Optimization Analysis of Excavation Procedure Design of Underground Powerhouses under High In Situ Stress in China

Abstract

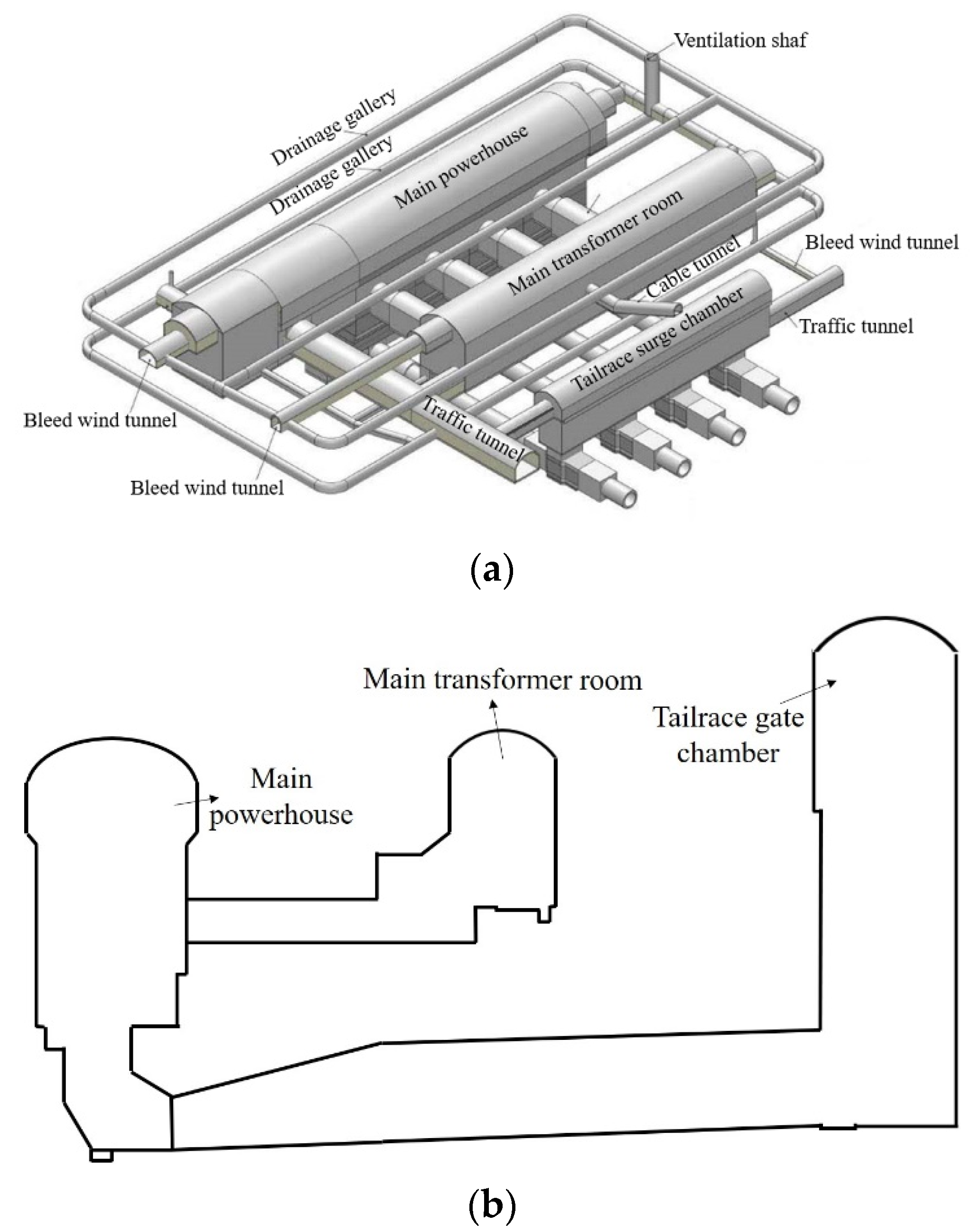

:1. Introduction

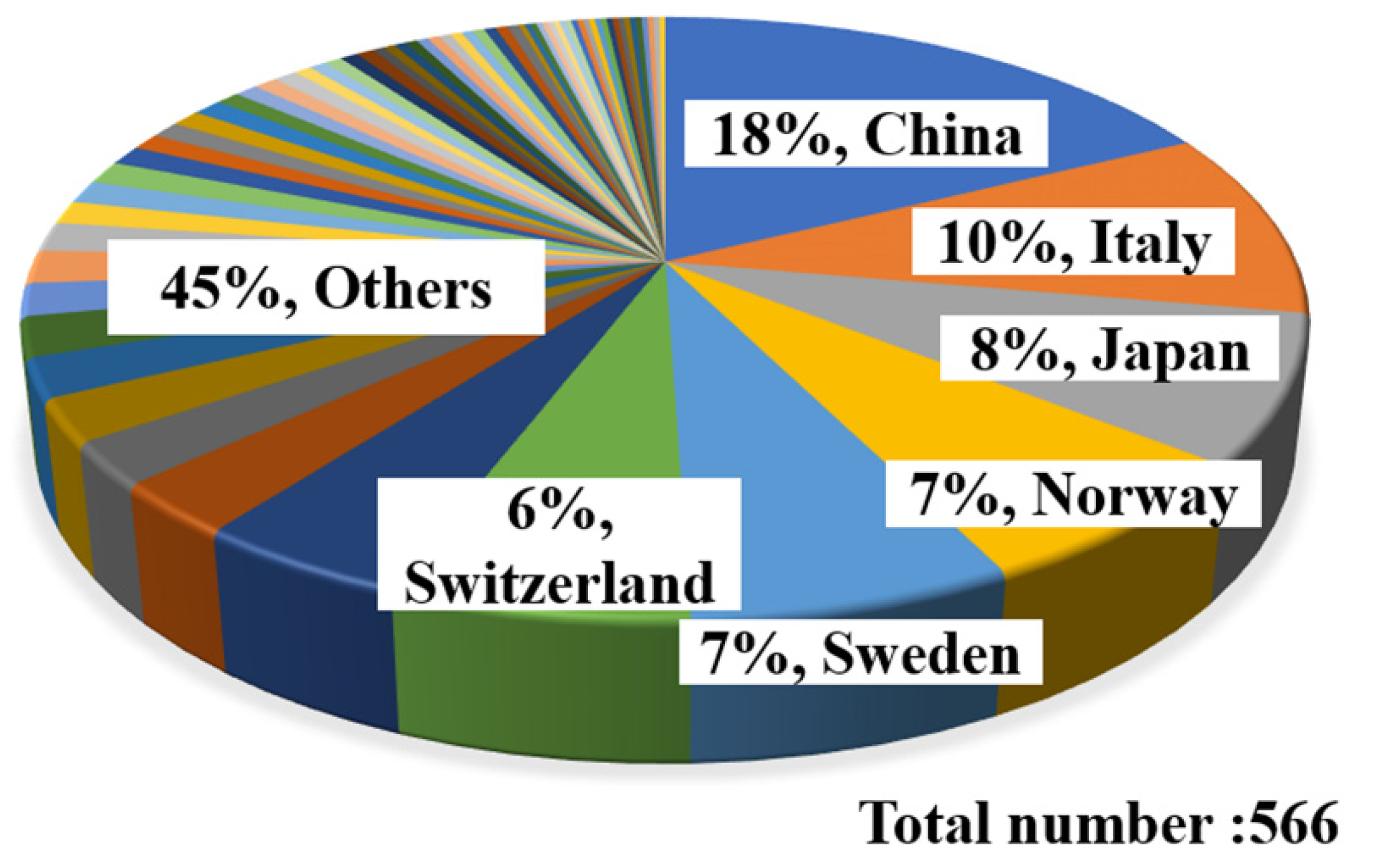

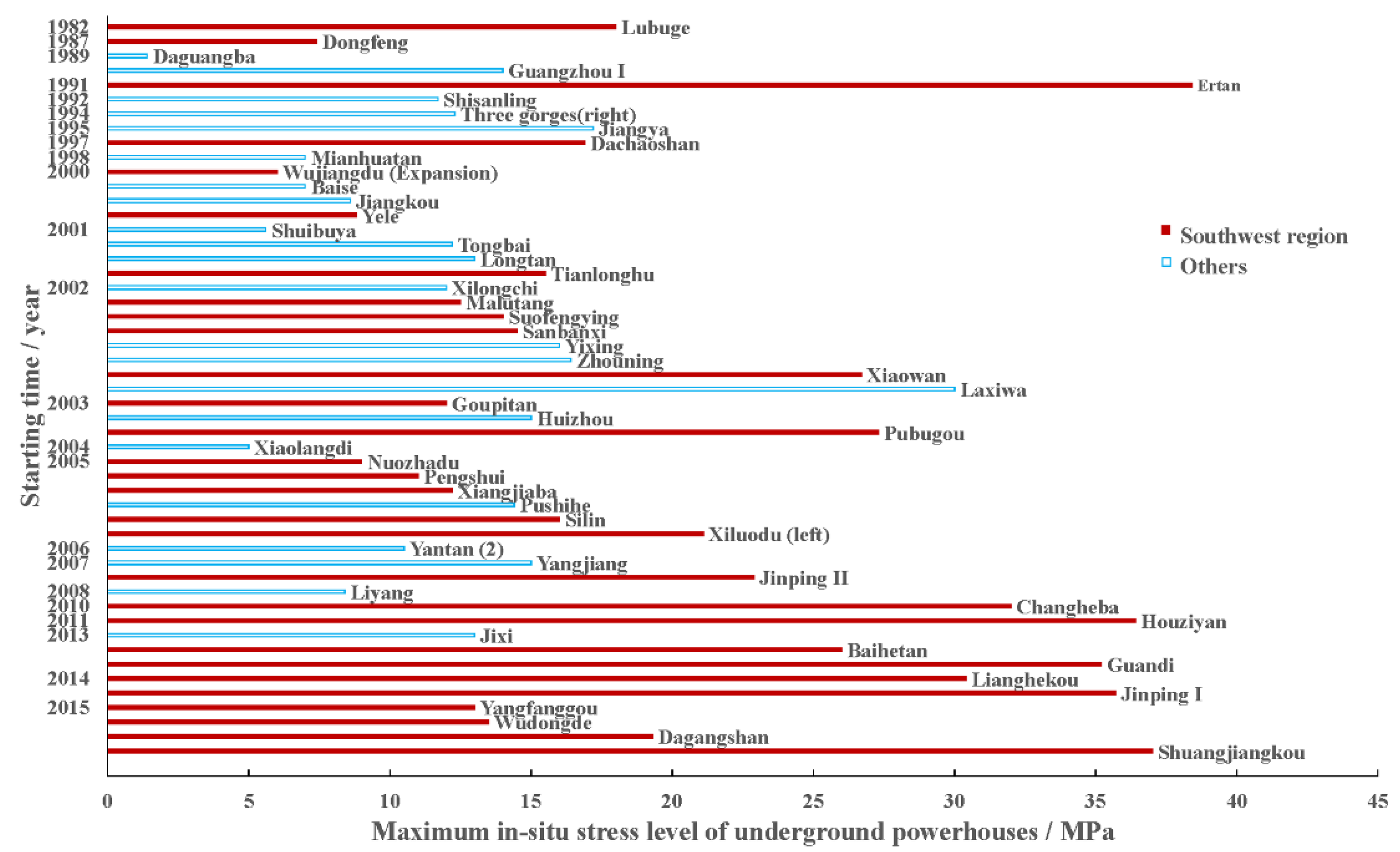

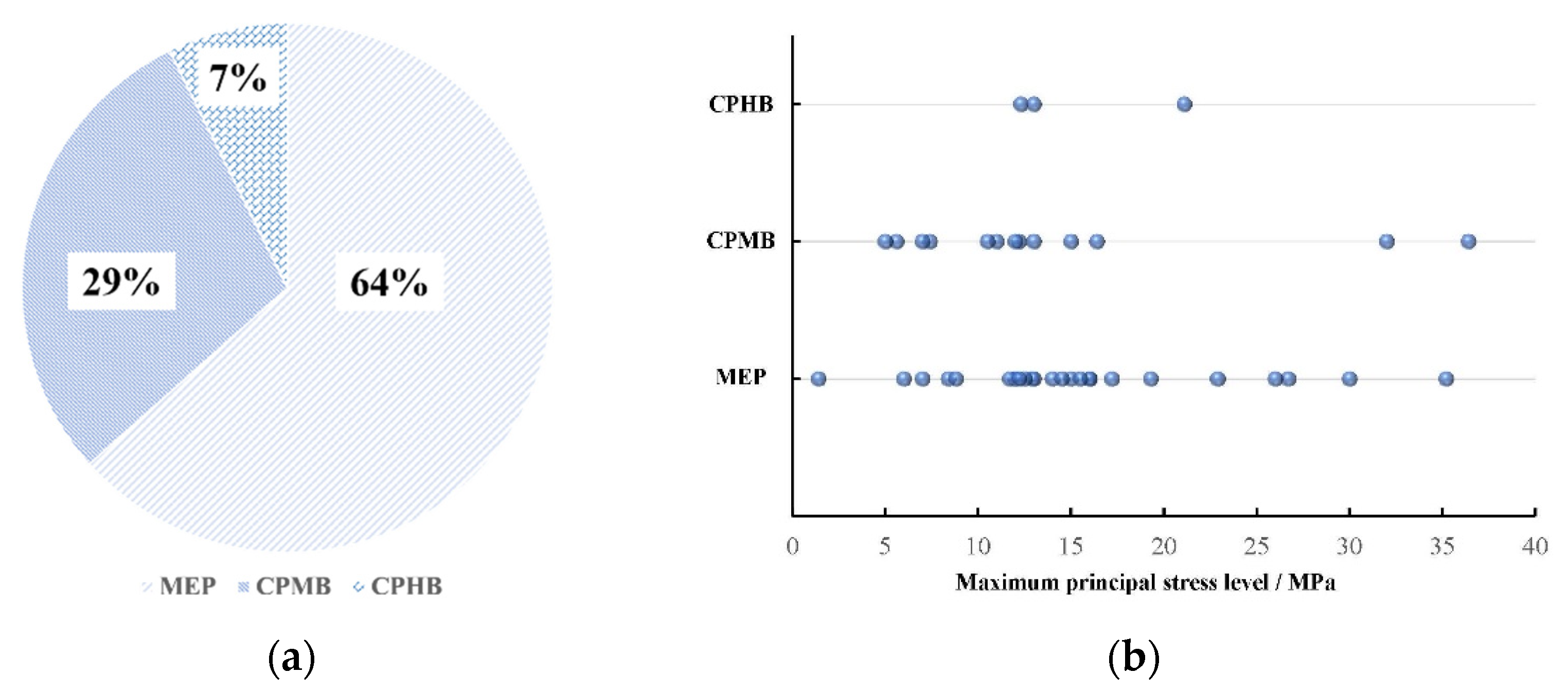

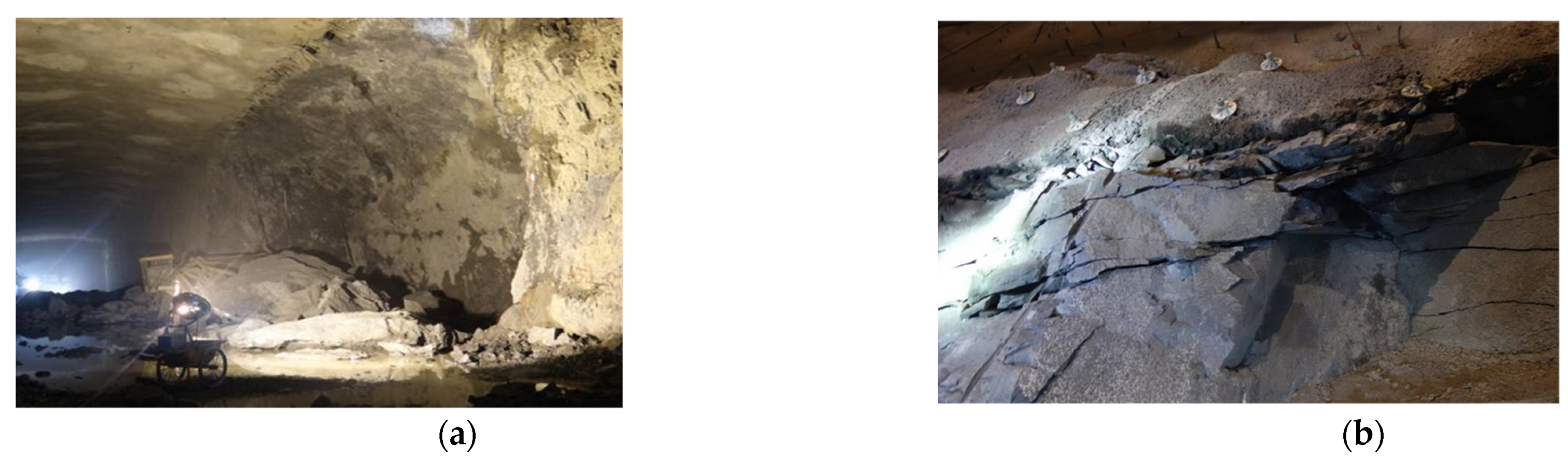

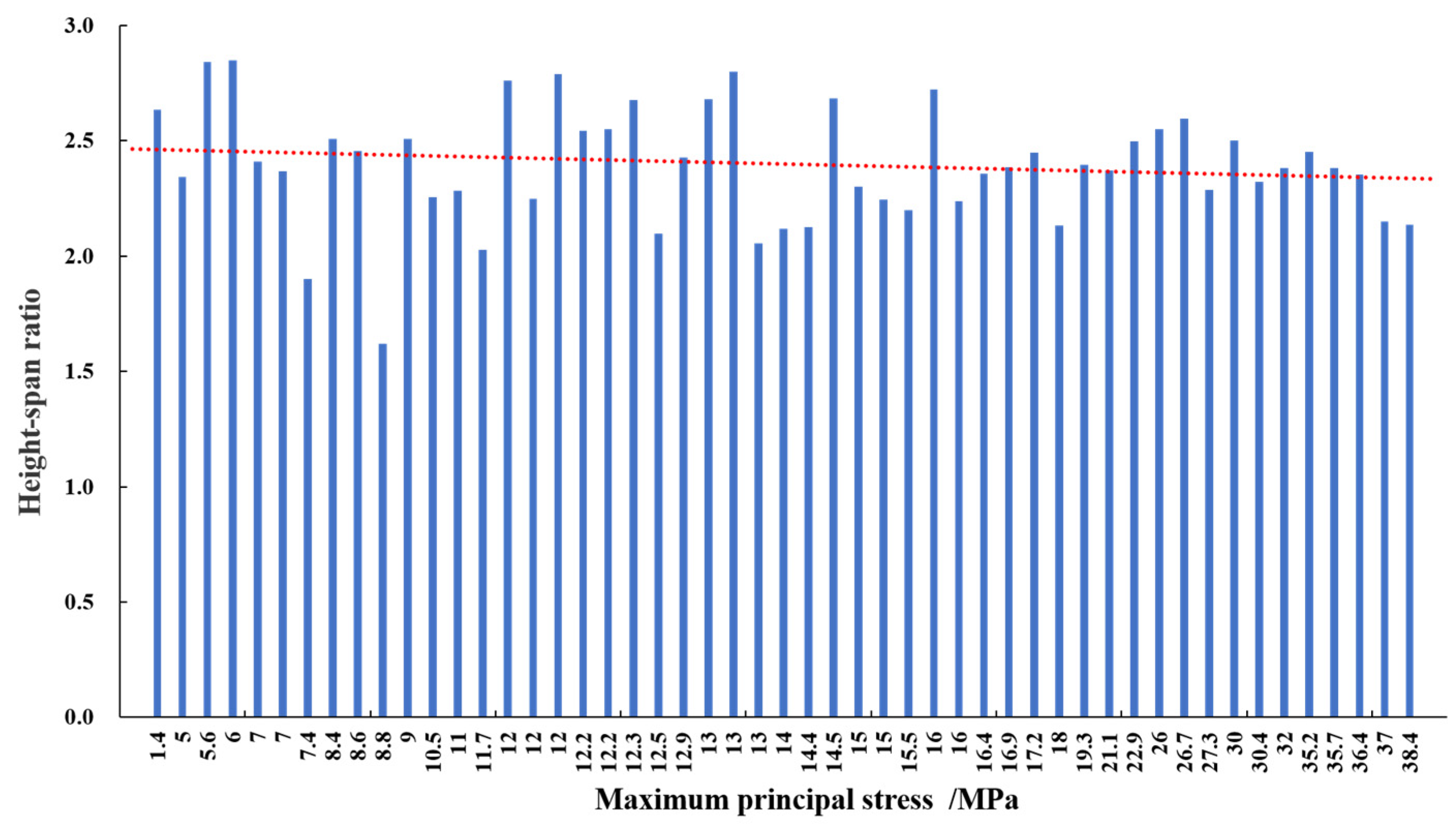

2. Overviews of In Situ Stress and Fifty-One Underground Powerhouses in China

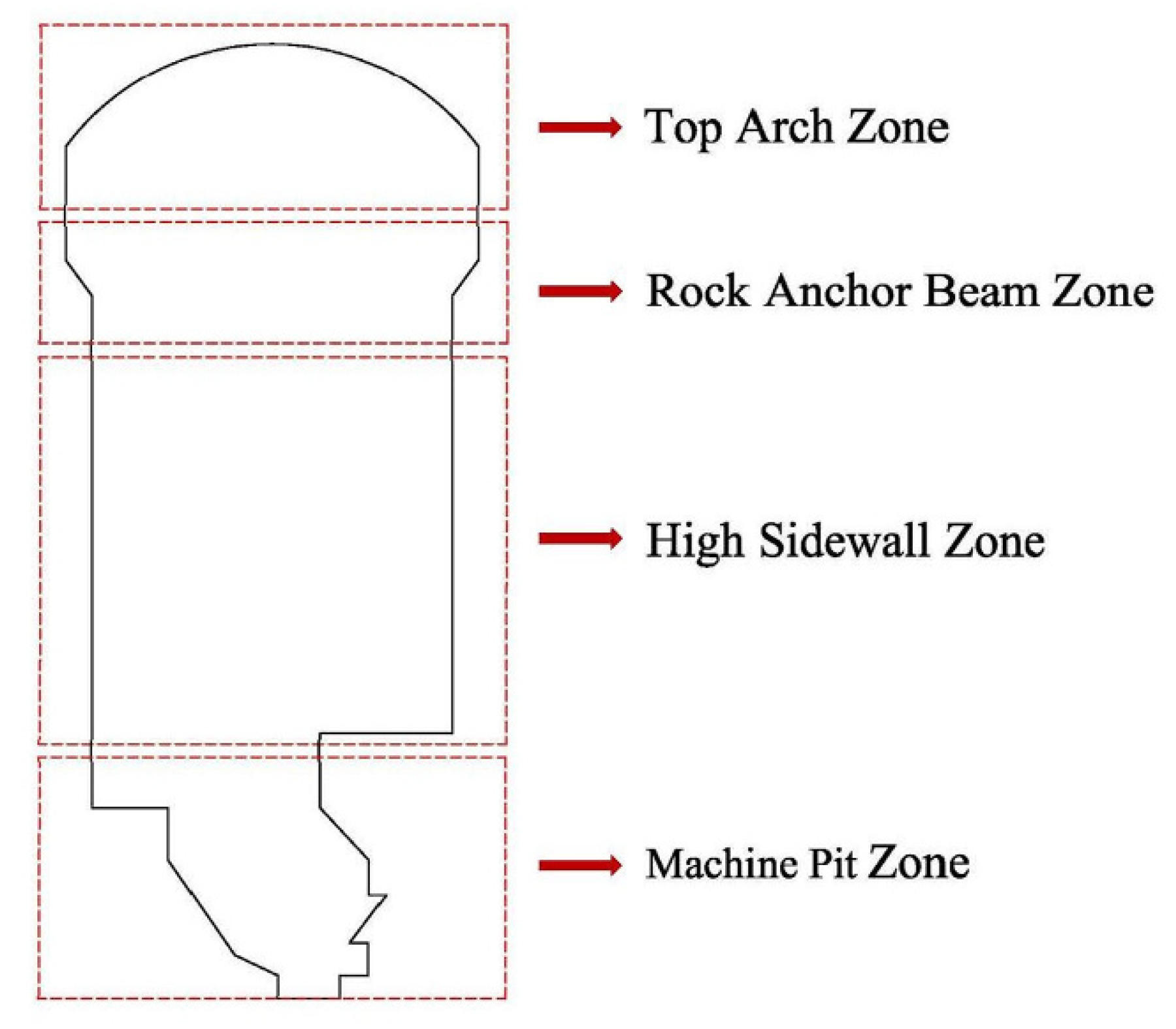

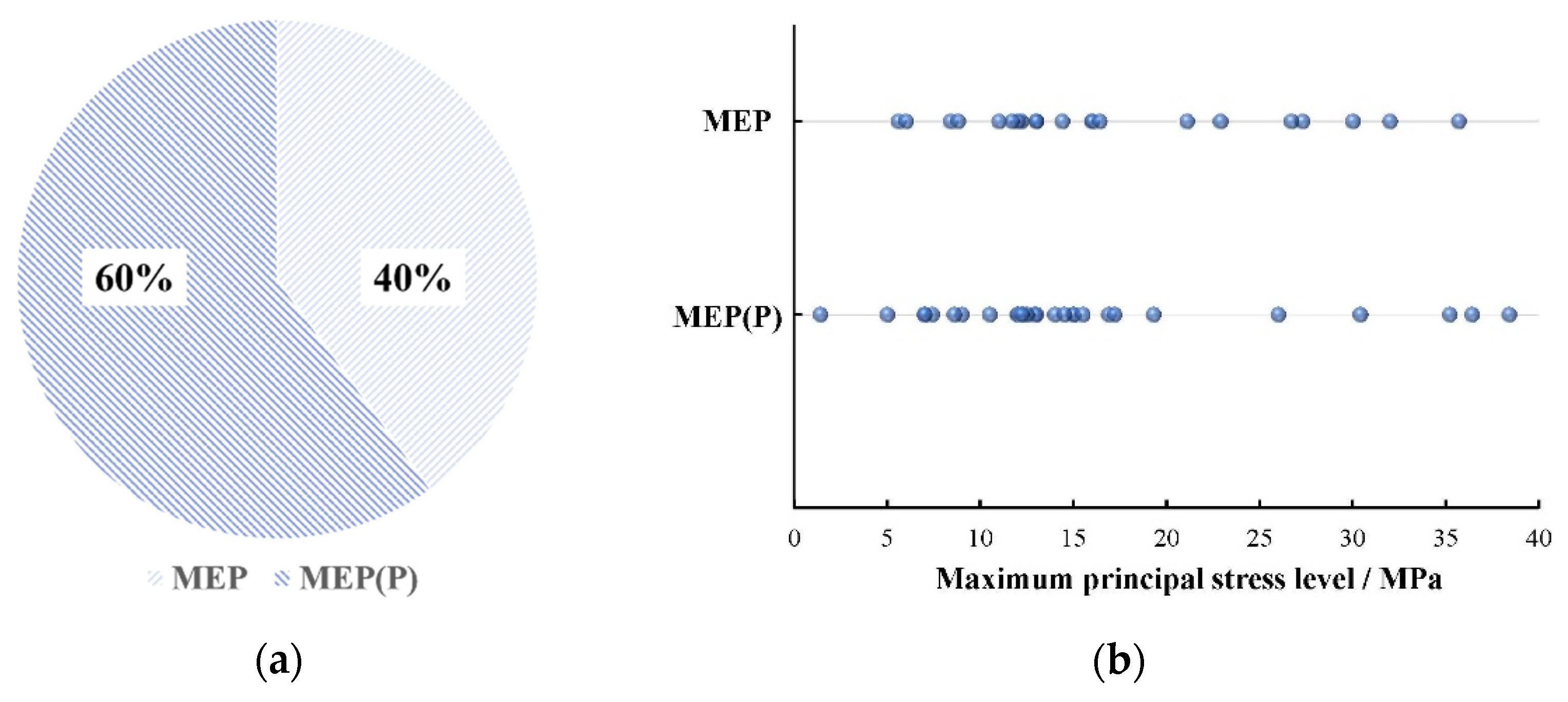

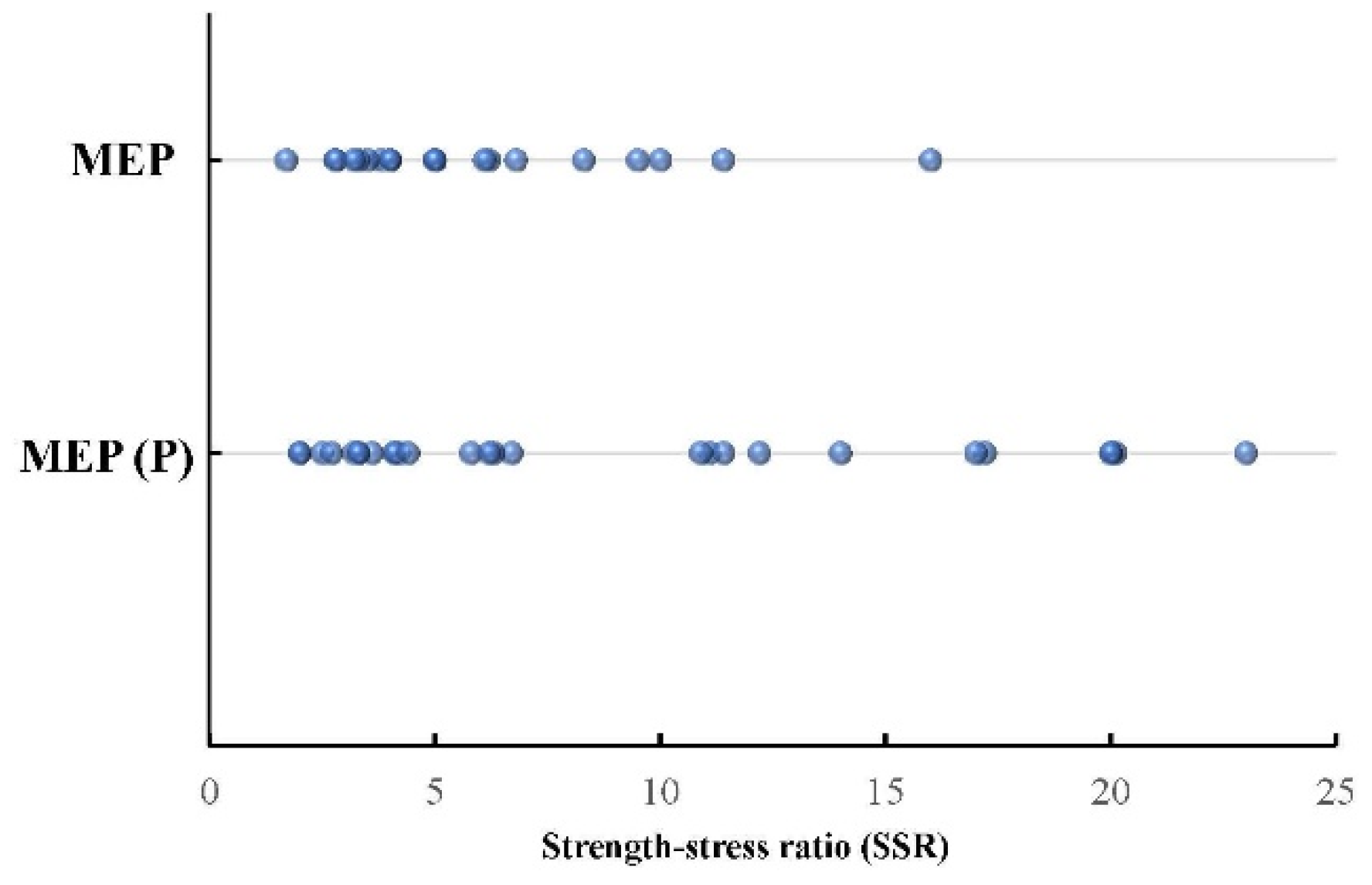

3. Excavation Procedures and In Situ Stress Level

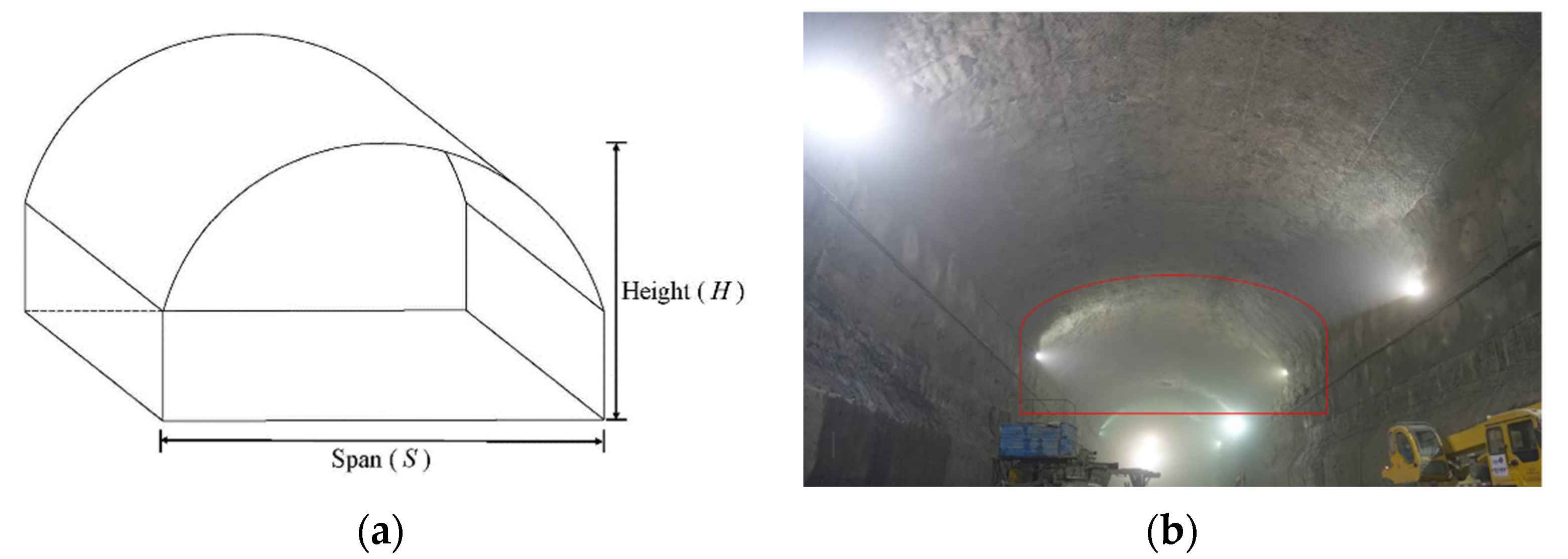

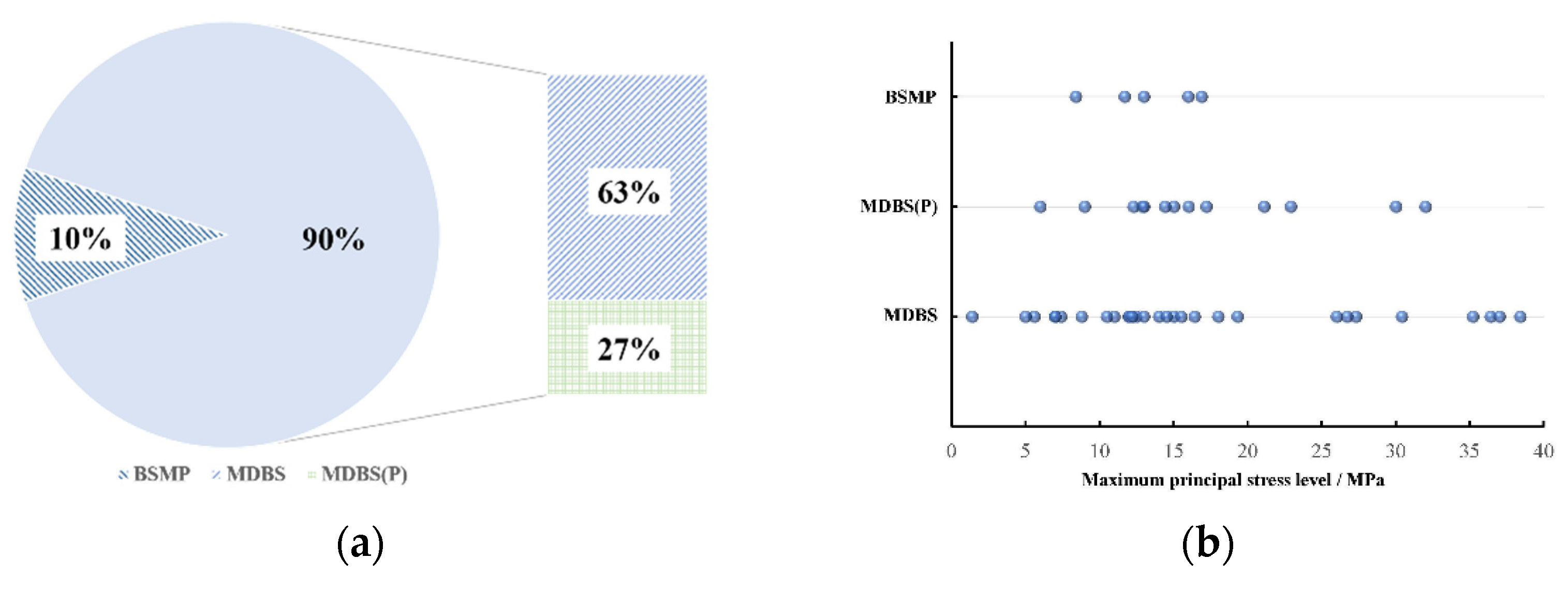

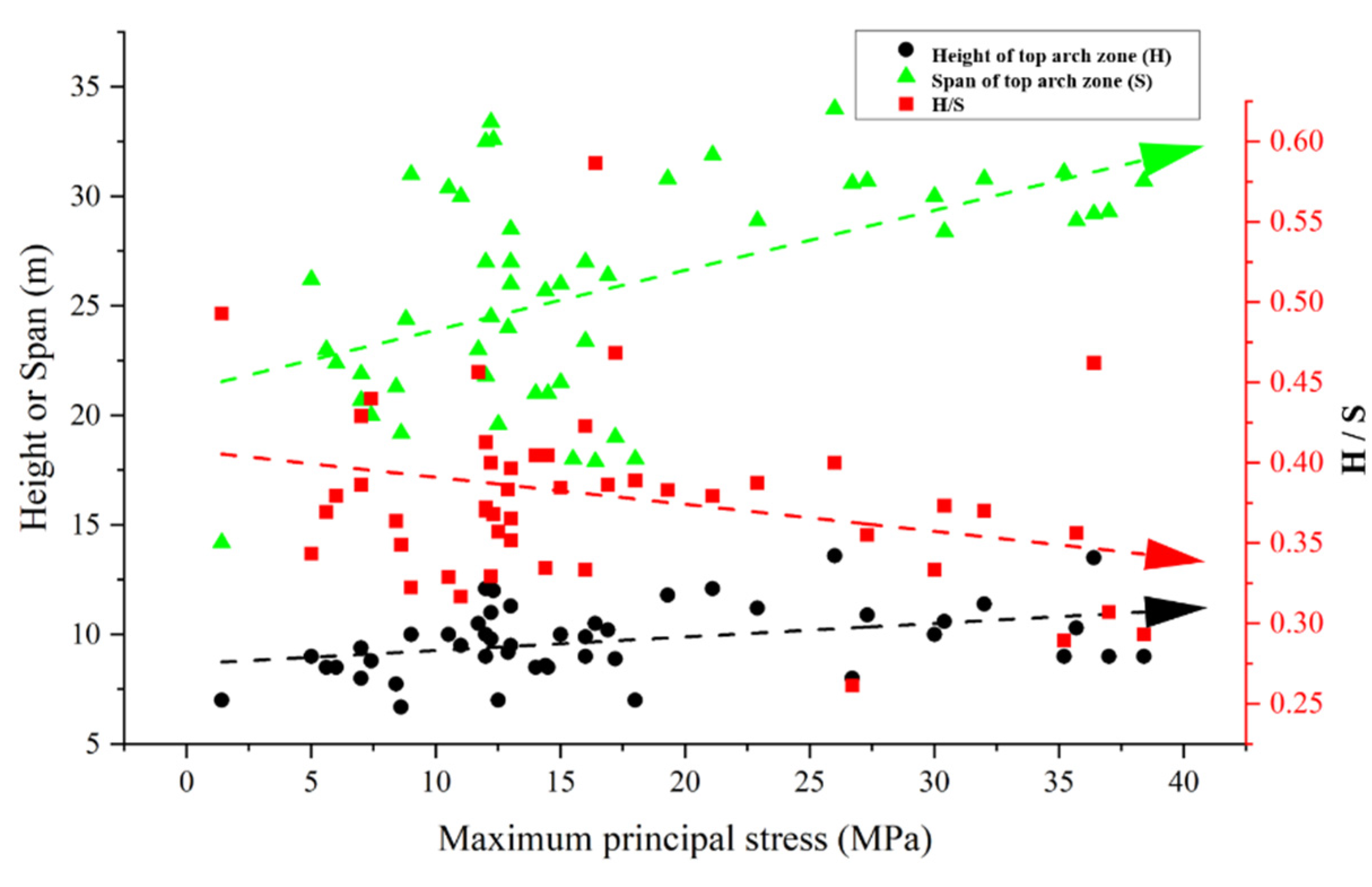

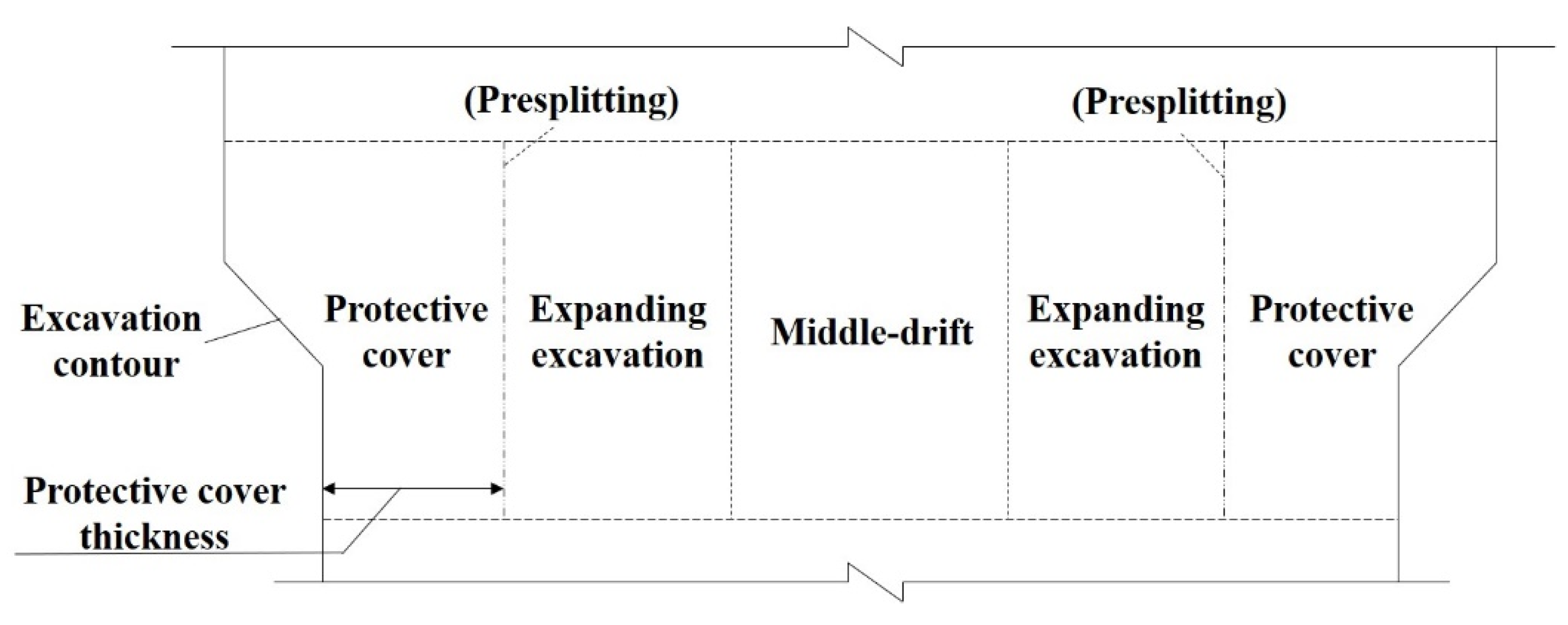

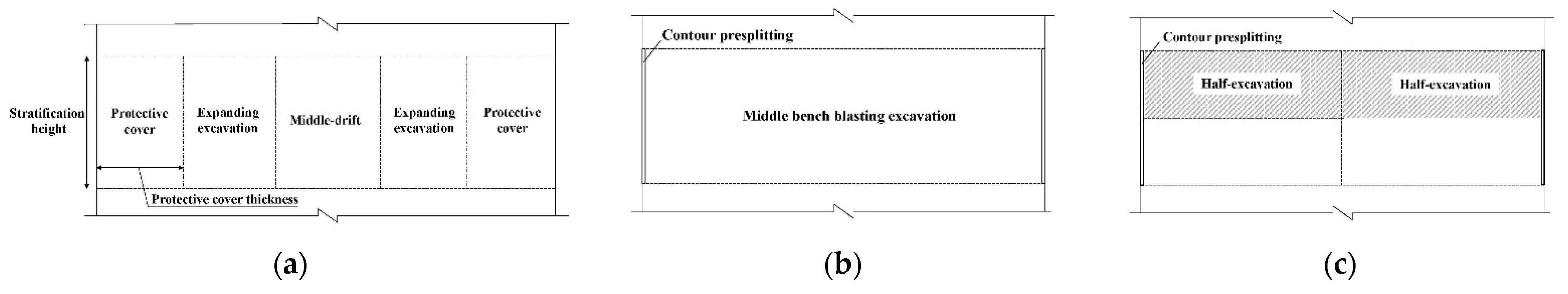

3.1. Top Arch Zone

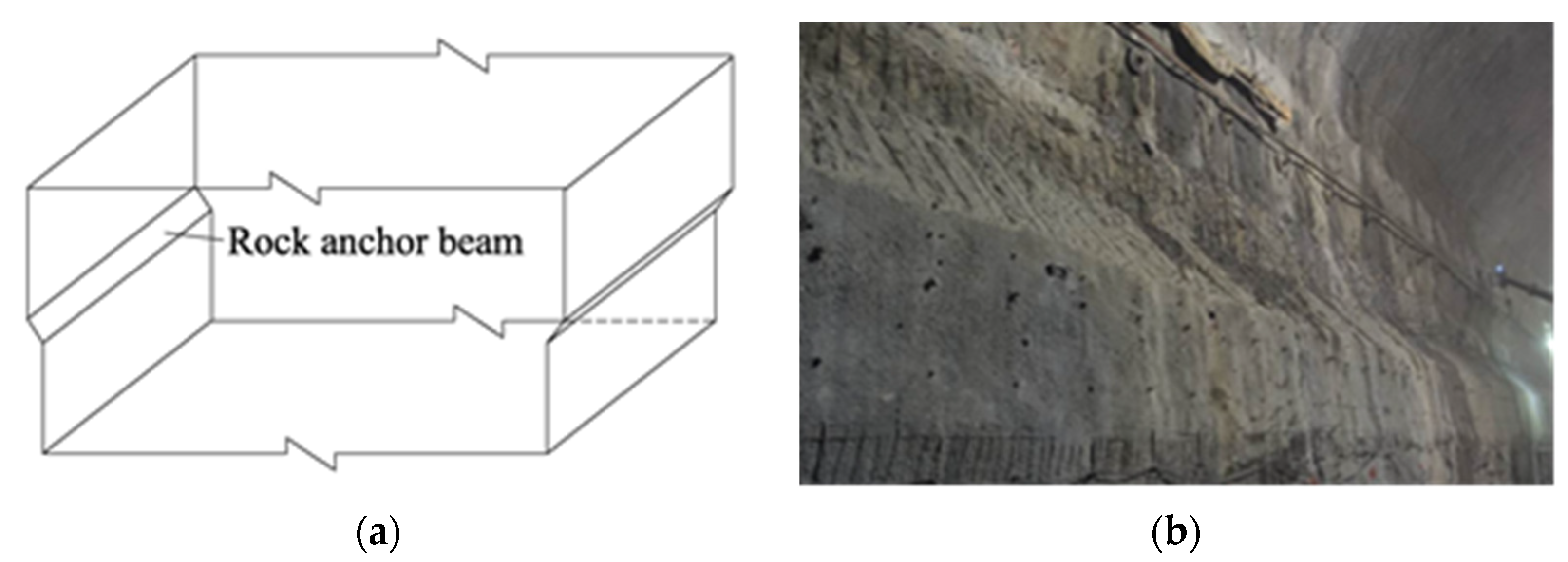

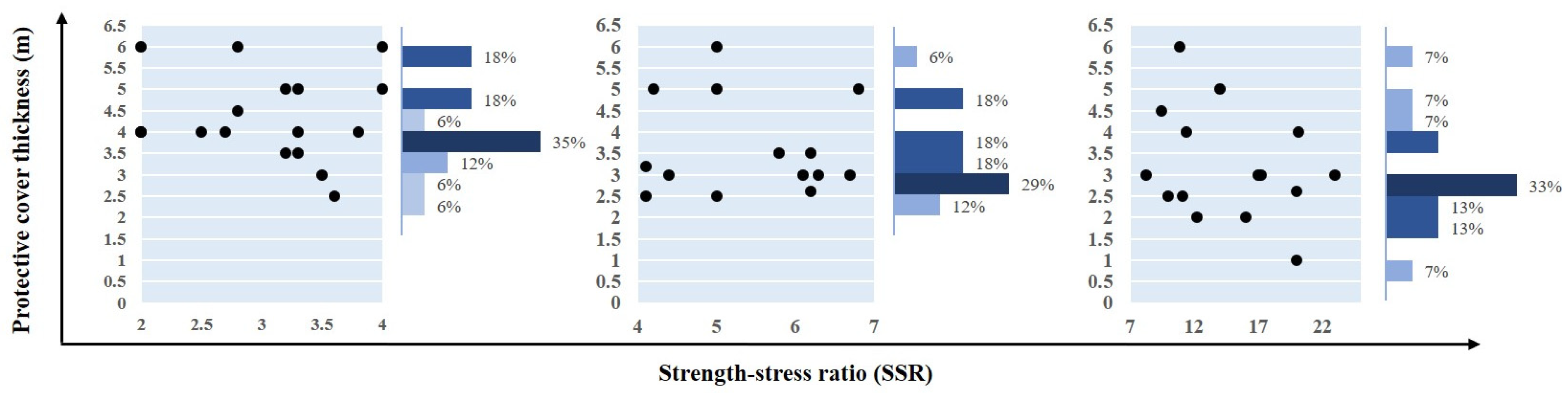

3.2. Rock Anchor Beam Zone

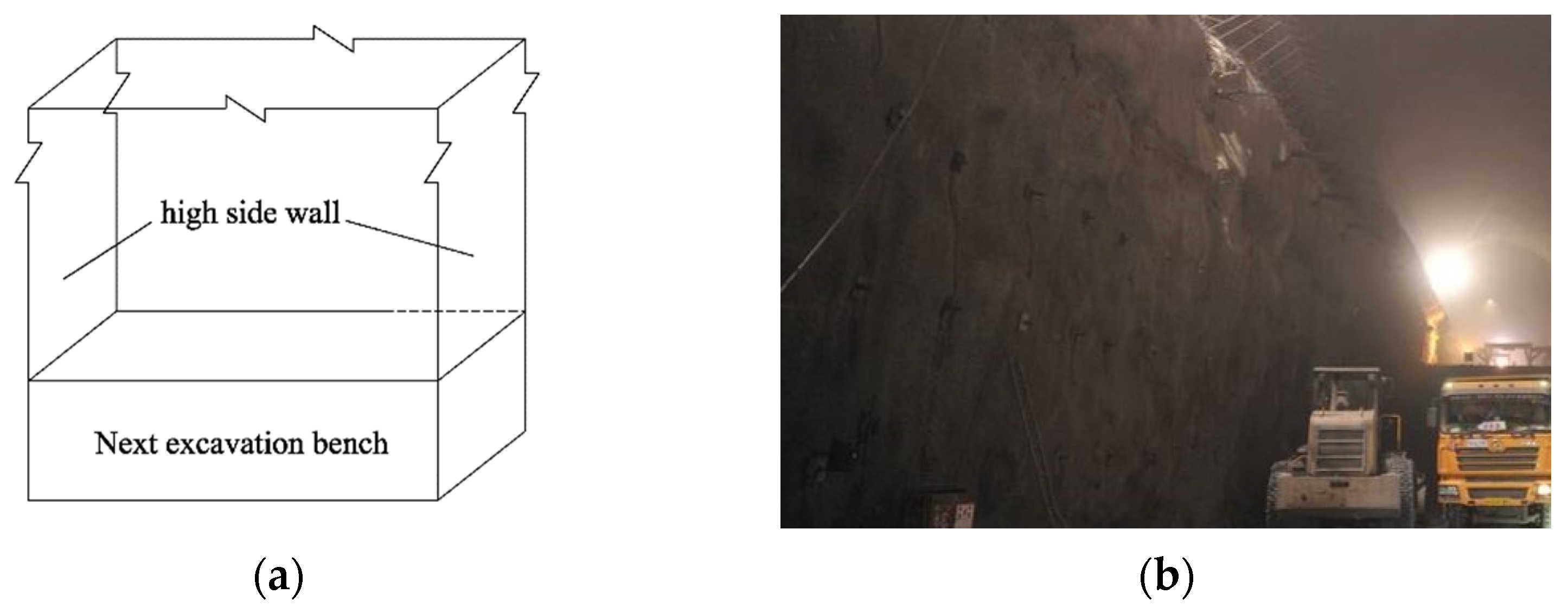

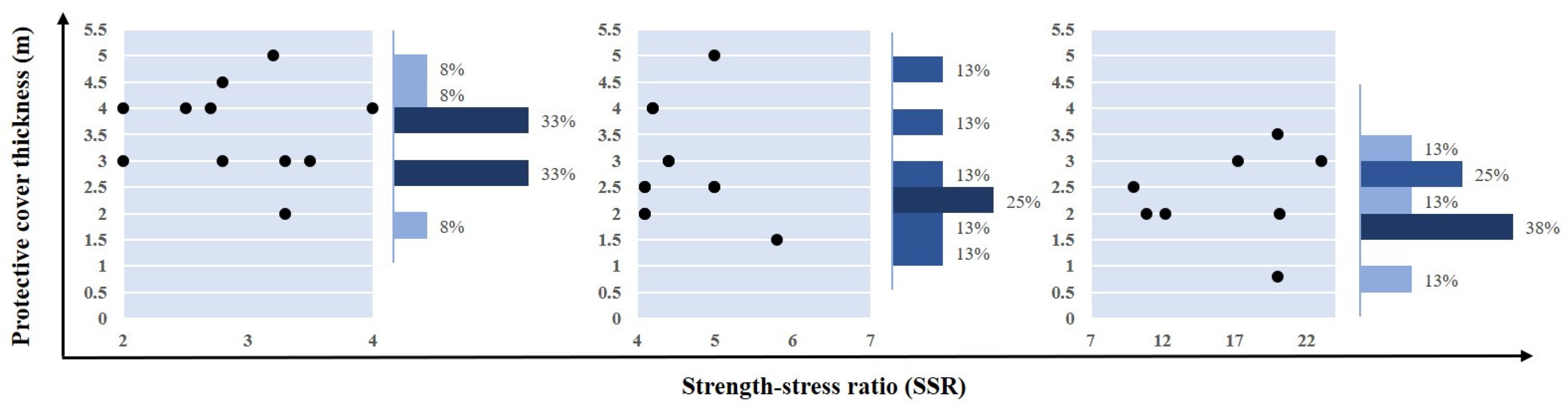

3.3. High Side Wall Zone

4. Excavation Design Based on SSR and Stress Unloading Effect

4.1. Excavation Procedure Design Based on the SSR

4.2. Blasting Excavation and Stress Transient Unloading Effect

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, A.; Dai, F.; Liu, Y.; Du, H.; Jiang, R. Dynamic stability evaluation of underground cavern sidewalls against flexural toppling considering excavation-induced damage. Tunn. Undergr. Space Technol. 2021, 112, 103903. [Google Scholar] [CrossRef]

- Dai, F.; Li, B.; Xu, N.; Zhu, Y. Microseismic early warning of surrounding rock mass deformation in the underground powerhouse of the Houziyan hydropower station, China. Tunn. Undergr. Space Technol. 2017, 62, 64–74. [Google Scholar] [CrossRef]

- Xiao, P.; Li, T.; Xu, N.; Zhou, Z.; Liu, X. Microseismic monitoring and deformation early warning of the underground caverns of Lianghekou hydropower station, Southwest China. Arab. J. Geosci. 2019, 12, 496. [Google Scholar] [CrossRef]

- Xu, J.; Jiang, J.; Xu, N.; Liu, Q.; Gao, Y. A new energy index for evaluating the tendency of rockburst and its engineering application. Eng. Geol. 2017, 230, 46–54. [Google Scholar] [CrossRef]

- Xie, L.; Yan, P.; Lu, W.; Chen, M.; Wang, G. Comparison of seismic effects during deep tunnel excavation with different methods. Earthq. Eng. Eng. Vib. 2018, 17, 208–224. [Google Scholar] [CrossRef]

- Wang, W.; Liu, G.; Su, Q.; Han, R. Analysis of Excavation Procedure and Stability in Jointed Rock Masses of the Large Underground Caverns; Springer International Publishing: Cham, Switzerland, 2019; pp. 1358–1362. [Google Scholar]

- Li, H.-B.; Liu, M.-C.; Xing, W.-B.; Shao, S.; Zhou, J.-W. Failure mechanisms and evolution assessment of the excavation damaged zones in a large-scale and deeply buried underground powerhouse. Rock Mech. Rock Eng. 2017, 50, 1883–1900. [Google Scholar] [CrossRef]

- Qin, Z.; Cao, B.; Liu, Y.; Li, T. Study on in situ stress measurement and surrounding rock control technology in deep mine. Geofluids 2020, 2020, 8839333. [Google Scholar] [CrossRef]

- Cai, H. Safety Monitoring and Engineering Treatment Measures for the Underground Plant of a Pumped Storage Power Station in Pushi River. Ph.D. Thesis, Jilin University, Jilin, China, 2013. [Google Scholar]

- He, S.; Ma, L. Summary of construction technology of hydropower and water conservancy underground engineering in China. Water Conserv. Hydropower Constr. 2016. [Google Scholar]

- Yan, P.; He, Q.; Lu, W.; He, Y.; Zhou, W.; Chen, M. Coring damage extent of rock cores retrieved from high in-situ stress condition: A case study. KSCE J. Civ. Eng. 2017, 21, 2946–2957. [Google Scholar] [CrossRef]

- Yang, L.; Chen, S.; Fang, S.; Huang, C.; Xie, H. Model experimental study on the effects of in situ stresses on pre-splitting blasting damage and strain development. Int. J. Rock Mech. Min. Sci. 2021, 138, 104587. [Google Scholar] [CrossRef]

- Manouchehrian, A.; Cai, M. Simulation of unstable rock failure under unloading conditions. Can. Geotech. J. 2016, 53, 22–34. [Google Scholar] [CrossRef]

- Lu, W.; Yang, J.; Yan, P.; Chen, M.; Fan, Y. Mechanism and Effect of Transient Unloading in Deep Rock Excavation; Science Press: Beijing, China, 2018; ISBN 978-7-03-056868-7. [Google Scholar]

- Yang, J.; Lu, W.; Li, P.; Yan, P. Evaluation of rock vibration generated in blasting excavation of deep-buried tunnels. KSCE J. Civ. Eng. 2017, 22, 2593–2608. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Z. Surrounding rock effect on coal burst under unloading condition: A numerical study. Arab. J. Geosci. 2021, 14, 1742. [Google Scholar] [CrossRef]

- Chen, M.; Lu, W.B.; Yan, P.; Hu, Y.G. Blasting excavation induced damage of surrounding rock masses in deep-buried tunnels. KSCE J. Civ. Eng. 2016, 20, 933–942. [Google Scholar] [CrossRef]

- Wu, P.; Yang, T.; Jia, W. Reliability analysis and prediction on tunnel roof under blasting disturbance. KSCE J. Civ. Eng. 2019, 23, 4036–4046. [Google Scholar] [CrossRef]

- Chen, F.; He, C.; Deng, J. Concept of high geostress and its qualitative and quantitative definitions. Rock Soil Mech. 2015, 4, 971–980. [Google Scholar] [CrossRef]

- Yang, J.-C.; Liu, K.-W.; Li, X.-D.; Liu, Z.-X. Stress initialization methods for dynamic numerical simulation of rock mass with high in-situ stress. J. Cent. South. Univ. 2020, 27, 3149–3162. [Google Scholar] [CrossRef]

- Fan, Y.; Zheng, J.; Hu, X.; Cui, X.; He, W. Study on energy release of surrounding rock under the multiple unloading disturbance during tunnel excavation. Math. Probl. Eng. 2020, 2020, 6486815. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhou, H.; Lu, J.; Gao, Y.; Zhang, C.; Chen, J. Analysis of stress evolution characteristics during TBM excavation in deep buried tunnels. Bull. Int. Assoc. Eng. Geol. 2019, 78, 5177–5194. [Google Scholar] [CrossRef]

- Niu, L.; Zhu, W.; Cheng, Z.; Guan, K.; Qin, T. Numerical simulation on excavation-induced damage of rock under quasi-static unloading and dynamic disturbance. Environ. Earth Sci. 2017, 76, 614. [Google Scholar] [CrossRef]

- Jian-Po, L.; Yuan-Hui, L.; Shi-Da, X. Relationship between microseismic activities and mining parameters during deep mining process. J. Appl. Geophys. 2018, 159, 814–823. [Google Scholar] [CrossRef]

- Wang, C.; Xie, M.-Z.; Xiong, Z.-Q.; Wang, C.; Cheng, L.-P. Energy evolution law of ore-bearing rock during unloading under high static stress and frequent disturbance. Complexity 2020, 2020, 3806521. [Google Scholar] [CrossRef]

- Chen, S.-J.; Feng, F.; Wang, Y.-J.; Li, D.-Y.; Huang, W.-P.; Zhao, X.-D.; Jiang, N. Tunnel failure in hard rock with multiple weak planes due to excavation unloading of in-situ stress. J. Cent. South Univ. 2020, 27, 2864–2882. [Google Scholar] [CrossRef]

- Cheng, Y.; Song, Z.; Chang, X.; Wang, T. Energy evolution principles of shock-wave in sandstone under unloading stress. KSCE J. Civ. Eng. 2020, 24, 2912–2922. [Google Scholar] [CrossRef]

- Lu, W.; Yang, J.; Yan, P.; Chen, M.; Zhou, C.; Luo, Y.; Jin, L. Dynamic response of rock mass induced by the transient release of in-situ stress. Int. J. Rock Mech. Min. Sci. 2012, 53, 129–141. [Google Scholar] [CrossRef]

- Zhang, J. Study on Excavation Sequence Selection of Large Underground Caverns and Construction Technology of Underground Powerhouse; University Tianjin: Tianjin, China, 2007. [Google Scholar]

- Qiu, S.; Eliasson, V. Interaction and coalescence of multiple simultaneous and non-simultaneous blast waves. Shock Waves 2015, 26, 287–297. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, G.; Wu, L.; Zuo, Q.; Liu, Y.; Zhang, C. Comparative study on tunnel blast-induced vibration for the underground cavern group. Environ. Earth Sci. 2021, 80, 68. [Google Scholar] [CrossRef]

- Qinghua, X.; Jianguo, L.; Shenxiang, L.; Bo, G. A new method for calculating energy release rate in tunnel excavation subjected to high in situ stress. Perspect. Sci. 2016, 7, 292–298. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.-P.; Xu, G.; Dong, J.; Li, Z.; Wang, J.; Chen, C. Deformation and fracture of surrounding rock mass of underground caverns at Houziyan Hydropower Station. Chin. J. Rock Mech. Eng. 2014, 33, 2291–2300. [Google Scholar] [CrossRef]

- Xu, W.-Y.; Nie, W.-P.; Zhou, X.-Q.; Shi, C.; Wang, W.; Feng, S.-R. Long-term stability analysis of large-scale underground plant of Xiangjiaba hydro-power station. J. Cent. South Univ. 2011, 18, 511–520. [Google Scholar] [CrossRef]

- Jiang, Q.; Su, G.; Feng, X.-T.; Chen, G.; Zhang, M.-Z.; Liu, C. Excavation optimization and stability analysis for large underground caverns under high geostress: A case study of the Chinese Laxiwa Project. Rock Mech. Rock Eng. 2018, 52, 895–915. [Google Scholar] [CrossRef]

- Hu, Y.; Lu, W.; Wu, X.; Liu, M.; Li, P. Numerical and experimental investigation of blasting damage control of a high rock slope in a deep valley. Eng. Geol. 2018, 237, 12–20. [Google Scholar] [CrossRef]

- Wang, M.; Li, H.-B.; Han, J.-Q.; Xiao, X.-H.; Zhou, J.-W. Large deformation evolution and failure mechanism analysis of the multi-freeface surrounding rock mass in the Baihetan underground powerhouse. Eng. Fail. Anal. 2019, 100, 214–226. [Google Scholar] [CrossRef]

- Huang, J. Study on Fine Blasting Excavation of Deep Underground Cavern Based on Timing Sequence Control Fracture and Borehole Notching; Wuhan University of Technology: Wuhan, China, 2018. [Google Scholar]

- Xu, C.; Yin, Q. Fine blasting technology in excavation of super large underground powerhouse of hydropower station. In Proceedings of the 9th National Engineering Blasting Academic Conference, Qingdao, China, 12–17 September 2008. [Google Scholar]

- Li, H. Study on Construction Procedure and Excavation Method of Large Underground Powerhouse; Wuhan University: Wuhan, China, 2004. [Google Scholar]

- Yang, J.; Huang, S.; Liu, Z. Relationship between deformation failure and strength-to-stress ratio of surrounding rock of large-scale underground hard rock caverns under high geo-stress. J. Yangtze River Sci. Res. Inst. 2019, 36, 67–74. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, P.; Chen, L.-J. Method of layout design based on ratio of rock strength to in-situ stress for large underground caverns. Chin. J. Rock Mech. Eng. 2014, 33, 2314–2331. [Google Scholar] [CrossRef]

- Li, B.; Ding, Q.-F.; Xu, N.-W.; Lei, Y.-F.; Xu, Y.; Zhu, Z.-P.; Liu, J.-F. Mechanical response and stability analysis of rock mass in high geostress underground powerhouse caverns subjected to excavation. J. Cent. South Univ. 2020, 27, 2971–2984. [Google Scholar] [CrossRef]

- Vazaios, I.; Vlachopoulos, N.; Diederichs, M.S. Mechanical analysis and interpretation of excavation damage zone formation around deep tunnels within massive rock masses using hybrid finite–discrete element approach: Case of Atomic Energy of Canada Limited (AECL) Underground Research Laboratory (URL) test tunnel. Can. Geotech. J. 2019, 56, 35–59. [Google Scholar] [CrossRef]

- Wang, Z.-Y.; Gu, D.-M.; Zhang, W.-G. Influence of excavation schemes on slope stability: A DEM study. J. Mt. Sci. 2020, 17, 1509–1522. [Google Scholar] [CrossRef]

- Han, H.; Fukuda, D.; Liu, H.; Salmi, E.F.; Sellers, E.; Liu, T.; Chan, A. FDEM simulation of rock damage evolution induced by contour blasting in the bench of tunnel at deep depth. Tunn. Undergr. Space Technol. 2020, 103, 103495. [Google Scholar] [CrossRef]

- Tao, J.; Yang, X.-G.; Li, H.-T.; Zhou, J.-W.; Qi, S.-C.; Lu, G.-D. Numerical investigation of blast-induced rock fragmentation. Comput. Geotech. 2020, 128, 103846. [Google Scholar] [CrossRef]

- Chai, C.; Ling, S.; Wu, X.; Hu, T.; Sun, D. Characteristics of the in situ stress field and engineering effect along the Lijiang to Shangri-La Railway on the Southeastern Tibetan Plateau, China. Adv. Civ. Eng. 2021, 2021, 6652790. [Google Scholar] [CrossRef]

- Hasegawa, H.S.; Adams, J.; Yamazaki, K. Upper crustal stresses and vertical stress migration in eastern Canada. J. Geophys. Res. Space Phys. 1985, 90, 3637–3648. [Google Scholar] [CrossRef]

- Heidbach, O.; Rajabi, M.; Cui, X.; Fuchs, K.; Müller, B.; Reinecker, J.; Reiter, K.; Tingay, M.; Wenzel, F.; Xie, F.; et al. The world stress map database release 2016: Crustal stress pattern across scales. Tectonophysics 2018, 744, 484–498. [Google Scholar] [CrossRef]

- Heidbach, O.; Rajabi, M.; Cui, X.; Fuchs, K.; Müller, B.; Reinecker, J.; Tingay, M.; Reiter, K.; Wenzel, F.; Xie, F.; et al. World Stress Map Database Release 2016: Crustal stress pattern across scales. Tectonophysics 2018, 744, 484–498. [Google Scholar] [CrossRef]

- Ma, H.; Zhou, Y.; He, S. Construction of Underground Hydro Works in China; China Water and Power Press: Beijing, China, 2011; ISBN 978-7-5084-8304-7. [Google Scholar]

- Jiang, J.; Gao, B. Summarization of underground chambers blasting excavation. J. Yangtze River Sci. Res. Inst. 2003, 20, 32–34. [Google Scholar] [CrossRef]

- Xiao, X.-H.; Xiao, P.-W.; Dai, F.; Li, H.-B.; Zhang, X.-B.; Zhou, J.-W. Large deformation characteristics and reinforcement measures for a rock pillar in the Houziyan underground powerhouse. Rock Mech. Rock Eng. 2017, 51, 561–578. [Google Scholar] [CrossRef]

- Duan, S.-Q.; Feng, X.-T.; Liu, G.-F.; Pei, S.-F.; Fan, Y.-L.; Jiang, Q. In situ observation of failure mechanisms controlled by rock masses with weak interlayer zones in large underground cavern excavations under high geostress. Rock Mech. Rock Eng. 2017, 50, 2465–2493. [Google Scholar] [CrossRef]

- Hu, Z.; Xu, N.; Li, B.; Xu, Y.; Xu, J.; Wang, K. Stability analysis of the arch crown of a large-scale underground powerhouse during excavation. Rock Mech. Rock Eng. 2020, 53, 2935–2943. [Google Scholar] [CrossRef]

- Feng, X.-T.; Xu, H.; Qiu, S.-L.; Li, S.-J.; Yang, C.-X.; Guo, H.-S.; Cheng, Y.; Gao, Y.-H. In situ observation of rock spalling in the deep tunnels of the China Jinping underground laboratory (2400 m depth). Rock Mech. Rock Eng. 2018, 51, 1193–1213. [Google Scholar] [CrossRef]

- Zhou, Y.-Y.; Xu, D.-P.; Gu, G.-K.; Liu, K.; Wan, L.-P.; Wang, T.-L.; Yang, J.-B. The failure mechanism and construction practice of large underground caverns in steeply dipping layered rock masses. Eng. Geol. 2019, 250, 45–64. [Google Scholar] [CrossRef]

- Xue, R.; Liang, Z.; Xu, N. Rockburst prediction and analysis of activity characteristics within surrounding rock based on microseismic monitoring and numerical simulation. Int. J. Rock Mech. Min. Sci. 2021, 142, 104750. [Google Scholar] [CrossRef]

- Zhou, Y.-Y.; Xu, D.-P.; Liu, K.; Chen, D.-F. Understanding the failure mechanism of a large underground cavern in steeply dipping layered rock mass using an enhanced ubiquitous-joint model. Bull. Int. Assoc. Eng. Geol. 2021, 80, 4621–4638. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, Z.; Pan, Y.; Gao, Y.; Zhou, H.; Cui, G. Influence of amygdale on crack evolution and failure behavior of basalt. Eng. Fract. Mech. 2020, 226, 106843. [Google Scholar] [CrossRef]

- Zhao, J.; Feng, X.-T.; Zhang, X.; Yang, C. Brittle and ductile creep behavior of Jinping marble under true triaxial stress. Eng. Geol. 2019, 258, 105157. [Google Scholar] [CrossRef]

- Zhao, J.-S.; Feng, X.-T.; Jiang, Q.; Zhou, Y.-Y. Microseismicity monitoring and failure mechanism analysis of rock masses with weak interlayer zone in underground intersecting chambers: A case study from the Baihetan Hydropower Station, China. Eng. Geol. 2018, 245, 44–60. [Google Scholar] [CrossRef]

- Wang, A.; Deng, Z. Development of underground powerhouse of hydropower station in China. Water Power 2015, 41, 65–68. [Google Scholar] [CrossRef]

- Du, B.; Du, Y.; Xu, F.; He, P. Conception and exploration of using data as a service in tunnel construction with the NATM. Engineering 2018, 4, 123–130. [Google Scholar] [CrossRef]

- Yu, W.; Li, K. Deformation mechanism and control technology of surrounding rock in the deep-buried large-span chamber. Geofluids 2020, 2020, 8881319. [Google Scholar] [CrossRef]

- Broch, E. Planning and utilisation of rock caverns and tunnels in Norway. Tunn. Undergr. Space Technol. 2016, 55, 329–338. [Google Scholar] [CrossRef]

- Kong, X.; Liu, Q.; Zhang, Q.; Wu, Y.; Zhao, J. A method to estimate the pressure arch formation above underground excavation in rock mass. Tunn. Undergr. Space Technol. 2018, 71, 382–390. [Google Scholar] [CrossRef]

- Kong, X.; Liu, Q.; Pan, Y.; Liu, J. Stress redistribution and formation of the pressure arch above underground excavation in rock mass. Eur. J. Environ. Civ. Eng. 2021, 25, 722–736. [Google Scholar] [CrossRef]

- Shi, G.-B.; Li, N. Arch shape optimization of large Caverns under high land stress. Chin. J. Appl. Mech. 2005, 4, 661–664. [Google Scholar] [CrossRef]

- Li, X.; Lv, J.; Luo, Y.; Liu, T. Mechanism study on elevation effect of blast wave propagation in high side wall of deep underground powerhouse. Shock Vib. 2018, 2018, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Hydropower and Water Conservancy Planning and Design Institute. Design Code for Underground Powerhouses of Hydro-Power Stations (NBT35090-2016); Ministry of Housing and Urban Rural Development: Beijing, China, 2017. [Google Scholar]

- China Federation of Electric Power Enterprises. Code for Hydropower Engineering Geological Investigation (GB 50287-2016); National Energy Administration: Beijing, China, 2016. [Google Scholar]

- Yan, P.; Lu, W.; Li, H.; Chen, M.; Zhou, C. Influences of geo-stress on energy distribution of vibration induced by blasting excavation. Explos. Shock Waves 2009, 29, 182–187. [Google Scholar] [CrossRef]

- Yang, J.; Lu, W.; Jiang, Q.; Yao, C.; Jiang, S.; Tian, L. A study on the vibration frequency of blasting excavation in highly stressed rock masses. Rock Mech. Rock Eng. 2016, 49, 2825–2843. [Google Scholar] [CrossRef]

- Sun, D.; Li, Y.; Chen, X.; Yang, Q. A study on the normal transmission of a one-dimensional P-wave across a single nonlinear joint in a rockmass. Adv. Civ. Eng. 2019, 2019, 5762487. [Google Scholar] [CrossRef]

- Skrzypkowski, K. Case studies of rock bolt support loads and rock mass monitoring for the room and pillar method in the Legnica-Gogów Copper District in Poland. Energies 2020, 13, 2998. [Google Scholar] [CrossRef]

| Project Name | Installation Capacity (MW); | Main Powerhouse Size (Length × Width × Height)/m | Lithology | Rock Classification | In Situ Stress Level (MPa) |

|---|---|---|---|---|---|

| Ertan | 6 × 550 | 280.3 × 30.7 × 65.6 | Syenite, Basalt | II, III | 17.2~38.4 |

| Shuangjiangkou | 4 × 500 | 132.6 × 29.3 × 63.0 | Granite | II | 16.0~37.0 |

| Houziyan | 4 × 425 | 219.5 × 29.2 × 68.7 | Limestone | II, III | 21.5~36.4 |

| Jinping I | 6 × 600 | 277.0 × 28.9 × 68.8 | Marble | III | 20.0~35.7 |

| Guandi | 4 × 600 | 243.4 × 31.1 × 76.3 | Basalt | II, III | 25.0~35.2 |

| Changheba | 4 × 650 | 228.8 × 30.8 × 73.4 | Granite | II, III | 16.0~32.0 |

| Lianghekou | 6 × 500 | 275.9 × 28.4 × 66.0 | Sandy slate | III | 21.6~30.4 |

| Laxiwa | 6 × 700 | 311.8 × 30.0 × 75.0 | Granite | I, II | 14.6~30.0 |

| Pubugou | 6 × 550 | 294.1 × 30.7 × 70.2 | Granite | II, III | 21.1~27.3 |

| Xiaowan | 6 × 700 | 298.4 × 30.6 × 79.4 | Gneiss | I, II | 16.5~26.7 |

| Baihetan | 16 × 1000 | 438.0 × 34.0 × 86.7 | Basalt | III | 19.0~26.0 |

| Jinping II | 8 × 600 | 352.4 × 28.9 × 72.2 | Marble | III | 10.1~22.9 |

| Xiluodu (left) | 9 × 770 | 439.7 × 31.9 × 75.6 | Basalt | I, II | 14.8~21.1 |

| Dagangshan | 4 × 650 | 226.6 × 30.8 × 73.8 | Granite | II, III | 11.4~19.3 |

| Lubuge | 4 × 150 | 125.0 × 18.0 × 38.4 | Limestone, Dolomite | II, III, IV | 13.5~18.0 |

| Jiangya | 3 × 100 | 107.0 × 19.0 × 46.5 | Limestone | II | 17.2 |

| Dachaoshan | 6 × 225 | 233.5 × 26.4 × 63.0 | Basalt | II, III | 13.0~16.9 |

| Zhouning | 2 × 125 | 66.8 × 17.9 × 42.2 | Granite | I, II | 14.6~16.4 |

| Silin | 4 × 262.5 | 177.8 × 27.0 × 73.5 | Limestone | II, III | 9.7~16.0 |

| Yixing | 4 × 250 | 155.3 × 23.4 × 52.4 | Sandstone | III, IV | 8.3~16.0 |

| Tianlonghu | 180 | 77.0 × 18.0 × 39.6 | Metasandstone, Phyllite | III, IV, V | 9.7~15.5 |

| Yangjiang | 6 × 400 | 216.0 × 26.0 × 59.8 | Biotite granite | I, II | 14.0~15.0 |

| Huizhou | 8 × 300 | 152.0 × 21.5 × 48.3 | Granite | I, II | 12.0~15.0 |

| Sanbanxi | 4 × 250 | 146.4 × 21.0 × 56.4 | Sandstone | II, III | 14.5 |

| Pushihe | 4 × 300 | 173.3 × 25.7 × 54.6 | Migmatitic granite | II, III | 14.4 |

| Guangzhou I | 4 × 300 | 146.5 × 21.0 × 44.5 | Granite | II, III | 14.0 |

| longtan | 9 × 700 | 388.5 × 28.5 × 76.4 | Sandstone, Shale | II, III | 12.0~13.0 |

| Yangfanggou | 4 × 375 | 228.5 × 27.0 × 75.6 | Granodiorite | II, III | 12.6~13.0 |

| Jixi | 6 × 300 | 210.0 × 26.0 × 53.4 | Granite | II, III | 10.0~13.0 |

| Suofengying | 3 × 200 | 135.5 × 24.0 × 58.3 | Limestone | II, III | 12.9 |

| Malutang II | 3 × 100 | 97.4 × 19.6 × 41.1 | Gneiss | I | 9.0~12.5 |

| Three gorges (right) | 6 × 700 | 311.3 × 32.6 × 87.3 | granite | I, II | 11.2~12.3 |

| Tongbai | 4 × 300 | 182.7 × 24.5 × 62.3 | Granite | II, III | 10.9~12.2 |

| Xiangjiaba | 4 × 800 | 255.4 × 33.4 × 85.2 | Sandstone | II | 8.2~12.2 |

| Wudongde | 12 × 850 | 330.0 × 32.5 × 89.8 | Limestone, Dolomite | II, III | 6.0~12.0 |

| Xilongchi | 4 × 300 | 149.3 × 21.8 × 49.0 | Limestone | III | 12.0 |

| Goupitan | 5 × 600 | 230.5 × 27.0 × 75.3 | Limestone, Claystone | II, III | 12.0 |

| Shisanling | 4 × 200 | 145.0 × 23.0 × 46.6 | Conglomerate, Andesite | II, III | 9.5~11.7 |

| Pengshui | 5 × 350 | 252.0 × 30.0 × 68.5 | Limestone, Calcareous shale | II, III | 8.5~11.0 |

| Yantan (2) | 2 × 300 | 127.2 × 30.4 × 68.6 | Diabase | II, III | 10.5 |

| Nuozhadu | 9 × 700 | 418.0 × 31.0 × 77.8 | Granite | II, III | 6.0~9.0 |

| Yele | 2 × 120 | 72.1 × 24.4 × 39.5 | Quartz diorite | III, IV | 8.8 |

| Jiangkou | 3 × 100 | 89.8 × 19.2 × 47.0 | Limestone, Dolomite | I, II | 7.7~8.6 |

| Liyang | 6 × 250 | 179.9 × 21.3 × 53.4 | Quartz sandstone | III, IV | 8.4 |

| Dongfeng | 3 × 170 | 105.5 × 20.0 × 38.0 | Limestone, Shale | / | 7.4 |

| Mianhuatan | 4 × 150 | 129.5 × 21.9 × 52.8 | granite | I, II | 6.5~7.0 |

| Baise | 4 × 135 | 147.0 × 20.7 × 49.0 | Diabase | II, III | 5.0~7.0 |

| Wujiangdu (Expansion) | 2 × 250 | 84.2 × 22.4 × 63.8 | Limestone | II, III | 6.0 |

| Shuibuya | 4 × 400 | 168.5 × 23.0 × 65.4 | Limestone | II, IV | 5.6 |

| Xiaolangdi | 4 × 300 | 251.5 × 26.2 × 61.4 | Sandstone, Clay Rock | II, III | 5.0 |

| Daguangba | 4 × 60 | 87.1 × 14.2 × 37.4 | Granite | I, II | 1.4 |

| Classification of In Situ Stress | Maximum Principal Stress (MPa) | Strength–Stress Ratio (SSR) |

|---|---|---|

| Extremely high | ≥ 40 | <2 |

| high | < 40 | 2~4 |

| Medium | 10 ≤ < 20 | 4~7 |

| Low | < 10 | >7 |

| Project Name | SSR | Project Name | SSR | Project Name | SSR |

|---|---|---|---|---|---|

| Jinping I | 2.0~3.8 | Laxiwa | 4 | Pushihe | 8.3 |

| Houziyan | 2.0~4.0 | Shuangjiangkou | 4 | Xiluodu (left) | 9.5~20.2 |

| Lianghekou | 2.0~4.6 | Jiangya | 4.1 | Wujiangdu (Expansion) | 10 |

| Ertan | 2.5~8.7 | Suofengying | 4.1 | Tongbai | 10.9 |

| Baihetan | 2.7~4.7 | Dagangshan | 4.2~7.0 | Three gorges (right) | 11.1 |

| Pubugou | 2.8~22 | Malutang II | 4.4~6.0 | Yantan (2) | 11.4 |

| Jinping II | 2.8~8.0 | longtan | 5.0~10.0 | Yele | 11.4 |

| Guandi | 3.2~7.3 | Goupitan | 5 | Jiangkou | 12.2 |

| Liyang | 3.2~16.3 | Shisanling | 5 | Dongfeng | 14 |

| Wudongde | 3.3 | Guangzhou I | 5.8 | Shuibuya | 16 |

| Xilongchi | 3.3~5.0 | Zhouning | 6.1~7.9 | Baise | 17 |

| Pengshui | 3.3~6.0 | Yangfanggou | 6.2 | Sanbanxi | 17.2 |

| Xiaowan | 3.5 | Xiangjiaba | 6.2~9.8 | Xiaolangdi | 20 |

| Dachaoshan | 3.6~6.5 | Huizhou | 6.3 | Daguangba | 20 |

| Lubuge | 3.7 | Yangjiang | 6.7 | Nuozhadu | 20.1~30.2 |

| Changheba | 3.8~7.5 | Yixing | 6.8 | Mianhuatan | 23 |

| SSR | Rock Anchor Beam Zone | High Side Wall Zone | |

|---|---|---|---|

| Protective Cover Thickness | Stratification Height | Protective Cover Thickness | |

| 2.0~4.0 | 3.5~6.0 | 3.0~7.0 | 3.0~5.0 |

| 4.0~7.0 | 2.5~5.0 | 4.5~8.0 | 1.5~5.0 |

| >7.0 | 1.0~5.0 | 5.0~8.0 | 1.0~3.5 |

| Evolved Methods | Excavation Procedures and Sequences |

|---|---|

| MEP-1 | BB(Presplitting)→Z1 (Middle-drift)→AA (Presplitting)→Z2 (Expanding)→Z3 (buffer blasting) |

| MEP-2 | Z1(Middle-drift)→Z2(Expanding)→BB(smooth blasting)→Z3(Loose blasting)→AA(smooth blasting) |

| MEP-3 | BB (Presplitting)→Z1 (Middle-drift)→Z2 (Expanding)→Z3(buffer blasting)→AA (smooth blasting) |

| MEP-4 | Z1 (Middle-drift)→BB (Presplitting)→Z2 (Expanding)→Z3(Loose blasting)→AA (smooth blasting) |

| MEP-5 | Z1 (Middle-drift)→BB (Presplitting)→Z2 (Expanding)→AA(Presplitting)→Z3 (Loose blasting) |

| The Stress Perpendicular to the Axis of Powerhouse (MPa) | Recommended Blasting Excavation Technology Firstly |

|---|---|

| <10 | Contour presplitting, Middle-drift, Expanding |

| >(10~12) | Middle-drift, Expanding |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Yan, P.; Chen, M.; Luo, S.; Lu, A.; Lu, W.; Wang, G.; Huang, S. Optimization Analysis of Excavation Procedure Design of Underground Powerhouses under High In Situ Stress in China. Appl. Sci. 2021, 11, 10252. https://doi.org/10.3390/app112110252

Liu X, Yan P, Chen M, Luo S, Lu A, Lu W, Wang G, Huang S. Optimization Analysis of Excavation Procedure Design of Underground Powerhouses under High In Situ Stress in China. Applied Sciences. 2021; 11(21):10252. https://doi.org/10.3390/app112110252

Chicago/Turabian StyleLiu, Xiao, Peng Yan, Ming Chen, Sheng Luo, Ang Lu, Wenbo Lu, Gaohui Wang, and Shuling Huang. 2021. "Optimization Analysis of Excavation Procedure Design of Underground Powerhouses under High In Situ Stress in China" Applied Sciences 11, no. 21: 10252. https://doi.org/10.3390/app112110252

APA StyleLiu, X., Yan, P., Chen, M., Luo, S., Lu, A., Lu, W., Wang, G., & Huang, S. (2021). Optimization Analysis of Excavation Procedure Design of Underground Powerhouses under High In Situ Stress in China. Applied Sciences, 11(21), 10252. https://doi.org/10.3390/app112110252