Anisotropic Shear Strength Behavior of Soil–Geogrid Interfaces

Abstract

:1. Introduction

2. Experimental Program

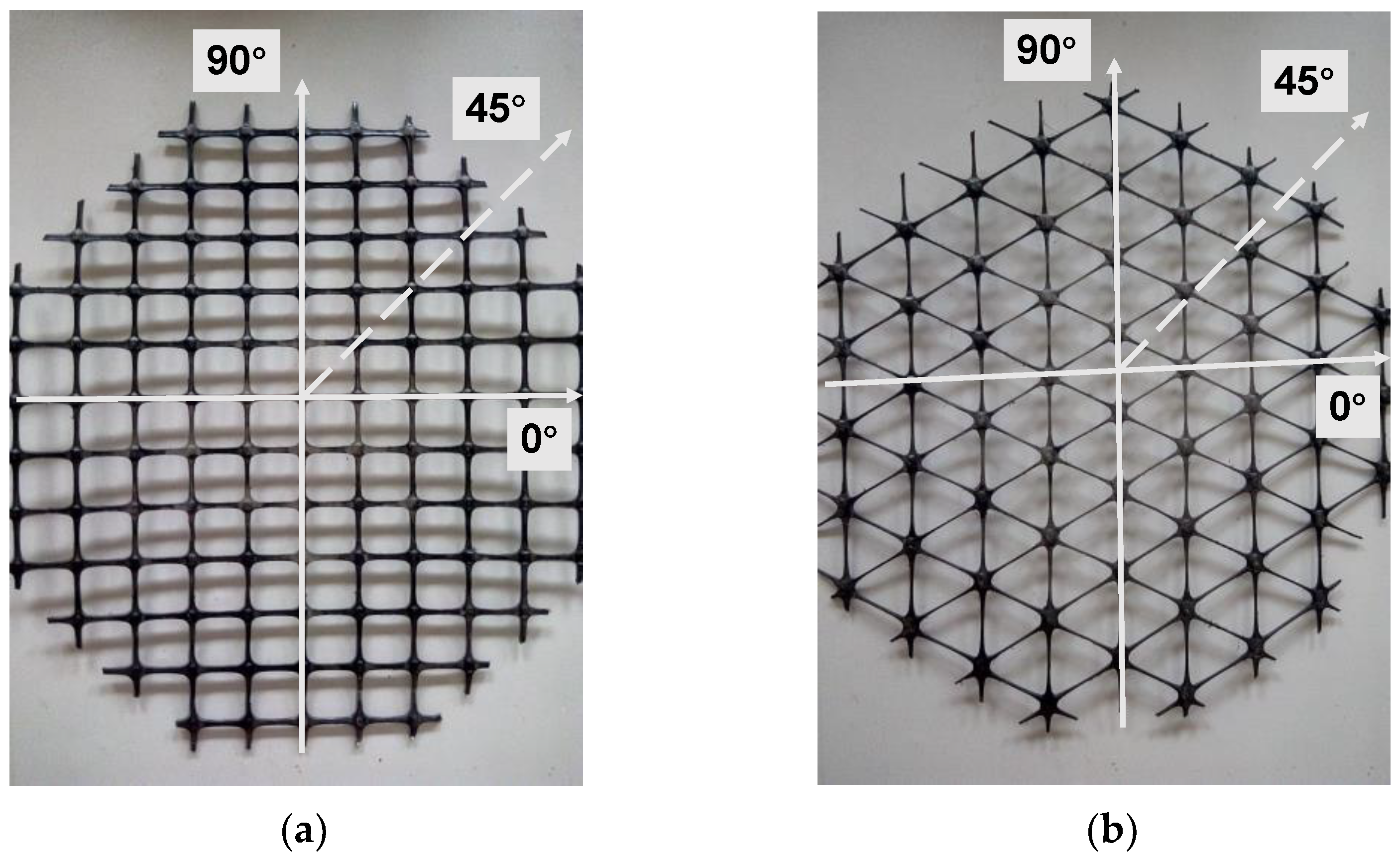

2.1. Materials

2.2. Testing Apparatus

2.3. Testing Procedures

3. Experimental Results

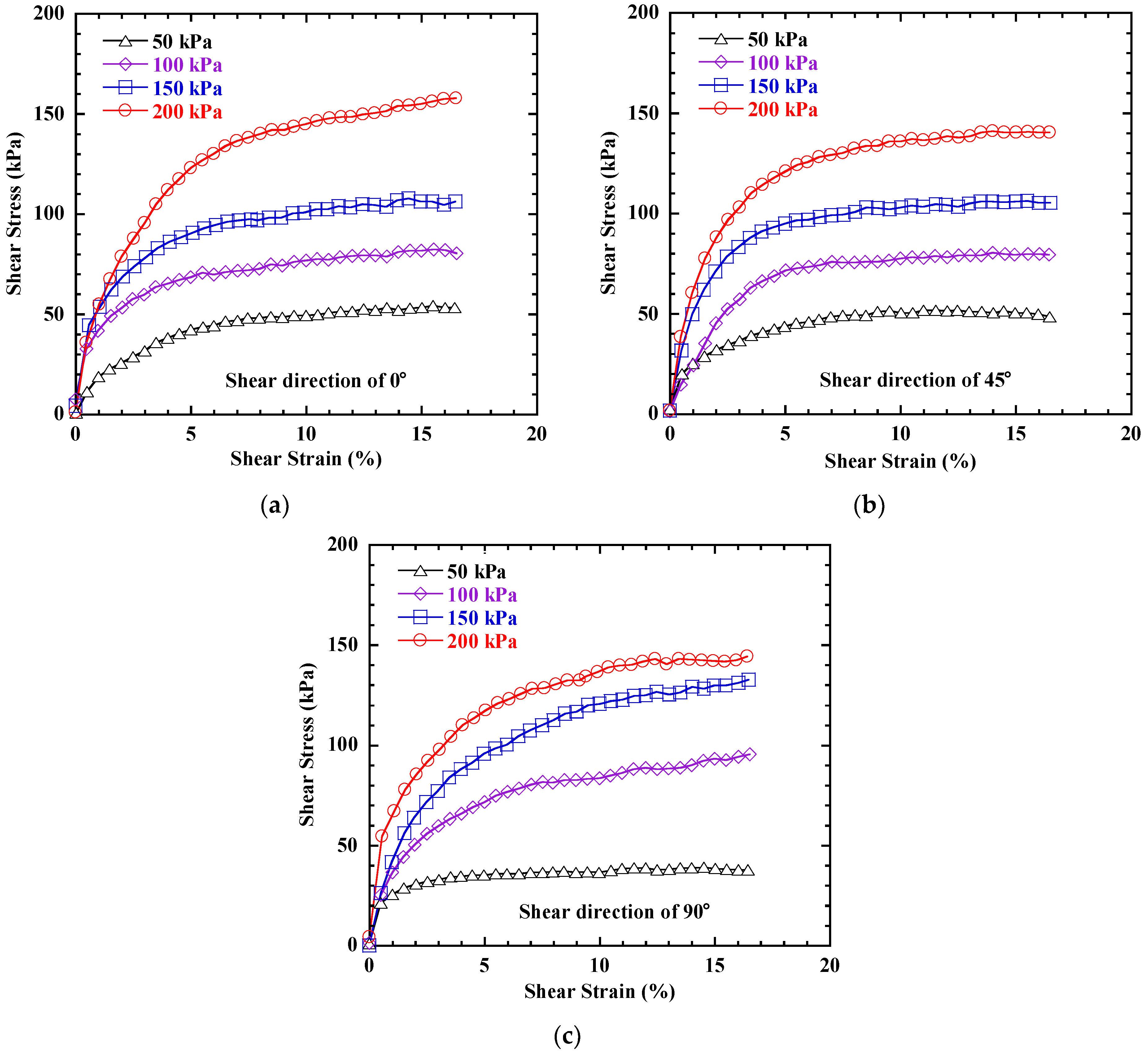

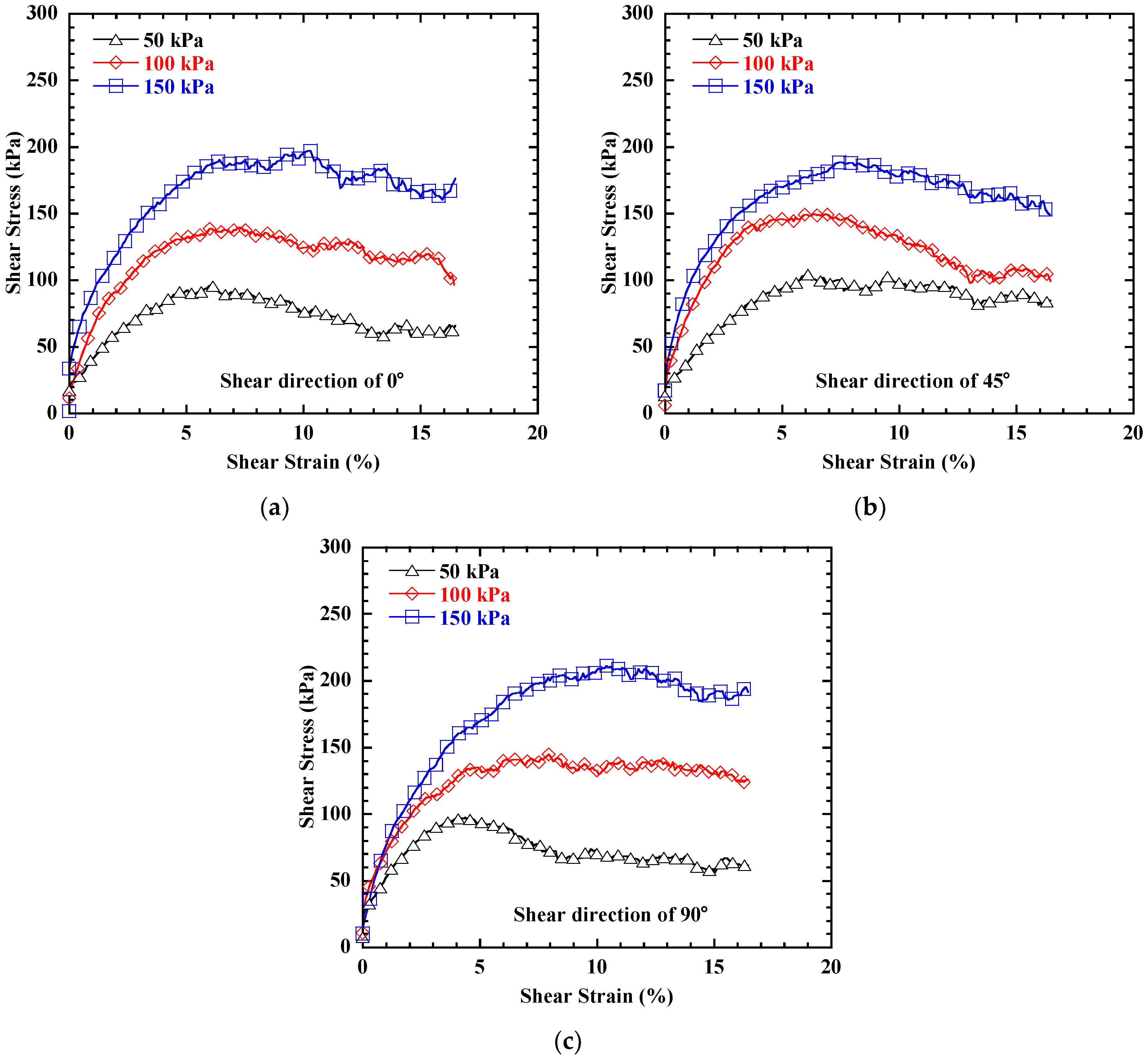

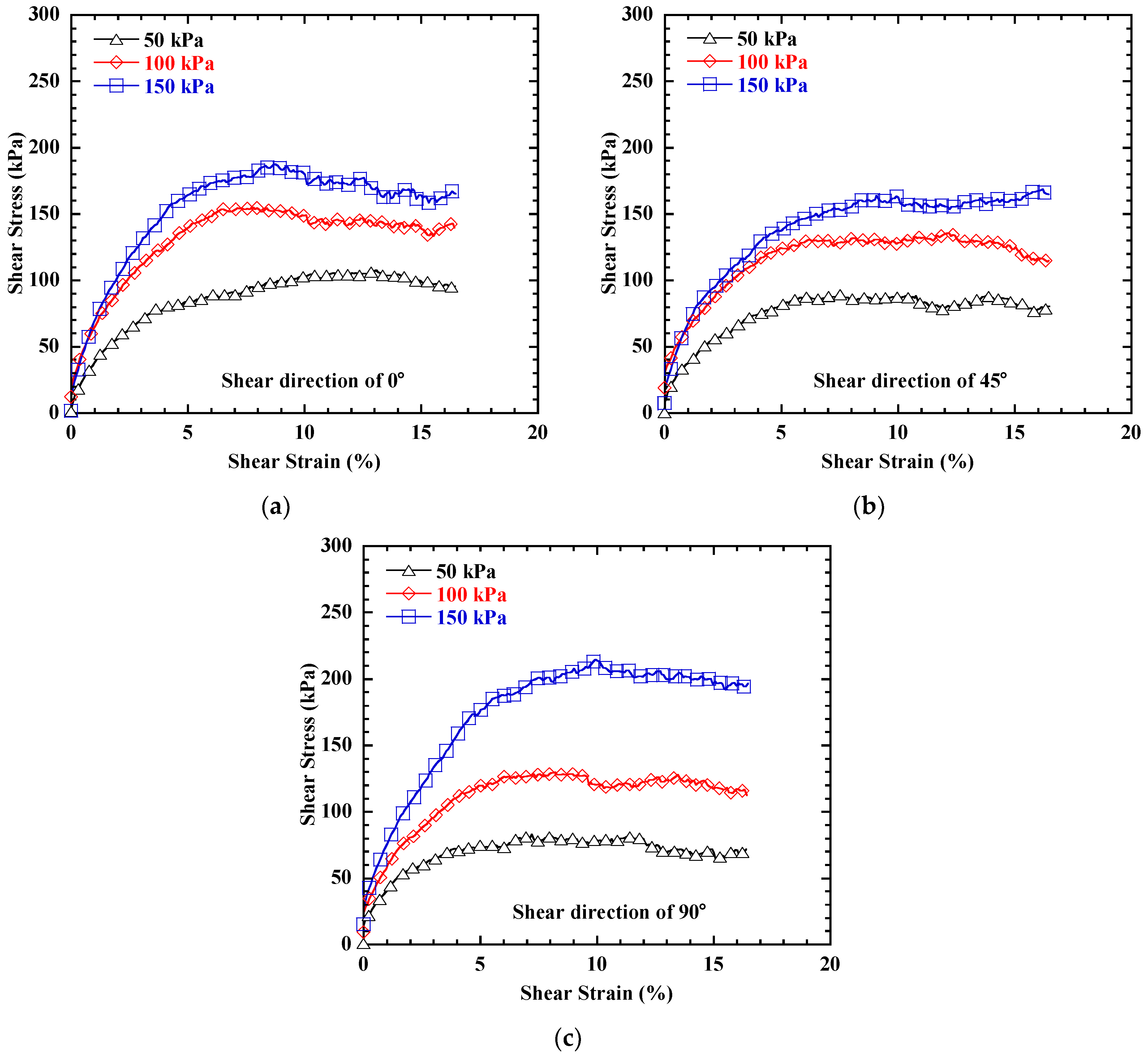

3.1. Shear Strength Behavior

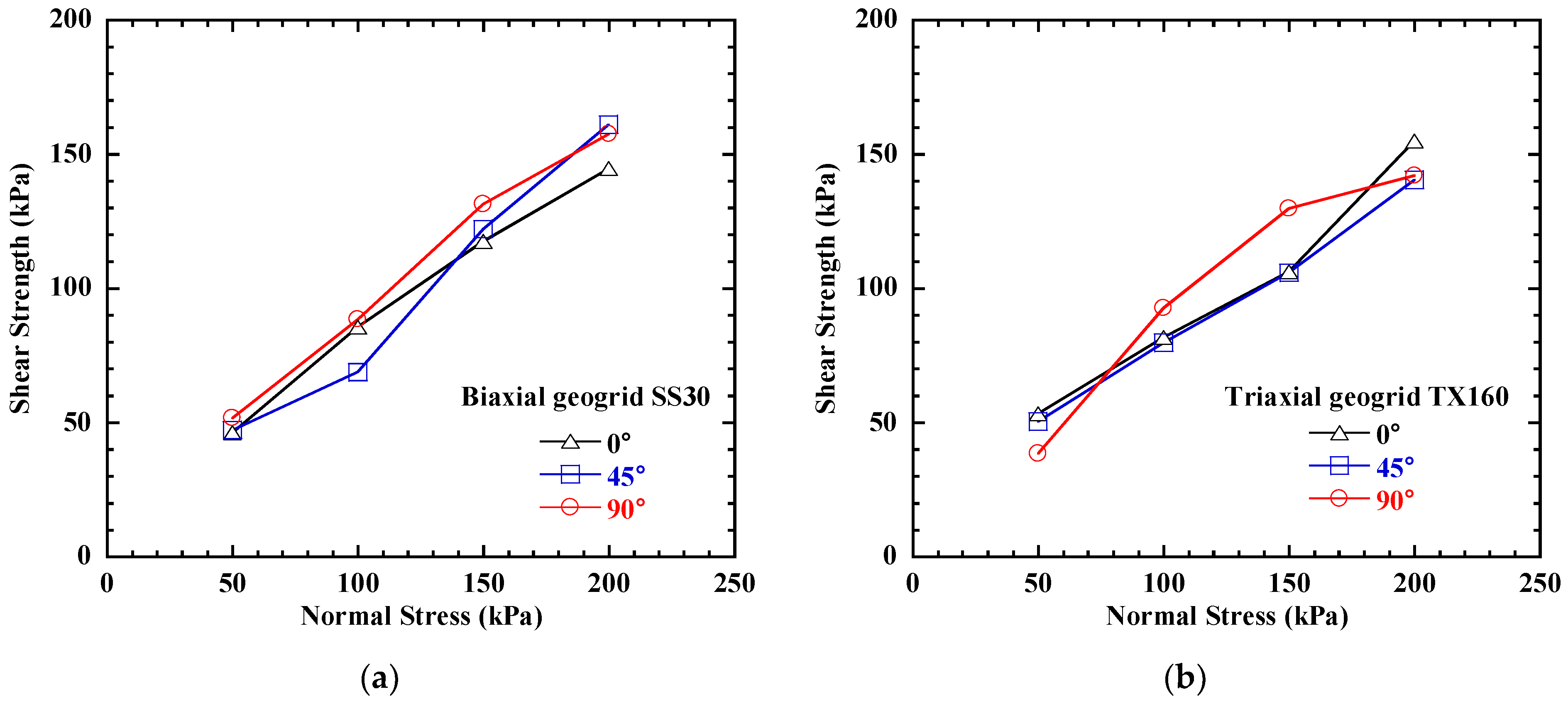

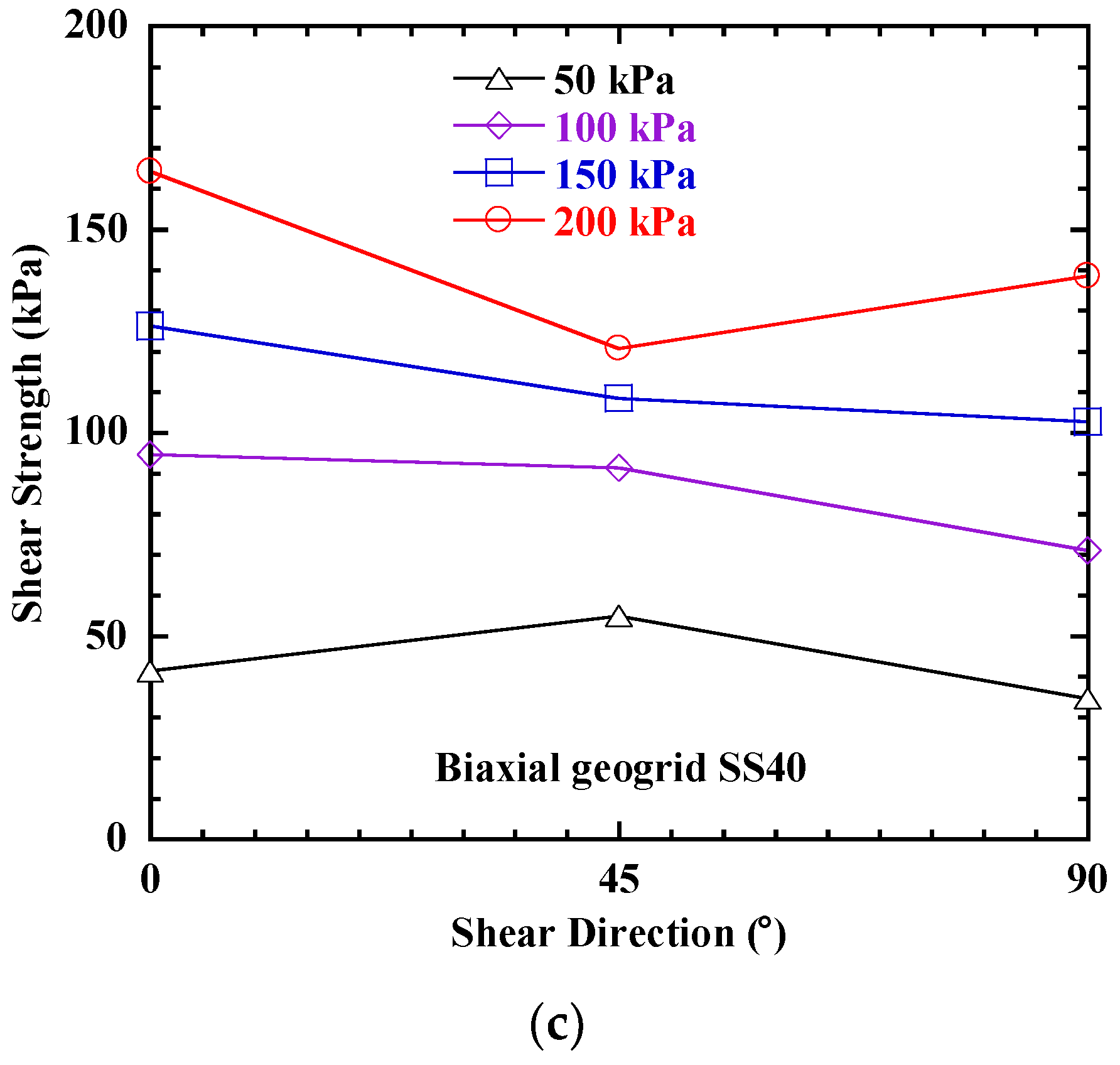

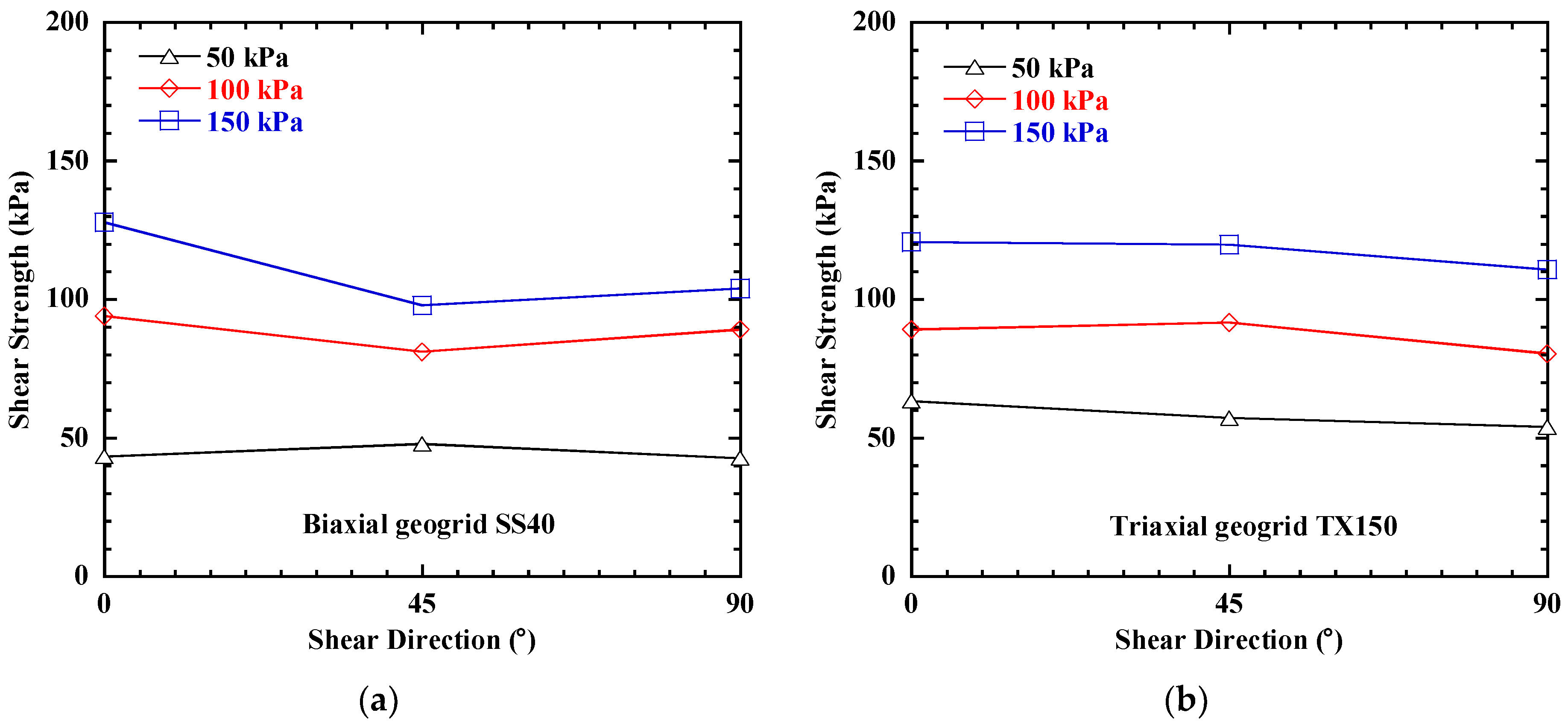

3.2. Influence of Shear Direction

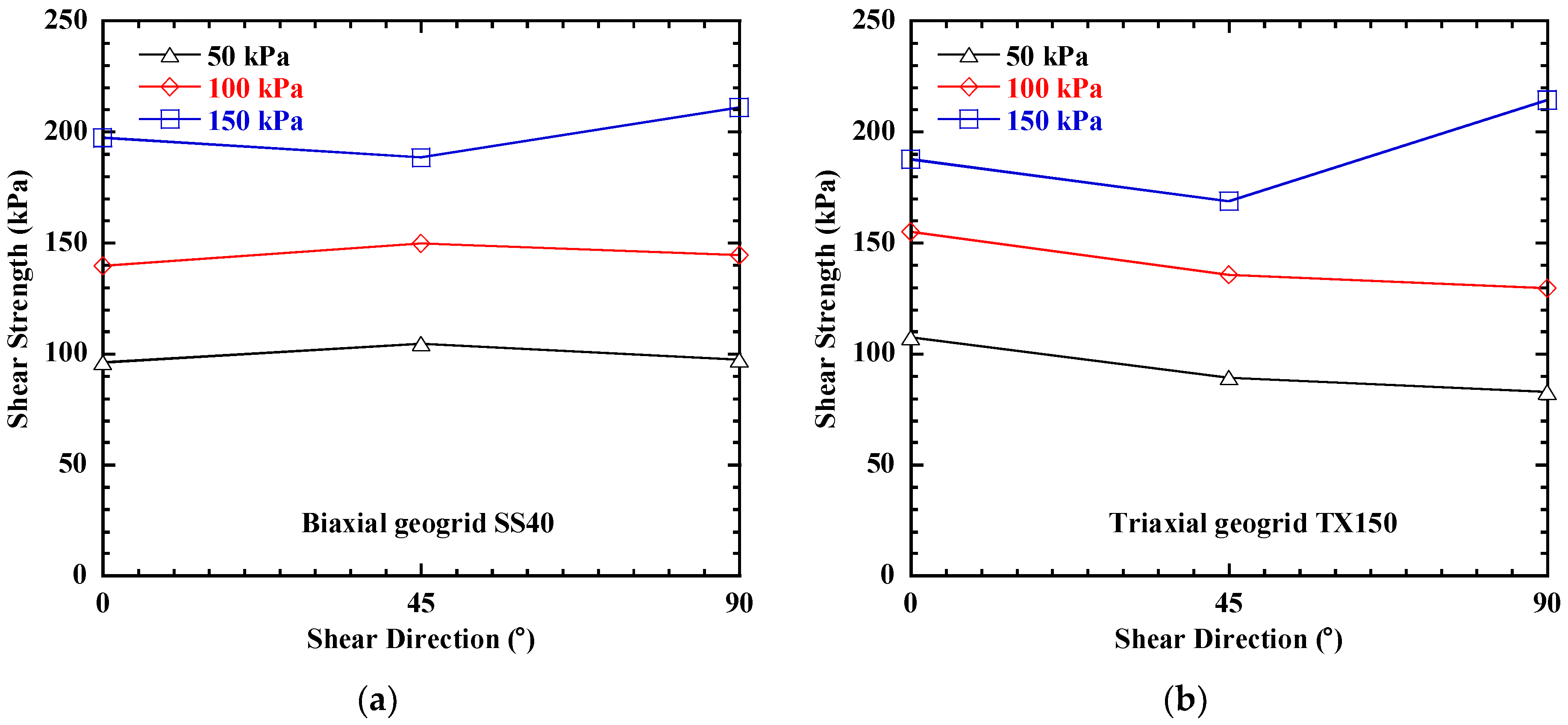

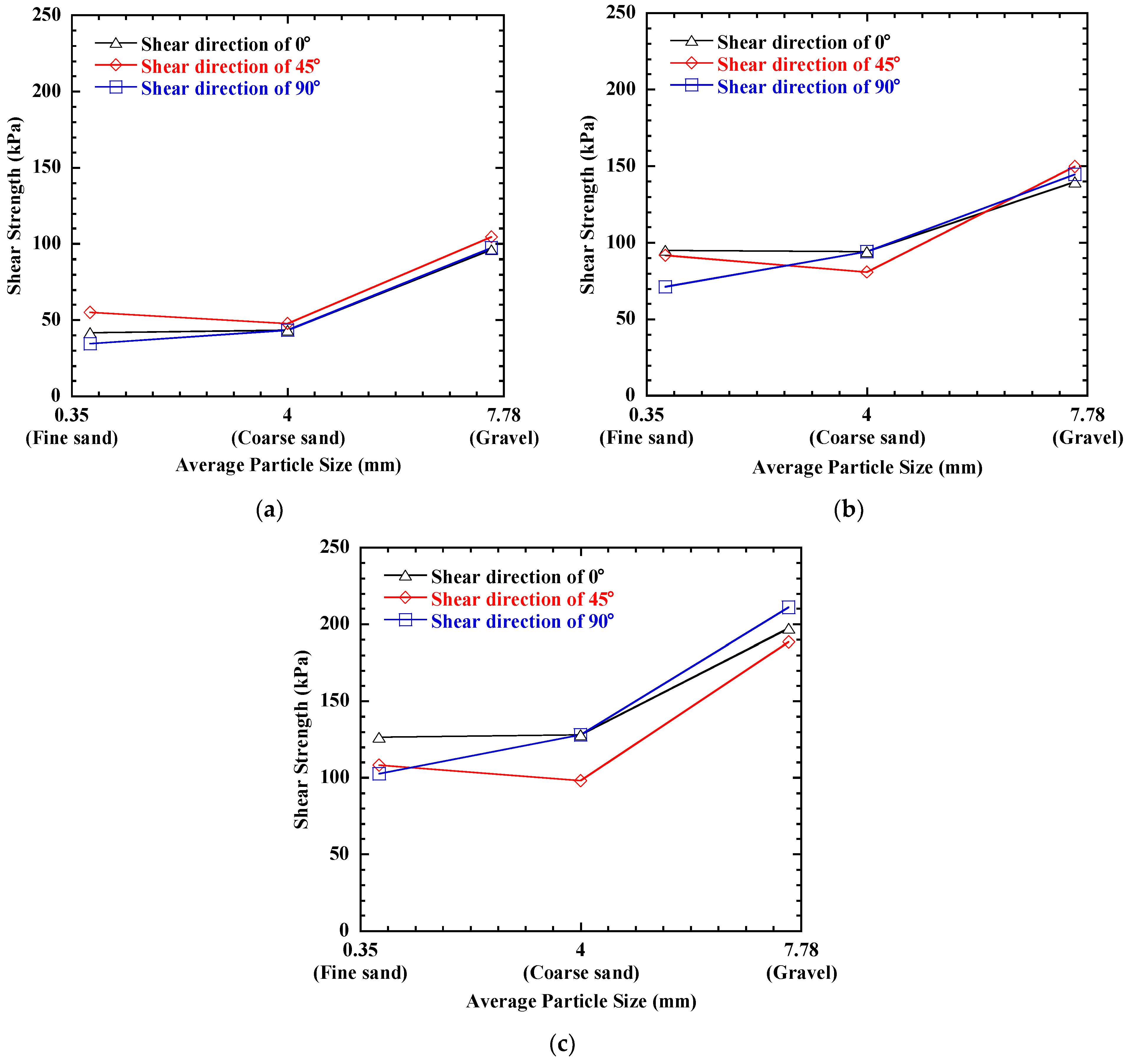

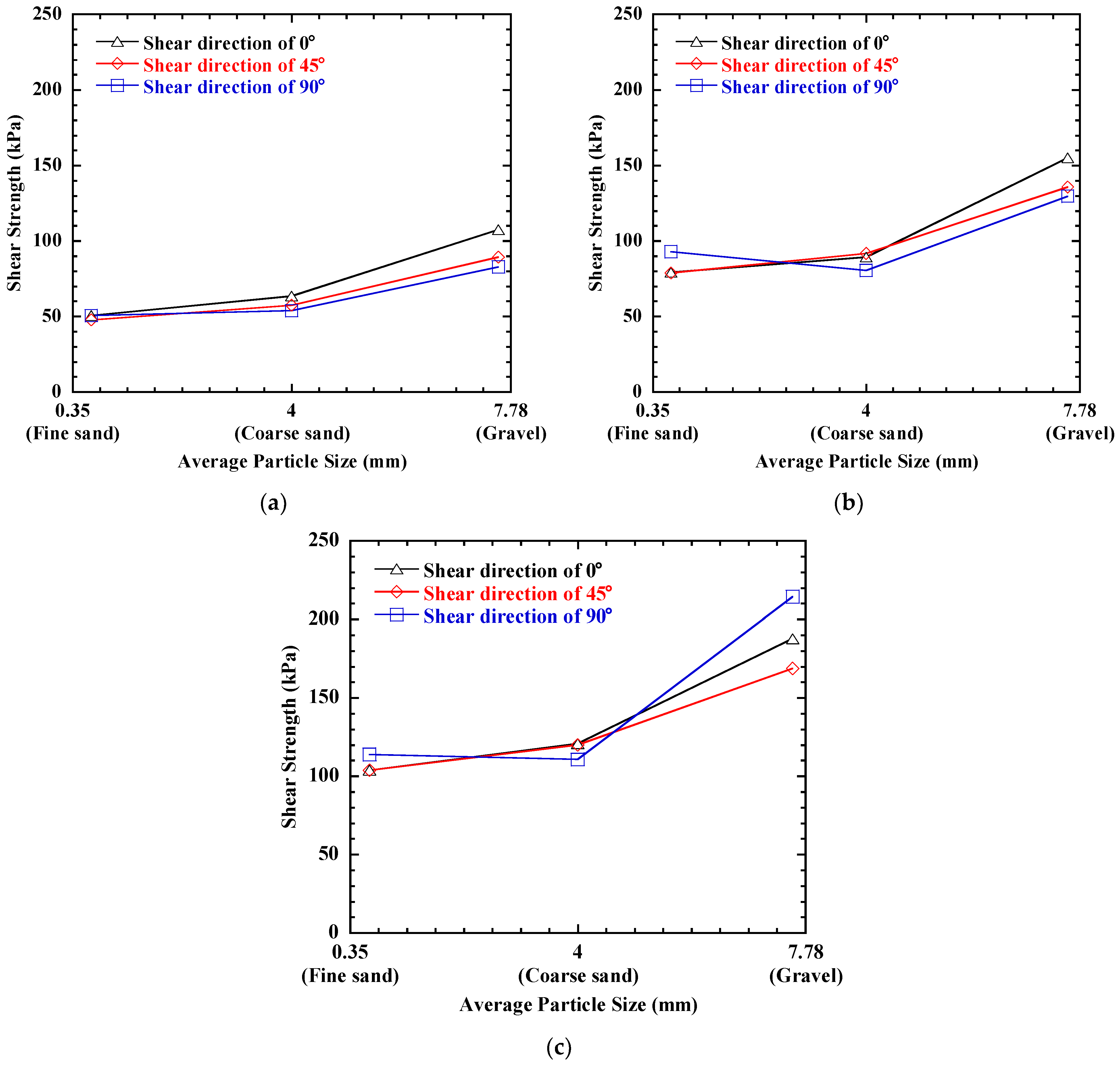

3.3. Influence of Particle Size

4. Conclusions

- (1)

- The interface shear strength under the same normal stress varies with shear directions for all biaxial and triaxial geogrids, which indicates the anisotropic shear strength behavior of soil–geogrid interfaces. The anisotropy decreases with the increase in normal stress because greater normal stress could generate a more stable interlocking structure between the soil particles and the geogrid aperture.

- (2)

- The percentages of shear strength variation could be relatively large (e.g., 59.59% for the soil–biaxial geogrid interface and 37.99% for the soil–triaxial geogrid interface). These large values indicate strong anisotropic shear strength behavior of soil–geogrid interfaces, which is ignored in the current soil–geosynthetic interface testing standard, but could be important for the safe design of reinforced soil structures.

- (3)

- The soil–biaxial geogrid interface shows stronger anisotropic shear strength behavior than the soil–triaxial geogrid interface. This is because the triangular aperture of the triaxial geogrid is more stable than the rectangular aperture of the biaxial geogrid, which makes the soil–triaxial geogrid interaction less sensitive to shear direction. The stable aperture shape of the triaxial geogrid could improve the interlocking effect between the soil particles and geogrid apertures, and thus show less anisotropic shear strength behavior for the soil–triaxial geogrid interface.

- (4)

- As the particle size increases, the friction and interlocking between the soil and geogrid plays a more significant role. Particle size also has a great influence on the anisotropy behavior of soil–geogrid interfaces. With the increase in particle size, the anisotropy behavior of the soil–triaxial geogrid interface becomes stronger, but the anisotropy behavior of the soil–biaxial geogrid interface becomes weaker.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, J.; Gabr, M.A. Numerical analysis of geosynthetic-reinforced and pile-supported earth platforms over soft soil. J. Geotech. Geoenviron. Eng. 2002, 128, 44–53. [Google Scholar] [CrossRef]

- Ling, H.I.; Mohri, Y.; Leshchinsky, D.; Burke, C.; Matsushima, K.; Liu, H. Large-scale shaking table tests on modular block reinforced soil retaining walls. J. Geotech. Geoenviron. Eng. 2005, 131, 465–476. [Google Scholar] [CrossRef]

- Bathurst, R.J.; Vlachopoulos, N.; Walters, D.L.; Burgess, P.G.; Allen, T.M. The influence of facing stiffness on the performance of two geosynthetic reinforced soil retaining walls. Can. Geotech. J. 2006, 43, 1225–1237. [Google Scholar] [CrossRef]

- Leshchinsky, B.; Xie, Y. MSE walls as bridge abutments: Optimal reinforcement density. Geotext. Geomembr. 2015, 43, 128–138. [Google Scholar]

- Rowe, R.K.; Liu, K.W. Three-dimensional finite element modelling of a full-scale geosynthetic-reinforced, pile-supported embankment. Can. Geotech. J. 2015, 52, 2041–2054. [Google Scholar] [CrossRef]

- Zheng, Y.; McCartney, J.S.; Shing, P.B.; Fox, P.J. Physical model tests of half-scale geosynthetic reinforced soil bridge abutments. II: Dynamic loading. J. Geotech. Geoenviron. Eng. 2019, 145, 04019095. [Google Scholar] [CrossRef] [Green Version]

- Palmeira, E.M. Soil-geosynthetic interaction: Modelling and analysis. Geotext. Geomembr. 2009, 27, 368–390. [Google Scholar] [CrossRef]

- Wang, Z.; Jacobs, F.; Ziegler, M. Experimental and DEM investigation of geogrid-soil interaction under pullout loads. Geotext. Geomembr. 2016, 44, 230–246. [Google Scholar] [CrossRef]

- Lopes, M.L.; Ladeira, M. Role of specimen geometry, soil height, and sleeve length on the pull-out behaviour of geogrids. Geosynth. Int. 1996, 3, 701–719. [Google Scholar] [CrossRef]

- Palmeira, E.M. Loading force mobilisation in pull-out tests on geogrids. Geotext. Geomembr. 2004, 22, 481–509. [Google Scholar] [CrossRef]

- Vieira, C.S.; Lopes, M.L.; Caldeira, L.M. Sand-geotextile interface characterisation through monotonic and cyclic direct shear tests. Geosynth. Int. 2013, 20, 26–38. [Google Scholar] [CrossRef]

- Hatami, K.; Esmaili, D. Unsaturated soil–woven geotextile interface strength properties from small-scale pullout and interface tests. Geosynth. Int. 2015, 22, 161–172. [Google Scholar] [CrossRef]

- Mosallanezhad, M.; Alfaro, M.C.; Hataf, N.; Sadat Taghavi, S.H. Performance of the new reinforcement system in the increase of shear strength of typical geogrid interface with soil. Geotext. Geomembr. 2016, 44, 457–462. [Google Scholar] [CrossRef]

- Morsy, A.M.; Zornberg, J.G.; Han, J.; Leshchinsky, D. A new generation of soil-geosynthetic interaction experimentation. Geotext. Geomembr. 2019, 47, 459–476. [Google Scholar] [CrossRef]

- Morsy, A.M.; Zornberg, J.G.; Han, J.; Leshchinsky, D.; Han, J. Soil-reinforcement interaction: Effect of reinforcement spacing and normal stress. J. Geotech. Geoenviron. Eng. 2019, 145, 04019115. [Google Scholar] [CrossRef]

- Swan, R.H., Jr.; Lovell, C.W. Interaction between tire shreds, rubber-sand and geosynthetics. Geosynth. Int. 1997, 4, 623–643. [Google Scholar]

- Perkins, S.W.; Cuelho, E.V. Soil-geosynthetic interface strength and stiffness relationships from pullout tests. Geosynth. Int. 1999, 6, 321–346. [Google Scholar] [CrossRef]

- Lee, K.M.; Manjunath, V.R. Soil-geotextile interface friction by direct shear tests. Can. Geotech. J. 2000, 37, 238–252. [Google Scholar] [CrossRef]

- Abu-Farsakh, M.; Coronel, J.; Tao, M. Effect of soil moisture content and dry density on cohesive soil-geosynthetic interactions using large direct shear tests. J. Mater. Civ. Eng. 2007, 19, 540–549. [Google Scholar] [CrossRef]

- Liu, C.N.; Ho, Y.H.; Huang, J.W. Large scale direct shear tests of soil/PET-yarn geogrid interfaces. Geotext. Geomembr. 2009, 27, 19–30. [Google Scholar] [CrossRef]

- Liu, C.N.; Zornberg, J.G.; Chen, T.C.; Ho, Y.H.; Lin, B.H. Behavior of geogrid-sand interface in direct shear mode. J. Geotech. Geoenviron. Eng. 2009, 135, 1863–1871. [Google Scholar] [CrossRef]

- Sayeed, M.M.A.; Ramaiah, B.J.; Rawal, A. Interface shear characteristics of jute/polypropylene hybrid nonwoven geotextiles and sand using large size direct shear test. Geotext. Geomembr. 2014, 42, 63–68. [Google Scholar] [CrossRef]

- Ferreira, F.B.; Vieira, C.S.; Lopes, M.L. Direct shear behaviour of residual soil-geosynthetic interfaces-influence of soil moisture content, soil density and geosynthetic type. Geosynth. Int. 2015, 22, 257–272. [Google Scholar] [CrossRef]

- Vangla, P.; Gali, M.L. Effect of particle size of sand and surface asperities of reinforcement on their interface shear behaviour. Geotext. Geomembr. 2016, 44, 254–268. [Google Scholar] [CrossRef]

- Abdi, M.R.; Mirzaeifar, H. Experimental and PIV evaluation of grain size and distribution on soil-geogrid interactions in pullout test. Soils Found. 2017, 57, 1045–1058. [Google Scholar] [CrossRef]

- Wang, H.L.; Chen, R.P.; Liu, Q.W.; Kang, X.; Wang, Y.W. Soil–geogrid interaction at various influencing factors by pullout tests with applications of FBG sensors. J. Mater. Civ. Eng. 2019, 31, 04018342. [Google Scholar] [CrossRef]

- Liu, F.Y.; Wang, P.; Geng, X.; Wang, J.; Lin, X. Cyclic and post-cyclic behaviour from sand–geogrid interface large-scale direct shear tests. Geosynth. Int. 2016, 23, 129–139. [Google Scholar] [CrossRef]

- Wang, J.; Liu, F.Y.; Wang, P.; Cai, Y.Q. Particle size effects on coarse soil-geogrid interface response in cyclic and post-cyclic direct shear tests. Geotext. Geomembr. 2016, 44, 854–861. [Google Scholar] [CrossRef]

- Sweta, K.; Hussaini, S.K.K. Effect of shearing rate on the behavior of geogrid-reinforced railroad ballast under direct shear conditions. Geotext. Geomembr. 2018, 46, 251–256. [Google Scholar] [CrossRef]

- ASTM International. ASTM D5321-20. In Standard Test Method for Determining the Shear Strength of Soil-Geosynthetic and Geosynthetic-Geosynthetic Interfaces by Direct Shear; ASTM International: West Conshohocken, PA, USA, 2021. [Google Scholar]

- Dong, Y.L.; Han, J.; Bai, X.H. Numerical analysis of tensile behavior of geogrids with rectangular and triangular apertures. Geotext. Geomembr. 2011, 29, 83–91. [Google Scholar] [CrossRef]

- Zornberg, J.G.; Ferreira, J.A.Z.; Roodi, G.H. Experimental Results on Soil-Geosynthetic Interaction Stiffness; Report No. FHWA/TX-12/5-4829-01-3; Center for Transportation Research (CTR): Austin, TX, USA, 2012. [Google Scholar]

- Roodi, G.H.; Zornberg, J.G.; Aboelwafa, M.M.; Phillips, J.R.; Zheng, L.; Martinez, J. Soil-Geosynthetic Interaction Test to Develop Specifications for Geosynthetic Stabilized Roadways; Report No. FHWA/TX-18/5-4829-03-1; Center for Transportation Research (CTR): Austin, TX, USA, 2018. [Google Scholar]

- Athanasopoulos, G.A. Effect of particle size on the mechanical behavior of sand-geotextile composite. Geotext. Geomembr. 1993, 12, 255–273. [Google Scholar] [CrossRef]

- Lopes, M.J.; Lopes, M.L. Soil-geosynthetic interaction—Influence of soil particle size and geosynthetic structure. Geosynth. Int. 1999, 6, 261–282. [Google Scholar] [CrossRef]

| Geogrid | Direction of Tensile Loading | ||||

|---|---|---|---|---|---|

| 0° | 22.5° | 45° | 67.5° | 90° | |

| SS20 | 26.29 | 17.90 | 10.72 | 17.98 | 26.68 |

| SS30 | 33.97 | 22.14 | 12.95 | 21.50 | 34.58 |

| SS40 | 48.26 | 28.29 | 17.98 | 29.53 | 47.82 |

| TX150 | 15.97 | 13.15 | 12.83 | 12.26 | 17.55 |

| TX160 | 21.57 | 16.20 | 13.47 | 13.81 | 19.28 |

| TX170 | 23.82 | 21.43 | 22.39 | 21.71 | 25.15 |

| Geogrid | Normal Stress (kPa) | |||

|---|---|---|---|---|

| 50 | 100 | 150 | 200 | |

| SS20 | 41.55 | 18.14 | 13.59 | 0.68 |

| SS30 | 11.72 | 29.01 | 11.65 | 11.52 |

| SS40 | 59.29 | 33.19 | 22.97 | 36.15 |

| TX150 | 6.01 | 18.03 | 9.85 | 14.00 |

| TX160 | 37.99 | 16.20 | 22.60 | 10.20 |

| TX170 | 29.39 | 11.62 | 7.83 | 11.42 |

| Particle | Normal Stress (kPa) | ||

|---|---|---|---|

| 50 | 100 | 150 | |

| Fine sand | 59.29 | 33.18 | 22.97 |

| Coarse sand | 10.51 | 16.21 | 30.67 |

| Gravel | 8.74 | 7.36 | 11.95 |

| Particle | Normal Stress (kPa) | ||

|---|---|---|---|

| 50 | 100 | 150 | |

| Fine sand | 6.01 | 18.03 | 9.85 |

| Coarse sand | 17.54 | 14.25 | 9.12 |

| Gravel | 30.06 | 19.44 | 27.24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Ji, M.; Jia, Y.; Miao, C.; Wang, C.; Zhao, Z.; Zheng, Y. Anisotropic Shear Strength Behavior of Soil–Geogrid Interfaces. Appl. Sci. 2021, 11, 11387. https://doi.org/10.3390/app112311387

Zhang J, Ji M, Jia Y, Miao C, Wang C, Zhao Z, Zheng Y. Anisotropic Shear Strength Behavior of Soil–Geogrid Interfaces. Applied Sciences. 2021; 11(23):11387. https://doi.org/10.3390/app112311387

Chicago/Turabian StyleZhang, Jun, Mingchang Ji, Yafei Jia, Chenxi Miao, Cheng Wang, Ziyang Zhao, and Yewei Zheng. 2021. "Anisotropic Shear Strength Behavior of Soil–Geogrid Interfaces" Applied Sciences 11, no. 23: 11387. https://doi.org/10.3390/app112311387