Abstract

Most regulations only allow the use of the coarse fraction of recycled concrete aggregate (RCA) for the manufacture of new concrete, although the heterogeneity of RCA makes it difficult to predict the compressive strength of concrete, which is an obstacle to the incorporation of RCA in concrete production. The compressive strength of recycled aggregate concrete is closely related to the dosage of its constituents. This article proposes a novel artificial neural network (ANN) model to predict the 28-day compressive strength of recycled aggregate concrete. The ANN used in this work has 11 neurons in the input layer: the mass of cement, fly ash, water, superplasticizer, fine natural aggregate, coarse natural or recycled aggregate, and their properties, such as: sand fineness modulus of sand, water absorption capacity, saturated surface dry density of the coarse aggregate mix and the maximum particle size. Two training methods were used for the ANN combining 15 and 20 hidden layers: Levenberg–Marquardt (LM) and Bayesian Regularization (BR). A database with 177 mixes selected from 15 studies incorporating RCA were selected, with the aim of having an underlying set of data heterogeneous enough to demonstrate the efficiency of the proposed approach, even when data are heterogeneous and noisy, which is the main finding of this work.

1. Introduction

Concrete is the second-most consumed material globally (after water). Every year more than 10 billion tons of concrete are used, and its production will increase between 12–23% until 2050 [1]. The production of one cubic meter of concrete emits between 0.2–0.4 tons of CO2 [2] which represents 8% of global CO2 emissions [3]. Furthermore, concrete is made up of aggregates (80% by weight), extracted mostly from alluvial deposits or quarries, which implies a high consumption of nonrenewable natural resources. The natural aggregates required to manufacture concrete could reach 60 billion tons in 2030 [4]. For all these reasons, concrete is considered an environmentally unfriendly material. At the end of their useful life, concrete structures are demolished, generating concrete waste with a high potential to be recycled [5].

One of the possible ways to reduce the carbon footprint and environmental impact of concrete is the replacement of natural aggregates (NA) with recycled concrete aggregates (RCA) [6]. In this way, it is possible to reduce the consumption of natural aggregates, avoid landfilling of concrete waste and promote the new paradigm of circular economy. RCAs are mainly composed of concrete and natural stone particles (>90% by weight).

Concrete particles are composed of natural aggregates covered with old mortar and cement paste. This layer is called attached mortar and represent between 20–30% of the RCA volume. The RCA properties are closely related to the type and quality of the attached mortar paste, which shows higher porosity, heterogeneity, and fragility in the interfacial transition zone [7,8] than natural aggregate. The mortar paste also shows tiny cracks that develop during the crushing process. Most of the studies relate the worst physical–mechanical and chemical properties of RCA with the presence of attached mortar paste [9]. RCA show a lower density, higher water absorption and less resistance to fragmentation than the NA [10]. From a chemical point of view, RCA show a higher number of sulfates and soluble salts than natural aggregates [11].

Most regulations only allow the use of the coarse RCA fraction for the manufacture of concrete [12]. The substitution of NA by RCA normally leads to a reduction in the mechanical properties of concrete (compressive and tensile strength, modulus of elasticity and abrasion resistance). Compressive strength at 28 days is the most representative property for evaluating the mechanical performance of concrete [5]. The compressive strength of concrete has been used in models to predict the modulus of elasticity and its evolution over time [13]. Additionally, the elastic modulus plays a significant role in the dynamics of Reinforced and Prestressed Concrete structures [14]. The increase in RCA content and water-to-cement ratio impairs the durability properties of concrete, such as water absorption by immersion and water absorption by capillarity, chloride penetration resistance, carbonation depth, frost resistance and acid resistance. From a rheological point of view, the shrinkage and creep increase [15,16]. The compressive strength is one of the parameters to be considered by the RILEM Technical Committee TC-242-MDC to predict creep, drying shrinkage and autogenous shrinkage of normal and high-strength concrete with multidecade applicability [17]. In order to produce a more durable recycled aggregate concrete it is suggested to use pozzolanic materials and CO2 treatment prior to use in concrete [15].

The compressive strength of concretes made with recycled aggregates is closely related to the dosage of its constituents. The compressive strength of concrete depends mainly on the amount of cement, the water-to-cement ratio, the amount of sand and coarse aggregates, the use of additives and additions, the percentage of incorporation and the moisture conditions of the RCA [18]. The quality of the primitive concrete (high, medium or low strength) determines the water absorption capacity and the density of the RCA particles, which affects the compressive strength of the new concrete [19].

In this sense, most studies on the use of RCA in the manufacture of concrete show that the incorporation of the coarse fraction of RCA reduces the compressive strength values [20], although in some cases the values of the reference concrete are maintained [21]. Silva et al. [20] found that the incorporation of 100% coarse RCA reduces compressive strength by approximately 50%. Limbachiya et al. [22] found no differences if the percentage of substitution of NA for RCA was less than 30%. In this context, several authors have demonstrated the usefulness of RCA to obtain concretes good enough for construction purposes, but the heterogeneity of the materials used, and the diversity of the variables considered to estimate the compressive strength make it difficult to create a general way to estimate a priori the compressive strength of the resulting concrete, which complicates the generalization of the use of this type of concrete. So, it is necessary to explore the possibility to obtain good estimates of compressive strength without having to make individual tests for each one of the possible combinations, type of constituent and range of the physical properties of the materials used. In this way, Artificial Intelligence (AI) methods have been shown to be useful in this and other fields.

AI methods are useful to predict concrete parameters and they have been widely used in the literature. Recently, Artificial Neural Networks (ANN) have been used for estimating compressive strength of concrete [23,24] as well as other properties, since it is a powerful method for dealing with multivariable problems and generating easy-to-use models, even when the number of inputs is large. Artificial intelligence methods have been shown to be more accurate than multiple regression models (MLR) in predicting the compressive strength of concrete. For example, Patil et al. [25] have recently proposed an MLR to predict the 28-day compressive strength, taking into account the quantity of cement, natural fine aggregates, coarse recycled concrete aggregates, water, water-to-cement ratio, and the following aggregate properties: water absorption, specific gravity, aggregate impact value and aggregate abrasion value, finding R2 values less than 0.55 in the training phase and less than 0.75 in the test phase, which highlights the invalidity of the MLR method to predict the mechanical properties of concretes. These same authors also proposed an ANN model with a better accuracy than the MLR model. The R2 value of the ANN models was more than 0.8 in the training phase and more than 0.9 in the test phase, which shows that the ANN is a good alternative to predict the mechanical properties of RCA concrete.

Özcan et al. [26] compared the accuracy of obtaining the compressive strength of silica-fume concrete with Artificial Neural Networks (ANN) and Fuzzy Logic (FL). They used 48 different samples with four water-to-cement ratios, three cement dosages and three partial silica-fume replacement ratios, obtaining better results with ANN than with FL. Nevertheless, they concluded that ANN and FL can be alternative methods to predict compressive strength, since the number of samples as well as the number of input parameters used were small. In a similar way, Nazari and Riahi [27] compared ANN and Genetic Programming (GEP) for predicting split tensile strength and percentage of water absorption of concretes containing TiO2 nanoparticles. They used 144 samples with 16 mixture proportions and cement content, nanoparticle content, aggregate type, water content, amount of superplasticizer, type of curing medium and age of curing were used as input variables. They obtained better results with ANN, but those obtained with GEP were reasonably accurate too, while this a simpler method. In a similar way, Nazari [28] modeled, by means of gene expression programming, the compressive strength of geopolymers produced by Portland cement as an aluminosilicate source. The main factors considered were NaOH concentration, water-glass-to-NaOH-weight ratio, alkali-activator-to-cement-weight ratio, oven curing temperature, oven curing time, and water curing regime, with each one of them at four levels. They obtained good results. Castelli et al. [29] used genetic programming with geometric, semantic, genetic operators to predict compressive strength of high-performance concrete using quantities of cement, fly ashes, blast furnace slag, water, superplasticizer, coarse aggregate, fine aggregate, and age of testing as input variables, outperforming the results previously obtained with standard genetic programing.

González-Taboada et al. [30] predicted compressive strength, modulus of elasticity, and splitting tensile strength of recycled concrete considering the recycled percentage, the quality of the recycled aggregates, and the production method. They analyzed 1831 samples obtained from 81 studies by means of multivariable regression and genetic programming, obtaining good enough results in comparison with those previously identified. Finally, Gholampour et al. [31] used gene expression programming for predicting mechanical properties of recycled aggregate concrete. As well as the above-mentioned authors, many samples were extracted from the literature. They proposed expressions for predicting compressive strength, elastic modulus, flexural strength, and splitting tensile strength, obtaining results comparable with the previously known models.

Recently, ANN have been used for estimating compressive strength of concrete [23,24] as well as other properties, since it is a powerful method for dealing with multivariable problems and giving easy-to-use models, even when the number of inputs is large. So, Moradi et al. [32] tried to predict the compressive strength of concrete containing metakaoline, extracting data from the literature in a total of 239 samples (in two sets of 105 and 134 samples, respectively). Results showed MSE of 0.002 and 0.0017, and their predicted data was within ±20% of the sample data. In the same way, Kostić and Vasović [33] proposed a model estimating compressive strength of concrete by means of neural networks. They used 75 samples with various water-to-cement ratios, and their compressive strength was determined at different ages of 7, 20 and 32 days. They only used water-to-cement ratio, age, and number of freeze/thaw cycles as input variables, obtaining a coefficient of determination of R2 > 0.87 and maintaining predicted data in ±15% of sample data. Table 1 summarize the recent approaches to predict concrete’s parameters by means of AI techniques. As Table 1 shows, there is a variety of papers searching for estimating different parameters of concretes based on their constituents (especially compressive strength), but there is no consensus about the number of subjacent input parameters to be considered, neither the number of previous tests to be carried out in order to obtain good predictions. Thus, there is still a question to be answered: whether there is a possibility of obtaining good predictions even when using a heterogeneous set of samples and a wide range of input values.

Table 1.

Summary of AI approaches for estimating concrete parameters.

In this way, and according to the above-mentioned literature, several works study the usefulness of RCA as a good alternative to replace NA. Nevertheless, the variety of kind of materials used, and the wide range of their physical properties’ values, make it difficult to obtain an accurate prediction of the compressive strength without the necessity of making individual and costly tests. This paper is focused on searching for an easy way to obtain a priori a prediction of the compressive strength of concretes made using RCA, even though the kind of constituents are heterogeneous and difficult to be classified, with the aim of providing a good working tool to concrete manufacturers. With this aim, several samples have been taken out from the literature, using different natural and recycled aggregates ratios from a variety of sources, to obtain a good estimation of 28-day compressive strength in the newly proposed model.

2. Materials and Methods

A database with 177 mixes selected from 15 studies on the effect of incorporating RCA on the compressive strength of concrete were selected (Appendix A). The compressive strength of concrete is the strength of hardened concrete measured from cylindrical specimens (15 × 30 cm) or cubic specimens (10 × 10 cm) of concrete in a compression machine. The compressive strength of concrete is calculated by dividing the breaking load by the cross-sectional area that resists the load, using the megapascal (MPa) as the unit of measure. The following standards have been used in the referenced studies: ACTM C39 (Standard method for compressive strength of cylindrical concrete specimens), BS 1881-Part 116 (Testing concrete part 116: method for determination of compressive strength of concrete cubes) and EN 12390-3 (Testing hardened concrete—Part 3: compressive strength of test specimens).

In accordance with González-Taboada et al. [30] all RCA showed a water absorption capacity under 8.5%. The amount of components in a concrete mix, such as the mass of cement (C), fly ash (FA), water (W), superplasticizer (SP), fine natural aggregate (FNA), coarse natural or recycled aggregate (CNA, RCA) and their properties, such as: sand fineness modulus of sand (FM of FNA), water absorption capacity (WA), saturated surface dry density of the coarse aggregate mix (SSD), and maximum particle size of coarse aggregate (TM), are the main factors selected as input parameters used to construct the ANN models. The 28-day compressive strength was the only output value considered in this study. All the results were converted into equivalent 15 × 30 cm cylindrical compressive strength [24]. Table 2. summarizes the properties of constituents used (detailed in Appendix A), their ranges, the amount of data in every one of them, mean and standard deviation. So, the set of data chosen for making the estimations is heterogeneous enough for the purposes of the proposed approach. The RILEM Technical Committee TC-242-MDC [17] also recommends considering all admixtures and reactive additives such as fly ash separately, to predict the creep, drying shrinkage and autogenous shrinkage of normal and high-strength concrete with multidecade applicability. This same technical committee highlighted the importance of the type of aggregate in the prediction of shrinkage and creep.

Table 2.

Summarized values of the dataset used.

Artificial Neural Networks have been shown to be useful to obtain good predictions in nonlinear processes and have been successfully used in several fields as control, for pattern recognition, learning, medical diagnosis, and a wide range of engineering applications, among others [40], and they present a special effectiveness when data are incomplete and noisy. In general, an ANN has three layers: and input layer, where input parameters are represented; several hidden layers, where data are processed; and an output layer, where output data are presented. Each one of the elements in the layers is called a neuron. The layers are interconnected by means of weights that must be modified along a training process, to obtain better fitting between the previously observed data and those generated in the output layer.

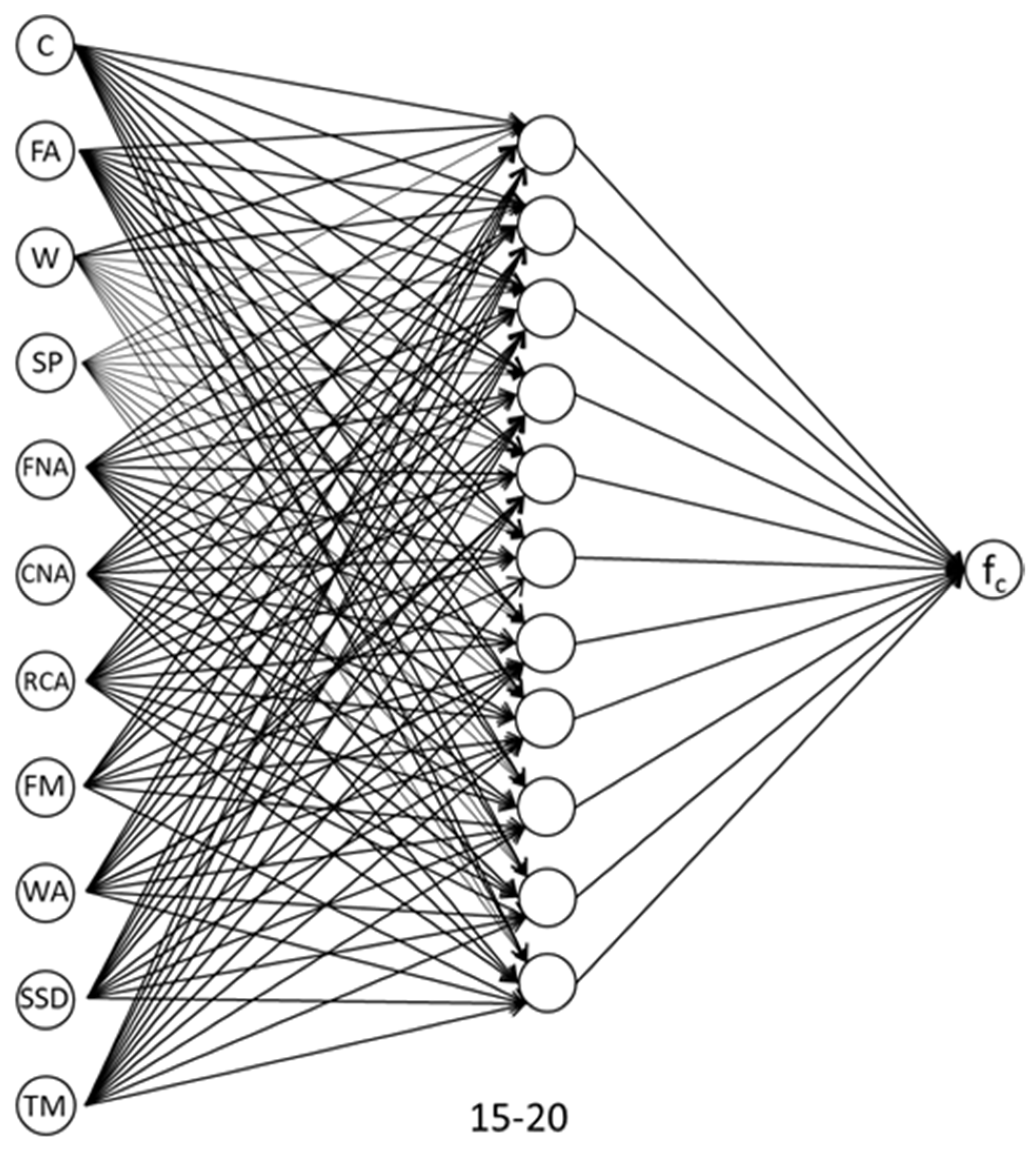

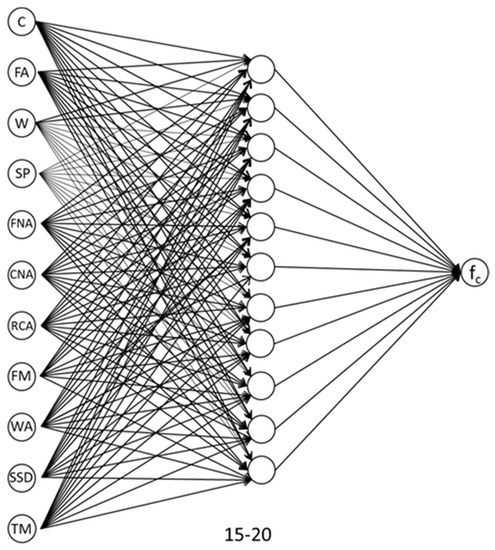

The Artificial Neural Network used in this work has 11 neurons in the input layer and only 1 in the output layer, and four sets of trainings have been carried out combining 15 and 20 hidden layers (Figure 1.) with the training methods of Levenberg–Marquardt (LM) and Bayesian Regularization (BR). The first one, LM, is recommended for nonlinear optimization problems and it is supposed to display a better performance than the traditional Gauss–Newton Method. The second one, BR, gives a better generalization when data are difficult [41]. So, four training processes have been carried out to obtain the best possible fitting of the synaptic weights. For the training process of the ANN, data have been divided into three sets: a training set of 123 datapoints (70%), a validation set of 27 datapoints (15%), and a testing set of 27 datapoints (15%).

Figure 1.

ANN architecture followed in the tests.

Finally, to delimit the errors existing between estimated and observed data, and consequently choose the best option among the four tested, we used the mean absolute error (MAE) Equation (1), complemented with the standard deviation, the mean absolute percentage error (MAPE) Equation (2), and the root mean square error (RMSE) Equation (3), as well as the correlation coefficient (R2):

where t and o are the predicted and observed data, respectively, and n is the total amount of data.

In the same way, the results obtained with the ANN have been compared with others from classical regression methods, such as Gaussian Process Regression (Matern 5/2), Support-Vector Machines (SVM), and Linear Regression.

Additionally, to determine the impact of the input parameters on the compressive strength values, new ANN have been carried out eliminating some of them. The following alternatives have been proposed: (i) unify the amount of cement (C) and fly ash (FA) in a single input parameter called the cementitious binder [42]; (ii) do not consider the superplasticizer input (SP), since the use of superplasticizer significantly reduces the amount of water (W) in the mix and both parameters could be related [43]; (iii) within the properties of the aggregates, the fineness modulus (FM) that indicates the average size of the sand particles; and iv) the maximum particle sizes ™ of the coarse fractures may be candidates not to be taken into account in the new ANN.

3. Results and Discussion

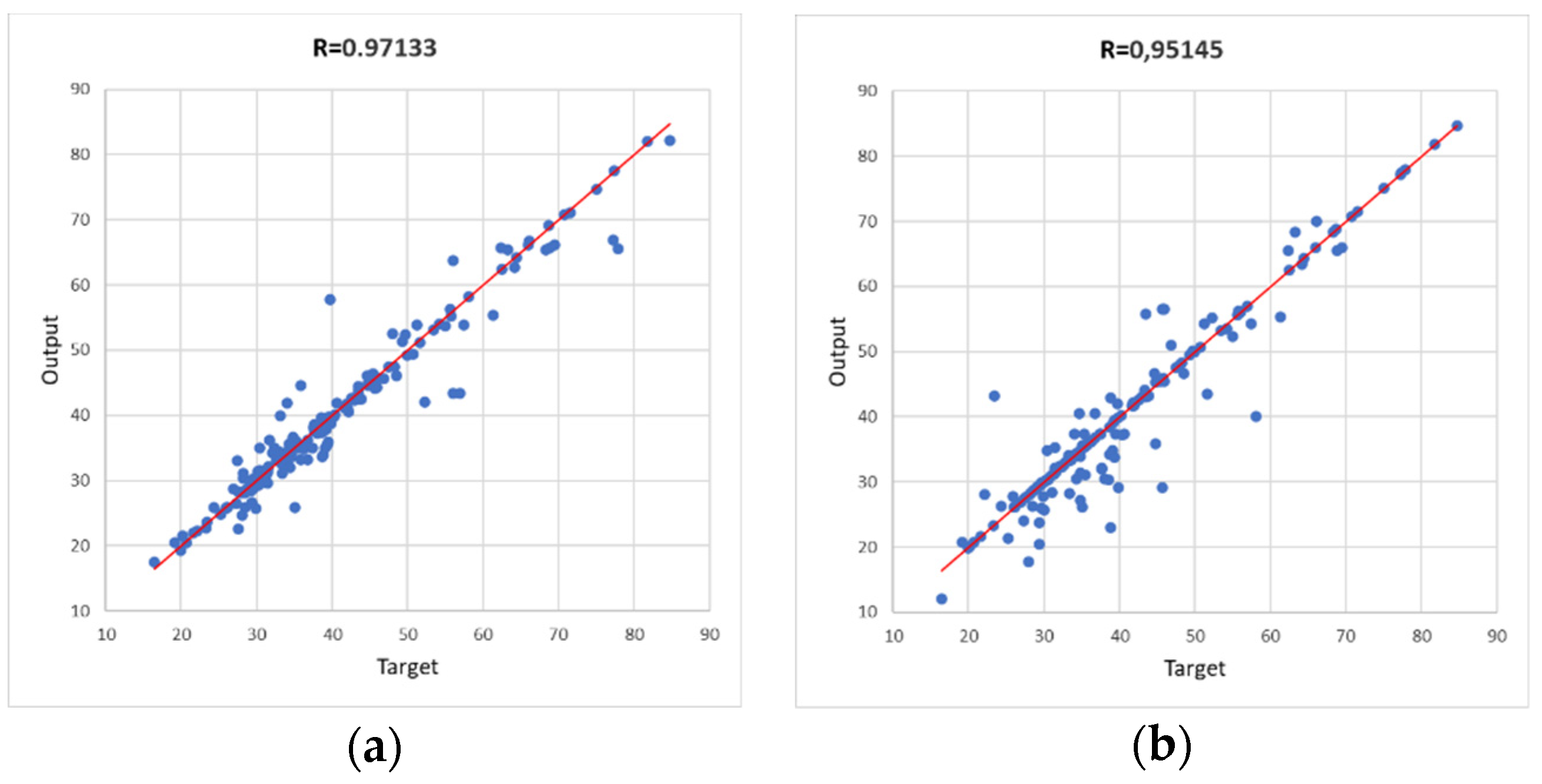

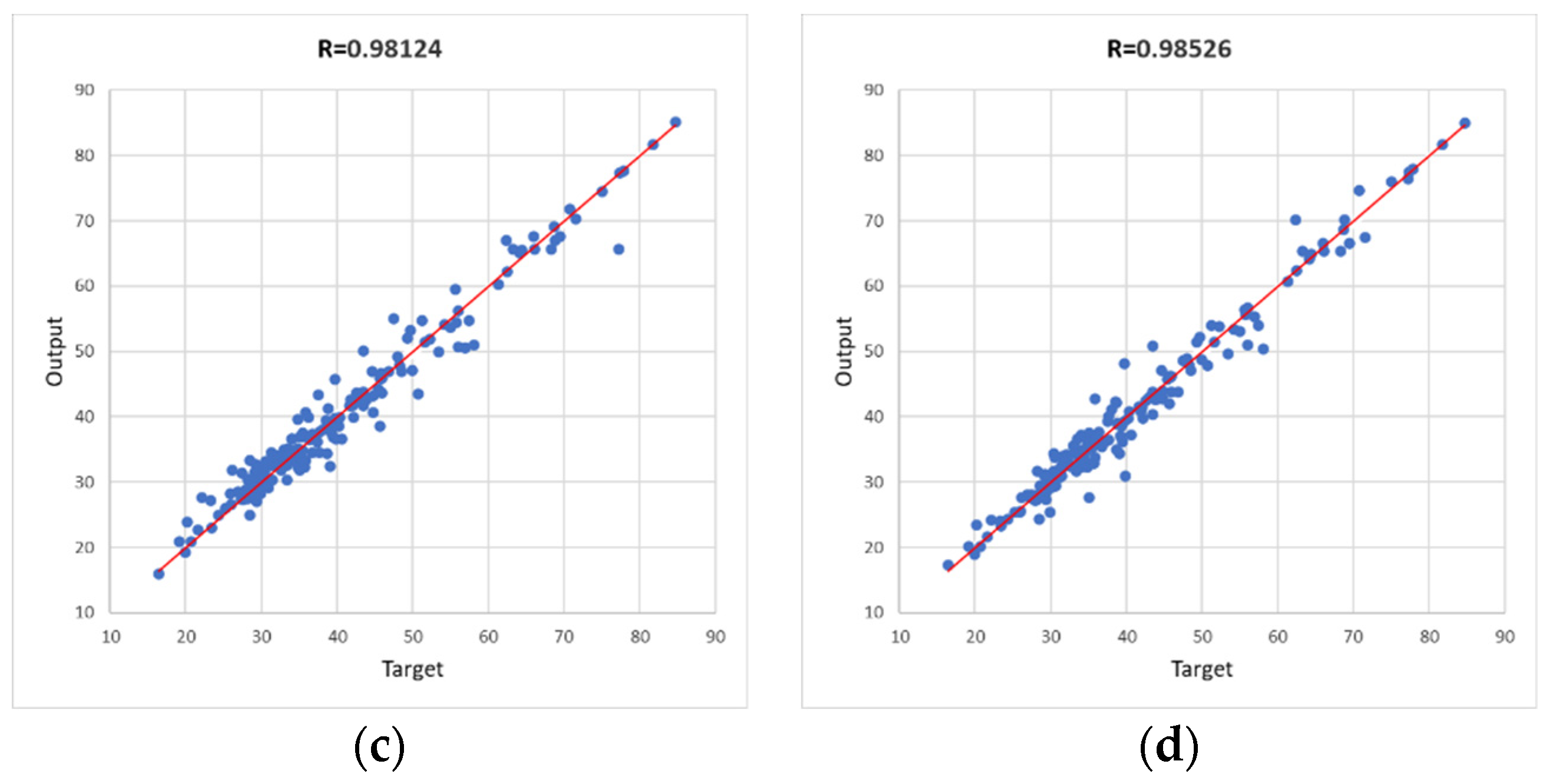

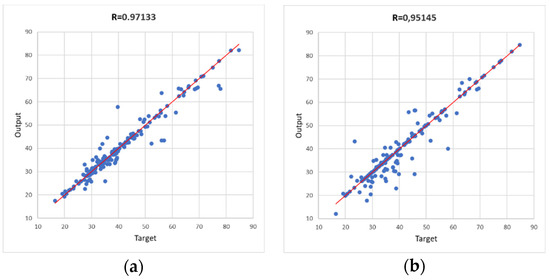

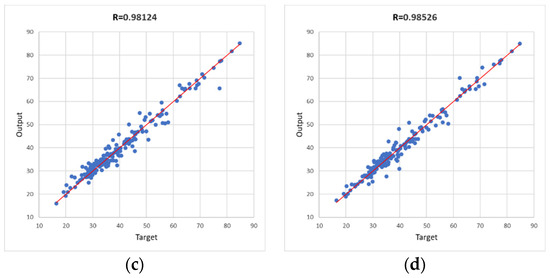

The results obtained with the ANN are good in all cases tested and have been summarized in Table 3 and in Figure 2 and Figure 3.

Table 3.

Summary of results obtained in ANN trainings.

Figure 2.

Correlations between target and output data for the four cases tested. (a): LM-15; (b): LM-20; (c) BR-15; (d): BR-20.

Figure 3.

Distribution of errors for the training methods tested. (a): LM-15; (b): LM-20; (c) BR-15; (d): BR-20.

All the results obtained are good enough for estimating the compression strength of concrete with recycled aggregates. Furthermore, the BR training method has shown to be better than LM for obtaining predicted data perhaps due to the heterogeneity of the input data, which is justified by the different dosages and properties of the tested concretes. Especially, for the case of BR-20, 170 of 177 predicted compression resistances (96.05%) fall within a difference interval from −3 to +5 units away from target data, while in the case of BR-15, 176 outputs are between −7 and +8. In the case of LM-15, 170 outputs cover a range from −8 to +7 units of differences from targets, and in the case of LM-20, 160 outputs cover a range from −5 to +6. The test carried out with 20 hidden layers and Bayesian Regularization training method has been shown to be the best for all the metrics calculated.

Duan et al. [24] also developed an ANN model to predict the 28-day compressive strength of recycled aggregate concrete. These authors used 14 inputs: the mass of water, cement, sand, natural coarse aggregate, recycled coarse aggregate used in the mix designs, water-to-cement ratio of concrete, fineness modulus of sand, water absorption of the aggregates, saturated surface-dried (SSD) density, maximum size, and impurity content of recycled coarse aggregate, the replacement ratio of recycled coarse aggregate by volume, and the coefficient of different concrete specimens. All of these parameters were the same as those used in this study, except the impurity content of recycled coarse aggregate, the replacement ratio of recycled coarse aggregate by volume and the coefficient of different concrete specimens. The results obtained in the training set (146 sets) were: R2 = 0.998; RMSE = 1.7958 and MAPE = 0.2622, while in the testing set (22 sets) they were R2 = 0.9955; RMS = 3.6804 and MAPE = 1.6777. From an engineering point of view, the 14-input ANN model does not present significant differences with respect to the 11-input ANN models proposed in this study.

In order to compare the results obtained with the ANN, Gaussian Process Regression, Matern 5/2 (GPR); Support-Vector Machines (SVM); and Linear Regressions (LR) have been carried out on the same data using MATLAB. The results of each of these methods appear in Table 4. where the superiority of ANN over the other methods is clearly revealed.

Table 4.

Results of regressions methods.

Once it is clear that ANN provides the best results for these kinds of data, there is still a question to be answered: whether it is possible to simplify the process of obtaining compressive strength predictions while eliminating some of the input data. For that purpose, four analyses have been carried out with the same ANN: (i) substituting C and FA by their sum; (ii) eliminating SP; (iii) eliminating FM of FNA; and (iv) eliminating TM. The results of each one of these new tests are shown in Table 5.

Table 5.

Results of the simplified ANNs.

In all the new cases tested, the results are worse than those obtained with the complete ANN. Only in the case (iv) of eliminating the maximum particle size of coarse aggregate (TM), are the results similar to those of the complete ANN. Regardless, the difference seems not to be enough to opt for this set of data, since it does not simplify the model substantially.

4. Conclusions

A novel ANN model has been presented in this paper for predicting compressive strength of concrete made with recycled concrete aggregates. The heterogeneity of RCA makes it difficult to predict the compressive strength of new concrete, which is an obstacle to the incorporation of this kind of aggregate in concrete production. Nevertheless, it has been proved that it is possible to obtain good predictions of the final 28-day compressive strength using the composition as input variables. In this case, 11 inputs variables have been used: the mass of cement (C), fly ash (FA), water (W), superplasticizer (SP), fine natural aggregate (FNA), coarse natural or recycled aggregate (CAN, RCA) and their properties, such as: sand fineness modulus of sand (FM of FNA), water absorption capacity (WA), saturated surface dry density of the coarse aggregate mix (SSD), maximum particle size of coarse aggregate (TM), and the resulting ANN, with 20 hidden layers, has shown to be accurate enough for a set of real data. Based on the results obtained, the best option is the Bayesian Regularization and 20 hidden layers. Additional tests attempting to analyze other regression methods, and simplified ANNs eliminating some inputs variables from the study, also gave good results, although the first-designed ANN was shown to obtain the best results. Furthermore, comparing with other studies aiming to obtain predictions of performance of concretes containing recycled aggregates [24,25], the results are similar or better in terms of accuracy, but the heterogeneity of data used in this study is an important factor, since results have been better or equivalent, even using a smaller amount of input data.

The proposed ANN model allows us to predict with enough accuracy the compressive strength value of a concrete from 11 input parameters, which will allow manufacturers to save time and laboratory testing when proposing new concrete dosages from recycled concrete aggregates of different sources and physical–mechanical properties.

Author Contributions

Conceptualization, L.S.-M. and J.R.J.; methodology, J.R.J.; software, L.S.-M.; validation, L.S.-M. and L.G.-H.; investigation, J.R.J.; resources, L.S.-M. and J.R.J.; data curation, D.S.-M.; writing—original draft preparation, D.S.-M.; writing—review and editing, L.S.-M. and J.R.J.; supervision, L.G.-H.; project administration, L.S.-M. and J.R.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are included in the Appendix A.

Acknowledgments

The authors thank C.S. Poon (Department of Civil and Structural Engineering, Hong Kong Polytechnic University, Kowloon, Hong Kong, China) for their collaboration and input of the necessary data to carry out this research. D.Suescum-Morales also acknowledges funding from Ministerio de Educación, Cultura y Deporte. Spain FPU 17/04329.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Data base with 177 mixes selected from 15 studies on the effect of incorporating RCA.

Table A1.

Data base with 177 mixes selected from 15 studies on the effect of incorporating RCA.

| N° | C | FA | W | SP | FNA | CNA | RCA | FM of FNA | WA | SSD | TM | Fc | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kg | kg | kg | % | kg | kg | kg | % | g/cm3 | mm | MPa | |||

| 1 | 500 | 0 | 150 | 0.1 | 725 | 1087 | 0 | 2.11 | 1.1 | 2.62 | 10 | 77.2 | [44] |

| 2 | 400 | 100 | 150 | 0.16 | 707 | 1087 | 0 | 2.11 | 1.1 | 2.62 | 10 | 75.04 | |

| 3 | 637 | 0 | 150 | 2.89 | 711 | 936 | 0 | 2.16 | 1.1 | 2.62 | 10 | 77.92 | [45] |

| 4 | 475 | 158 | 150 | 2.89 | 681 | 924 | 0 | 2.16 | 1.1 | 2.62 | 10 | 84.72 | |

| 5 | 347 | 283 | 148 | 3.76 | 639 | 920 | 0 | 2.16 | 1.1 | 2.62 | 10 | 71.52 | |

| 6 | 702 | 0 | 135 | 5 | 641 | 949 | 0 | 2.16 | 1.1 | 2.62 | 10 | 77.44 | |

| 7 | 512 | 173 | 133 | 5.07 | 620 | 932 | 0 | 2.16 | 1.1 | 2.62 | 10 | 81.84 | |

| 8 | 372 | 305 | 130 | 4.99 | 608 | 927 | 0 | 2.16 | 1.1 | 2.62 | 10 | 70.8 | |

| 9 | 390 | 0 | 195 | 0 | 768 | 917 | 0 | 2.11 | 1.1 | 2.62 | 20 | 28.64 | [46] |

| 10 | 312 | 78 | 195 | 0 | 615 | 1143 | 0 | 2.11 | 1.1 | 2.62 | 20 | 31.44 | |

| 11 | 500 | 0 | 150 | 0.5 | 758 | 927 | 0 | 2.11 | 1.1 | 2.62 | 20 | 68.72 | [47] |

| 12 | 400 | 100 | 150 | 0.8 | 618 | 1147 | 0 | 2.11 | 1.1 | 2.62 | 20 | 66.16 | |

| 13 | 350 | 150 | 150 | 0.7 | 615 | 1143 | 0 | 2.11 | 1.1 | 2.62 | 20 | 64.16 | |

| 14 | 300 | 200 | 150 | 0.7 | 613 | 1139 | 0 | 2.11 | 1.1 | 2.62 | 20 | 61.36 | |

| 15 | 390 | 0 | 195 | 0 | 768 | 917 | 0 | 2.11 | 1.1 | 2.62 | 20 | 28.64 | |

| 16 | 273 | 117 | 195 | 0 | 626 | 1133 | 0 | 2.11 | 1.1 | 2.62 | 20 | 31.44 | |

| 17 | 234 | 156 | 195 | 0 | 625 | 1129 | 0 | 2.11 | 1.1 | 2.62 | 20 | 29.52 | |

| 18 | 350 | 115 | 175 | 1.6 | 785 | 735 | 0 | 2.64 | 0.85 | 2.63 | 20 | 38.8 | [48] |

| 19 | 270 | 145 | 160 | 2.23 | 870 | 750 | 0 | 2.64 | 0.85 | 2.63 | 20 | 51.6 | |

| 20 | 500 | 0 | 150 | 1.5 | 724 | 1086 | 0 | 2.16 | 1.1 | 2.62 | 10 | 69.44 | [49] |

| 21 | 425 | 75 | 150 | 1.5 | 700 | 1086 | 0 | 2.16 | 1.1 | 2.62 | 10 | 68.8 | |

| 22 | 375 | 125 | 150 | 1.85 | 683 | 1086 | 0 | 2.16 | 1.1 | 2.62 | 10 | 68.32 | |

| 23 | 275 | 225 | 150 | 2.1 | 650 | 1086 | 0 | 2.16 | 1.1 | 2.62 | 10 | 57.44 | |

| 24 | 225 | 275 | 150 | 2.6 | 634 | 1086 | 0 | 2.16 | 1.1 | 2.62 | 10 | 45.92 | |

| 25 | 400 | 0 | 160 | 1 | 710 | 1157 | 0 | 2.16 | 1.1 | 2.62 | 20 | 48.56 | |

| 26 | 340 | 60 | 160 | 1.1 | 690 | 1157 | 0 | 2.16 | 1.1 | 2.62 | 20 | 44.8 | |

| 27 | 300 | 100 | 160 | 1.2 | 660 | 1157 | 0 | 2.16 | 1.1 | 2.62 | 20 | 39.44 | |

| 28 | 220 | 180 | 160 | 1.3 | 634 | 1157 | 0 | 2.16 | 1.1 | 2.62 | 20 | 35.12 | |

| 29 | 180 | 220 | 160 | 1.6 | 621 | 1157 | 0 | 2.16 | 1.1 | 2.62 | 20 | 29.84 | |

| 30 | 410 | 0 | 205 | 0 | 609 | 1132 | 0 | 2.16 | 1.1 | 2.62 | 20 | 40.64 | |

| 31 | 348.5 | 61.5 | 205 | 0 | 589 | 1132 | 0 | 2.16 | 1.1 | 2.62 | 20 | 39.12 | |

| 32 | 307.5 | 102.5 | 205 | 0 | 576 | 1132 | 0 | 2.16 | 1.1 | 2.62 | 20 | 33.36 | |

| 33 | 225.5 | 184.5 | 205 | 0 | 549 | 1132 | 0 | 2.16 | 1.1 | 2.62 | 20 | 28.48 | |

| 34 | 184.5 | 225.5 | 205 | 0 | 536 | 1132 | 0 | 2.16 | 1.1 | 2.62 | 20 | 19.2 | |

| 35 | 500 | 0 | 150 | 1.5 | 724 | 1086 | 0 | 2.16 | 1.1 | 2.62 | 10 | 66 | [49] |

| 36 | 425 | 75 | 150 | 1.5 | 700 | 1086 | 0 | 2.16 | 1.1 | 2.62 | 10 | 62.32 | |

| 37 | 375 | 125 | 150 | 1.85 | 683 | 1086 | 0 | 2.16 | 1.1 | 2.62 | 10 | 63.28 | |

| 38 | 275 | 225 | 150 | 2.1 | 650 | 1086 | 0 | 2.16 | 1.1 | 2.62 | 10 | 51.2 | |

| 39 | 225 | 275 | 150 | 2.6 | 634 | 1086 | 0 | 2.16 | 1.1 | 2.62 | 10 | 45.68 | |

| 40 | 400 | 0 | 160 | 1 | 710 | 1157 | 0 | 2.16 | 1.1 | 2.62 | 20 | 44.64 | |

| 41 | 340 | 60 | 160 | 1.1 | 690 | 1157 | 0 | 2.16 | 1.1 | 2.62 | 20 | 35.84 | |

| 42 | 300 | 100 | 160 | 1.2 | 660 | 1157 | 0 | 2.16 | 1.1 | 2.62 | 20 | 35.28 | |

| 43 | 220 | 180 | 160 | 1.3 | 634 | 1157 | 0 | 2.16 | 1.1 | 2.62 | 20 | 26.16 | |

| 44 | 180 | 220 | 160 | 1.6 | 621 | 1157 | 0 | 2.16 | 1.1 | 2.62 | 20 | 25.92 | |

| 45 | 410 | 0 | 205 | 0 | 609 | 1132 | 0 | 2.16 | 1.1 | 2.62 | 20 | 34.08 | |

| 46 | 348.5 | 61.5 | 205 | 0 | 589 | 1132 | 0 | 2.16 | 1.1 | 2.62 | 20 | 30.48 | |

| 47 | 307.5 | 102.5 | 205 | 0 | 576 | 1132 | 0 | 2.16 | 1.1 | 2.62 | 20 | 28.16 | |

| 48 | 225.5 | 184.5 | 205 | 0 | 549 | 1132 | 0 | 2.16 | 1.1 | 2.62 | 20 | 24.32 | |

| 49 | 184.5 | 225.5 | 205 | 0 | 536 | 1132 | 0 | 2.16 | 1.1 | 2.62 | 20 | 20.72 | |

| 50 | 410 | 0 | 225 | 0 | 642 | 1048 | 0 | 2.11 | 1.1 | 2.62 | 20 | 38.88 | [50] |

| 51 | 410 | 0 | 225 | 0 | 642 | 840 | 204 | 2.11 | 1.62 | 2.61 | 20 | 36.24 | |

| 52 | 410 | 0 | 225 | 0 | 642 | 524 | 506 | 2.11 | 2.41 | 2.58 | 20 | 34 | |

| 53 | 410 | 0 | 225 | 0 | 642 | 210 | 814 | 2.11 | 3.22 | 2.56 | 20 | 31.36 | |

| 54 | 410 | 0 | 225 | 0 | 642 | 0 | 1017 | 2.11 | 3.77 | 2.54 | 20 | 29.68 | |

| 55 | 307.5 | 102.5 | 225 | 0 | 628 | 1048 | 0 | 2.11 | 1.1 | 2.62 | 20 | 37.68 | |

| 56 | 307.5 | 102.5 | 225 | 0 | 628 | 840 | 204 | 2.11 | 1.62 | 2.61 | 20 | 35.04 | |

| 57 | 307.5 | 102.5 | 225 | 0 | 628 | 524 | 506 | 2.11 | 2.41 | 2.58 | 20 | 34.24 | |

| 58 | 307.5 | 102.5 | 225 | 0 | 628 | 210 | 814 | 2.11 | 3.22 | 2.56 | 20 | 31.12 | |

| 59 | 307.5 | 102.5 | 225 | 0 | 628 | 0 | 1017 | 2.11 | 3.77 | 2.54 | 20 | 29.36 | |

| 60 | 410 | 0 | 225 | 0 | 642 | 0 | 1017 | 2.11 | 3.77 | 2.53 | 20 | 30.48 | [51] |

| 61 | 307.5 | 102.5 | 225 | 0 | 611 | 1048 | 0 | 2.11 | 1.11 | 2.62 | 20 | 34.88 | |

| 62 | 307.5 | 102.5 | 225 | 0 | 611 | 840 | 204 | 2.11 | 1.64 | 2.6 | 20 | 34.24 | |

| 63 | 307.5 | 102.5 | 225 | 0 | 611 | 524 | 506 | 2.11 | 2.44 | 2.58 | 20 | 33.36 | |

| 64 | 307.5 | 102.5 | 225 | 0 | 611 | 0 | 1017 | 2.11 | 3.77 | 2.53 | 20 | 29.44 | |

| 65 | 266.5 | 143.5 | 225 | 0 | 598 | 1048 | 0 | 2.11 | 1.11 | 2.62 | 20 | 32.56 | |

| 66 | 267.5 | 143.6 | 225 | 0 | 598 | 840 | 204 | 2.11 | 1.64 | 2.6 | 20 | 32.8 | |

| 67 | 268.5 | 143.7 | 225 | 0 | 598 | 524 | 506 | 2.11 | 2.44 | 2.58 | 20 | 29.68 | |

| 68 | 269.5 | 143.8 | 225 | 0 | 598 | 0 | 1017 | 2.11 | 3.77 | 2.53 | 20 | 20.16 | |

| 69 | 400 | 0 | 180 | 0 | 708 | 1108 | 0 | 2.11 | 1.11 | 2.62 | 20 | 53.44 | |

| 70 | 400 | 0 | 180 | 0 | 708 | 886 | 215 | 2.11 | 1.64 | 2.6 | 20 | 49.92 | |

| 71 | 400 | 0 | 180 | 0 | 708 | 554 | 538 | 2.11 | 2.44 | 2.58 | 20 | 45.44 | |

| 72 | 400 | 0 | 180 | 0 | 708 | 0 | 1075 | 2.11 | 3.77 | 2.53 | 20 | 41.68 | |

| 73 | 300 | 100 | 180 | 0 | 688 | 1108 | 0 | 2.11 | 1.11 | 2.62 | 20 | 43.52 | |

| 74 | 300 | 100 | 180 | 0 | 688 | 886 | 215 | 2.11 | 1.64 | 2.6 | 20 | 39.76 | |

| 75 | 300 | 100 | 180 | 0 | 688 | 554 | 538 | 2.11 | 2.44 | 2.58 | 20 | 35.44 | |

| 76 | 300 | 100 | 180 | 0 | 688 | 0 | 1075 | 2.11 | 3.77 | 2.53 | 20 | 31.6 | |

| 77 | 260 | 140 | 180 | 0 | 688 | 1108 | 0 | 2.11 | 1.11 | 2.62 | 20 | 36.72 | |

| 78 | 260 | 140 | 180 | 0 | 688 | 886 | 215 | 2.11 | 1.64 | 2.6 | 20 | 34.88 | |

| 79 | 260 | 140 | 180 | 0 | 688 | 554 | 538 | 2.11 | 2.44 | 2.58 | 20 | 32.32 | |

| 80 | 260 | 140 | 180 | 0 | 688 | 0 | 1075 | 2.11 | 3.77 | 2.53 | 20 | 30.64 | |

| 81 | 390 | 0 | 195 | 0 | 678 | 1107 | 0 | 2.11 | 1.12 | 2.62 | 20 | 46 | [11] |

| 82 | 390 | 0 | 195 | 0 | 678 | 527 | 539 | 2.11 | 2.56 | 2.57 | 20 | 42.24 | |

| 83 | 390 | 0 | 195 | 0 | 678 | 0 | 1078 | 2.11 | 4.01 | 2.52 | 20 | 39.2 | |

| 84 | 253.5 | 136.5 | 195 | 0 | 640 | 1107 | 0 | 2.11 | 1.12 | 2.62 | 20 | 34 | |

| 85 | 253.5 | 136.5 | 195 | 0 | 640 | 527 | 539 | 2.11 | 2.56 | 2.57 | 20 | 34.8 | |

| 86 | 253.5 | 136.5 | 195 | 0 | 640 | 0 | 1078 | 2.11 | 4.01 | 2.52 | 20 | 29.6 | |

| 87 | 380 | 0 | 190 | 0 | 687 | 1120 | 0 | 2.11 | 0.74 | 2.64 | 20 | 44.8 | |

| 88 | 380 | 0 | 190 | 0 | 687 | 0 | 1025 | 2.11 | 6.74 | 2.4 | 20 | 39.84 | |

| 89 | 380 | 0 | 190 | 0 | 687 | 0 | 1039 | 2.11 | 3.03 | 2.44 | 20 | 40.32 | |

| 90 | 380 | 0 | 190 | 0 | 687 | 0 | 1043 | 2.11 | 1.87 | 2.44 | 20 | 42.08 | |

| 91 | 355 | 0 | 195 | 0 | 690 | 1127 | 0 | 2.11 | 1.11 | 2.62 | 20 | 35.04 | [52] |

| 92 | 355 | 0 | 195 | 0 | 690 | 902 | 205 | 2.11 | 1.6 | 2.6 | 20 | 33.52 | |

| 93 | 355 | 0 | 195 | 0 | 690 | 564 | 543 | 2.11 | 2.41 | 2.57 | 20 | 30.56 | |

| 94 | 355 | 0 | 195 | 0 | 690 | 0 | 1085 | 2.11 | 3.76 | 2.52 | 20 | 29.2 | |

| 95 | 355 | 0 | 195 | 0 | 690 | 902 | 193 | 2.11 | 1.97 | 2.58 | 20 | 32.96 | |

| 96 | 355 | 0 | 195 | 0 | 690 | 564 | 520 | 2.11 | 3.44 | 2.52 | 20 | 29.12 | |

| 97 | 355 | 0 | 195 | 0 | 690 | 0 | 1038 | 2.11 | 5.96 | 2.42 | 20 | 27.44 | |

| 98 | 355 | 0 | 195 | 0 | 690 | 902 | 199 | 2.11 | 2.04 | 2.6 | 20 | 33.28 | |

| 99 | 355 | 0 | 195 | 0 | 690 | 564 | 534 | 2.11 | 3.6 | 2.55 | 20 | 30.24 | |

| 100 | 355 | 0 | 195 | 0 | 690 | 0 | 1068 | 2.11 | 6.23 | 2.48 | 20 | 28.48 | |

| 101 | 353 | 0 | 209 | 0 | 666 | 1093 | 0 | 2.11 | 1.24 | 2.62 | 20 | 36.8 | [8] |

| 102 | 353 | 0 | 206 | 0 | 661 | 864 | 216 | 2.11 | 2.34 | 2.57 | 20 | 34.4 | |

| 103 | 353 | 0 | 207 | 0 | 649 | 531 | 531 | 2.11 | 3.98 | 2.49 | 20 | 30.48 | |

| 104 | 353 | 0 | 209 | 0 | 625 | 0 | 1026 | 2.11 | 6.71 | 2.36 | 20 | 31.28 | |

| 105 | 353 | 0 | 214 | 0 | 667 | 1086 | 0 | 2.11 | 1.24 | 2.62 | 20 | 38.64 | [8] |

| 106 | 353 | 0 | 221 | 0 | 667 | 1080 | 0 | 2.11 | 1.24 | 2.62 | 20 | 32.16 | |

| 107 | 353 | 0 | 217 | 0 | 660 | 861 | 209 | 2.11 | 2.31 | 2.57 | 20 | 35.92 | |

| 108 | 353 | 0 | 230 | 0 | 661 | 853 | 202 | 2.11 | 2.29 | 2.57 | 20 | 34.56 | |

| 109 | 353 | 0 | 229 | 0 | 647 | 527 | 513 | 2.11 | 3.94 | 2.49 | 20 | 35.76 | |

| 110 | 353 | 0 | 247 | 0 | 647 | 524 | 496 | 2.11 | 3.9 | 2.49 | 20 | 31.76 | |

| 111 | 353 | 0 | 241 | 0 | 625 | 0 | 993 | 2.11 | 6.71 | 2.36 | 20 | 37.44 | |

| 112 | 353 | 0 | 271 | 0 | 625 | 0 | 959 | 2.11 | 6.7 | 2.36 | 20 | 34.64 | |

| 113 | 379 | 0 | 190 | 0 | 623 | 1237 | 0 | 2.1 | 1.24 | 2.62 | 20 | 33.2 | [7] |

| 114 | 379 | 0 | 190 | 0 | 590 | 0 | 1171 | 2.1 | 8.2 | 2.41 | 20 | 26.08 | |

| 115 | 379 | 0 | 190 | 0 | 590 | 0 | 1171 | 2.1 | 6.61 | 2.39 | 20 | 30.96 | |

| 116 | 420 | 105 | 184 | 0.7 | 668 | 1002 | 0 | 2.11 | 1.1 | 2.62 | 20 | 56 | [53] |

| 117 | 420 | 105 | 184 | 0.7 | 668 | 0 | 916 | 2.11 | 6.49 | 2.4 | 20 | 39.68 | |

| 118 | 420 | 105 | 184 | 0.7 | 668 | 0 | 938 | 2.11 | 5.55 | 2.45 | 20 | 43.44 | |

| 119 | 420 | 105 | 184 | 0.7 | 668 | 0 | 922 | 2.11 | 5.81 | 2.41 | 20 | 50.72 | |

| 120 | 420 | 105 | 184 | 0.7 | 668 | 0 | 940 | 2.11 | 5.53 | 2.46 | 20 | 56 | |

| 121 | 420 | 105 | 184 | 0.7 | 668 | 0 | 923 | 2.11 | 6.59 | 2.41 | 20 | 58.16 | |

| 122 | 300 | 0 | 205 | 0 | 697 | 1143 | 0 | 2.19 | 1.01 | 2.6 | 20 | 27.6 | [54] |

| 123 | 300 | 0 | 205 | 0 | 697 | 0 | 1075 | 2.19 | 3.36 | 2.48 | 20 | 28 | |

| 124 | 300 | 0 | 205 | 0 | 697 | 0 | 1027 | 2.19 | 6.14 | 2.36 | 20 | 23.36 | |

| 125 | 300 | 0 | 205 | 0 | 697 | 0 | 1040 | 2.19 | 6.44 | 2.36 | 20 | 22.16 | |

| 126 | 350 | 0 | 180 | 0 | 706 | 1158 | 0 | 2.19 | 1.01 | 2.6 | 20 | 38.64 | |

| 127 | 350 | 0 | 180 | 0 | 706 | 0 | 1089 | 2.19 | 3.36 | 2.48 | 20 | 38.08 | |

| 128 | 350 | 0 | 180 | 0 | 706 | 0 | 1041 | 2.19 | 6.14 | 2.36 | 20 | 33.6 | |

| 129 | 350 | 0 | 180 | 0 | 706 | 0 | 1054 | 2.19 | 6.44 | 2.36 | 20 | 34.32 | |

| 130 | 425 | 0 | 185 | 0 | 696 | 1092 | 0 | 2.19 | 1.01 | 2.6 | 20 | 49.28 | |

| 131 | 425 | 0 | 185 | 0 | 696 | 0 | 1028 | 2.19 | 3.36 | 2.48 | 20 | 48 | |

| 132 | 425 | 0 | 185 | 0 | 696 | 0 | 982 | 2.19 | 6.14 | 2.36 | 20 | 42.96 | |

| 133 | 425 | 0 | 185 | 0 | 696 | 0 | 994 | 2.19 | 6.44 | 2.36 | 20 | 42.56 | |

| 134 | 485 | 0 | 165 | 0 | 685 | 1094 | 0 | 2.19 | 1.01 | 2.6 | 20 | 64.4 | |

| 135 | 485 | 0 | 165 | 0 | 685 | 0 | 1030 | 2.19 | 3.36 | 2.48 | 20 | 62.56 | |

| 136 | 485 | 0 | 165 | 0 | 685 | 0 | 979 | 2.19 | 6.14 | 2.36 | 20 | 56.96 | |

| 137 | 485 | 0 | 165 | 0 | 685 | 0 | 982 | 2.19 | 6.44 | 2.36 | 20 | 52.32 | |

| 138 | 350 | 0 | 180 | 0 | 675 | 0 | 1089 | 2.19 | 6.14 | 2.36 | 20 | 39.36 | |

| 139 | 350 | 0 | 180 | 0 | 654 | 0 | 1041 | 2.19 | 6.44 | 2.36 | 20 | 34.88 | |

| 140 | 425 | 0 | 185 | 0 | 637 | 0 | 1028 | 2.19 | 6.14 | 2.36 | 20 | 48.32 | |

| 141 | 425 | 0 | 185 | 0 | 618 | 0 | 982 | 2.19 | 6.44 | 2.36 | 20 | 45.84 | |

| 142 | 440 | 0 | 155 | 0 | 666 | 1166 | 0 | 2.19 | 0.71 | 2.66 | 20 | 55.68 | |

| 143 | 440 | 0 | 155 | 0 | 666 | 0 | 1070 | 2.19 | 6.38 | 2.41 | 20 | 47.52 | |

| 144 | 440 | 0 | 155 | 0 | 666 | 0 | 1077 | 2.19 | 5.18 | 2.42 | 20 | 55.84 | |

| 145 | 440 | 0 | 155 | 0 | 666 | 0 | 1083 | 2.19 | 5.36 | 2.44 | 20 | 54.24 | |

| 146 | 440 | 0 | 155 | 0 | 666 | 0 | 1090 | 2.19 | 5.3 | 2.45 | 20 | 54.96 | |

| 147 | 440 | 0 | 155 | 0 | 666 | 0 | 1094 | 2.19 | 5.36 | 2.46 | 20 | 49.68 | |

| 148 | 380 | 0 | 190 | 0 | 710 | 1110 | 0 | 2.19 | 0.71 | 2.66 | 20 | 43.52 | |

| 149 | 380 | 0 | 190 | 0 | 710 | 1055 | 44 | 2.19 | 1.27 | 2.63 | 20 | 43.52 | |

| 150 | 380 | 0 | 190 | 0 | 710 | 999 | 88 | 2.19 | 1.85 | 2.61 | 20 | 43.92 | |

| 151 | 380 | 0 | 190 | 0 | 710 | 944 | 132 | 2.19 | 2.44 | 2.58 | 20 | 42 | |

| 152 | 380 | 0 | 190 | 0 | 710 | 1055 | 43 | 2.19 | 1.53 | 2.63 | 20 | 43.36 | |

| 153 | 380 | 0 | 190 | 0 | 710 | 999 | 86 | 2.19 | 2.38 | 2.61 | 20 | 41.84 | |

| 154 | 380 | 0 | 190 | 0 | 710 | 944 | 129 | 2.19 | 3.24 | 2.61 | 20 | 37.52 | |

| 155 | 370 | 0 | 185 | 0 | 732 | 1090 | 0 | 2.19 | 1.01 | 2.6 | 20 | 38.56 | |

| 156 | 370 | 0 | 185 | 0 | 732 | 545 | 463 | 2.19 | 2.31 | 2.55 | 20 | 40.24 | |

| 157 | 370 | 0 | 185 | 0 | 732 | 0 | 924 | 2.19 | 3.85 | 2.49 | 20 | 39.36 | |

| 158 | 425 | 0 | 192 | 0.19 | 730 | 963 | 0 | 2.58 | 1.4 | 2.61 | 25 | 35.52 | [55] |

| 159 | 428 | 0 | 193 | 0.18 | 734 | 969 | 0 | 2.58 | 1.4 | 2.61 | 25 | 34.24 | |

| 160 | 429 | 0 | 193 | 0.22 | 736 | 729 | 230 | 2.58 | 2.24 | 2.58 | 25 | 30.16 | |

| 161 | 423 | 0 | 190 | 0.18 | 726 | 479 | 453 | 2.58 | 3.1 | 2.54 | 25 | 31.44 | |

| 162 | 427 | 0 | 192 | 0.28 | 733 | 242 | 687 | 2.58 | 3.99 | 2.51 | 25 | 28.24 | |

| 163 | 426 | 0 | 192 | 0.35 | 731 | 0 | 913 | 2.58 | 4.9 | 2.47 | 25 | 30.08 | |

| 164 | 431 | 0 | 195 | 0.1 | 741 | 489 | 457 | 2.58 | 3.33 | 2.53 | 25 | 28.08 | |

| 165 | 433 | 0 | 195 | 0.27 | 744 | 0 | 918 | 2.58 | 5.4 | 2.44 | 25 | 29.04 | |

| 166 | 427 | 0 | 192 | 0.19 | 734 | 484 | 451 | 2.58 | 3.28 | 2.52 | 25 | 26.88 | |

| 167 | 432 | 0 | 194 | 0.23 | 742 | 0 | 912 | 2.58 | 5.3 | 2.43 | 25 | 27.52 | |

| 168 | 430 | 0 | 193 | 0.2 | 737 | 0 | 917 | 2.58 | 4.7 | 2.46 | 25 | 25.28 | |

| 169 | 429 | 0 | 193 | 0.22 | 737 | 0 | 909 | 2.58 | 5.1 | 2.44 | 25 | 27.28 | |

| 170 | 316 | 0 | 194 | 0.11 | 803 | 953 | 0 | 2.58 | 1.4 | 2.61 | 25 | 23.44 | |

| 171 | 320 | 0 | 192 | 0.13 | 819 | 0 | 914 | 2.58 | 4.9 | 2.47 | 25 | 21.68 | |

| 172 | 322 | 0 | 193 | 0.09 | 823 | 0 | 908 | 2.58 | 5.4 | 2.44 | 25 | 19.92 | |

| 173 | 320 | 0 | 192 | 0.1 | 819 | 0 | 899 | 2.58 | 5.3 | 2.43 | 25 | 16.4 | |

| 174 | 645 | 0 | 194 | 0.36 | 563 | 973 | 0 | 2.58 | 1.4 | 2.61 | 25 | 46.8 | |

| 175 | 645 | 0 | 193 | 0.46 | 563 | 0 | 921 | 2.58 | 4.9 | 2.47 | 25 | 36.4 | |

| 176 | 642 | 0 | 192 | 0.51 | 561 | 0 | 905 | 2.58 | 5.4 | 2.44 | 25 | 45.68 | |

| 177 | 642 | 0 | 192 | 0.44 | 561 | 0 | 902 | 2.58 | 5.3 | 2.43 | 25 | 37.68 |

References

- Gursel, A.P.; Masanet, E.; Horvath, A.; Stadel, A. Life-cycle inventory analysis of concrete production: A critical review. Cem. Concr. Compos. 2014, 51, 38–48. [Google Scholar] [CrossRef]

- Higuchi, T.; Morioka, M.; Yoshioka, I.; Yokozeki, K. Development of a new ecological concrete with CO2 emissions below zero. Constr. Build. Mater. 2014, 67, 338–343. [Google Scholar] [CrossRef]

- Lippiatt, N.; Ling, T.-C.; Pan, S.-Y. Towards carbon-neutral construction materials: Carbonation of cement-based materials and the future perspective. J. Build. Eng. 2020, 28, 101062. [Google Scholar] [CrossRef]

- Tam, V.W.; Soomro, M.; Evangelista, A.C.J. Quality improvement of recycled concrete aggregate by removal of residual mortar: A comprehensive review of approaches adopted. Constr. Build. Mater. 2021, 288, 123066. [Google Scholar] [CrossRef]

- Silva, R.; Jiménez, J.; Agrela, F.; De Brito, J. Real-scale applications of recycled aggregate concrete. In New Trends in Eco-efficient and Recycled Concrete; Woodhead Publishing: Sawston, UK, 2019; pp. 573–589. [Google Scholar] [CrossRef]

- Suescum-Morales, D.; Kalinowska-Wichrowska, K.; Fernández, J.M.; Jiménez, J.R. Accelerated carbonation of fresh cement-based products containing recycled masonry aggregates for CO2 sequestration. J. CO2 Util. 2021, 46, 101461. [Google Scholar] [CrossRef]

- Poon, C.; Shui, Z.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Poon, C.; Shui, Z.; Lam, L.; Fok, H.; Kou, S. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem. Concr. Res. 2004, 34, 31–36. [Google Scholar] [CrossRef]

- de Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Matar, P.; Barhoun, J. Effects of waterproofing admixture on the compressive strength and permeability of recycled aggregate concrete. J. Build. Eng. 2020, 32, 101521. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.S.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Agrela, F.; Alaejos, P.; Thomas, C.; Rueda, J.; Silva, R.; Moreno-Juez, J.; Sanjuán, M.; de Brito, J.; de Rojas, M.S. Normative review and necessary advances to promote the use of recycled aggregates and by-products in cement-based materials. In Waste and Byproducts in Cement-Based Materials; Woodhead Publishing: Sawston, UK, 2021; pp. 735–776. [Google Scholar] [CrossRef]

- Singh, B.P.; Yazdani, N.; Ramirez, G. Effect of a Time Dependent Concrete Modulus of Elasticity on Prestress Losses in Bridge Girders. Int. J. Concr. Struct. Mater. 2013, 7, 183–191. [Google Scholar] [CrossRef] [Green Version]

- Bonopera, M.; Chang, K.C. Elastic modulus of prestressed and reinforced concrete beams in Taiwan under dynamic flexural loading. J. Chin. Inst. Civ. Hydraul. Eng. 2021, 33, 83–92. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.-C.; Zhang, H.; Wang, Y. Durability of recycled aggregate concrete—A review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Thomas, J.; Thaickavil, N.N.; Wilson, P. Strength and durability of concrete containing recycled concrete aggregates. J. Build. Eng. 2018, 19, 349–365. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Hubler, M.H.; Wendner, R. RILEM draft recommendation: TC-242-MDC multi-decade creep and shrinkage of concrete: Material model and structural analysis. Mater. Struct. 2015, 48, 753–770. [Google Scholar] [CrossRef] [Green Version]

- Rashid, K.; Rehman, M.U.; de Brito, J.; Ghafoor, H. Multi-criteria optimization of recycled aggregate concrete mixes. J. Clean. Prod. 2020, 276, 124316. [Google Scholar] [CrossRef]

- Ajdukiewicz, A.; Kliszczewicz, A. Influence of recycled aggregates on mechanical properties of HS/HPC. Cem. Concr. Compos. 2002, 24, 269–279. [Google Scholar] [CrossRef]

- Silva, R.; de Brito, J.; Dhir, R. The influence of the use of recycled aggregates on the compressive strength of concrete: A review. Eur. J. Environ. Civ. Eng. 2015, 19, 825–849. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Concrete with fine recycled aggregates: A review. Eur. J. Environ. Civ. Eng. 2014, 18, 129–172. [Google Scholar] [CrossRef]

- Limbachiya, M.C.; Leelawat, T.; Dhir, R.K. Use of recycled concrete aggregate in high-strength concrete. Mater. Struct. 2000, 33, 574–580. [Google Scholar] [CrossRef]

- Lin, C.-J.; Wu, N.-J. An ANN Model for Predicting the Compressive Strength of Concrete. Appl. Sci. 2021, 11, 3798. [Google Scholar] [CrossRef]

- Duan, Z.; Kou, S.; Poon, C. Prediction of compressive strength of recycled aggregate concrete using artificial neural networks. Constr. Build. Mater. 2013, 40, 1200–1206. [Google Scholar] [CrossRef]

- Patil, S.V.; Rao, K.B.; Nayak, G. Prediction of recycled coarse aggregate concrete mechanical properties using multiple linear regression and artificial neural network. J. Eng. Des. Technol. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Özcan, F.; Atis, C.; Karahan, O.; Uncuoğlu, E.; Tanyildizi, H. Comparison of artificial neural network and fuzzy logic models for prediction of long-term compressive strength of silica fume concrete. Adv. Eng. Softw. 2009, 40, 856–863. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. The effects of TiO2 nanoparticles on physical, thermal and mechanical properties of concrete using ground granulated blast furnace slag as binder. Mater. Sci. Eng. A 2011, 528, 2085–2092. [Google Scholar] [CrossRef]

- Nazari, A. Compressive strength of geopolymers produced by ordinary Portland cement: Application of genetic programming for design. Mater. Des. 2013, 43, 356–366. [Google Scholar] [CrossRef]

- Castelli, M.; Vanneschi, L.; Silva, S. Prediction of high performance concrete strength using Genetic Programming with geometric semantic genetic operators. Expert Syst. Appl. 2013, 40, 6856–6862. [Google Scholar] [CrossRef]

- González-Taboada, I.; González-Fonteboa, B.; Martínez-Abella, F.; Pérez-Ordóñez, J.L. Prediction of the mechanical properties of structural recycled concrete using multivariable regression and genetic programming. Constr. Build. Mater. 2016, 106, 480–499. [Google Scholar] [CrossRef]

- Gholampour, A.; Gandomi, A.; Ozbakkaloglu, T. New formulations for mechanical properties of recycled aggregate concrete using gene expression programming. Constr. Build. Mater. 2017, 130, 122–145. [Google Scholar] [CrossRef]

- Moradi, M.; Khaleghi, M.; Salimi, J.; Farhangi, V.; Ramezanianpour, A. Predicting the compressive strength of concrete containing metakaolin with different properties using ANN. Measurement 2021, 183, 109790. [Google Scholar] [CrossRef]

- Kostić, S.; Vasović, D. Prediction model for compressive strength of basic concrete mixture using artificial neural networks. Neural Comput. Appl. 2015, 26, 1005–1024. [Google Scholar] [CrossRef]

- Sarıdemir, M. Predicting the compressive strength of mortars containing metakaolin by artificial neural networks and fuzzy logic. Adv. Eng. Softw. 2009, 40, 920–927. [Google Scholar] [CrossRef]

- Gandomi, A.; Alavi, A.H.; Kazemi, S.; Gandomi, M. Formulation of shear strength of slender RC beams using gene expression programming, part I: Without shear reinforcement. Autom. Constr. 2014, 42, 112–121. [Google Scholar] [CrossRef]

- Sarıdemir, M. Effect of specimen size and shape on compressive strength of concrete containing fly ash: Application of genetic programming for design. Mater. Des. 2014, 56, 297–304. [Google Scholar] [CrossRef]

- Chopra, P.; Kumar Sharma, R.; Kumar, M. Prediction of compressive strength of concrete using Artificial Neural Network and Genetic Programming. Lect. Notes Civ. Eng. 2016, 25, 471–483. [Google Scholar] [CrossRef] [Green Version]

- Gandomi, A.H.; Alavi, A.H.; Gandomi, M.; Kazemi, S. Formulation of shear strength of slender RC beams using gene expression programming, part II: With shear reinforcement. Measurement 2017, 95, 367–376. [Google Scholar] [CrossRef]

- Congro, M.; Monteiro, V.M.D.A.; Brandão, A.L.; dos Santos, B.F.; Roehl, D.; Silva, F.D.A. Prediction of the residual flexural strength of fiber reinforced concrete using artificial neural networks. Constr. Build. Mater. 2021, 303, 124502. [Google Scholar] [CrossRef]

- Rafiq, M.; Bugmann, G.; Easterbrook, D. Neural network design for engineering applications. Comput. Struct. 2001, 79, 1541–1552. [Google Scholar] [CrossRef]

- Burden, F.; Winkler, D. Bayesian Regularization of Neural Networks. Methods Mol. Biol. 2008, 458, 23–42. [Google Scholar] [CrossRef]

- Lima, C.; Caggiano, A.; Faella, C.; Martinelli, E.; Pepe, M.; Realfonzo, R. Physical properties and mechanical behaviour of concrete made with recycled aggregates and fly ash. Constr. Build. Mater. 2013, 47, 547–559. [Google Scholar] [CrossRef]

- Cartuxo, F.; de Brito, J.; Evangelista, L.; Jiménez, J.R.; Ledesma, E.F. Rheological behaviour of concrete made with fine recycled concrete aggregates—Influence of the superplasticizer. Constr. Build. Mater. 2015, 89, 36–47. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Pore Size Distribution of High Performance Metakaolin Concrete. J. Wuhan Univ. Technol. 2002, 17, 42–46. [Google Scholar] [CrossRef]

- Poon, C.; Lam, L.; Wong, Y. A study on high strength concrete prepared with large volumes of low calcium fly ash. Cem. Concr. Res. 2000, 30, 447–455. [Google Scholar] [CrossRef]

- Poon, C.S.; Azhar, S. Deterioration and Recovery of Metakaolin Blended Concrete Subjected to High Temperature. Fire Technol. 2003, 39, 35–45. [Google Scholar] [CrossRef]

- Poon, C.S.; Azhar, S.; Anson, M.; Wong, Y.-L. Comparison of the strength and durability performance of normal- and high-strength pozzolanic concretes at elevated temperatures. Cem. Concr. Res. 2001, 31, 1291–1300. [Google Scholar] [CrossRef]

- Poon, C.; Ho, D. A feasibility study on the utilization of r-FA in SCC. Cem. Concr. Res. 2004, 34, 2337–2339. [Google Scholar] [CrossRef]

- Lam, L.; Wong, Y.L.; Poon, C.A. Effect of Fly Ash and Silica Fume on Compressive and Fracture Behaviors of Concrete. Cem. Concr. Res. 1998, 28, 271–283. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Influence of recycled aggregate on slump and bleeding of fresh concrete. Mater. Struct. 2007, 40, 981–988. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Chan, D. Influence of Fly Ash as Cement Replacement on the Properties of Recycled Aggregate Concrete. J. Mater. Civ. Eng. 2007, 19, 709–717. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.S. Mechanical properties of 5-year-old concrete prepared with recycled aggregates obtained from three different sources. Mag. Concr. Res. 2008, 60, 57–64. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C. Effect of quality of parent concrete on the mechanical properties of high performance recy-cled aggregate concrete. Kuei Suan Jen Hsueh Pao/J. Chin. Ceram. Soc. 2012, 40, 7–11. [Google Scholar]

- Duan, S.; Liao, H.; Ma, Z.; Cheng, F.; Fang, L.; Gao, H.; Yang, H. The relevance of ultrafine fly ash properties and mechanical properties in its fly ash-cement gelation blocks via static pressure forming. Constr. Build. Mater. 2018, 186, 1064–1071. [Google Scholar] [CrossRef]

- Schoppe, B.M. Shrinkage & Modulus of Elasticity in Concrete with Recycled Aggregates. Master’s Thesis, Faculty of California Polytechnic State University, San Luis, CA, USA, 2016. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).