Design and Fabrication Technology of Metal Mirrors Based on Additive Manufacturing: A Review

Abstract

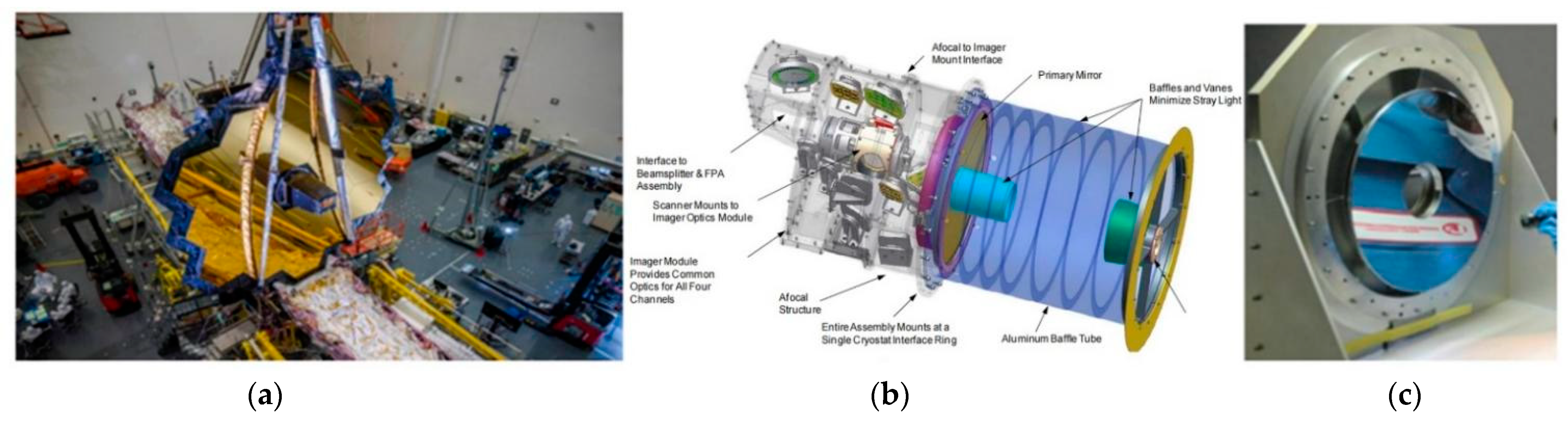

:1. Introduction

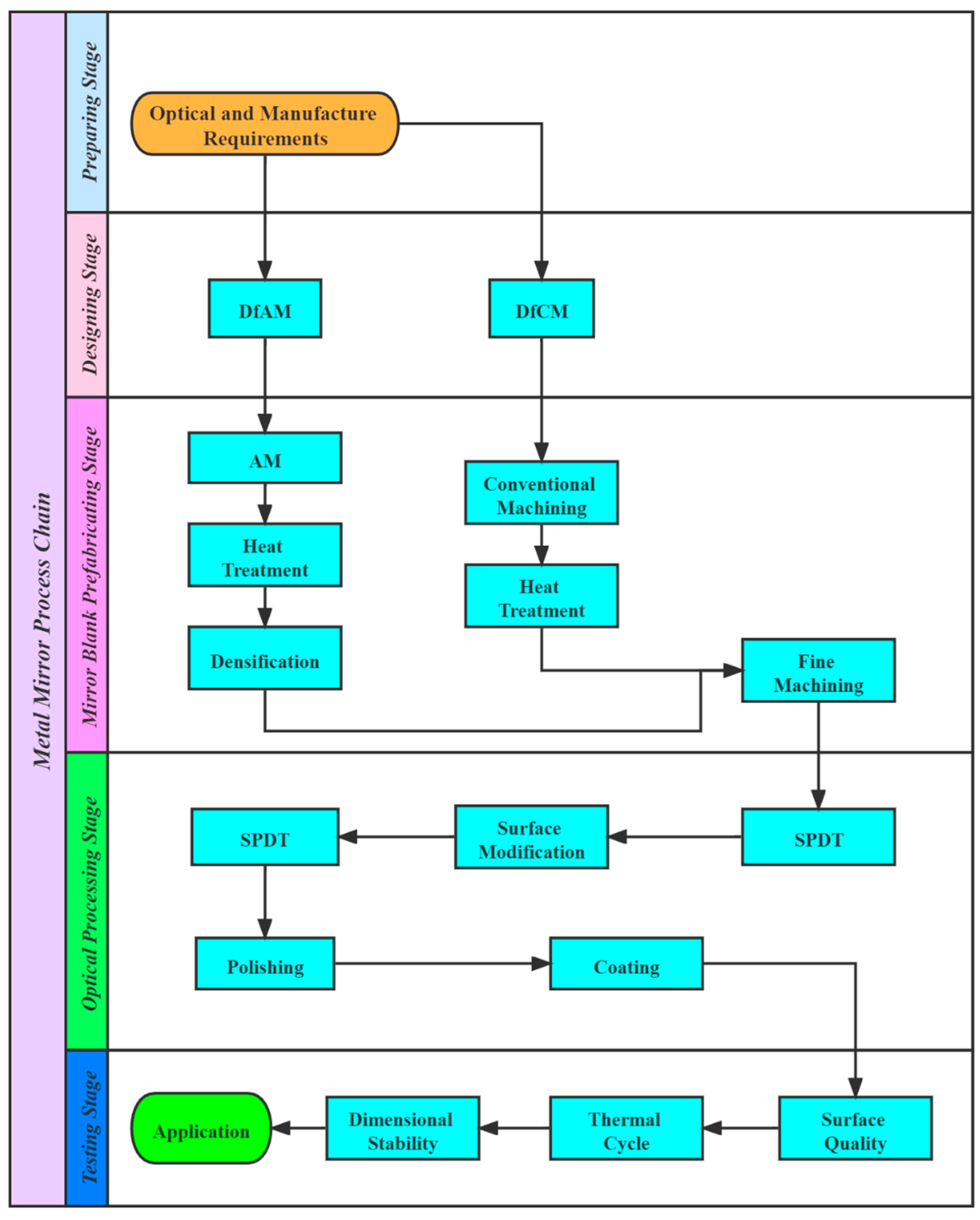

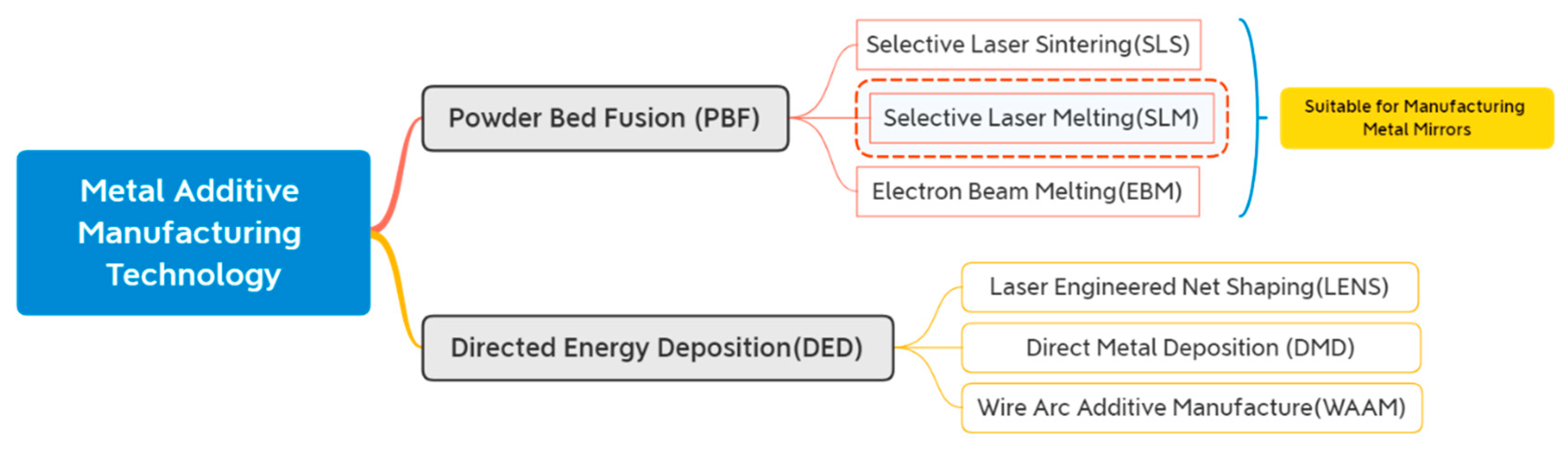

2. Additive Manufacturing Technology for Metal Mirrors

2.1. Metal Additive Manufacturing Technology

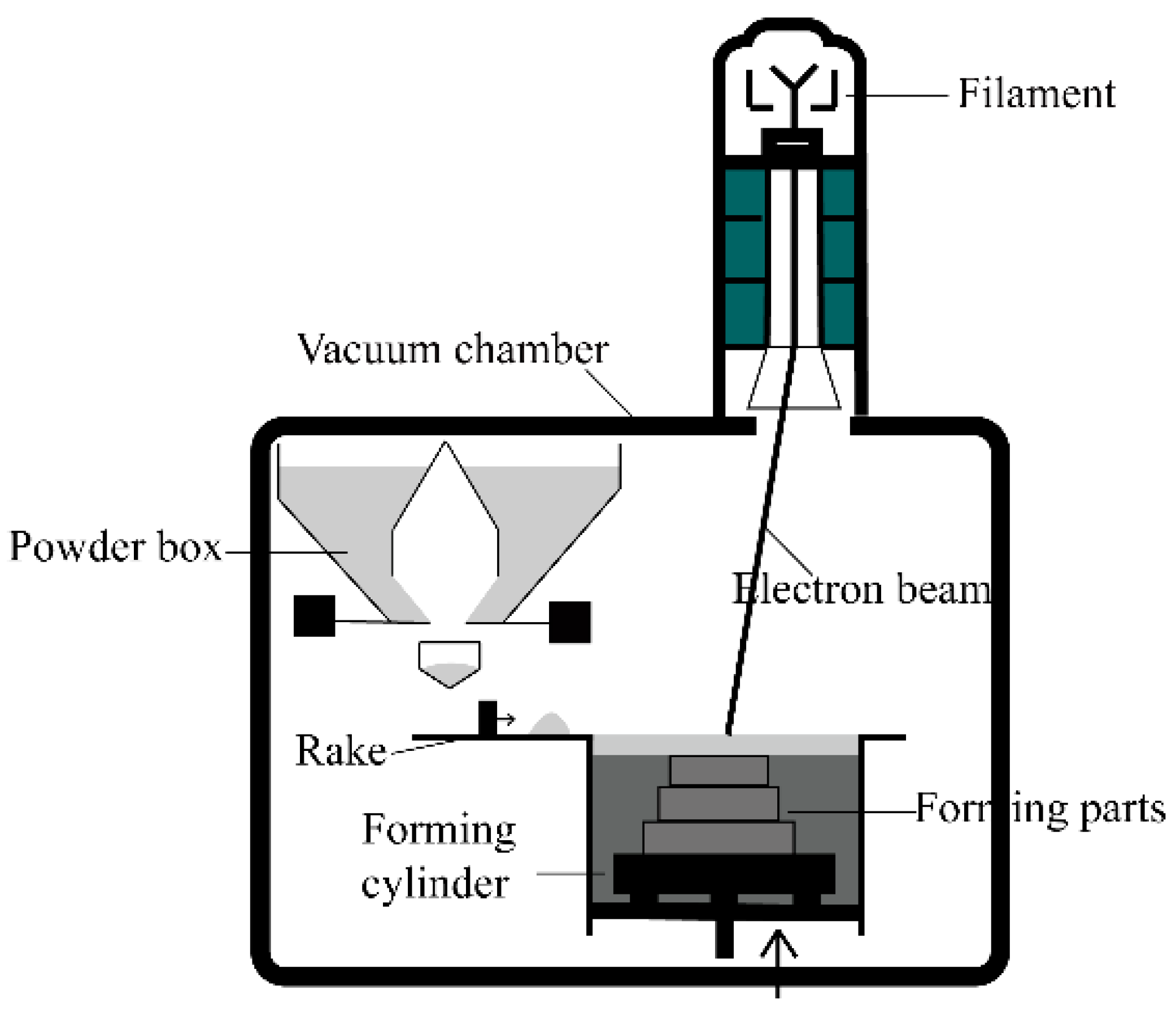

2.1.1. Electron Beam Melting (EBM)

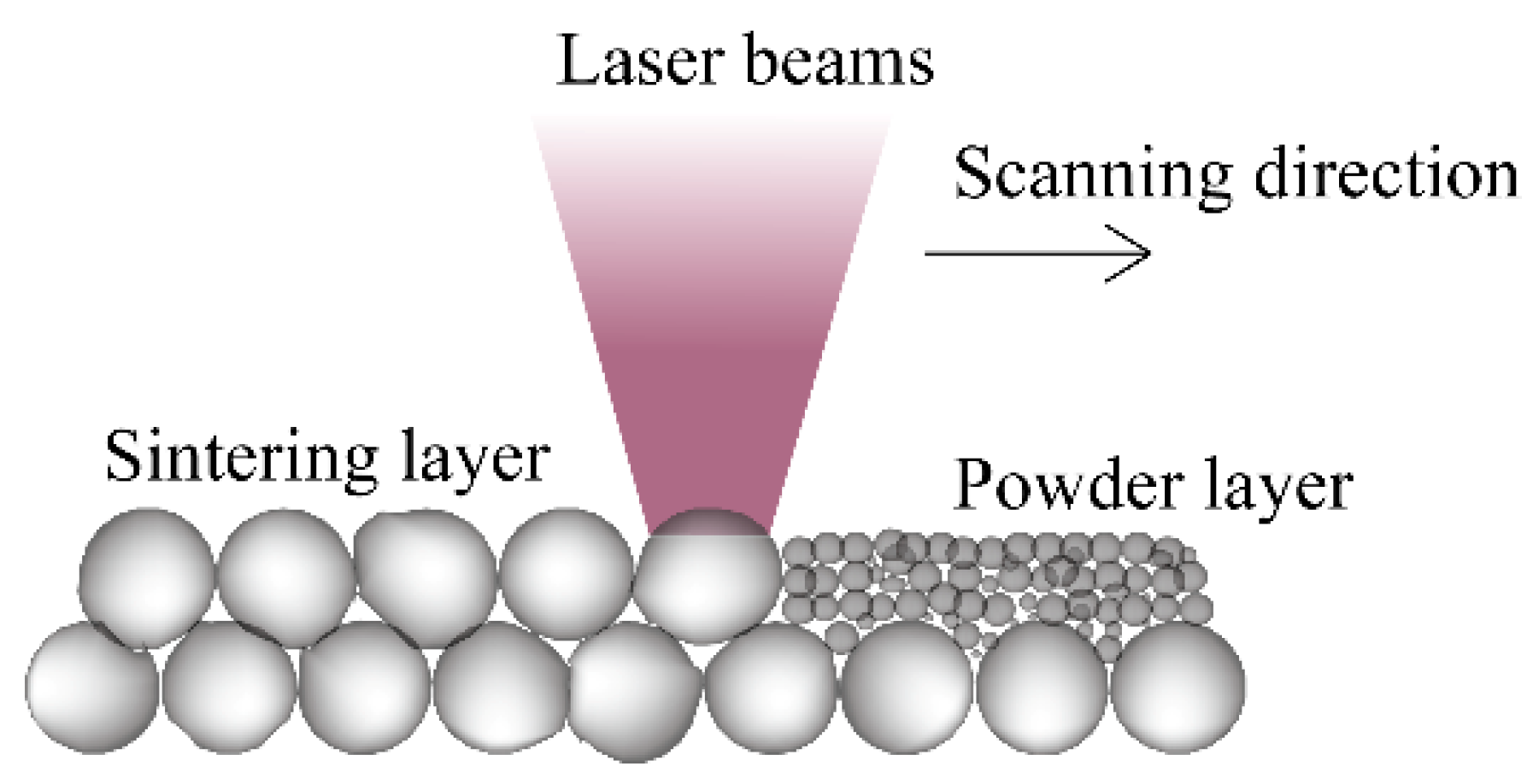

2.1.2. Selective Laser Sintering (SLS)

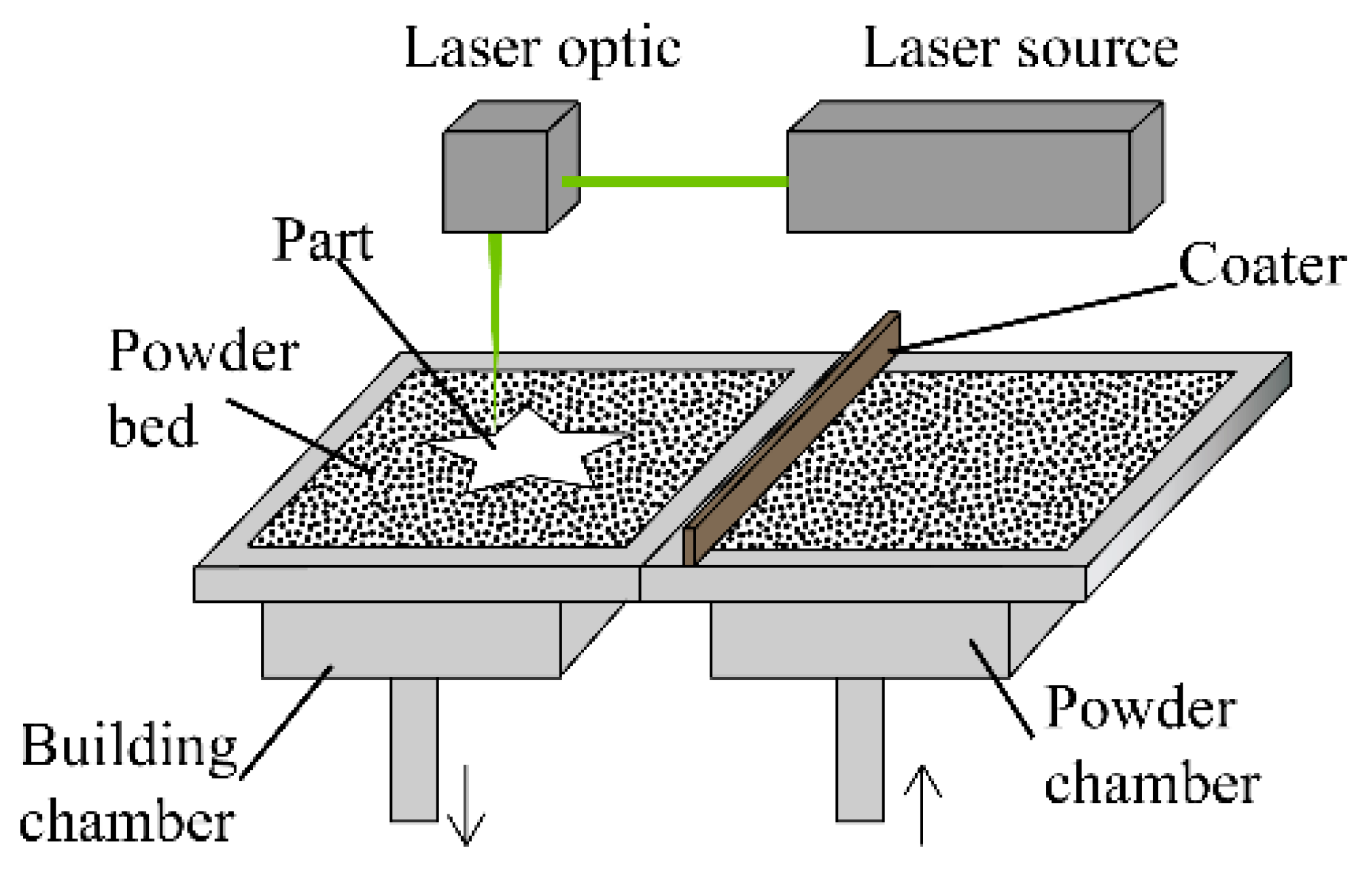

2.1.3. Selective Laser Melting (SLM)

2.2. Additive Manufacturing Metal Mirror Fabricating Considerations

2.2.1. Material Type

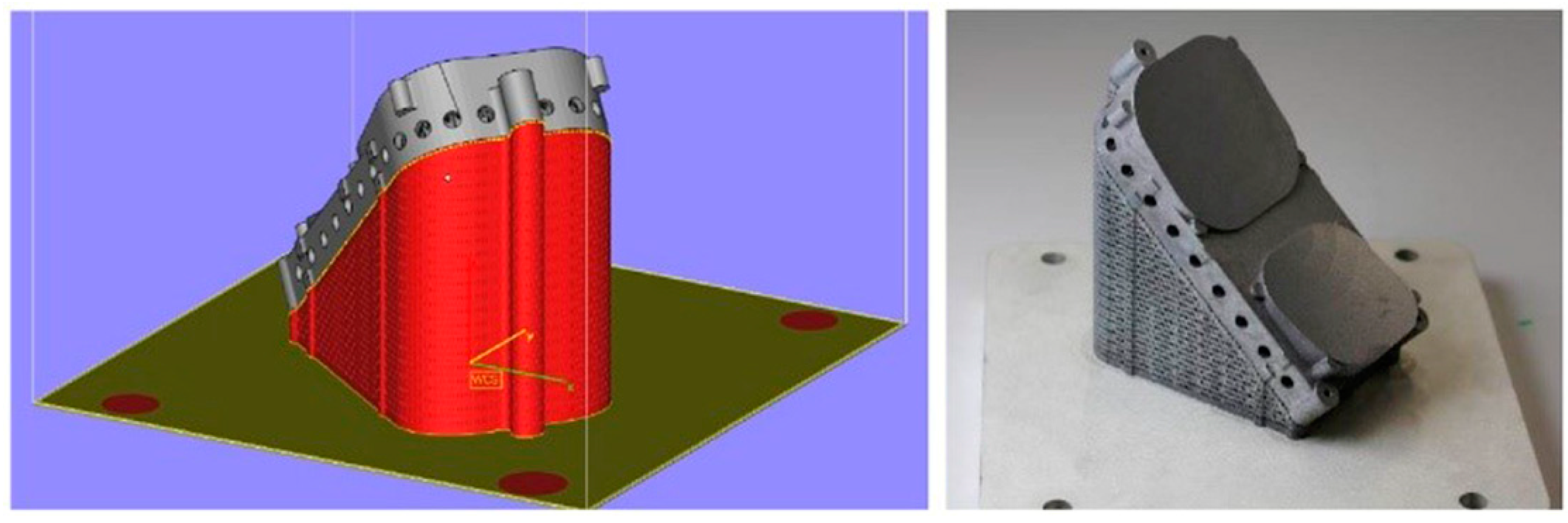

2.2.2. Design of Support

2.2.3. Connectivity Constraints

3. Design Technology of Additively Manufactured Metal Mirrors

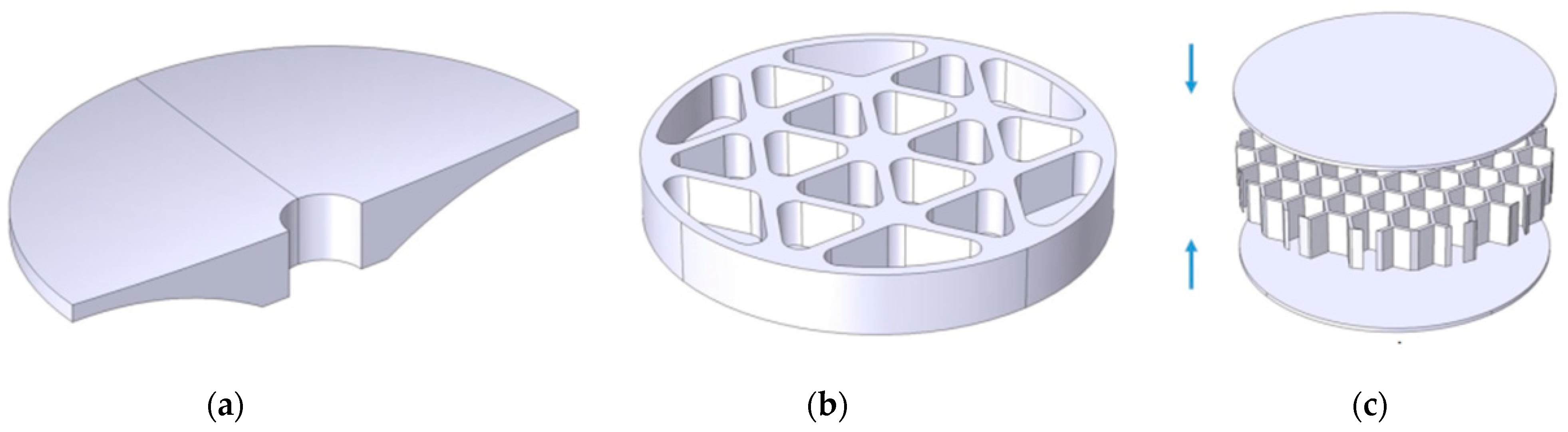

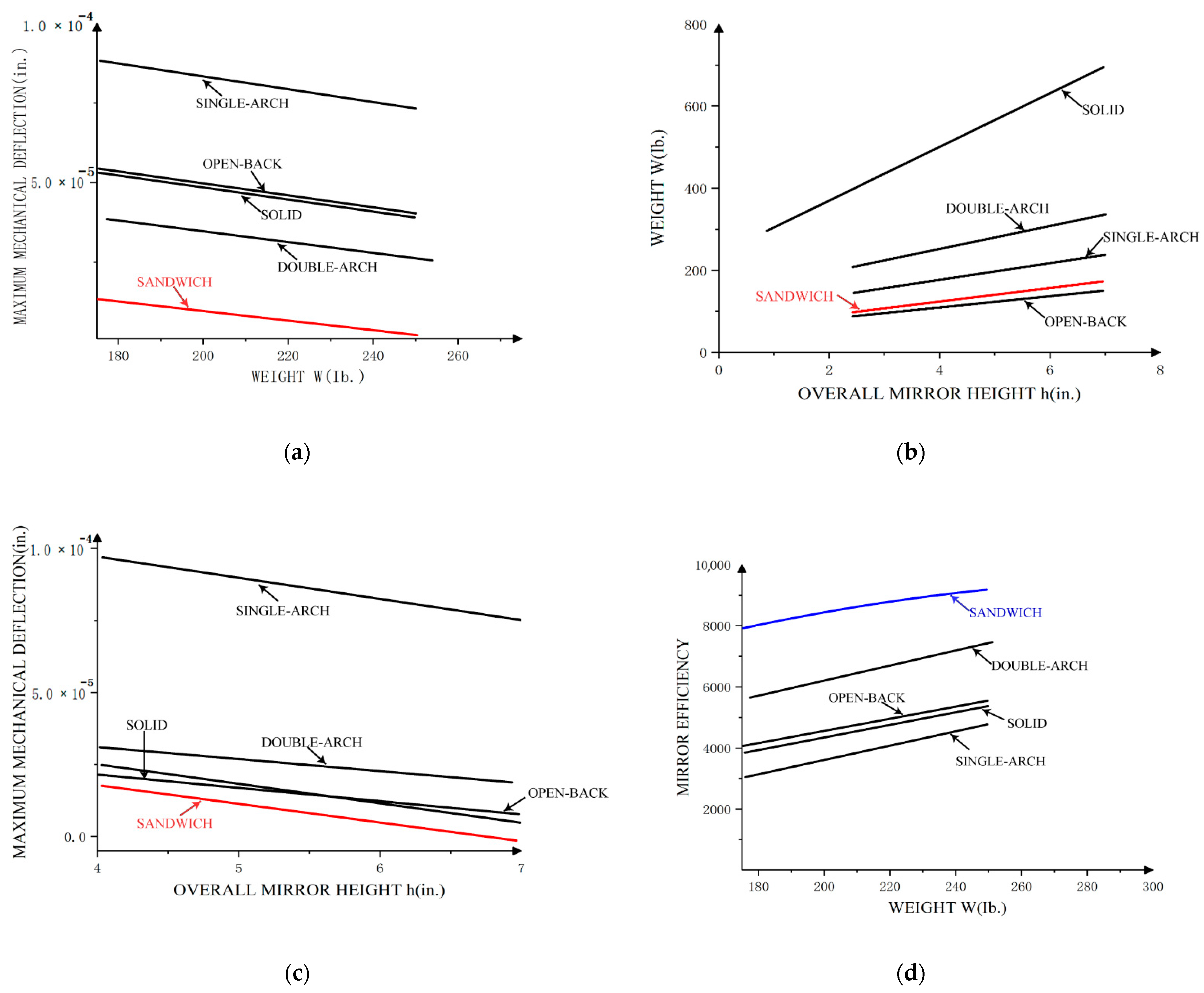

3.1. Conventional Design

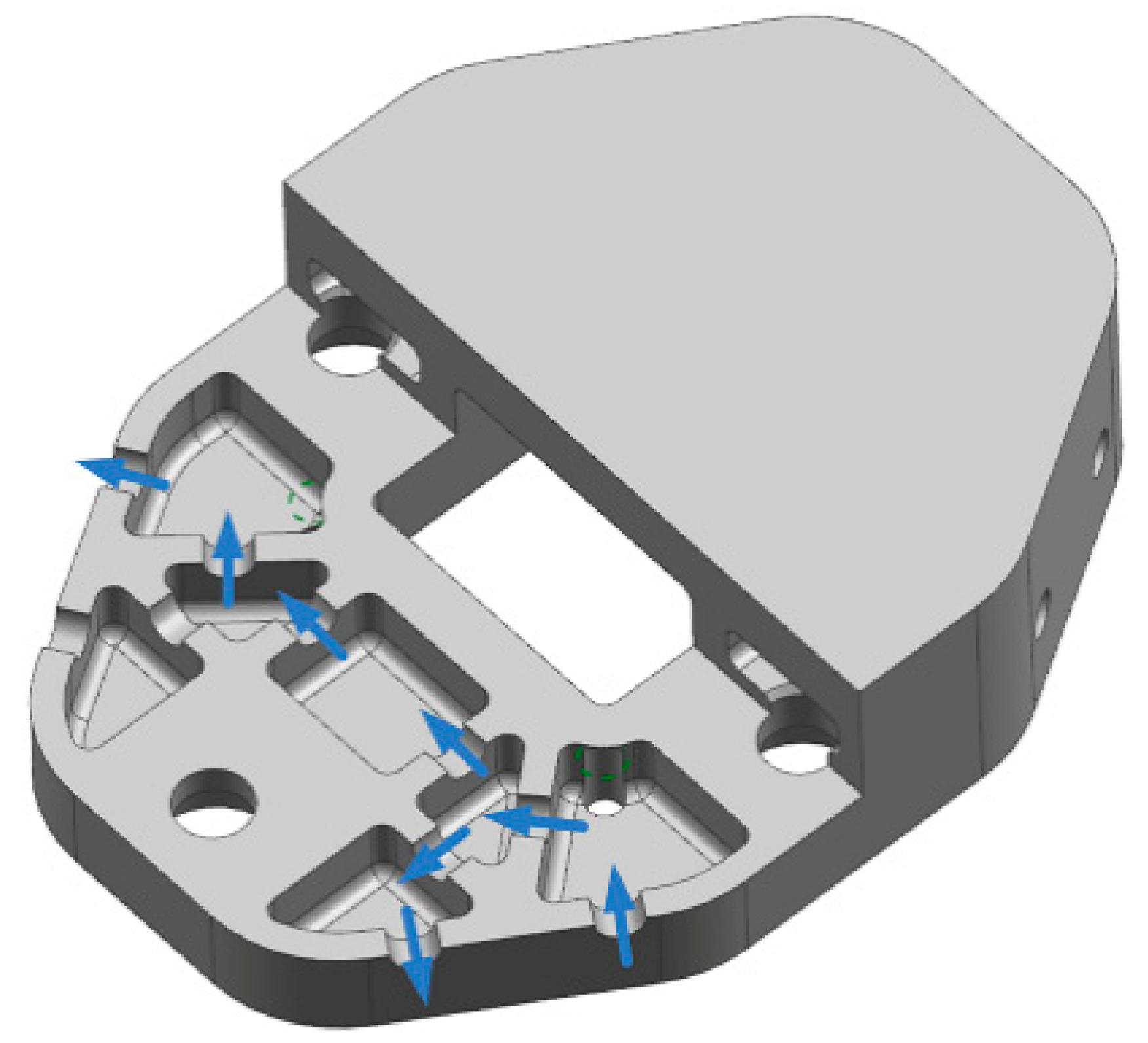

3.2. Topology Optimization (TO)

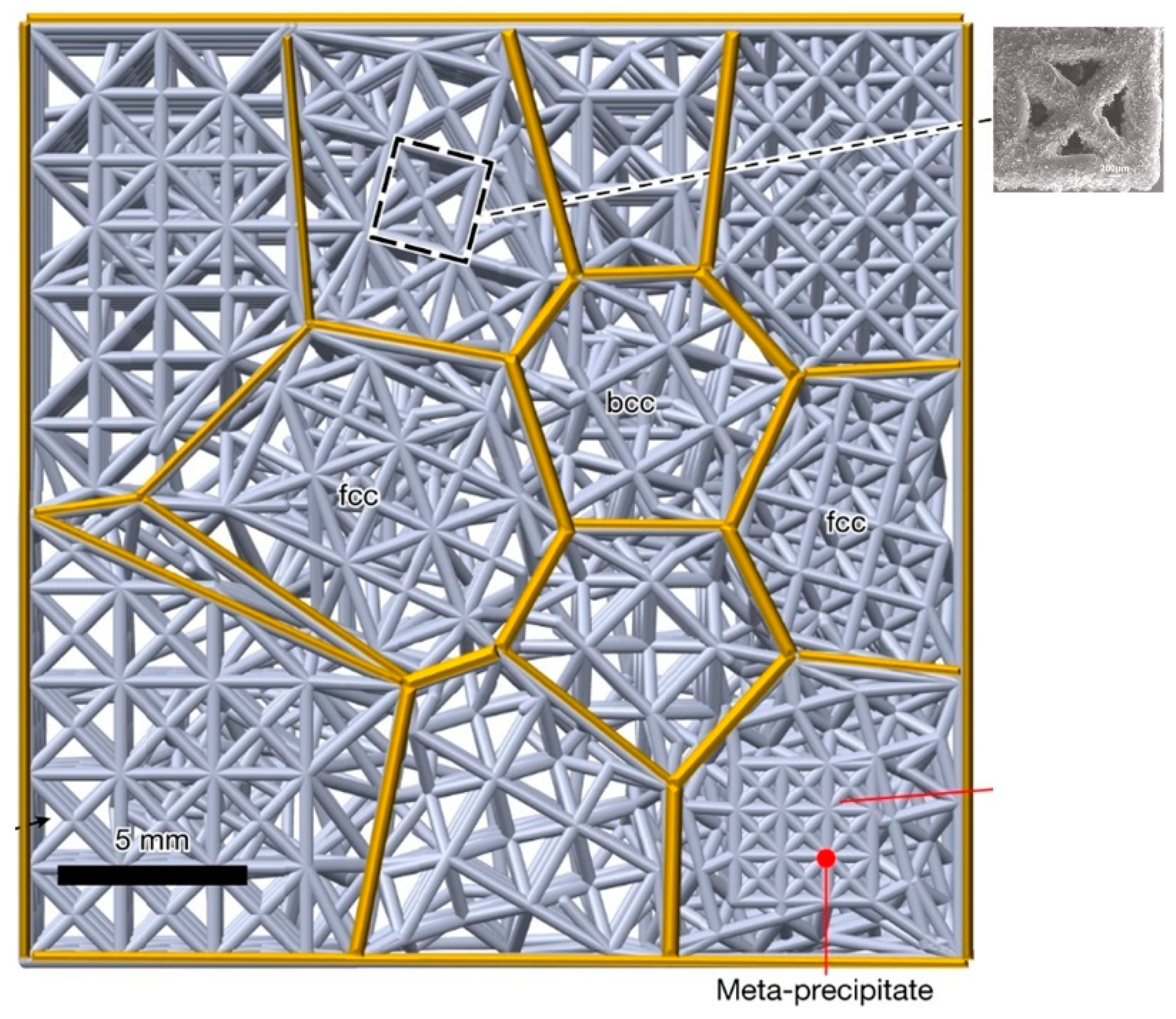

3.3. Lattice

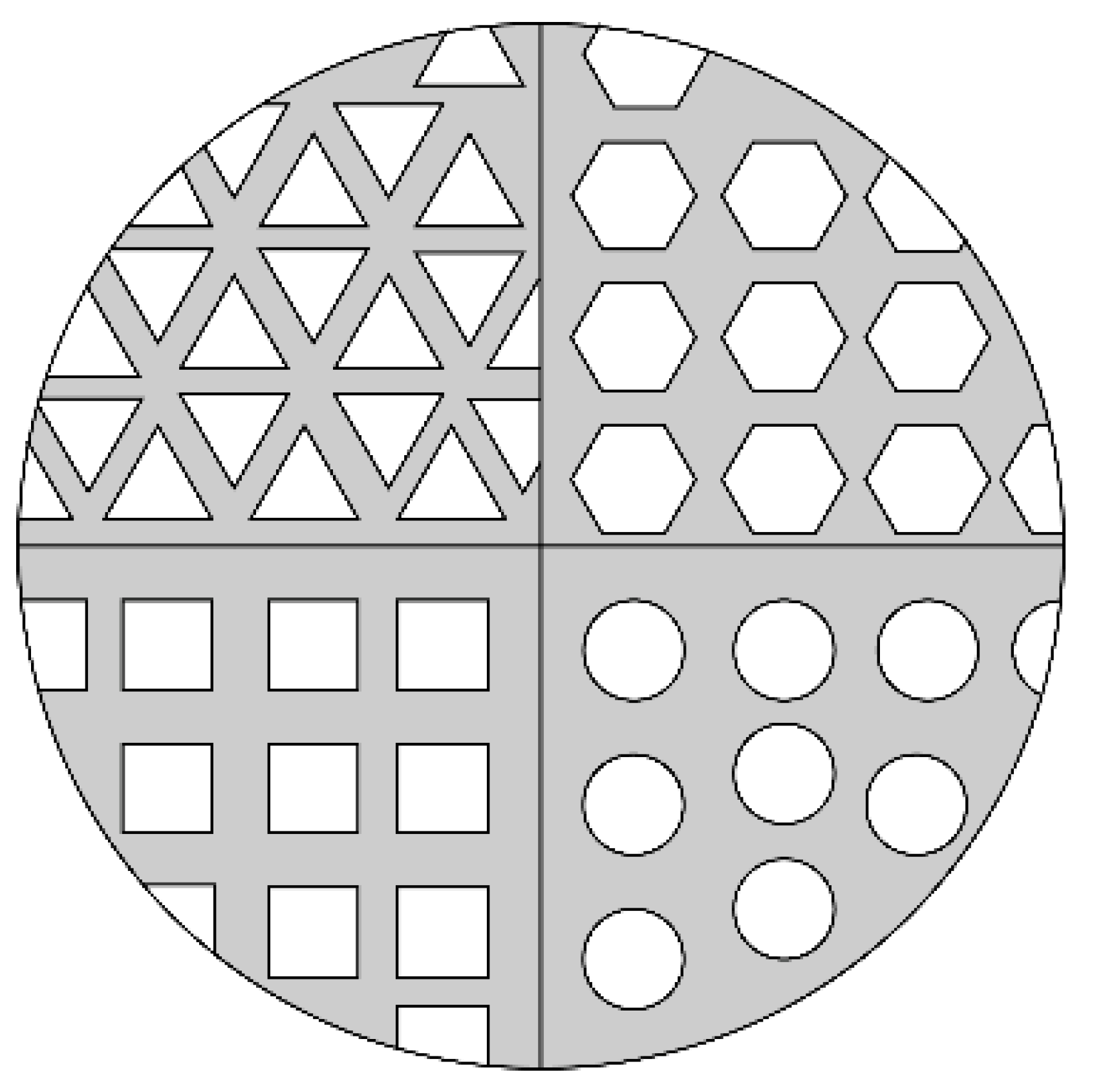

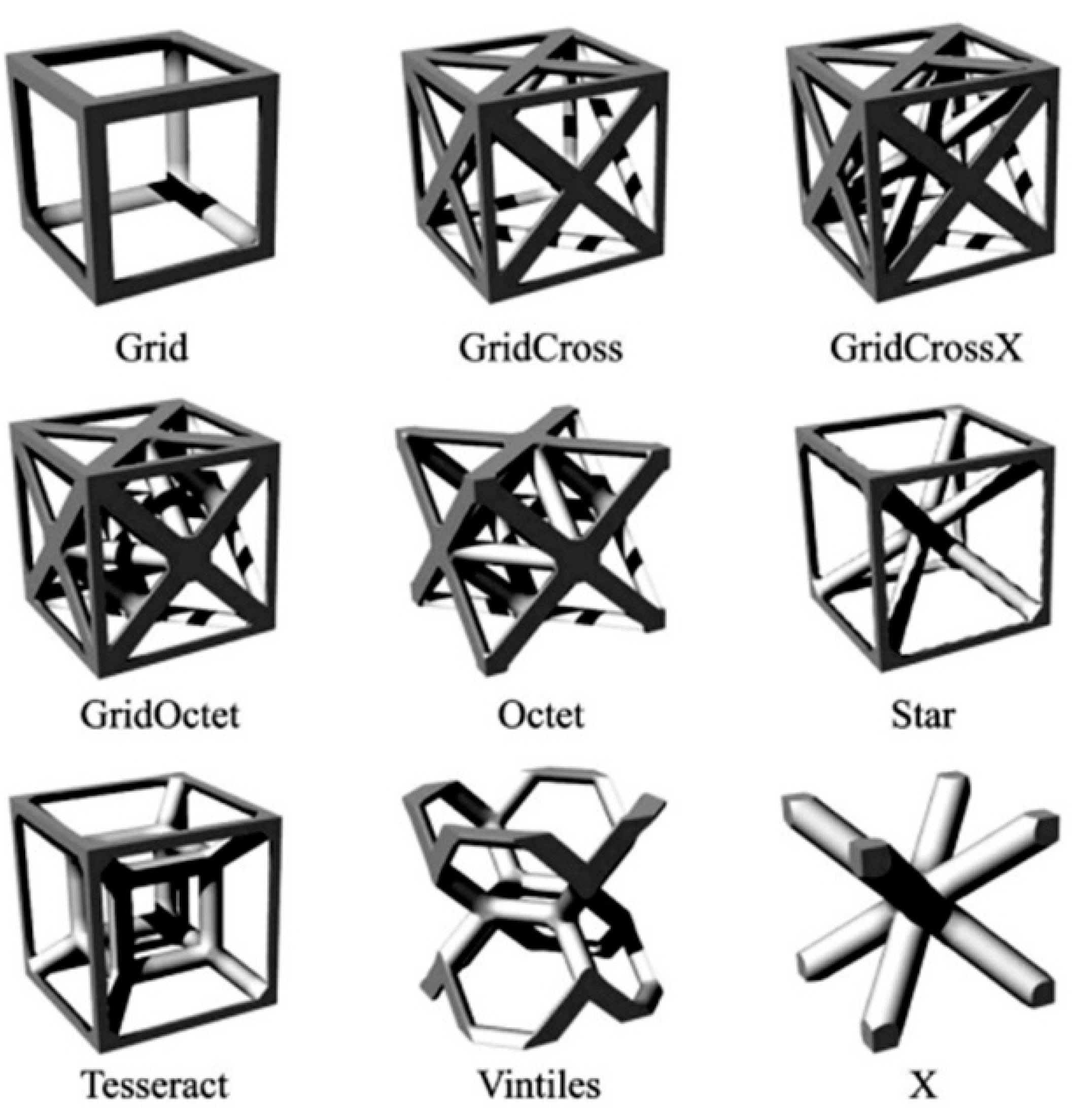

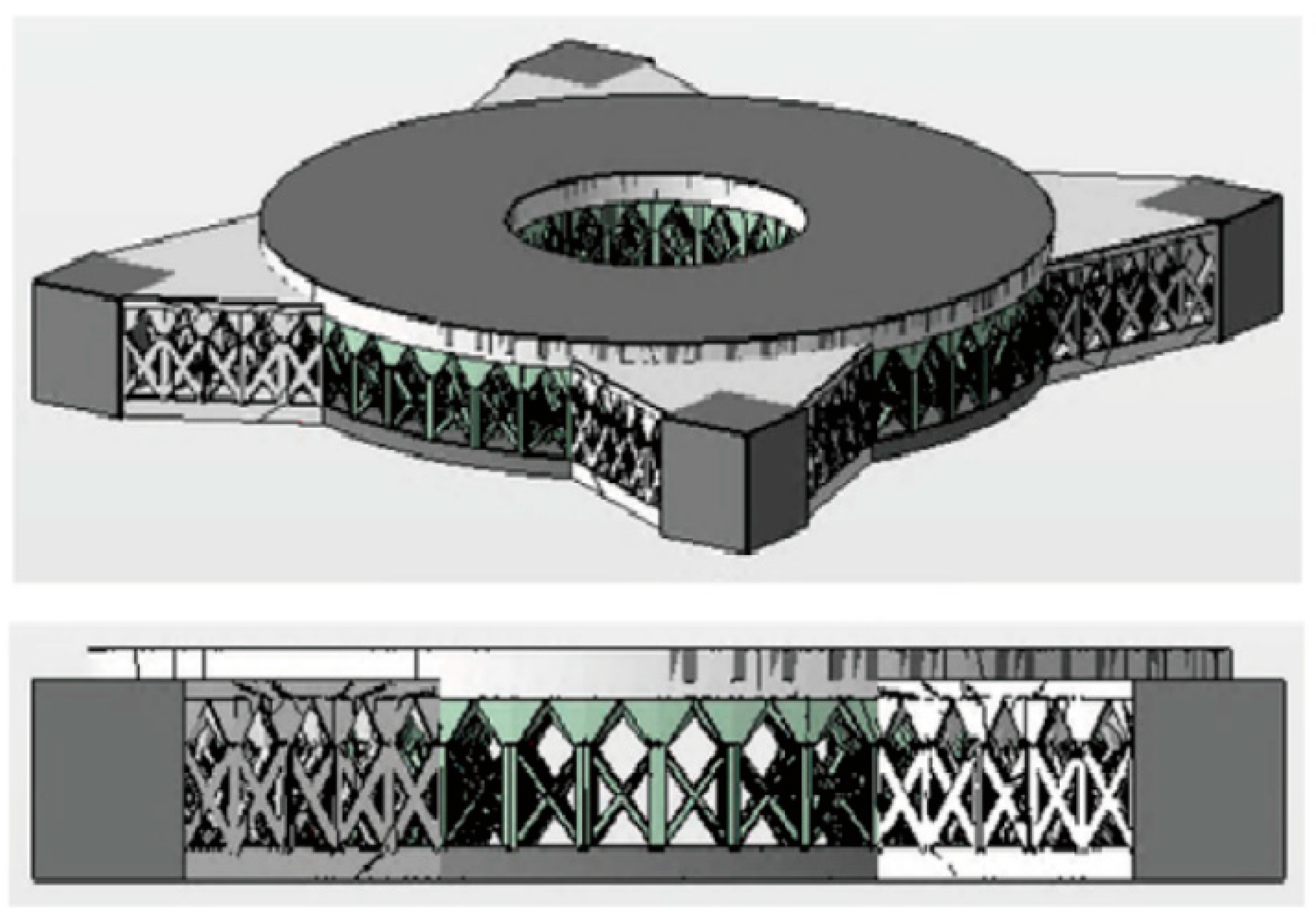

3.3.1. Uniform Lattice

3.3.2. Non-Uniform Lattice

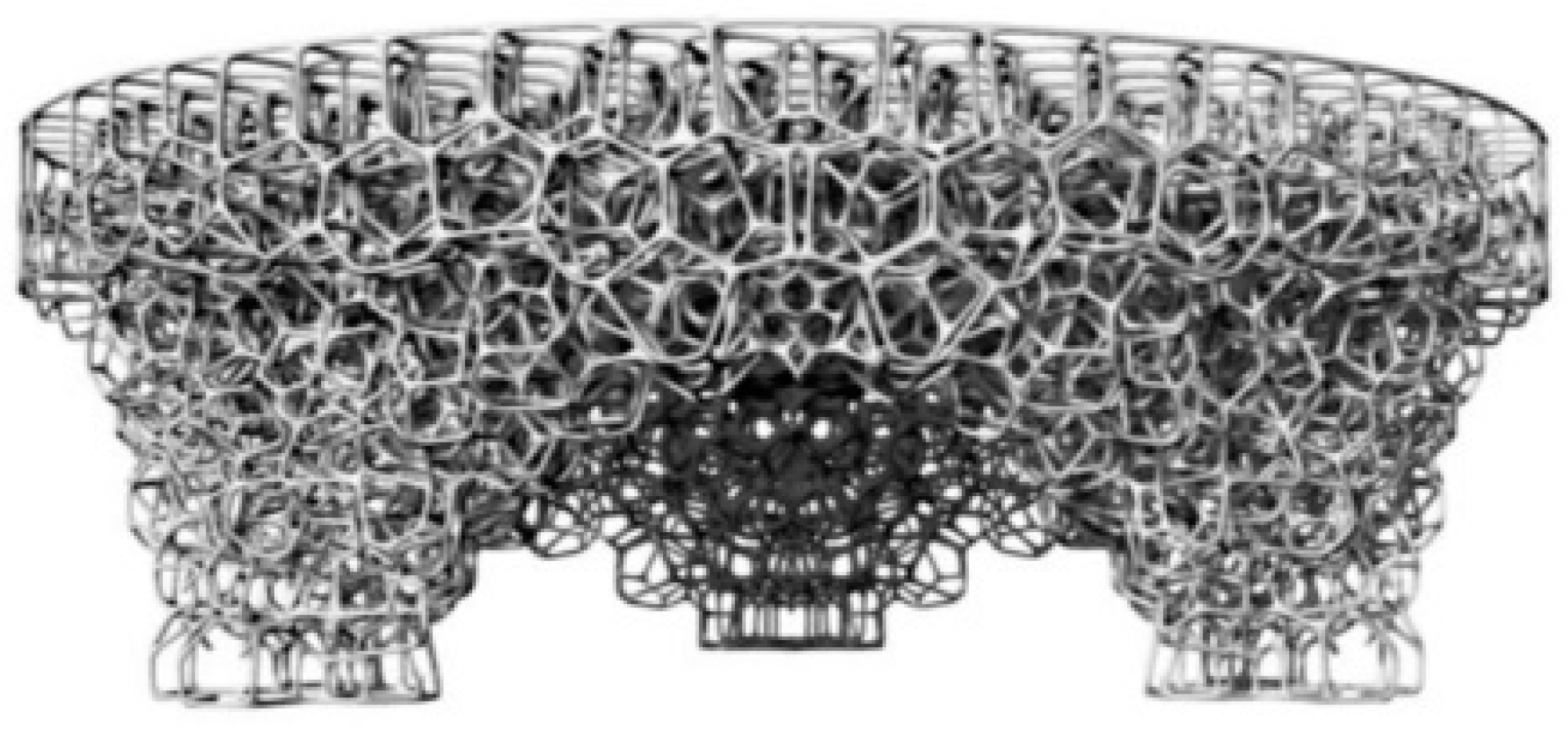

3.4. Voronoi

3.4.1. 3D Voronoi

3.4.2. 2D Voronoi

3.5. Summarization

4. Challenges Faced in the Development of AM Metal Mirror

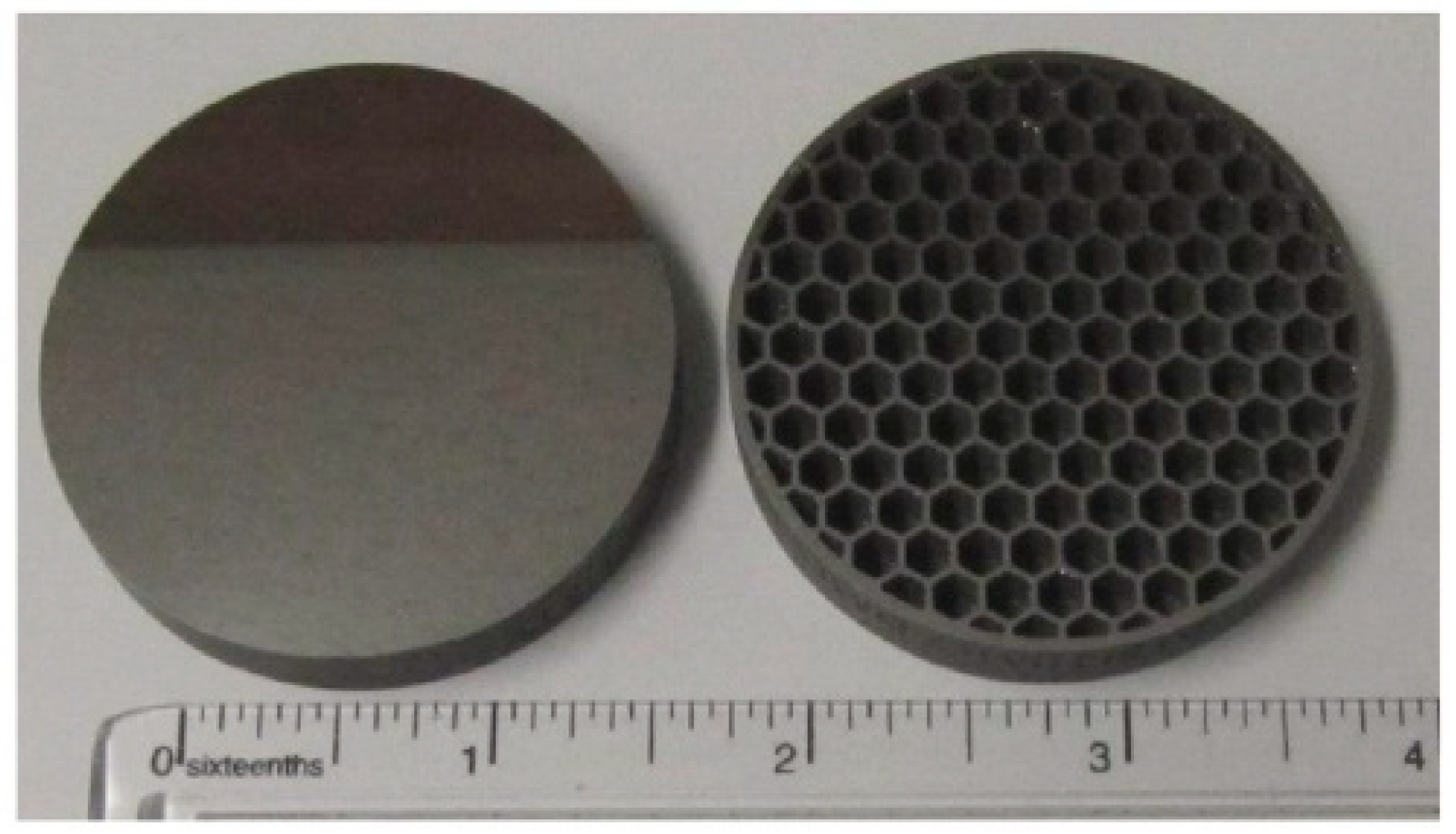

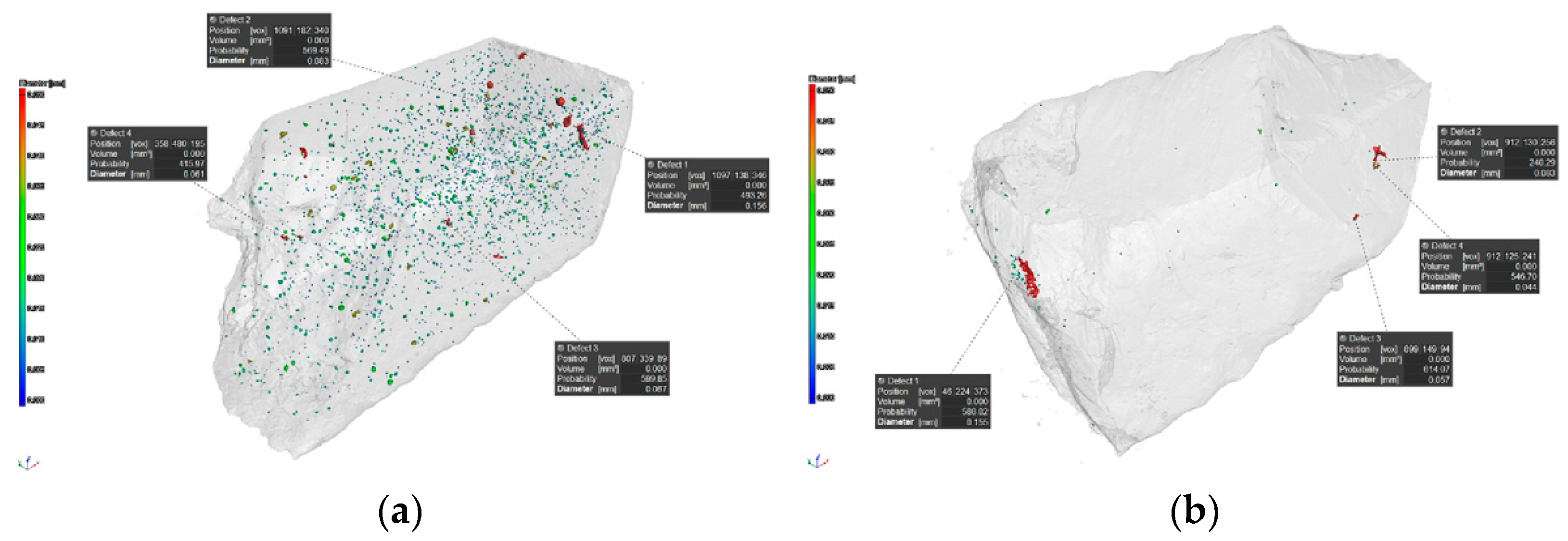

4.1. Porosity

4.1.1. Powder Quality

4.1.2. Hot Isostatic Pressing (HIP)

4.2. Dimensional Stability

4.2.1. Material Characteristics

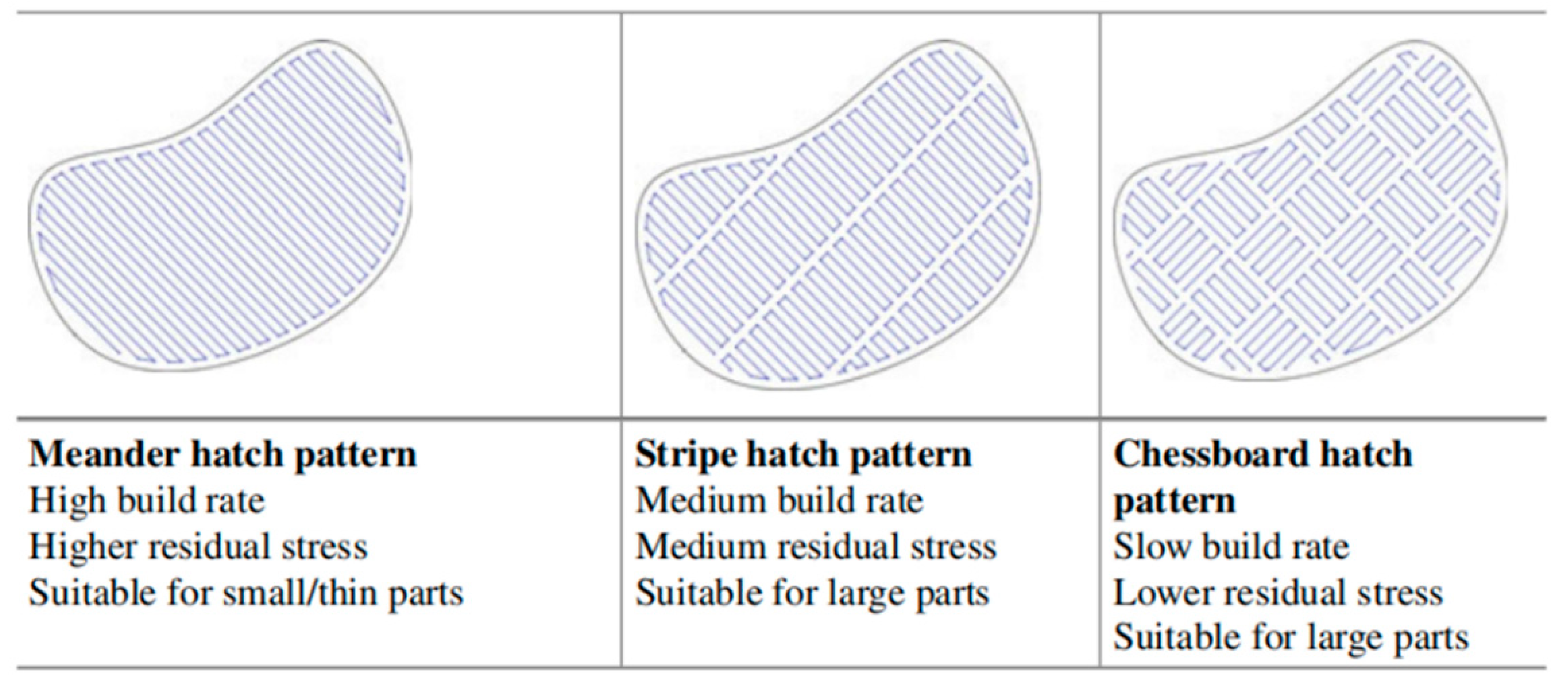

4.2.2. Process Parameters

4.3. Heat Treatment

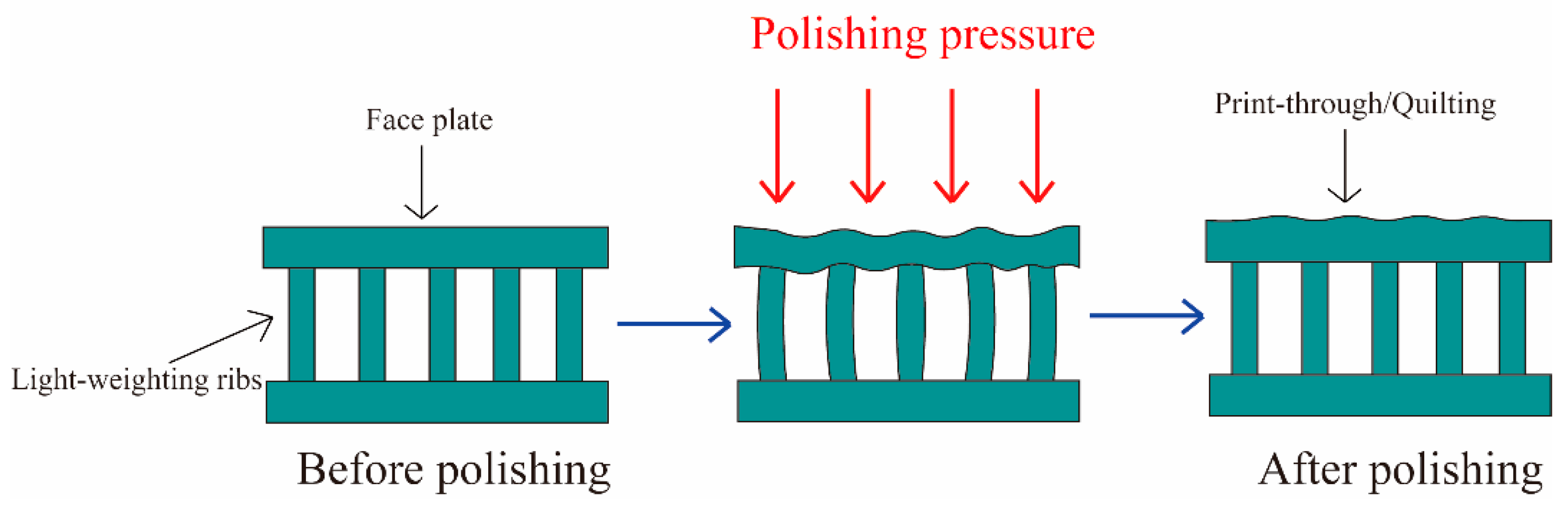

4.4. Quilting

5. Conclusions and Future Trends

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, T.; Zhu, J.; Hou, W.; Jin, G. Design method of freeform off-axis reflective imaging systems with a direct construction process. Opt. Express 2014, 22, 9193–9205. [Google Scholar] [CrossRef]

- Zhang, W.W.; Allgood, K.D.; Biskach, M.P.; Chan, K.-W.; Hlinka, M.; Kearney, J.D.; Mazzarella, J.R.; McClelland, R.S.; Numata, A.; Riveros, R.E. High-resolution, lightweight, and low-cost x-ray optics for the Lynx observatory. J. Astron. Telesc. Instrum. Syst. 2019, 5, 021012. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J. Design and Manufacture of an Off-axis Aluminum Mirror for Visible-light Imaging. Curr. Opt. Photonics 2017, 1, 364–371. [Google Scholar] [CrossRef]

- Steinkopf, R.; Gebhardt, A.; Scheiding, S.; Rohde, M.; Stenzel, O.; Gliech, S.; Giggel, V.; Loscher, H.; Ullrich, G.; Rucks, P.; et al. Metal mirrors with excellent figure and roughness. In Optical Fabrication, Testing, and Metrology III; International Society for Optics and Photonics: Bellingham, WA, USA, 2008; Volume 7102, p. 71020C. [Google Scholar] [CrossRef]

- Matson, L.E.; Chen, M.Y. Enabling materials and processes for large aerospace mirrors. In Proceedings of the Advanced Optical and Mechanical Technologies in Telescopes and Instrumentation, Marseille, France, 23–28 June 2008; p. 70180L. [Google Scholar]

- Vukobratovich, D.; Hatheway, A.E.; Schaefer, J.P. Large stable aluminum optics for aerospace applications. In Proceedings of the Optomechanics 2011: Innovations and Solutions, San Diego, CA, USA, 22–25 August 2011. [Google Scholar]

- Moeggenborg, K.; Vincer, T.; Lesiak, S.; Salij, R. Super-polished aluminum mirrors through the application of chemical mechanical polishing techniques. In Current Developments in Lens Design and Optical Engineering VII; International Society for Optics and Photonics: Bellingham, WA, USA, 2006; Volume 6288, p. 62880L. [Google Scholar] [CrossRef]

- Moeggenborg, K.J.; Barros, C.; Lesiak, S.; Naguib, N.; Reggie, S. Low-scatter bare aluminum optics via chemical mechanical polishing. In Proceedings of the SPIE-The International Society for Optical Engineering, San Jose, CA, USA, 20–23 January 2008; Volume 7060, pp. 706002–706008. [Google Scholar]

- Atad-Ettedgui, E.; ter Horst, R.; Lemke, D.; Tromp, N.; de Haan, M.; Navarro, R.; Venema, L.; Pragt, J. Directly polished lightweight aluminum mirror. In Proceedings of the Advanced Optical and Mechanical Technologies in Telescopes and Instrumentation, Marseille, France, 23–28 June 2008. [Google Scholar]

- Andresen, B.F.; Carrigan, K.G.; Fulop, G.F.; Norton, P.R. Visible quality aluminum and nickel superpolish polishing technology enabling new missions. In Proceedings of the Infrared Technology and Applications XXXVII, Orlando, FL, USA, 25–29 April 2011. [Google Scholar]

- Xie, Y.; Mao, X.; Li, J.; Wang, F.; Wang, P.; Gao, R.; Li, X.; Ren, S.; Xu, Z.; Dong, R.; et al. Optical design and fabrication of an all-aluminum unobscured two-mirror freeform imaging telescope. Appl. Opt. 2020, 59, 833–840. [Google Scholar] [CrossRef]

- Andresen, B.F.; Patel, A.M.; Carrigan, K.G.; Fulop, G.F.; Norton, P.R. Update on Tinsley visible quality (VQ) aluminum optics. In Proceedings of the Infrared Technology and Applications XXXVIII, Baltimore, MD, USA, 23–27 April 2012; pp. 83532C–83537C. [Google Scholar]

- Clampin, M. The James Webb Space Telescope (JWST). Adv. Space Res. 2008, 41, 1983–1991. [Google Scholar] [CrossRef]

- Schwalm, M.; Akerstrom, A.; Barry, M.; Guregian, J.; Ugolini, V. Cryogenic telescope, scanner, and imaging optics for the Wide-field Infrared Survey Explorer (WISE). In Proceedings of the Space Telescopes and Instrumentation 2008: Optical, Infrared, and Millimeter, Marseille, France, 23–28 June 2008. [Google Scholar]

- Sampath, D.; Akerstrom, A.; Barry, M.; Guregian, J.; Schwalm, M.; Ugolini, V. The WISE telescope and scanner: Design choices and hardware results. In Proceedings of the SPIE—The International Society for Optical Engineering 2010, San Diego, CA, USA, 7 September 2010; Volume 7796. [Google Scholar]

- Ahmad, A. Handbook of Optomechanical Engineering; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Woodard, K.S.; Myrick, B.H. Progress on high-performance rapid prototype aluminum mirrors. In Proceedings of the Society of Photo-optical Instrumentation Engineers, Anaheim, CA, USA, 11 May 2017. [Google Scholar]

- Atkins, C.; Feldman, C.; Brooks, D.; Watson, S.; Cochrane, W.; Roulet, M.; Hugot, E.; Beardsley, M.; Harris, M.; Spindloe, C.; et al. Topological design of lightweight additively manufactured mirrors for space. In Proceedings of the Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation III, Austin, TX, USA, 10–15 June 2018. [Google Scholar]

- Atkins, C.; van de Vorst, B. OPTICON A2IM Cookbook: An introduction to additive manufacture for astronomy (Final). Zenodo 2021, 3, 18. [Google Scholar] [CrossRef]

- Valente, T.M.; Vukobratovich, D. A Comparison of the merits of open-back, symmetric sandwich, and contoured back mirrors as light-weighted optics. In Proceedings of the Precision Engineering and Optomechanics, San Diego, CA, USA, 10–11 August 1989; pp. 20–36. [Google Scholar]

- Sweeney, M.; Acreman, M.; Vettese, T.; Myatt, R.; Thompson, M. Application and testing of additive manufacturing for mirrors and precision structures. In Material Technologies and Applications to Optics, Structures, Components, and Sub-Systems II; International Society for Optics and Photonics: Bellingham, WA, USA, 2015; Volume 9574, p. 957406. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, X.; Xu, L.; Ding, J.; Ma, Z.; Xie, Y. Fabrication of a lightweight Al alloy mirror through 3D printing and replication methods. Appl. Opt. 2018, 57, 8096–8101. [Google Scholar] [CrossRef] [PubMed]

- Diegel, O.; Nordin, A.; Motte, D. A Practical Guide to Design for Additive Manufacturing; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Han, X.; Cao, J.; Lyu, H.; Wang, C.; Ge, J.; Yu, Y. Applications and Development of Additive Manufacturing for Space Optical Remote Sensors. Spacecr. Recovery Remote Sens. 2021, 42, 74–83. [Google Scholar]

- Gibson, I.; Rosen, D.W.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2021; Volume 17. [Google Scholar]

- Kumar, S. Additive Manufacturing Processes; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Debroy, T.; Wei, H.L.; Zuback, J.; Mukherjee, T.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Woodard, K.S.; Comstock, L.E.; Wamboldt, L.; Sutherland, J.S. Optimum selection of high performance mirror substrates for diamond finishing. In Proceedings of the Advanced Optics for Defense Applications: UV through LWIR, Baltimore, MD, USA, 18–19 April 2016; p. 98220C. [Google Scholar]

- Herzog, H.; Segal, J.; Smith, J.P.; Bates, R.D.; Calis, J.; De La Torre, A.; Kim, D.W.; Mici, J.; Mireles, J.; Stubbs, D.M.; et al. Optical fabrication of lightweighted 3D printed mirrors. In Optomechanical Engineering 2015; International Society for Optics and Photonics: Bellingham, WA, USA, 2015; Volume 9573, p. 957308. [Google Scholar] [CrossRef]

- Mici, J.; Rothenberg, B.; Brisson, E.; Wicks, S.; Stubbs, D.M. Optomechanical performance of 3D-printed mirrors with embedded cooling channels and substructures. In Optomechanical Engineering 2015; International Society for Optics and Photonics: Bellingham, WA, USA, 2015; Volume 9573, p. 957306. [Google Scholar] [CrossRef]

- Whitsitt, R.; Medicus, K.; Brunelle, M.J.; Ferralli, I. Current use and potential of additive manufacturing for optical applications. In Optifab 2017; International Society for Optics and Photonics: Bellingham, WA, USA, 2017. [Google Scholar] [CrossRef]

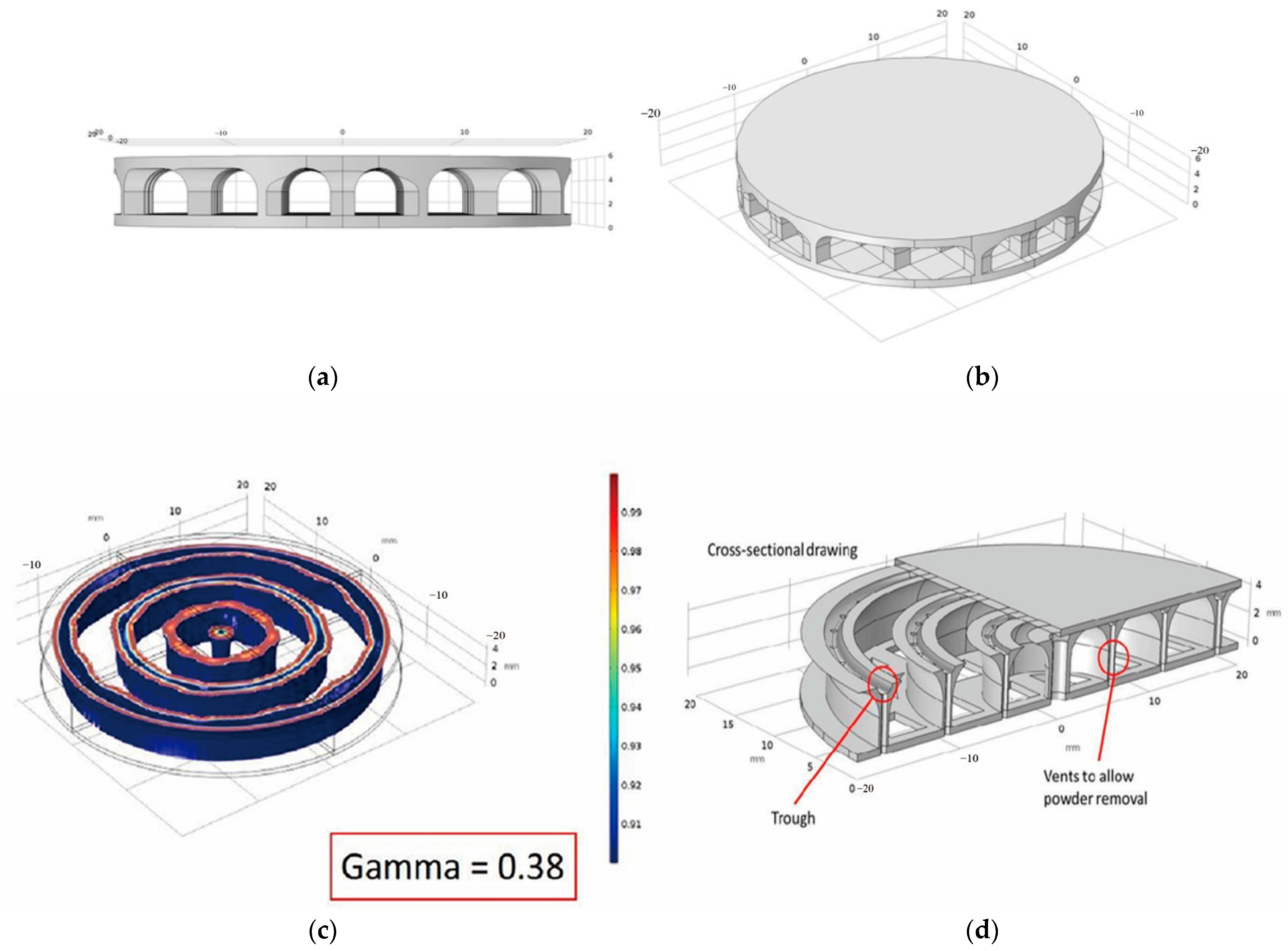

- Hilpert, E.; Hartung, J.; Risse, S.; Eberhardt, R.; Tünnermann, A. Precision manufacturing of a lightweight mirror body made by selective laser melting. Precis. Eng. 2018, 53, 310–317. [Google Scholar] [CrossRef] [Green Version]

- Hilpert, E.; Hartung, J.; Von Lukowicz, H.; Herffurth, T.; Heidler, N. Design, additive manufacturing, processing, and characterization of metal mirror made of aluminum silicon alloy for space applications. Opt. Eng. 2019, 58, 092613. [Google Scholar] [CrossRef] [Green Version]

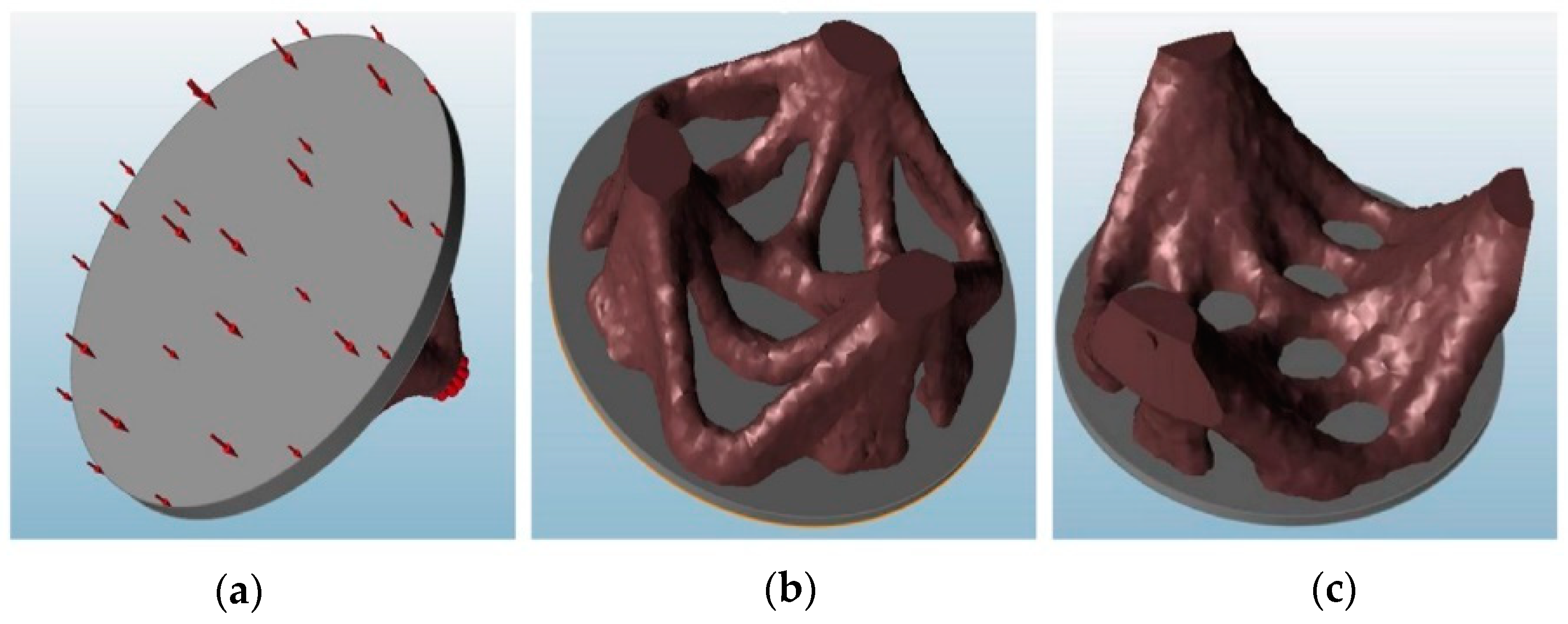

- Roulet, M.; Atkins, C.; Hugot, E.; Lemared, S.; Lombardo, S.; Ferrari, M. 3D printing for astronomical mirrors. In Proceedings of the 3D Printed Optics and Additive Photonic Manufacturing, Strasbourg, France, 23–24 April 2018; p. 1067504. [Google Scholar]

- Atkins, C.; Feldman, C.H.; Brooks, D.; Willingale, R.; Doel, P.; Roulet, M.; Watson, S.; Cochrane, W.; Hugot, E. Additive manufactured x-ray optics for astronomy. In Optics for EUV, X-Ray, and Gamma-Ray Astronomy VIII; International Society for Optics and Photonics: Bellingham, WA, USA, 2017; Volume 10399, p. 103991G. [Google Scholar] [CrossRef] [Green Version]

- Tan, S.; Ding, Y.; Xu, Y.; Shi, L. Design and fabrication of additively manufactured aluminum mirrors. Opt. Eng. 2020, 59, 013103. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Bian, H.; Aoyagi, K.; Zhao, Y.; Maeda, C.; Mouri, T.; Chiba, A. Microstructure refinement for superior ductility of Al–Si alloy by electron beam melting. Addit. Manuf. 2019, 32, 100982. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2018, 35, 270–284. [Google Scholar] [CrossRef]

- AlMangour, B. Additive Manufacturing of Emerging Materials; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Kumar, H.A.; Elvis, P.; Manoharan, M.; Jayapal, J.; Kumaraguru, S. Tailored Support Structures for Additive Manufacturing. In Advances in Additive Manufacturing and Joining; Springer: Singapore, 2020. [Google Scholar]

- Jiang, J.; Xu, X.; Stringer, J. Support Structures for Additive Manufacturing: A Review. J. Manuf. Mater. Process. 2018, 2, 64. [Google Scholar] [CrossRef] [Green Version]

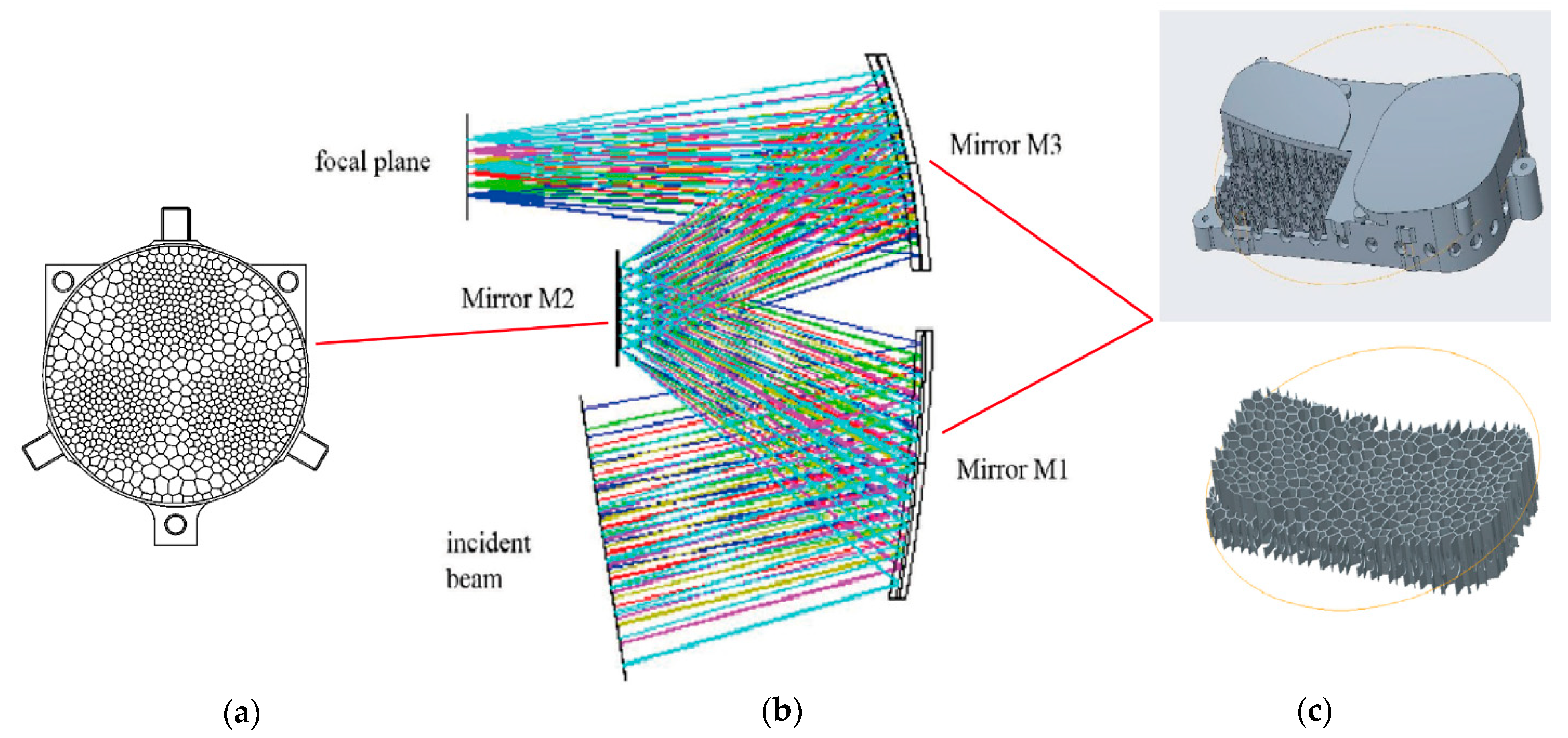

- Heidler, N.; Hilpert, E.; Hartung, J.; Von Lukowicz, H.; Damm, C.; Peschel, T.; Risse, S. Additive manufacturing of metal mirrors for TMA telescope. In Optical Fabrication, Testing, and Metrology VI; International Society for Optics and Photonics: Bellingham, WA, USA, 2018; Volume 10692, p. 106920C. [Google Scholar] [CrossRef]

- Wang, C.; Qian, X. Simultaneous optimization of build orientation and topology for additive manufacturing. Addit. Manuf. 2020, 34, 101246. [Google Scholar] [CrossRef]

- Zou, J.; Zhang, Y.; Feng, Z. Topology optimization for additive manufacturing with self-supporting constraint. Struct. Multidiscip. Optim. 2021, 63, 2341–2353. [Google Scholar] [CrossRef]

- Leary, M.; Merli, L.; Torti, F.; Mazur, M.; Brandt, M. Optimal topology for additive manufacture: A method for enabling additive manufacture of support-free optimal structures. Mater. Des. 2014, 63, 678–690. [Google Scholar] [CrossRef]

- Xiong, Y.; Yao, S.; Zhao, Z.; Xie, Y.M. A new approach to eliminating enclosed voids in topology optimization for additive manufacturing. Addit. Manuf. 2019, 32, 101006. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, W. Topology optimization method with elimination of enclosed voids. Struct. Multidiscip. Optim. 2019, 60, 117–136. [Google Scholar] [CrossRef]

- Li, Q.; Chen, W.; Liu, S.; Tong, L. Structural topology optimization considering connectivity constraint. Struct. Multidiscip. Optim. 2016, 54, 971–984. [Google Scholar] [CrossRef]

- Yan, Y.; Jin, G.; Yang, H.-B. Design and analysis of large spaceborne light-weighted primary mirror and its support system. In Proceedings of the 3rd International Symposium on Advanced Optical Manufacturing and Testing Technologies: Large Mirrors and Telescopes, Chengdu, China, 8–12 July 2007; Volume 6721, p. 67210V. [Google Scholar] [CrossRef]

- Qu, Y.; Jiang, Y.; Feng, L.; Li, X.; Liu, B.; Wang, W. Lightweight Design of Multi-Objective Topology for a Large-Aperture Space Mirror. Appl. Sci. 2018, 8, 2259. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Bo, J. Topology optimization design of a space mirror. In Selected Proceedings of the Photoelectronic Technology Committee Conferences held June–July 2015, 2015, Hefei, Suzhou, and Harbin, China; International Society for Optics and Photonics: Bellingham, WA, USA, 2015; Volume 9795, p. 97952Y. [Google Scholar]

- Qu, Y.; Wei, W.; Bei, L.; Li, X. Topology optimization design of space rectangular mirror. In Proceedings of the International Symposium on Optoelectronic Technology & Application, Beijing, China, 9 May 2016. [Google Scholar]

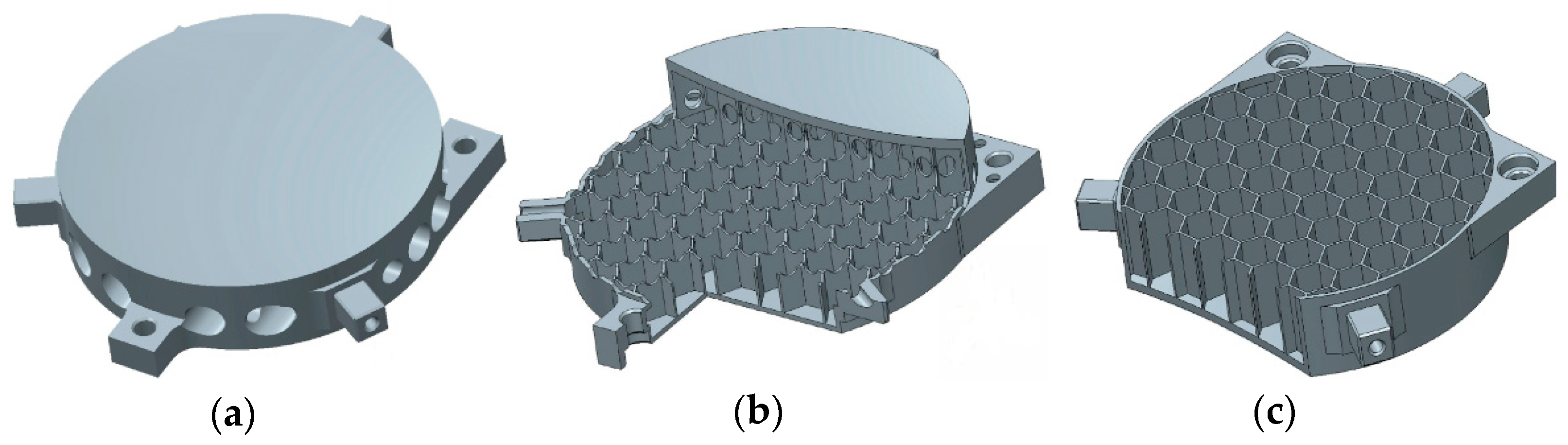

- Hu, R.; Chen, W.; Li, Q.; Liu, S.; Zhou, P.; Dong, Z.; Kang, R. Design Optimization Method for Additive Manufacturing of the Primary Mirror of a Large-Aperture Space Telescope. J. Aerosp. Eng. 2017, 30, 04016093. [Google Scholar] [CrossRef]

- Dong, G.; Tang, Y.; Zhao, Y.F. A Survey of Modeling of Lattice Structures Fabricated by Additive Manufacturing. J. Mech. Des. 2018, 139, 100906. [Google Scholar] [CrossRef]

- Liu, X.; Sekizawa, K.; Suzuki, A.; Takata, N.; Kobashi, M.; Yamada, T. Compressive Properties of Al-Si Alloy Lattice Structures with Three Different Unit Cells Fabricated via Laser Powder Bed Fusion. Materials 2020, 13, 2902. [Google Scholar] [CrossRef]

- Mueller, J.; Matlack, K.H.; Shea, K.; Daraio, C. Energy Absorption Properties of Periodic and Stochastic 3D Lattice Materials. Adv. Theory Simul. 2019, 2, 1900081. [Google Scholar] [CrossRef] [Green Version]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Li, C.; Lei, H.; Zhang, Z.; Zhang, X.; Zhou, H.; Wang, P.; Fang, D. Architecture design of periodic truss-lattice cells for additive manufacturing. Addit. Manuf. 2020, 34, 101172. [Google Scholar] [CrossRef]

- Pdf, T. Virtual Material Design in 3D Printing Makes Headway with Multiscale Modeling. COMSOL 2015, 21, 22–24. [Google Scholar]

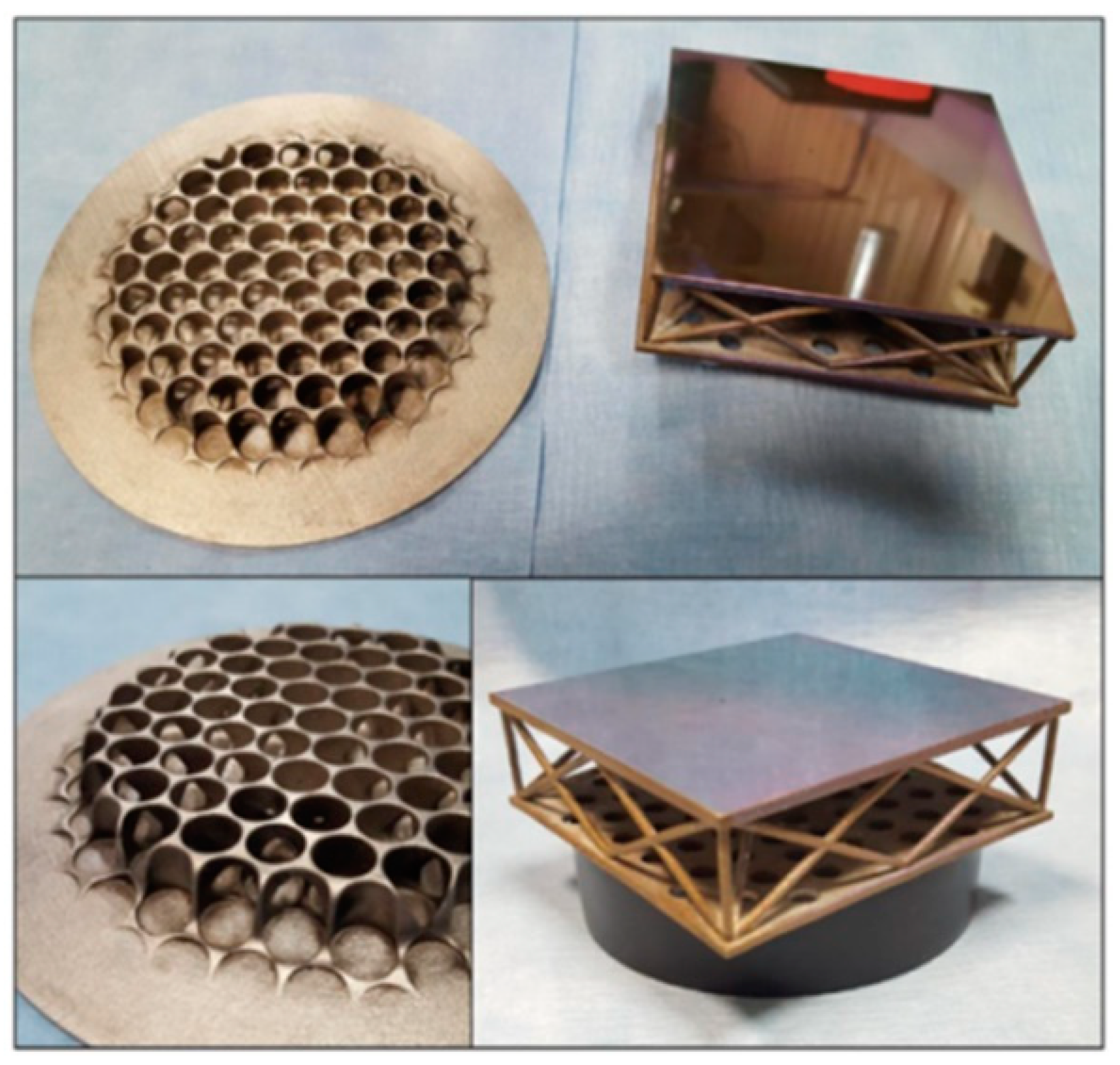

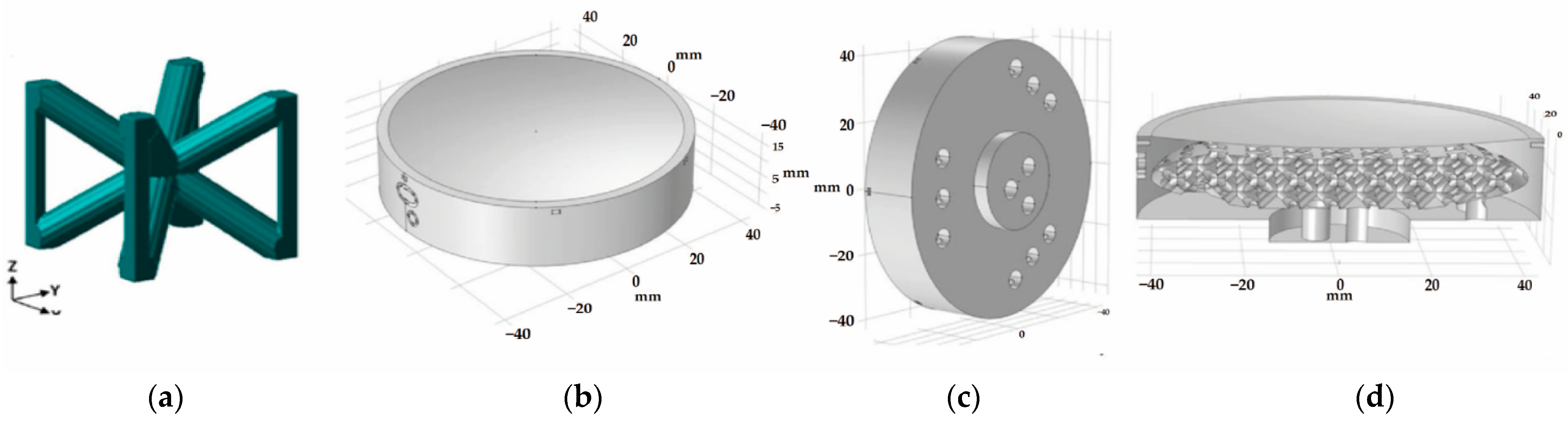

- Atkins, C.; Brzozowski, W.; Dobson, N.; Milanova, M.; Todd, S.; Pearson, D.; Bourgenot, C.; Brooks, D.; Snell, R.; Sun, W. Additively manufactured mirrors for CubeSats. In Astronomical Optics: Design, Manufacture, and Test of Space and Ground Systems II; International Society for Optics and Photonics: Bellingham, WA, USA, 2019. [Google Scholar]

- Atkins, C.; Brzozowski, W.; Dobson, N.; Milanova, M.; Todd, S.; Pearson, D.; Bourgenot, C.; Brooks, D.; Snell, R.M.; Sun, W.; et al. Lightweighting design optimisation for additively manufactured mirrors. In Astronomical Optics: Design, Manufacture, and Test of Space and Ground Systems II; International Society for Optics and Photonics: Bellingham, WA, USA, 2019; Volume 11116, p. 1111617. [Google Scholar] [CrossRef] [Green Version]

- Snell, R.M.; Atkins, C.; Schnetler, H.; Todd, I.; Harris, M. An additive manufactured CubeSat mirror incorporating a novel circular lattice. In Proceedings of the Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation IV, Online, 14–18 December 2020. [Google Scholar]

- Vega-Moreno, A.; Sanginés, F.T.; Márquez-Rodríguez, J.F.; Calvo-Tovar, J.; Schnetler, H.; Atkins, C.; Miller, C.; Morris, K.; Snell, R.M.; Van De Vorst, B.; et al. Design for additive manufacture (DfAM): The “equivalent continuum material” for cellular structures analysis. In Society of Photo-Optical Instrumentation Engineers (SPIE) Conference Series; International Society for Optics and Photonics: Bellingham, WA, USA, 2020; Volume 11450, p. 1145028. [Google Scholar] [CrossRef]

- Okabe, A.; Boots, B.; Sugihara, K. Nearest neighbourhood operations with generalized Voronoi diagrams: A review. Int. J. Geogr. Inf. Syst. 1994, 8, 43–71. [Google Scholar] [CrossRef]

- Kinast, J.; Hilpert, E.; Lange, N.; Gebhardt, A.; Tünnermann, A. Minimizing the bimetallic bending for cryogenic metal optics based on electroless nickel. In Proceedings of the SPIE Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation, Montréal, QC, Canada, 18 July 2014. [Google Scholar]

- Kinast, J.; Hilpert, E.; Rohloff, R.-R.; Gebhardt, A.; Tünnermann, A. Thermal expansion coefficient analyses of electroless nickel with varying phosphorous concentrations. Surf. Coat. Technol. 2014, 259, 500–503. [Google Scholar] [CrossRef]

- Kinast, J.; Grabowski, K.; Gebhardt, A.; Rohloff, R.R.; Tünnermann, A. Dimensional stability of metal optics on nickel plated AlSi40. In Proceedings of the International Conference on Space Optics, Tenerife, Canary Islands, Spain, 17 November 2014. [Google Scholar]

- Kinast, J.; Beier, M.; Gebhardt, A.; Risse, S.; Tünnermann, A. Polishability of thin electrolytic and electroless NiP layers. In Optifab 2015; International Society for Optics and Photonics: Bellingham, WA, USA, 2015; Volume 9633, p. 963311. [Google Scholar] [CrossRef]

- Kinast, J.; Rohloff, R.R.; Seifert, W.; Scheiding, S.; Peschel, T. Athermal metal optics made of nickel plated AlSi40. In Proceedings of the International Conference on Space Optics, Naha, Japan, 14–16 November 2017. [Google Scholar]

- Eberle, S.; Reutlinger, A.; Curzadd, B.; Mueller, M.; Riede, M.; Wilsnack, C.; Brandão, A.; Pambaguian, L.; Seidel, A.; López, E.; et al. Additive manufacturing of an AlSi40 mirror coated with electroless nickel for cryogenic space applications. In International Conference on Space Optics—ICSO 2018; International Society for Optics and Photonics: Bellingham, WA, USA, 2019; Volume 11180, p. 1118015. [Google Scholar] [CrossRef] [Green Version]

- Hartung, J.; Von Lukowicz, H.; Kinast, J. Theoretical compensation of static deformations of freeform multimirror substrates. Appl. Opt. 2018, 57, 4020–4031. [Google Scholar] [CrossRef] [Green Version]

- Hartung, J.; Risse, S.; Beier, M. Novel applications based on freeform technologies. In Optical Fabrication, Testing, and Metrology VI; International Society for Optics and Photonics: Bellingham, WA, USA, 2018; Volume 10692, p. 106920K. [Google Scholar] [CrossRef]

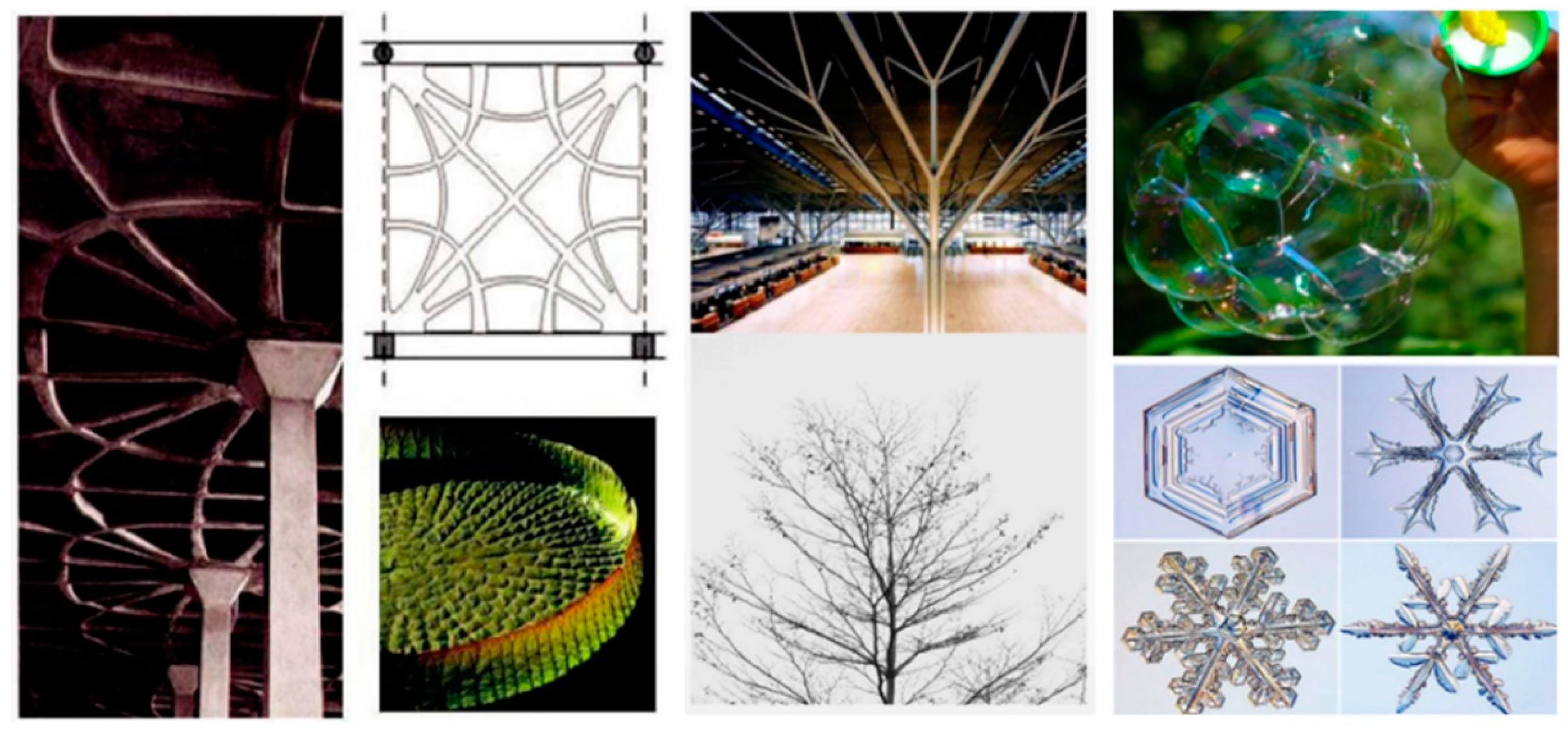

- Pearce, P. Structure in Nature is a Strategy for Design; MIT Press: Cambridge, MA, USA, 1990. [Google Scholar]

- García, A.P.; Martinez, F.G. Natural structures: Strategies for geometric and morphological optimization. OAI 2010, 3, 893–906. [Google Scholar]

- Liu, Z.; Meyers, M.A.; Zhang, Z.; Ritchie, R.O. Functional gradients and heterogeneities in biological materials: Design principles, functions, and bioinspired applications. Prog. Mater. Sci. 2017, 88, 467–498. [Google Scholar] [CrossRef]

- Yang, L.; Hsu, K.; Baughman, B.; Godfrey, D.; Medina, F.; Menon, M.; Wiener, S. Additive Manufacturing of Metals: The Technology, Materials, Design and Production; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Chen, G.; Zhao, S.; Tan, P.; Wang, J.; Xiang, C.; Tang, H. A comparative study of Ti-6Al-4V powders for additive manufacturing by gas atomization, plasma rotating electrode process and plasma atomization. Powder Technol. 2018, 333, 38–46. [Google Scholar] [CrossRef]

- Hoeges, S.; Zwiren, A.; Schade, C. Additive manufacturing using water atomized steel powders. Met. Powder Rep. 2017, 72, 111–117. [Google Scholar] [CrossRef]

- Hohmann, M.; Jonsson, S. Modern systems for production of high quality metal alloy powder. Vacuum 1990, 41, 2173–2176. [Google Scholar] [CrossRef]

- Moll, J.H. Utilization of gas-atomized titanium and titanium-aluminide powder. JOM 2000, 52, 32–34. [Google Scholar] [CrossRef]

- Capus, J. Titanium powder developments for AM—A round-up. Met. Powder Rep. 2017, 72, 384–388. [Google Scholar] [CrossRef]

- Chen, C.; Xie, Y.; Yan, X.; Yin, S.; Fukanuma, H.; Huang, R.; Zhao, R.; Wang, J.; Ren, Z.; Liu, M.; et al. Effect of hot isostatic pressing (HIP) on microstructure and mechanical properties of Ti6Al4V alloy fabricated by cold spray additive manufacturing. Addit. Manuf. 2019, 27, 595–605. [Google Scholar] [CrossRef]

- Flodin, A.; Andersson, M.; Miedzinski, A. Full density powder metal components through Hot Isostatic Pressing. Met. Powder Rep. 2017, 72, 107–110. [Google Scholar] [CrossRef]

- Mower, T.M.; Long, M.J. Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Mater. Sci. Eng. A 2016, 651, 198–213. [Google Scholar] [CrossRef]

- Paquin, R.A. Dimensional stability: An overview. In Proceedings of the SPIE-The International Society for Optical Engineering, San Diego, CA, USA, 1 November 1990; Volume 1335, pp. 2–19. [Google Scholar]

- Paquin, R.A. Dimensional instability of materials: How critical is it in the design of optical instruments? In Optomechanical Design: A Critical Review; International Society for Optics and Photonics: Bellingham, WA, USA, 1992; Volume 10265, p. 1026509. [Google Scholar]

- Marschall, C.; Maringer, R.E. Dimensional Instability: An Introduction; Pergamon Press: New York, NY, USA, 1977; Volume 22, pp. 154–196. [Google Scholar]

- Paquin, R.A. Materials for mirror systems: An overview. In Proceedings of the SPIE-The International Society for Optical Engineering 1995, San Jose, CA, USA, 6–8 February 1995. [Google Scholar]

- Mugwagwa, L.; Dimitrov, D.; Matope, S.; Yadroitsev, I. Influence of process parameters on residual stress related distortions in selective laser melting. Procedia Manuf. 2018, 21, 92–99. [Google Scholar] [CrossRef]

- Olakanmi, E.; Cochrane, R.; Dalgarno, K. Densification mechanism and microstructural evolution in selective laser sintering of Al–12Si powders. J. Mater. Process. Technol. 2011, 211, 113–121. [Google Scholar] [CrossRef]

- Adeyemi, A.; Akinlabi, E.T.; Mahamood, R.M. Powder Bed Based Laser Additive Manufacturing Process of Stainless Steel: A Review. Mater. Today Proc. 2018, 5, 18510–18517. [Google Scholar] [CrossRef]

- Lewandowski, J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef] [Green Version]

- Kempen, K.; Thijs, L.; Van Humbeeck, J.; Kruth, J.P. Processing AlSi10Mg by Selective Laser Melting: Parameter optimization and material characterization. Mater. Sci. Technol. 2015, 31, 917–923. [Google Scholar] [CrossRef]

- Hebert, R.J. Viewpoint: Metallurgical Aspects of Powder Bed Metal Additive Manufacturing. J. Mater. Sci. 2016, 51, 1165–1175. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical propertie. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef] [Green Version]

- Girelli, L.; Tocci, M.; Conte, M.; Giovanardi, R.; Veronesi, P.; Gelfi, M.; Pola, A. Effect of the T6 heat treatment on corrosion behaviorof additive manufactured and gravity cast AlSi10Mg alloy. Mater. Corros. 2019, 70, 1808–1816. [Google Scholar] [CrossRef]

- Zhuo, L.; Wang, Z.; Zhang, H.; Yin, E.; Wang, Y.; Xu, T.; Li, C. Effect of post-process heat treatment on microstructure and properties of selective laser melted AlSi10Mg alloy. Mater. Lett. 2018, 234, 196–200. [Google Scholar] [CrossRef]

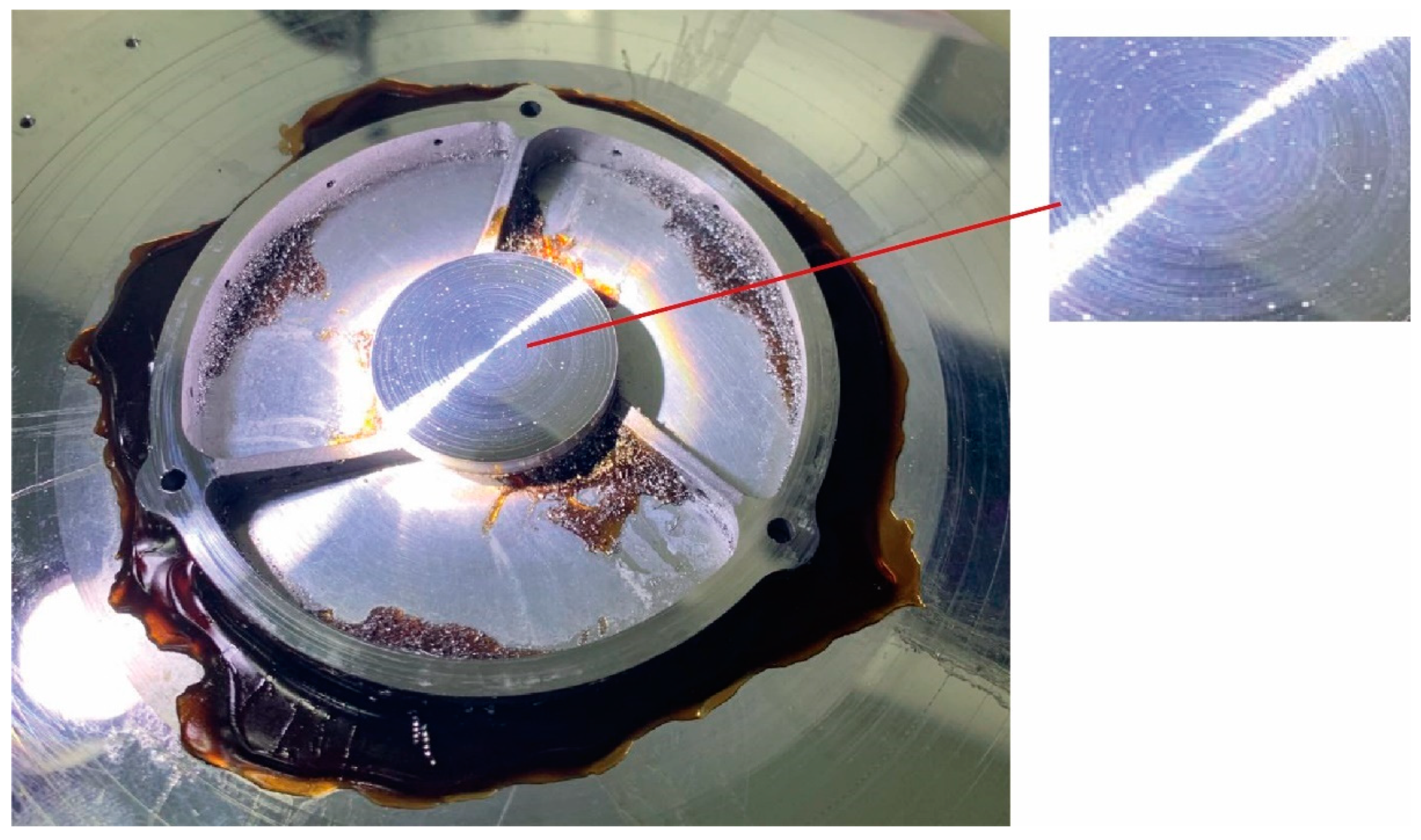

- Hedges, A.; Parker, R. Low stress, vacuum-chuck mounting techniques for the diamond machining of thin substrates. In Proceedings of the Advances in Fabrication and Metrology for Optics and Large Optics, San Diego, CA, USA, 15–18 August 1988; pp. 13–18. [Google Scholar]

- Heinrich, A. 3D Printing of Optical Components; Springer: Berlin/Heidelberg, Germany, 2021; Volume 233. [Google Scholar]

- Heinrich, A.; Börret, R.; Merkel, M.; Riegel, H. Additive manufacturing of reflective and transmissive optics: Potential and new solutions for optical systems. In Proceedings of the Laser 3D Manufacturing V, San Francisco, CA, USA, 29 January–1 February 2018; Volume 10523, p. 1052302. [Google Scholar] [CrossRef]

- Lepine, T.; Rousselet, N.; Surrel, Y.; Houllier, T. Advanced optical freeform substrates fabricated by ceramic 3D printing and controlled by deflectometry. In Proceedings of the Optical Fabrication, Testing, and Metrology VI, Frankfurt, Germany, 15–17 May 2018. [Google Scholar]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufacturing: A Review of Common Processes, Industrial Applications, and Current Challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, H. Micro Machining of Bulk Metallic Glasses: A Review. Int. J. Adv. Manuf. Technol. 2018, 100, 637–661. [Google Scholar] [CrossRef]

- Li, X.; Kang, C.; Huang, H.; Sercombe, T. The role of a low-energy–density re-scan in fabricating crack-free Al85Ni5Y6Co2Fe2 bulk metallic glass composites via selective laser melting. Mater. Des. 2014, 63, 407–411. [Google Scholar] [CrossRef] [Green Version]

- Pham, M.S.; Liu, C.; Todd, I.; Lertthanasarn, J. Damage-tolerant architected materials inspired by crystal microstructure. Nature 2019, 565, 305–311. [Google Scholar] [CrossRef] [PubMed]

| Material | Specific Stiffness E/ρ m2/s2 | Thermal Expansion α K−1 | Thermal Distortion Index α/k m/watt | Thermal Diffusivity k/(ρ-cρ) m2/s |

|---|---|---|---|---|

| Aluminum alloy, 6061-T6 | 255 × 106 | 23.6 × 10−6 | 141 × 10−9 | 690 × 10−3 |

| Corning Pyrex 7740 | 283 × 106 | 3.3 × 10−6 | 2.92 × 10−6 | 483 × 10−9 |

| Corning fused silica 7980 | 330 × 106 | 520 × 10−9 | 400 × 10−9 | 788 × 10−9 |

| Corning fused silica ULE® 7972 | 307 × 106 | 30 × 10−9 | 22.9 × 10−9 | 776 × 10−9 |

| Schott Zerodur® | 357 × 106 | 20 × 10−9 | 68.5 × 10−9 | 721 × 10−9 |

| Expectation | Large | Small | Small | Large |

| Forming Process | AM | Forging | Casting |

|---|---|---|---|

| Material utilization rate | 2/3 | <1/10 | 1/5 |

| Design modification time | 1–2 days | 6 months | 3 months |

| Processing time | 1–2 days | 4 months | 6–12 months |

| Consumable | Inert gas | Mold | Mold, gating system |

| Repair rate | Low | Low | High |

| Cost | Low | High | Medium |

| R and D Unit | Time | Material | Technology Type | Surface Accuracy |

|---|---|---|---|---|

| Corning [29] | 2015 | AlSi7Mg0.3 | DMLS | 1.5 nm (RMS) |

| General Dynamics [21] | 2015 | AlSi10Mg | DMLS | 43.2 nm (RMS) |

| University of Arizona [30] | 2015 | AlSi10Mg | DMLS | 255 nm (PV) |

| University of Arizona [30] | 2015 | Ti6Al4V | EBM | / |

| Lockheed Martin [31] | 2016 | AlSi10Mg | SLM | / |

| Optimax Systems [32] | 2017 | FeNi36 | SLM | / |

| IOF [33] | 2018 | AlSi12 | SLM | 12.5 nm (RMS) |

| IOF [34] | 2019 | AlSi40 | SLM | 7.3 nm (RMS) |

| UKAT [18,35,36] | 2020 | AlSi10Mg | DMLS | 16 nm |

| CIOMP [37] | 2020 | AlSi10Mg | SLM | 58 nm (RMS) |

| Manufacturing Method | P (W) | H (J/mm) | Post-Treatment | Orientation | E (GPa) | Ductility (%) | HV | |||

|---|---|---|---|---|---|---|---|---|---|---|

| PBF | 250 | 500 | 0.50 | As built | Longitudinal Transverse | 250 240 | 350 280 | 2.5 1.2 | 145 | |

| T6 | Longitudinal Transverse | 285 290 | 340 330 | 4.5 2.2 | 116 | |||||

| 250 | 500 | 0.5 | As built | Longitudinal Transverse | 125 140 | 250 270 | 6.6 4.6 | 75 | ||

| T6 | Longitudinal Transverse | 295 285 | 350 340 | 6.5 4.9 | 118 | |||||

| As built | Longitudinal Transverse | 75 ± 10 70 ± 10 | 270 ± 10 240 ± 10 | 460 ± 20 460 ± 20 | 9 ± 2 6 ± 2 | 119 ± 5 | ||||

| 2 h/300 °C | Longitudinal Transverse | 70 ± 10 60 ± 10 | 230 ± 15 230 ± 15 | 345 ± 10 350 ± 10 | 12 ± 2 11 ± 2 | |||||

| 200 | 1400 | 0.14 | As built | Longitudinal Transverse | 68 ± 3 | 391 ± 6 396 ± 8 | 5.55 ± 0.4 3.47 ± 0.6 | 127 | ||

| 200 | 1400 | 0.14 | As built | Longitudinal | 68 ± 3 | 396 ± 8 | 3.5 ± 0.6 | 136 ± 9 | ||

| 6 h/175 °C | Longitudinal | 66 ± 5 | 399 ± 7 | 3.3 ± 0.3 | 152 ± 5 | |||||

| 195 | 800 | 0.24 | 2 h/300 °C | Longitudinal Transverse | 252 ± 10 240 ± 5 | 348 ± 5 347 ± 6 | 6.6 ± 0.3 5,1 ± 0.3 | 105 ± 2 108 ± 3 | ||

| 195 | 800 | 0.24 | 2 h/300 °C | Longitudinal Transverse | 73 ± 1 72 ± 1 | 243 ± 7 231 ± 3 | 330 ± 3 329 ± 2 | 6.2 ± 0.3 4.1 ± 0.2 | ||

| 200 | 571 | 0.35 | As built | Transverse | 33 ± 10 | 1.4 ± 0.3 | ||||

| 6 h/160 °C | Transverse | 292 ± 4 | 3.9 ± 0.5 | |||||||

| 175 | 1025 | 0.17 | As built | Longitudinal Transverse | 250 225 | 340 320 | 1.2 1 | |||

| 400 | 1000 | 0.40 | 2 h/300 °C | Longitudinal Transverse | 182 ± 5 184 ± 5 | 282 ± 5 288 ± 5 | 25.2 ± 1 18.3 ± 1 | |||

| 1000 | 2 h/300 °C | Longitudinal Transverse | 70.2 70.7 | 169 169 | 267 273 | 9.1 8.2 | 94 ± 5 | |||

| 370 | 1300 | 0.28 | 2 h/300 °C | Longitudinal Transverse | 181 177 | 284 285 | 18 15 | |||

| 370 | 1300 | 0.28 | 2 h/300 °C | Longitudinal Transverse | 182 180 | 285 285 | 18 14 | |||

| 370 | 1300 | 0.28 | 2 h/300 °C | Longitudinal Transverse | 260 260 | 375 340 | 2.8 2.4 | |||

| Traditionally processed | HPDC | 71 | 160–185 | 300–350 | 3–5 | 95–105 | ||||

| HPDC-T6 | 71 | 285–330 | 330–365 | 3.5 | 130–133 | |||||

| Performance | Best | Better | Good |

|---|---|---|---|

| Lightweight rate | Quadrilateral | Hexagon | Triangle |

| Stiffness | Triangle | Quadrilateral | Hexagon |

| Deformation resistance of axial temperature gradient | Quadrilateral | Hexagon | Triangle |

| Deformation resistance of radial temperature gradient | Triangle | Quadrilateral | Hexagon |

| Material | Post-Treatment | Surface Shape/RMS | Roughness | |

|---|---|---|---|---|

| 1 | AlSi10Mg | SPDT | 30 nm | 5.64 nm |

| 2 | AlSi10Mg | SPDT | 28 nm | 4.85 nm |

| 3 | RSA 6061 | SPDT | 25 nm | 4.96 nm |

| 4 | AlSi10Mg + NiP | Polishing | 35 nm | 2 nm |

| 5 | AlSi10Mg | Polishing | 83 nm | 15 nm |

| 6 | Ti6Al4V | Polishing | 28 nm | 2 nm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Qu, H.; Guan, H.; Zhang, J.; Zhang, X.; Xie, X.; Yan, L.; Wang, C. Design and Fabrication Technology of Metal Mirrors Based on Additive Manufacturing: A Review. Appl. Sci. 2021, 11, 10630. https://doi.org/10.3390/app112210630

Zhang K, Qu H, Guan H, Zhang J, Zhang X, Xie X, Yan L, Wang C. Design and Fabrication Technology of Metal Mirrors Based on Additive Manufacturing: A Review. Applied Sciences. 2021; 11(22):10630. https://doi.org/10.3390/app112210630

Chicago/Turabian StyleZhang, Kai, Hemeng Qu, Haijun Guan, Jizhen Zhang, Xin Zhang, Xiaolin Xie, Lei Yan, and Chao Wang. 2021. "Design and Fabrication Technology of Metal Mirrors Based on Additive Manufacturing: A Review" Applied Sciences 11, no. 22: 10630. https://doi.org/10.3390/app112210630