3.1. Acquisition of Conceptual Solutions and PSS Evaluation Criteria for CV

The systematic approach presented by Beitz [

37] was adopted to perform requirement analysis, extract the overall function of the products, and decompose this function into energy, material, and signal flows, to ultimately obtain subfunctions for the principal solution. Among them, sub-function

t (

α ≤

t ≤

F) can be realized by multiple principle solutions, and the principle solution in each sub-function are selected to be combined into a conceptual scheme. Then, to obtain a structure that satisfies the aforementioned subfunctions and CV requirements, and construct the product morphology matrix shown in

Table 2, the product knowledge database was searched according to customer demands (

Table 3). A total of

PS combinations can then be created, where t denotes the number of principal solutions. Subsequently, to eliminate unfeasible solutions, Pugh’s table [

38] was used to screen the solutions according to the basic configuration and designed purpose of the product.

To evaluate the customer satisfaction for a candidate PSS design, one must determine whether the conceptual solution will provide the services demanded by the customer, and whether the customer will obtain reliable service quality from the product. Therefore, PSS evaluation is a conventional multiple-criteria problem that includes customer demands such as environmental, cost, and sustainability demands [

39]. Based on previous studies on PSS evaluation [

12,

40], the performance elements of a PSS can be defined as the lowest level performance requirements of a system, which are obtained by decomposing a system to its most basic elements. These system performance requirements can then be adopted by the product and service designer to convert CVs into specific design criteria. According to the service quality tool (SERVQUAL) model [

41] and CV hierarchy theory [

42,

43], the CVs of a PSS can be divided into six: reliability, environmental, flexibility, social, and economic values. These CVs can be converted into ten PSS design criteria, as presented in

Table 3. Therefore, to ensure that the PSS in the conceptual solution provides an adequate level of service quality with minimal product design costs, it is necessary to analyze the disparity between the PS value and economic requirements during the design of the PSS.

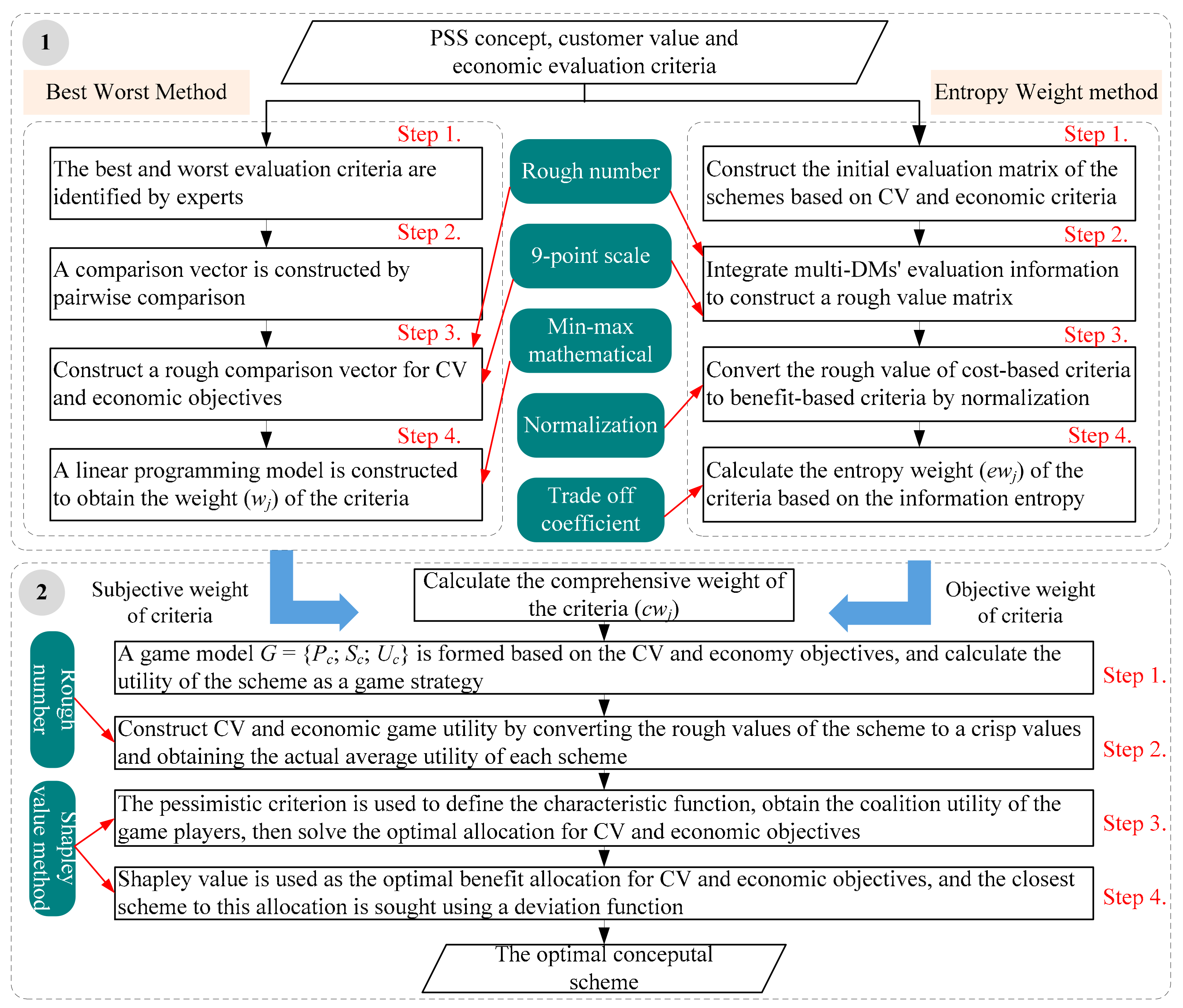

3.2. Calculation of Evaluation Criteria Weights Based on Rough BWM and Entropy Weight Method

In this section, the rough BWM and EWM methods are adopted simultaneously to compute the comprehensive weights of the CV and economic criteria. This approach circumvents the weakness of objective weight calculations (i.e., weights that do not consider DM preferences), and also reduces the uncertainty triggered by subjective preferences. In addition, the preference evaluation for criteria is evaluated by the DM using the so-called 9-point scale [

34,

44], which is defined as follows: 1, very low (VL); 3, low (L); 5, moderate (M); 7, high (H); 9, very high (VH); and 2, 4, 6, 8, intermediate values between the two adjacent judgments.

3.2.1. Calculation of Subjective Weights of Evaluation Criteria Using Rough BWM

Step 1. Let the set of CV evaluation criteria be {

a1,

a2, …,

an}. The importance of each criterion is assessed via expert questionnaires [

45], and the results of this assessment are adopted to identify the best criterion

cB and worst criterion

cW.

Step 2. Based on the 9-point scale, by determining the preference of the optimal criterion over other criterions, a best-to-others vector HkB = (hkB1, hkB2, …, hkBn) is constructed. Similarly, the preference of other criteria for the worst criterion is evaluated, and an others-to-worst vector HkW = (hk1W, hk2W, …, hknW) is constructed, where hkWj represents the preference of DM k (1 ≤ k ≤ m) for other criteria j (1 ≤ j≤ n) compared to the worst criterion.

Step 3. Rough comparison vectors are constructed for all of the DMs [

10,

38]. Suppose that

RkB1 = {

h1B1,

h2B1 …,

hmB1}, where any preference assessment relative to Criterion 1 is

hp ∈

hkB1,

X ∈

RkB1. The lower (

) and upper (

) approximations can then be defined as:

Then, based on Equation (2), the rough number

RN(

hp) is defined by its lower limit (

) and the upper limit (

), respectively.

Equations (1) and (2) are used to construct rough comparison vectors,

RN(

hBj) and

RN(

hjW), for criterion

j, as expressed in Equation (3).

Subsequently, the averages of the rough series can be expressed as rough numbers of the comparison vectors. The rough numbers,

(

hBj) and

(

hjW), defined by Equation (4), can be transformed as follows:

(

hBj) = {[

,

], [

,

], …, [

,

]},

(

hjW) = {[

,

], [

,

], …, [

,

]}.

where

and

represent the upper and lower boundaries of the rough number

(

hBj), respectively, while

and

denote the upper and lower bounds of the rough number

(

hjW), respectively.

Step 4. A nonlinear min-max mathematical programming problem is constructed, as expressed in Equation (5). This is used to evaluate the rough weight of each criterion,

RN(

wj). In addition,

d([

x],[

y]) represents the degree of separation between the

RN(

x) and

RN(

y) rough sets [

46], while [

wB] and [

wW] denote the weights of the best and worst criteria, respectively, as expressed in Equation (6).

Based on the rules of arithmetic operations with rough numbers and the characteristics of min-max programming problems [

13], to obtain the optimal weights

wj = [

w1*,

w2*, …,

wn*] and goals constraint

ξ, an improved mathematical model was proposed by Rezaei [

47], and the objective function was customized as follows:

where

ξ denotes the goals constraint, and {[

], [

], …, [

]} represent the optimal rough weights of criteria.

The Lingo18 software is used to solve the aforementioned linear programming problem, while Equation (8) is adopted to normalize the rough weights of the evaluation criteria and calculate their crisp weights (

wj, where

wj ∈ [0,1).

3.2.2. Calculation of Objective Weights of Evaluation Criteria Using the Entropy Weight Method

The entropy weight method describes the uncertainty of evaluation information in objectively analyzing the importance of the evaluation criteria [

38,

48]. To address biases in the subjective weighting solutions, an initial evaluation matrix for solution values is first constructed using the evaluation criteria. The EWM is then adopted to calculate the objective weight of each evaluation criterion.

Step 1. The CV evaluation criteria are first divided into quantitative and qualitative criteria. Then, the DM k evaluates the solution, and the evaluations of all DMs are gathered to construct the initial evaluation matrix IEM = (xij)K×n, where 1 ≤ i ≤ K. In particular, qualitative criteria are evaluated using a 9-point scale. For quantitative criteria, each DM suggests an appropriate value according to his own perception and experience. For example, based on the criterion E1 in our case, the value judgments of CS1 are assigned by four DMs, which are 1.75 (t), 1.80 (t), 1.50 (t), and 1.75 (t), respectively.

Step 2. Equations (1) and (2) are used to convert the evaluation data of the DMs into rough numbers and construct the rough value matrix (RVM) of the solutions, RVM = (x’ij)K×n. This matrix is adopted to compute objective evaluation data for the criteria weights.

Step 3. The RVM of the solutions in terms of CV criteria is first constructed, and then normalized using Equation (8). Subsequently, the rough values of the solutions in terms of cost criteria are converted into utility values to produce the normalized rough value matrix NRM = (

fij)

K×n, which is adopted in subsequent dimensionless entropy weight and criteria effect calculations, as expressed in Equation (9).

where

fijL and

fijU denote the lower and upper bounds of the rough number of criteria j in solution i, respectively.

Step 4. The information entropy ej of each evaluation criterion is calculated based on the normalized RVM.

ej represents a measure of the uncertainty of the solution values for each criterion

j; the higher the value of

ej, the more consistent the data for an evaluation criterion, and the lower its weight. The formulas for calculating

ej are expressed in Equations (10) and (11):

where

λ (0 <

λ < 1) is the balancing coefficient for the median of the rough number and uncertainty of DM evaluations. In this study,

λ was set to 0.5 in all

ej calculations.

Finally, Equation (12) is adopted to compute the entropy weight of each evaluation criterion using their information entropy, thus generating their objective weights.

Based on Equation (13), the normalized comprehensive weight function

cwj is constructed by integrating the subjective weight and objective entropy weight of each criterion in the aforementioned

Section 3.2.1 and

Section 3.2.2, and to ensure the stability of the ranking results of schemes.

3.3. Decision of the Optimal Solution Based on the Coalitional Game Model

Within the context of this study, the coalitional game model is a multi-objective cooperative game model that is used to analyze design preferences and internal relationships in CV and economic objectives. In this section, the coalitional game model will be used to analyze the coalitional utility of CV and economic objectives in different solutions. The Shapley value will then be adopted to obtain a fair allocation of utilities, to ensure that none of the players (objectives) will try to leave the coalition. Furthermore, the Shapley value of each objective is a fair payoff, which considers the interactions between all objectives in calculating the optimal payoff that maximizes coalitional utility. The Shapley values were obtained via the following procedure:

Step 1. Construction of the coalition game: Firstly, one must define the players, strategies, and utility of the coalition game model. The model is expressed as G = {Pc; Sc; Uc}, c ∈ P, E, while the CV and economic objectives are projected as players Pp and PE, respectively. The strategy of Pp is Sp(CSi) = {P1(CSi), …, PM(CSi)}, where M denotes the number of CV criteria, respectively. Similarly, the strategy of PE is SE(CSi) = {P1(CSi), …, PN(CSi)}, where N denotes the number of economic criteria. Because each conceptual solution corresponds to the strategy sets of a pair of players, S = (SP(CSi), SE(CSi)), if one selects some strategy set such as CSi, the player utilities are UP(SP(CSi), SE(CSi)), and UE(SP(CSi), SE(CSi)). Therefore, once a strategy has been determined for one player, the strategy of the other player is also determined. However, because the solution values of PP and PE in each evaluation criterion are different, any change in the strategy of Pp will inevitably affect the designed expectation of PE, thereby changing the overall designed expectation of the solution. The conflict of interest between Pp and PE must be balanced by selecting the strategy set that best satisfies the design expectations of both players, i.e., the optimal conceptual solution.

Step 2. Calculation of player utilities: Given that each strategy set (

SP(CS

i),

SE(CS

i)) corresponds to a conceptual solution, the player utilities reflect the expected value of each solution for a given strategy. Because each solution represents an attempt by the designer to balance the design requirements of the PSS, the evaluations of the solutions will exhibit conflicts or dependencies with each other, and the utility of one player will inevitably influence that of the other. The objective of the coalitional game is to determine the optimal allocation of utilities to CV and economic objectives, despite their mutual antagonism, to maximize the overall utility of the solution. After the strategy (CS

i) has been determined, it is necessary to consider the effects of the evaluation criteria (which have different weights) on player utility under the selected strategy set, and then objectively compute the utility of each player. First, the criteria weights (Equation (8)) are adopted to transform the solution’s normalized rough values in CV and economic objectives into crisp values

r’ij (

α = 0.5). The weights are then applied to obtain the actual utilities of the players. To ensure that the utilities are expressed in a consistent, comparable and intuitive manner, the actual utilities of each player are averaged by their number of criteria. Finally, the relative average of all criteria relative to the average utility is considered the utility of the CV and economic objectives, as expressed in Equations (14) and (15).

where

ave(

Ji) represents the average of all solution values in the criterion

j,

jp and

jE denote the CV and economic objective, while

r’

j(CS

i) is the crisp value of the criterion

j in solution

i.

Based on the utility function, the normalized rough values of each solution are adopted to obtain the CV and economic utilities of the various conceptual solutions. These utilities are then used to construct the utility matrix presented in

Table 4.

Step 3. Finding the optimal allocation of utilities: in a coalitional game, the players cooperate to maximize the utility of the coalition and their personal utility, as well as obtain a practical allocation of utilities (i.e., Shapley values). In the current context, the CV and economic objectives form a coalition

N that attempts to maximize coalitional utility, where

N = {P, E}. Three possible non-empty coalitions

c exist: {P}, {E}, and {P, E}. To ensure that all players gain utility by cooperating with each other, instead of abandoning the coalition to form single coalitions (such as {P} or {E}), a pessimistic standard [

25,

49] was adapted to define the characteristic function that calculates the coalitional utility

v({

c}) of each player, as expressed in Equation (16). This approach ensures that coalitional utility is maximized if the players cooperate with each other, regardless of the strategy adopted by the coalition {

c}.

where

c represents the players P and E.

The coalition {P, E}, which exists if the players are cooperating, has the characteristic function

v({P, E}) = min{

UP +

UE}. Therefore, coalitional utility is maximized if the CV and economic players (P and E) cooperate with each other. This also implies that the coalition will still maximize the utility of each player despite their conflicting interests. The Shapley value is defined as

φ(

v) = (

φ1(

v),

φ2(

v), ...,

φL(

v)), and it is the optimal allocation of player utilities that will optimize the overall utility of the coalition. Because

L is 2,

φ(

v) = (

φP(

v),

φE(

v)). In other words, the Shapley value balances the interests of the solution’s CV and economic objectives to provide the optimal allocation of utilities that maximizes coalitional and player utility in a competitive environment, as expressed in Equation (17). In addition, the Shapley value can be regarded as the expectation of each player’s utility in the overall coalition utility, thereby reflecting the importance degree of different players on the overall interest. The Shapley value is proportional to the contribution of a player to the designed value of the solution, as well as the influence of the player on the coalition’s overall utility.

where

S is an arbitrary subset of coalition

N that does not contain

c, |

S| is the number of players included in

S,

v = (

S∪{

c}) represents the coalition utility when

S and the game player

c cooperate, and

d represents the number of players.

Step 4. Ranking solutions based on their Shapley values: Equation (18) is adopted to compute the optimal expected ratio of the players, (

φP(

v),

φE(

v)). The deviation function [

50] is then used to compute the deviation of all solutions from this ratio. The solution with the smallest deviation is the design that maximizes the overall utility of the PSS; hence, it is the optimal solution.

φP(

v) and

φE(

v) represent the optimal balance between CV and economic objectives, respectively, and they ensure that the CV requirements will be satisfied with minimal losses in economic value. This will provide a fresh perspective for designers and enterprises, as it was impossible to evaluate the product-service value and cost during the early design phase. Moreover, the relative importance between the intrinsic service value and economic objectives of the scheme can be mined without auxiliary functions or parameters because the Shapley values were computed from the evaluation data of the initial solutions. Hence, this approach improves the objectivity of the decision.

where

UE(Sch

j) and

UT(Sch

j) are the economic and technical utilities of solution

j,

D(CS

i) represents the deviation of solution

i from the optimal distribution of utilities, and

φ(

v) = (

φP(

v),

φE(

v)).