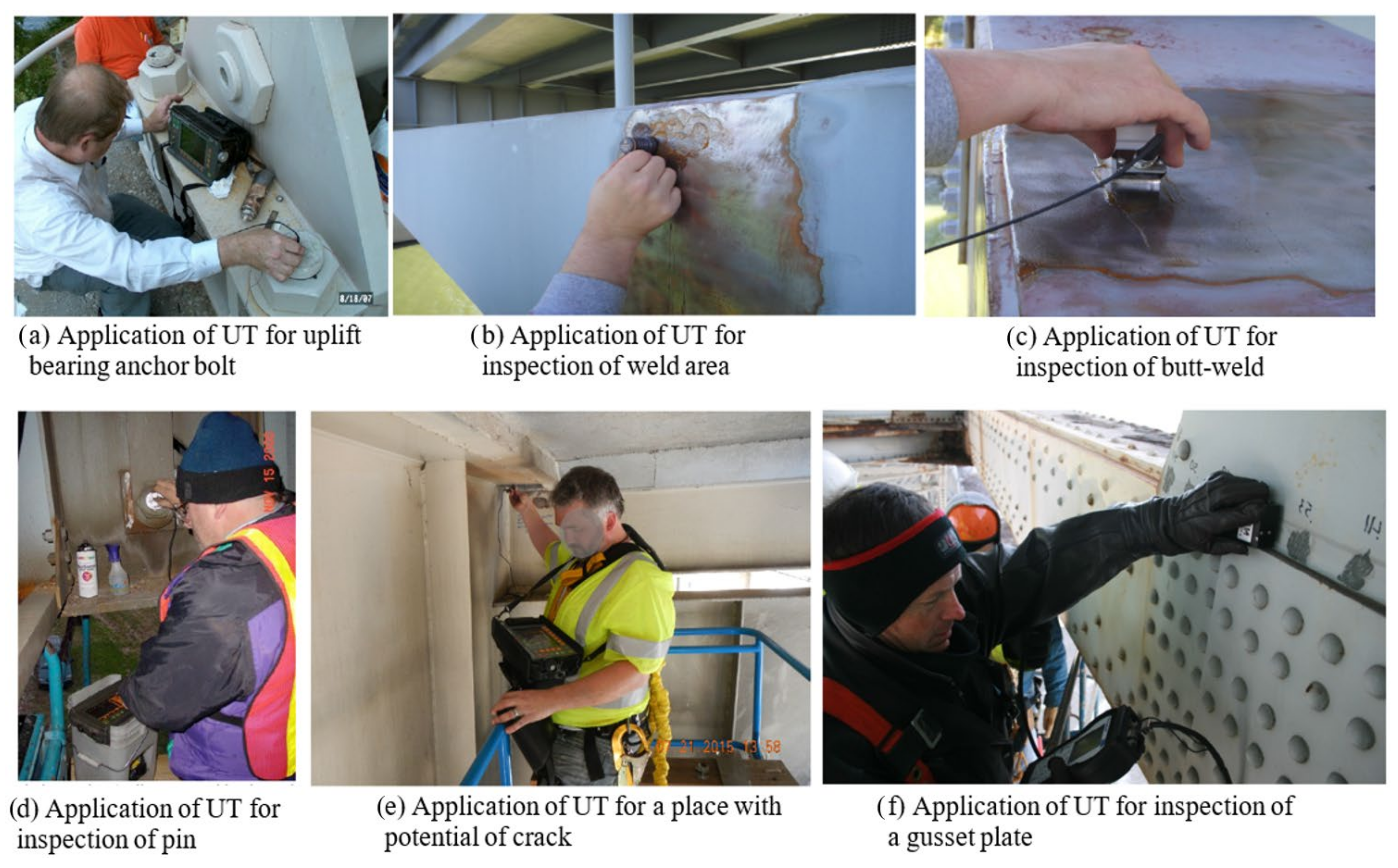

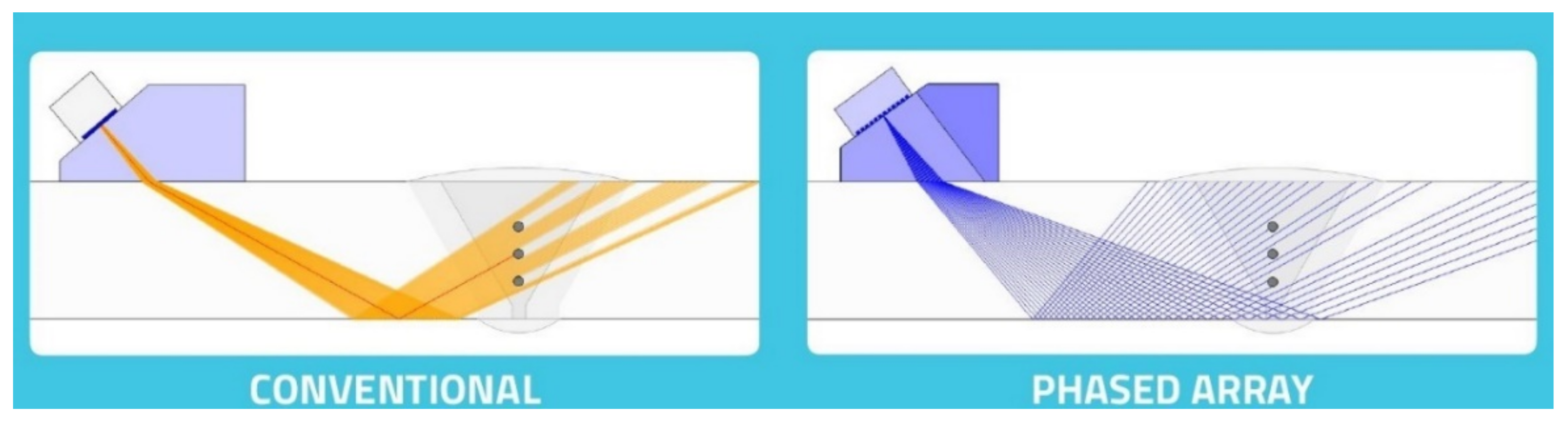

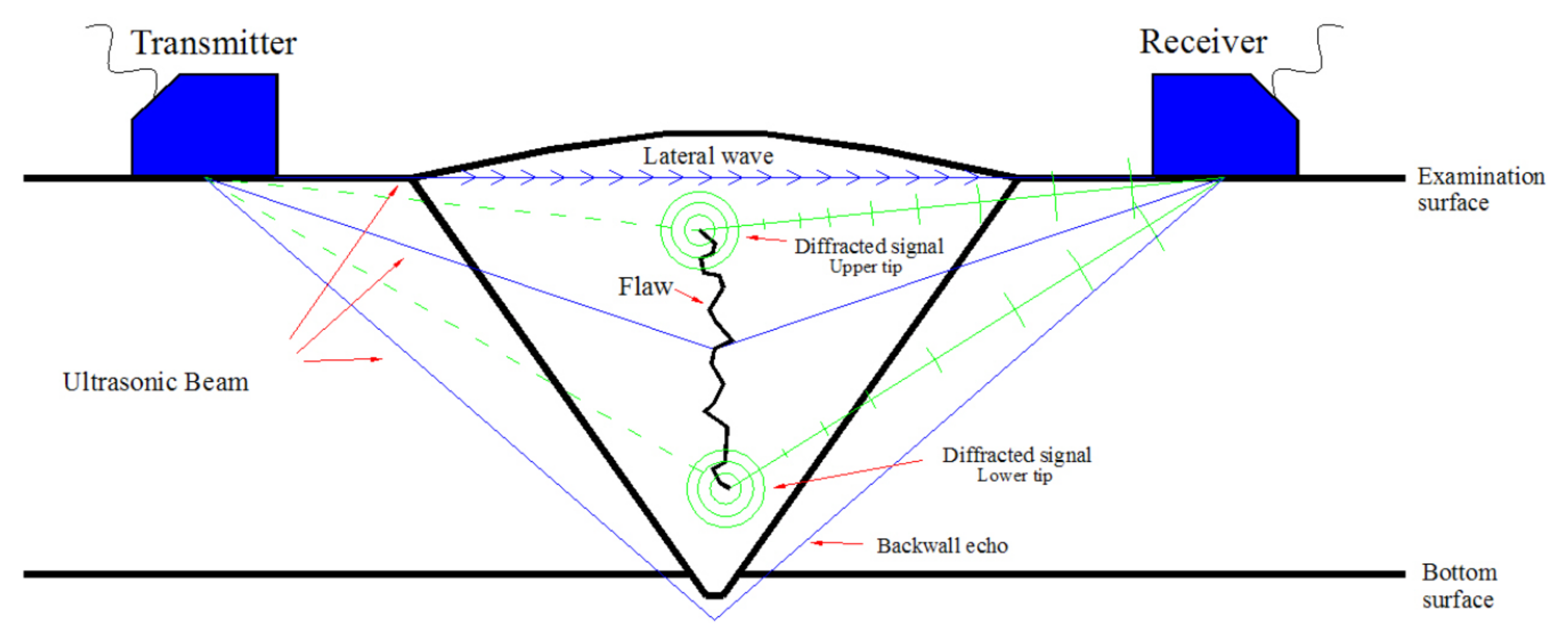

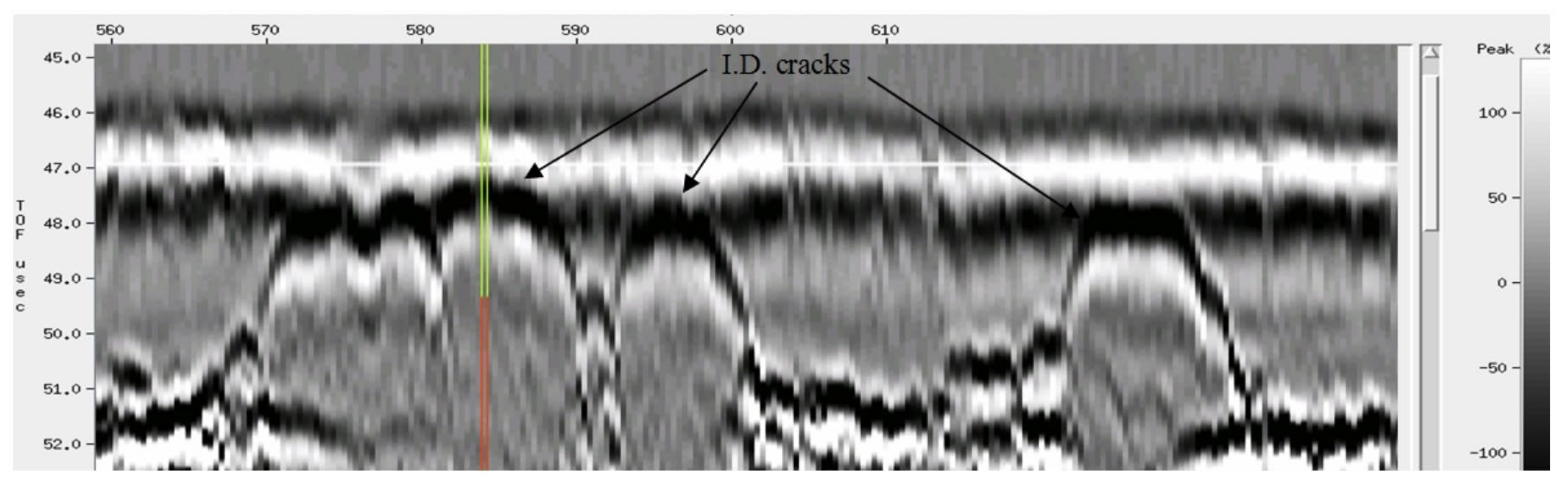

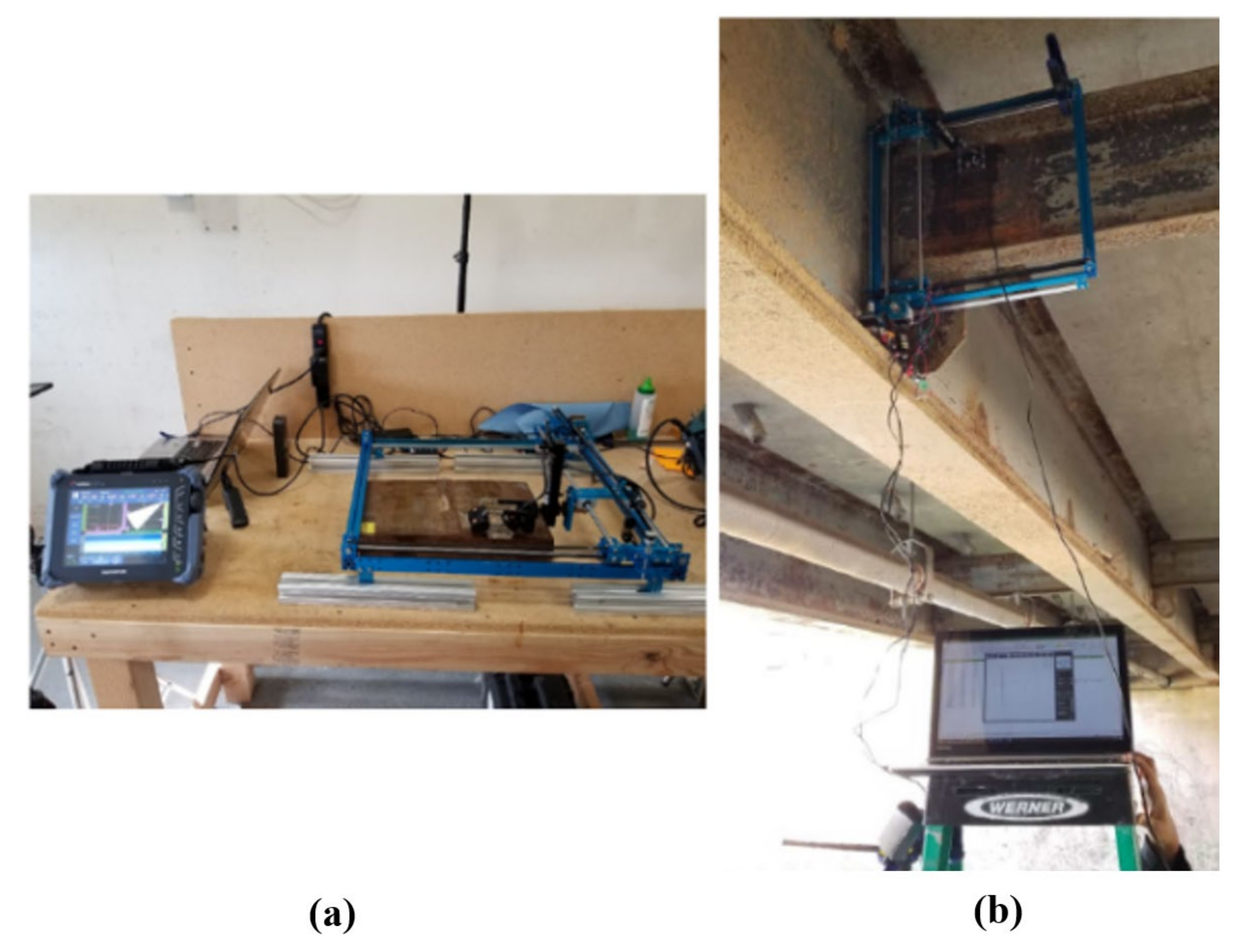

3.2.1. Ultrasonic Testing (UT)

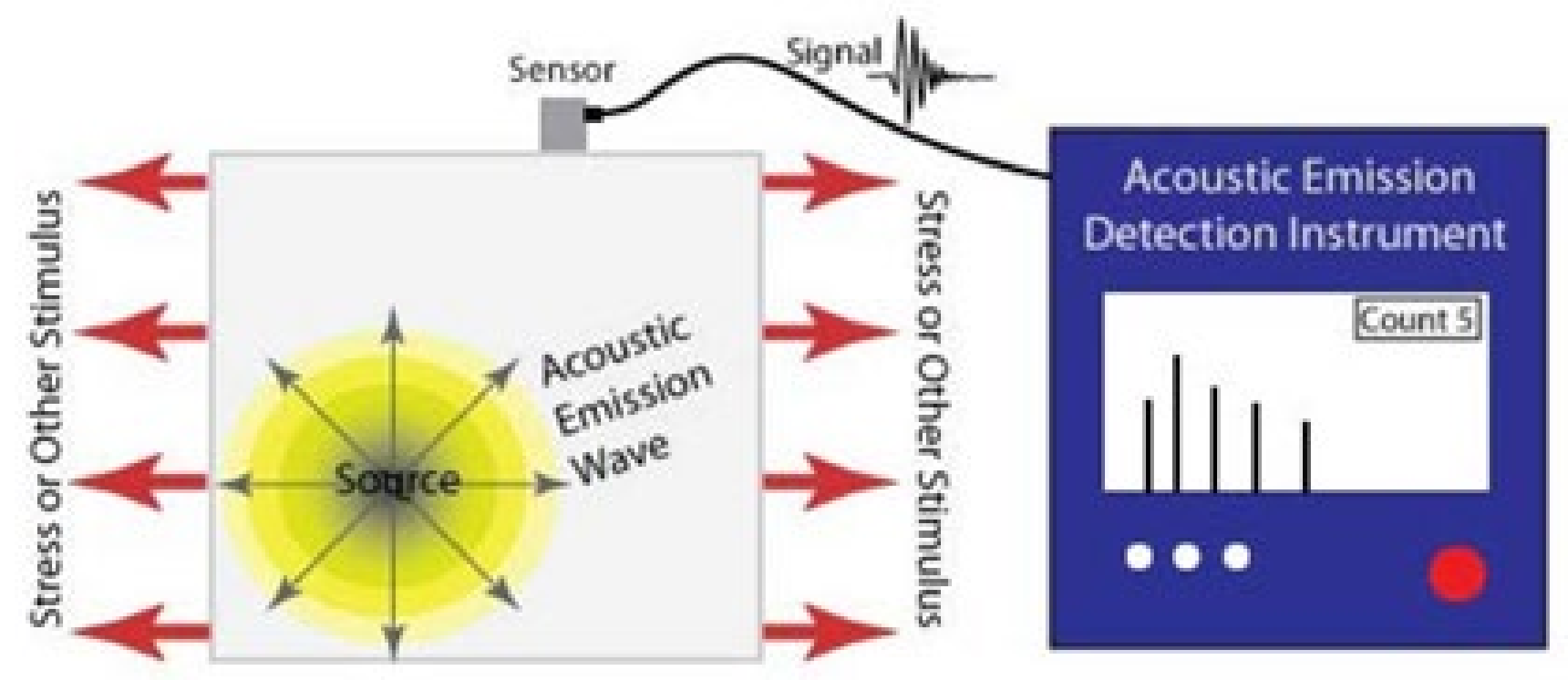

3.2.2. Acoustic Emission Testing (AE)

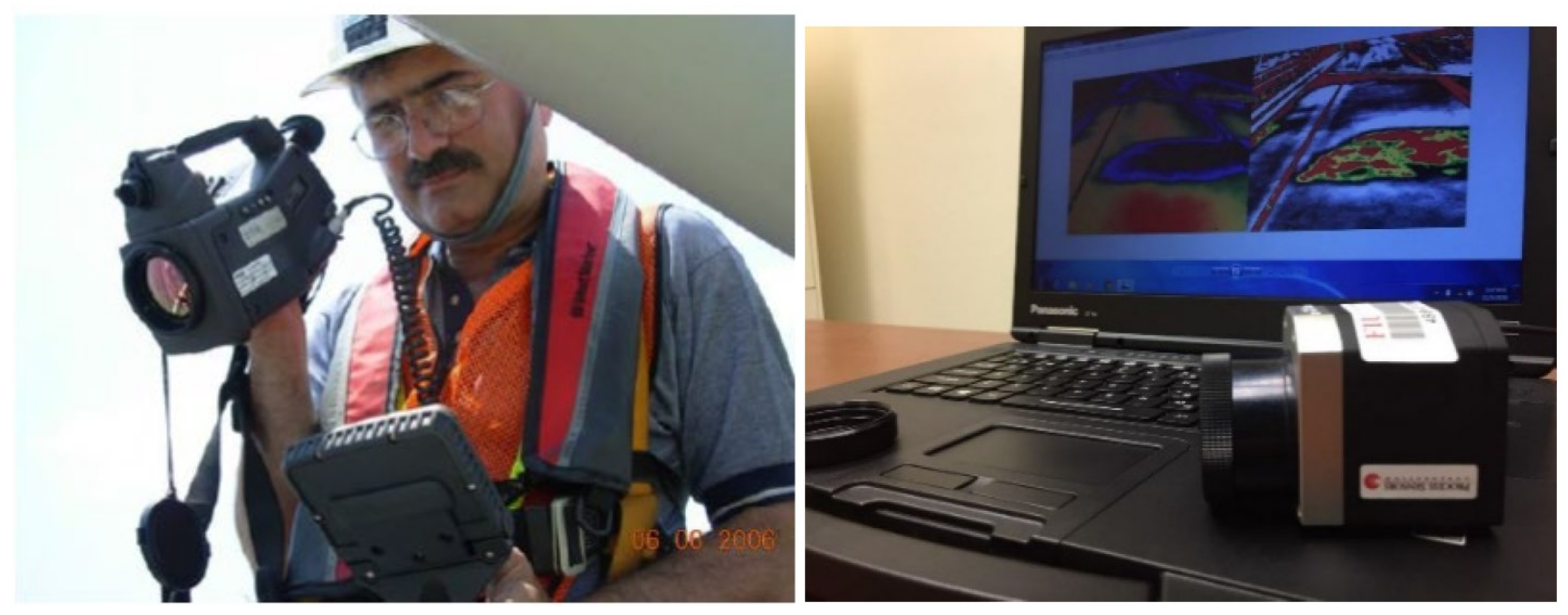

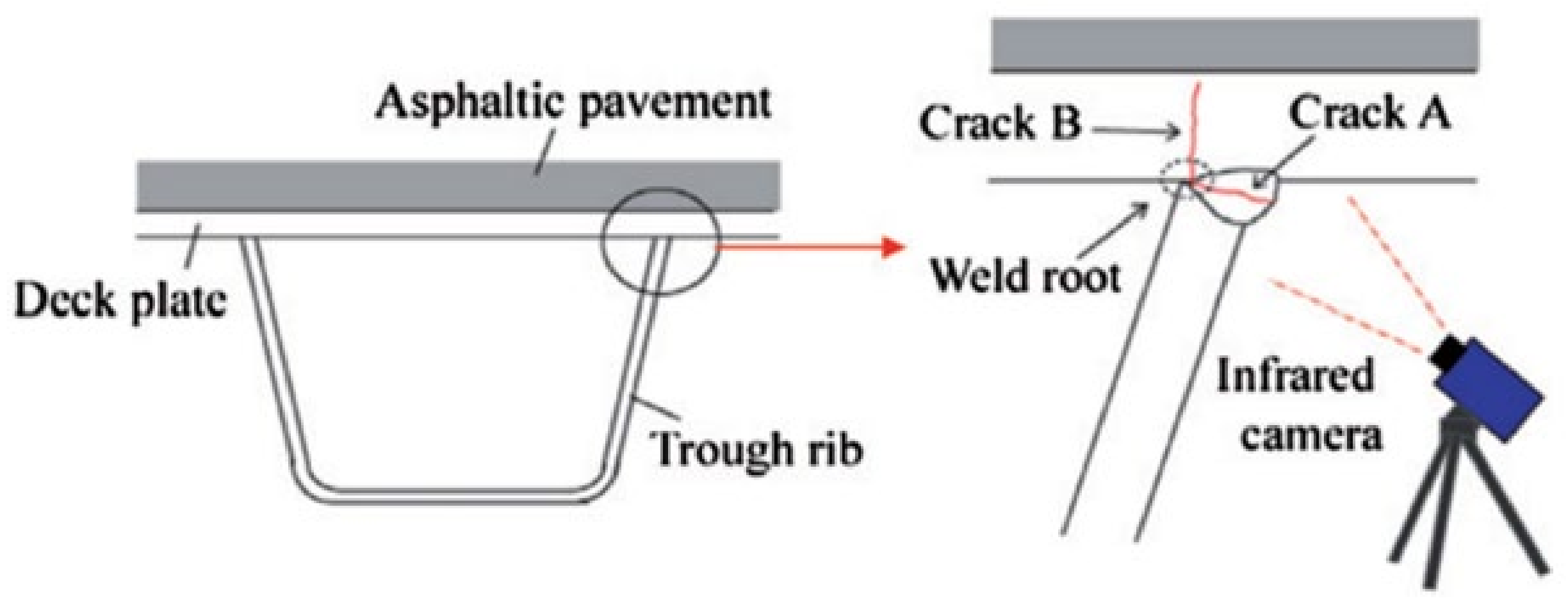

3.2.3. Infrared Thermography Testing (IT)

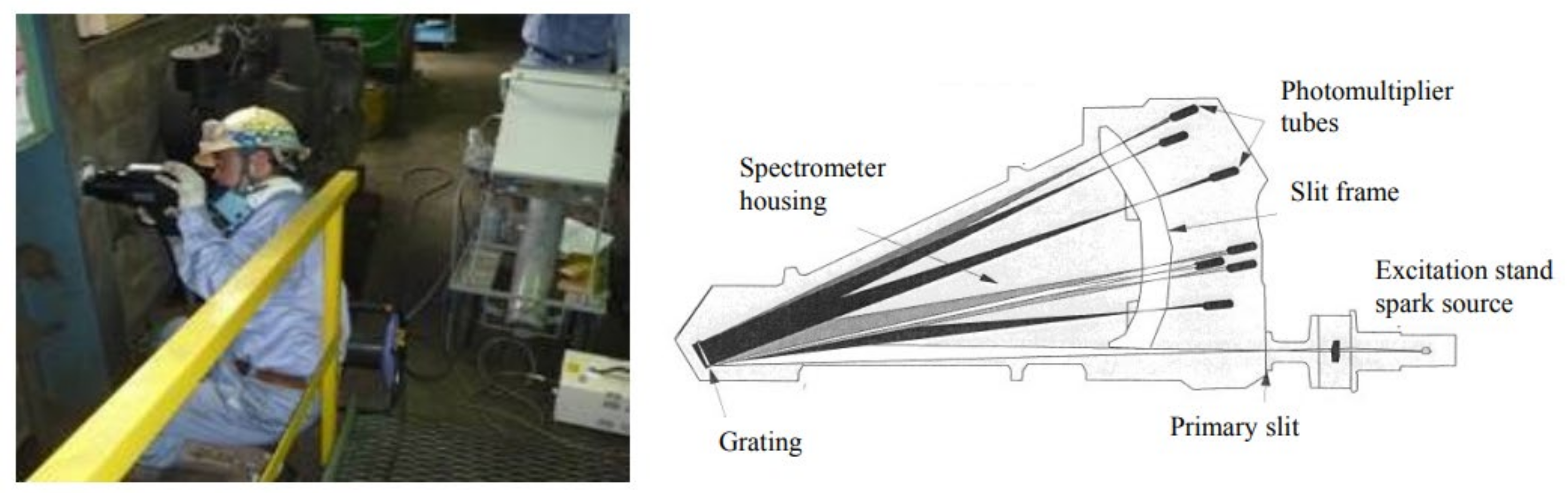

3.2.4. Radiographic Testing (RT)

3.2.5. Laser Testing Method (LT)

3.3. Test Methods Applicable to Structural Steel Cables, Tendons, and Ropes

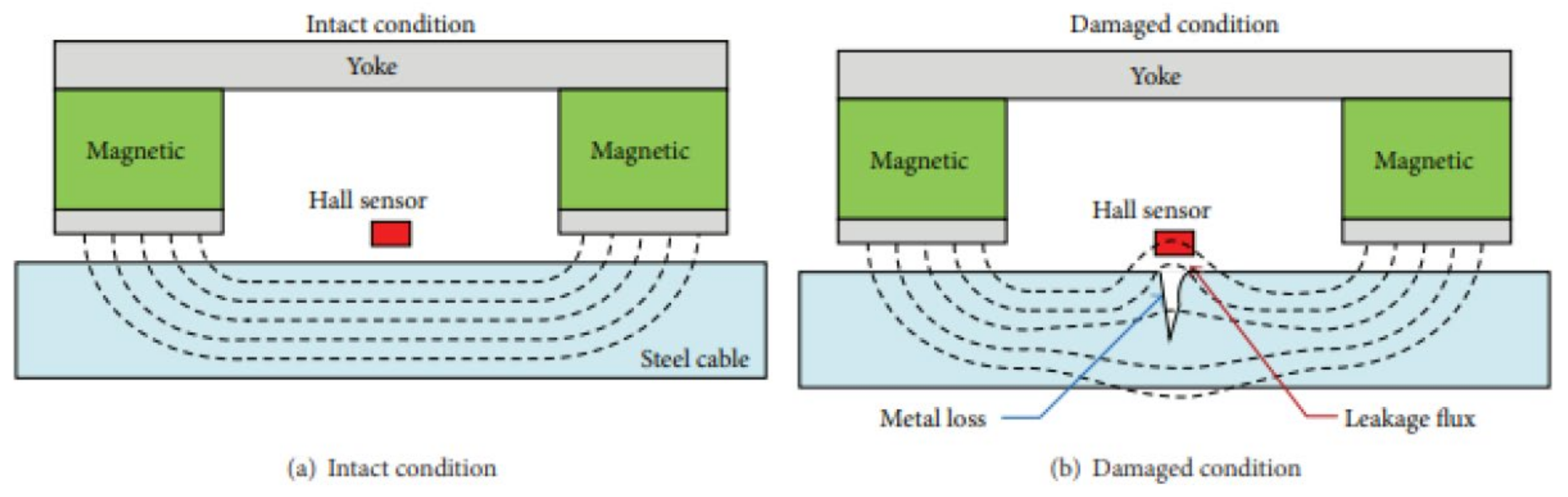

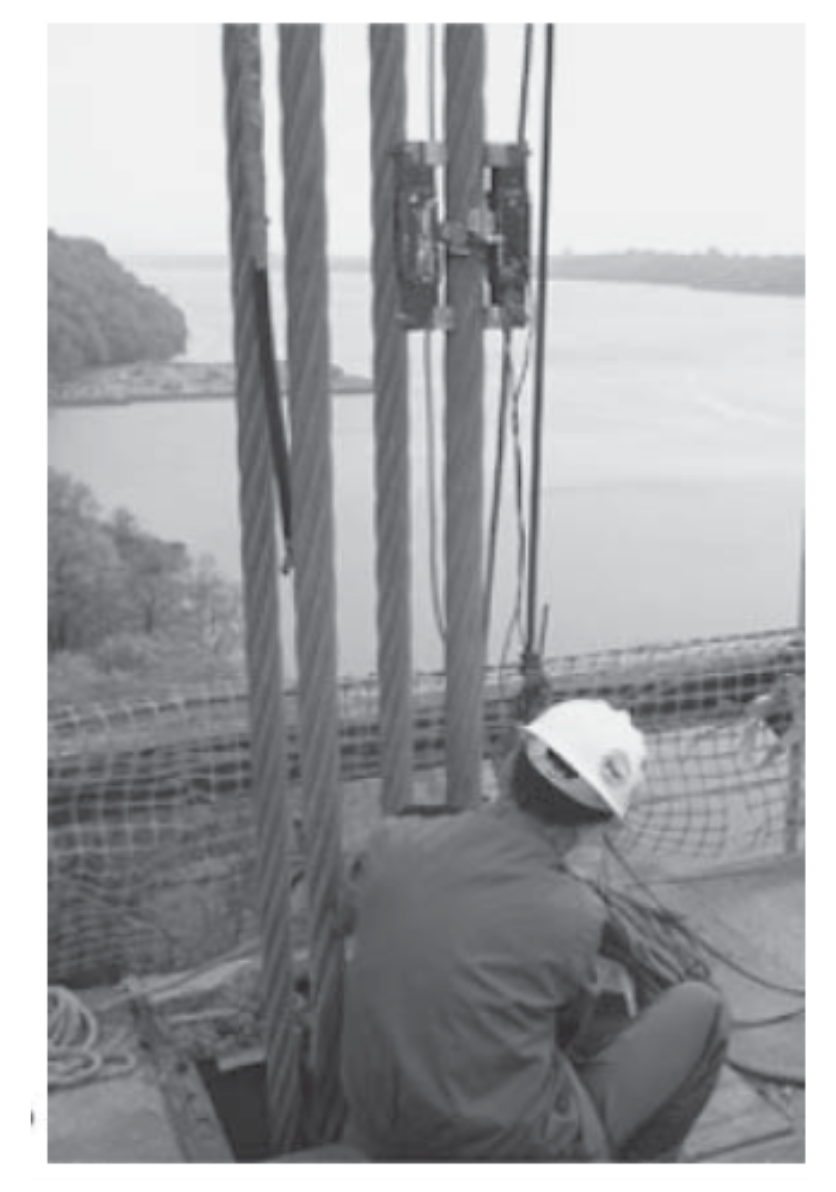

3.3.1. Magnetic Flux Leakage Testing (MFL)

3.3.2. Magnetostriction

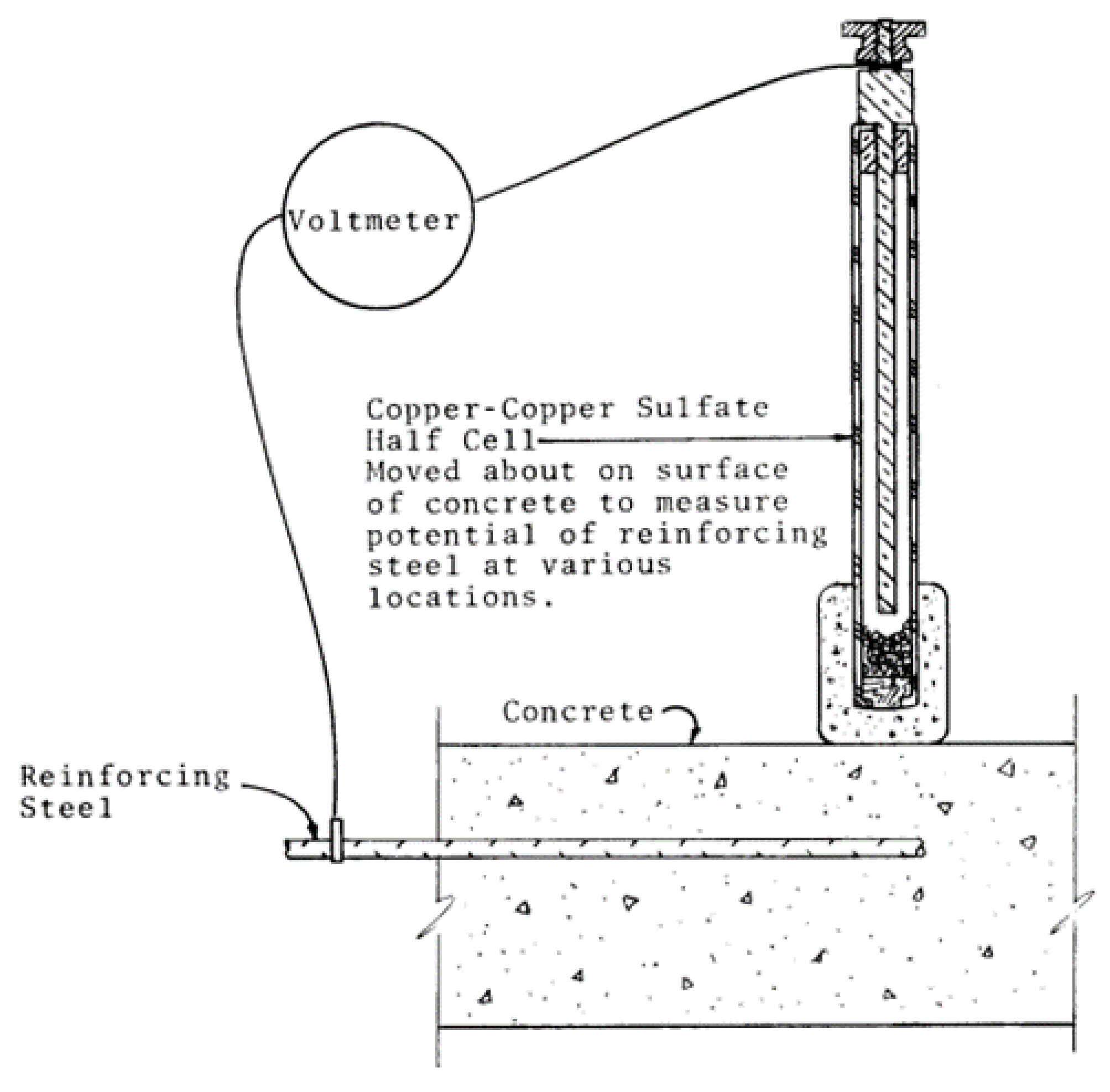

3.3.3. Chemical and Electrical Testing (CET)

3.3.4. Vibration Method for Detecting Cross-Section Loss

4. New and Developing Methods

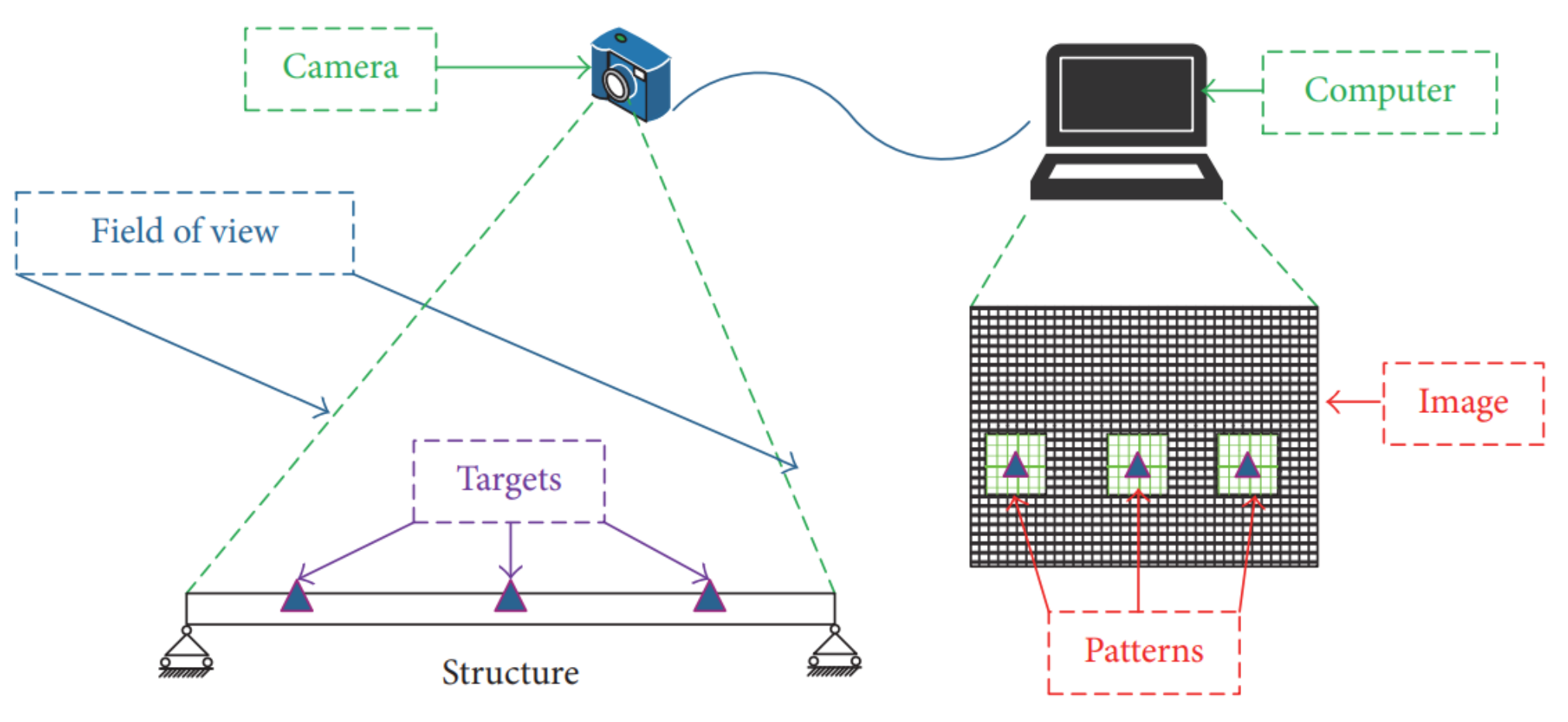

4.1. Vision-Based Inspection Methods

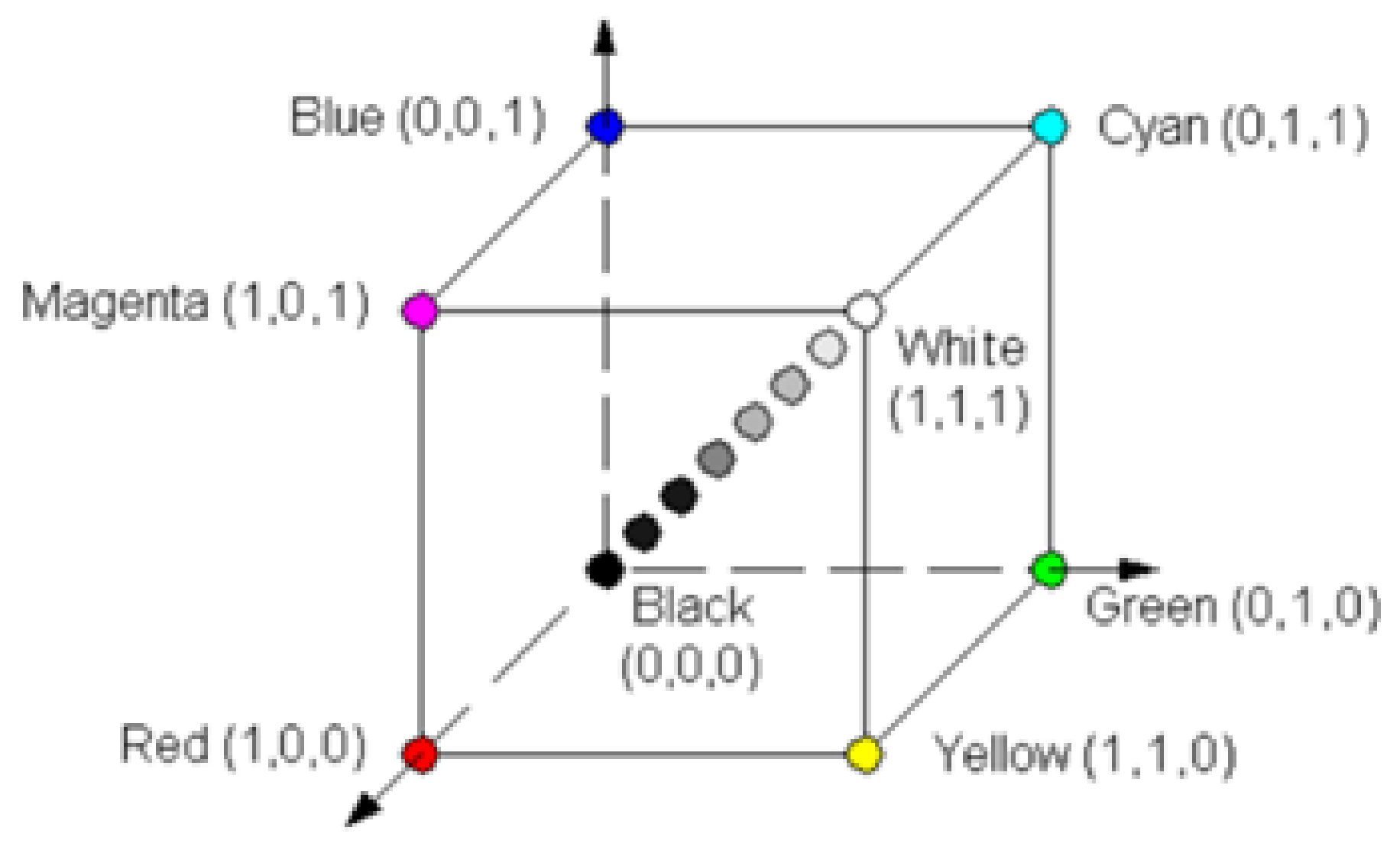

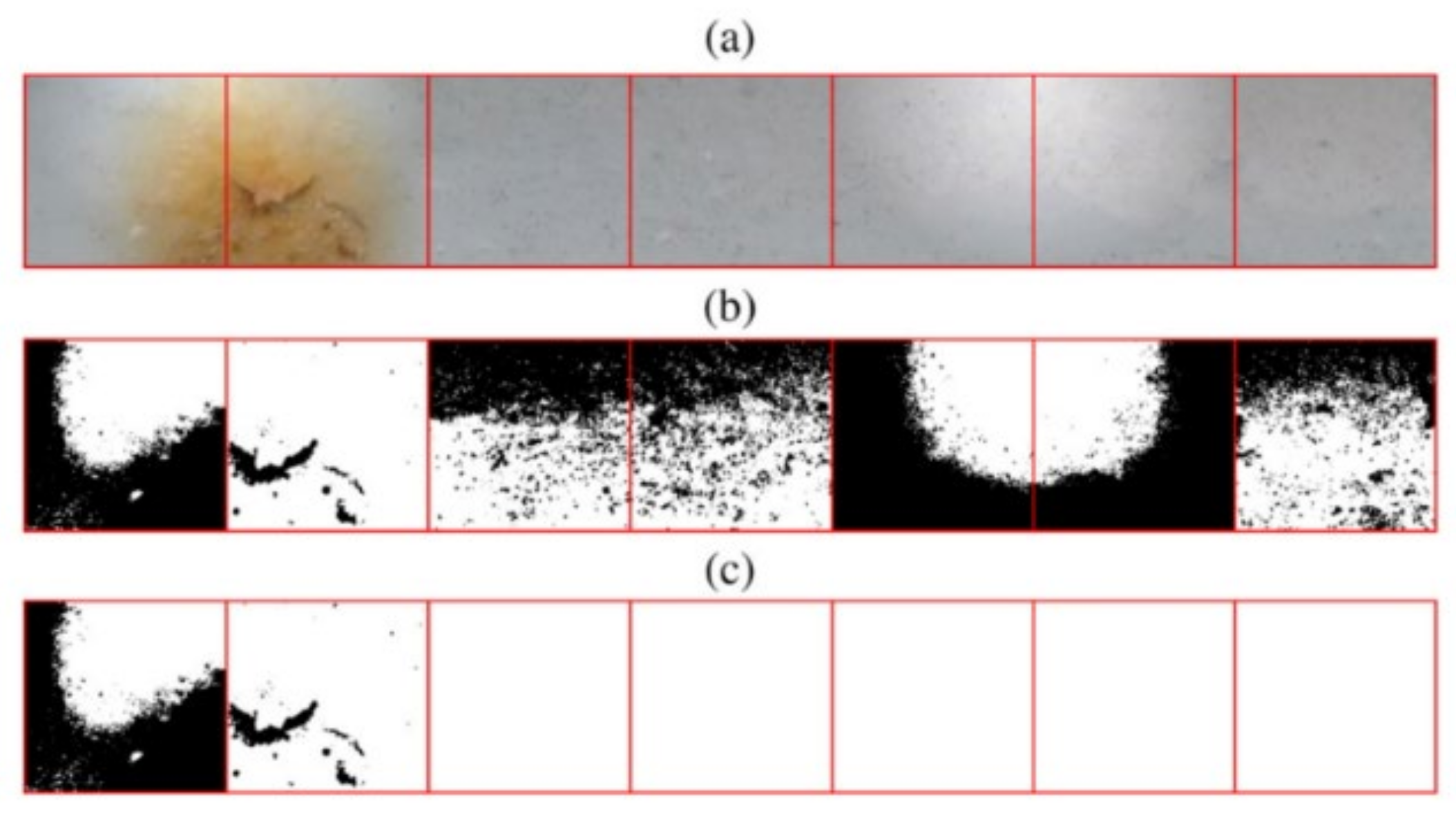

4.2. Digital Image Processing Method

5. Complementary to NDT Methods

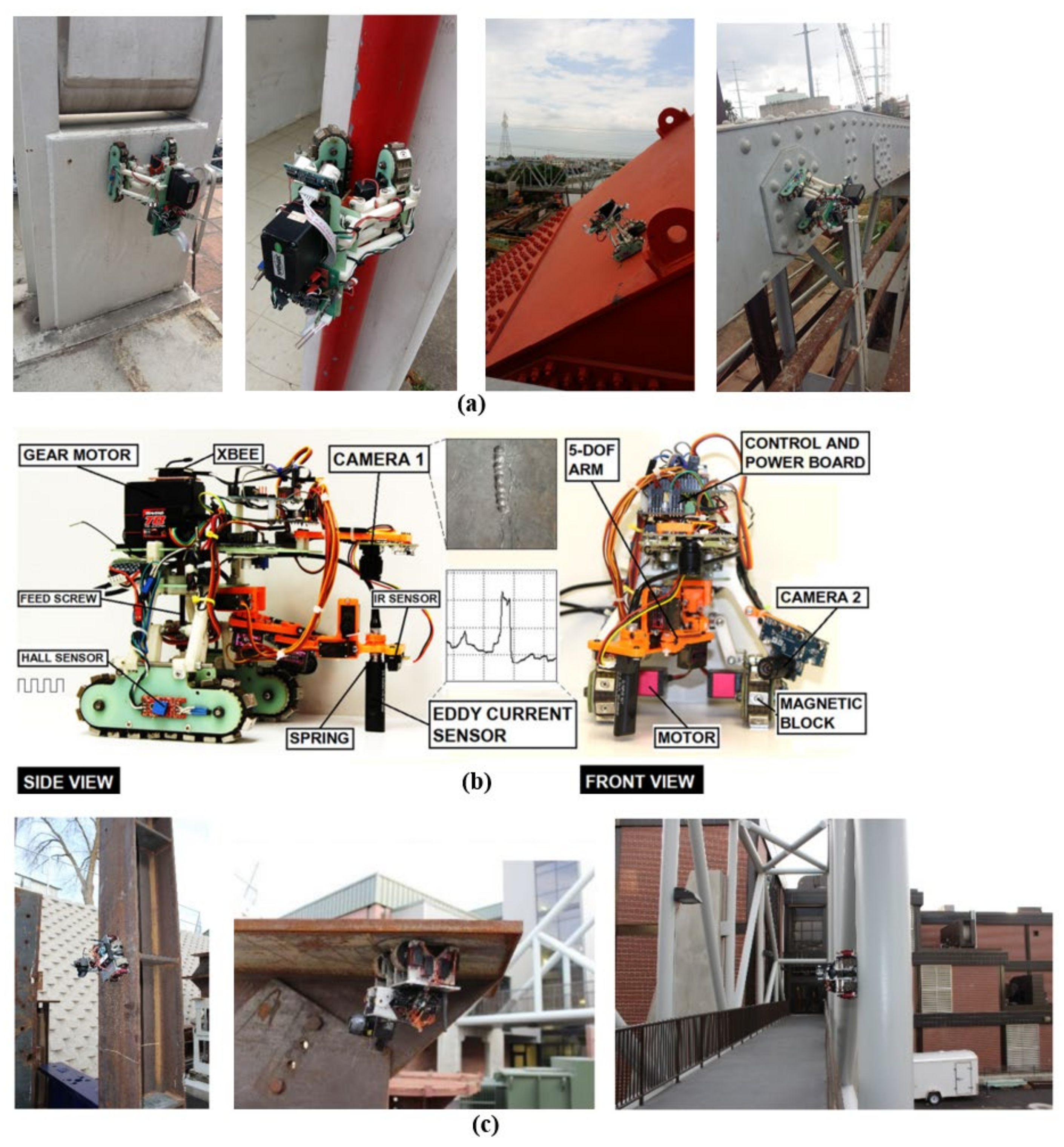

5.1. Implementation of Robotic Technology

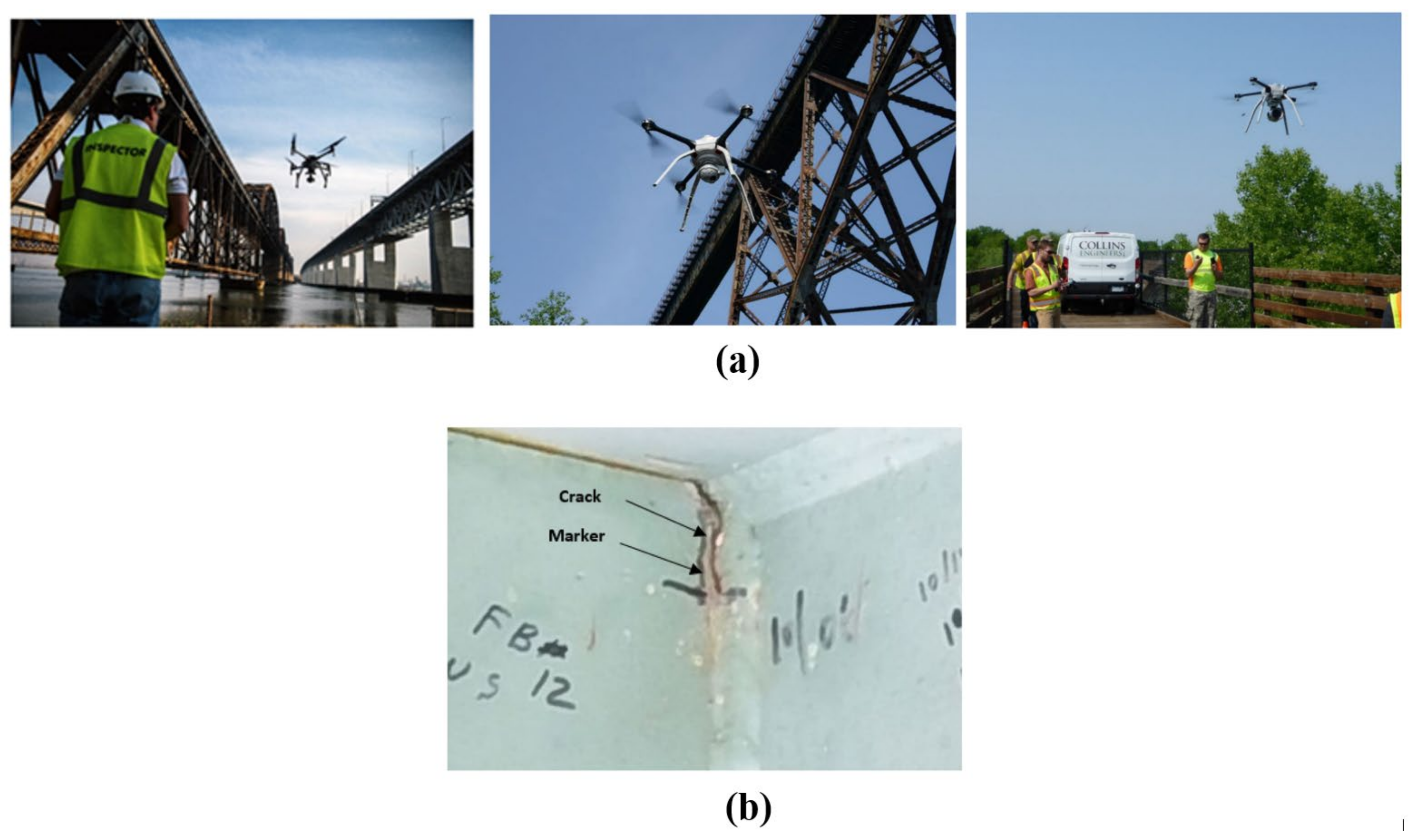

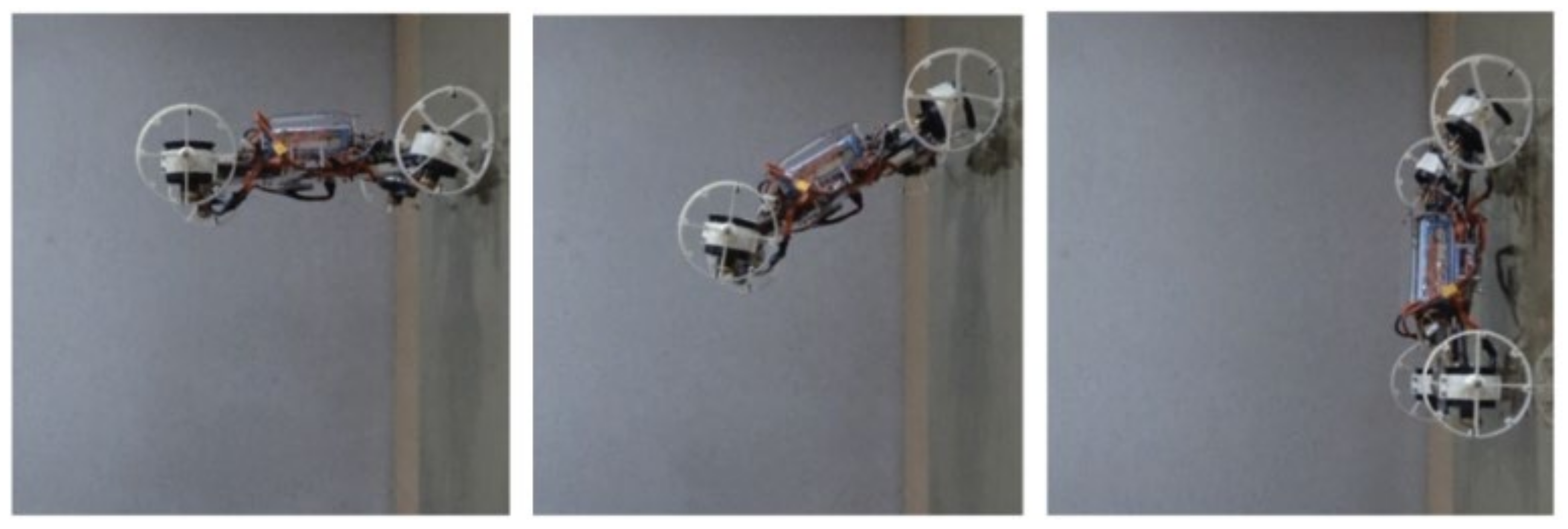

5.1.1. Aerial Robots

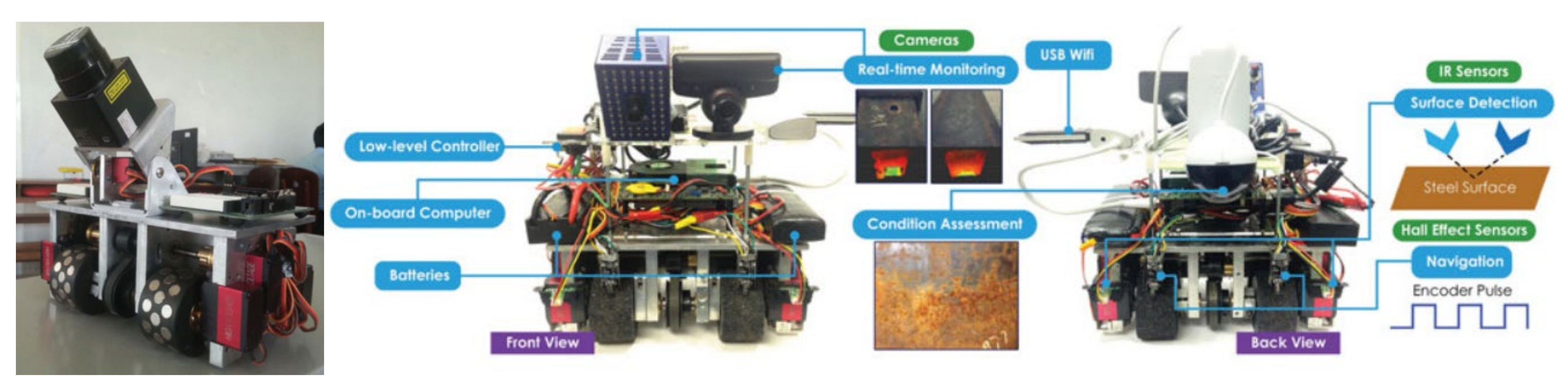

5.1.2. Ground Robots

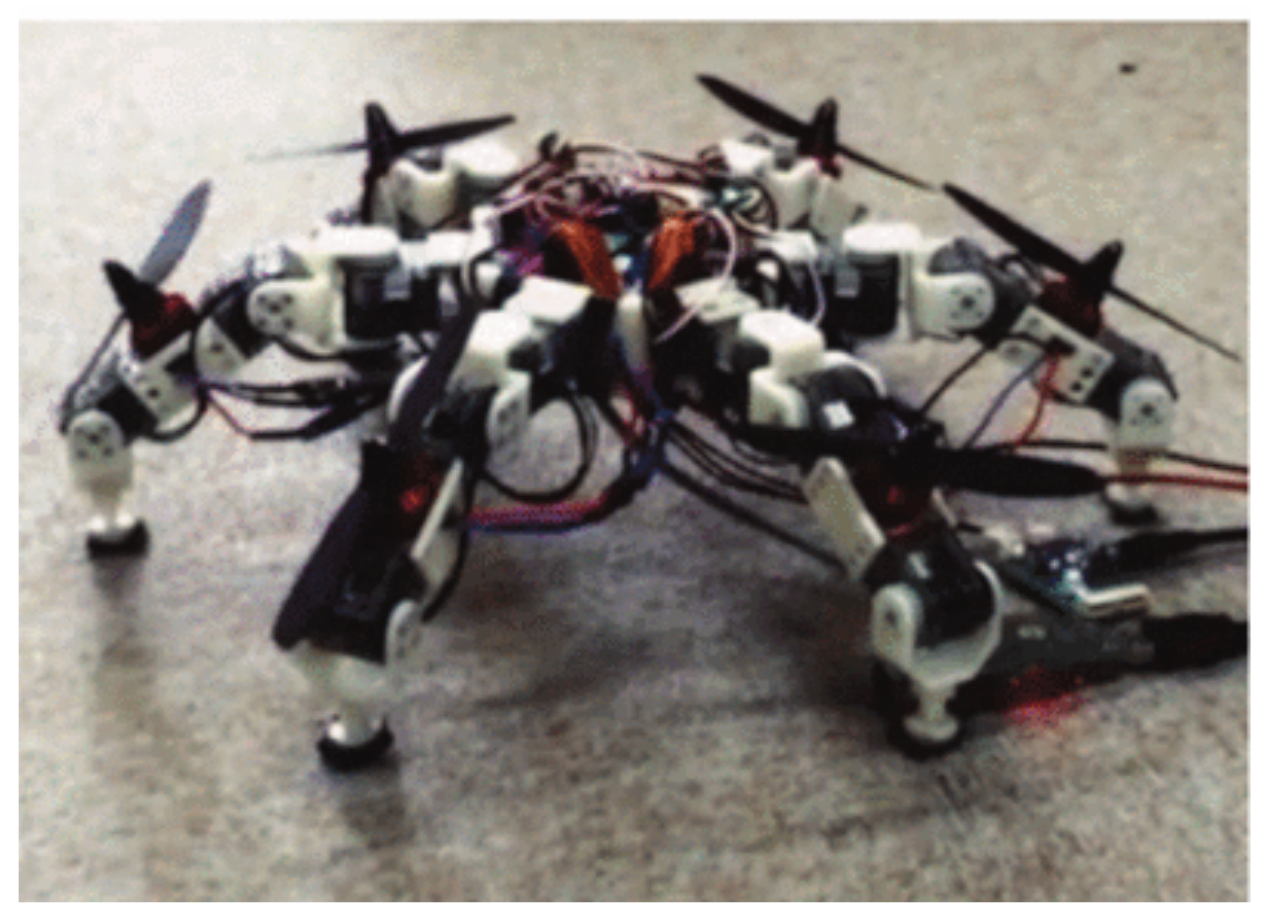

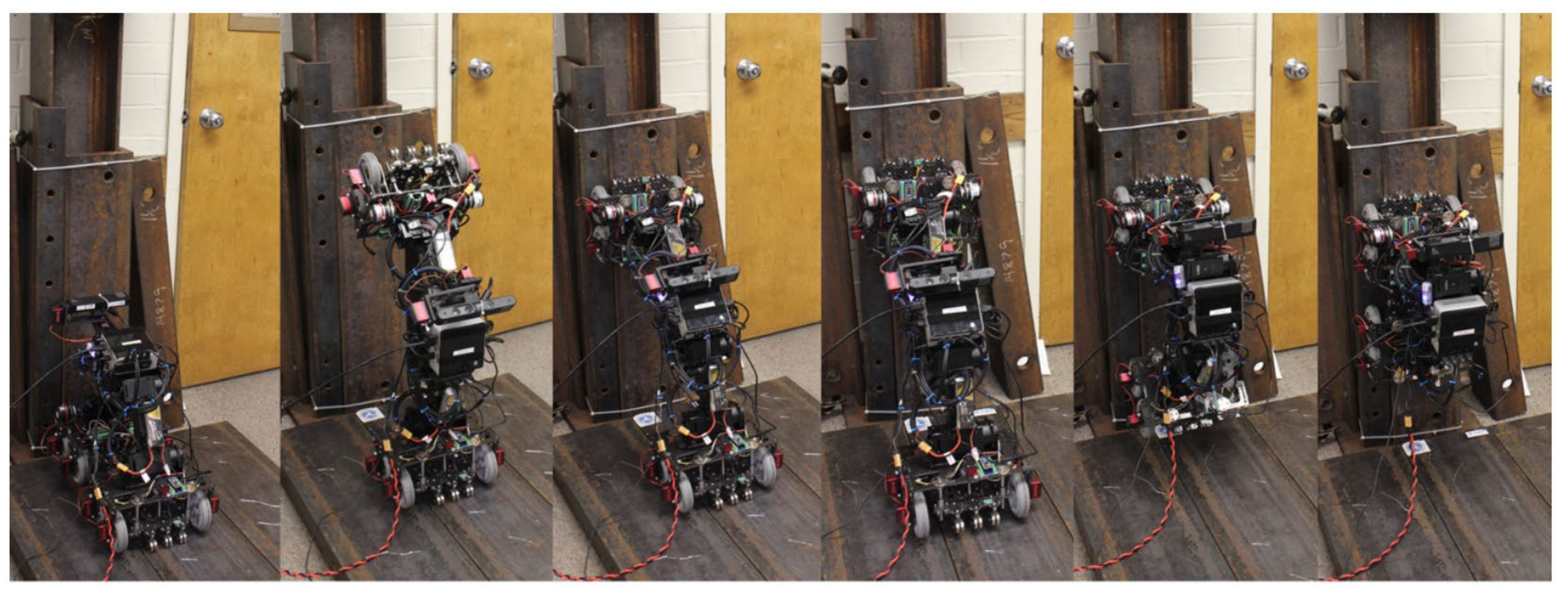

5.1.3. Hybrid Robots

5.2. Global Structural Response Testing (GSR)

6. Summary and Conclusions

- NDT methods are used to detect and characterize any flaws in the steel components with no or minimal damage to the member.

- Among all NDT techniques, visual inspection is the least costly and easiest method. However, because visual inspection depends strongly on the level of experience and expertise of the inspector, the results are subjective, and different results might be obtained when different inspectors are involved. Accordingly, when potential for critical damage exists, other techniques should be used in conjunction with this method to assure valuable results. Use of visual aids as well as vision-based techniques with digital processing can increase the accuracy and reliability of inspection results.

- NDT methods are normally categorized based on their ability to detect internal defects or external defects, having in mind that some methods can detect defects both on and beneath the surface. Considering the type of steel elements, the type and location of damages, and the capability of NDT methods in detecting the internal and external defects, testing methods applicable to steel bridges were categorized and discussed in this paper.

- Visual inspection, dye penetrant, magnetic particle, and eddy current are NDT methods applicable to only surface defects. Visual inspection is the most common and appropriate NDT method for detecting noticeable flaws, which is used for the majority of steel bridges. The dye penetrant method is a practical way for the detection of flaws in non-porous surfaces. Magnetic particle testing is a fast and inexpensive NDT method suitable for ferromagnetic materials that requires minimum training for inspectors. The eddy current method is a rapid inspection technique that can be implemented with automation. This method can also be used for the detection of flaws for surfaces with conductive and non-conductive coatings requiring little or no surface preparation.

- Acoustic Emission Testing, Infrared Thermography Testing, Ultrasonic Testing, radiographic testing, and laser testing methods are normally used for the detection of subsurface or internal defects in steel bridges, but they can be implemented for the detection of surface damages as well. Care should be taken with radiographic testing methods, as the radiation can pose a health hazard. Despite its slow and costly process, it can detect porosity, cracks, and inclusions in weld interiors with a high accuracy. The Ultrasonic Testing method is practical for the detection of subsurface volumetric flaws. It is very sensitive and accurate but requires relatively expensive equipment. The infrared thermography is cost-effective for the inspection of steel bridges with large areas. However, it cannot be implemented to accurately inspect thick components. Acoustic Emission Testing is a suitable method for the detection of active and incipient cracks, but it cannot be implemented to detect existing inactive defects.

- For structural tension elements such as cables, tendons, and ropes, certain NDT methods are more common. These include Magnetic Flux Leakage Testing, Chemical and Electrical Testing, Chemical and Electrical Testing, Radiographic Testing (RT), and Acoustic Emission Testing. Ultrasonic Testing can be used for the detection of wire cross-section losses in the anchorage zones, and infrared thermography and Tap/Impact testing can be employed to detect defects in corrosion barriers. The non-contact and contact vibration method is another NDT method that can indirectly indicate flaws in cables and tension elements. The advantage of this method is its ability to detect flaws without being in a close vicinity of the component, and normally does not cause any interruption to traffic.

- The implementation of robotics technology for NDT of steel bridges has improved the reliability and accuracy of testing, reduced the cost and time of inspection, and eased the process significantly.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Structurally Deficient Bridges|Bridge Infrastructure|ASCE’s 2021 Infrastructure Report Card. Available online: https://infrastructurereportcard.org/cat-item/bridges/ (accessed on 23 May 2021).

- Highways and Bridges—NACE. Available online: https://www.nace.org/resources/industries-nace-serves/highways-bridges (accessed on 23 May 2021).

- FHWA—FAPG 23 CFR 650C, National Bridge Inspection Standards. 2004. Available online: https://www.fhwa.dot.gov/legsregs/directives/fapg/cfr0650c.htm (accessed on 23 May 2021).

- Rus, G. Nondestructive Evaluation Laboratory 2010. U.S. Department of Transportation, Federal Highway Administration. 2010. Available online: https://highways.dot.gov/research/laboratories/nondestructive-evaluation-laboratory/nondestructive-evaluation-laboratory-overview (accessed on 23 May 2021).

- Dolati, S.S.K.; Mehrabi, A. Review of available systems and materials for splicing prestressed-precast concrete piles. Structures 2021, 30, 850–865. [Google Scholar] [CrossRef]

- Mehrabi, A.B.; Khedmatgozar Dolati, S.S. Alternative Materials and Configurations for Prestressed-Precast Concrete Pile Splice Connection; ABC-UTC Rep.; Accelerated Bridge Construction University Transportation Center (ABC-UTC): Miami, FL, USA, 2020. [Google Scholar]

- Corrosion of Steel—Reliant Institute of Technology. 2018. Available online: http://www.relianttechnologyinstitute.com/blog/tekla/corrosion-of-steel/ (accessed on 23 May 2021).

- Dogan, M. Delamination failure of steel single angle sections. Eng. Fail. Anal. 2011, 18, 1800–1807. [Google Scholar] [CrossRef]

- Haghani, R.; Al-Emrani, M.; Heshmati, M. Fatigue-prone details in steel bridges. Buildings 2012, 2, 456–476. [Google Scholar] [CrossRef]

- Hopwood, T.; Gof, C.; Fairchild, J.; Palle, S. Nondestructive Evaluation of Steel Bridges: Methods and Applications; Kentucky Transportation Center, University of Kentucky: Lexington, KY, USA, 2016. [Google Scholar]

- Phares, B.M.; Rolander, D.D.; Graybeal, B.A.; Washer, G.A. Reliability of visual bridge inspection. Public Roads 2001, 64, 22–29. [Google Scholar]

- Campbell, L.E.; Connor, R.J.; Whitehead, J.M.; Washer, G.A. Benchmark for Evaluating Performance in Visual Inspection of Fatigue Cracking in Steel Bridges. J. Bridg. Eng. 2020, 25, 04019128. [Google Scholar] [CrossRef]

- Dye Penetrant Testing (PT)—Nondestructive Evaluation (NDE) Web Manual. Federal Highway of Administration Research and Technology. 2015. Available online: https://cms7.fhwa.dot.gov/research/projects/nondestructive-evaluation-nde-web-manual (accessed on 28 September 2021).

- Achille Peiris, B.S. Capillary Action—Chemistry LibreTexts; LibreTexts: Davis, CA, USA, 2017. [Google Scholar]

- Dwivedi, S.K.; Vishwakarma, M.; Soni, A. Advances and researches on non destructive testing: A review. Mater. Today Proc. 2018, 5, 3690–3698. [Google Scholar] [CrossRef]

- FMB Oxford Non Destructive Testing—Dye Penetrant Inspection. Ionisation Chambers. Available online: http://www.wermac.org/others/ndt_dyepenetrant.html (accessed on 28 May 2021).

- Worman, J. Liquid Penetrant Examination. 2011. Available online: http://www.nationalboard.org/index.aspx?pageID=164&ID=374 (accessed on 29 May 2021).

- Willcox, M.; Downes, G. A Brief Description of NDT Techniques; Toronto NDT Equip. Ltd.: Bedford, VA, USA, 2003. [Google Scholar]

- Magnetic Particle Inspection, Inspection Services. Available online: http://ccindt.com/magnetic-particle-inspection.php (accessed on 28 September 2021).

- Globetrace Magnetic Particle Inspection (MPI). Available online: http://www.globetrace.co.uk/?page_id=96 (accessed on 30 May 2021).

- Simionescu, D.; Mitelea, I.; Karancsi, O.; Utu, I.-D. Research on the nondestructive examination of narrow gap MAG welding of API 5L X65M thermomechanical treated steel. Mater. Today Proc. 2021, 45, 4105–4111. [Google Scholar] [CrossRef]

- Eddy Current Testing|Institut Dr; Foerster GmbH und Co., KG. Available online: http://www.foerstergroup.com/en/usa/technology/eddy-current-testing/ (accessed on 29 May 2021).

- Sophian, A.; Tian, G.; Fan, M. Pulsed Eddy Current Non-destructive Testing and Evaluation: A Review. Chinese J. Mech. Eng. 2017, 30, 500–514. [Google Scholar] [CrossRef] [Green Version]

- García-Martín, J.; Gómez-Gil, J.; Vázquez-Sánchez, E. Non-destructive techniques based on eddy current testing. Sensors 2011, 11, 2525–2565. [Google Scholar] [CrossRef] [Green Version]

- Lamtenzan, D.; Washer, G.; Lozev, M. Detection and Sizing of Cracks in Structural Steel Using the Eddy Current Method; FHWA-RD-00; Turner-Fairbank Highway Research Center: McLean, VA, USA, 2000. [Google Scholar]

- Hellier, C.J. Handbook of Nondestructive Evaluation; McGraw-Hill Education: New York, NY, USA, 2013; ISBN 0071777148. [Google Scholar]

- Shokouhi, P.; Wolf, J.; Wiggenhauser, H. Detection of delamination in concrete bridge decks by joint amplitude and phase analysis of ultrasonic array measurements. J. Bridge Eng. 2014, 19, 4013005. [Google Scholar] [CrossRef]

- Farhangdoust, S.; Mehrabi, A. Health monitoring of closure joints in accelerated bridge construction: A review of non-destructive testing application. J. Adv. Concr. Technol. 2019, 17, 381–404. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, O.A.; Rens, K.L. Ultrasonic testing of properties of 50 year old concrete. Mater. Eval. 2001, 59, 1426–1430. [Google Scholar]

- Ongpeng, J.M.C.; Oreta, A.W.C.; Hirose, S. Contact and noncontact ultrasonic nondestructive test in reinforced concrete beam. Adv. Civ. Eng. 2018, 2018, 1–10. [Google Scholar] [CrossRef]

- Mehrabi, A.; Farhangdoust, S. NDT Methods Applicable to Health Monitoring of ABC Closure Joints; Accelerated Bridge Construction University Transportation Center (ABC-UTC): Miami FL, USA, 2019. [Google Scholar]

- Dube, N. Introduction to Phased Array Ultrasonic Technology Applications, 4th ed.; Olympus Technical Communications Service, Ed.; Olymous: Waltham, MA, USA, 2004. [Google Scholar]

- Lin, Z.B.; Azarmi, F.; Al-Kaseasbeh, Q.; Azimi, M.; Yan, F. Advanced Ultrasonic Testing Technologies with Applications to Evaluation of Steel Bridge Welding—An Overview. Appl. Mech. Mater. 2015, 727–728, 785–789. [Google Scholar] [CrossRef]

- Phased Array Services—Acuren. Available online: https://www.acuren.com/inspection/advanced-nde-ndt/phased-array/ (accessed on 29 May 2021).

- Sinclair, A.N.; Fortin, J.; Shakibi, B.; Honarvar, F.; Jastrzebski, M.; Moles, M.D.C. Enhancement of ultrasonic images for sizing of defects by time-of-flight diffraction. NDT E Int. 2010, 43, 258–264. [Google Scholar] [CrossRef]

- Time-of-Flight Diffraction (TOFD) vs Phased Array Methods: What’s the Difference?|Zetec. Available online: https://www.zetec.com/blog/time-of-flight-diffraction-tofd-vs-phased-array-methods-whats-the-difference/ (accessed on 29 May 2021).

- Baskaran, G.; Balasubramaniam, K.; Lakshmana Rao, C. Shear-wave time of flight diffraction (S-TOFD) technique. NDT E Int. 2006, 39, 458–467. [Google Scholar] [CrossRef]

- TOFD—AUT Solutions. Available online: https://autsolutions.net/ndt-resources/tofd/ (accessed on 29 May 2021).

- Laprise, F.; Berlanger, J.; Maes, G. Sectorial Scan PAUT Combined with TOFD, a Robust Weld Inspection Technique in Lieu of RT. In Proceedings of the 18th Conference on Nondestructive Testing, Durban, South Africa, 16–20 April 2012. [Google Scholar]

- Hay, D.R.; Cavaco, J.A.; Mustafa, V. Monitoring the civil infrastructure with acoustic emission: Bridge case studies. J. Acoust. Emiss. 2009, 27. [Google Scholar]

- Kosnik, D.E.; Marron, D.R. Acoustic Emission Evaluation of Retrofits on the I-80 Bryte Bend Bridge, Sacramento, California. In Proceedings of the AEWG-50/ICAE-6. Acoustic Emission Working Group, CO, USA, and Acoustic Emission Group, Encino, CA, USA, Lake Tahoe, NV, USA, 29 October–2 November 2007. [Google Scholar]

- Tabatabai, H. Inspection and Maintenance of Bridge Stay Cable Systems: A Synthesis of Highway Practice; Transportation Research Board: Washington, DC, USA, 2005; Volume 353, ISBN 0309097606. [Google Scholar]

- Qu, Z.; Jiang, P.; Zhang, W. Development and application of infrared thermography non-destructive testing techniques. Sensors 2020, 20, 3851. [Google Scholar] [CrossRef]

- Mehrabi, A.B. In-service evaluation of cable-stayed bridges, overview of available methods and findings. J. Bridge Eng. 2006, 11, 716–724. [Google Scholar] [CrossRef]

- Díaz, F.A.; Patterson, E.A.; Tomlinson, R.A.; Yates, J.R. Measuring stress intensity factors during fatigue crack growth using thermoelasticity. Fatigue Fract. Eng. Mater. Struct. 2004, 27, 571–583. [Google Scholar] [CrossRef]

- Sakagami, T.; Izumi, Y.; Kubo, S. Application of infrared thermography to structural integrity evaluation of steel bridges. In Proceedings of the Journal of Modern Optics; Taylor & Francis Group: London, UK, 2010; Volume 57, pp. 1738–1746. [Google Scholar]

- Izumi, Y.; Sakagami, T.; Kubo, S. Stress Intensity Factor Measurements for Fatigue Cracks in Steel Bridges Based on Thermoelastic Stress Analysis. In Proceedings of the 12th International Conference on Fracture 2009 (ICF-12), Ottawa, ON, Canada, 12–17 July 2009. [Google Scholar]

- Tuli, S.; Mulaveesala, R. Defect detection by pulse compression in frequency modulated thermal wave imaging. Quant. Infrared Thermogr. J. 2005, 2, 41–54. [Google Scholar] [CrossRef]

- Maldague, X.; Galmiche, F.; Ziadi, A. Advances in pulsed phase thermography. Infrared Phys. Technol. 2002, 43, 175–181. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-Martín, M.; Lagüela, S.; González-Aguilera, D.; Martinez, J. Prediction of depth model for cracks in steel using infrared thermography. Infrared Phys. Technol. 2015, 71, 492–500. [Google Scholar] [CrossRef]

- Wimsatt, A.J.; Scullion, T.; Fernando, E.G.; Hurlebaus, S.; Lytton, R.L.; Zollinger, D.G.; Walker, R.S. A Plan for Developing High-Speed, Nondestructive Testing Procedures for Both Design Evaluation and Construction Inspection; TRB: Washington, DC, USA, 2009. [Google Scholar]

- Gamma Radiography (RT). Available online: https://www.shawcor.com/integrity-management-solutions/ndt-and-inspection-services/onshore-inspection-services/gamma-radiography-(rt) (accessed on 28 May 2021).

- Sukesh, O.P. Radiographic Testing (RT)-NDT. Available online: https://www.slideshare.net/SukeshOP/ndt-module-5 (accessed on 28 May 2021).

- Kumar, S.; Mahto, D. Recent Trends in Industrial and Other Engineering Applications of Non Destructive Testing: A ReviewNo Title. Int. J. Sci. Eng. Res. 2013, 4, 13. [Google Scholar]

- De Pinna, M.A. Focus: Applications of high energy X-ray inspection of post-tensioned concrete structures and cable stay bridges. PTI J. 2003, 1, 43–48. [Google Scholar]

- Wilkinson, S.; Duke, S.M. Comparative Testing of Radiographic Testing, Ultrasonic Testing and Phased Array Advanced Ultrasonic Testing Non Destructive Testing Techniques in Accordance with the AWS D1.5 Bridge Welding Code; Florida Department of Transportation: Tallahassee, FL, USA, 2014; p. 38.

- Lee, S.; Kalos, N. Non-destructive testing methods in the US for bridge inspection and maintenance. KSCE J. Civ. Eng. 2014, 18, 1322–1331. [Google Scholar] [CrossRef]

- Elbeheri, A.; Zayed, T. Non-destructive Evaluation Techniques for Steel Bridges Inspection. In Proceedings of the TAC 2016: Efficient Transportation-Managing the Demand-2016 Conference and Exhibition of the Transportation Association of Canada, Vancouver, BC, Canada, 25–28 September 2016. [Google Scholar]

- Guldur, B.; Yan, Y.; Hajjar, J.F. Condition assessment of bridges using terrestrial laser scanners. In Proceedings of the Structures Congress 2015, Portland, OR, USA, 23–25 April 2015; pp. 355–366. [Google Scholar]

- Hurlebaus, S.; Hueste, M.B.D.; Karthik, M.M.; Terzioglu, T. Condition Assessment of Bridge Post-tensioning and Stay Cable Systems Using NDE Methods; Transportation Research Board of the National Academies, Texas A&M Transportation Institute: College Station, TX, USA, 2016. [Google Scholar]

- Shi, Y.; Zhang, C.; Li, R.; Cai, M.; Jia, G. Theory and application of magnetic flux leakage pipeline detection. Sensors 2015, 15, 31036–31055. [Google Scholar] [CrossRef]

- Bergamini, A. Nondestructive Testing of Stay Cables; International Association for Bridge and Structural Engineering: Zürich, Switzerland, 2001; Volume 84, pp. 16–23. [Google Scholar]

- Bartels, K.A.; Kwun, H.; Hanley, J.J. Magnetostrictive sensors for the characterization of corrosion in rebars and prestressing strands. In Proceedings of the Nondestructive Evaluation of Bridges and Highways, Scottsdale, AZ, USA, 4 December 1996; International Society for Optics and Photonics: Bellingham, WA, USA, 1996; Volume 2946, pp. 40–50. [Google Scholar] [CrossRef]

- Kalogeropoulos, A. Non-Destructive Determination of Chloride and Water Content in Concrete Using Ground Penetrating Radar; EPFL: Lausanne, Switzerland, 2012. [Google Scholar] [CrossRef]

- Fujita, M.; Masuda, T. Application of various NDT methods for the evaluation of building steel structures for reuse. Materials 2014, 7, 7130–7144. [Google Scholar] [CrossRef] [Green Version]

- American Society for Testing and Materials. ASTM C876-99 Standard, Test Method for Half-Cell Potentials of Uncoated Reinforcing Steel in Concrete; American Society for Testing and Materials: West Conshohocken, PA, USA, 1999. [Google Scholar]

- Ahmed, S. Corrosion Potential Mapping. Available online: https://faculty.kfupm.edu.sa/CE/sud/Teaching/CE%20401-112/03%20-%20Half-Cell%20Potential.pdf (accessed on 28 May 2021).

- Sathiyanarayanan, S.; Natarajan, P.; Saravanan, K.; Srinivasan, S.; Venkatachari, G. Corrosion monitoring of steel in concrete by galvanostatic pulse technique. Cem. Concr. Compos. 2006, 28, 630–637. [Google Scholar] [CrossRef]

- Elsener, B.; Andrade, C.; Gulikers, J.; Polder, R.; Raupach, M. Half-cell potential measurements—Potential mapping on reinforced concrete structures. Mater. Struct. 2003, 36, 461–471. [Google Scholar] [CrossRef]

- Mehrabi, A.B. Performance of cable-stayed bridges: Evaluation methods, observations, and a rehabilitation case. J. Perform. Constr. Facil. 2016, 30, C4014007. [Google Scholar] [CrossRef]

- Mehrabi, A.B.; Tabatabai, H. Unified finite difference formulation for free vibration of cables. J. Struct. Eng. 1998, 124, 1313–1322. [Google Scholar] [CrossRef]

- Mehrabi, A.B.; Farhangdoust, S. A laser-based noncontact vibration technique for health monitoring of structural cables: Background, success, and new developments. Adv. Acoust. Vib. 2018, 2018, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Gentile, C. Deflection measurement on vibrating stay cables by non-contact microwave interferometer. NDT E Int. 2010, 43, 231–240. [Google Scholar] [CrossRef]

- Gentile, C.; Cabboi, A. Vibration-based structural health monitoring of stay cables by microwave remote sensing. Smart Struct. Syst 2015, 16, 263–280. [Google Scholar] [CrossRef]

- Marécos, J.; Castanheta, M.; Trigo, J.T. Field observation of Tagus river suspension bridge. J. Struct. Div. 1969, 95, 555–583. [Google Scholar] [CrossRef]

- Stephen, G.A.; Brownjohn, J.M.W.; Taylor, C.A. Measurements of static and dynamic displacement from visual monitoring of the Humber Bridge. Eng. Struct. 1993, 15, 197–208. [Google Scholar] [CrossRef] [Green Version]

- Macdonald, J.H.G.; Dagless, E.L.; Thomas, B.T.; Taylor, C.A. Dynamic measurements of the second severn crossing. In Proceedings of the Institution of Civil Engineers-Transport; Thomas Telford-ICE Virtual Library: London, UK, 1997; Volume 123, pp. 241–248. [Google Scholar]

- Lee, J.J.; Fukuda, Y.; Shinozuka, M.; Cho, S.; Yun, C.-B. Development and application of a vision-based displacement measurement system for structural health monitoring of civil structures. Smart Struct. Syst. 2007, 3, 373–384. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M.Q. Vision-based multipoint displacement measurement for structural health monitoring. Struct. Control Health Monit. 2016, 23, 876–890. [Google Scholar] [CrossRef]

- Choi, I.; Kim, J.; Kim, D. A target-less vision-based displacement sensor based on image convex hull optimization for measuring the dynamic response of building structures. Sensors 2016, 16, 2085. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, Y.; Brownjohn, J.; Kong, D. A non-contact vision-based system for multipoint displacement monitoring in a cable-stayed footbridge. Struct. Control Health Monit. 2018, 25, e2155. [Google Scholar] [CrossRef] [Green Version]

- Liao, W.Y.; Chen, W.H.; Ni, Y.; Xia, Y. Development of a vision-based real-time displacement measurement system for Guangzhou New TV Tower. In Proceedings of the 5th European Workshop on Structural Health Monitoring 2010, Naples, Italy, 29 June–4 July 2010; pp. 450–455. [Google Scholar]

- Ribeiro, D.; Calçada, R.; Ferreira, J.; Martins, T. Non-contact measurement of the dynamic displacement of railway bridges using an advanced video-based system. Eng. Struct. 2014, 75, 164–180. [Google Scholar] [CrossRef]

- Wahbeh, A.M.; Caffrey, J.P.; Masri, S.F. A vision-based approach for the direct measurement of displacements in vibrating systems. Smart Mater. Struct. 2003, 12, 785. [Google Scholar] [CrossRef]

- Caetano, E.; Silva, S.; Bateira, J. Application of a vision system to the monitoring of cable structures. In Proceedings of the Seventh International Symposium on Cable Dynamics; Citeseer: Princeton, NJ, USA, 2007; pp. 225–236. [Google Scholar]

- Ye, X.-W.; Dong, C.-Z.; Liu, T. A review of machine vision-based structural health monitoring: Methodologies and applications. J. Sensors 2016, 2016, 7103039. [Google Scholar] [CrossRef] [Green Version]

- Liao, K.W.; Lee, Y.T. Detection of rust defects on steel bridge coatings via digital image recognition. Autom. Constr. 2016, 71, 294–306. [Google Scholar] [CrossRef]

- Lee, S.; Chang, L.M. Digital image processing methods for assessing bridge painting rust defects and their limitations. In Proceedings of the 2005 ASCE International Conference on Computing in Civil Engineering; American Society of Civil Engineer: Cancun, Mexico, 2005; pp. 841–852. [Google Scholar]

- Lee, S.; Chang, L.M.; Skibniewski, M. Automated recognition of surface defects using digital color image processing. Autom. Constr. 2006, 15, 540–549. [Google Scholar] [CrossRef]

- Chen, P.H.; Chang, L.M. Intelligent steel bridge coating assessment using neuro-fuzzy recognition approach. Comput. Civ. Infrastruct. Eng. 2002, 17, 307–319. [Google Scholar] [CrossRef]

- Medeiros, F.N.S.; Ramalho, G.L.B.; Bento, M.P.; Medeiros, L.C.L. On the evaluation of texture and color features for nondestructive corrosion detection. EURASIP J. Adv. Signal Process. 2010, 2010, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Shen, H.K.; Chen, P.H.; Chang, L.M. Automated steel bridge coating rust defect recognition method based on color and texture feature. Autom. Constr. 2013, 31, 338–356. [Google Scholar] [CrossRef]

- Riccitelli, F. Performance of Existing Abc Projects: Inspection Case Studies; Accelerated Bridge Construction University Transportation Center (ABC-UTC): Miami, FL, USA, 2020. [Google Scholar]

- Taeby, M.; Mehrabi, A.B. Decision Support Framework for Inspection and Maintenance: A Focus on Bridges using Post-Tensioning Tendons. Curr. Trends Civil. Struct. Eng. 2019, 3. [Google Scholar] [CrossRef]

- Murphy, R.R.; Steimle, E.; Hall, M.; Lindemuth, M.; Trejo, D.; Hurlebaus, S.; Medina-Cetina, Z.; Slocum, D. Robot-assisted bridge inspection. In Proceedings of the Journal of Intelligent and Robotic Systems: Theory and Applications; Springer: Berlin/Heidelberg, Germany, 2011; Volume 64, pp. 77–95. [Google Scholar]

- Liu, Q.; Liu, Y. An approach for auto bridge inspection based on climbing robot. In Proceedings of the 2013 IEEE International Conference on Robotics and Biomimetics, ROBIO 2013, Shenzhen, China, 12–14 December 2013; IEEE Computer Society: Washington, DC, USA, 2013; pp. 2581–2586. [Google Scholar]

- Jimenez-Cano, A.E.; Braga, J.; Heredia, G.; Ollero, A. Aerial manipulator for structure inspection by contact from the underside. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Hamburg, Germany, 28 September–3 October 2015; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2015; Volume 2015, pp. 1879–1884. [Google Scholar]

- Pham, N.H.; La, H.M. Design and implementation of an autonomous robot for steel bridge inspection. In Proceedings of the 54th Annual Allerton Conference on Communication, Control, and Computing, Allerton, IL, USA, 27–30 September 2016; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2017; pp. 556–562. [Google Scholar]

- Ratsamee, P.; Kriengkomol, P.; Arai, T.; Kamiyama, K.; Mae, Y.; Kiyokawa, K.; Mashita, T.; Uranishi, Y.; Takemura, H. A hybrid flying and walking robot for steel bridge inspection. In Proceedings of the SSRR 2016—International Symposium on Safety, Security and Rescue Robotics, Lausanne, Switzerland, 23–27 October 2016; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2016; pp. 62–67. [Google Scholar]

- Ellenberg, A.; Kontsos, A.; Moon, F.; Bartoli, I. Bridge deck delamination identification from unmanned aerial vehicle infrared imagery. Autom. Constr. 2016, 72, 155–165. [Google Scholar] [CrossRef]

- Sirken, A.; Knizhnik, G.; McWilliams, J.; Bergbreiter, S. Bridge risk investigation diagnostic grouped exploratory (BRIDGE) bot. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Vancouver, BC, Canada, 24–28 September 2017; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2017; Volume 2017, pp. 6526–6532. [Google Scholar]

- Ikeda, T.; Yasui, S.; Fujihara, M.; Ohara, K.; Ashizawa, S.; Ichikawa, A.; Okino, A.; Oomichi, T.; Fukuda, T. Wall contact by octo-rotor UAV with one DoF manipulator for bridge inspection. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems; Vancouver, BC, Canada, 24–28 September 2017, Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2017; Volume 2017, pp. 5122–5127. [Google Scholar]

- Zheng, Z.; Yuan, X.; Huang, H.; Yu, X.; Ding, N. Mechanical Design of a Cable Climbing Robot for Inspection on a Cable-Stayed Bridge. In Proceedings of the World Congress on Intelligent Control and Automation (WCICA), Changsha, China, 4–8 July 2018; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019; Volume 2018, pp. 1680–1684. [Google Scholar]

- Zheng, Z.; Hu, S.; Ding, N. A Biologically Inspired Cable Climbing Robot: CCRobot—Design and Implementation. In Proceedings of the 2018 IEEE International Conference on Robotics and Biomimetics, ROBIO 2018, Kuala Lumpur, Malaysia, 12–15 December 2018; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2018; pp. 2354–2359. [Google Scholar]

- Zheng, M.; Yang, M.; Yuan, X.; Ding, N. A Light-Weight Wheel-Based Cable Inspection Climbing Robot: From Simulation to Reality. In Proceedings of the 2018 IEEE International Conference on Robotics and Biomimetics, ROBIO 2018, Kuala Lumpur, Malaysia, 12–15 December 2018; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2018; pp. 1365–1370. [Google Scholar]

- Li, X.; Gao, C.; Guo, Y.; He, F.; Shao, Y. Cable surface damage detection in cable-stayed bridges using optical techniques and image mosaicking. Opt. Laser Technol. 2019, 110, 36–43. [Google Scholar] [CrossRef]

- Bui, H.D.; Nguyen, S.; Billah, U.H.; Le, C.; Tavakkoli, A.; La, H.M. Control Framework for a Hybrid-steel Bridge Inspection Robot. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 24–30 October 2020. [Google Scholar]

- Bridge Inspection|UAV America. Available online: https://uavamerica.com/bridge-inspection/ (accessed on 21 May 2021).

- Mike O’Callaghan-Pat Tillman Memorial Bridge Inspection. Available online: https://www.stantec.com/en/projects/united-states-projects/m/dm-ocallaghan-tillman-bridge-project (accessed on 21 May 2021).

- La, H.M.; Dinh, T.H.; Pham, N.H.; Ha, Q.P.; Pham, A.Q. Automated robotic monitoring and inspection of steel structures and bridges. Robotica 2019, 37, 947–967. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.; Kawamura, Y. An Automated Sensing System for Steel Bridge Inspection Using GMR Sensor Array and Magnetic Wheels of Climbing Robot. J. Sensors 2016, 2016, 8121678. [Google Scholar] [CrossRef] [Green Version]

- Kocer, B.B.; Tjahjowidodo, T.; Pratama, M.; Seet, G.G.L. Inspection-while-flying: An autonomous contact-based nondestructive test using UAV-tools. Autom. Constr. 2019, 106, 102895. [Google Scholar] [CrossRef]

- Lei, B.; Wang, N.; Xu, P.; Song, G. New Crack Detection Method for Bridge Inspection Using UAV Incorporating Image Processing. J. Aerosp. Eng. 2018, 31, 04018058. [Google Scholar] [CrossRef]

- Dorafshan, S.; Maguire, M.; Hoffer, N.V.; Coopmans, C. Challenges in bridge inspection using small unmanned aerial systems: Results and lessons learned. In Proceedings of the 2017 International Conference on Unmanned Aircraft Systems, ICUAS 2017, Miami, FL, USA, 13–16 June 2017; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2017; pp. 1722–1730. [Google Scholar]

- Dorafshan, S.; Thomas, R.J.; Maguire, M. Fatigue Crack Detection Using Unmanned Aerial Systems in Fracture Critical Inspection of Steel Bridges. J. Bridg. Eng. 2018, 23, 04018078. [Google Scholar] [CrossRef]

- Seo, J.; Duque, L.; Wacker, J. Drone-enabled bridge inspection methodology and application. Autom. Constr. 2018, 94, 112–126. [Google Scholar] [CrossRef]

- Tognon, M.; Chavez, H.A.T.; Gasparin, E.; Sable, Q.; Bicego, D.; Mallet, A.; Lany, M.; Santi, G.; Revaz, B.; Cortes, J.; et al. A Truly-Redundant Aerial Manipulator System with Application to Push-and-Slide Inspection in Industrial Plants. IEEE Robot. Autom. Lett. 2019, 4, 1846–1851. [Google Scholar] [CrossRef] [Green Version]

- Minnesota Department of Transportation. Unmanned Aerial Vehicle Bridge Inspection Demonstration Project; Report MN/RC 2015-40; Minnesota Department of Transportation: St. Paul, MN, USA, 2015.

- Zink, J.; Lovelace, B. Unmanned Aerial Vehicle Bridge Inspection Demonstration Project; TRB: Washington, DC, USA, 2015. [Google Scholar]

- Feroz, S.; Abu Dabous, S. UAV-Based Remote Sensing Applications for Bridge Condition Assessment. Remote Sens. 2021, 13, 1809. [Google Scholar] [CrossRef]

- Abedin, M.; Mokhtari, S.; Mehrabi, A.B. Bridge damage detection using machine learning algorithms. In Proceedings of the Health Monitoring of Structural and Biological Systems XV; International Society for Optics and Photonics: Bellingham, WA, USA, 2021; Volume 11593, p. 115932P. [Google Scholar]

- Aerial Inspections | Best Crane Inspections|Bridge Inspections. Available online: https://www.infrastructurepc.com/aerial-inspections/ (accessed on 30 May 2021).

- Nguyen, S.T.; La, H.M. Development of a Steel Bridge Climbing Robot. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Macau, China, 3–8 November 2019; pp. 1912–1917. [Google Scholar]

- Pham, N.H.; La, H.M.; Ha, Q.P.; Dang, S.N.; Vo, A.H.; Dinh, Q.H. Visual and 3D mapping for steel bridge inspection using a climbing robot. In Proceedings of the ISARC 2016—33rd International Symposium on Automation and Robotics in Construction, Auburn, AL, USA, 18–21 July 2016; pp. 141–149. [Google Scholar]

- Cho, K.H.; Jin, Y.H.; Kim, H.M.; Moon, H.; Koo, J.C.; Choi, H.R. Caterpillar-based cable climbing robot for inspection of suspension bridge hanger rope. In Proceedings of the IEEE International Conference on Automation Science and Engineering, Lyon, France, 23–27 August 2013; pp. 1059–1062. [Google Scholar]

- Zheng, Z.; Ding, N. Design and implementation of CCRobot-II: A palm-based cable climbing robot for cable-stayed bridge inspection. In Proceedings of the IEEE International Conference on Robotics and Automation, Montreal, QC, Canada, 20–24 May 2019; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019; Volume 2019, pp. 9747–9753. [Google Scholar]

- Nguyen, S.T.; Pham, A.Q.; Motley, C.; La, H.M. A Practical Climbing Robot for Steel Bridge Inspection. In Proceedings of the IEEE International Conference on Robotics and Automation, Paris, France, 31 May–31 August 2020; pp. 9322–9328. [Google Scholar]

- Ahmed, H.; La, H.M.; Gucunski, N. Review of non-destructive civil infrastructure evaluation for bridges: State-of-the-art robotic platforms, sensors and algorithms. Sensors 2020, 20, 3954. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Watson, R.; Dobie, G.; MacLeod, C.; Pierce, G. Autonomous Ultrasonic Inspection Using Unmanned Aerial Vehicle. In Proceedings of the IEEE International Ultrasonics Symposium, IUS, Kobe, Japan, 22–25 October 2018; IEEE Computer Society: Washington, DC, USA, 2018; Volume 2018. [Google Scholar]

- Meksen, T.M.; Boudraa, B.; Drai, R.; Boudraa, M. Automatic crack detection and characterization during ultrasonic inspection. J. Nondestruct. Eval. 2010, 29, 169–174. [Google Scholar] [CrossRef]

- Petersen, D.; Link, R.; Miki, C.; Kazuhiro, N.; Hiromi, S.; Minoru, T. Performance Evaluation Test of Automatic Ultrasonic Testing Systems for Welded Joints of Steel Bridges. J. Test. Eval. 2005, 33, 12443. [Google Scholar] [CrossRef]

- Boone, S.D.; Sauser, P.; Cohen, J.A. Nchrp idea Program Testing of in-Service Bridges Using Automated Ultrasonic Testing Methods Final Report for Nchrp Idea Project 191; TRB: Washington, DC, USA, 2019. [Google Scholar]

- Deleye, X.; Horchens, L.; Chougrani, K. Experimental comparison of wave-field based ultrasonic imaging with other advanced ultrasonic weld inspection techniques. In Proceedings of the 18th World Conference on Nondestructive Testing, Durban, South Africa, 16–20 April 2012. [Google Scholar]

- Myeong, W.; Myung, H. Development of a Wall-Climbing Drone Capable of Vertical Soft Landing Using a Tilt-Rotor Mechanism. IEEE Access 2019, 7, 4868–4879. [Google Scholar] [CrossRef]

- Liang, Z.; Lee, G.C.; Kong, F. On detection of damage location of bridges. In Proceedings of the 15th International Modal Analysis Conference, Orlando, FL, USA, 3–6 February 1997; Volume 3089, p. 308. [Google Scholar]

- Mashayekhi, M.; Santini-Bell, E. Detection of Damage-induced Fatigue Response Based on Structural Health Monitoring Data of In-service Steel Bridges Using Artificial Neural Network. Struct. Health Monit 2019. [Google Scholar] [CrossRef]

- Adams, T.; Mashayekhizadeh, M.; Santini-Bell, E.; Wosnik, M.; Baldwin, K.; Fu, T. Structural Response Monitoring of a Vertical Lift Truss Bridge; TRB: Washington, DC, USA, 2017. [Google Scholar]

- Abedin, M.; Mehrabi, A.B. Novel approaches for fracture detection in steel girder bridges. Infrastructures 2019, 4, 42. [Google Scholar] [CrossRef] [Green Version]

- Abedin, M.; Mehrabi, A.B. Bridge damage identification through frequency changes. In Proceedings of the Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems; Online, 22–26 March 2021, International Society for Optics and Photonics: Bellingham, WA, USA, 2021; Volume 11591, p. 1159109. [Google Scholar]

- Abedin, M.; Farhangdoust, S.; Mehrabi, A. Fracture detection in steel girder bridges using self-powered wireless sensors. In Risk-based Bridge Engineering; CRC Press: Boca Raton, FL, USA, 2019; pp. 216–228. ISBN 0367815648. [Google Scholar]

- Abedin, M.; Mehrabi, A.B. Health Monitoring of Steel Box Girder Bridges Using Non-Contact Sensors. Structures 2021, 34, 4012–4024. [Google Scholar] [CrossRef]

| Corrosion Rating | Description | Area to Be Painted |

|---|---|---|

| 10 | No rust, less than 0.01% rust | 0 |

| 9 | Minute rust, less than 0.03% rust | 0 |

| 8 | Few isolated rust spots, less than 0.1% rust | 0 |

| 7 | Less than 0.3% rust | 0 |

| 6 | Extensive rust spots, less than 1% rust | 8 |

| 5 | Less than 3% rust | 18 |

| 4 | Less than 10% rust | 40 |

| 3 | Approximately 1/6 of surface rusted | 60 |

| 2 | Approximately 1/3 of surface rusted | 100 |

| 1 | Approximately 1/2 of surface rusted | 100 |

| 0 | Approximately 100% of surface rusted | 100 |

| NDT Technology | Applications and Defects/Anomalies Detected by Relevant Method |

|---|---|

| Visual Inspection |

|

| Dye-Penetrant Testing |

|

| Vision-based method/Digital Image Processing |

|

| Eddy Current Testing |

|

| Radiographic Testing |

|

| Ultra-Sonic Testing |

|

| Infrared Thermography |

|

| Laser Technology |

|

| Magnetic flux leakage |

|

| Chemical and Electrical Testing (CET) |

|

| Vibration Method |

|

| Magnetostriction |

|

| Acoustic Emission |

|

| NDT Technology | Advantages | Disadvantages |

|---|---|---|

| Visual Inspection |

|

|

| Dye-Penetrant Testing |

|

|

| Vision-based method/Digital Image Processing |

|

|

| Eddy Current Testing |

|

|

| Radiographic Testing |

|

|

| Ultra-Sonic Testing |

|

|

| Infrared Thermography |

|

|

| Laser Technology |

|

|

| Magnetic Flux Leakage |

|

|

| Chemical and Electrical Testing (CET) |

|

|

| Magnetostriction |

|

|

| Vibration Method |

|

|

| Acoustic Emission |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khedmatgozar Dolati, S.S.; Caluk, N.; Mehrabi, A.; Khedmatgozar Dolati, S.S. Non-Destructive Testing Applications for Steel Bridges. Appl. Sci. 2021, 11, 9757. https://doi.org/10.3390/app11209757

Khedmatgozar Dolati SS, Caluk N, Mehrabi A, Khedmatgozar Dolati SS. Non-Destructive Testing Applications for Steel Bridges. Applied Sciences. 2021; 11(20):9757. https://doi.org/10.3390/app11209757

Chicago/Turabian StyleKhedmatgozar Dolati, Seyed Saman, Nerma Caluk, Armin Mehrabi, and Seyed Sasan Khedmatgozar Dolati. 2021. "Non-Destructive Testing Applications for Steel Bridges" Applied Sciences 11, no. 20: 9757. https://doi.org/10.3390/app11209757

APA StyleKhedmatgozar Dolati, S. S., Caluk, N., Mehrabi, A., & Khedmatgozar Dolati, S. S. (2021). Non-Destructive Testing Applications for Steel Bridges. Applied Sciences, 11(20), 9757. https://doi.org/10.3390/app11209757