Environmental and Economic Evaluation of Mechanical Biological Treatment System for Municipal Waste Considering the Political Framework in Ichihara City

Abstract

1. Introduction

2. Materials and Methods

2.1. Goal and Scope Definition

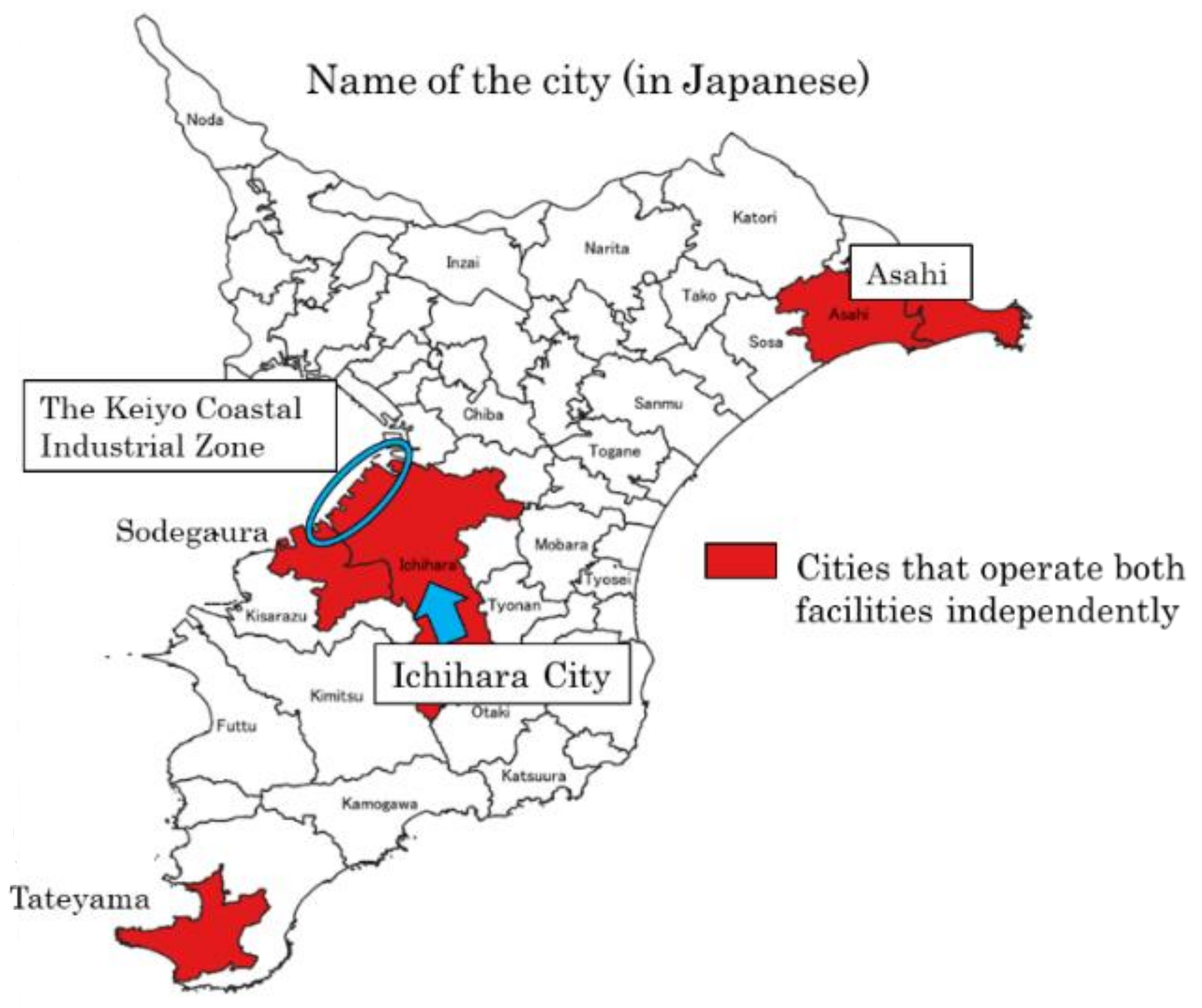

2.1.1. Model Area Settings

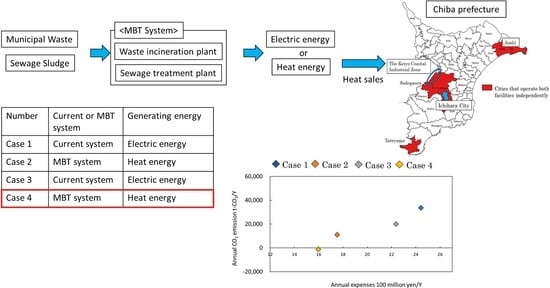

2.1.2. Evaluation Case Settings

2.1.3. Establishment of Waste Quality and Sewage Sludge Components

- HLHV = Lower heating value [kJ/kg]

- FLHV = Lower heating value for food waste [kJ/kg]

- (c) = Weight percentage of carbon [%]

- (o) = Weight percentage of oxygen [%]

- (h) = Weight percentage of hydrogen [%]

- (s) = Weight percentage of carbon [%]

- (w) = Weight percentage of water [%]

- (f) = Weight percentage of combustible content [%].

2.1.4. Calculation of Power Output and Steam Generation

- OI = Output of the generator of the waste incineration plant [kW]

- CLHV = Lower heating value of combustible waste [kJ/kg]

- SI = Scale of incinerator treatment [t/D].

- OS = Output of the generator of the sewage treatment plant [kW]

- BLHV = Lower heating value of biogas = 22,000 [kJ/Nm3]

- VT = Gas conversion volume of thickened sludge = 0.55 [Nm3/kg-input VS for thickened sludge]

- AT = Amount of thickened sludge [t/D]

- VF = Gas conversion volume of food waste = 0.84 [Nm3/kg-digestion VS for food waste]

- AB = Amount of VS for food waste before fermentation = 25.6 [t/D]

- AA = Amount of VS for food waste after fermentation = 5.8 [t/D].

2.1.5. Method for Estimating Construction Costs

2.1.6. Method of Estimating Maintenance and Management Expenses

2.1.7. Method for Estimating CO2 Emissions

- ECO2 = Total annual CO2 emissions for each case [t-CO2/Y]

- E1 = Total annual CO2 emissions from waste incineration [t-CO2/Y]

- E2 = Total annual CO2 emissions from electricity consumption of the waste incineration plant during suspension periods [t-CO2/Y]

- E3 = Total annual CO2 emissions from electricity consumption of biogas power generation facilities [t-CO2/Y]

- E4 = Total annual CO2 emissions generated during transportation [t-CO2/Y]

- E5 = Total annual CO2 emissions from N2O generated during waste incineration [t-CO2/Y]

- S1 = Total annual CO2 emissions reduced by waste power generation [t-CO2/Y]

- S2 = Total annual CO2 emissions reduced by biogas power generation [t-CO2/Y]

- S3 = Total annual CO2 emissions that could be reduced through in-house consumption or heat supply to neighboring facilities. [t-CO2/Y].

- VW = Annual waste disposal volume = 145,600 or 128,484 [t-waste/Y]

- γp = Weight composition percentage of plastic = 13.7 or 15.5 [%]

- γo = Weight composition percentage of other waste = 26.2 or 29.7 [%]

- γpc = Percentage of combustible content of plastic = 74 [%]

- γoc = Percentage of combustible content of other waste = 51 [%]

- Cp = Percentage of carbon content in plastic = 74 [%]

- Co = Percentage of carbon content in other waste = 40 [%].

- Εe = Electric power emission factor = 0.512 [kg-CO2/kWh].

- E3-1 = Total annual electricity consumption during mixing process [kWh/Y]

- E3-2 = Total annual electricity consumption during digestion process [kWh/Y]

- E3-3 = Total annual electricity consumption during dewatering process [kWh/Y]

- E3-4 = Total annual electricity consumption during incineration process [kWh/Y].

- Q1 = Mixing tank capacity = 1269 [m3].

- D = round-trip distance = 20 [km/time]

- Nr = Number of round trips = 3 [time/unit]

- d = Number of working days = 280 [days]

- Nt = Number of trucks required = 5 or 3 [units]

- F = Fuel efficiency of 10-ton truck = 4.15 [km/L]

- Εd = Diesel fuel emission factor = 2.619 [kg-CO2/L] [39].

- ENOx = Annual NOx emissions = 24.41 or 21.54 [t/Y]

- RN2O = Ratio of N2O in NOx = 1.54 [%]

- ΕN2O = N2O warming coefficient = 298 [t-CO2/t-N2O] [40].

- OI = Output of the generator of the waste incineration plant [kW]

- PS1 = Annual power consumption required for waste incineration [kWh/Y]

- Pm = Annual power consumption required for machine sorting [kWh/Y].

- Q2 = Amount of food waste disposed = 177.8 [t/D].

- OI = Output of the generator of the waste incineration plant [kW]

- OS = Output of the generator of the sewage treatment plant [kW]

- Q3 = Heat demand (Required heating value for biogas power generation facility) [MJ/Y]

- Vk = Kerosene calorific value = 36.49 [MJ/L]

- Εk = Kerosene emission factor = 2.489 [kg-CO2/L] [40]

- VS = Steam heating value = 44.5 or 42.0 [MJ/s].

- m = Amount of sludge input to the fermenter [t]

- c = Specific heat [kJ/kg °C]

- T = Fermenter temperature (wet medium temperature) = 35 [°C]

- T’ = Atmospheric temperature = 15 [°C]

- A = Heat dissipation = 20 [%].

2.2. Inventory Data Analysis

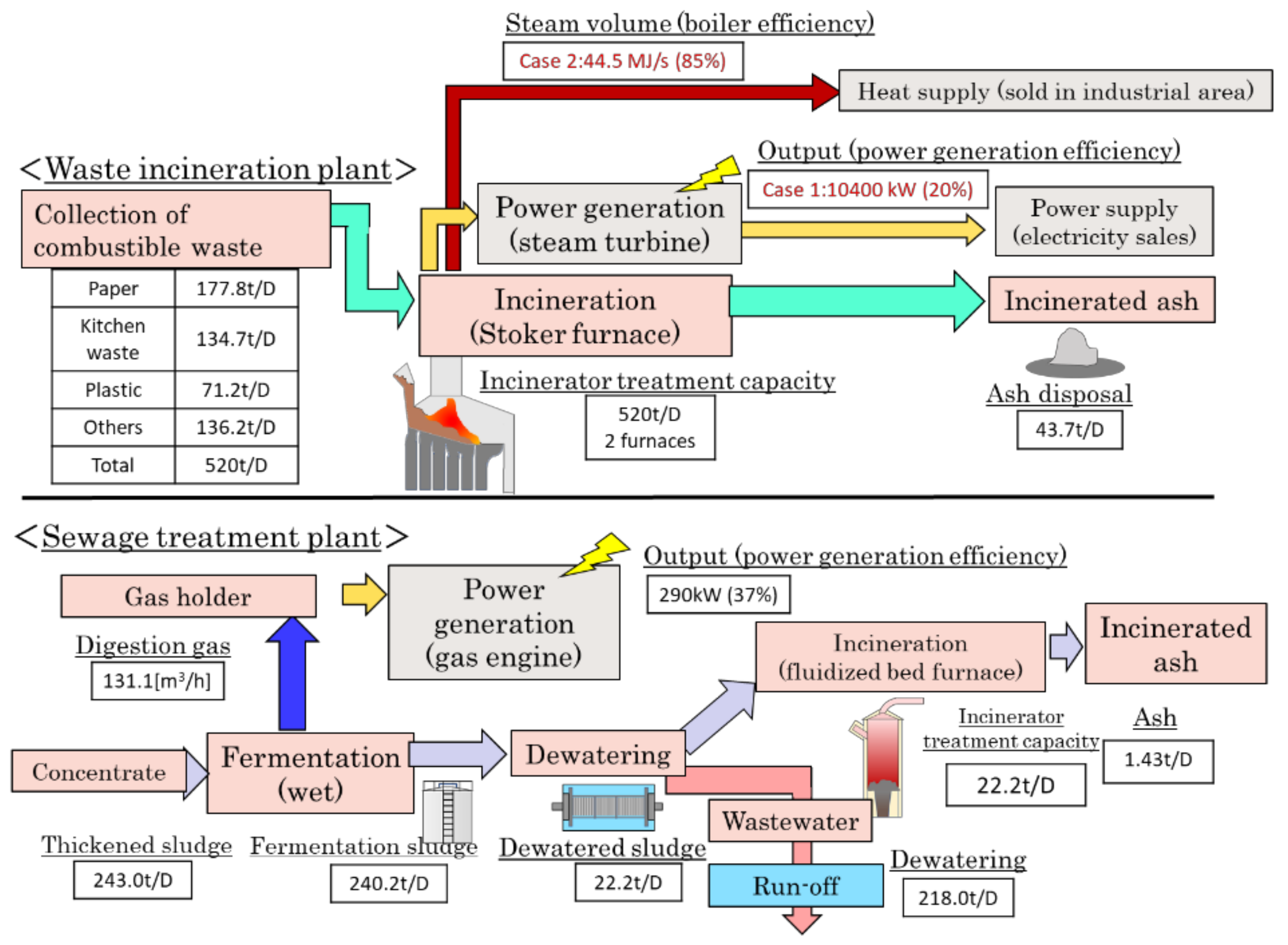

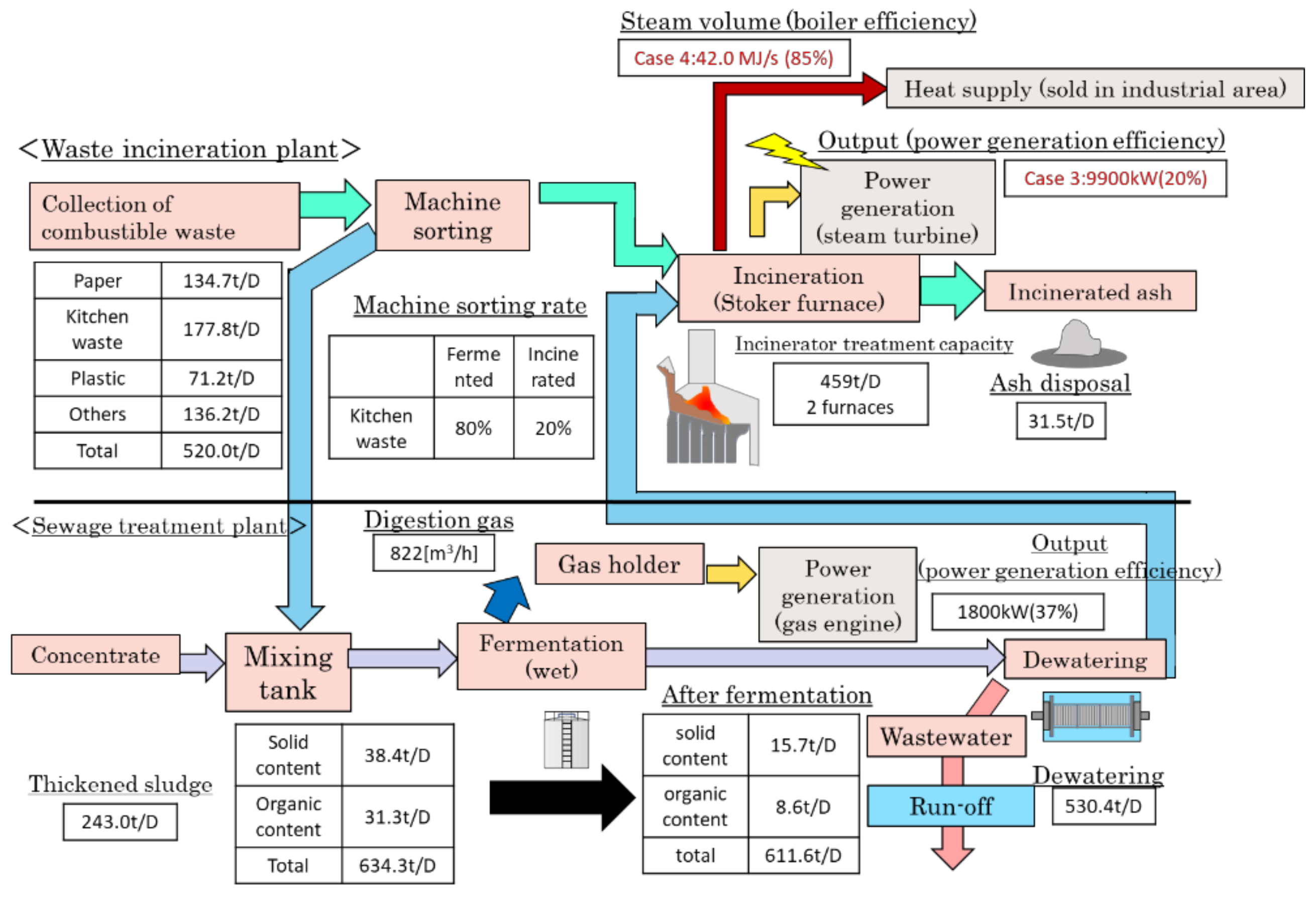

2.2.1. Treatment Flow and Material Balance in Each Case

2.2.2. Energy Balance in Each Case

2.3. Inventory Data Analysis

2.3.1. Sensitivity Analysis Method for Food Waste Ratio and Plastic Ratio

2.3.2. Sensitivity Analysis Method for Steam Transport Piping Distance

3. Results and Discussion

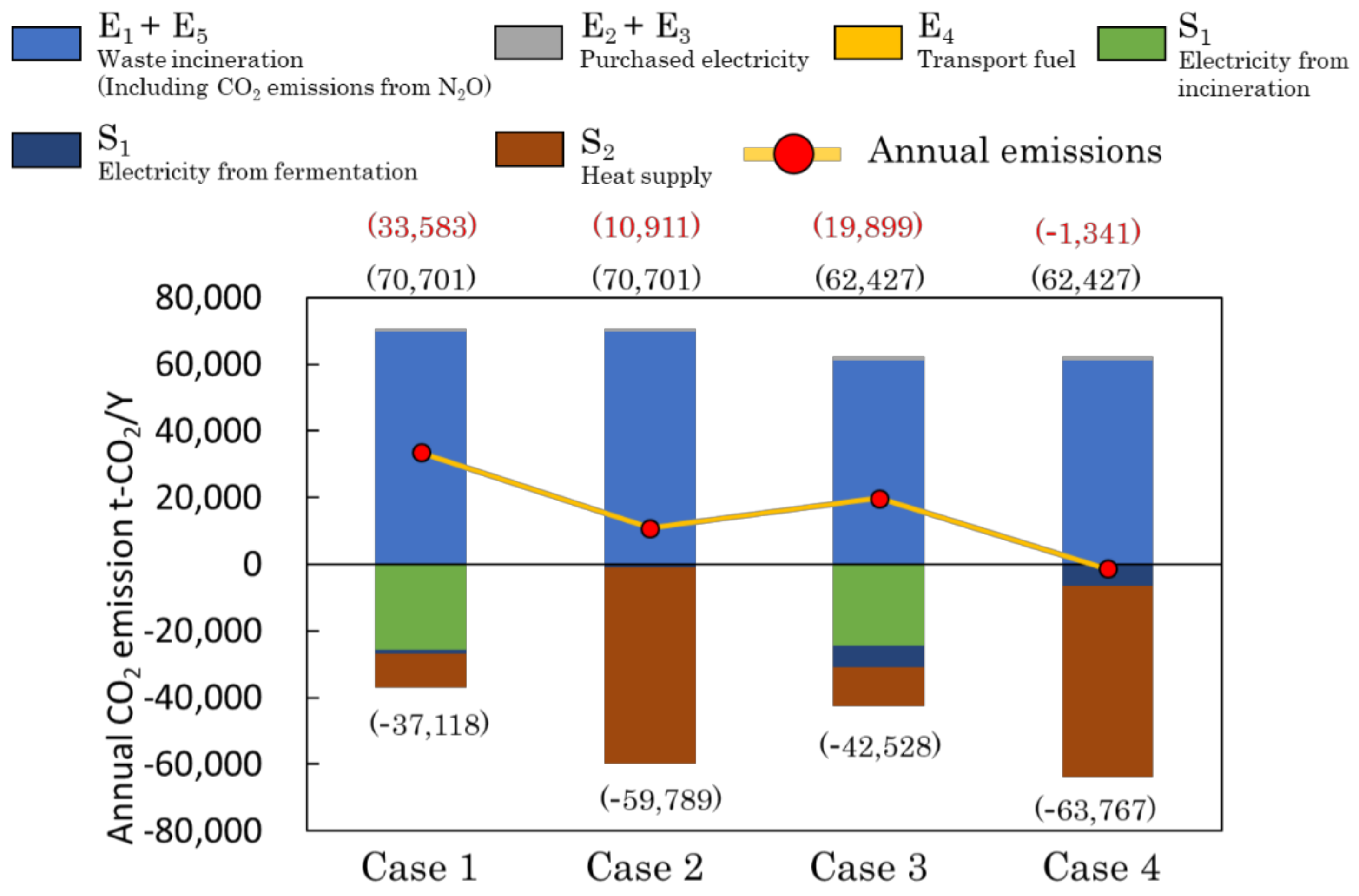

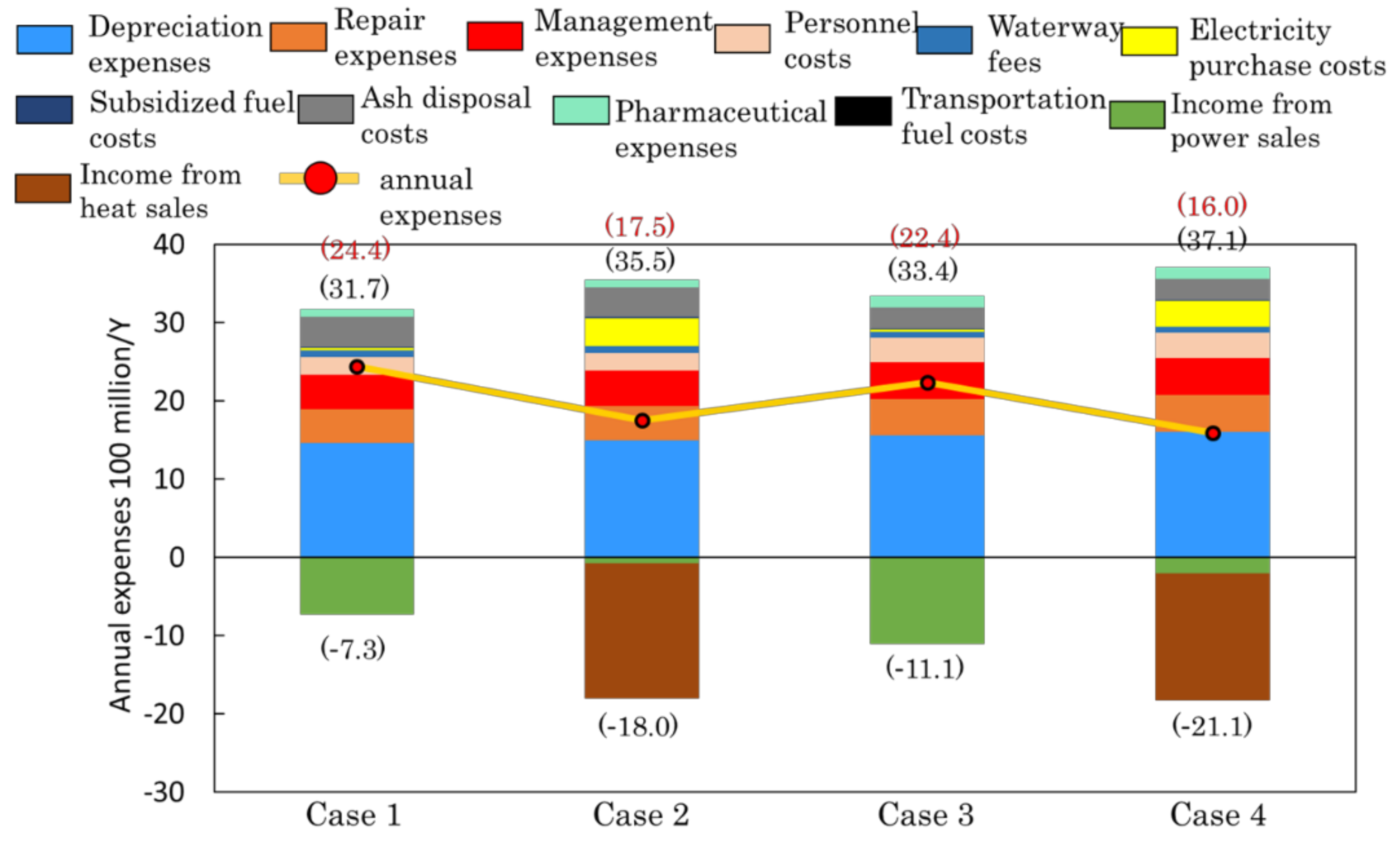

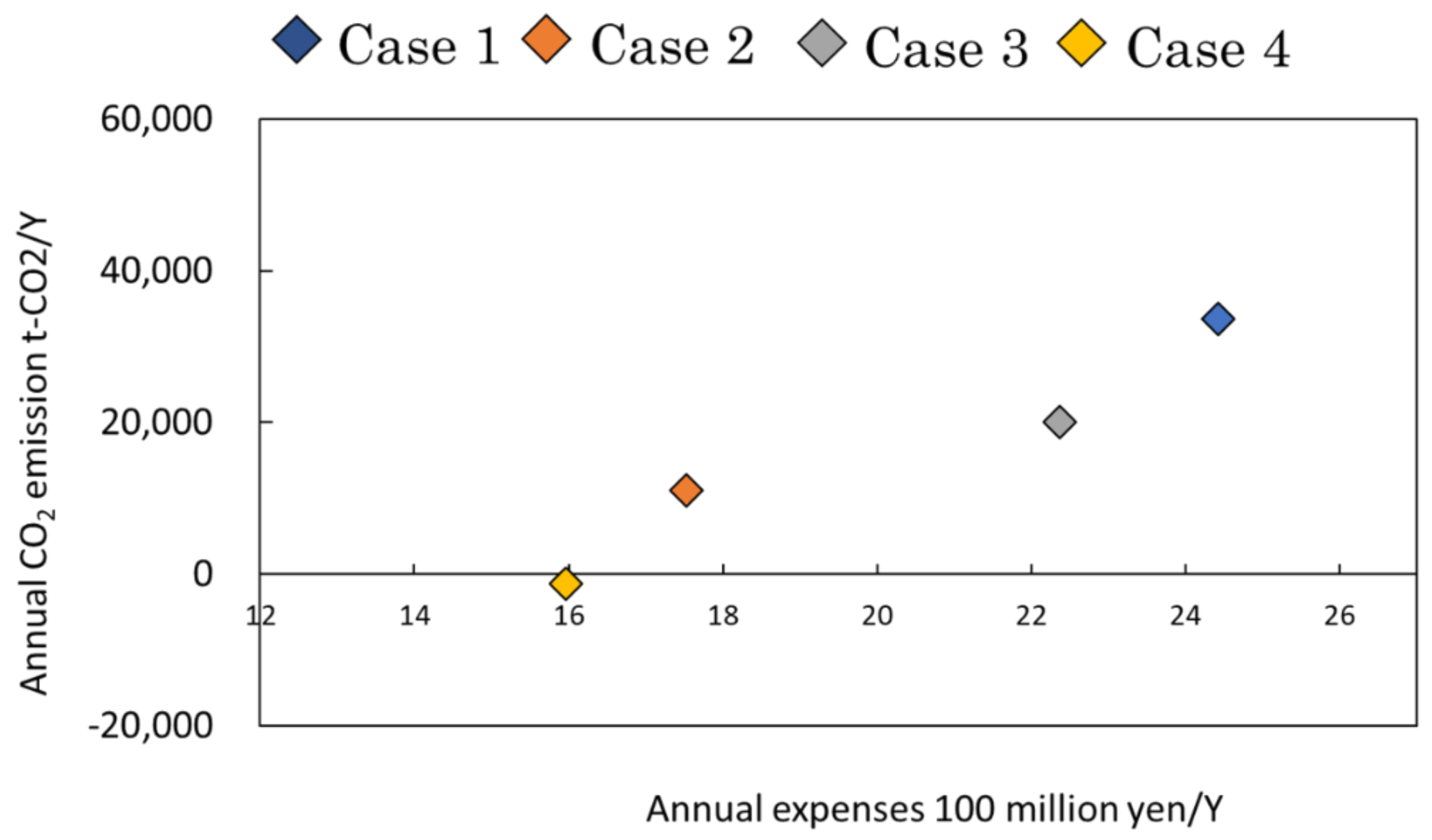

3.1. Results of CO2 Emissions and Economic Evaluation

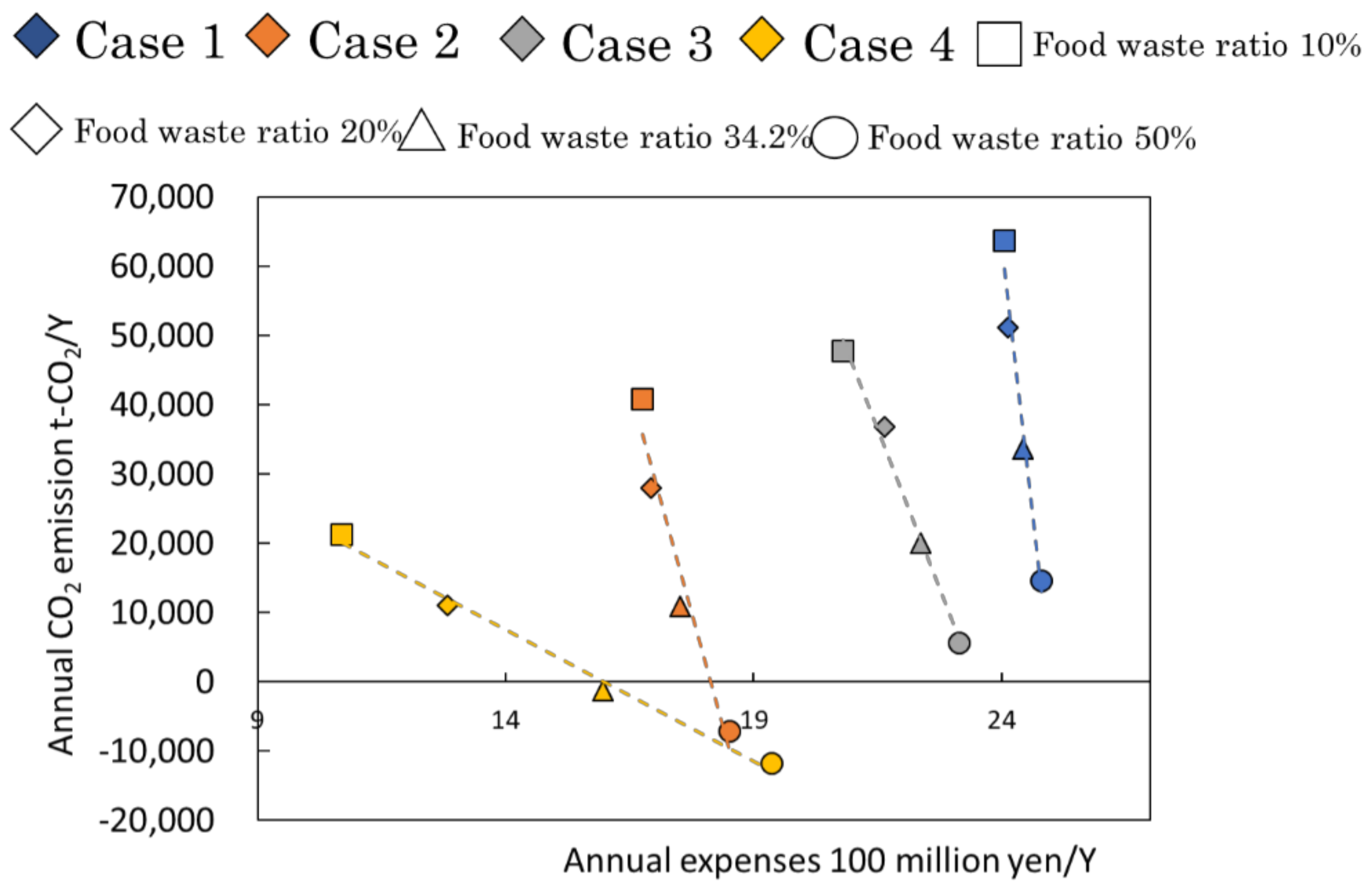

3.2. Sensitivity Analysis of Food Waste Ratio

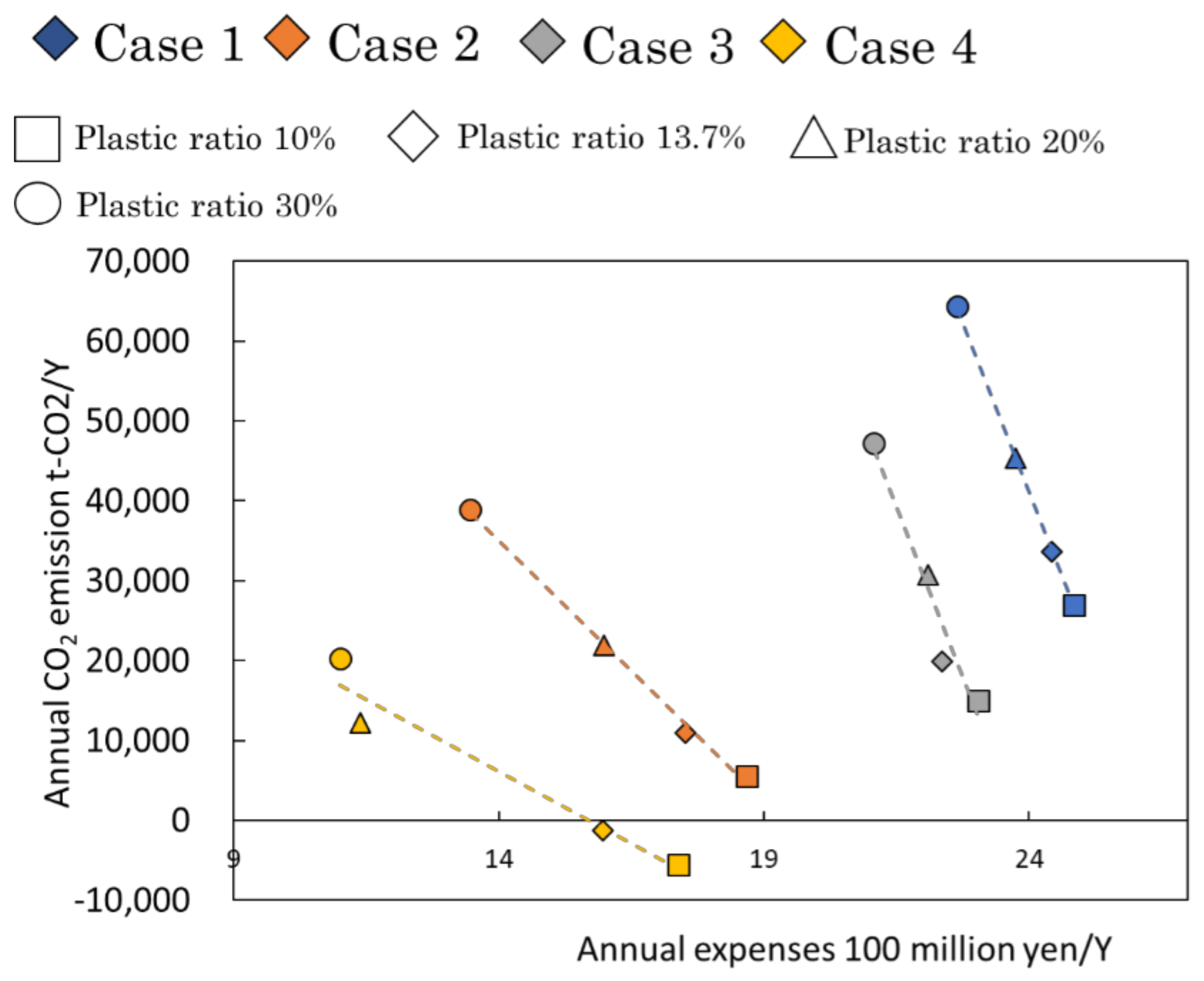

3.3. Sensitivity Analysis of Plastic Ratio

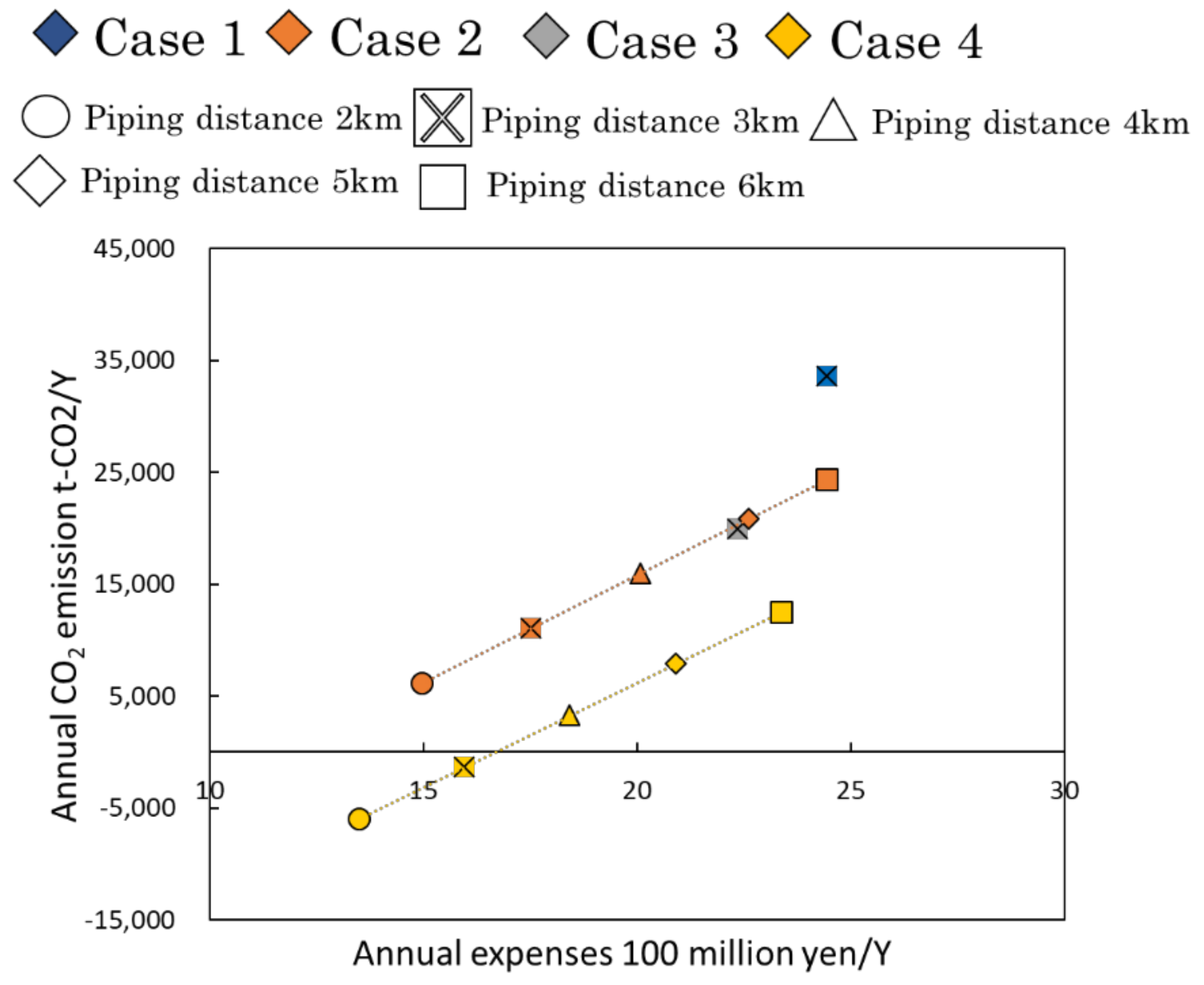

3.4. Sensitivity Analysis of Piping Distance

3.5. Discussion on Evaluation Results

3.6. Discussion on Sensitivity Analysis of Food Waste Ratio

3.7. Sensitivity Analysis of Plastic Ratio

3.8. Sensitivity Analysis of Piping Distance

3.9. Discussion of Issues

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sekiguchi, T.; Hayashi, N.; Sugino, H. The Effects of Differences in Individual Characteristics and Regional Living Environments on the Motivation to Immigrate to Hometowns: A Decision Tree Analysis. Appl. Sci. 2019, 9, 2748. [Google Scholar] [CrossRef]

- Wider Area of Waste Treatment and Integration of Waste Treatment Facility to Ensure Sustainable Proper Treatment. Available online: https://www.env.go.jp/hourei/11/000652.html (accessed on 14 August 2021). (In Japanese)

- Zhang, Z.; Oshita, K.; Takaoka, M.; Fujimori, T.; Nagano, A.; Koseki, T. Cooperation of Urban Metabolic Facilities by Considering Co-Incineration of Dewatered Fecal Sludge and Municipal Solid Waste. J. JSCE 2017, 73, III_275–III_286. [Google Scholar] [CrossRef]

- Okuda, T.; Nakano, A.; Yamamoto, Y.; Nakakubo, T.; Yoshda, N. Study on reduction of greenhouse gas emission with sewage sludge fuels by collaboration of industrial and environmental infrastructures. J. JSCE 2016, 72, II_57–II_66. [Google Scholar]

- Nakakubo, T. Building energy system in a msw incineration plant by linking up with a neighboring sewage treatment plant. J. JSCE 2018, 74, II_129–II_140. [Google Scholar] [CrossRef]

- Maki, S.; Ohnishi, S.; Fujii, M.; Goto, N.; Sun, L. Technical and economic analysis of potential steam supply from waste treatment plants to industries in Aichi Prefecture, Japan. Optim. Eng. 2021, 22, 1755–1782. [Google Scholar] [CrossRef]

- Yoshidome, D.; Karasawa, T.; Onoda, S.; Seto, T. A Study on Waste to Energy system for Industrial heat utilization (1st Report: Investigation of actual status of heat demand in an industrial area). Symp. Environ. Eng. 2020, 2020, 30. [Google Scholar]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.-P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life cycle Assessment: Part 1: Framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.; Zhao, R.; Omura, K.; Onoda, H. Development of a Municipal Waste Management System from Environmental and Economic Evaluation Perspectives: A Best Available System Methodology. In Technologies and Eco-Innovation towards Sustainability II; Springer: Singapore, 2019; pp. 81–97. [Google Scholar]

- Bigazoli, L.; Falbo, A.; Forte, F.; Grosso, M.; Rigamonti, L. Mass balance and life cycle assessment of the waste electrical and electronic equipment management system implemented in Lombardia Region (Italy). Sci. Total Environ. 2015, 524–525, 361–375. [Google Scholar] [CrossRef] [PubMed]

- Menna, F.D.; Dietershagen, J.; Loubiere, M.; Vittuari, M. Life cycle costing of food waste: A review of methodological approaches. Waste Manag. 2018, 73, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Khandelwal, H.; Dhar, H.; Thalla, A.K.; Kumar, S. Application of life cycle assessment in municipal solid waste management: A worldwide critical review. J. Clean. Prod. 2019, 209, 630–654. [Google Scholar] [CrossRef]

- Nabavi-Pelesaraei, A.; Bayat, R.; Hosseinzadeh-Bandbafha, H.; Afrasyabi, H.; Chau, K. Modeling of energy consumption and environmental life cycle assessment for incineration and landfill systems of municipal solid waste management—A case study in Tehran Metropolis of Iran. J. Clean. Prod. 2017, 148, 427–440. [Google Scholar] [CrossRef]

- Liikanen, M.; Havukainen, J.; Hupponen, M.; Horttanainen, M. Influence of different factors in the life cycle assessment of mixed municipal solid waste management systems—A comparison of case studies in Finland and China. J. Clean. Prod. 2017, 154, 389–400. [Google Scholar] [CrossRef]

- Ripa, M.; Fiorentino, G.; Vacca, V.; Ulgiati, S. The relevance of site-specific data in Life Cycle Assessment (LCA). The case of the municipal solid waste management in the metropolitan city of Naples (Italy). J. Clean. Prod. 2017, 142, 445–460. [Google Scholar] [CrossRef]

- Tahara, K.; Inaba, A.; Sakane, Y.; Kojima, T. The Effect of Garbage Separation Treatment on Municipal Waste Management. J. Jpn. Soc. Waste Manag. Experts 2004, 15, 276–282. [Google Scholar] [CrossRef][Green Version]

- Zaharioiu, A.; Bucura, F.; Ionete, E.I.; Ionete, R.E.; Ebrasu, E.; Sandru, C.; Marin, F.; Oancea, S.; Niculescu, V.; Miricioiu, M.G.; et al. Thermochemical Decomposition of Sewage Sludge—An Eco-Friendly Solution for a Sustainable Energy Future by Using Wastes. Rev. Chim. 2020, 71, 171–181. [Google Scholar] [CrossRef]

- Farrell, M.; Jones, D.L. Critical evaluation of municipal solid waste composting and potential compost markets. Bioresour. Technol. 2009, 100, 4301–4310. [Google Scholar] [CrossRef] [PubMed]

- Yoshikawa, K.; Kakuta, Y. Investigative Report of MBT Technology and EU Model Facilities. J. Mater. Cycles Waste Manag. 2016, 27, 325–332. [Google Scholar] [CrossRef]

- Montejo, C.; Tonini, D.; Márquez, M.C.; Astrup, T. Mechanical–biological treatment: Performance and potentials. An LCA of 8 MBT plants including waste characterization. J. Environ. Manag. 2013, 128, 661–673. [Google Scholar] [CrossRef]

- Fei, F.; Wen, Z.; Huang, S.; De Clercq, D. Mechanical biological treatment of municipal solid waste: Energy efficiency, environmental impact and economic feasibility analysis. J. Clean. Prod. 2018, 178, 731–739. [Google Scholar] [CrossRef]

- Abeliotis, K.; Kalogeropoulos, A.; Lasaridi, K. Life Cycle Assessment of the MBT plant in Ano Liossia, Athens, Greece. Waste Manag. 2012, 32, 213–219. [Google Scholar] [CrossRef] [PubMed]

- Ishii, K.; Furuichi, T. Applicability of Mechanical Biological Treatment to Waste Management Systems in Japan. J. Mater. Cycles Waste Manag. 2016, 27, 355–361. [Google Scholar] [CrossRef]

- Tyagi, V.K.; Kapoor, A.; Arora, P.; Rajesh Banu, J.; Das, S.; Pipesh, S.; Kazmi, A.A. Mechanical-biological treatment of municipal solid waste: Case study of 100 TPD Goa plant, India. J. Environ. Manag. 2021, 292, 112741. [Google Scholar] [CrossRef]

- Rigamonti, L.; Borghi, G.; Martignon, G.; Grosso, M. Life cycle costing of energy recovery from solid recovered fuel produced in MBT plants in Italy. Waste Manag. 2019, 99, 154–162. [Google Scholar] [CrossRef] [PubMed]

- Makovetska, Y.; Omelianenko, T.; Omelchenko, A. Prospects for environmentally safe mechanical biological treatment of municipal solid waste in Ukraine. E3S Web Conf. ISCMEE 2021, 255, 01002. [Google Scholar] [CrossRef]

- Ogawa, A.; Watanabe, D.; Ko, K.; Onoda, H.; Watanabe, Y.; Yamaguchi, J. Environmental and economic evaluation of combined system of the garbage facility and sewage treatment facility. Symp. Environ. Eng. 2019, 2019, 29. [Google Scholar] [CrossRef]

- Ogawa, A.; Pandyaswargo, A.H.; Yoshidome, D.; Onoda, H. Environmental and Economic Evaluation of a Mechanical Biological Treatment System for a Small and Medium-Sized Waste Treatment Facility Considering the Karatsu Smart Disaster-Resilience Base Construction Project. Int. J. Autom. Technol. 2020, 14, 984–998. [Google Scholar] [CrossRef]

- Ogawa, A.; Onoda, H. Feasibility Study of Cooperation between Waste Incineration Plants and Sewage Treatment Plants ~Questionnaire Survey for Local Governments and GIS Visualization~. Pap. Environ. Inf. Sci. 2020, 34, 305–310. [Google Scholar]

- QGIS—The Leading Open Source Desktop GIS. Available online: https://qgis.org/en/site/about/index.html (accessed on 14 August 2021).

- Ichihara City Basic Plan for General Waste Disposal. 2017. Available online: https://www.city.ichihara.chiba.jp/article?articleId=602371cfece4651c88c17fed (accessed on 14 August 2021). (In Japanese).

- Notes on Guidance for General Waste Management Businesses. 1977. Available online: https://www.env.go.jp/hourei/11/000013.html (accessed on 14 August 2021). (In Japanese)

- Manual for Utilization of Local Biomass in Sewage Treatment Plants. 2017. Available online: https://www.mlit.go.jp/mizukokudo/sewerage/mizukokudo_sewerage_tk_000466.html (accessed on 14 August 2021). (In Japanese)

- Guidelines for Sewage Sludge Energy Conversion Technology. 2018. Available online: https://www.mlit.go.jp/mizukokudo/sewerage/mizukokudo_sewerage_tk_000364.html (accessed on 14 August 2021). (In Japanese)

- New Energy and Industrial Technology Development Organization (NEDO) Demonstration Project for Local Self-Sustaining System of Biomass Energy: Requirements and Technical Guidelines for Introduction of Local Self-Sustaining System of Biomass Energy, 5th ed.; New Energy and Industrial Technology Development Organization, Japan. 2021. Available online: https://www.nedo.go.jp/library/biomass_shishin.html (accessed on 14 August 2021). (In Japanese)

- Experimental Evaluation of Room Temperature Heat Transport and Thermal Storage for Effective Use of Waste Heat from Refuse Incineration. 2013. Available online: https://www.data.go.jp/data/dataset/env_20170508_0210/resource/6b238a15-d04f-4f45-9a65-a61450db4401 (accessed on 14 August 2021). (In Japanese)

- Emission Factors by Electric Utility (for Calculating Greenhouse Gas Emissions of Specific Emitters). Available online: https://www.env.go.jp/press/105720.html (accessed on 14 August 2021). (In Japanese)

- Sewage Sludge Wide-Area Utilization Study Manual. 2019. Available online: https://www.mlit.go.jp/common/001286384.pdf (accessed on 5 October 2021). (In Japanese)

- Examples of Carbon Dioxide Emissions by Fuel. Available online: https://www.env.go.jp/council/16pol-ear/y164-04/mat04.pdf (accessed on 14 August 2021). (In Japanese)

- Guidelines for Calculating Total Greenhouse Gas Emissions Version 1.0. Available online: https://www.env.go.jp/policy/local_keikaku/data/guideline.pdf (accessed on 14 August 2021). (In Japanese)

- Survey of General Waste Utilization. 2016. Available online: http://www.env.go.jp/recycle/waste_tech/ippan/h28/index.html (accessed on 14 August 2021). (In Japanese)

- Pandyaswargo, A.H.; Gamaralalage, P.J.D.; Liu, C.; Kanaus, M.; Onoda, H.; Mahichi, F.; Guo, Y. Challenges and an Implementation Framework for Sustainable Municipal Organic Waste Management Using Biogas Technology in Emerging Asian Countries. Sustainability 2019, 11, 6331. [Google Scholar] [CrossRef]

- Geyer, G.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

| Item | Lower Heating Value (MJ/kg) | Three Components (%) | Elemental Composition (%) | Weight Composition Percentage (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Combustible Content | Water Content | Ash Content | C | H | O | N | S | Cl | Case 1 and 2 | Case 3 and 4 | |||

| Paper | 10.7 | 70 | 20 | 10 | 44 | 6 | 49 | 0,20 | 0.02 | 0.40 | 25.9 | 29.4 | |

| Food waste | 1.4 | 18 | 78 | 4 | 47 | 7 | 42 | 3.8 | 0.10 | 0.40 | 34.2 | 7.8 | |

| Plastics | 27.1 | 74 | 17 | 9 | 74 | 11 | 11 | 0.20 | 0.02 | 3.90 | 13.7 | 15.5 | |

| Others | 7.4 | 51 | 24 | 2 | 40 | 5 | 30 | 1.0 | 0 | 1.00 | 26.2 | 29.7 | |

| Dewatered residue | 1.0 | 10 | 81 | 9 | 49 | 7 | 37.9 | 5.4 | 0.7 | 0.3 | - | 17.7 | |

| Total | Case 1 and 2 | 8.7 | 47 | 44 | 8.4 | 50 | 6.9 | 35 | 0.8 | 0.04 | 1.2 | 100 | - |

| Case 3 and 4 | 9.3 | 51 | 36 | 6.9 | 49 | 6.7 | 35 | 1.6 | 0.2 | 1.0 | - | 100 | |

| Sewage | Thickened Sludge | Fermentation Sludge | Dewatered Sludge | Incinerated | |

|---|---|---|---|---|---|

| Moisture | 99 | 33 | 33 | 2.5 | 0 |

| Organic content | 0.8 | 0.8 | 0.4 | 0.4 | 0 |

| Inorganic content | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Total | 100 | 34 | 33.6 | 3.1 | 0.2 |

| Item | Moisture Content (t/D) | TS(t/D) | VS (t/D) | Unsuitable Material (t/D) | |

|---|---|---|---|---|---|

| Before fermentation | Food waste | - | 31.3 | 25.6 | 5.7 |

| Sewage sludge | - | 7.2 | 5.7 | 1.4 | |

| Total | 595.8 | 38.4 | 31.3 | 7.1 | |

| After fermentation | Food waste | - | 11.5 | 5.8 | 5.7 |

| Sewage sludge | - | 4.29 | 2.9 | 1.4 | |

| Total | 595.8 | 15.7 | 8.6 | 7.1 | |

| Item | Estimated Formula (100 Million Yen) | Notes |

|---|---|---|

| Acceptance and supply equipment | Y = 1.4214 × A0.4344 | A: Acceptance amount t/D |

| Pre-treatment equipment (Wet methane fermentation) | Y = 1.9481 × B0.6657 | B: Pre-treatment amount t/D |

| Incinerator and boiler | Y = 0.4643 × C0.8999 | C: Incineration amount t/D |

| Incinerator power generation equipment | Y = 0.0438 × D0.7228 | D: Power generation capacity kW |

| Exhaust gas treatment equipment | Y = 2.9569 × C0.3299 | C: Incineration amount t/D |

| Ash treatment equipment | Y = 2.1337 × E0.5658 | E: Ash treatment amount t/D |

| Wastewater treatment equipment | Y = 0.0767 × F0.8637 | F: Wastewater amount m3/D |

| Item | Estimation Formula | Notes |

|---|---|---|

| Food waste pre-treatment equipment Machinery and equipment expenses | Y = 98.6 × A0.475 [million yen] | A: Waste treatment amount t/D |

| Food waste pre-treatment equipment Electrical equipment expenses | Y = 29.6 × A0.512 [million yen] | |

| Food waste pre-treatment equipment Civil engineering expenses | Y = 22.4 × A0.504 [million yen] | |

| Food waste pre-treatment equipment Construction expenses | Y = 75.9 × A0.342 [million yen] | |

| Mixing equipment Machinery and equipment expenses | Y = 8.26 × B0.400 [million yen] | B: Mixing tank capacity m3 |

| Mixing equipment Electrical equipment expenses | Y = 0.836 × B0.535 [million yen] | |

| Mixing equipment Construction expenses | Y = 2.01 × B0.583 [million yen] | |

| Fermenter Civil engineering construction facility expenses | Y = 44.1 × (C/500)0.6 [million yen] | C: Fermenter capacity m3 |

| Fermenter Machinery and equipment | Y = 124 × (C/500)0.6 [million yen] | |

| Desulfurization tower Construction expenses | Y = 0.878 × D0.761 [million yen] | D: Desulfurization tower processing capacity m3/h |

| Gas holder Construction expenses | Y = 10.4 × E0.437 [million yen] | E: Gas holder capacity m3 |

| Gas engine Construction expenses | Y = 0.1104 × F0.6605 [100 million yen] | F: Biogas power generation function kW |

| Dewatering equipment Civil engineering construction facility expenses | Y = 1.2413 × G0.35 [100 million yen] | G: Sludge treatment amount before dewatering t/D |

| Incinerator Machinery and equipment expenses | Y = 1.361 × H.380 [100 million yen] | H: Incineration treatment scale t/D |

| Incinerator Electrical equipment expenses | Y = 1.888 × H0.597 [100 million yen] |

| Item | Value | |

|---|---|---|

| Years of depreciation (years) | 20 | |

| d: Number of working days (days) | 280 | |

| Repair and management expenses | 1.5% of each construction expense | |

| Personnel costs (10,000 yen/person) | 650 | |

| Number of employees at waste incineration facility (people) | 30 | |

| Number of employees at sewage treatment facility (people) | 5 | |

| Power consumption of waste incineration during operation (kWh/t) | 140 | |

| Power consumption of waste incineration during suspension (kWh/t) | 5.5 | |

| Power consumption during digestion process (kWh/m3-thickened sludge) | 5.3 | |

| Power consumption during dewatering process (kWh/t-wet dewatered sludge) | 20 | |

| Power consumption during incineration process (kWh/t-wet dewatered sludge) | 92 | |

| Kerosene consumption during incineration process (L/t-wet dewatered sludge) | 25 | |

| Electricity purchase unit price (Yen/kWh Kerosene L/t) | 16 | |

| Waste power generation unit price (Yen/kWh) | 13 | |

| Biogas power generation unit price (Yen/kWh) | 39 | |

| Unit price of heat sales (Yen/MJ) | 2 | |

| Kerosene (L/t-waste) | 0.66 | |

| Kerosene unit price (Yen/L) | 80 | |

| Chemicals used | Slaked lime (kg/t) | 11 |

| Activated carbon (kg/t) | 0.48 | |

| Ammonia (kg/t) | 2.3 | |

| Clean water (m3/t) | 0.69 | |

| Industrial waterdle (m3/t) | 0.46 | |

| Sewage (m3/t) | 0.79 | |

| Water supply unit price (Yen/m3) | 380 | |

| Industrial water unit price (Yen/m3) | 100 | |

| Sewage unit price (Yen/m3) | 320 | |

| Kerosene unit price (Yen/L) | 80 | |

| Activated carbon unit price (Yen/kg) | 215 | |

| Slaked lime unit price (Yen/kg) | 21.4 | |

| Ammonia unit price (Yen/kg) | 32.3 | |

| Desulfurizing agent (Yen/m3-fermentation gas) | 7.3 | |

| Dewatering agent (Yen/t-water) | 499 | |

| Water treatment chemical unit price (Yen/t-water) | 91.3 | |

| Ash treatment (Yen/t) | 30,000 | |

| Item | Value |

|---|---|

| Distance between facilities (km) | 10 |

| Sewage sludge transport volume (t/D) | 81.1 |

| Food waste transportation amount (t/D) | 142 |

| Number of round trips (t/D) | 3 |

| Truck load capacity (t/unit) | 10 |

| Truck price (10,000 Yen/unit) | 1500 |

| Truck fuel consumption (km/L) | 4.15 |

| Number of sewage sludge transport units (units) | 4 |

| Number of food waste transportation units (units) | 6 |

| Year of depreciation (years) | 10 |

| Number of truck drivers (people/unit) | 2 |

| Annual income (10,000 Yen/person) | 450 |

| Fuel consumption (diesel fuel) unit price (Yen/L) | 120 |

| Item | Value |

|---|---|

| Steam transportation distance (km) | 3 |

| Steam piping unit price (100 million Yen/km) | 13.95 |

| Piping heat loss (%) | 20 |

| Item | Weight Composition Percentage (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Food Waste Ratio 10.0% | Food Waste Ratio 20.0% | Food Waste Ratio 34.2% | Food Waste Ratio 50.0% | Plastic Ratio 10.0% | Plastic Ratio 13.7% | Plastic Ratio 20.0% | Plastic Ratio 30.0% | |

| Paper | 34.0 | 30.6 | 25.9 | 20.6 | 27.1 | 25.9 | 23.8 | 20.5 |

| Food waste | 10.0 | 20.0 | 34.2 | 50.0 | 35.4 | 34.2 | 32.1 | 28.8 |

| Plastics | 21.8 | 18.4 | 13.7 | 8.4 | 10.0 | 13.7 | 20.0 | 30.0 |

| Others | 34.2 | 31.0 | 26.2 | 21.0 | 27.5 | 26.2 | 24.1 | 20.7 |

| E1 t-CO2/Y | E2 t-CO2/Y | E3 t-CO2/Y | E4 t-CO2/Y | E5 t-CO2/Y | S1 t-CO2/Y | S2 t-CO2/Y | S3 t-CO2/Y | |

|---|---|---|---|---|---|---|---|---|

| Case 1 | 69,636 | 410 | 540 | 0 | 115 | 25,680 | 1020 | 10,418 |

| Case 2 | 69,636 | 410 | 540 | 0 | 115 | 0 | 1020 | 58,770 |

| Case 3 | 61,079 | 362 | 879 | 8 | 99 | 24,401 | 6391 | 11,733 |

| Case 4 | 61,079 | 362 | 879 | 8 | 99 | 0 | 6391 | 57,376 |

| Depreciation Expenses | Repair Expenses | Management Expenses | Personnel Costs | Waterway Fees | Electricity Purchase Costs | Subsidized Fuel Costs | Ash Disposal Costs | Pharmaceutical Expenses | Income from Power Sales | Income from Heat Sales | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 million/Y | |||||||||||

| Case 1 | 14.6 | 4.4 | 4.4 | 2.3 | 0.8 | 0.3 | 0.2 | 1.0 | 3.8 | 0 | 7.3 |

| Case 2 | 14.9 | 4.5 | 4.5 | 2.3 | 0.8 | 3.6 | 0.2 | 1.0 | 3.8 | 0 | 0.8 |

| Case 3 | 15.6 | 4.6 | 4.6 | 3.2 | 0.7 | 0.4 | 0.1 | 1.5 | 2.6 | 0.04 | 11.1 |

| Case 4 | 16.0 | 4.8 | 4.8 | 3.2 | 0.7 | 3.4 | 0.1 | 1.5 | 2.6 | 0.04 | 2.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogawa, A.; Ono, S.; Onoda, H. Environmental and Economic Evaluation of Mechanical Biological Treatment System for Municipal Waste Considering the Political Framework in Ichihara City. Appl. Sci. 2021, 11, 10296. https://doi.org/10.3390/app112110296

Ogawa A, Ono S, Onoda H. Environmental and Economic Evaluation of Mechanical Biological Treatment System for Municipal Waste Considering the Political Framework in Ichihara City. Applied Sciences. 2021; 11(21):10296. https://doi.org/10.3390/app112110296

Chicago/Turabian StyleOgawa, Akihisa, Shimpei Ono, and Hiroshi Onoda. 2021. "Environmental and Economic Evaluation of Mechanical Biological Treatment System for Municipal Waste Considering the Political Framework in Ichihara City" Applied Sciences 11, no. 21: 10296. https://doi.org/10.3390/app112110296

APA StyleOgawa, A., Ono, S., & Onoda, H. (2021). Environmental and Economic Evaluation of Mechanical Biological Treatment System for Municipal Waste Considering the Political Framework in Ichihara City. Applied Sciences, 11(21), 10296. https://doi.org/10.3390/app112110296