A Multidisciplinary Approach for Improving Resource Efficiency in the Indian Surimi Supply Chain

Abstract

:1. Introduction

1.1. Seafood Sector in India

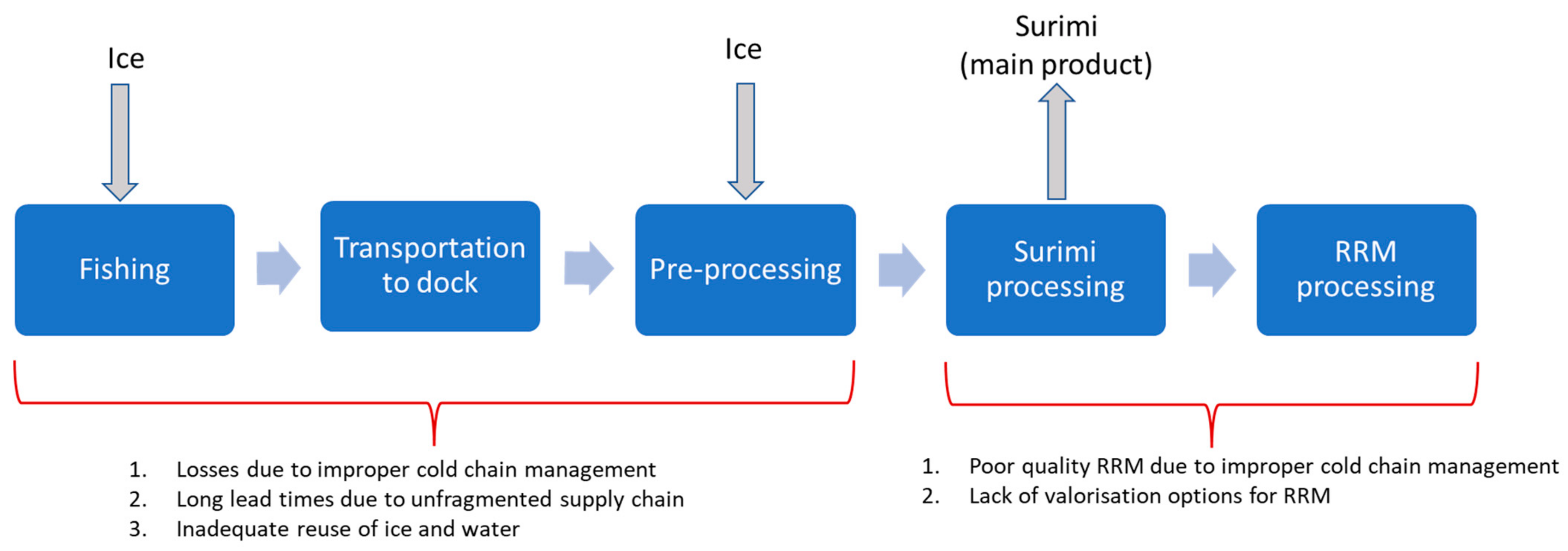

1.2. Surimi Supply Chain

1.3. Need for Multidisciplinary Research

2. Methodology

- i.

- Mapping of the cold chain and an industrial refrigeration system simulation.

- ii.

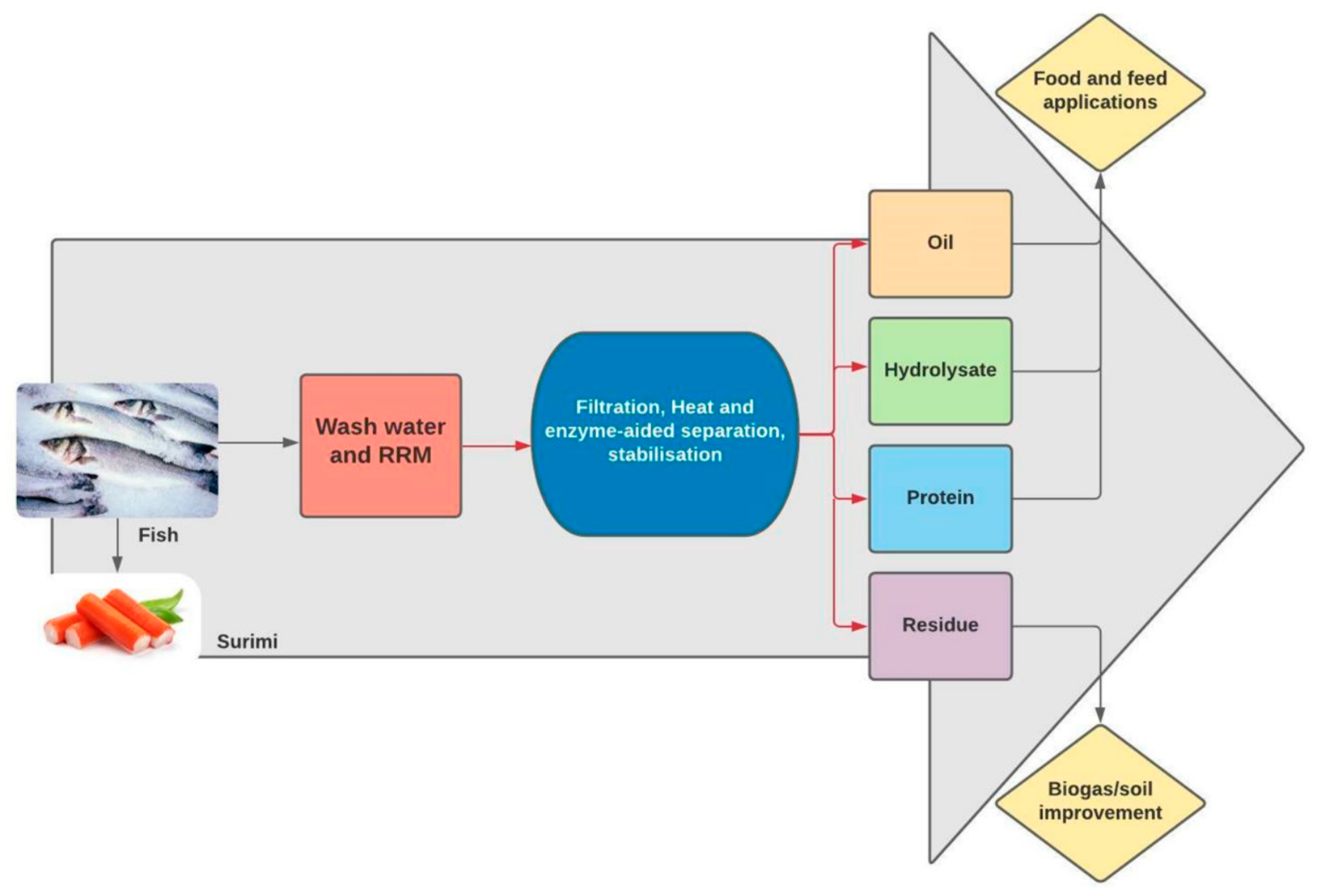

- Development of valorisation options for improving resource efficiency and developing value-added products. These valorisation options were selected based on the chemical composition, quantity, and quality of RRM.

- iii.

- Review of the regulatory frameworks for utilisation of RRM in India and Europe. Conversion of RRM from the fish supply chains is governed by a set of regulations both in India and Europe. These regulations were reviewed, and their implications on the utilisation of the rest of the raw materials were analysed.

3. Synthesis of Key ReValue Results

- i.

- Improvement of cold chain management in the surimi supply chain

- ii.

- Valorisation options for surimi RRM into value-added ingredients

- iii.

- Regulatory framework for utilisation of RRM in India and Europe

3.1. Cold Chain Management

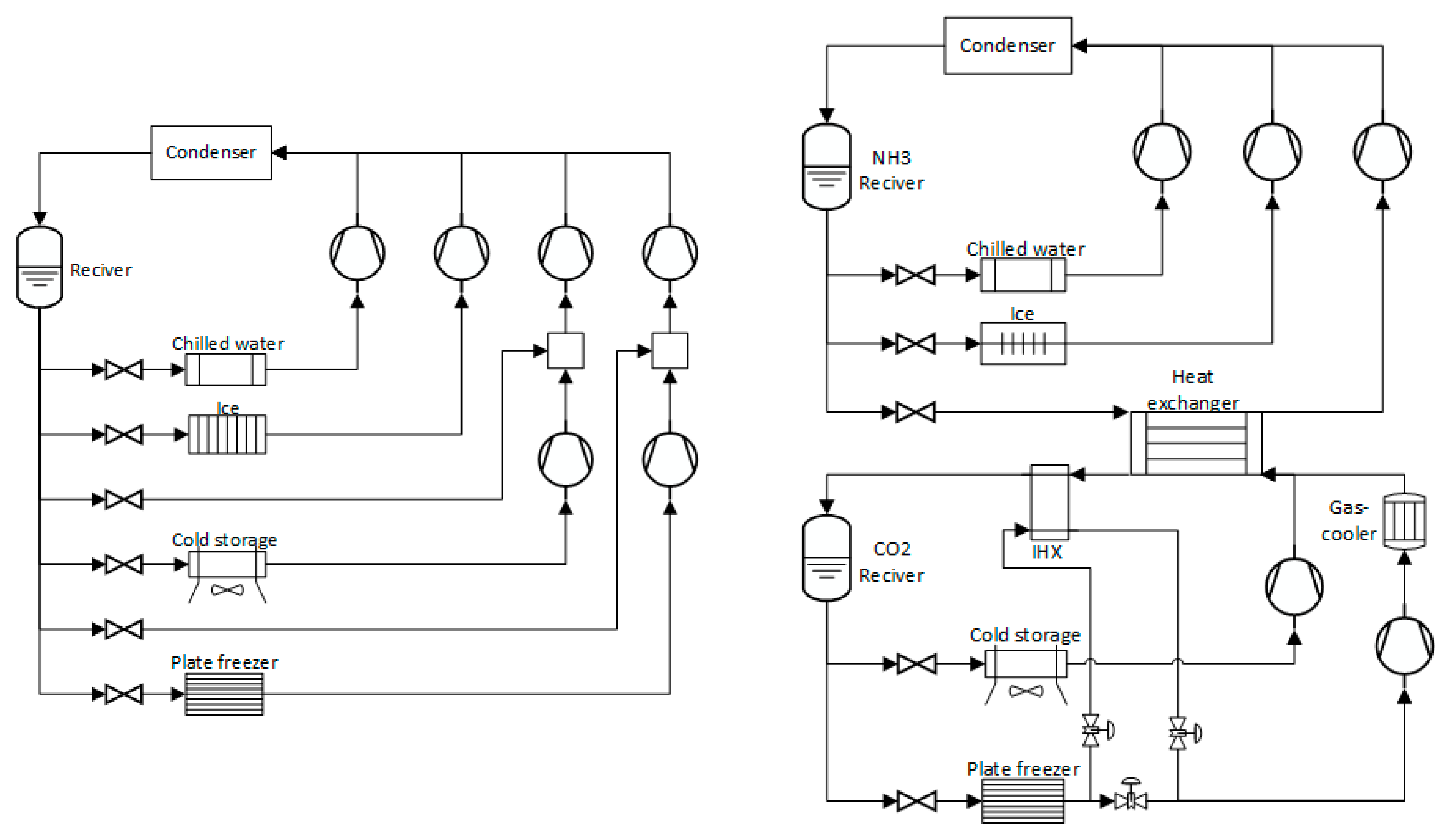

Refrigeration System Simulation

3.2. Valorisation Options for Upscaling

3.3. Regulatory Framework in India and Europe

4. SDGs and Impacts

4.1. Environmental Impacts

4.2. Economic and Health Impacts

4.3. Market Exploitation

- (1)

- promoting the use of ReValue materials, components, and systems in high value-added applications while keeping costs competitive,

- (2)

- strengthening and differentiating the EU and Indian Industry,

- (3)

- increasing workers’ skills.

5. Conclusions and Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Philp, J.; Winickoff, D.E. Realising the Circular Bioeconomy; OECD Science: Paris, France, 2018. [Google Scholar] [CrossRef]

- Zschieschang, E.; Denz, N.; Lambrecht, H.; Viere, T. Resource efficiency-oriented optimization of material flow networks in chemical process engineering. Procedia CIRP 2014, 15, 373–378. [Google Scholar] [CrossRef] [Green Version]

- EU DIRECTIVE 2008/98/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 19 November 2008 on waste and repealing certain Directives (Text with EEA relevance). Off. J. Eur. Union 2008, L 312/3, 3–30.

- Kruijssen, F.; Tedesco, I.; Ward, A.; Pincus, L.; Love, D.; Thorne-Lyman, A.L. Loss and waste in fish value chains: A review of the evidence from low and middle-income countries. Glob. Food Secur. 2020, 26, 100434. [Google Scholar] [CrossRef]

- Ghosh, P.R.; Fawcett, D.; Sharma, S.B.; Poinern, G.E.J. Progress towards sustainable utilisation and management of food wastes in the global economy. Int. J. Food Sci. 2016, 2016, 3563478. [Google Scholar] [CrossRef] [Green Version]

- Lemaire, A.; Limbourg, S. How can food loss and waste management achieve sustainable development goals? J. Clean. Prod. 2019, 234, 1221–1234. [Google Scholar] [CrossRef]

- Gustavsson, J.; Cederberg, C.; Sonesson, U. Global Food Losses and Food Waste Extent, Causes and Prevention; SIK report No. 857; The Swedish Institute for Food and Biotechnology: Goteborg, Sweden, 2011. [Google Scholar]

- Kowalska, A. The issue of food losses and waste and its determinants. LogForum 2017, 13, 7–18. [Google Scholar] [CrossRef]

- United Nations. Resolution Adopted by the General Assembly on 11 September 2015; A/RES/70/1; General Assembly United Nations: New York, NY, USA, 2015. [Google Scholar]

- Global Hunger Index. GLOBAL HUNGER INDEX 2021: INDIA. 2021. Available online: https://www.globalhungerindex.org/pdf/en/2021/India.pdf (accessed on 29 January 2021).

- NAAS 2019. Saving the Harvest: Reducing the Food Loss and Waste; Policy Brief No. 5; National Academy of Agricultural Sciences: New Delhi, India, 2019; 10p. [Google Scholar]

- Ritchie, H.; Reay, D.; Higgins, P. Sustainable food security in India—Domestic production and macronutrient availability. PLoS ONE 2018, 13, e0193766. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rais, M.; Acharya, S.; Sharma, N. Food processing industry in India: S&T capability, skills and employment opportunities. J. Rural. Dev. 2014, 32, 451–478. [Google Scholar]

- Food and Agriculture Ofanization of the United Nations. Food Loss and Waste Database. 2019. Available online: https://www.fao.org/platform-food-loss-waste/flw-data/en/ (accessed on 28 January 2021).

- Mukherjee, S.; Ikbal, A.; Ngasotter, S.; Bharti, D.; Jana, S.; Mondal, A.; Pahari, T. Impact of COVID-19 on Indian Seafood Industry and Potential Measures for Recovery: A Mini-review. Curr. J. Appl. Sci. Technol. 2020, 39, 519–527. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. World Exports decline due to the COVID-19 Impact. 2021. Available online: https://www.fao.org/in-action/globefish/news-events/trade-and-market-news/april-2021/en/ (accessed on 10 August 2021).

- Getu, A.; Misganaw, K.; Bazezew, M. Post-harvesting and major related problems of fish production. Fish. Aquac. J. 2015, 6, 1000154. [Google Scholar] [CrossRef]

- Towers, L. Post Harvest Fish Losses. The Fish Site 2011. Available online: https://thefishsite.com/articles/post-harvest-fish-losses (accessed on 28 January 2021).

- Rasmussen, R. Quantifying the Economic Impacts of Viral Disease in Norwegian Aquaculture. Master’s Thesis, University of Stavanger, Stavanger, Norway, 2020. [Google Scholar]

- Park, J.W.; Morrissey, M.T. Manufacturing of surimi from light muscle fish. In Surimi and Surimi Seafood; Park, J.W., Dekker, M., Eds.; Marcel Dekker, Inc.: New York, NY, USA, 2000; pp. 23–58. [Google Scholar]

- Park, J.W. Surimi and Surimi Seafood; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- World Health Organization. Vitamin and Mineral Requirements in Human Nutrition; World Health Organization: Geneva, Switzerland, 2004. [Google Scholar]

- Sultan, F.A.; Routroy, S.; Thakur, M. A simulation-based performance investigation of downstream operations in the Indian Surimi Supply Chain using environmental value stream mapping. J. Clean. Prod. 2021, 286, 125389. [Google Scholar] [CrossRef]

- Routroy, S.; Dasgupta, M.S.; Thakur, M.; Bhattacharyya, S.; Windell, K.N. Surimi value chain in India: A strategy for improved resource utilization. In Proceedings of the 25th IIR International Congress of Refrigeration, Montréal, QC, Canada, 24–30 August 2019. [Google Scholar]

- Ravishankar, C.N. Losses in the Indian seafood sector: Causes and potential value addition solutions. In Proceedings of the RE-food, Abstracts and Summaries, 1st Symposium, Goa, India, 8–9 February 2018. [Google Scholar]

- Singh, S.; Ramakrishna, S.; Gupta, M.K. Towards zero waste manufacturing: A multidisciplinary review. J. Clean. Prod. 2017, 168, 1230–1243. [Google Scholar] [CrossRef]

- Soceanu, A.; Dobrinas, S.; Sirbu, A.; Manea, N.; Popescu, V. Economic aspects of waste recovery in the wine industry. A multidisciplinary approach. Sci. Total Environ. 2021, 759, 143543. [Google Scholar] [CrossRef] [PubMed]

- Tayebi-Khorami, M.; Edraki, M.; Corder, G.; Golev, A. Re-thinking mining waste through an integrative approach led by circular economy aspirations. Minerals 2019, 9, 286. [Google Scholar] [CrossRef] [Green Version]

- Ames, G.; Clucas, I.; Paul, S.S. Post-Harvest Losses of Fish in the Tropics; Natural Resources Institute: Chatham, UK, 1991. [Google Scholar]

- Dasgupta, M.S.; Routroy, S.; Widell, K.N.; Bhattacharyya, S.; Thakur, M. A Strategy for improved temperature control in the supply and processing stages of Surimi cold chain in India. In Proceedings of the IIR International Congress Refriger, Montreal, QC, Canada, 24–30 August 2019. [Google Scholar]

- Sultan, F.A.; Routroy, S.; Thakur, M. Introducing traceability in the Indian Surimi supply chain. Mater. Today Proc. 2020, 28, 964–969. [Google Scholar] [CrossRef]

- Sultan, F.A.; Routroy, S.; Dasgupta, M.S.; Bhattacharyya, S.; Thakur, M.; Widell, K.N. Developing cold chain for Indian surimi supply chain. In Proceedings of the 6th IIR International Conference on Sustainability and the Cold Chain, Nantes, France, 26–28 August 2020. [Google Scholar]

- Dasgupta, M.S.; Routroy, S.; Bhattacharyya, S.; Sultan, A.; Saini, S.K.; Gupta, K.; Kaushik, N.; Widell, K.N.; Tveit, G.M.; Thakur, M. Value Stream Map and Supply Chain Interdependencies in India-Surimi Case-OC2020 A-010 (SINTEF Report); SINTEF Ocean: Trondheim, Norway, 2019. [Google Scholar]

- Vikas, P.; Badrinarayanan, M. Value Addition and Technology Enhancement in Indian Seafood Industry-Frozen Sector. Int. J. Glob. Bus. Manag. Res. 2018, 7, 9–14. [Google Scholar]

- Saini, S.K.; Dasgupta, M.S.; Widell, K.N.; Bhattacharyya, S. Thermal and economic analysis of an on-board compensatory refrigeration system for small fishing boats. In Proceedings of the 25th National and 3rd International ISHMT-ASTFE Heat and Mass Transfer Conference, Roorkee, India, 28–31 December 2019. [Google Scholar]

- Dasgupta, M.S.; Routroy, S.; Bhattacharyya, S.; Sultan, A.; Saini, S.K.; Widell, K.N.; Thakur, M. ReValue Project Report–D1. 3: Report on Energy Efficient Refrigeration Systems-Surimi Case (SINTEF Report); SINTEF Ocean: Trondheim, Norway, 2020. [Google Scholar]

- Saini, S.; Dasgupta, M.; Widell, K.; Bhattacharyya, S. Performance evaluation of a multievaporator NH3-CO2 cascade refrigeration system with IHX for seafood processing industry. In Proceedings of the 14th IIR-Gustav Lorentzen Conference on Natural Refrigerants, Kyoto, Japan, 6–9 December 2020. [Google Scholar] [CrossRef]

- Saini, S.K.; Dasgupta, M.S.; Widell, K.N.; Bhattacharyya, S. Comparative Analysis of a Few Novel Multi-evaporator CO2-NH3 Cascade Refrigeration System for Seafood Processing & Storage. Int. J. Refrig. 2021, 131, 817–825. [Google Scholar]

- Đorđević, V.; Balanč, B.; Belščak-Cvitanović, A.; Lević, S.; Trifković, K.; Kalušević, A.; Kostić, I.; Komes, D.; Bugarski, B.; Nedović, V. Trends in encapsulation technologies for delivery of food bioactive compounds. Food Eng. Rev. 2015, 7, 452–490. [Google Scholar] [CrossRef]

- Sarabandi, K.; Mahoonak, A.S.; Hamishekar, H.; Ghorbani, M.; Jafari, S.M. Microencapsulation of casein hydrolysates: Physicochemical, antioxidant and microstructure properties. J. Food Eng. 2018, 237, 86–95. [Google Scholar] [CrossRef]

- Kaushik, N.; Fabregat, C.; Calleja, A.; Rafart, M.J.; Slizyte, R.; Kumari, A.; Gupta, K. Stabilization, Concentration and Fractionation of Protein Rich Fractions, Deliverable 2.3 in ReValue Project (SINTEF Report); SINTEF Ocean: Trondheim, Norway, 2021. [Google Scholar]

- Food and Agriculture Ofanization of the United Nations. EU Requirements for Food Safety and Traceability of Fish and Fishery Products. 2018. Available online: http://www.fao.org/3/CA2915EN/ca2915en.pdf (accessed on 29 January 2021).

- Kulkarni, P. The Marine Seafood Export Supply Chain in India. 2015. Available online: https://www.iisd.org/system/files/publications/tkn_marine_export_india.pdf (accessed on 29 January 2021).

- European Commission. Countries and Regions-India. 2019. Available online: https://ec.europa.eu/trade/policy/countries-and-regions/countries/india/#:~:text=The%20EU%20is%20India’s%20largest,the%20total)%20after%20the%20USA (accessed on 29 January 2021).

- National Fisheries Development Board. About Indian Fisheries. 2020. Available online: https://nfdb.gov.in/about-indian-fisheries (accessed on 29 January 2021).

- Sasidharan, A.; Baiju, K.; Mathew, S. Seafood processing waste management and its impact on local community in Cochin Corporation, India. Int. J. Environ. Waste Manag. 2013, 12, 422–441. [Google Scholar] [CrossRef]

- Gowen, R.J. Aquaculture and the environment. In Aquaculture and the Environment: Reviews of the International Conference Aquaculture Europe ‘91, Dublin, Ireland, 10–12 June 1991; De Pauw, N., Joyce, J., Eds.; European Aquaculture Society: Ghent, Belgium, 1991; pp. 30–38. [Google Scholar]

- Pillay, T.V.R. Aquaculture and the Environment; Blackwell Scientific Publications: London, UK, 1991. [Google Scholar]

- Sultan, F.A.; Routroy, S.; Thakur, M. Evaluating sustainability of the surimi supply chain in India: A life cycle assessment approach. Int. J. Life Cycle Assess. 2021, 26, 1319–1337. [Google Scholar] [CrossRef]

- Binsi, P. Overview of Waste Generation in Fish and Shellfish Processing Industry; ICAR-Central Institute of Fisheries Technology: Cochin, India, 2018. [Google Scholar]

- Food and Agriculture Organization of the United Nations. Food Loss and Waste in Fish Value Chains|Food Loss and Waste in Fish Value Chains|Food and Agriculture Organization of the United Nations. 2021. Available online: http://www.fao.org/flw-in-fish-value-chains/overview/food-loss-and-waste-in-fish-value-chains/en/ (accessed on 28 January 2021).

- Jayathilakan, K.; Sultana, K.; Radhakrishna, K.; Bawa, A. Utilization of byproducts and waste materials from meat, poultry and fish processing industries: A review. J. Food Sci. Technol. 2012, 49, 278–293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karun, S. India’s seafood exports declines by 7%. The Times of India, 20 August 2020. [Google Scholar]

- World Health Organization. Food Safety. 2020. Available online: https://www.who.int/news-room/fact-sheets/detail/food-safety (accessed on 29 January 2021).

- CDC. Estimates of Foodborne Illness in the United. 2015. Available online: http://www.cdc.gov/foodborneburden (accessed on 28 January 2021).

- Vemula, S.R.; Kumar, R.N.; Polasa, K. Foodborne diseases in India—A review. Br. Food J. 2012, 114, 661–680. [Google Scholar] [CrossRef]

- Parfitt, J.; Barthel, M.; Macnaughton, S. Food waste within food supply chains: Quantification and potential for change to 2050. Philos. Trans. R. Soc. B Biol. Sci. 2010, 365, 3065–3081. [Google Scholar] [CrossRef] [Green Version]

- OECD. Fisheries, Aquaculture and COVID-19: Issues and Policy Responses. 2020. Available online: http://www.oecd.org/coronavirus/policy-responses/fisheries-aquaculture-and-covid-19-issues-and-policy-responses-a2aa15de/ (accessed on 28 January 2021).

- European Commission. Monthly Highlights–EUMOFA. No. 3/2018. 2018. Available online: https://www.eumofa.eu/documents/20178/114144/MH+3+2018.pdf (accessed on 15 January 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thakur, M.; Cowan, E.; Widell, K.N.; Mozuraityte, R.; Slizyte, R. A Multidisciplinary Approach for Improving Resource Efficiency in the Indian Surimi Supply Chain. Appl. Sci. 2021, 11, 10984. https://doi.org/10.3390/app112210984

Thakur M, Cowan E, Widell KN, Mozuraityte R, Slizyte R. A Multidisciplinary Approach for Improving Resource Efficiency in the Indian Surimi Supply Chain. Applied Sciences. 2021; 11(22):10984. https://doi.org/10.3390/app112210984

Chicago/Turabian StyleThakur, Maitri, Emily Cowan, Kristina Norne Widell, Revilija Mozuraityte, and Rasa Slizyte. 2021. "A Multidisciplinary Approach for Improving Resource Efficiency in the Indian Surimi Supply Chain" Applied Sciences 11, no. 22: 10984. https://doi.org/10.3390/app112210984

APA StyleThakur, M., Cowan, E., Widell, K. N., Mozuraityte, R., & Slizyte, R. (2021). A Multidisciplinary Approach for Improving Resource Efficiency in the Indian Surimi Supply Chain. Applied Sciences, 11(22), 10984. https://doi.org/10.3390/app112210984