Towards Explainable Augmented Intelligence (AI) for Crack Characterization

Abstract

:1. Introduction

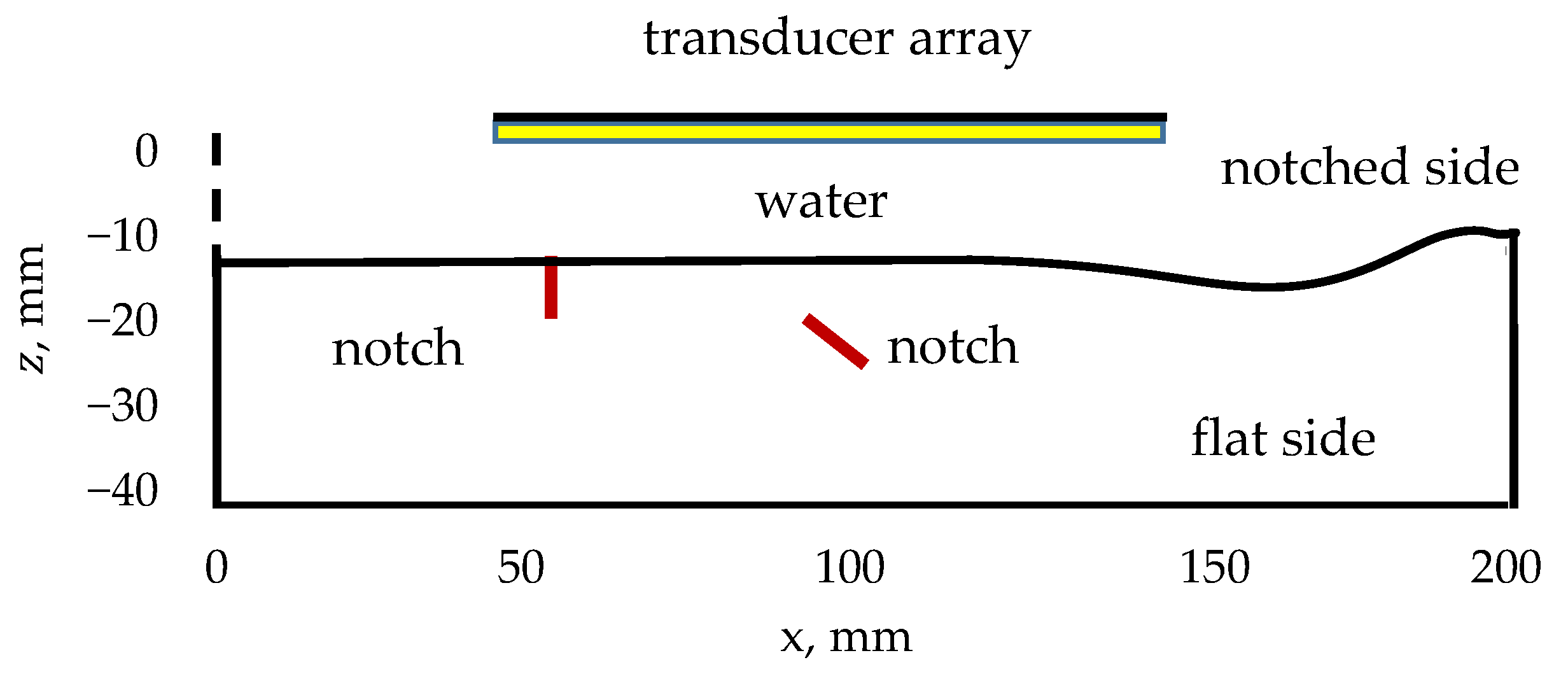

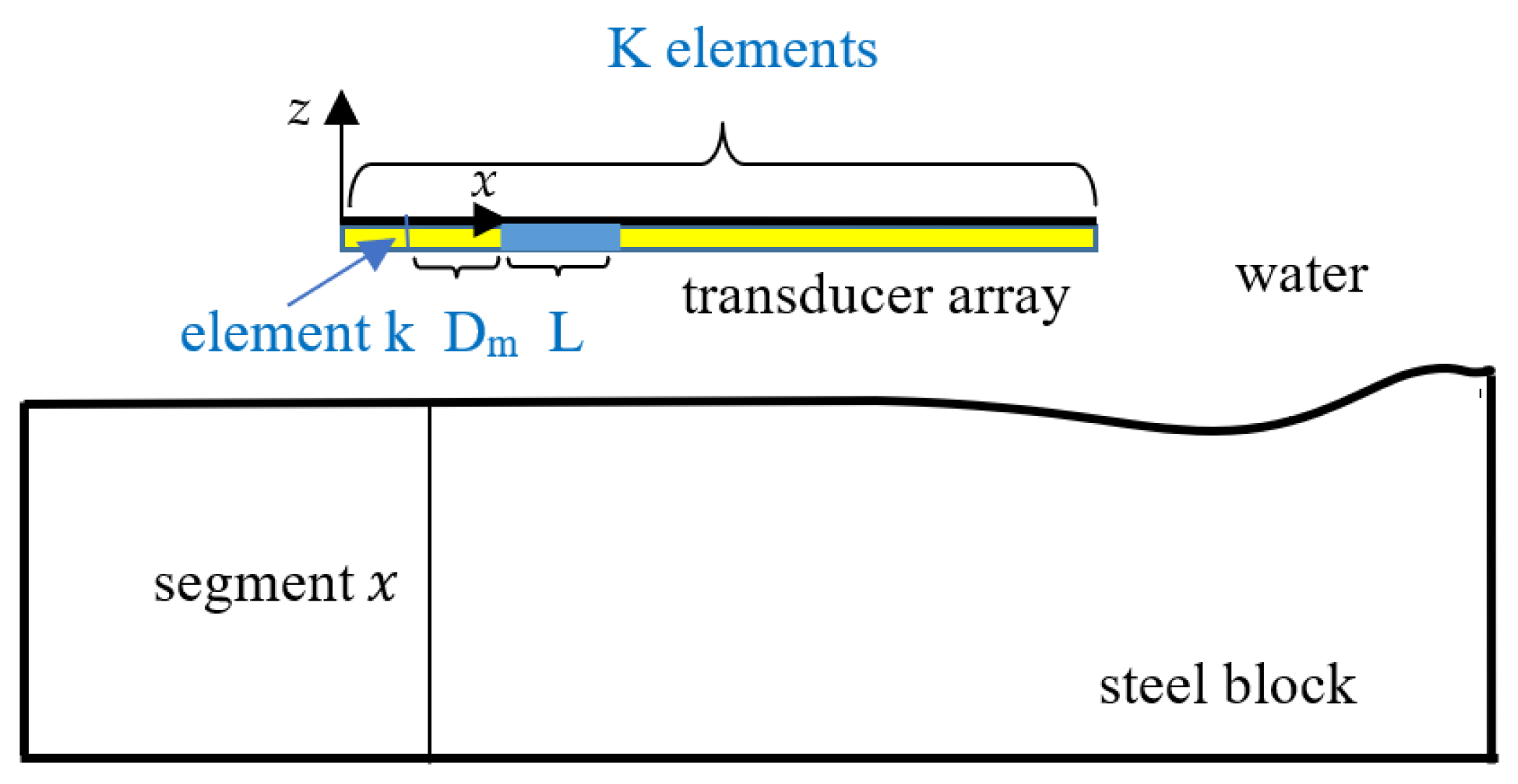

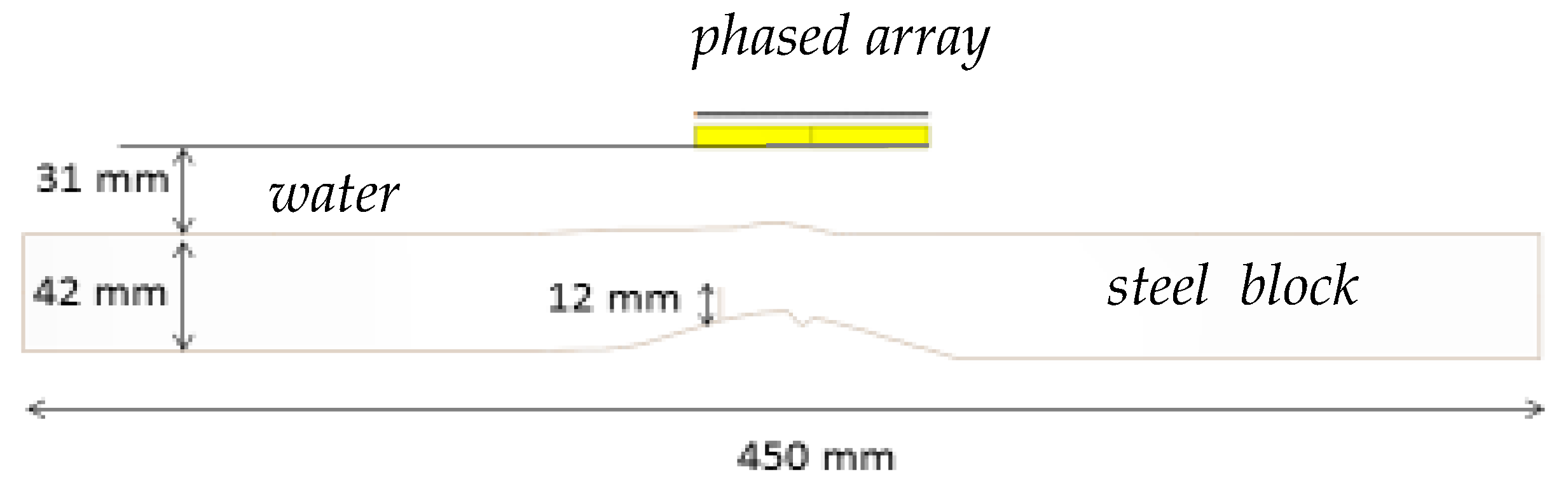

2. The Experimental Set-Up

3. The AutoNDE Code for Semi-Automatic Crack Characterization

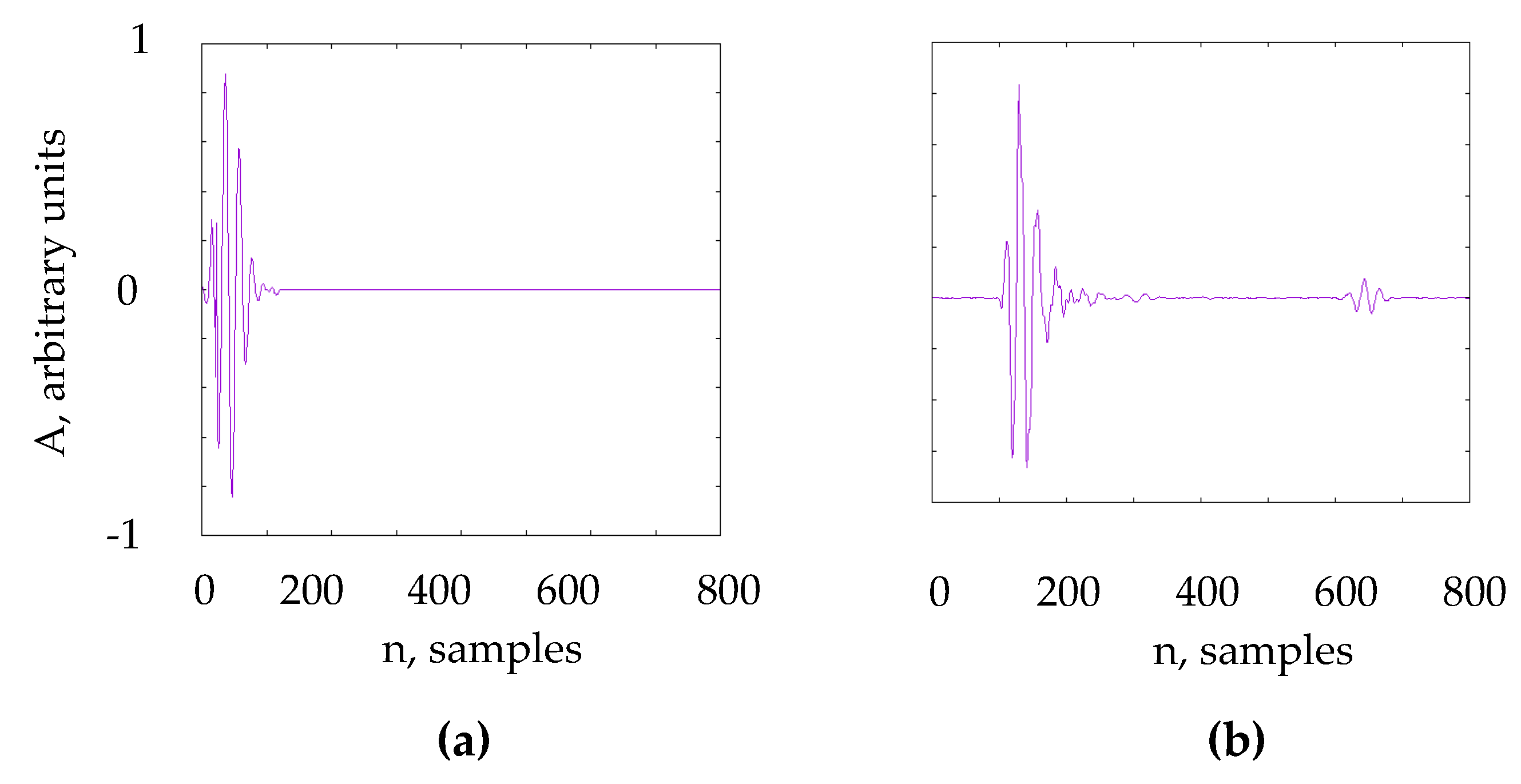

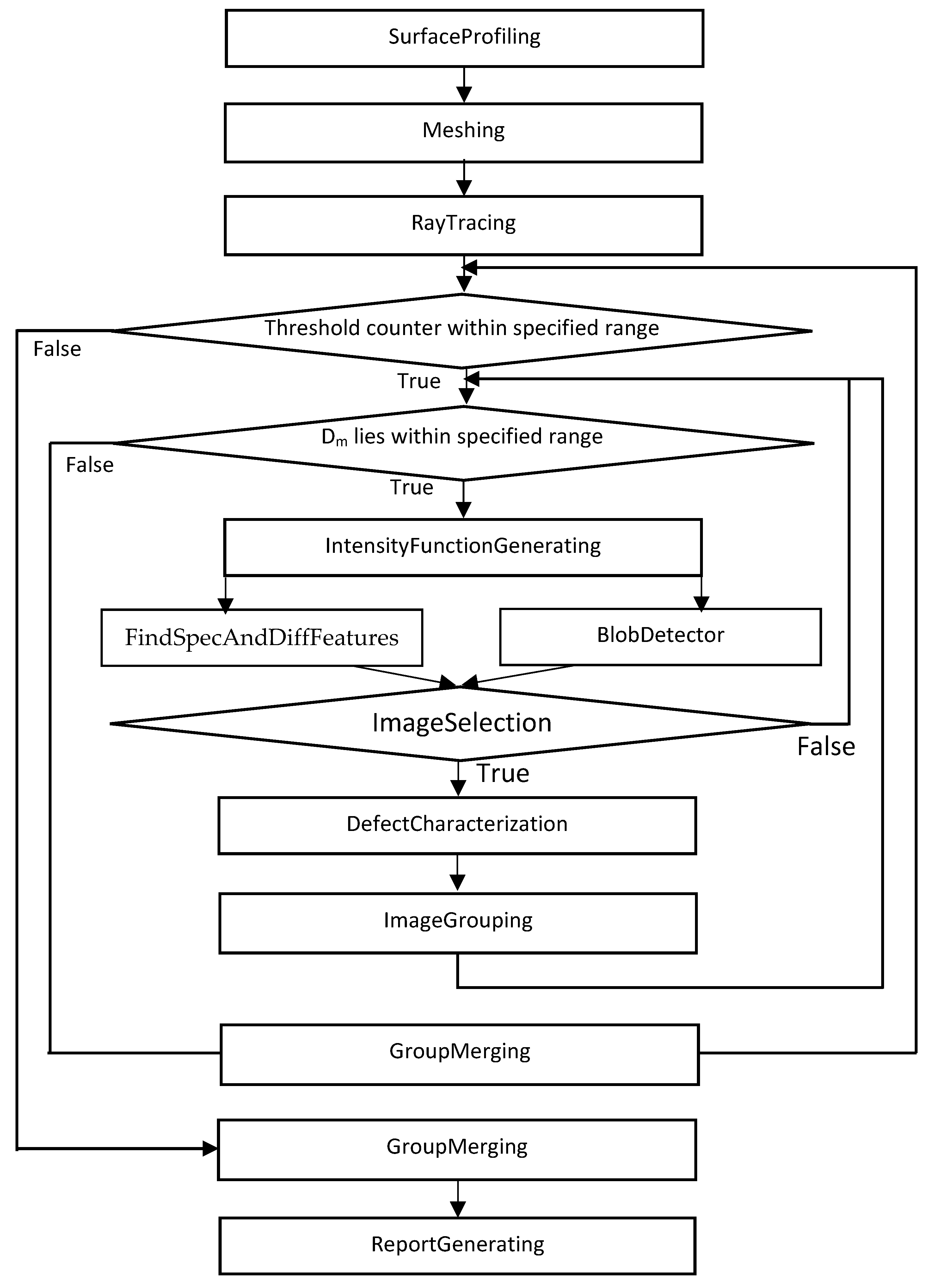

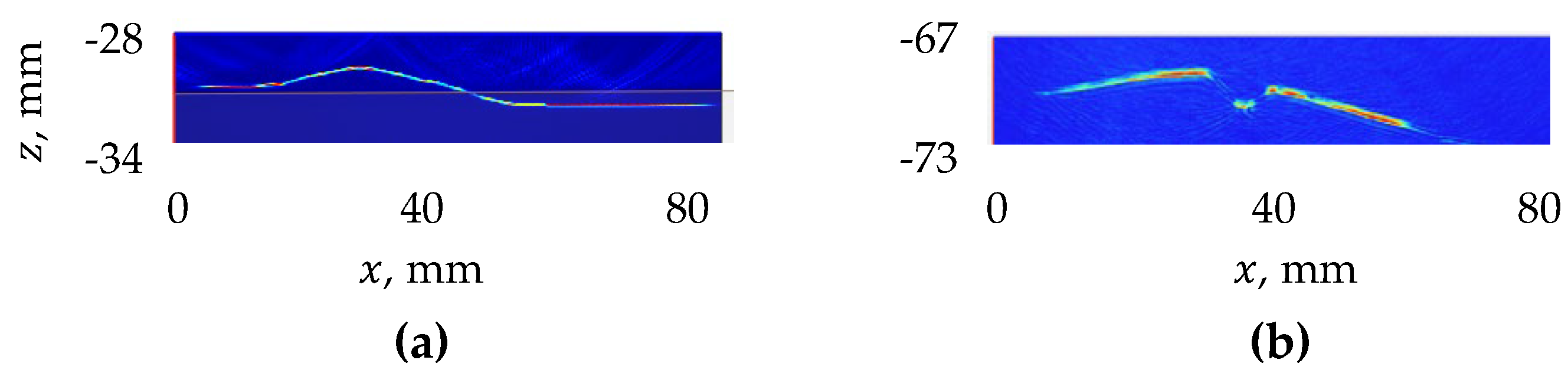

3.1. Signal Processing

- SurfaceProfiling effects profiling by (1) locating for each array element the surface point directly underneath and (2) interpolating the acquired surface points using polynomial regression. The first step is performed by convolving h(A)(N − t), the Hilbert transform of the time inverse of the input pulse with the corresponding pulse scattered by the surface. Only A-scans received by the same transducers that transmitted them are utilized. Hence the maximum number of surface points collected during the first step is K. The regression model used in interpolation iswhere the response vector z, the parameter vector b, the design matrix X and the error vector e are given, respectively, byz = X b + e,

- Originally, the polynomial degree to produce good results with the DPS data has been found by trial and error to be .

- In the latest version of AutoNDE the degree p is selected automatically. There is a number of approaches recommended for this purpose in the literature on machine learning. We have found that the most common of those, the bias-variance trade-off leads to ill-conditioned the Vandermonde matrix and overfitting of the DPS data. Since for all DPS datasets SurfaceProfiling acquires surface points whose location error is random it is reasonable to assume that their underlying error distribution is normal. Therefore, we attempted and found satisfactory a method that involves the Wald test [18] based on the t-statistic of the leading coefficient.

- In order to apply this method we first estimate and , where is the highest polynomial degree that can be reliably estimated from the available data and is the maximum number of digits of accuracy on top of what would be lost to the numerical method due to loss of precision from arithmetic methods [19]. A well-known rule-of-thumb suggests that and the training of AutoNDE on the DPS data suggests that for realistic random surface undulations used in this experiment = 6.

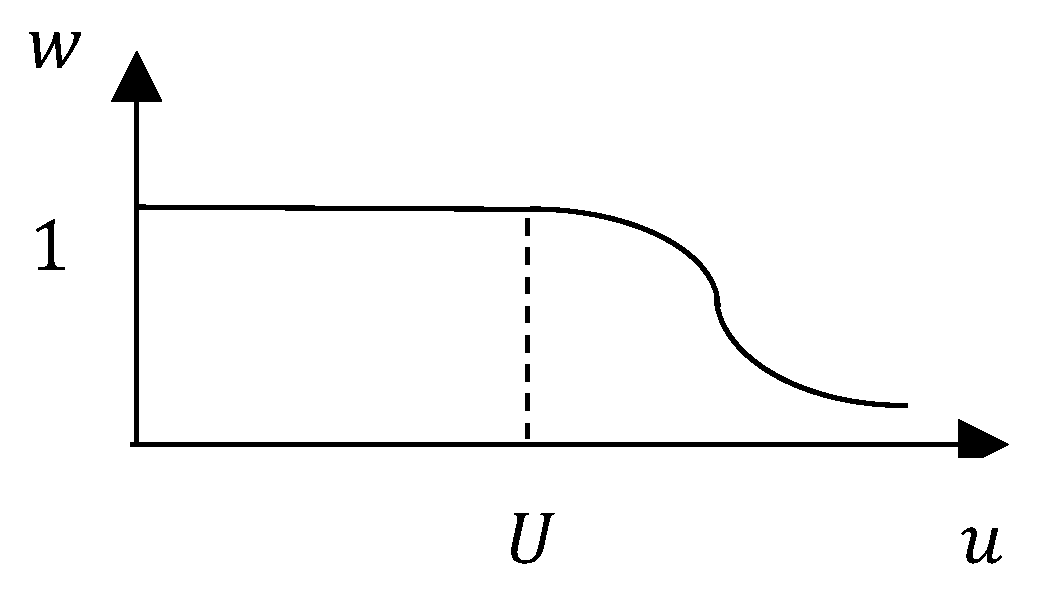

- The suggested method utilizes the algorithm presented in Figure 4. Note that since all values are non-zero and distinct for every p = p’ all Vandermonde matrices are invertible [20]. Note too that the t-statistic is normally applied to assess significance of regression parameters, while here is used to test the null hypothesis that the leading coefficient = 0. It follows that the algorithm selects the polynomial of the highest significant degree. The threshold assures that if the error in location of surface points has a normal distribution, the null hypothesis that the leading coefficient is zero can be rejected at the 95% significance level.

- 2.

- Meshing of the specimen is performed by specifying a regular grid of evenly spaced rows and columns, covering the portion of the specimen, which lies underneath the probe. The meshing module also specifies the region of interest. If the measurements are taken only when the crack is located more or less underneath the array center the region of interest is reduced to the central region underneath the probe. Any reduction of the region of interest speeds up the crack characterization process.

- 3.

- RayTracing starts by issuing a fan of rays from each array element. The central angle of each fan is −90° to the x-axis, the optimal vertex angle has been found to be 60° and the optimal difference between the angles of neighboring rays, 0.057°. These values effect a trade-off between the code accuracy and speed. For each ray the RayTracing submodule locates the point where it hits the upper surface, finds the refracted ray issuing from this point (in the current version no shadowing is accounted for) and calculates the time it takes the ray to reach each row in the region of interest. In the present version of AutoNDE mode conversion is allowed as well as one reflection from the backwall.

- 4.

- IntensityFunctionGenerating utilizes the matrix of A-scans to generate the intensity function

3.2. Image Processing

- FindSpecAndDiffFeatures relies on the OpenCV FindContour function to select two types of features, large (longer than 7 mm) and small (between 1 mm and 7 mm long). If one of the features is 7 mm or slightly smaller and there are several other small features smaller than 3 mm in extent the small features are neglected and the larger one is treated as a specular reflection.

- The BlobDetector relies on the OpenCV DetectBlob function to filter blobs by size between 80 and 160 pixels. The BlobDetector is particularly useful when dealing with surface-breaking cracks, because in these situations the probe often picks up only one crack tip. When only one blob is picked up the final crack characterization can be made only by a human inspector. In cases like this the AutoNDE flags the situation by putting the question mark after every defect characteristic and estimate of the report quality (the definition of quality is given below). All the feature and blob parameters mentioned above have been chosen by trial and error to maximize the number of true positives and minimize the number of false positives selected by the code.

3.3. Explainable AI

- ImageSelection submodule selects images containing one or two blobs (bright spots), two small contour selected features, one large feature or maybe, one blob and one small feature. If a blob and a contour selected feature are detected at the same location it is the feature parameters that are used to characterize the potential diffraction spot. If one of the contour selected features is slightly bigger than 7 mm it is still treated as a possible diffraction spot.

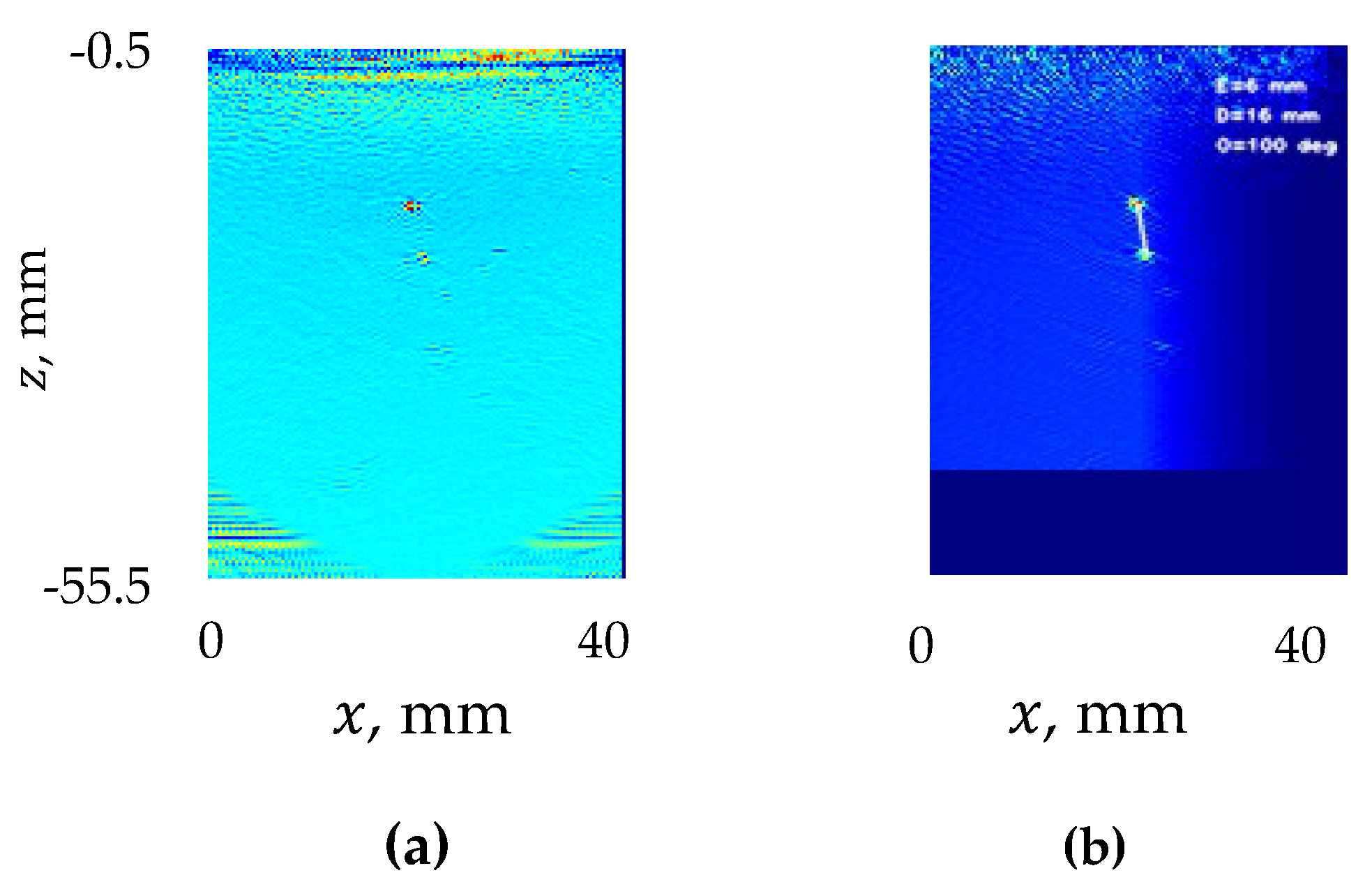

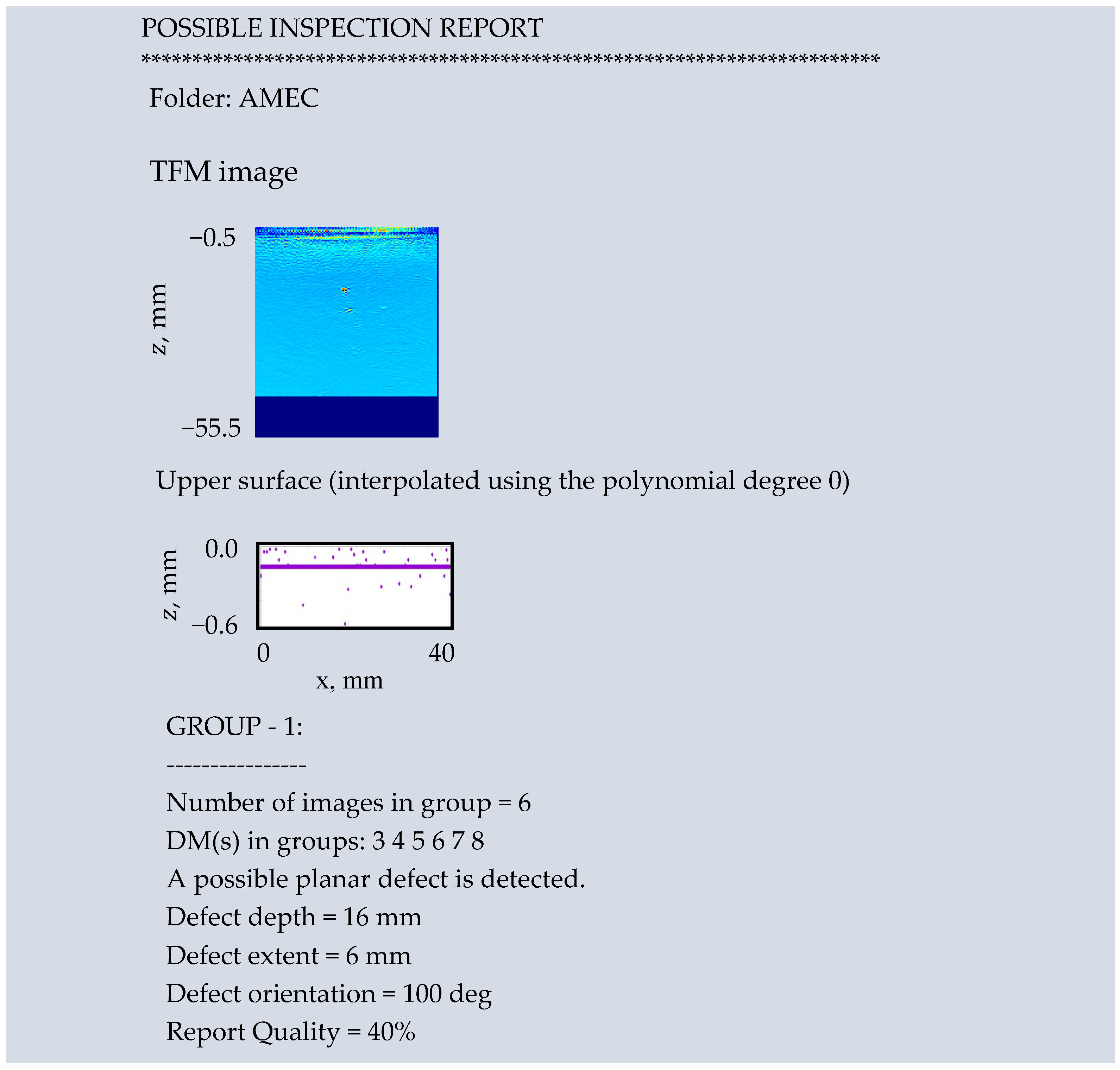

- DefectCharacterization carries out calculations of the extent (notch length in the imaged plane), depth (the smallest of distances between notch tips and specimen surfaces) and orientation (the angle the notch makes in the imaged plane with the mean specimen surface) of the detected planar defect. The calculations are based on parameters of the bounding boxes, which the FindContour OpenCV function draws around the objects or else on parameters of blobs detected by the DetectBlob function. Planar cracks are expected to produce two types of images, specular reflections and TOFD (Time of Diffraction) images, which contain two diffraction spots surrounding notch tips. When the image contains one large feature (interpreted as a specular notch image), the extent is calculated as the longest box side; the depth, as the shortest distance between box vertices and specimen surfaces; and orientation as orientation of box’s longest side. For TOFD, the extent is calculated as the largest distance between vertices of their bounding boxes; the depth, as the shortest distance between vertices of these boxes and specimen surfaces; and orientation, as orientation of the line connecting the gravity centers of the boxes. If only two small features are identified the code draws a straight yellow line connecting their gravity centers.

- ImageGrouping checks whether each selected image appears to be similar to the pivot image in the group g = 1, 2, …, G, that is contains a notch with a similar extent E and orientation O at a similar location C (so that the coordinates of the gravity centers of the notches are similar). The pivot is the image with the smallest in the group. If the image is similar to the pivot it is added to the group; otherwise, it is used as a pivot for the next group. The crack parameters are referred to below as v = E, O, C, respectively. For each group a preliminary report is compiled, describing the weighted averages .

- 4.

- GroupMerging employs similar principles to ImageGrouping, working with group averages instead of individual crack characteristics. Group merging is performed first for each intensity threshold: the first of all groups on the list is chosen as a pivot, the next group on the list is merged with it if the extents of their defects differ by no more than 2.1 mm; the distance between the gravity centers of these defects is no more than 2.5 mm; and their orientations differ by no more 21°. The remaining groups form a new list and the merging process is repeated. For a given intensity threshold, only groups detected by the same method (FindContour or BlobDetector) can be merged. No such restriction is used when merging groups identified using different intensity thresholds. Otherwise, this last merging is performed using the same principles as above but with deviations in extents and distances allowed to reach 3 mm.

- 5.

- ReportGenerating reports the group(s) with the maximum probability. If more than one group with the maximum probability is reported the final choice has to be made by the human inspector on scrutinizing the TFM image.

4. Training AutoNDE

4.1. Training AutoNDE on DPS Data

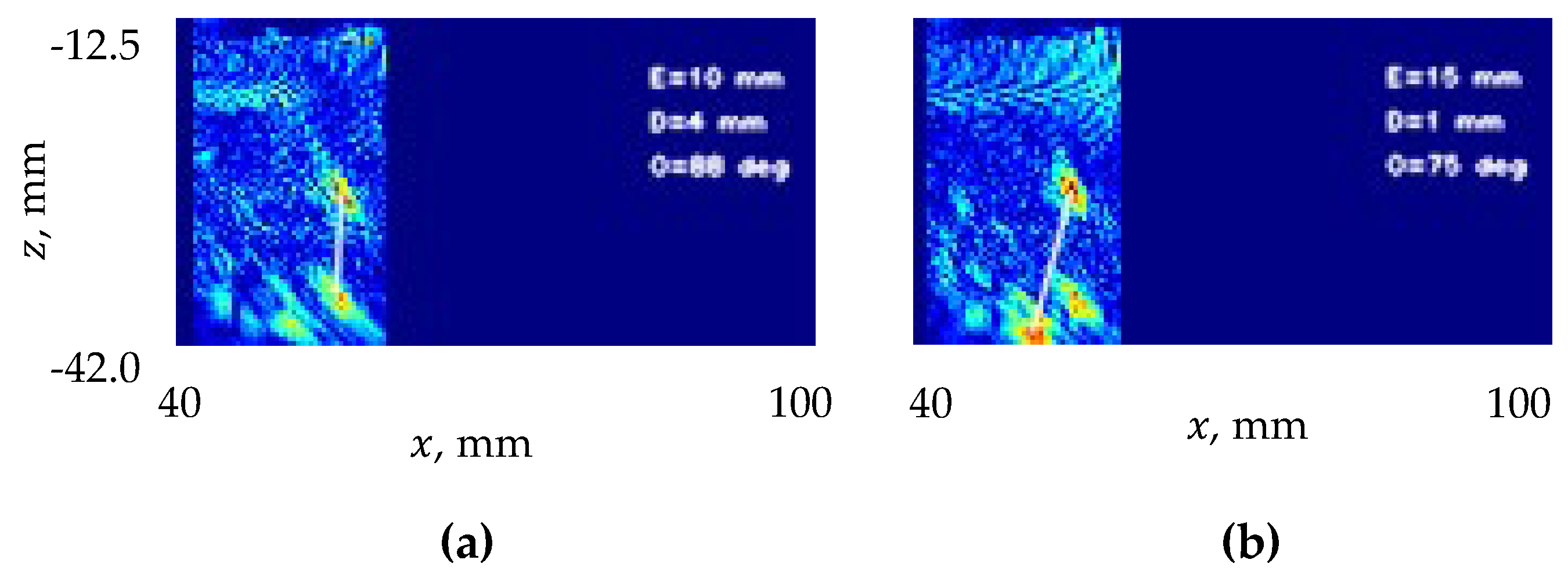

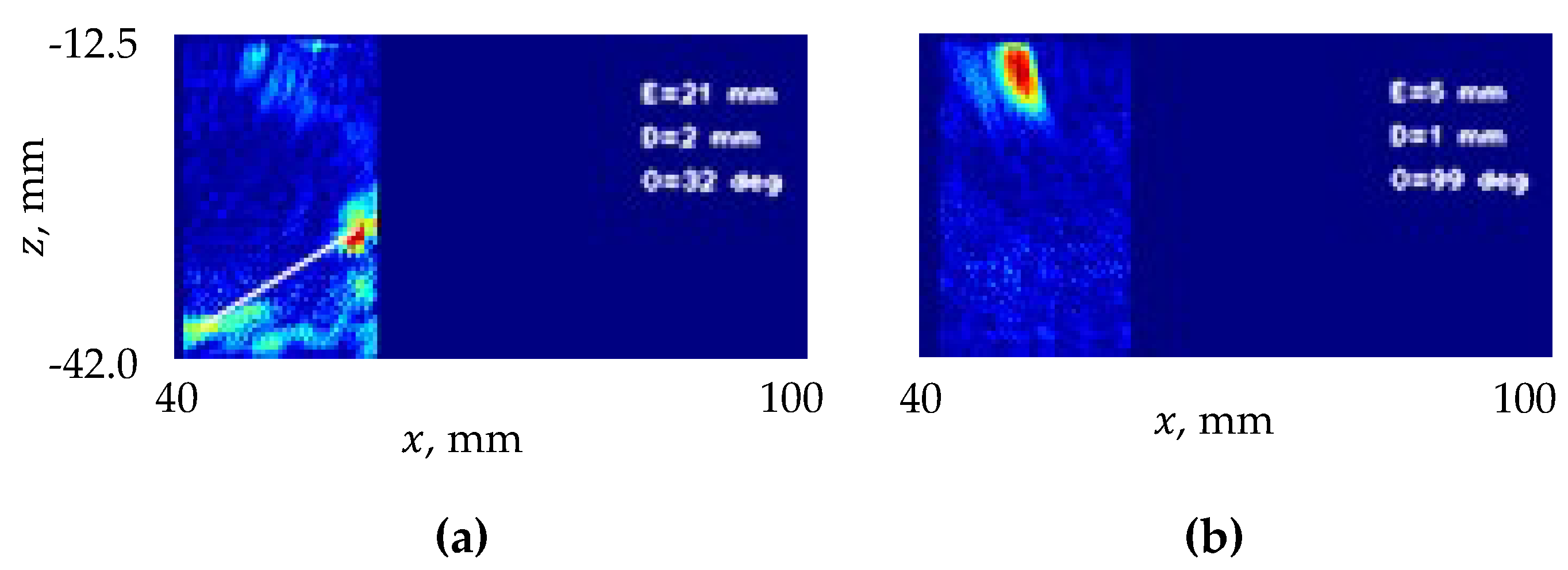

4.2. Testing AutoNDE on AMEC Data

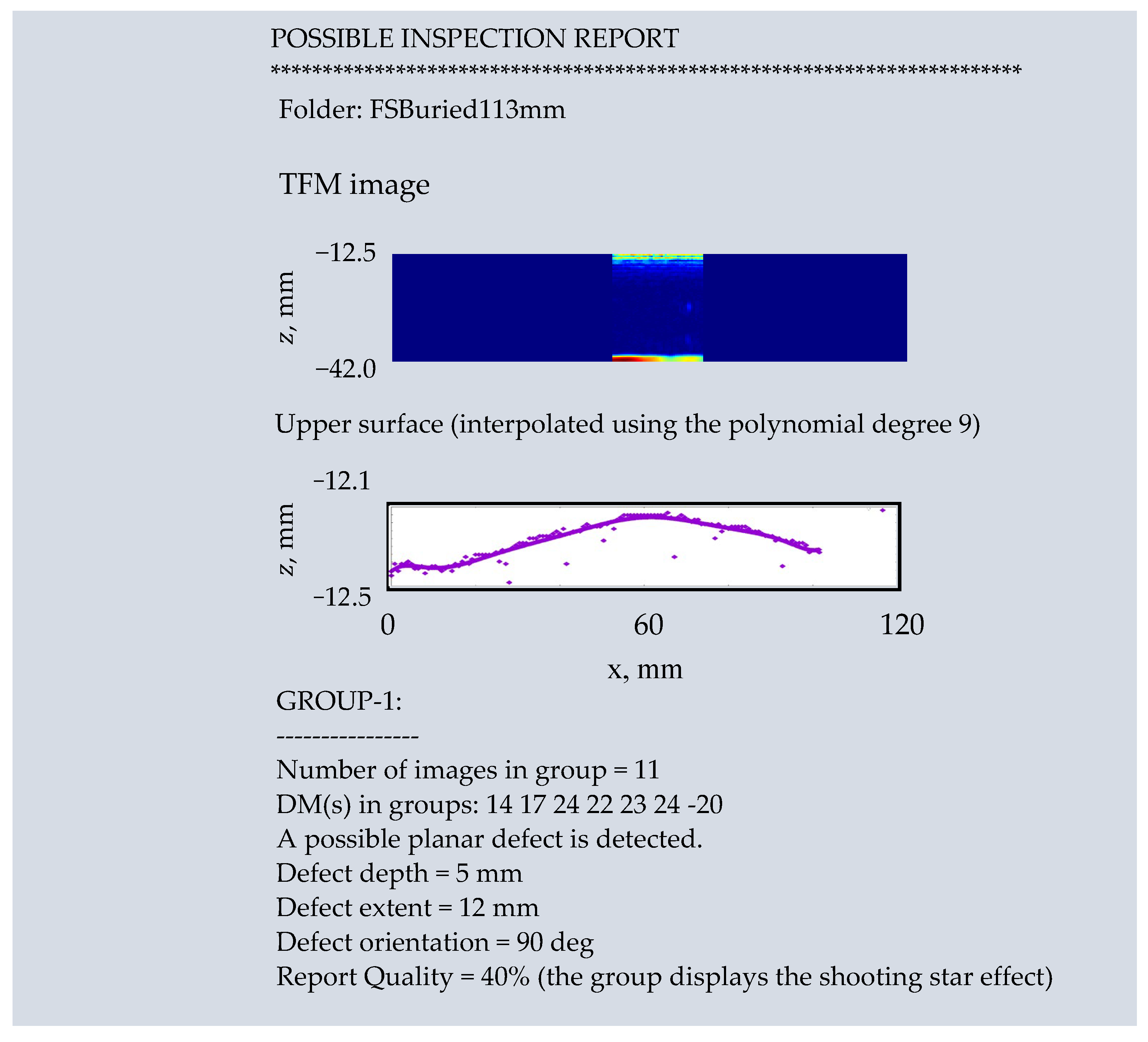

4.3. Testing AutoNDE on CEA Data

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schneider, C.; Bird, C. Reliability of Manually Applied Phased Array Inspection. In Proceedings of the 4th European-American Workshop on Reliability NDE, Berlin, Germany, 24–26 June 2009. [Google Scholar]

- Hunter, A.J.; Drinkwater, B.W.; Wilcox, P.D. Least-squares estimation of imaging parameters for an ultrasonic array using known geometric image features. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2011, 58, 414–426. [Google Scholar] [CrossRef]

- Marengo, E.A.; Gruber, F.K.; Simonetti, F. Time-Reversal MUSIC Imaging of Extended Targets. IEEE Trans. Image Process. 2007, 16, 1967–1984. [Google Scholar] [CrossRef] [PubMed]

- Champagnat, F.; Goussard, Y.; Idier, J. Unsupervised deconvolution of sparse spike trains using stochastic approximation. IEEE Trans. Signal Process. 1996, 44, 2988–2998. [Google Scholar] [CrossRef] [Green Version]

- Holmes, C.; Drinkwater, B.W.; Wilcox, P. Advanced post-processing for scanned ultrasonic arrays: Application to defect detection and classification in non-destructive evaluation. Ultrasonics 2008, 48, 636–642. [Google Scholar] [CrossRef] [PubMed]

- Hunter, A.J.; Drinkwater, B.W.; Wilcox, P. The wavenumber algorithm for full-matrix imaging using an ultrasonic array. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2008, 55, 2450–2462. [Google Scholar] [CrossRef] [PubMed]

- Iakovleva, E.; Chatillon, S.; Bredif, P.; Mahaut, S. Multi-mode TFM imaging with artifacts filtering using CIVA UT forwards models. AIP Conf. Proc. 2014, 1581, 72–79. [Google Scholar] [CrossRef]

- Le Jeune, L.; Robert, S.; Villaverde, E.L.; Prada, C. Plane Wave Imaging for ultrasonic non-destructive testing: Generalization to multimodal imaging. Ultrasonics 2016, 64, 128–138. [Google Scholar] [CrossRef] [Green Version]

- Bannouf, S.; Robert, S.; Casula, O.; Prada, C. Noise filtering in the total focusing method by decomposition of the time reversal operator and the virtual array approach. AIP Conf. Proc. 2013, 1511, 857–864. [Google Scholar] [CrossRef]

- Villaverde, E.L.; Robert, S.; Prada, C. Ultrasonic imaging of defects in coarse-grained steels with the decomposition of the time reversal operator. J. Acoust. Soc. Am. 2016, 140, 541–550. [Google Scholar] [CrossRef]

- Robert, S.; Casula, O.; Roy, O.; Neau, G. Real-time nondestructive testing of composite aeronautical structures with a self-adaptive ultrasonic technique. Meas. Sci. Technol. 2013, 24, 074011. [Google Scholar] [CrossRef]

- Pyle, R.J.; Rhodri, L.T.; Bevan, R.R.; Hughes, R.K.; Rachev, A.A.S.A.; Wilcox, P.D. Deep Learning for Ultrasonic Crack Characterization in NDE. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2021, 68, 1854–1865. [Google Scholar] [CrossRef] [PubMed]

- Bai, L.; Le Bourdais, F.; Miorelli, R.; Calmon, P.; Velichko, A.; Drinkwater, B.W. Ultrasonic Defect Characterization Using the Scattering Matrix: A Performance Comparison Study of Bayesian Inversion and Machine Learning Schemas. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2021, 68, 3143–3155. [Google Scholar] [CrossRef] [PubMed]

- Shipway, N.; Huthwaite, P.; Lowe, M.; Barden, T. Using ResNets to perform automated defect detection for Fluorescent Penetrant Inspection. NDT E Int. 2021, 119, 102400. [Google Scholar] [CrossRef]

- Nageswaran, C. The Snooker Algorithm for Ultrasonic Imaging of Fatigue Cracks in order touse Parameter-Spaces to Aid Machine Learning. Preprints 2021, 2021070269. [Google Scholar] [CrossRef]

- Fradkin, L.; Zernov, V.; Elston, G.; Taneja, R.; Bell, I.; Lines, D.; Wharrie, J.; Fitzgerald, P.J. Towards semi-automated crack characterisation. J. Phys. Conf. Ser. 2013, 457, 012008. [Google Scholar] [CrossRef] [Green Version]

- Badeau, N.; Painchaud-April, G.; Le Duff, A. Use of the Total Focusing Method with the Envelope Feature. Available online: https://www.olympus-ims.com/en/resources/white-papers/use-of-the-total-focusing-method-with-the-envelope-feature/ (accessed on 1 November 2021).

- Fahrmeir, L.; Kneib, T.; Lang, S.; Marx, B. Regression: Models, Methods and Applications; Springer: Berlin, Germany, 2013. [Google Scholar]

- Cheney, W.; Kincaid, D. Numerical Mathematics and Computing, 7th ed.; BROOKS/COLE Sengale Learning: Boston, MA, USA, 2013. [Google Scholar]

- Macon, B.; Spitzbart, X. Inverses of Vandermonde Matrices. Am. Math. Mon. 1958, 65, 95–100. [Google Scholar] [CrossRef]

- Home—OpenCV. Available online: https://opencv.org (accessed on 1 November 2021).

- Available online: http://www.extende.com/ (accessed on 1 November 2021).

- Mahaut, S.; Chatillon, S.; Darmon, M.; Leymarie, N.; Raillon, R.; Calmon, P. An Overview of Ultrasonic Beam Propagation and Flaw Scattering Models in the Civa Software. AIP Conf. Proc. 2010, 1211, 2133–2140. [Google Scholar]

- Toullelan, G.; Raillon, R.; Chatillon, S. Results of the 2013 UT modeling benchmark obtained with models implemented in CIVA. AIP Conf. Proc. 2014, 1581, 2093–2100. [Google Scholar] [CrossRef] [Green Version]

- Raillon-Picot, R.; Toullelan, G.; Darmon, M.; Calmon, P.; Lonné, S. Validation of CIVA Ultrasonic Simulation in Canonical Configurations. In Proceedings of the 18th World Conference on Non-destructive Testing (WCNDT), Durban, South Africa, 16–20 April 2012. [Google Scholar]

- Raillon, R.; Bey, S.; Dubois, A.; Mahaut, S.; Darmon, M. Results of the 2010 Ut Modeling Benchmark Obtained with Civa: Responses of Backwall And Surface Breaking Notches. AIP Conf. Proc. 2011, 1335, 1777–1784. [Google Scholar] [CrossRef]

- Raillon, R.; Bey, S.; Dubois, A.; Mahaut, S.; Darmon, M. Results of the 2009 Ut Modeling Benchmark Obtained with Civa: Responses of Notches, Side-drilled Holes and Flat-bottom Holes of Various Sizes. AIP Conf. Proc. 2010, 1211, 2157–2164. [Google Scholar] [CrossRef]

- Ferrand, A.; Darmon, M.; Chatillon, S.; Deschamps, M. Modeling of ray paths of head waves on irregular interfaces in TOFD inspection for NDE. Ultrasonics 2014, 54, 1851–1860. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Darmon, M.; Dorval, V.; Baqué, F. Acoustic Scattering Models from Rough Surfaces: A Brief Review and Recent Advances. Appl. Sci. 2020, 10, 8305. [Google Scholar] [CrossRef]

| Inspection Surface/ Approximate Notch Depth/ Notch Distance from Edge | Report Quality/Comments | Defect Parameters | ||

|---|---|---|---|---|

| Extent, in mm Est/Exp | Orientation, in deg Est/Exp | Depth, in mm Est/Exp | ||

| Flatside/Buried/24 mm | 60% | 9/10 | 105/110 | 8/5 |

| Flatside/Buried/62 mm | 40% | 6/5 | 105/110 | 5/5 |

| Flatside/Buried/113 mm | 40% | 12/10 | 90/90 | 5/5 |

| Flatside/Buried/149 mm | 20%hc | 5/5 | 85/90 | 6/5 |

| Flatside/Breaking/25 mm | 60% | 6/5 | 80/90 | 0/0 |

| Flatside/Breaking/64 mm | 90% | 11/10 | 90/90 | 0/0 |

| Flatside/Breaking/113 mm | 60% | 7/5 | 100/110 | 0/0 |

| Flatside/Breaking/150 mm | 90% | 12/10 | 110/110 | 1/0 |

| Notchside/Buried/24 mm | 60% | 11/10 | 110/110 | 5/5 |

| Notchside/Buried/62 mm | 70% | 6/5 | 110/110 | 5/5 |

| Notchside/Buried/113 mm | 30% | 12/10 | 90/90 | 4/5 |

| Notchside/Buried/149 mm | 30% | 5/5 | 80/90 | 3/5 |

| Notchside/Breaking/25 mm | 40% | 5/5 | 100/90 | 1/0 |

| Notchside/Breaking/70 mm | 30%hc | 8/10 | 90/90 | 2/0 |

| Notchside/Breaking/113 mm | 30% | 5/5 | 115/110 | 1/0 |

| Notchside/Breaking/155 mm | 50% | 8/10 | 115/110 | 2/0 |

| Reading Data | Profiling | Raytracing | Creating an Image | I/O Handling | Total |

|---|---|---|---|---|---|

| 1.5 | 2 | 2 | 1.5 | 4 | 12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fradkin, L.; Uskuplu Altinbasak, S.; Darmon, M. Towards Explainable Augmented Intelligence (AI) for Crack Characterization. Appl. Sci. 2021, 11, 10867. https://doi.org/10.3390/app112210867

Fradkin L, Uskuplu Altinbasak S, Darmon M. Towards Explainable Augmented Intelligence (AI) for Crack Characterization. Applied Sciences. 2021; 11(22):10867. https://doi.org/10.3390/app112210867

Chicago/Turabian StyleFradkin, Larissa, Sevda Uskuplu Altinbasak, and Michel Darmon. 2021. "Towards Explainable Augmented Intelligence (AI) for Crack Characterization" Applied Sciences 11, no. 22: 10867. https://doi.org/10.3390/app112210867

APA StyleFradkin, L., Uskuplu Altinbasak, S., & Darmon, M. (2021). Towards Explainable Augmented Intelligence (AI) for Crack Characterization. Applied Sciences, 11(22), 10867. https://doi.org/10.3390/app112210867