Filament X-ray Tube Current Control Method Using Indirect Filament Temperature Estimation

Abstract

:1. Introduction

- The filament is heated at a high temperature, and thermal electrons are emitted into a vacuum [2].

- The emitted electrons are accelerated to an anode, generating a tube current that flows through the vacuum tube.

- The accelerated electrons are converted into X-rays after their collision with the anode.

- An image is obtained after the photons that reach the detector undergo image processing.

2. Principle of Operation

2.1. Thermionic Emission

2.2. Tungsten Thermal Properties

3. Indirect Filament Temperature Estimation Algorithm

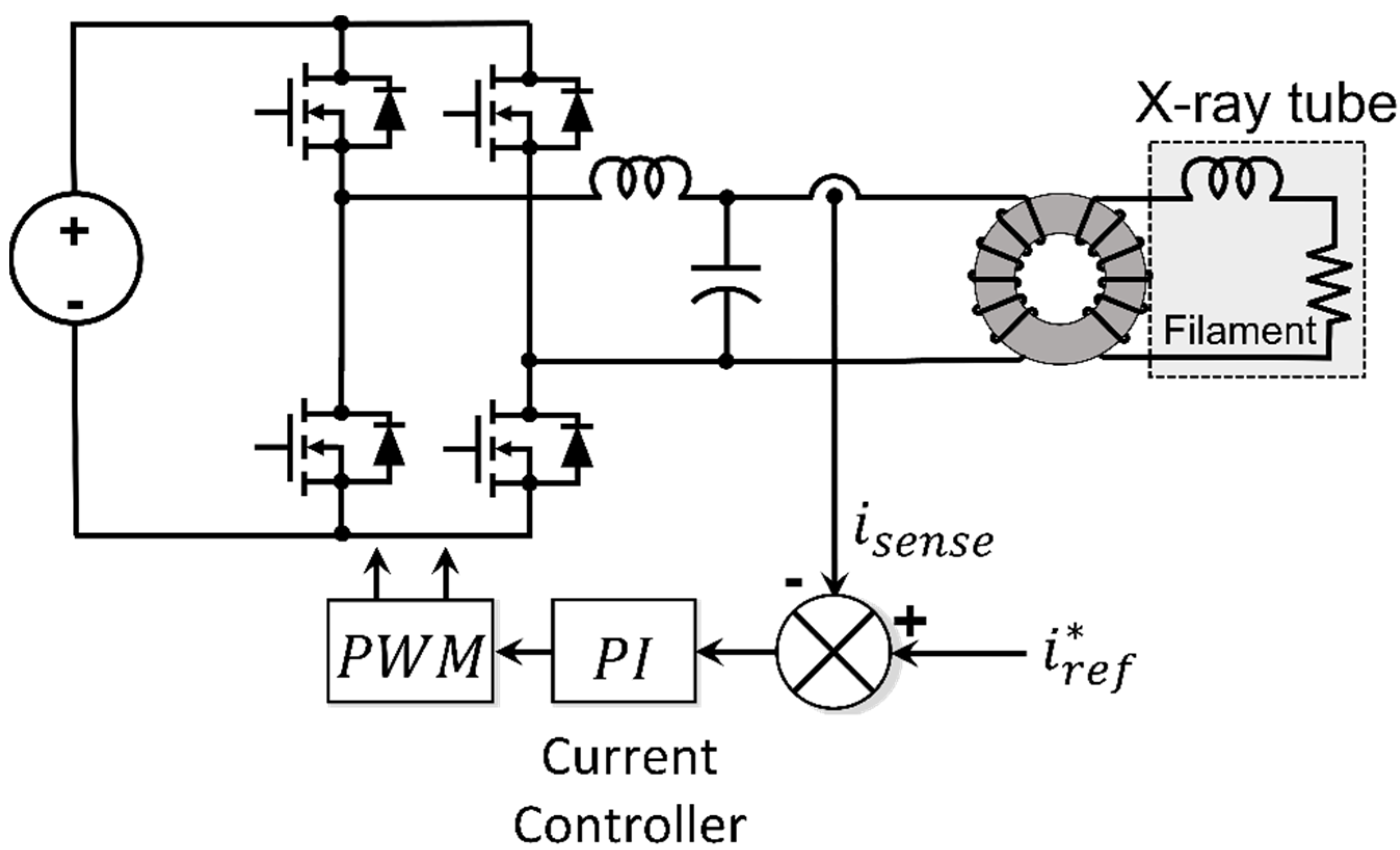

3.1. Conventional Method

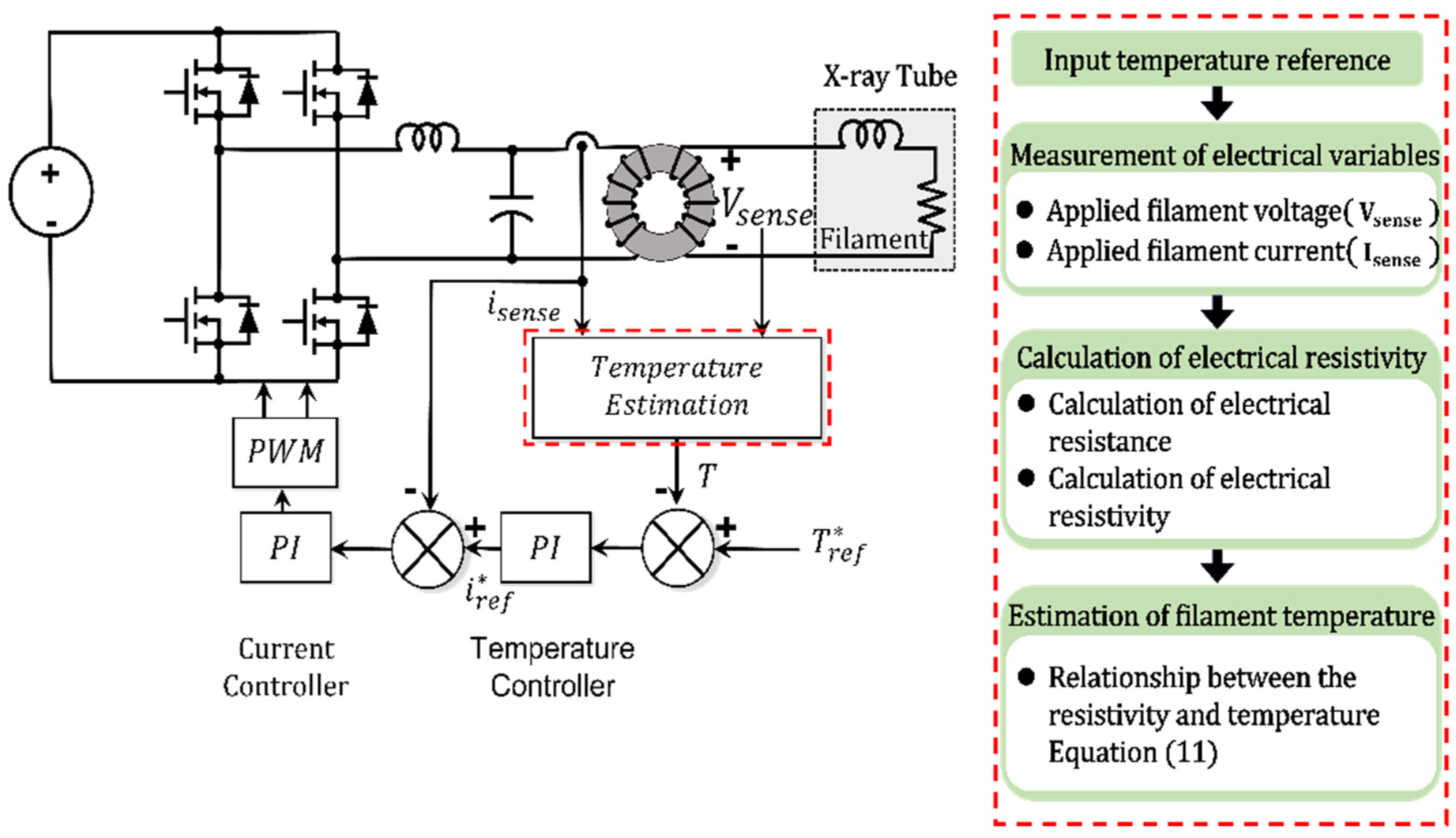

3.2. Proposed Method

- The voltage is measured at both ends of the filament;

- The primary current of the transformer is measured for insulation;

- The measured voltage is divided by the current to calculate the resistance of the tungsten filament. If the heating current is 0 A, the resistance cannot be calculated. Therefore, the calculation must be performed considering the resistance value obtained when the current exceeds a certain value. The heating current at this point represents the maximum heating current value on the filament datasheet, and the flowing current is limited through software;

- The calculated resistance is converted into resistivity based on the length and cross-sectional area of the filament;

- The temperature of the filament is estimated using the resistivity, as indicated in Equation (11).

4. Experiments

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Seibert, J.A. X-ray imaging physics for nuclear medicine technologists. Part 1: Basic principles of X-ray production. J. Nucl. Med. Technol. 2004, 32, 139–147. [Google Scholar] [PubMed]

- Behling, R. X-ray tubes development-IOMP history of medical physics. Hist. Med. Phys. 2018, 1, 7–55. [Google Scholar]

- Falavigna, A.; Ramos, M.B.; Wong, C.C.; Barbagallo, G.; Brodk, D.; Al-Mutair, A.; Ghogawala, Z.; Riew, K.D. Commentary: Worldwide knowledge and attitude of spine surgeons regarding radiation exposure. Neurosurgery 2018, 83, E153–E161. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mahesh, M. The AAPM/RSNA physics tutorial for residents fluoroscopy: Patient radiation exposure issues 1. Radiographics 2001, 21, 1033–1045. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bushberg, J.T.; Seibert, J.A.; Leidholdt, E.M., Jr.; Boone, J.M. The Essential Physics of Medical Imaging, 2nd ed.; Lippincott Williams & Wilkins: Philadelphia, PA, USA, 2001; pp. 97–144. [Google Scholar]

- Kim, Y.J.; Maruyama, Y.; Nakaoka, M. Practical evaluations of resonant pole-assisted ZVS-PWM DC/DC converter with series capacitor-connected transformer parasitic parallel resonant tank. In Proceedings of the Annual IEEE Power Electronics Specialist Conference, Seattle, WA, USA, 20–24 June 1993. [Google Scholar]

- Seo, Y.M.; Byun, M.S.; Hong, S.C. Hybrid type X-ray generator for fluoroscopy X-ray system available in low-capacity AC power source. In Proceedings of the 9th International Conference Power Electronics, Seoul, Korea, 1–5 June 2015. [Google Scholar]

- Villegas, P.J.; Díaz, J.; Pernía, A.M.; Martínez, J.A.; Nuño, F.; Prieto, M.J. Filament power supply for electron beam welding machine. IEEE Trans. Ind. Electron. 2015, 62, 1421–1430. [Google Scholar] [CrossRef]

- Sasic, B.; Pindrys, S.; Willsey, J. Functional Role of X-ray Generators in Industrial Applications; Spellman High Voltage Electronics Corporation: Hauppauge, NY, USA, 2018. [Google Scholar]

- Faraj, K.A.; Ali, R.T.; Saeed, A.O. Quality control and radiation dose rates measurement from diagnostic X-ray examination at different places of hospitals in Sulaimania. Int. J. Recent Res. Appl. Stud. 2013, 16, 62–72. [Google Scholar]

- Bruno, A.C.; Mazaro, S.J.; Amaral, L.L.; Rego, E.M.; Oliveira, H.F.; Pavoni, J.F. Biological X-ray irradiator characterization for use with small animals and cells. Braz. J. Med. Biol. Res. 2017, 50. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nottingham, W.B. Thermionic Emission; The Research Laboratory of Electronics Massachusetts Institute of Technology: Cambridge, MA, USA, 1956. [Google Scholar]

- Schonenberger, C.; Oberholzer, S. Shot Noise: From Schottky’s Vacuum Tube to Present-Day Quantum Devices. In Fluctuations and Noise in Materials (Proceedings of SPIE); SPIE: Washington, DC, USA, 2004; p. 5469. [Google Scholar]

- Forsythe, W.E.; Watson, E.M. Resistance and radiation of tungsten as a function of temperature. J. Opt. Soc. Am. 1934, 24, 114–118. [Google Scholar] [CrossRef]

- Zerda, T.W. Stefan Boltzmann Lamp 1008523; 3B Scientific Physics: Hamburg, Germany, 2013. [Google Scholar]

- Shabalin, I.L. Ultra High Temperature Materials; Springer: Heidelberg, Germany, 2014; pp. 237–315. [Google Scholar]

- Cezairliyan, A.; McClure, J.L. High speed (subsecond) measurement of heat capacity, electrical resistivity, and thermal radiation properties of tungsten in the range 2000 to 3600 K. J. Res. Nat. Bur. Stand. 1971, 75, 283–290. [Google Scholar] [CrossRef]

- Tanabe, T.; Eamchotchawalit, C.; Busabok, C.; Taweethavorn, S.; Fujitsuka, M.; Shikama, T. Temperature dependence of thermal conductivity in W and W–Re alloys from 300 to 1000 K. Mater. Lett. 2003, 57, 2950–2953. [Google Scholar] [CrossRef]

- Borgea, S.; Campbell, N.; Gomes, A.; Raszkowski, A.M.; Rook, J.W.; Sanderud, A.; Vallinga, A.; Vouillamoz, A.; Buissink, C. Experimental article—Maintaining image quality for pediatric chest CTs while lowering dose: FBP versus SAFIRE. Reconstruction in CT. In Proceedings of the OPTIMAX 2014: Radiation Dose and Image Quality Optimisation in Medical Imaging, Portugal, Lisbon, 1–31 August 2014; pp. 16–20, ISBN 978-1-907842-60-3. [Google Scholar]

- Chondrakis, N.G.; Topalis, F.V. Evaluation of heat transfer coefficient of tungsten filaments at low pressures and high temperatures. Appl. Therm. Eng. 2010, 31, 258–267. [Google Scholar] [CrossRef] [Green Version]

- Mortimer, G.W. Real-time measurement of dynamic filament resistance. J. Illum. Eng. Soc. 1998, 27, 22–28. [Google Scholar] [CrossRef]

| Temperature (K) | Temperature (K) | Temperature (K) | Temperature (K) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.0 | 300 | 5.65 | 5.48 | 1200 | 30.98 | 10.63 | 2100 | 60.06 | 16.29 | 3000 | 92.04 |

| 1.43 | 400 | 8.06 | 6.03 | 1300 | 34.08 | 11.24 | 2200 | 63.48 | 16.95 | 3100 | 95.76 |

| 1.87 | 500 | 10.56 | 6.58 | 1400 | 37.19 | 11.84 | 2300 | 66.91 | 17.62 | 3200 | 99.54 |

| 2.34 | 600 | 13.23 | 7.14 | 1500 | 40.36 | 12.46 | 2400 | 70.39 | 18.28 | 3300 | 103.3 |

| 2.85 | 700 | 16.09 | 7.71 | 1600 | 43.55 | 13.08 | 2500 | 73.91 | 18.97 | 3400 | 107.2 |

| 3.36 | 800 | 19.00 | 8.28 | 1700 | 46.78 | 13.72 | 2600 | 77.49 | 19.66 | 3500 | 111.1 |

| 3.88 | 900 | 21.94 | 8.86 | 1800 | 50.05 | 14.34 | 2700 | 81.04 | 20.35 | 3600 | 115.0 |

| 4.41 | 1000 | 24.93 | 9.44 | 1900 | 53.35 | 14.99 | 2800 | 84.70 | |||

| 4.95 | 1100 | 27.94 | 10.03 | 2000 | 56.67 | 15.63 | 2900 | 88.33 |

| Temperature Reference (K) | Maximum Error Temperature (K) | Minimum Error Temperature (K) | Average Estimation Temperature (K) | Average Error (K) |

|---|---|---|---|---|

| 1700 | 23 | −14 | 1702.1 | 2.1 |

| 1800 | 25 | −22 | 1806.1 | 6.1 |

| 1900 | 27 | −23 | 1906.0 | 6.0 |

| 2000 | 1 | −3 | 2001.0 | 1.0 |

| 2100 | 25 | −18 | 2102.1 | 2.1 |

| Estimated Temperature (K) | Conventional Method (mA) | Proposed Method (mA) | Ratio (%) |

|---|---|---|---|

| 1900 | 0.543 | 0.464 | 117 |

| 1950 | 0.992 | 0.906 | 109 |

| Estimated Temperature (K) | Conventional Method (mSv/h) | Proposed Method (mSv/h) | Ratio (%) |

|---|---|---|---|

| 1900 | 867 | 777 | 89 |

| 1950 | 1466 | 1383 | 94 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, J.-J.; Zhu, H.-L.; Mok, H.-S. Filament X-ray Tube Current Control Method Using Indirect Filament Temperature Estimation. Appl. Sci. 2021, 11, 10588. https://doi.org/10.3390/app112210588

Jang J-J, Zhu H-L, Mok H-S. Filament X-ray Tube Current Control Method Using Indirect Filament Temperature Estimation. Applied Sciences. 2021; 11(22):10588. https://doi.org/10.3390/app112210588

Chicago/Turabian StyleJang, Je-Jin, He-Lin Zhu, and Hyung-Soo Mok. 2021. "Filament X-ray Tube Current Control Method Using Indirect Filament Temperature Estimation" Applied Sciences 11, no. 22: 10588. https://doi.org/10.3390/app112210588