Consequences of Deep Rolling at Elevated Temperature on Near-Surface and Fatigue Properties of High-Manganese TWIP Steel X40MnCrAl19-2

Abstract

:1. Introduction

2. Material and Methods

3. Results and Discussion

3.1. Near-Surface Properties

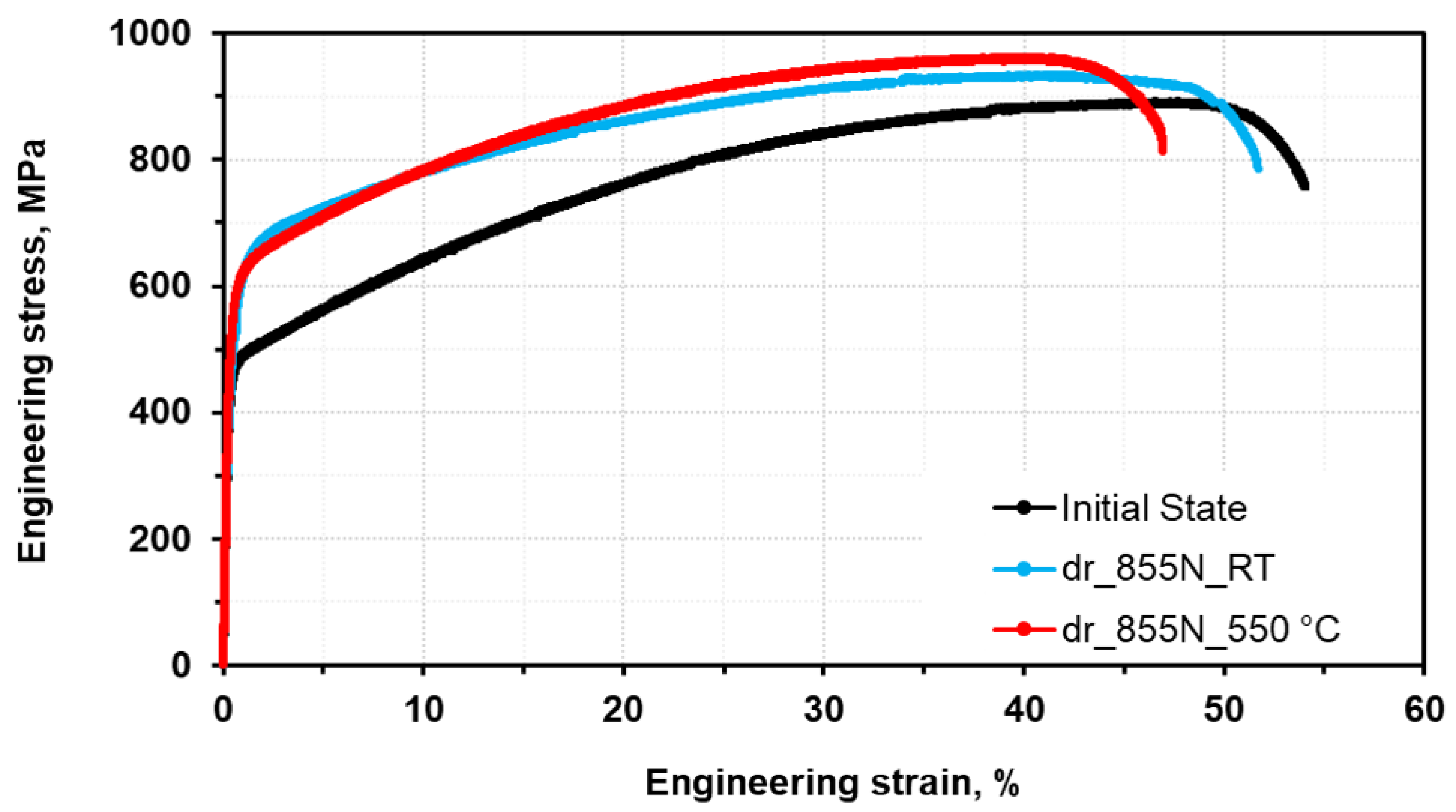

3.2. Material Behavior under Quasistatic and Cyclic Loads

4. Summary and Conclusions

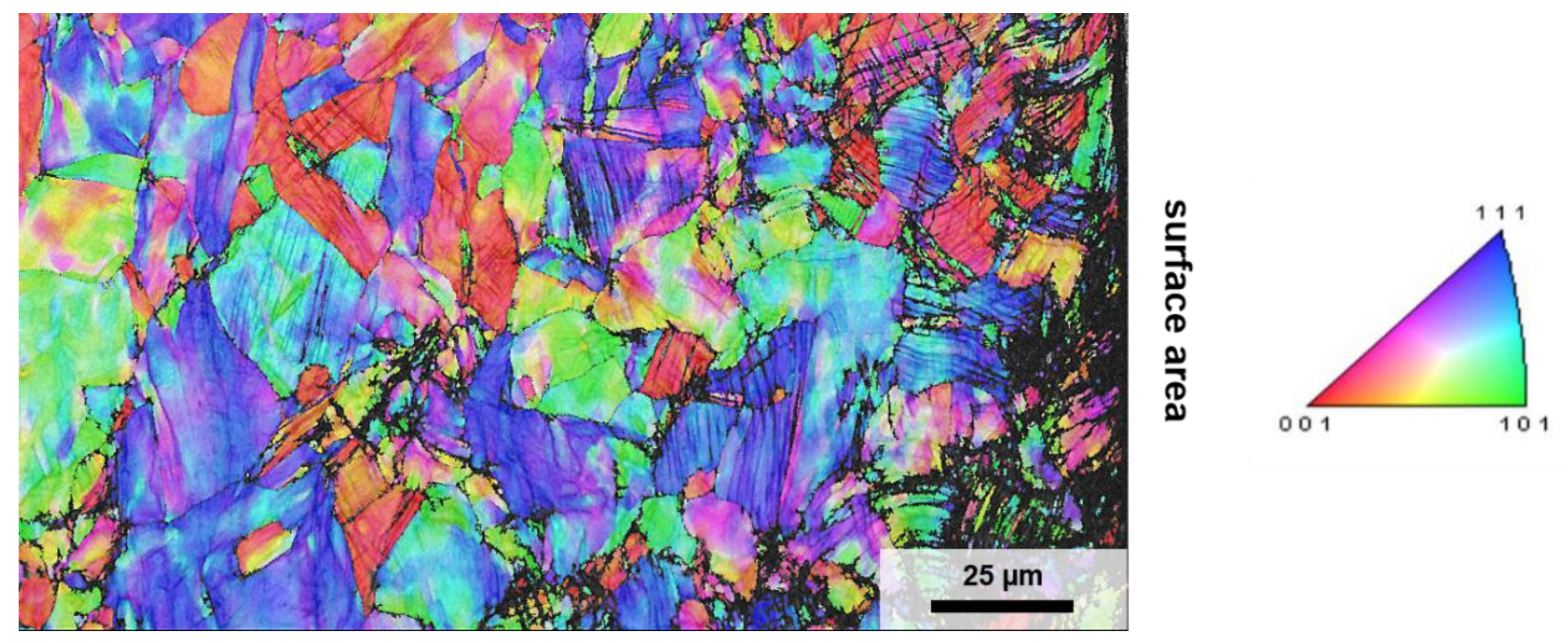

- EBSD maps of the investigated condition reveal a highly deformed near-surface microstructure, indicating a high dislocation density. Despite the increase in the SFE due to the elevated temperature, deformation-induced twinning can still be seen as a result of the multiaxial stress state induced by deep rolling.

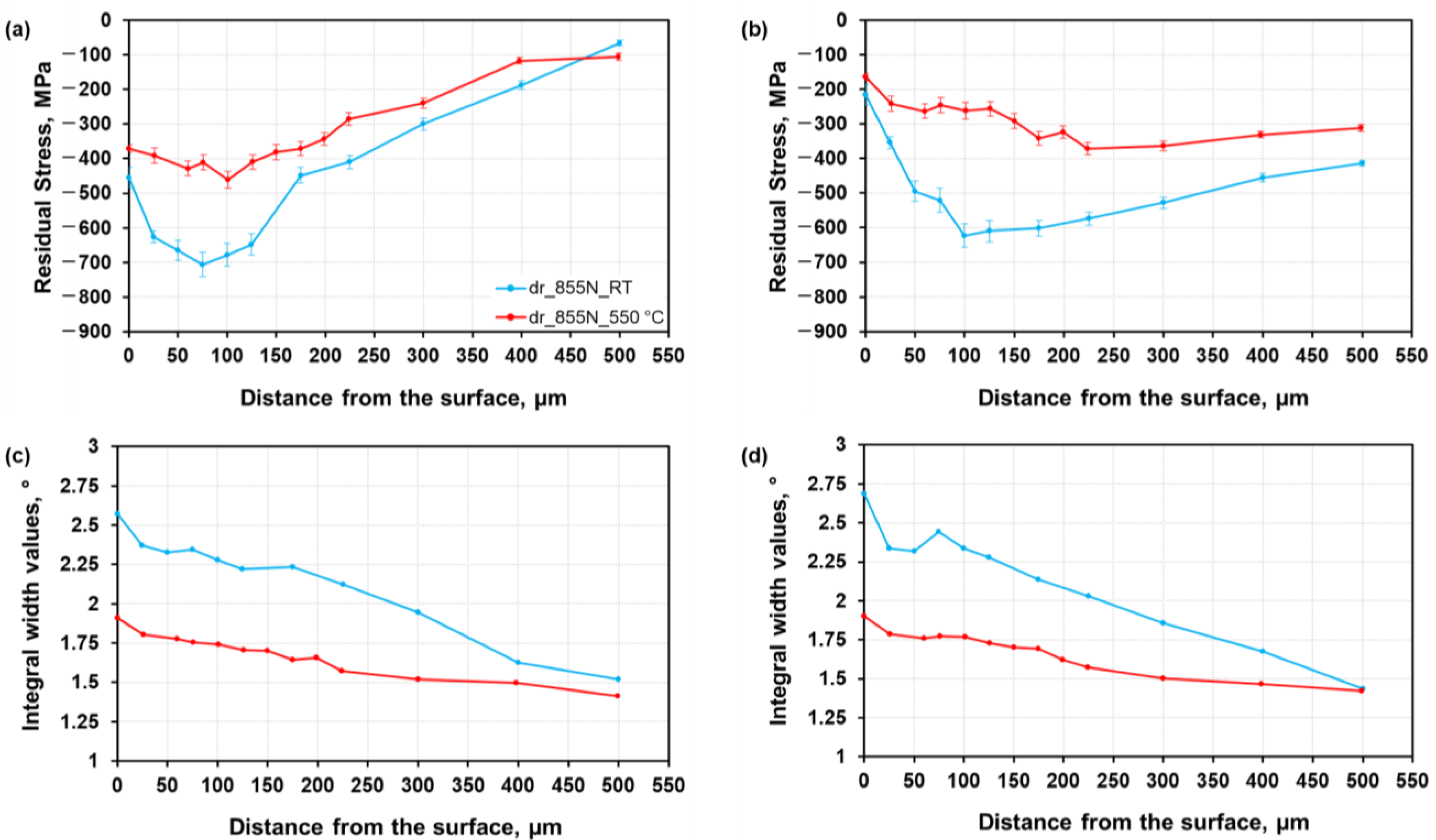

- Deep rolling at 550 °C yields lower hardness and residual stress depth profiles when compared to RT deep rolled counterparts. Obviously, stress relaxation induced by recovery effects appears to outweigh the positive effects of warm deep rolling.

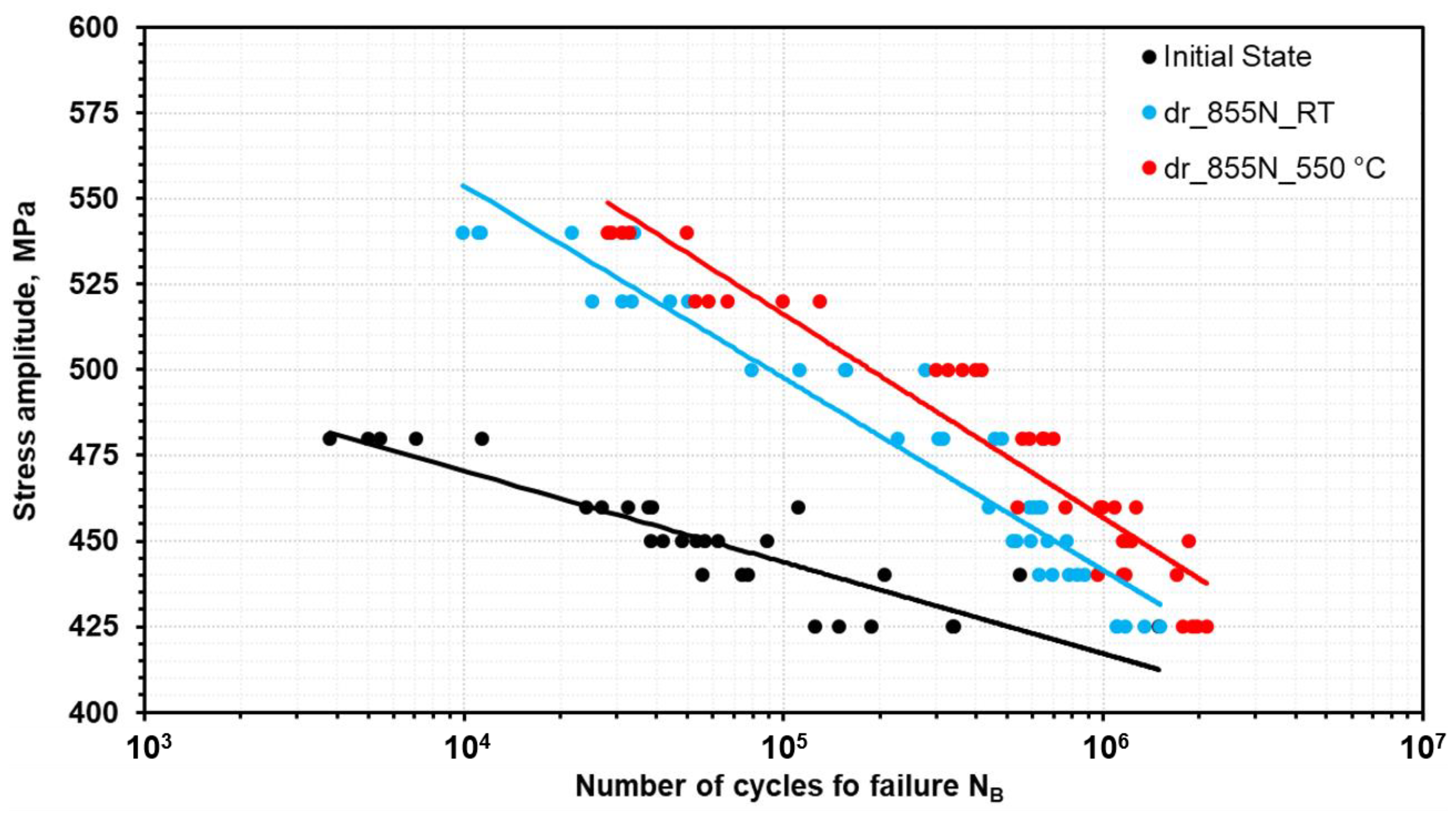

- Despite the nominally lower residual stress values and hardness profiles, specimens deep rolled at elevated temperature are characterized by a noticeable increase in fatigue life due to a stabilized near-surface microstructure. Irrespective of the stress amplitude considered, fatigue properties were improved by a factor of two. As a result, deep rolling at elevated temperatures eventually paves the way for safe and reliable industrial applications of HMnS components being subjected to fatigue loading, such as whishbones in the automotive sector.

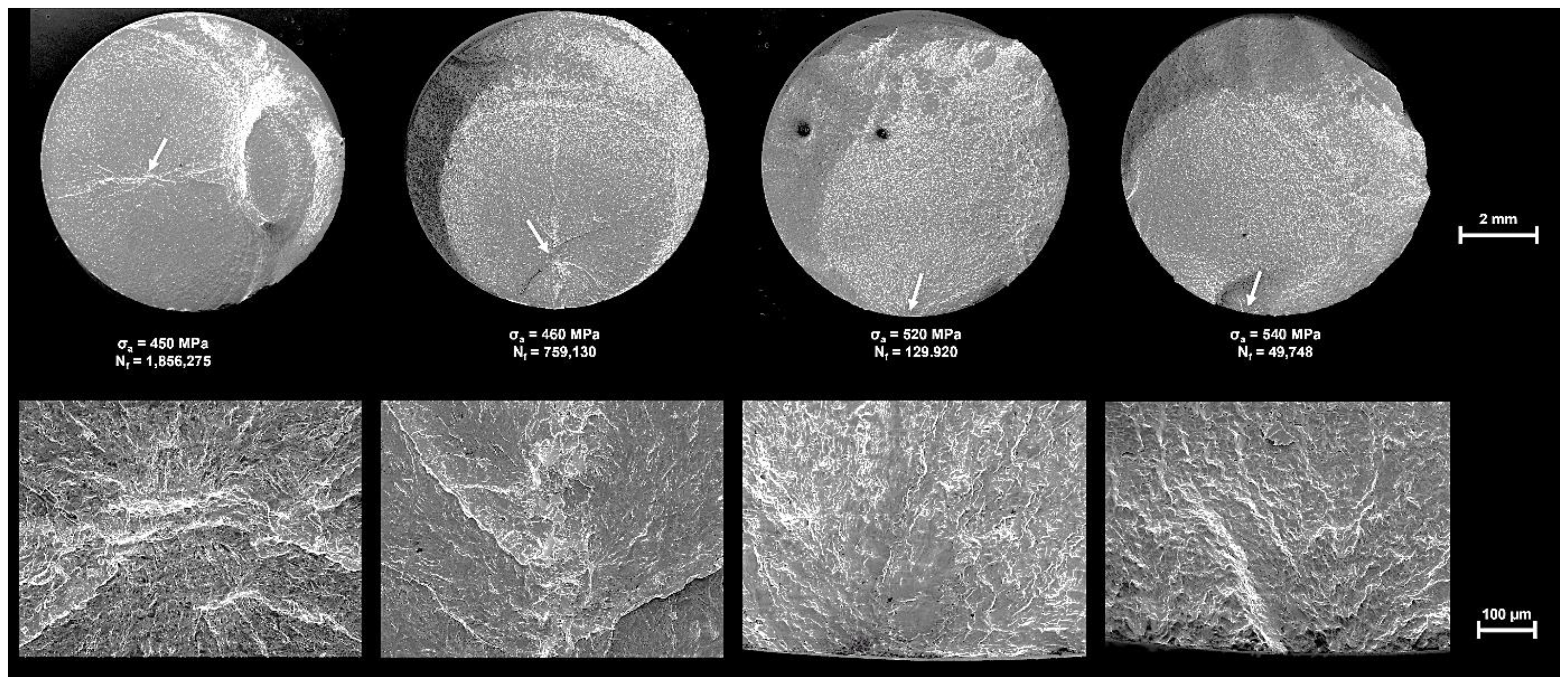

- Fractography revealed crack initiation in the interior of the specimen for low- and medium-stress amplitudes, whereas at high-stress amplitudes, cracks were initiated at the direct vicinity of the surface. It is thought that the compressive residual stresses in the surface layer, shifting the location of crack initiation to the interior of the specimen, lose their effect at the increased stress amplitudes.

- Residual stress profiles after half-life fatigue (NB/2) show superior stability after deep rolling at 550 °C compared to RT deep rolled specimens, rationalizing the results obtained based on fatigue and fractography investigations. The superior residual stress stability can be attributed to dynamic strain aging effects.

- Future work should focus on in-depth evaluation of the plastic strain amplitude of the conditions deep rolled at different temperatures in order to further analyze the different elementary effects being active. Additionally, the stability of residual stresses under thermal load should be part of future investigations.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fonstein, N. Advanced High Strength Sheet Steels; Springer: New York, NY, USA, 2015; pp. 193–195. [Google Scholar]

- Kuziak, R.; Kawalla, R.; Waengler, S. Advanced high strength steels for automotive industry. Arch. Civ. Mech. Eng. 2008, 8, 103–117. [Google Scholar] [CrossRef]

- Matlock, D.K.; Speer, J.G. Third Generation of AHSS: Microstructure Design Concepts. In Arunansu Haldar, Satyam Suwas und Debashish Bhattacharjee (Hg.): Microstructure and Texture in Steels; Springer: London, UK, 2009; pp. 185–205. [Google Scholar]

- Heintzel, A. Leichtbau als Innovationstreiber. ATZproduktion 2019, 6, 3. [Google Scholar] [CrossRef]

- Weidner, A. Deformation Processes in TRIP/TWIP Steels; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- De Cooman, B.C.; Kwon, O.; Chin, K.-G. State-of-the-knowledge on TWIP steel. Mater. Sci. Technol. 2012, 28, 513–527. [Google Scholar] [CrossRef]

- Bleck, W.; Phiu-On, K. Microalloying of Cold-Formable Multi Phase Steel Grades. Mater. Sci. Forum 2005, 500–501, 97–114. [Google Scholar] [CrossRef]

- Kwon, O.; Lee, K.Y.; Kim, G.S.; Chin, K.G. New Trends in Advanced High Strength Steel Developments for Automotive Application. Mater. Sci. Forum 2010, 638-642, 136–141. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, Y.; Qin, X. Some aspects of high manganese twinning-induced plasticity (TWIP) steel, a review. Acta Metall. Sin. (Engl. Lett.) 2013, 26, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Grässel, O.; Krüger, L.; Frommeyer, G.; Meyer, L. High strength Fe–Mn–(Al, Si) TRIP/TWIP steels develop-ment—Properties—Application. Int. J. Plast. 2000, 16, 1391–1409. [Google Scholar] [CrossRef]

- Hadfield, R.A. Hadfield’s Manganese Steel. Science 1888, ns-12, 284–286. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Kwang-geun, C.; Jinkyung, K. High Mn TWIP Steels for Automotive Applications. In Marcello Chiaberge (Hg.): New Trends and Developments in Automotive System Engineering; InTech: London, UK, 2011. [Google Scholar]

- Allain, S.; Chateau, J.-P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe–Mn–C alloys. Mater. Sci. Eng. A 2004, 387–389, 158–162. [Google Scholar] [CrossRef]

- Bouaziz, O.; Allain, S.; Scott, C.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels: A review of the microstructure properties relationships. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Kim, J.; De Cooman, B.C. On the Stacking Fault Energy of Fe-18 Pct Mn-0.6 Pct C-1.5 Pct Al Twinning-Induced Plasticity Steel. Metall. Mater. Trans. A 2011, 42, 932–936. [Google Scholar] [CrossRef] [Green Version]

- Jin, J.-E.; Lee, Y.-K. Strain hardening behavior of a Fe–18Mn–0.6C–1.5Al TWIP steel. Mater. Sci. Eng. A 2009, 527, 157–161. [Google Scholar] [CrossRef]

- Lee, T.-H.; Shin, E.; Oh, C.-S.; Ha, H.-Y.; Kim, S.-J. Correlation between stacking fault energy and deformation microstructure in high-interstitial-alloyed austenitic steels. Acta Mater. 2010, 58, 3173–3186. [Google Scholar] [CrossRef]

- Dumay, A.; Chateau, J.-P.; Allain, S.; Migot, S.; Bouaziz, O. Influence of addition elements on the stacking-fault energy and mechanical properties of an austenitic Fe–Mn–C steel. Mater. Sci. Eng. A 2008, 483-484, 184–187. [Google Scholar] [CrossRef]

- Hamada, A. Manufacturing, Mechanical Properties and Corrosion Behaviour of High-Mn TWIP Steels; Oulu University Press: Oulu, Finland, 2007. [Google Scholar]

- Frommeyer, G.; Brüx, U.; Neumann, P. Supra-Ductile and High-Strength Manganese-TRIP/TWIP Steels for High Energy Absorption Purposes. ISIJ Int. 2003, 43, 438–446. [Google Scholar] [CrossRef] [Green Version]

- Remy, L.; Pineau, A. Twinning and strain-induced F.C.C. → H.C.P. transformation in the Fe-Mn-Cr-C system. Mater. Sci. Eng. 1977, 28, 99–107. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Mosecker, L.; Schwedt, A.; Bleck, W. Characterization and Prediction of Flow Behavior in High-Manganese Twinning Induced Plasticity Steels: Part I. Mechanism Maps and Work-Hardening Behavior. Metall. Mater. Trans. A 2011, 43, 1688–1704. [Google Scholar] [CrossRef]

- Song, W.; Ingendahl, T.; Bleck, W. Control of Strain Hardening Behavior in High-Mn Austenitic Steels. Acta Metall. Sin. Lett. 2014, 27, 546–556. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Grajcar, A. Corrosion resistance of high-Mn austenitic steels for the automotive industry. Corros. Resist. 2012, 30, 353–376. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Rana, R.; Haldar, A.; Ray, R.K. Current state of Fe-Mn-Al-C low density steels. Prog. Mater. Sci. 2017, 89, 345–391. [Google Scholar] [CrossRef]

- Frommeyer, G.; Brüx, U. Microstructures and Mechanical Properties of High-Strength Fe-Mn-Al-C Light-Weight TRIPLEX Steels. Steel Res. Int. 2006, 77, 627–633. [Google Scholar] [CrossRef]

- Yoo, J.D.; Park, K.-T. Microband-induced plasticity in a high Mn–Al–C light steel. Mater. Sci. Eng. A 2008, 496, 417–424. [Google Scholar] [CrossRef]

- Haase, C.; Zehnder, C.; Ingendahl, T.; Bikar, A.; Tang, F.; Hallstedt, B.; Hu, W.; Bleck, W.; Molodov, D.A. On the deformation behavior of κ-carbide-free and κ-carbide-containing high-Mn light-weight steel. Acta Mater. 2017, 122, 332–343. [Google Scholar] [CrossRef]

- Welsch, E.; Ponge, D.; Haghighat, S.H.; Sandlöbes, S.; Choi, P.; Herbig, M.; Zaefferer, S.; Raabe, D. Strain hardening by dynamic slip band refinement in a high-Mn lightweight steel. Acta Mater. 2016, 116, 188–199. [Google Scholar] [CrossRef]

- Wegener, T.; Haase, C.; Liehr, A.; Niendorf, T. On the influence of ϰ-carbides on the low-cycle fatigue behavior of high-Mn light-weight steels. Int. J. Fatigue 2021, 150, 106327. [Google Scholar] [CrossRef]

- Lee, Y.-K.; Lee, S.-J.; Han, J. Critical assessment 19: Stacking fault energies of austenitic steels. Mater. Sci. Technol. 2016, 32, 1–8. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Imlau, J.; Prahl, U.; Bleck, W. Derivation and Variation in Composition-Dependent Stacking Fault Energy Maps Based on Subregular Solution Model in High-Manganese Steels. Metall. Mater. Trans. A 2009, 40, 3076–3090. [Google Scholar] [CrossRef]

- Volosevich, P.U.; Gridnev, V.N.; Petrov, Y.U.N. Influence of Mn and the stacking fault energy of Fe-Mn alloys. In Physics of Metals and Metallography; Springer: New York, NY, USA, 1976; Volume 42. [Google Scholar]

- Schumann, H. Einfluß der Stapelfehlerenergie auf den kristallographischen Umgitterungsmechanismus der γ/α-Umwandlung in hochlegierten Stählen. Cryst. Res. Technol. 1974, 9, 1141–1152. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. Kinetics of strain-induced martensitic nucleation. Metall. Mater. Trans. A 1975, 6, 791–795. [Google Scholar] [CrossRef]

- Grässel, O.; Frommeyer, G.; Derder, C.; Hofmann, H. Phase Transformations and Mechanical Properties of Fe-Mn-Si-Al TRIP-Steels. J. Phys. Colloq. 1997, 7, C5-383–C5-388. [Google Scholar] [CrossRef] [Green Version]

- Rüsing, C.J.; Lambers, H.-G.; Lackmann, J.; Frehn, A.; Nagel, M.; Schaper, M.; Maier, H.; Niendorf, T. Property Optimization for TWIP Steels—Effect of Pre-deformation Temperature on Fatigue Properties. Mater. Today Proc. 2015, 2, S681–S685. [Google Scholar] [CrossRef]

- Oevermann, T.; Wegener, T.; Niendorf, T. On the Evolution of Residual Stresses, Microstructure and Cyclic Performance of High-Manganese Austenitic TWIP-Steel after Deep Rolling. Metals 2019, 9, 825. [Google Scholar] [CrossRef] [Green Version]

- Mughrabi, H. Cyclic Slip Irreversibilities and the Evolution of Fatigue Damage. Metall. Mater. Trans. A 2009, 40, 431–453. [Google Scholar] [CrossRef]

- Skorupski, R.; Smaga, M.; Eifler, D. Influence of Surface Morphology on the Fatigue Behavior of Metastable Austenitic Steel. Adv. Mater. Res. 2014, 891–892, 464–469. [Google Scholar] [CrossRef]

- Kumar, D.; Idapalapati, S.; Wang, W.; Narasimalu, S. Effect of Surface Mechanical Treatments on the Microstruc-ture-Property-Performance of Engineering Alloys. Materials 2019, 12, 2503. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Delgado, P.; Cuesta, I.; Alegre, J.M.; Díaz, A. State of the art of Deep Rolling. Precis. Eng. 2016, 46, 1–10. [Google Scholar] [CrossRef]

- Schulze, V. Modern Mechanical Surface Treatment—States, Stability, Effects; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2006. [Google Scholar]

- Teichmann, C.; Wagner, L. Shot peening of TWIP steel—Influence on mechanical properties. In Proceedings of the ICSP-12, Goslar, Germany, 15–18 September 2014; pp. 499–503. [Google Scholar]

- Kongthep, J.; Timmermann, K.; Scholtes, B.; Niendorf, T. On the impact of deep rolling at different temperatures on the near surface microstructure and residual stress state of steel AISI 304. Mater. und Werkst. 2019, 50, 788–795. [Google Scholar] [CrossRef]

- Oevermann, T.; Wegener, T.; Liehr, A.; Hübner, L.; Niendorf, T. Evolution of residual stress, microstructure and cyclic performance of the equiatomic high-entropy alloy CoCrFeMnNi after deep rolling. Int. J. Fatigue 2021, 153, 106513. [Google Scholar] [CrossRef]

- James, N. Residual stress influences on structural reliability. Eng. Fail. Anal. 2011, 18, 1909–1920. [Google Scholar] [CrossRef]

- Hensel, J.; Nitschke-Pagel, T.; Dilger, K. Effects of residual stresses and compressive mean stresses on the fatigue strength of longitudinal fillet-welded gussets. Weld. World 2016, 60, 267–281. [Google Scholar] [CrossRef]

- Gadallah, R.; Osawa, N.; Tanaka, S.; Tsutsumi, S. Critical investigation on the influence of welding heat input and welding residual stress on stress intensity factor and fatigue crack propagation. Eng. Fail. Anal. 2018, 89, 200–221. [Google Scholar] [CrossRef]

- Syed, A.K.; Ahmad, B.; Guo, H.; Machry, T.; Eatock, D.; Meyer, J.; Fitzpatrick, M.E.; Zhang, X. An experimental study of residual stress and direction-dependence of fatigue crack growth behaviour in as-built and stress-relieved selec-tive-laser-melted Ti6Al4V. Mater. Sci. Eng. A 2019, 755, 246–257. [Google Scholar] [CrossRef]

- Wu, S.; Luo, Y.; Shen, Z.; Zhou, L.; Zhang, W.; Kang, G. Collaborative crack initiation mechanism of 25CrMo4 alloy steels subjected to foreign object damages. Eng. Fract. Mech. 2020, 225, 106844. [Google Scholar] [CrossRef]

- Perić, M.; Nižetić, S.; Garašić, I.; Gubeljak, N.; Vuherer, T.; Tonković, Z. Numerical calculation and experimental measure-ment of temperatures and welding residual stresses in a thick-walled T-joint structure. J. Therm. Anal. Calorim. 2020, 141, 313–322. [Google Scholar] [CrossRef]

- Nitschke-Pagel, T. Recommendations for the measurement of residual stresses in welded joints by means of X-ray diffrac-tion—Results of the WG6-RR test. Weld. World 2020, 65, 1–12. [Google Scholar] [CrossRef]

- Klein, M.W.; Blinn, B.; Smaga, M.; Beck, T. High cycle fatigue behavior of high-Mn TWIP steel with different surface mor-phologies. Int. J. Fatigue 2020, 134, 105499. [Google Scholar] [CrossRef]

- Klein, M.W.; Smaga, M.; Beck, T. Surface Morphology and Its Influence on Cyclic Deformation Behavior of High-Mn TWIP Steel. Metals 2018, 8, 832. [Google Scholar] [CrossRef] [Green Version]

- Torabi, S.A.; Amini, K.; Gharavi, F. The effect of shot peening and precipitation hardening on the wear behavior of high manganese austenitic steels. Metall. Res. Technol. 2017, 114, 507. [Google Scholar] [CrossRef]

- Nikitin, I.; Besel, M. Residual stress relaxation of deep-rolled austenitic steel. Scr. Mater. 2008, 58, 239–242. [Google Scholar] [CrossRef]

- Lee, H.; Mall, S. Stress relaxation behavior of shot-peened Ti–6Al–4V under fretting fatigue at elevated temperature. Mater. Sci. Eng. A 2004, 366, 412–420. [Google Scholar] [CrossRef]

- John, R.; Buchanan, D.J.; Caton, M.J.; Jha, S.K. Stability of shot peen residual stresses in IN100 subjected to creep and fatigue loading. Procedia Eng. 2010, 2, 1887–1893. [Google Scholar] [CrossRef] [Green Version]

- Holzapfel, H.; Schulze, V.; Vöhringer, O.; Macherauch, E. Residual stress relaxation in an AISI 4140 steel due to quasistatic and cyclic loading at higher temperatures. Mater. Sci. Eng. A 1998, 248, 9–18. [Google Scholar] [CrossRef]

- Eigenmann, B.; Schulze, V.; Vohringer, O. Surface Residual Stress Relaxation in Steels by Thermal or Mechanical Treatment. In Proceedings of the 4th International Conference on Residual Stresses, Baltimore, MD, USA, 8–10 June 1994; pp. 598–607. [Google Scholar]

- Rüsing, C.J. Optimierung der Monotonen und Zyklischen Eigenschaften von Hoch Manganhaltigen TWIP-Stählen: Einfluss von Temperatur und Vorverformung auf die Mikrostrukturentwicklung: Universitätsbibliothek. 2015. Available online: https://books.google.de/books?id=-HMMyAEACAAJ (accessed on 16 October 2021).

- Moore, M.G.; Evans, W.P. Mathematical Correction for Stress in Removed Layers in X-ray Diffraction Residual Stress Analysis. In SAE Technical Paper Series; Pre-1964 SAE Technical Papers; SAE International: Warrendale, PA, USA, 1906. [Google Scholar]

- Nikitin, I.; Scholtes, B. Deep rolling of austenitic steel AISI 304 at different temperatures—Near surface microstructures and fatigue. HTM J. Heat Treat. Mater. 2012, 67, 188–194. [Google Scholar] [CrossRef]

- Saalfeld, S.; Krochmal, M.; Wegener, T.; Scholtes, B.; Niendorf, T. On the fatigue behavior of differently deep rolled condi-tions of SAE 1045 in the very-high-cycle fatigue regime. Int. J. Fatigue 2021, 151, 106360. [Google Scholar] [CrossRef]

- McCLUNG, R.C. A literature survey on the stability and significance of residual stresses during fatigue. Fatigue Fract. Eng. Mater. Struct. 2007, 30, 173–205. [Google Scholar] [CrossRef]

- Koyama, M.; Akiyama, E.; Lee, Y.-K.; Raabe, D.; Tsuzaki, K. Overview of hydrogen embrittlement in high-Mn steels. Int. J. Hydrogen Energy 2017, 42, 12706–12723. [Google Scholar] [CrossRef]

- Angkurarach, L.; Juijerm, P. Effects of High-Temperature Deep Rolling on Fatigue, Work Hardening, and Residual Stress Relaxation of Martensitic Stainless Steel AISI J. Mater. Eng. Perform. 2020, 29, 1416–1423. [Google Scholar] [CrossRef]

- Altenberger, I.; Nikitin, I.; Scholtes, B. Static and dynamic strain aging of deep-rolled plain carbon steel SAE 1045 for opti-mized fatigue strength. In Proceedings of the 9th International Conference on Shot Peening, Paris, France, 6–9 September 2005; Schulze, V., Niku-Lari, A., Eds.; IITT-International: Paris, France, 2005; pp. 253–260. [Google Scholar]

| EBSD | Hardness | Residual Stress Profiles | Tensile Tests | Fatigue Tests | Residual Stress Stability | Fracture Surface Analysis | |

|---|---|---|---|---|---|---|---|

| dr_855_RT | - | Recompiled from [39] | Recompiled from [39] | Recompiled from [39] | Partly recompiled from [39] | X | - |

| dr_855_550 °C | X | X | X | X | X | X | X |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wegener, T.; Krochmal, M.; Oevermann, T.; Niendorf, T. Consequences of Deep Rolling at Elevated Temperature on Near-Surface and Fatigue Properties of High-Manganese TWIP Steel X40MnCrAl19-2. Appl. Sci. 2021, 11, 10406. https://doi.org/10.3390/app112110406

Wegener T, Krochmal M, Oevermann T, Niendorf T. Consequences of Deep Rolling at Elevated Temperature on Near-Surface and Fatigue Properties of High-Manganese TWIP Steel X40MnCrAl19-2. Applied Sciences. 2021; 11(21):10406. https://doi.org/10.3390/app112110406

Chicago/Turabian StyleWegener, Thomas, Marcel Krochmal, Torben Oevermann, and Thomas Niendorf. 2021. "Consequences of Deep Rolling at Elevated Temperature on Near-Surface and Fatigue Properties of High-Manganese TWIP Steel X40MnCrAl19-2" Applied Sciences 11, no. 21: 10406. https://doi.org/10.3390/app112110406

APA StyleWegener, T., Krochmal, M., Oevermann, T., & Niendorf, T. (2021). Consequences of Deep Rolling at Elevated Temperature on Near-Surface and Fatigue Properties of High-Manganese TWIP Steel X40MnCrAl19-2. Applied Sciences, 11(21), 10406. https://doi.org/10.3390/app112110406