Uses of Nanoclays and Adsorbents for Dye Recovery: A Textile Industry Review

Abstract

:Featured Application

Abstract

1. Introduction

2. Sewage Treatment

2.1. General Textile Recovery

2.2. With Nanotechnologies

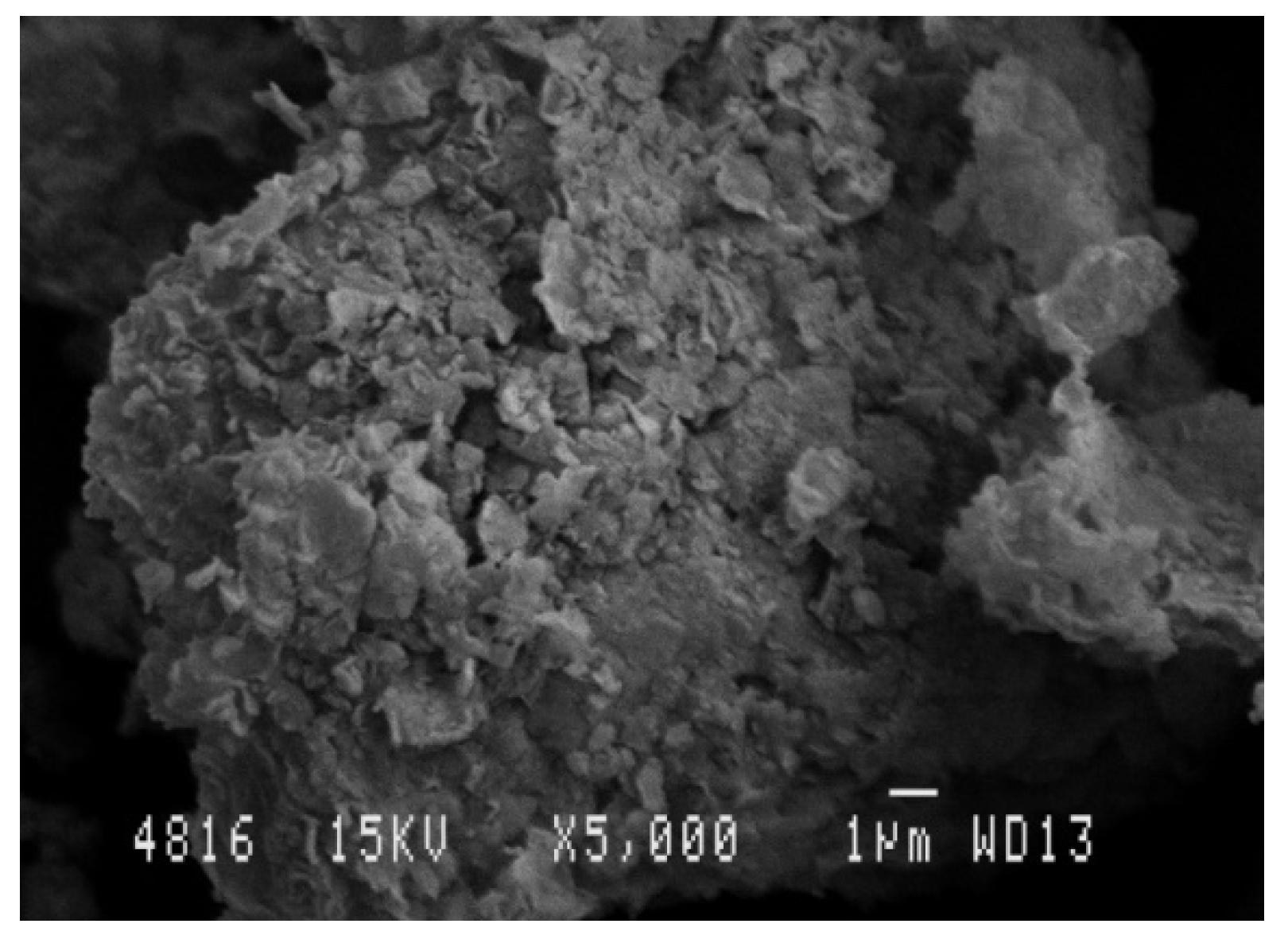

2.2.1. Nanoclays

2.2.2. Montmorillonite (MMT)

2.2.3. Zeolite

2.2.4. Halloysite

2.2.5. Saponite

2.2.6. Sepiolite

2.2.7. Bentonite

2.2.8. Laponite

2.2.9. Hydrotalcite

3. Reused Waste Water Dyes

3.1. Pigment

3.2. Dyes

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Semeraro, P.; Rizzi, V.; Fini, P.; Matera, S.; Cosma, P.; Franco, E.; García, R.; Ferrándiz, M.; Núñez, E.; Gabaldón, J.A.; et al. Interaction between Industrial Textile Dyes and Cyclodextrins. Dye. Pigment. 2015, 119, 84–94. [Google Scholar] [CrossRef]

- Sana, D.; Jalila, S. A Comparative Study of Adsorption and Regeneration with Different Agricultural Wastes as Adsorbents for the Removal of Methylene Blue from Aqueous Solution. Chin. J. Chem. Eng. 2017, 25, 1282–1287. [Google Scholar] [CrossRef]

- Sanchez, L.M.; Ollier, R.P.; Gonzalez, J.S.; Alvarez, V.A. Nanocomposite Materials for Dyes Removal. In Handbook of Nanomaterials for Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 922–951. [Google Scholar] [CrossRef]

- Erkanlı, M.; Yilmaz, L.; Çulfaz-Emecen, P.Z.; Yetis, U. Brackish Water Recovery from Reactive Dyeing Wastewater via Ultrafiltration. J. Clean. Prod. 2017, 165, 1204–1214. [Google Scholar] [CrossRef]

- Ranjan, P.; Verma, P.; Agrawal, S.; Rao, T.R.; Samanta, S.K.; Thakur, A.D. Inducing Dye-Selectivity in Graphene Oxide for Cationic Dye Separation Applications. Mater. Chem. Phys. 2019, 226, 350–355. [Google Scholar] [CrossRef]

- Mahmoud, M.E.; Nabil, G.M.; Khalifa, M.A.; El-Mallah, N.M.; Hassouba, H.M. Effective Removal of Crystal Violet and Methylene Blue Dyes from Water by Surface Functionalized Zirconium Silicate Nanocomposite. J. Environ. Chem. Eng. 2019, 7, 103009. [Google Scholar] [CrossRef]

- Azzaz, A.A.; Assadi, A.A.; Jellali, S.; Bouzaza, A.; Wolbert, D.; Rtimi, S.; Bousselmi, L. Discoloration of Simulated Textile Effluent in Continuous Photoreactor Using Immobilized Titanium Dioxide: Effect of Zinc and Sodium Chloride. J. Photochem. Photobiol. A Chem. 2018, 358, 111–120. [Google Scholar] [CrossRef]

- Azzaz, A.A.; Jellali, S.; Akrout, H.; Assadi, A.A.; Bousselmi, L. Dynamic Investigations on Cationic Dye Desorption from Chemically Modified Lignocellulosic Material Using a Low-Cost Eluent: Dye Recovery and Anodic Oxidation Efficiencies of the Desorbed Solutions. J. Clean. Prod. 2018, 201, 28–38. [Google Scholar] [CrossRef]

- Rizvi, M.A.; Moosvi, S.K.; Jan, T.; Bashir, S.; Kumar, P.; Roos, W.D.; Swart, H.C. Dielectric, Magnetic and Photocatalytic Activity of PolyPyrrole/Prussian Red Nanocomposite for Waste Water Treatment Applications. Polymer 2019, 163, 1–12. [Google Scholar] [CrossRef]

- Park, J.-H.; Wang, J.J.; Meng, Y.; Wei, Z.; DeLaune, R.D.; Seo, D.-C. Adsorption/Desorption Behavior of Cationic and Anionic Dyes by Biochars Prepared at Normal and High Pyrolysis Temperatures. Colloids Surfaces A Physicochem. Eng. Asp. 2019, 572, 274–282. [Google Scholar] [CrossRef]

- Jadhav, S.A.; Garud, H.B.; Patil, A.H.; Patil, G.D.; Patil, C.R.; Dongale, T.D.; Patil, P.S. Recent Advancements in Silica Nanoparticles Based Technologies for Removal of Dyes from Water. Colloid Interface Sci. Commun. 2019, 30, 100181. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, W.; Wang, L.; Wu, H.; Wu, D.; Lu, S.; Huang, X. Synthesis Rod-like Mesoporous MgO Using Sodium Polystyrenesulfonate (PSS) as Structure-Direct Template and Its Application to Plumbum Absorption in Waste Water. Mater. Lett. 2020, 285, 129051. [Google Scholar] [CrossRef]

- Nong, G.Z.; Xing, D.Y.; Li, Y.J.; Zhu, T.; Wu, J.L.; Gan, W.X.; Wang, S.F.; Li, X.R. Recycle Cooking Wood Chips with the Residue Liquid Removed out of Lignin by Calcification for Increasing Pulp Yield and Reducing Waste Water Discharge. J. Clean. Prod. 2020, 277, 124028. [Google Scholar] [CrossRef]

- Mahmoud, M.E.; Nabil, G.M.; Khalifa, M.A.; El-Mallah, N.M.; Hassouba, H.M.; Negin, C.; Ali, S.; Xie, Q.; Liu, H.; Li, X.R.; et al. A Review on Biocatalytic Decomposition of Azo Dyes and Electrons Recovery. J. Clean. Prod. 2017, 246, 275–281. [Google Scholar] [CrossRef]

- Liu, H.; Li, X.; Li, M.; Zhang, Y.; Tang, K.; Liu, J.; Zheng, X.; Pei, Y. A Simple and Sustainable Beamhouse by the Recycling of Waste-Water from KCl-Dispase Synergistic Unhairing in Leather Making. J. Clean. Prod. 2020, 124535. [Google Scholar] [CrossRef]

- Negin, C.; Ali, S.; Xie, Q. Application of Nanotechnology for Enhancing Oil Recovery—A Review. Petroleum 2016, 2, 324–333. [Google Scholar] [CrossRef]

- Zhong, P.S.; Widjojo, N.; Chung, T.-S.; Weber, M.; Maletzko, C. Positively Charged Nanofiltration (NF) Membranes via UV Grafting on Sulfonated Polyphenylenesulfone (SPPSU) for Effective Removal of Textile Dyes from Wastewater. J. Membr. Sci. 2012, 417–418, 52–60. [Google Scholar] [CrossRef]

- Senoussi, H.; Bouhidel, K.-E. Feasibility and Optimisation of a Batch Mode Capacitive Deionization (BM CDI) Process for Textile Cationic Dyes (TCD) Removal and Recovery from Industrial Wastewaters. J. Clean. Prod. 2018, 205, 721–727. [Google Scholar] [CrossRef]

- Mathew, M.L.; Gopalakrishnan, A.; Aravindakumar, C.T.; Aravind, U.K. Low–Cost Multilayered Green Fiber for the Treatment of Textile Industry Waste Water. J. Hazard. Mater. 2019, 365, 297–305. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, D.; Liang, Y. Nanotechnology in Remediation of Water Contaminated by Poly- and Perfluoroalkyl Substances: A Review. Environ. Pollut. 2019, 247, 266–276. [Google Scholar] [CrossRef] [PubMed]

- Wakkel, M.; Khiari, B.; Zagrouba, F. Textile Wastewater Treatment by Agro-Industrial Waste: Equilibrium Modelling, Thermodynamics and Mass Transfer Mechanisms of Cationic Dyes Adsorption onto Low-Cost Lignocellulosic Adsorbent. J. Taiwan Inst. Chem. Eng. 2019, 96, 439–452. [Google Scholar] [CrossRef]

- Nath, J.; Bag, S.; Bera, D.; Ray, L. Biotreatment of Malachite Green from Aqueous Solution and Simulated Textile Effluent by Growing Cells (Batch Mode) and Activated Sludge System. Groundw. Sustain. Dev. 2019, 8, 172–178. [Google Scholar] [CrossRef]

- Bankole, P.O.; Adekunle, A.A.; Obidi, O.F.; Olukanni, O.D.; Govindwar, S.P. Degradation of Indigo Dye by a Newly Isolated Yeast, Diutina Rugosa from Dye Wastewater Polluted Soil. J. Environ. Chem. Eng. 2017, 5, 4639–4648. [Google Scholar] [CrossRef]

- Deniz, F.; Karaman, S. Removal of an Azo-Metal Complex Textile Dye from Colored Aqueous Solutions Using an Agro-Residue. Microchem. J. 2011, 99, 296–302. [Google Scholar] [CrossRef]

- Sanz Carbonell, J.F. Tratamiento de Aguas Textiles Industriales Mediante Fotocatálisis Solar y Reutilización en Nuevas Tinturas. Ph.D. Thesis, Universitat Politècnica de València, València, Spain, 2016. [Google Scholar]

- Chorawalaa, K.K.; Mehta, M.J. Applications of Nanotechnology in Wastewater Treatment. Int. J. Innov. Emerg. Res. Eng. 2015, 2, 21–26. [Google Scholar]

- Sayan, B.; Indranil, S.; Aniruddha, M.; Dhrubajyoti, C.; Uday, C.G.; Debashis, C. Role of Nanotechnology in Water Treatment and Purification: Potential Applications and Implications. Int. J. Chem. Sci. Technol. 2013, 3, 59. [Google Scholar]

- Hua, M.; Zhang, S.; Pan, B.; Zhang, W.; Lv, L.; Zhang, Q. Heavy Metal Removal from Water/Wastewater by Nanosized Metal Oxides: A Review. J. Hazard. Mater. 2012, 211, 317–331. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Chawla, J. Removal of Cadmium Ion from Water/Wastewater by Nano-Metal Oxides: A Review. Water Qual. Expo. Health 2014, 5, 215–226. [Google Scholar] [CrossRef]

- Rajput, S.; Pittman, C.U., Jr.; Mohan, D. Magnetic Magnetite (Fe3O4) Nanoparticle Synthesis and Applications for Lead (Pb2+) and Chromium (Cr6+) Removal from Water. J. Colloid Interface Sci. 2016, 468, 334–346. [Google Scholar] [CrossRef]

- Cheriyamundath, S.; Vavilala, S.L. Nanotechnology-based Wastewater Treatment. Water Environ. J. 2021, 35, 123–132. [Google Scholar] [CrossRef]

- Gupta, V.K.; Saleh, T.A. Sorption of Pollutants by Porous Carbon, Carbon Nanotubes and Fullerene-an Overview. Environ. Sci. Pollut. Res. 2013, 20, 2828–2843. [Google Scholar] [CrossRef]

- Iannazzo, D.; Pistone, A.; Ziccarelli, I.; Espro, C.; Galvagno, S.; Giofré, S.V.; Romeo, R.; Cicero, N.; Bua, G.D.; Lanza, G. Removal of Heavy Metal Ions from Wastewaters Using Dendrimer-Functionalized Multi-Walled Carbon Nanotubes. Environ. Sci. Pollut. Res. 2017, 24, 14735–14747. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Xu, Y.; Zhang, C.; Rong, H.; Zeng, G. New Trends in Removing Heavy Metals from Wastewater. Appl. Microbiol. Biotechnol. 2016, 100, 6509–6518. [Google Scholar] [CrossRef]

- Pendergast, M.M.; Hoek, E.M. V A Review of Water Treatment Membrane Nanotechnologies. Energy Environ. Sci. 2011, 4, 1946–1971. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Chen, B.; Ghaffar, A.; Zhu, X. Nanocomposite Membrane with Polyethylenimine-Grafted Graphene Oxide as a Novel Additive to Enhance Pollutant Filtration Performance. Environ. Sci. Technol. 2018, 52, 5920–5930. [Google Scholar] [CrossRef] [PubMed]

- Peng, K.; Yang, H. Carbon Hybridized Montmorillonite Nanosheets: Preparation, Structural Evolution and Enhanced Adsorption Performance. Chem. Commun. 2017, 53, 6085–6088. [Google Scholar] [CrossRef] [PubMed]

- Sharma, V.; Sharma, A. Nanotechnology: An Emerging Future Trend in Wastewater Treatment with Its Innovative Products and Processes. Nanotechnology 2012, 2. Available online: https://www.semanticscholar.org/paper/Nanotechnology-%3A-An-Emerging-Future-Trend-in-with-Sharma-Sharma/c4a78b0b044126e137ad6cf2daf63590c15ab49d (accessed on 22 November 2021).

- Wang, J.-C.; Lou, H.-H.; Xu, Z.-H.; Cui, C.-X.; Li, Z.-J.; Jiang, K.; Zhang, Y.-P.; Qu, L.-B.; Shi, W. Natural Sunlight Driven Highly Efficient Photocatalysis for Simultaneous Degradation of Rhodamine B and Methyl Orange Using I/C Codoped TiO2 Photocatalyst. J. Hazard. Mater. 2018, 360, 356–363. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Ma, Y.; Xi, L.; Zhu, G.; Li, X.; Shi, D.; Fan, J. Highly Efficient Photocatalytic Removal of Multiple Refractory Organic Pollutants by BiVO4/CH3COO (BiO) Heterostructured Nanocomposite. Sci. Total Environ. 2019, 647, 245–254. [Google Scholar] [CrossRef]

- Ramakrishna, K.R.; Viraraghavan, T. Dye Removal Using Low Cost Adsorbents. Water Sci. Technol. 1997, 36, 189–196. [Google Scholar] [CrossRef]

- Clarke, E.A.; Anliker, R. Organic Dyes and Pigments. In Anthropogenic compounds; Springer: Berlin/Heidelberg, Germany, 1980; pp. 181–215. [Google Scholar]

- Zollinger, H. Color Chemistry: Syntheses, Properties and Applications of Organic Dyes and Pigments, 3rd ed.; Wiley-VHCA: Zurich, Switzerland, 2003; pp. 15–65. ISBN 3-906390-23-3. [Google Scholar]

- Akarslan, F.; Demiralay, H. Effects of Textile Materials Harmful to Human Health. Acta Phys. Pol. A 2015, 128, 407–409. [Google Scholar] [CrossRef]

- Anliker, R. Color Chemistry and the Environment. Ecotoxicol. Environ. Saf. 1977, 1, 211–237. [Google Scholar] [CrossRef]

- Clement, R.E.; Koester, C.J.; Eiceman, G.A. Environmental Analysis. Anal. Chem. 1993, 65, 85–116. [Google Scholar] [CrossRef]

- Tchobanoglous, G.; Burton, F.L.; Stensel, H.D. Wastewater Engineering. Management 1991, 7, 4. [Google Scholar]

- Pollard, S.J.T.; Fowler, G.D.; Sollars, C.J.; Perry, R. Low-Cost Adsorbents for Waste and Wastewater Treatment: A Review. Sci. Total Environ. 1992, 116, 31–52. [Google Scholar] [CrossRef]

- Andreo-Martínez, P.; García-Martínez, N.; Almela, L. Domestic Wastewater Depuration Using a Horizontal Subsurface Flow Constructed Wetland and Theoretical Surface Optimization: A Case Study under Dry Mediterranean Climate. Water 2016, 8, 434. [Google Scholar] [CrossRef] [Green Version]

- Cossu, R.; Fantinato, G.; Pivato, A.; Sandon, A. Further Steps in the Standardization of BOD5/COD Ratio as a Biological Stability Index for MSW. Waste Manag. 2017, 68, 16–23. [Google Scholar] [CrossRef] [PubMed]

- Cossu, R.; Lai, T.; Sandon, A. Standardization of BOD5/COD Ratio as a Biological Stability Index for MSW. Waste Manag. 2012, 32, 1503–1508. [Google Scholar] [CrossRef]

- Cazaudehore, G.; Schraauwers, B.; Peyrelasse, C.; Lagnet, C.; Monlau, F. Determination of Chemical Oxygen Demand of Agricultural Wastes by Combining Acid Hydrolysis and Commercial COD Kit Analysis. J. Environ. Manag. 2019, 250, 109464. [Google Scholar] [CrossRef]

- Ghorbani, M.; Salem, S. Solar Treatment of Sewage Discharged from Industrial Estate for Reduction of Chemical Oxygen Demand over Degussa P-25 Titania. Chemosphere 2020, 129123. [Google Scholar] [CrossRef] [PubMed]

- Fronczyk, J.; Radziemska, M.; Dynowski, P.; Mazur, Z.; Bazydło, M. Quality of Water in the Road Drainage Systems in the Warsaw Agglomeration, Poland. Water 2016, 8, 429. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; Liu, L.; Xue, Q.; Yang, Y.; Zhang, Y.; Fei, X. A Systematic Assessment of Aeration Rate Effect on Aerobic Degradation of Municipal Solid Waste Based on Leachate Chemical Oxygen Demand Removal. Chemosphere 2021, 263, 128218. [Google Scholar] [CrossRef] [PubMed]

- Patel, N.; Ruparelia, J.; Barve, J. Prediction of Total Suspended Solids Present in Effluent of Primary Clarifier of Industrial Common Effluent Treatment Plant: Mechanistic and Fuzzy Approach. J. Water Process Eng. 2020, 34, 101146. [Google Scholar] [CrossRef]

- Crespi, M. Reutilización de Los Efluentes Textiles En Europa. Boletín INTEXTER 1989, 96, 87–106. [Google Scholar]

- Ren, J.; Zhang, A.; Wang, X. Jo Ur Na l P Re. Pharmacol. Res. 2020, 104743. [Google Scholar] [CrossRef]

- Skuse, C.; Gallego-Schmid, A.; Azapagic, A.; Gorgojo, P. Can Emerging Membrane-Based Desalination Technologies Replace Reverse Osmosis? Desalination 2020, 114844. [Google Scholar] [CrossRef]

- Rahimi, B.; Shirvani, H.; Asghar, A.; Farhadi, F. A Feasibility Study of Solar-Powered Reverse Osmosis Processes Kingdom of Saudi Arabia. Desalination 2020, 114885. [Google Scholar] [CrossRef]

- Ozbey-Unal, B.; Omwene, P.I.; Yagcioglu, M.; Balcik-Canbolat, Ç.; Karagunduz, A.; Keskinler, B.; Dizge, N. Treatment of Organized Industrial Zone Wastewater by Microfiltration/Reverse Osmosis Membrane Process for Water Recovery: From Lab to Pilot Scale. J. Water Process Eng. 2020, 38, 101646. [Google Scholar] [CrossRef]

- Lebron, Y.A.R.; Moreira, V.R.; Furtado, T.P.B.; da Silva, S.C.; Lange, L.C.; Amaral, M.C.S. Vinasse Treatment Using Hybrid Tannin-Based Coagulation-Microfiltration-Nanofiltration Processes: Potential Energy Recovery, Technical and Economic Feasibility Assessment. Sep. Purif. Technol. 2020, 248, 117152. [Google Scholar] [CrossRef]

- Manouchehri, M.; Kargari, A. Water Recovery from Laundry Wastewater by the Cross Flow Microfiltration Process: A Strategy for Water Recycling in Residential Buildings. J. Clean. Prod. 2017, 168, 227–238. [Google Scholar] [CrossRef]

- Ağtaş, M.; Yılmaz, Ö.; Dilaver, M.; Alp, K.; Koyuncu, İ. Hot Water Recovery and Reuse in Textile Sector with Pilot Scale Ceramic Ultrafiltration/Nanofiltration Membrane System. J. Clean. Prod. 2020, 256, 120359. [Google Scholar] [CrossRef]

- Selvaraj, H.; Chandrasekaran, K.; Murugan, R.; Sundaram, M. An Integrated Biological and Electrochemical Process for Recovery of Sulfur from an Industrial Effluent Contaminated Pond Water and Its Preliminary Application in High Performance Battery. Sep. Purif. Technol. 2017, 180, 133–141. [Google Scholar] [CrossRef]

- Ma, C.; Pei, S.; You, S. Closed Bipolar Electrode for Decoupled Electrochemical Water Decontamination and Hydrogen Recovery. Electrochem. Commun. 2019, 109, 106611. [Google Scholar] [CrossRef]

- Chen, P.; Yin, D.; Song, P.; Liu, Y.; Cai, L.; Wang, H.; Zhang, L. Demulsification and Oil Recovery from Oil-in-Water Cutting Fluid Wastewater Using Electrochemical Micromembrane Technology. J. Clean. Prod. 2020, 244, 118698. [Google Scholar] [CrossRef]

- Buscio Olivera, V. Tratamiento y Reutilización de Efluentes de La Industria Textil Mediante Técnicas de Membranas. TDX (Tesis Dr. en Xarxa). Universitat Politècnica de Catalunya. Departament d’Enginyeria Tèxtil i Paperera. 2015. Available online: http://hdl.handle.net/2117/96008 (accessed on 22 November 2021).

- Cheng, D.; Liu, Y.; Ngo, H.H.; Guo, W.; Chang, S.W.; Nguyen, D.D.; Zhang, S.; Luo, G.; Liu, Y. A Review on Application of Enzymatic Bioprocesses in Animal Wastewater and Manure Treatment. Bioresour. Technol. 2020, 313, 123683. [Google Scholar] [CrossRef]

- He, H.; Zhang, X.; Yang, C.; Zeng, G.; Li, H.; Chen, Y. Treatment of Organic Wastewater Containing High Concentration of Sulfate by Crystallization-Fenton-SBR. J. Environ. Eng. 2018, 144, 4018041. [Google Scholar] [CrossRef]

- Shao, J.; Cheng, Y.; Yang, C.; Zeng, G.; Liu, W.; Jiao, P.; He, H. Efficient Removal of Naphthalene-2-ol from Aqueous Solutions by Solvent Extraction. J. Environ. Sci. 2016, 47, 120–129. [Google Scholar] [CrossRef] [PubMed]

- Ordonez, D.; Valencia, A.; Chang, N.-B.; Wanielista, M.P. Synergistic Effects of Aluminum/Iron Oxides and Clay Minerals on Nutrient Removal and Recovery in Water Filtration Media. J. Clean. Prod. 2020, 275, 122728. [Google Scholar] [CrossRef]

- Hube, S.; Eskafi, M.; Hrafnkelsdóttir, K.F.; Bjarnadóttir, B.; Bjarnadóttir, M.Á.; Axelsdóttir, S.; Wu, B. Direct Membrane Filtration for Wastewater Treatment and Resource Recovery: A Review. Sci. Total Environ. 2020, 710, 136375. [Google Scholar] [CrossRef] [PubMed]

- El-Diasty, A.I.; Ragab, A.M. Applications of Nanotechnology in the oil & gas industry: Lastest trends wordwilde & future challenges in Egypt. Porceedings of the North Africa Technical Conference and Exhibition, Cairo, Egypt, 15 April 2013; One Petro: Cairo, Egypt, 2013. Paper Number SPE-164716-MS. [Google Scholar] [CrossRef]

- Yang, Y.; Han, S.; Fan, Q.; Ugbolue, S.C. Nanoclay and Modified Nanoclay as Sorbents for Anionic, Cationic and Nonionic Dyes. Text. Res. J. 2005, 75, 622–627. [Google Scholar] [CrossRef]

- López Arbeloa, F.; Martínez Martínez, V.; Bañuelos Prieto, J.; López Arbeloa, I. Adsorption of Rhodamine 3B Dye on Saponite Colloidal Particles in Aqueous Suspensions. Langmuir 2002, 18, 2658–2664. [Google Scholar] [CrossRef]

- Yang, S.; Gao, M.; Luo, Z. Adsorption of 2-Naphthol on the Organo-Montmorillonites Modified by Gemini Surfactants with Different Spacers. Chem. Eng. J. 2014, 256, 39–50. [Google Scholar] [CrossRef]

- Luo, Z.; Gao, M.; Ye, Y.; Yang, S. Modification of Reduced-Charge Montmorillonites by a Series of Gemini Surfactants: Characterization and Application in Methyl Orange Removal. Appl. Surf. Sci. 2015, 324, 807–816. [Google Scholar] [CrossRef]

- Zhu, T.T.; Zhou, C.H.; Kabwe, F.B.; Wu, Q.Q.; Li, C.S.; Zhang, J.R. Exfoliation of Montmorillonite and Related Properties of Clay/Polymer Nanocomposites. Appl. Clay Sci. 2019, 169, 48–66. [Google Scholar] [CrossRef]

- Zheng, L.; Xu, H.; Rutqvist, J.; Reagan, M.; Birkholzer, J.; Villar, M.V.; Fernández, A.M. The Hydration of Bentonite Buffer Material Revealed by Modeling Analysis of a Long-Term in Situ Test. Appl. Clay Sci. 2020, 185, 105360. [Google Scholar] [CrossRef]

- Gupta, V.K.; Agarwal, S.; Olgun, A.; Demir, H.İ.; Yola, M.L.; Atar, N. Adsorptive Properties of Molasses Modified Boron Enrichment Waste Based Nanoclay for Removal of Basic Dyes. J. Ind. Eng. Chem. 2016, 34, 244–249. [Google Scholar] [CrossRef]

- Carretero, M.I.; Pozo, M.; Sánchez, C.; García, F.J.; Medina, J.A.; Bernabé, J.M. Comparison of Saponite and Montmorillonite Behaviour during Static and Stirring Maturation with Seawater for Pelotherapy. Appl. Clay Sci. 2007, 36, 161–173. [Google Scholar] [CrossRef]

- Taleb, K.; Pillin, I.; Grohens, Y.; Saidi-Besbes, S. Gemini Surfactant Modified Clays: Effect of Surfactant Loading and Spacer Length. Appl. Clay Sci. 2018, 161, 48–56. [Google Scholar] [CrossRef]

- Ngulube, T.; Gumbo, J.R.; Masindi, V.; Maity, A. An Update on Synthetic Dyes Adsorption onto Clay Based Minerals: A State-of-Art Review. J. Environ. Manag. 2017, 191, 35–57. [Google Scholar] [CrossRef] [PubMed]

- Dolez, P.I. Nanomaterials Definitions, Classifications, and Applications. Nanoengineering 2015, 3–40. [Google Scholar] [CrossRef]

- Rasouli, F.; Aber, S.; Salari, D.; Khataee, A.R. Optimized Removal of Reactive Navy Blue SP-BR by Organo-Montmorillonite Based Adsorbents through Central Composite Design. Appl. Clay Sci. 2014, 87, 228–234. [Google Scholar] [CrossRef]

- Zayed, A.M.; Abdel Wahed, M.S.M.; Mohamed, E.A.; Sillanpää, M. Insights on the Role of Organic Matters of Some Egyptian Clays in Methyl Orange Adsorption: Isotherm and Kinetic Studies. Appl. Clay Sci. 2018, 166, 49–60. [Google Scholar] [CrossRef]

- Stagnaro, S.M.; Volzone, C.; Huck, L. Nanoclay as Adsorbent: Evaluation for Removing Dyes Used in the Textile Industry. Procedia Mater. Sci. 2015, 8, 586–591. [Google Scholar] [CrossRef] [Green Version]

- Nyankson, E.; Agyei-Tuffour, B.; Annan, E.; Yaya, A.; Mensah, B.; Onwona-Agyeman, B.; Amedalor, R.; Kwaku-Frimpong, B.; Efavi, J.K. Ag2CO3-Halloysite Nanotubes Composite with Enhanced Removal Efficiency for Water Soluble Dyes. Heliyon 2019, 5, e01969. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, Q.; Gao, M.; Luo, Z.; Yang, S. Enhanced Removal of Bisphenol A from Aqueous Solution by Organo-Montmorillonites Modified with Novel Gemini Pyridinium Surfactants Containing Long Alkyl Chain. Chem. Eng. J. 2016, 285, 27–38. [Google Scholar] [CrossRef]

- Selvitepe, N.; Balbay, A.; Saka, C. Optimisation of Sepiolite Clay with Phosphoric Acid Treatment as Support Material for CoB Catalyst and Application to Produce Hydrogen from the NaBH4 Hydrolysis. Int. J. Hydrogen Energy 2019, 44, 16387–16399. [Google Scholar] [CrossRef]

- Daraei, P.; Madaeni, S.S.; Salehi, E.; Ghaemi, N.; Ghari, H.S.; Khadivi, M.A.; Rostami, E. Novel Thin Film Composite Membrane Fabricated by Mixed Matrix Nanoclay/Chitosan on PVDF Microfiltration Support: Preparation, Characterization and Performance in Dye Removal. J. Membr. Sci. 2013, 436, 97–108. [Google Scholar] [CrossRef]

- Olvera, R.C.; Silva, S.L.; Robles-Belmont, E.; Lau, E.Z. Review of Nanotechnology Value Chain for Water Treatment Applications in Mexico. Resour. Technol. 2017, 3, 1–11. [Google Scholar] [CrossRef]

- Kausar, A.; Iqbal, M.; Javed, A.; Aftab, K.; Nazli, Z.-H.; Bhatti, H.N.; Nouren, S. Dyes Adsorption Using Clay and Modified Clay: A Review. J. Mol. Liq. 2018, 256, 395–407. [Google Scholar] [CrossRef]

- Darwish, A.A.A.; Rashad, M.; AL-Aoh, H.A. Methyl Orange Adsorption Comparison on Nanoparticles: Isotherm, Kinetics, and Thermodynamic Studies. Dye. Pigment. 2019, 160, 563–571. [Google Scholar] [CrossRef]

- Santhosh, C.; Velmurugan, V.; Jacob, G.; Jeong, S.K.; Grace, A.N.; Bhatnagar, A. Role of Nanomaterials in Water Treatment Applications: A Review. Chem. Eng. J. 2016, 306, 1116–1137. [Google Scholar] [CrossRef]

- Schoonheydt, R.A.; Heughebaert, L. Clay adsorbed dyes: Methylene blue on laponite. Clay Miner. 1992, 27, 91–100. [Google Scholar] [CrossRef]

- Yagub, M.T.; Sen, T.K.; Afroze, S.; Ang, H.M. Dye and Its Removal from Aqueous Solution by Adsorption: A Review. Adv. Colloid Interface Sci. 2014, 209, 172–184. [Google Scholar] [CrossRef] [PubMed]

- Anjum, M.; Miandad, R.; Waqas, M.; Gehany, F.; Barakat, M.A. Remediation of Wastewater Using Various Nano-Materials. Arab. J. Chem. 2016. [Google Scholar] [CrossRef] [Green Version]

- Liang, Y.; Li, H. A Comparison of Trimeric Surfactant Intercalated Montmorillonite with Its Gemini Modified One: Characterization and Application in Methyl Orange Removal. J. Mol. Liq. 2017, 227, 139–146. [Google Scholar] [CrossRef]

- Vanamudan, A.; Pamidimukkala, P. Chitosan, Nanoclay and Chitosan–Nanoclay Composite as Adsorbents for Rhodamine-6G and the Resulting Optical Properties. Int. J. Biol. Macromol. 2015, 74, 127–135. [Google Scholar] [CrossRef] [PubMed]

- Fontaine, F.; Christidis, G.E.; Yans, J.; Hollanders, S.; Hoffman, A.; Fagel, N. Characterization and Origin of Two Fe-Rich Bentonites from Westerwald (Germany). Appl. Clay Sci. 2020, 187, 105444. [Google Scholar] [CrossRef]

- Topuz, F.; Uyar, T. Electrospinning of Nanocomposite Nanofibers from Cyclodextrin and Laponite. Compos. Commun. 2019, 12, 33–38. [Google Scholar] [CrossRef]

- Zhou, C.H.; Zhou, Q.; Wu, Q.Q.; Petit, S.; Jiang, X.C.; Xia, S.T.; Li, C.S.; Yu, W.H. Modification, Hybridization and Applications of Saponite: An Overview. Appl. Clay Sci. 2019, 168, 136–154. [Google Scholar] [CrossRef]

- De Gisi, S.; Lofrano, G.; Grassi, M.; Notarnicola, M. Characteristics and Adsorption Capacities of Low-Cost Sorbents for Wastewater Treatment: A Review. Sustain. Mater. Technol. 2016, 9, 10–40. [Google Scholar] [CrossRef] [Green Version]

- Colletti, C.G.; Massaro, M.; Lazzara, G.; Cavallaro, G.; Milioto, S.; Pibiri, I.; Noto, R.; Riela, S. Synthesis, Characterization and Study of Covalently Modified Triazole LAPONITE® Edges. Appl. Clay Sci. 2020, 187, 105489. [Google Scholar] [CrossRef]

- El-Zahhar, A.A.; Awwad, N.S.; El-Katori, E.E. Removal of Bromophenol Blue Dye from Industrial Waste Water by Synthesizing Polymer-Clay Composite. J. Mol. Liq. 2014, 199, 454–461. [Google Scholar] [CrossRef]

- Khodami, S.; Mehdipour-Ataei, S.; Babanzadeh, S. Preparation, Characterization, and Performance Evaluation of Sepiolite-Based Nanocomposite Membrane for Desalination. J. Ind. Eng. Chem. 2020, 82, 164–172. [Google Scholar] [CrossRef]

- Mittal, H.; Babu, R.; Dabbawala, A.A.; Stephen, S.; Alhassan, S.M. Zeolite-Y Incorporated Karaya Gum Hydrogel Composites for Highly Effective Removal of Cationic Dyes. Colloids Surfaces A Physicochem. Eng. Asp. 2020, 586, 124161. [Google Scholar] [CrossRef]

- Micó Vicent, B.; Martinez Verdu, F.M.; Gilabert Perez, J.E. Optimización de La Síntesis de Nanopigmentos de Origen Natural Para Biopolímeros Mediante El Uso Del Diseño de Experimentos. Ph.D. Thesis, Universitat Politècnica de València, 2015. Available online: http://hdl.handle.net/10251/59449 (accessed on 22 November 2021).

- Chong, A.S.; Manan, M.A.; Idris, A.K. Readiness of Lignosulfonate Adsorption onto Montmorillonite. Colloids Surfaces A Physicochem. Eng. Asp. 2021, 628, 127318. [Google Scholar] [CrossRef]

- Alexandre, M.; Dubois, P. Polymer-Layered Silicate Nanocomposites: Preparation, Properties and Uses of a New Class of Materials. Mater. Sci. Eng. R Rep. 2000, 28, 1–63. [Google Scholar] [CrossRef]

- Emmerich, K.; Kahr, G. The Cis-and Trans-Vacant Variety of a Montmorillonite: An Attempt to Create a Model Smectite. Appl. Clay Sci. 2001, 20, 119–127. [Google Scholar] [CrossRef]

- Li, J.; Cai, J.; Zhong, L.; Cheng, H.; Wang, H.; Ma, Q. Adsorption of Reactive Red 136 onto Chitosan/Montmorillonite Intercalated Composite from Aqueous Solution. Appl. Clay Sci. 2019, 167, 9–22. [Google Scholar] [CrossRef]

- Gireeshkumar, T.R.; Mathew, D.; Udayakrishnan, P.B.; Shameem, K.; KP, F.F.; Furtado, C.M.; Deepulal, P.M.; Nair, M.; Balachandran, K.K. Montmorillonite and Phosphorus Enrichment in Sediments as the Causative Factor for Mud Bank Formation along the Southwest Coast of India. Reg. Stud. Mar. Sci. 2020, 40, 101517. [Google Scholar] [CrossRef]

- Zheng, R.; Liu, D.; Tang, J.; Song, Q.; Yao, Q. Analysis of Montmorillonite Affecting Coke Formation during the Thermal Conversion of Heavy Oil. Fuel 2020, 288, 119687. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, Z. Effect and Mechanism of Cation Species on the Gel Properties of Montmorillonite. Colloids Surfaces A Physicochem. Eng. Asp. 2020, 611, 125824. [Google Scholar] [CrossRef]

- Hojiyev, R.; Ulcay, Y.; Çelik, M.S.; Carty, W.M. Effect of CEC Coverage of Hexadecyltributylphosphonium Modified Montmorillonite on Polymer Compatibility. Appl. Clay Sci. 2017, 141, 204–211. [Google Scholar] [CrossRef]

- Manning, D.A.C. Handbook of Clay Science (Developments in Clay Science, 1); Bergaya, F., Theng, B.K.G., Lagaly, G., Eds.; Elsevier: Oxford, UK, 2007. [Google Scholar]

- Capková, P.; Driessen, R.A.J.; Schenk, H.; Weiss, Z. Interlayer Porosity in Montmorillonite Intercalated with Keggin-like Cation Studied by Molecular Mechanics Simulation. Mol. Model. Annu. 1997, 3, 467–472. [Google Scholar] [CrossRef]

- Vazquez, A.; López, M.; Kortaberria, G.; Martín, L.; Mondragon, I. Modification of Montmorillonite with Cationic Surfactants. Thermal and Chemical Analysis Including CEC Determination. Appl. Clay Sci. 2008, 41, 24–36. [Google Scholar] [CrossRef]

- Zhu, H.Y.; Gao, W.H.; Vansant, E.F. The Porosity and Water Adsorption of Alumina Pillared Montmorillonite. J. Colloid Interface Sci. 1995, 171, 377–385. [Google Scholar] [CrossRef]

- Laird, D.A.; Shang, C. Relationship between Cation Exchange Selectivity and Crystalline Swelling in Expanding 2: 1 Phyllosilicates. Clays Clay Miner. 1997, 45, 681–689. [Google Scholar] [CrossRef]

- Wang, C.-C.; Juang, L.-C.; Hsu, T.-C.; Lee, C.-K.; Lee, J.-F.; Huang, F.-C. Adsorption of Basic Dyes onto Montmorillonite. J. Colloid Interface Sci. 2004, 273, 80–86. [Google Scholar] [CrossRef] [PubMed]

- Fahn, R.; Fenderl, K. Reaction Products of Organic Dye Molecules with Acid-Treated Montmorillonite. Clay Miner. 1983, 18, 447–458. [Google Scholar] [CrossRef]

- Mishael, Y.G.; Rytwo, G.; Nir, S.; Crespin, M.; Annabi-Bergaya, F.; Van Damme, H. Interactions of Monovalent Organic Cations with Pillared Clays. J. Colloid Interface Sci. 1999, 209, 123–128. [Google Scholar] [CrossRef]

- Penner, D.; Lagaly, G. Influence of Organic and Inorganic Salts on the Coagulation of Montmorillonite Dispersions. Clays Clay Miner. 2000, 48, 246–255. [Google Scholar] [CrossRef]

- Janek, M.; Lagaly, G. Proton Saturation and Rheological Properties of Smectite Dispersions. Appl. Clay Sci. 2001, 19, 121–130. [Google Scholar] [CrossRef]

- Antúnez-García, J.; Galván, D.H.; Petranovskii, V.; Murrieta-Rico, F.N.; Yocupicio-Gaxiola, R.I.; Shelyapina, M.G.; Fuentes-Moyado, S. The Effect of Chemical Composition on the Properties of LTA Zeolite: A Theoretical Study. Comput. Mater. Sci. 2021, 196. [Google Scholar] [CrossRef]

- Khaleque, A.; Alam, M.M.; Hoque, M.; Mondal, S.; Haider, J.B.; Xu, B.; Johir, M.A.H.; Karmakar, A.K.; Zhou, J.L.; Ahmed, M.B.; et al. Zeolite Synthesis from Low-Cost Materials and Environmental Applications: A Review. Environ. Adv. 2020, 2, 100019. [Google Scholar] [CrossRef]

- Si, D.; Zhu, M.; Sun, X.; Xue, M.; Li, Y.; Wu, T.; Gui, T.; Kumakiri, I.; Chen, X.; Kita, H. Formation Process and Pervaporation of High Aluminum ZSM-5 Zeolite Membrane with Fluoride-Containing and Organic Template-Free Gel. Sep. Purif. Technol. 2021, 257, 117963. [Google Scholar] [CrossRef]

- Lo, A.Y.; Taghipour, F. Review and Prospects of Microporous Zeolite Catalysts for CO2 Photoreduction. Appl. Mater. Today 2021, 23, 101042. [Google Scholar] [CrossRef]

- He, C.; Zhang, X.; Yu, J.; Xiang, Y.; Deng, L.; Zhao, S.; Gao, J.; Yuan, Y.; Lei, Y. Study on Adsorption Performance and Mechanism of Cr (VI) by Zn-LDHs Coating on Zeolites and Quartz Sands. Acta Sci. Circumstantiae 2019, 39, 399–409. [Google Scholar]

- Wang, C.; Cao, L.; Huang, J. Influences of Acid and Heat Treatments on the Structure and Water Vapor Adsorption Property of Natural Zeolite. Surf. Interface Anal. 2017, 49, 1249–1255. [Google Scholar] [CrossRef]

- Probst, J.; Outram, J.G.; Couperthwaite, S.J.; Millar, G.J.; Kaparaju, P. Sustainable Ammonium Recovery from Wastewater: Improved Synthesis and Performance of Zeolite N Made from Kaolin. Microporous Mesoporous Mater. 2021, 316, 110918. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, N. Applications of Natural Zeolites to Environmental Protection. Acta Mineral. Sin. 2003, 23, 250–254. [Google Scholar]

- Kaijun, W.; Wenyan, H.E.; Kuo, F. Analysis of the Application of Typical Ion Exchange Water Treatment Technology in Low Concentration Ammonia Nitrogen Recovery. Chin. J. Environ. Eng. 2019, 13, 2285–2301. [Google Scholar]

- Sharma, R.; Segato, T.; Delplancke, M.-P.; Terryn, H.; Baron, G.V.; Denayer, J.F.M.; Cousin-Saint-Remi, J. Hydrogen Chloride Removal from Hydrogen Gas by Adsorption on Hydrated Ion-Exchanged Zeolites. Chem. Eng. J. 2020, 381, 122512. [Google Scholar] [CrossRef]

- Shi, Y.; Sun, K. Preparation of Diphenylcarbazide-Directed CdSe Quantum Dots and Selective Determination for Cr (VI). J. Wuhan Univ. Technol. Sci. Ed. 2016, 31, 972–976. [Google Scholar] [CrossRef]

- Breck, D.W. Zeolite Molecular Sieves: Structure, Chemistry and Use; Krieger; John Wiley & Sons: New York, NY, USA, 1984; ISBN 0898746485. [Google Scholar]

- Wajima, T.; Yoshizuka, K.; Hirai, T.; Ikegami, Y. Synthesis of Zeolite X from Waste Sandstone Cake Using Alkali Fusion Method. Mater. Trans. 2008, 49, 612–618. [Google Scholar] [CrossRef] [Green Version]

- Shoppert, A.A.; Loginova, I.V.; Chaikin, L.I.; Rogozhnikov, D.A. Alkali Fusion-Leaching Method for Comprehensive Processing of Fly Ash. KnE Mater. Sci. 2017, 89–96. [Google Scholar] [CrossRef] [Green Version]

- Tsujiguchi, M.; Kobashi, T.; Oki, M.; Utsumi, Y.; Kakimori, N.; Nakahira, A. Synthesis and Characterization of Zeolite A from Crushed Particles of Aluminoborosilicate Glass Used in LCD Panels. J. Asian Ceram. Soc. 2014, 2, 27–32. [Google Scholar] [CrossRef] [Green Version]

- Perot, G.; Guisnet, M. Advantages and Disadvantages of Zeolites as Catalysts in Organic Chemistry. J. Mol. Catal. 1990, 61, 173–196. [Google Scholar] [CrossRef]

- Parades-Aguilar, J.; Reyes-Martínez, V.; Bustamante, G.; Almendáriz-Tapia, F.J.; Martínez-Meza, G.; Vílchez-Vargas, R.; Link, A.; Certucha-Barragán, M.T.; Calderón, K. Removal of Nickel (II) from Wastewater Using a Zeolite-Packed Anaerobic Bioreactor: Bacterial Diversity and Community Structure Shifts. J. Environ. Manag. 2021, 279, 111558. [Google Scholar] [CrossRef] [PubMed]

- Saqib, N.U.; Adnan, R.; Rahim, M.; Khan, A. Low-Cost Zeolite/TiO2 Composite for the Photocatalytically Enhanced Adsorption of Cd2+ from Aqueous Solution. J. Iran. Chem. Soc. 2021, 18, 2165–2180. [Google Scholar] [CrossRef]

- Lvov, Y.M.; DeVilliers, M.M.; Fakhrullin, R.F. The Application of Halloysite Tubule Nanoclay in Drug Delivery. Expert Opin. Drug Deliv. 2016, 13, 977–986. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Jia, Z.; Jia, D.; Zhou, C. Recent Advance in Research on Halloysite Nanotubes-Polymer Nanocomposite. Prog. Polym. Sci. 2014, 39, 1498–1525. [Google Scholar] [CrossRef]

- Lazaratou, C.V.; Panagiotaras, D.; Panagopoulos, G.; Pospíšil, M.; Papoulis, D. Ca Treated Palygorskite and Halloysite Clay Minerals for Ferrous Iron (Fe+2) Removal from Water Systems. Environ. Technol. Innov. 2020, 19, 100961. [Google Scholar] [CrossRef]

- Van Ranst, E.; Kips, P.; Mbogoni, J.; Mees, F.; Dumon, M.; Delvaux, B. Halloysite-Smectite Mixed-Layered Clay in Fluvio-Volcanic Soils at the Southern Foot of Mount Kilimanjaro, Tanzania. Geoderma 2020, 375, 114527. [Google Scholar] [CrossRef]

- Zhao, N.; Liu, Y.; Zhao, X.; Song, H. Liquid Crystal Self-Assembly of Halloysite Nanotubes in Ionic Liquids: A Novel Soft Nanocomposite Ionogel Electrolyte with High Anisotropic Ionic Conductivity and Thermal Stability. Nanoscale 2016, 8, 1545–1554. [Google Scholar] [CrossRef]

- Lazzara, G.; Cavallaro, G.; Panchal, A.; Fakhrullin, R.; Stavitskaya, A.; Vinokurov, V.; Lvov, Y. An Assembly of Organic-Inorganic Composites Using Halloysite Clay Nanotubes. Curr. Opin. Colloid Interface Sci. 2018, 35, 42–50. [Google Scholar] [CrossRef]

- Yendluri, R.; Otto, D.P.; De Villiers, M.M.; Vinokurov, V.; Lvov, Y.M. Application of Halloysite Clay Nanotubes as a Pharmaceutical Excipient. Int. J. Pharm. 2017, 521, 267–273. [Google Scholar] [CrossRef] [PubMed]

- Yuan, P.; Tan, D.; Annabi-Bergaya, F. Properties and Applications of Halloysite Nanotubes: Recent Research Advances and Future Prospects. Appl. Clay Sci. 2015, 112, 75–93. [Google Scholar] [CrossRef]

- Pasbakhsh, P.; Churchman, G.J.; Keeling, J.L. Characterisation of Properties of Various Halloysites Relevant to Their Use as Nanotubes and Microfibre Fillers. Appl. Clay Sci. 2013, 74, 47–57. [Google Scholar] [CrossRef]

- Makaremi, M.; Pasbakhsh, P.; Cavallaro, G.; Lazzara, G.; Aw, Y.K.; Lee, S.M.; Milioto, S. Effect of Morphology and Size of Halloysite Nanotubes on Functional Pectin Bionanocomposites for Food Packaging Applications. ACS Appl. Mater. Interfaces 2017, 9, 17476–17488. [Google Scholar] [CrossRef]

- Cavallaro, G.; Chiappisi, L.; Pasbakhsh, P.; Gradzielski, M.; Lazzara, G. A Structural Comparison of Halloysite Nanotubes of Different Origin by Small-Angle Neutron Scattering (SANS) and Electric Birefringence. Appl. Clay Sci. 2018, 160, 71–80. [Google Scholar] [CrossRef]

- Agafonov, A.V.; Kudryakova, N.O.; Ramenskaya, L.M.; Grishina, E.P. The Confinement and Anion Type Effect on the Physicochemical Properties of Ionic Liquid/Halloysite Nanoclay Ionogels. Arab. J. Chem. 2020, 13, 9090–9104. [Google Scholar] [CrossRef]

- Blagojević, B.; Četojević-Simin, D.; Parisi, F.; Lazzara, G.; Popović, B.M. Halloysite Nanotubes as a Carrier of Cornelian Cherry (Cornus Mas L.) Bioactives. Lwt 2020, 134, 110247. [Google Scholar] [CrossRef]

- Zhang, B.; Yuan, P.; Guo, H.; Deng, L.; Li, Y.; Li, L.; Wang, Q.; Liu, D. Effect of Curing Conditions on the Microstructure and Mechanical Performance of Geopolymers Derived from Nanosized Tubular Halloysite. Constr. Build. Mater. 2020, 121186. [Google Scholar] [CrossRef]

- Luo, P.; Zhao, Y.; Zhang, B.; Liu, J.; Yang, Y.; Liu, J. Study on the Adsorption of Neutral Red from Aqueous Solution onto Halloysite Nanotubes. Water Res. 2010, 44, 1489–1497. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Fizir, M.; Hu, F.; Li, A.; Hui, X.; Zha, J.; He, H. Mixed Hemimicelle Solid-Phase Extraction Based on Magnetic Halloysite Nanotubes and Ionic Liquids for the Determination and Extraction of Azo Dyes in Environmental Water Samples. J. Chromatogr. A 2018, 1551, 10–20. [Google Scholar] [CrossRef]

- Zhao, M.; Liu, P. Adsorption Behavior of Methylene Blue on Halloysite Nanotubes. Microporous Mesoporous Mater. 2008, 112, 419–424. [Google Scholar] [CrossRef]

- Luo, P.; Zhang, B.; Zhao, Y.; Wang, J.; Zhang, H.; Liu, J. Removal of Methylene Blue from Aqueous Solutions by Adsorption onto Chemically Activated Halloysite Nanotubes. Korean J. Chem. Eng. 2011, 28, 800–807. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, Y.; Wang, A. Response Surface Methodology for Optimizing Adsorption Process Parameters for Methylene Blue Removal by a Hydrogel Composite. Adsorpt. Sci. Technol. 2010, 28, 913–922. [Google Scholar] [CrossRef]

- Liu, L.; Wan, Y.; Xie, Y.; Zhai, R.; Zhang, B.; Liu, J. The Removal of Dye from Aqueous Solution Using Alginate-Halloysite Nanotube Beads. Chem. Eng. J. 2012, 187, 210–216. [Google Scholar] [CrossRef]

- Peng, Q.; Liu, M.; Zheng, J.; Zhou, C. Adsorption of Dyes in Aqueous Solutions by Chitosan–Halloysite Nanotubes Composite Hydrogel Beads. Microporous Mesoporous Mater. 2015, 201, 190–201. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, C.; Wei, J.; Tjiu, W.; Pan, J.; Chen, Y.; Liu, T. Surface Modifications of Halloysite Nanotubes with Superparamagnetic Fe3O4 Nanoparticles and Carbonaceous Layers for Efficient Adsorption of Dyes in Water Treatment. Chem. Res. Chin. Univ. 2014, 30, 971–977. [Google Scholar] [CrossRef]

- Nguyen, T.K.L.; Cao, X.T.; Park, C.; Lim, K.T. Preparation, Characterization and Application of Magnetic Halloysite Nanotubes for Dye Removal. Mol. Cryst. Liq. Cryst. 2017, 644, 153–159. [Google Scholar] [CrossRef]

- Wan, X.; Zhan, Y.; Long, Z.; Zeng, G.; He, Y. Core@ Double-Shell Structured Magnetic Halloysite Nanotube Nano-Hybrid as Efficient Recyclable Adsorbent for Methylene Blue Removal. Chem. Eng. J. 2017, 330, 491–504. [Google Scholar] [CrossRef]

- Farrokhi-Rad, M.; Mohammadalipour, M.; Shahrabi, T. Electrophoretically Deposited Halloysite Nanotubes Coating as the Adsorbent for the Removal of Methylene Blue from Aqueous Solution. J. Eur. Ceram. Soc. 2018, 38, 3650–3659. [Google Scholar] [CrossRef]

- Liu, R.; Fu, K.; Zhang, B.; Mei, D.; Zhang, H.; Liu, J. Removal of Methyl Orange by Modified Halloysite Nanotubes. J. Dispers. Sci. Technol. 2012, 33, 711–718. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, J.; Wu, J.; Yan, H. Selective Desorption Characteristics of Halloysite Nanotubes for Anionic Azo Dyes. RSC Adv. 2014, 4, 15389–15393. [Google Scholar] [CrossRef]

- Chen, H.; Yan, H.; Pei, Z.; Wu, J.; Li, R.; Jin, Y.; Zhao, J. Trapping Characteristic of Halloysite Lumen for Methyl Orange. Appl. Surf. Sci. 2015, 347, 769–776. [Google Scholar] [CrossRef]

- Ferrarini, F.; Bonetto, L.R.; Crespo, J.S.; Giovanela, M. Removal of Congo Red Dye from Aqueous Solutions Using a Halloysite-Magnetite-Based Composite. Water Sci. Technol. 2016, 73, 2132–2142. [Google Scholar] [CrossRef] [PubMed]

- Bessaha, F.; Mahrez, N.; Bendenia, S.; Kasmi, F.; Marouf-Khelifa, K.; Khelifa, A. Characterization and Spectroscopic Study of a Heat-Treated and Acid-Leached Halloysite Used in Congo Red Adsorption. Int. J. Intell. Eng. Syst. 2017, 10, 272–279. [Google Scholar] [CrossRef]

- Fard, F.S.; Akbari, S.; Pajootan, E.; Arami, M. Enhanced Acidic Dye Adsorption onto the Dendrimer-Based Modified Halloysite Nanotubes. Desalin. Water Treat. 2016, 57, 26222–26239. [Google Scholar] [CrossRef]

- Zango, Z.U.; Abu Bakar, N.H.H.; Tan, W.L.; Bakar, M.A. Enhanced Removal Efficiency of Methyl Red via the Modification of Halloysite Nanotubes by Copper Oxide. J. Dispers. Sci. Technol. 2018, 39, 148–154. [Google Scholar] [CrossRef]

- Cavallaro, G.; Gianguzza, A.; Lazzara, G.; Milioto, S.; Piazzese, D. Alginate Gel Beads Filled with Halloysite Nanotubes. Appl. Clay Sci. 2013, 72, 132–137. [Google Scholar] [CrossRef]

- Kiani, G.; Dostali, M.; Rostami, A.; Khataee, A.R. Adsorption Studies on the Removal of Malachite Green from Aqueous Solutions onto Halloysite Nanotubes. Appl. Clay Sci. 2011, 54, 34–39. [Google Scholar] [CrossRef]

- Bessaha, F.; Marouf-Khelifa, K.; Batonneau-Gener, I.; Khelifa, A. Characterization and Application of Heat-Treated and Acid-Leached Halloysites in the Removal of Malachite Green: Adsorption, Desorption, and Regeneration Studies. Desalin. Water Treat. 2016, 57, 14609–14621. [Google Scholar] [CrossRef]

- Duan, J.; Liu, R.; Chen, T.; Zhang, B.; Liu, J. Halloysite Nanotube-Fe3O4 Composite for Removal of Methyl Violet from Aqueous Solutions. Desalination 2012, 293, 46–52. [Google Scholar] [CrossRef]

- Bonetto, L.R.; Ferrarini, F.; De Marco, C.; Crespo, J.S.; Guégan, R.; Giovanela, M. Removal of Methyl Violet 2B Dye from Aqueous Solution Using a Magnetic Composite as an Adsorbent. J. Water Process Eng. 2015, 6, 11–20. [Google Scholar] [CrossRef] [Green Version]

- Tao, D.; Higaki, Y.; Ma, W.; Takahara, A. Halloysite Nanotube/Polyelectrolyte Hybrids as Adsorbents for the Quick Removal of Dyes from Aqueous Solution. Chem. Lett. 2015, 44, 1572–1574. [Google Scholar] [CrossRef] [Green Version]

- Desai, S.; Pandey, A.; Dahiya, M.S. Application of Hallosysite Nanotubes in Removal of Auramine Y and Auramine O Dyes. Int. J. PharmTech. Res. 2017, 10, 62–76. [Google Scholar]

- Khatri, N.; Tyagi, S.; Rawtani, D. Removal of Basic Dyes Auramine Yellow and Auramine O by Halloysite Nanotubes. Int. J. Environ. Waste Manag. 2016, 17, 44–59. [Google Scholar] [CrossRef]

- Mudhoo, A.; Gautam, R.K.; Ncibi, M.C.; Zhao, F.; Garg, V.K.; Sillanpää, M. Green Synthesis, Activation and Functionalization of Adsorbents for Dye Sequestration. Environ. Chem. Lett. 2019, 17, 157–193. [Google Scholar] [CrossRef]

- Riahi-Madvaar, R.; Taher, M.A.; Fazelirad, H. Synthesis and Characterization of Magnetic Halloysite-Iron Oxide Nanocomposite and Its Application for Naphthol Green B Removal. Appl. Clay Sci. 2017, 137, 101–106. [Google Scholar] [CrossRef]

- Massaro, M.; Colletti, C.G.; Lazzara, G.; Guernelli, S.; Noto, R.; Riela, S. Synthesis and Characterization of Halloysite–Cyclodextrin Nanosponges for Enhanced Dyes Adsorption. ACS Sustain. Chem. Eng. 2017, 5, 3346–3352. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Abdullayev, E.; Vasiliev, A.; Lvov, Y. Halloysite Nanotubule Clay for Efficient Water Purification. J. Colloid Interface Sci. 2013, 406, 121–129. [Google Scholar] [CrossRef] [PubMed]

- Jinhua, W.; Xiang, Z.; Bing, Z.; Yafei, Z.; Rui, Z.; Jindun, L.; Rongfeng, C. Rapid Adsorption of Cr (VI) on Modified Halloysite Nanotubes. Desalination 2010, 259, 22–28. [Google Scholar] [CrossRef]

- Al-Beladi, A.A.; Kosa, S.A.; Wahab, R.A.; Salam, M.A. Removal of Orange G Dye from Water Using Halloysite Nanoclay-Supported ZnO Nanoparticles. Desalin. Water Treat. 2020, 196, 287–298. [Google Scholar] [CrossRef]

- Kanani-Jazi, M.H.; Akbari, S. Amino-Dendritic and Carboxyl Functionalized Halloysite Nanotubes for Highly Efficient Removal of Cationic and Anionic Dyes: Kinetic, Isotherm, and Thermodynamic Studies. J. Environ. Chem. Eng. 2021, 9, 105214. [Google Scholar] [CrossRef]

- Brigatti, M.F.; Galan, E.; Theng, B.K.G. Structures and Mineralogy of Clay Minerals. Dev. Clay Sci. 2006, 1, 19–86. [Google Scholar]

- Sprynskyy, M.; Sokol, H.; Rafińska, K.; Brzozowska, W.; Railean-Plugaru, V.; Pomastowski, P.; Buszewski, B. Preparation of AgNPs/Saponite Nanocomposites without Reduction Agents and Study of Its Antibacterial Activity. Colloids Surf. B Biointerfaces 2019, 180, 457–465. [Google Scholar] [CrossRef]

- Lima, L.C.B.; Silva, F.C.; Silva-Filho, E.C.; Fonseca, M.G.; Zhuang, G.; Jaber, M. Saponite-Anthocyanin Derivatives: The Role of Organoclays in Pigment Photostability. Appl. Clay Sci. 2020, 191, 105604. [Google Scholar] [CrossRef]

- Brandão Lima, L.C.; Castro-Silva, F.; Silva-Filho, E.C.; Fonseca, M.G.; Jaber, M. Saponite-Anthocyanin Pigments: Slipping between the Sheets. Microporous Mesoporous Mater. 2020, 300, 110148. [Google Scholar] [CrossRef]

- Fatimah, I.; Nurillahi, R.; Sahroni, I.; Muraza, O. TiO2-Pillared Saponite and Photosensitization Using a Ruthenium Complex for Photocatalytic Enhancement of the Photodegradation of Bromophenol Blue. Appl. Clay Sci. 2019, 183, 105302. [Google Scholar] [CrossRef]

- Kenne Dedzo, G.; Rigolet, S.; Josien, L.; Ngameni, E.; Dzene, L. Functionalization of Synthetic Saponite: Identification of Grafting Sites and Application for Anions Sequestration. Appl. Surf. Sci. 2021, 567, 150911. [Google Scholar] [CrossRef]

- Fernández-González, M.V.; Carretero, M.I.; Martín-García, J.M.; Molinero-García, A.; Delgado, R. Peloids Prepared with Three Mineral-Medicinal Waters from Spas in Granada. Their Suitability for Use in Pelotherapy. Appl. Clay Sci. 2021, 202, 105969. [Google Scholar] [CrossRef]

- Casagrande, M.; Storaro, L.; Lenarda, M.; Rossini, S. Solid Acid Catalysts from Clays: Oligomerization of 1-Pentene on Al-Pillared Smectites. Catal. Commun. 2005, 6, 568–572. [Google Scholar] [CrossRef]

- Takagi, S.; Shimada, T.; Ishida, Y.; Fujimura, T.; Masui, D.; Tachibana, H.; Eguchi, M.; Inoue, H. Size-Matching Effect on Inorganic Nanosheets: Control of Distance, Alignment, and Orientation of Molecular Adsorption as a Bottom-up Methodology for Nanomaterials. Langmuir 2013, 29, 2108–2119. [Google Scholar] [CrossRef] [PubMed]

- Carrado, K.A.; Decarreau, A.; Petit, S.; Bergaya, F.; Lagaly, G. Synthetic Clay Minerals and Purification of Natural Clays. Dev. Clay Sci. 2006, 1, 115–139. [Google Scholar]

- Utracki, L.A.; Sepehr, M.; Boccaleri, E. Synthetic, Layered Nanoparticles for Polymeric Nanocomposites (PNCs). Polym. Adv. Technol. 2007, 18, 1–37. [Google Scholar] [CrossRef] [Green Version]

- Franco, F.; Benítez-Guerrero, M.; Gonzalez-Triviño, I.; Pérez-Recuerda, R.; Assiego, C.; Cifuentes-Melchor, J.; Pascual-Cosp, J. Low-Cost Aluminum and Iron Oxides Supported on Dioctahedral and Trioctahedral Smectites: A Comparative Study of the Effectiveness on the Heavy Metal Adsorption from Water. Appl. Clay Sci. 2016, 119, 321–332. [Google Scholar] [CrossRef]

- Suquet, H.; Iiyama, J.T.; Kodama, H.; Pezerat, H. Synthesis and Swelling Properties of Saponites with Increasing Layer Charge. Clays Clay Miner. 1977, 25, 231–242. [Google Scholar] [CrossRef]

- Kloprogge, J.T.; Komarneni, S.; Amonette, J.E. Synthesis of Smectite Clay Minerals: A Critical Review. Clays Clay Miner. 1999, 47, 529–554. [Google Scholar] [CrossRef]

- Zhang, D.; Zhou, C.-H.; Lin, C.-X.; Tong, D.-S.; Yu, W.-H. Synthesis of Clay Minerals. Appl. Clay Sci. 2010, 50, 1–11. [Google Scholar] [CrossRef]

- Jaber, M.; Komarneni, S.; Zhou, C.-H. Synthesis of Clay Minerals. In Developments in Clay Science; Elsevier: Amsterdam, The Netherlands, 2013; Volume 5, pp. 223–241. [Google Scholar]

- Carniato, F.; Bisio, C.; Psaro, R.; Marchese, L.; Guidotti, M. Niobium (V) Saponite Clay for the Catalytic Oxidative Abatement of Chemical Warfare Agents. Angew. Chem. Int. Ed. 2014, 53, 10095–10098. [Google Scholar] [CrossRef] [PubMed]

- Baldermann, A.; Dohrmann, R.; Kaufhold, S.; Nickel, C.; Letofsky-Papst, I.; Dietzel, M. The Fe-Mg-Saponite Solid Solution Series—A Hydrothermal Synthesis Study. Clay Miner. 2014, 49, 391–415. [Google Scholar] [CrossRef]

- Zhang, C.; He, H.; Tao, Q.; Ji, S.; Li, S.; Ma, L.; Su, X.; Zhu, J. Metal Occupancy and Its Influence on Thermal Stability of Synthetic Saponites. Appl. Clay Sci. 2017, 135, 282–288. [Google Scholar] [CrossRef]

- Trujillano, R.; Rico, E.; Vicente, M.A.; Herrero, M.; Rives, V. Microwave Radiation and Mechanical Grinding as New Ways for Preparation of Saponite-like Materials. Appl. Clay Sci. 2010, 48, 32–38. [Google Scholar] [CrossRef]

- Gebretsadik, F.B.; Salagre, P.; Cesteros, Y. Use of Polymer as Template in Microwave Synthesis of Saponite. Study of Several Factors of Influence. Appl. Clay Sci. 2014, 87, 170–178. [Google Scholar] [CrossRef]

- Suquet, H.; Malard, C.; Copin, E.; Pezerat, H. Variation Du Paramètre b et de La Distance Basale d001 Dans Une Série de Saponites à Charge Croissante: I. Etats Hydratés. Clay Miner. 1981, 16, 53–67. [Google Scholar] [CrossRef]

- Ferrage, E.; Lanson, B.; Michot, L.J.; Robert, J.-L. Hydration Properties and Interlayer Organization of Water and Ions in Synthetic Na-Smectite with Tetrahedral Layer Charge. Part 1. Results from X-Ray Diffraction Profile Modeling. J. Phys. Chem. C 2010, 114, 4515–4526. [Google Scholar] [CrossRef] [Green Version]

- Dazas, B.; Lanson, B.; Delville, A.; Robert, J.-L.; Komarneni, S.; Michot, L.J.; Ferrage, E. Influence of Tetrahedral Layer Charge on the Organization of Interlayer Water and Ions in Synthetic Na-Saturated Smectites. J. Phys. Chem. C 2015, 119, 4158–4172. [Google Scholar] [CrossRef]

- Ferrage, E. Investigation of the Interlayer Organization of Water and Ions in Smectite from the Combined Use of Diffraction Experiments and Molecular Simulations. A Review of Methodology, Applications, and Perspectives. Clays Clay Miner. 2016, 64, 348–373. [Google Scholar] [CrossRef]

- Eguchi, M.; Momotake, M.; Inoue, F.; Oshima, T.; Maeda, K.; Higuchi, M. Inert Layered Silicate Improves the Electrochemical Responses of a Metal Complex Polymer. ACS Appl. Mater. Interfaces 2017, 9, 35498–35503. [Google Scholar] [CrossRef] [PubMed]

- Kurokawa, H.; Hayasaka, M.; Yamamoto, K.; Sakuragi, T.; Ohshima, M.; Miura, H. Self-Assembled Heterogeneous Late Transition–Metal Catalysts for Ethylene Polymerization; New Approach to Simple Preparation of Iron and Nickel Complexes Immobilized in Clay Mineral Interlayer. Catal. Commun. 2014, 47, 13–17. [Google Scholar] [CrossRef]

- Sas, S.; Danko, M.; Bizovská, V.; Lang, K.; Bujdák, J. Highly Luminescent Hybrid Materials Based on Smectites with Polyethylene Glycol Modified with Rhodamine Fluorophore. Appl. Clay Sci. 2017, 138, 25–33. [Google Scholar] [CrossRef]

- Marcal, L.; de Faria, E.H.; Nassar, E.J.; Trujillano, R.; Martin, N.; Vicente, M.A.; Rives, V.; Gil, A.; Korili, S.A.; Ciuffi, K.J. Organically Modified Saponites: SAXS Study of Swelling and Application in Caffeine Removal. ACS Appl. Mater. Interfaces 2015, 7, 10853–10862. [Google Scholar] [CrossRef] [PubMed]

- Sato, K.; Fujimoto, K.; Dai, W.; Hunger, M. Quantitative Elucidation of Cs Adsorption Sites in Clays: Toward Sophisticated Decontamination of Radioactive Cs. J. Phys. Chem. C 2016, 120, 1270–1274. [Google Scholar] [CrossRef]

- Herney-Ramirez, J.; Silva, A.M.T.; Vicente, M.A.; Costa, C.A.; Madeira, L.M. Degradation of Acid Orange 7 Using a Saponite-Based Catalyst in Wet Hydrogen Peroxide Oxidation: Kinetic Study with the Fermi’s Equation. Appl. Catal. B Environ. 2011, 101, 197–205. [Google Scholar] [CrossRef]

- Huggett, J.M. Clay Minerals, 2nd ed.; Alderton, D., Ed.; Academic Press: Oxford, UK, 2021; pp. 341–349. ISBN 978-0-08-102909-1. [Google Scholar]

- Grim, R.E. Clay Mineralogy, 1st ed.; McGraw-Hill: New York, NY, USA, 1953. [Google Scholar]

- Ragu, S.; Dardillac, E.; Brooks, D.A.; Castro-Smirnov, F.A.; Aranda, P.; Ruiz-Hitzky, E.; Lopez, B.S. Responses of Human Cells to Sepiolite Interaction. Appl. Clay Sci. 2020, 194, 105655. [Google Scholar] [CrossRef]

- Wang, F.; Ding, Y.; Hao, M.; Fang, B.; Liang, J. Applied Clay Science Novel Fabrication of a Sepiolite Supported Cobalt-Based Catalyst via a Coprecipitation-Reduction Method. Appl. Clay Sci. 2020, 105909. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Z.; Zhuang, G.; Jiang, R. A New Method to Prepare ‘Maya Red’ Pigment from Sepiolite and Basic Red 46. Appl. Clay Sci. 2019, 174, 38–46. [Google Scholar] [CrossRef]

- Galán, E. Properties and Applications of Palygorskite-Sepiolite Clays. Clay Miner. 1996, 31, 443–453. [Google Scholar] [CrossRef]

- Hamid, Y.; Tang, L.; Hussain, B.; Usman, M.; Liu, L.; Ulhassan, Z.; He, Z.; Yang, X. Sepiolite Clay: A Review of Its Applications to Immobilize Toxic Metals in Contaminated Soils and Its Implications in Soil–Plant System. Environ. Technol. Innov. 2021, 23, 101598. [Google Scholar] [CrossRef]

- Han, Z.-X.; Zhu, Z.; Wu, D.-D.; Wu, J.; Liu, Y.-R. Adsorption Kinetics and Thermodynamics of Acid Blue 25 and Methylene Blue Dye Solutions on Natural Sepiolite. Synth. React. Inorg. Met.-Org. Nano-Met. Chem. 2014, 44, 140–147. [Google Scholar] [CrossRef]

- Rytwo, G.; Nir, S.; Margulies, L.; Casal, B.; Merino, J.; Ruiz-Hitzky, E.; Serratosa, J.M. Adsorption of Monovalent Organic Cations on Sepiolite: Experimental Results and Model Calculations. Clays Clay Miner. 1998, 46, 340–348. [Google Scholar] [CrossRef]

- Doke, K.M.; Khan, E.M. Equilibrium, Kinetic and Diffusion Mechanism of Cr (VI) Adsorption onto Activated Carbon Derived from Wood Apple Shell. Arab. J. Chem. 2017, 10, S252–S260. [Google Scholar] [CrossRef] [Green Version]

- Santos, S.C.R.; Boaventura, R.A.R. Adsorption Modelling of Textile Dyes by Sepiolite. Appl. Clay Sci. 2008, 42, 137–145. [Google Scholar] [CrossRef]

- Hamid, Y.; Tang, L.; Hussain, B.; Usman, M.; Rehman Hashmi, M.L.U.; Bilal Khan, M.; Yang, X.; He, Z. Immobilization and Sorption of Cd and Pb in Contaminated Stagnic Anthrosols as Amended with Biochar and Manure Combined with Inorganic Additives. J. Environ. Manag. 2020, 257, 109999. [Google Scholar] [CrossRef]

- Bilgiç, C. Investigation of the Factors Affecting Organic Cation Adsorption on Some Silicate Minerals. J. Colloid Interface Sci. 2005, 281, 33–38. [Google Scholar] [CrossRef] [PubMed]

- Tümsek, F.; Avcı, O. Investigation of Kinetics and Isotherm Models for the Acid Orange 95 Adsorption from Aqueous Solution onto Natural Minerals. J. Chem. Eng. Data 2013, 58, 551–559. [Google Scholar] [CrossRef]

- He, Z.; Ren, B.; Hursthouse, A.; Wang, Z. Efficient Removal of Cd (II) Using SiO2-Mg(OH)2 Nanocomposites Derived from Sepiolite. Int. J. Environ. Res. Public Health 2020, 17, 2223. [Google Scholar] [CrossRef] [Green Version]

- Santos, S.C.R.; Boaventura, R.A.R. Adsorption of Cationic and Anionic Azo Dyes on Sepiolite Clay: Equilibrium and Kinetic Studies in Batch Mode. J. Environ. Chem. Eng. 2016, 4, 1473–1483. [Google Scholar] [CrossRef]

- Cheng, H.; Zhu, Q.; Xing, Z. Adsorption of Ammonia Nitrogen in Low Temperature Domestic Wastewater by Modification Bentonite. J. Clean. Prod. 2019, 233, 720–730. [Google Scholar] [CrossRef]

- El Miz, M.; Akichoh, H.; Berraaouan, D.; Salhi, S.; Tahani, A. Chemical and Physical Characterization of Moroccan Bentonite Taken from Nador (North of Morocco). Am. J. Chem. 2017, 7, 105–112. [Google Scholar]

- Angar, Y.; Djelali, N.-E.; Kebbouche-Gana, S. Investigation of Ammonium Adsorption on Algerian Natural Bentonite. Environ. Sci. Pollut. Res. 2017, 24, 11078–11089. [Google Scholar] [CrossRef] [PubMed]

- Kaufhold, S.; Dohrmann, R.; Weber, C. Evolution of the PH Value at the Vicinity of the Iron-Bentonite Interface. Appl. Clay Sci. 2020, 201, 105929. [Google Scholar] [CrossRef]

- Drobíková, K.; Štrbová, K.; Tokarčíková, M.; Motyka, O.; Seidlerová, J. Magnetically Modified Bentonite: Characterization and Stability. Mater. Today Proc. 2021, 37, 53–57. [Google Scholar] [CrossRef]

- Sakr, M.A.; Mohamed, M.G.A.; Wu, R.; Shin, S.R.; Kim, D.; Kim, K.; Siddiqua, S. Development of Bentonite-Gelatin Nanocomposite Hybrid Hydrogels for Tissue Engineering. Appl. Clay Sci. 2020, 199, 105860. [Google Scholar] [CrossRef]

- El-nagar, D.A.; Hereimas, D. Soil & Tillage Research Synthesis and Characterization of Nano Bentonite and Its Effect on Some Properties of Sandy Soils. Soil Tillage Res. 2021, 208, 104872. [Google Scholar] [CrossRef]

- Peng, L.; Chen, B.; Zhao, Y. Quantitative Characterization and Comparsion of Bentonite Microstructure by Small Angle X-Ray Scattering and Nitrogen Adsorption. Constr. Build. Mater. 2020, 262, 120863. [Google Scholar] [CrossRef]

- Tohdee, K.; Kaewsichan, L. Enhancement of Adsorption Efficiency of Heavy Metal Cu (II) and Zn (II) onto Cationic Surfactant Modified Bentonite. J. Environ. Chem. Eng. 2018, 6, 2821–2828. [Google Scholar] [CrossRef]

- Jiménez-Castañeda, M.E.; Medina, D.I. Use of Surfactant-Modified Zeolites and Clays for the Removal of Heavy Metals from Water. Water 2017, 9, 235. [Google Scholar] [CrossRef] [Green Version]

- Munir, M.; Nazar, M.F.; Zafar, M.N. Removal of Amaranth Dye over Surfactant Modified Dull Pink Clay from Aqueous Medium. Int. J. Environ. Anal. Chem. 2021, 101, 2848–2865. [Google Scholar] [CrossRef]

- Nadeem, M.; Mahmood, A.; Shahid, S.A.; Shah, S.S.; Khalid, A.M.; McKay, G. Sorption of Lead from Aqueous Solution by Chemically Modified Carbon Adsorbents. J. Hazard. Mater. 2006, 138, 604–613. [Google Scholar] [CrossRef] [PubMed]

- Khobragade, M.U.; Pal, A. Adsorptive Removal of Mn (II) from Water and Wastewater by Surfactant-Modified Alumina. Desalin. Water Treat. 2016, 57, 2775–2786. [Google Scholar] [CrossRef]

- Fiol, N.; Villaescusa, I.; Martínez, M.; Miralles, N.; Poch, J.; Serarols, J. Sorption of Pb (II), Ni (II), Cu (II) and Cd (II) from Aqueous Solution by Olive Stone Waste. Sep. Purif. Technol. 2006, 50, 132–140. [Google Scholar] [CrossRef]

- AjayKumar, A.V.; Darwish, N.A.; Hilal, N. Study of Various Parameters in the Biosorption of Heavy Metals on Activated Sludge. World Appl. Sci. J. 2009, 5, 32–40. [Google Scholar]

- Abbasi, S.; Foroutan, R.; Esmaeili, H.; Esmaeilzadeh, F. Preparation of Activated Carbon from Worn Tires for Removal of Cu (II), Ni (II) and Co (II) Ions from Synthetic Wastewater. Desalin. Water Treat 2019, 141, 269–278. [Google Scholar] [CrossRef]

- Cai, C.; Wu, X.; Liu, W.; Zhu, W.; Chen, H.; Qiu, J.C.D.; Sun, C.-N.; Liu, J.; Wei, Q.; Shi, Y. Selective Laser Melting of Near-α Titanium Alloy Ti-6Al-2Zr-1Mo-1V: Parameter Optimization, Heat Treatment and Mechanical Performance. J. Mater. Sci. Technol. 2020, 57, 51–64. [Google Scholar] [CrossRef]

- Chen, J.; Cai, Y.; Clark, M.; Yu, Y. Equilibrium and Kinetic Studies of Phosphate Removal from Solution onto a Hydrothermally Modified Oyster Shell Material. PLoS ONE 2013, 8, e60243. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tamjidi, S.; Esmaeili, H. Chemically Modified CaO/Fe3O4 Nanocomposite by Sodium Dodecyl Sulfate for Cr (III) Removal from Water. Chem. Eng. Technol. 2019, 42, 607–616. [Google Scholar] [CrossRef]

- Mudzielwana, R.; Gitari, M.W.; Ndungu, P. Performance Evaluation of Surfactant Modified Kaolin Clay in As (III) and As (V) Adsorption from Groundwater: Adsorption Kinetics, Isotherms and Thermodynamics. Heliyon 2019, 5, e02756. [Google Scholar] [CrossRef] [Green Version]

- Xi, H.; Li, Q.; Yang, Y.; Zhang, J.; Guo, F.; Wang, X.; Xu, S.; Ruan, S. Highly Effective Removal of Phosphate from Complex Water Environment with Porous Zr-Bentonite Alginate Hydrogel Beads: Facile Synthesis and Adsorption Behavior Study. Appl. Clay Sci. 2021, 201, 105919. [Google Scholar] [CrossRef]

- de Queiroga, L.N.F.; França, D.B.; Rodrigues, F.; Santos, I.M.G.; Fonseca, M.G.; Jaber, M. Functionalized Bentonites for Dye Adsorption: Depollution and Production of New Pigments. J. Environ. Chem. Eng. 2019, 7, 103333. [Google Scholar] [CrossRef]

- Herrera, N.N.; Letoffe, J.-M.; Putaux, J.-L.; David, L.; Bourgeat-Lami, E. Aqueous Dispersions of Silane-Functionalized Laponite Clay Platelets. A First Step toward the Elaboration of Water-Based Polymer/Clay Nanocomposites. Langmuir 2004, 20, 1564–1571. [Google Scholar]

- Ghadiri, M.; Hau, H.; Chrzanowski, W.; Agus, H.; Rohanizadeh, R. Laponite Clay as a Carrier for in Situ Delivery of Tetracycline. RSC Adv. 2013, 3, 20193–20201. [Google Scholar] [CrossRef]

- Pálková, H.; Madejová, J.; Zimowska, M.; Bielańska, E.; Olejniczak, Z.; Lityńska-Dobrzyńska, L.; Serwicka, E.M. Laponite-Derived Porous Clay Heterostructures: I. Synthesis and Physicochemical Characterization. Microporous Mesoporous Mater. 2010, 127, 228–236. [Google Scholar] [CrossRef]

- Bienia, M.; Danglade, C.; Lecomte, A.; Brevier, J.; Pagnoux, C. Cylindrical Couette Flow of Laponite Dispersions. Appl. Clay Sci. 2018, 162, 83–89. [Google Scholar] [CrossRef]

- Loginov, M.; Lebovka, N.; Vorobiev, E. Laponite Assisted Dispersion of Carbon Nanotubes in Water. J. Colloid Interface Sci. 2012, 365, 127–136. [Google Scholar] [CrossRef]

- Manilo, M.V.; Lebovka, N.; Barany, S. Combined Effect of Cetyltrimethylammonium Bromide and Laponite Platelets on Colloidal Stability of Carbon Nanotubes in Aqueous Suspensions. J. Mol. Liq. 2017, 235, 104–110. [Google Scholar] [CrossRef]

- Silva, J.M.; Barud, H.S.; Meneguin, A.B.; Constantino, V.R.L.; Ribeiro, S.J.L. Inorganic-Organic Bio-Nanocomposite Films Based on Laponite and Cellulose Nanofibers (CNF). Appl. Clay Sci. 2019, 168, 428–435. [Google Scholar] [CrossRef]

- Le Coeur, C.; Lorthioir, C.; Feoktystov, A.; Wu, B.; Volet, G.; Amiel, C. Laponite/Poly(2-Methyl-2-Oxazoline) Hydrogels: Interplay between Local Structure and Rheological Behaviour. J. Colloid Interface Sci. 2021, 582, 149–158. [Google Scholar] [CrossRef]

- Yu, D.; Li, G.; Kong, F.; Wang, H.; Liu, W.; Song, Z.; Meng, X.; Zhao, J.R.H. Encapsulation of Alkenylsuccinic Anhydride Oil Droplets in Laponite Nanoparticles Modified by Carbon Nitride Quantum Dots: Enhancement of Emulsion Stability and Paper Sizing Performance. Appl. Clay Sci. 2020, 191, 105608. [Google Scholar] [CrossRef]

- Zhang, R.; Xie, L.; Wu, H.; Yang, T.; Zhang, Q.; Tian, Y.; Liu, Y.; Han, X.; Guo, W.; He, M.; et al. Alginate/Laponite Hydrogel Microspheres Co-Encapsulating Dental Pulp Stem Cells and VEGF for Endodontic Regeneration. Acta Biomater. 2020, 113, 305–316. [Google Scholar] [CrossRef] [PubMed]

- Elkatatny, S. Improved Carbonation Resistance and Durability of Saudi Class G Oil Well Cement Sheath in CO2 Rich Environments Using Laponite. J. Pet. Sci. Eng. 2021, 196, 107812. [Google Scholar] [CrossRef]

- Au, P.-I.; Hassan, S.; Liu, J.; Leong, Y.-K. Behaviour of LAPONITE® Gels: Rheology, Ageing, PH Effect and Phase State in the Presence of Dispersant. Chem. Eng. Res. Des. 2015, 101, 65–73. [Google Scholar] [CrossRef]

- Valencia, G.A.; Djabourov, M.; Carn, F.; Sobral, P.J.A. Novel Insights on Swelling and Dehydration of Laponite. Colloid Interface Sci. Commun. 2018, 23, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Jatav, S.; Joshi, Y.M. Chemical Stability of Laponite in Aqueous Media. Appl. Clay Sci. 2014, 97, 72–77. [Google Scholar] [CrossRef] [Green Version]

- Zhang, P.; Wang, J.; Jia, Y.; Li, W.; Tan, X.; Zhang, D.; Xu, S.; Zhang, P.; Wei, C.; Miao, S. Encapsulating Spinel Nancrystals in Laponite Cages and Applications in Molecular Oxidation of Cyclohexane. Appl. Clay Sci. 2019, 181, 105226. [Google Scholar] [CrossRef]

- Takeno, H.; Sato, C. Effects of Molecular Mass of Polymer and Composition on the Compressive Properties of Hydrogels Composed of Laponite and Sodium Polyacrylate. Appl. Clay Sci. 2016, 123, 141–147. [Google Scholar] [CrossRef]

- Zeng, H.; Yu, Z.; Peng, Y.; Zhu, L. Environmentally Friendly Electrostatically Driven Self-Assembled LDH/GO/PVDF Composite Membrane for Water Treatment. Appl. Clay Sci. 2019, 183, 105322. [Google Scholar] [CrossRef]

- Muller, F.; Salonen, A.; Glatter, O. Monoglyceride-Based Cubosomes Stabilized by Laponite: Separating the Effects of Stabilizer, PH and Temperature. Colloids Surf. A Physicochem. Eng. Asp. 2010, 358, 50–56. [Google Scholar] [CrossRef]

- van den Dungen, E.T.A.; Hartmann, P.C. Synergistic Effect of Laponite RD and Oil Soluble Surfactant in Stabilization of Miniemulsions. Appl. Clay Sci. 2012, 55, 120–124. [Google Scholar] [CrossRef]

- Taguchi, T.; Kohno, Y.; Shibata, M.; Tomita, Y.; Fukuhara, C.; Maeda, Y. An Easy and Effective Method for the Intercalation of Hydrophobic Natural Dye into Organo-Montmorillonite for Improved Photostability. J. Phys. Chem. Solids 2018, 116, 168–173. [Google Scholar] [CrossRef]

- Ribeiro, H.L.; de Oliveira, A.V.; de Brito, E.S.; Ribeiro, P.R.V.; Azeredo, H.M.C. Stabilizing Effect of Montmorillonite on Acerola Juice Anthocyanins. Food Chem. 2018, 245, 966–973. [Google Scholar] [CrossRef]

- Kohno, Y.; Senga, M.; Shibata, M.; Yoda, K.; Matsushima, R.; Tomita, Y.; Maeda, Y.; Kobayashi, K. Stabilization of Flavylium Dye by Incorporation into Fe-Containing Mesoporous Silicate. Microporous Mesoporous Mater. 2011, 141, 77–80. [Google Scholar] [CrossRef] [Green Version]

- Kohno, Y.; Asai, S.; Shibata, M.; Fukuhara, C.; Maeda, Y.; Tomita, Y.; Kobayashi, K. Improved Photostability of Hydrophobic Natural Dye Incorporated in Organo-Modified Hydrotalcite. J. Phys. Chem. Solids 2014, 75, 945–950. [Google Scholar] [CrossRef] [Green Version]

- Boyaci, T.; Orakdogen, N. Poly(N,N-Dimethylaminoethyl Methacrylate-Co-2-Acrylamido-2-Methyl-Propanosulfonic Acid)/Laponite Nanocomposite Hydrogels and Cryogels with Improved Mechanical Strength and Rapid Dynamic Properties. Appl. Clay Sci. 2016, 121–122, 162–173. [Google Scholar] [CrossRef]

- Wang, Z.; Li, J.; Sun, Y.; Peng, J.; Wang, J.; Hao, Y.; Li, W.; Zhang, P.; Ning, W.; Miao, S. Laponite Elementary Sheets Assisted Fluorescence Resonance Energy Transfer: A Demonstration by Langmuir-Blodgett Technique. Dye. Pigment. 2021, 196, 109800. [Google Scholar] [CrossRef]

- Prasannan, A.; Udomsin, J.; Tsai, H.-C.; Wang, C.-F.; Lai, J.-Y. Robust Underwater Superoleophobic Membranes with Bio-Inspired Carrageenan/Laponite Multilayers for the Effective Removal of Emulsions, Metal Ions, and Organic Dyes from Wastewater. Chem. Eng. J. 2020, 391, 123585. [Google Scholar] [CrossRef]

- Akil, J.; Ciotonea, C.; Siffert, S.; Royer, S.; Pirault-Roy, L.; Cousin, R.; Poupin, C. NO Reduction by CO under Oxidative Conditions over CoCuAl Mixed Oxides Derived from Hydrotalcite-like Compounds: Effect of Water. Catal. Today 2021. [Google Scholar] [CrossRef]

- Carlino, S. Chemistry between the Sheets. Chem. Br. 1997, 33, 59–62. [Google Scholar]

- Ulibarri, M.A.; Pavlovic, I.; Barriga, C.; Hermosın, M.C.; Cornejo, J. Adsorption of Anionic Species on Hydrotalcite-like Compounds: Effect of Interlayer Anion and Crystallinity. Appl. Clay Sci. 2001, 18, 17–27. [Google Scholar] [CrossRef]

- Bish, D.L. Anion-Exchange in Takovite: Applications to Other Hydroxide Minerals. Bull. Mineral. 1980, 103, 170–175. [Google Scholar] [CrossRef]

- Miyata, S. Physico-Chemical Properties of Synthetic Hydrotalcites in Relation to Composition. Clays Clay Miner. 1980, 28, 50–56. [Google Scholar] [CrossRef]

- Zhu, M.-X.; Li, Y.-P.; Xie, M.; Xin, H.-Z. Sorption of an Anionic Dye by Uncalcined and Calcined Layered Double Hydroxides: A Case Study. J. Hazard. Mater. 2005, 120, 163–171. [Google Scholar] [CrossRef]

- Lakraimi, M.; Legrouri, A.; Barroug, A.; Besse, J.-P. Removal of Pesticides from Water by Anionic Clays. J. Chim. Phys. Physico-Chim. Biol. 1999, 96, 470–478. [Google Scholar] [CrossRef]

- Sato, T.; Kato, K.; Endo, T.; Shimada, M. Preparation and Chemical Properties of Magnesium Aluminium Oxide Solid Solutions. React. Solids 1986, 2, 253–260. [Google Scholar] [CrossRef]

- Salomao, R.; Milena, L.M.; Wakamatsu, M.H.; Pandolfelli, V.C. Hydrotalcite Synthesis via Co-Precipitation Reactions Using MgO and Al(OH)3 Precursors. Ceram. Int. 2011, 37, 3063–3070. [Google Scholar] [CrossRef]

- Bouraada, M.; Lafjah, M.; Ouali, M.S.; de Menorval, L.C. Basic Dye Removal from Aqueous Solutions by Dodecylsulfate-and Dodecyl Benzene Sulfonate-Intercalated Hydrotalcite. J. Hazard. Mater. 2008, 153, 911–918. [Google Scholar] [CrossRef]

- Cavani, F.; Trifiro, F.; Vaccari, A. Hydrotalcite-Type Anionic Clays: Preparation, Properties and Applications. Catal. Today 1991, 11, 173–301. [Google Scholar] [CrossRef]

- Gasser, M.S.; Mekhamer, H.S.; Abdel Rahman, R.O. Optimization of the Utilization of Mg/Fe Hydrotalcite like Compounds in the Removal of Sr(II) from Aqueous Solution. J. Environ. Chem. Eng. 2016, 4, 4619–4630. [Google Scholar] [CrossRef]

- Ogawa, M.; Takee, R.; Okabe, Y.; Seki, Y. Bio-Geo Hybrid Pigment; Clay-Anthocyanin Complex Which Changes Color Depending on the Atmosphere. Dye. Pigment. 2017, 139, 561–565. [Google Scholar] [CrossRef]

- Guillermin, D.; Debroise, T.; Trigueiro, P.; de Viguerie, L.; Rigaud, B.; Morlet-Savary, F.; Balme, S.; Janot, J.-M.; Tielens, F.; Michot, L.; et al. New Pigments Based on Carminic Acid and Smectites: A Molecular Investigation. Dye. Pigment. 2019, 160, 971–982. [Google Scholar] [CrossRef]

- McKay, G.; Ramprasad, G.; Mowli, P. Desorption and Regeneration of Dye Colours from Low-Cost Materials. Water Res. 1987, 21, 375–377. [Google Scholar] [CrossRef]

- Voudrias, E.; Fytianos, K.; Bozani, E. Sorption-Desorption Isotherms of Dyes from Aqueous Solutions and Wastewaters with Different Sorbent Meterials. Global NEST Int. J. 2018, 4, 75–83. [Google Scholar] [CrossRef]

- Yuan, J.; Zhou, S.; You, B.; Wu, L. Organic Pigment Particles Coated with Colloidal Nano-Silica Particles via Layer-by-Layer Assembly. Chem. Mater. 2005, 17, 3587–3594. [Google Scholar] [CrossRef]

- Cao, L.; Fei, X.; Zhang, T.; Yu, L.; Gu, Y.; Zhang, B. Modification of CI Pigment Red 21 with Sepiolite and Lithopone in Its Preparation Process. Ind. Eng. Chem. Res. 2014, 53, 31–37. [Google Scholar] [CrossRef]

- Dejoie, C.; Martinetto, P.; Dooryhee, E.; Strobel, P.; Blanc, S.; Bordat, P.; Brown, R.; Porcher, F.; Sanchez del Rio, M.; Anne, M. Indigo@ Silicalite: A New Organic–Inorganic Hybrid Pigment. ACS Appl. Mater. Interfaces 2010, 2, 2308–2316. [Google Scholar] [CrossRef]

- Raha, S.; Ivanov, I.; Quazi, N.H.; Bhattacharya, S.N. Photo-Stability of Rhodamine-B/Montmorillonite Nanopigments in Polypropylene Matrix. Appl. Clay Sci. 2009, 42, 661–666. [Google Scholar] [CrossRef]

- Beltrán, M.I.; Benavente, V.; Marchante, V.; Dema, H.; Marcilla, A. Characterisation of Montmorillonites Simultaneously Modified with an Organic Dye and an Ammonium Salt at Different Dye/Salt Ratios. Properties of These Modified Montmorillonites EVA Nanocomposites. Appl. Clay Sci. 2014, 97, 43–52. [Google Scholar] [CrossRef]

- Van der Linden, E.G.; Malta, L.F.B.; Medeiros, M.E. Evaluation of Synthetic Routes to Pigmentary Grade Bismuth Vanadate. Dye. Pigment. 2011, 90, 36–40. [Google Scholar] [CrossRef]

- Wang, X.; Mu, B.; Wang, W.; Wang, Q.; Wang, A. A Comparative Study on Color Properties of Different Clay Minerals/BiVO4 Hybrid Pigments with Excellent Thermal Stability. Appl. Clay Sci. 2019, 181, 105221. [Google Scholar] [CrossRef]

- Yi, J.-Z.; Zhang, L.-M. Removal of Methylene Blue Dye from Aqueous Solution by Adsorption onto Sodium Humate/Polyacrylamide/Clay Hybrid Hydrogels. Bioresour. Technol. 2008, 99, 2182–2186. [Google Scholar] [CrossRef] [PubMed]

- Momina; Mohammad, S.; Suzylawati, I. Study of the Adsorption/Desorption of MB Dye Solution Using Bentonite Adsorbent Coating. J. Water Process Eng. 2020, 34, 101155. [Google Scholar] [CrossRef]

- Moujahid, E.M.; Lahkale, R.; Ouassif, H.; Bouragba, F.Z.; Elhatimi, W. New Organic Dye/Anionic Clay Hybrid Pigments: Preparation, Optical Properties and Structural Stability. Dye. Pigment. 2019, 162, 998–1004. [Google Scholar] [CrossRef]

| Family | Material | Fixation Degree (%) |

|---|---|---|

| Acids | Polyamide/Wool | 80–95 |

| Azoics | Cellulosic | 75–90 |

| Basics | Acrylic | 95–100 |

| Direct | Cellulosic | 70–95 |

| Scattered | Polyester | 90–100 |

| Premetallized | Wool | 85–95 |

| Reagents | Cellulosic | 60–90 |

| Sulphurous | Cellulosic | 60–86 |

| Adsorbent | Performance | Use | Observ. | Adsorption BC * | Biblio. Ref. |

|---|---|---|---|---|---|

| Saponite | High performance | Pigment | - | Acid Orange 7 > 90% | [76,82,224,301] |

| Montmorillonite | Thermal stability | Pigment | No desorption | Congo Red 84% | [37,301,302,314] |

| Sepiolite | Poor stability | Pigment/Dye | Desorption in ethanol | Cd 95% | [229,239] |

| Bentonite | No desorption High stability | Pigment | Low-cost. Absorbance at different pH. | Phosphates 95% | [261,262,303,304] |

| Laponite | - | Dye | 20–40% desorption | Rhodamine B% 100% Brilliant blue | [97,288,312] |

| Halloysite | Combined photocatalysis | Pigment | Novelty | 90% orange G | [89,192] |

| Zeolite | Regeneration for reuse | Dye | With cationic dyes | 99% Ni & Cd | [109,145,146] |

| Hydrotalcite | High performance | Pigment | Low-cost | Cationic dyes | [209,299] |

| Adsorbent | Structure | Charge | Biblio. Ref. |

|---|---|---|---|

| Saponite | Laminate | Cationic | [194] |

| Montmorillonite | Laminate | Cationic | [79] |

| Sepiolite | Channels | Cationic | [226,227,228,229] |

| Bentonite | Laminate | Cationic | [241] |

| Laponite | Laminate | Cationic | [97,275,276] |

| Halloysite | Tubular | Cationic/Anionic | [155] |

| Zeolite | Channels | Cationic | [109,137] |

| Hydrotalcite | Laminate | Cationic | [209,299] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Rodríguez, D.; Micó-Vicent, B.; Jordán-Núñez, J.; Bonet-Aracil, M.; Bou-Belda, E. Uses of Nanoclays and Adsorbents for Dye Recovery: A Textile Industry Review. Appl. Sci. 2021, 11, 11422. https://doi.org/10.3390/app112311422

López-Rodríguez D, Micó-Vicent B, Jordán-Núñez J, Bonet-Aracil M, Bou-Belda E. Uses of Nanoclays and Adsorbents for Dye Recovery: A Textile Industry Review. Applied Sciences. 2021; 11(23):11422. https://doi.org/10.3390/app112311422

Chicago/Turabian StyleLópez-Rodríguez, Daniel, Bàrbara Micó-Vicent, Jorge Jordán-Núñez, Marilés Bonet-Aracil, and Eva Bou-Belda. 2021. "Uses of Nanoclays and Adsorbents for Dye Recovery: A Textile Industry Review" Applied Sciences 11, no. 23: 11422. https://doi.org/10.3390/app112311422