Verification of the Radio Wave Absorption Effect in the Millimeter Wave Band of SWCNTs and Conventional Carbon-Based Materials

Abstract

:1. Introduction

2. Background of Electromagnetic Absorption

3. Experimental Procedure

3.1. Purpose of the Experiment

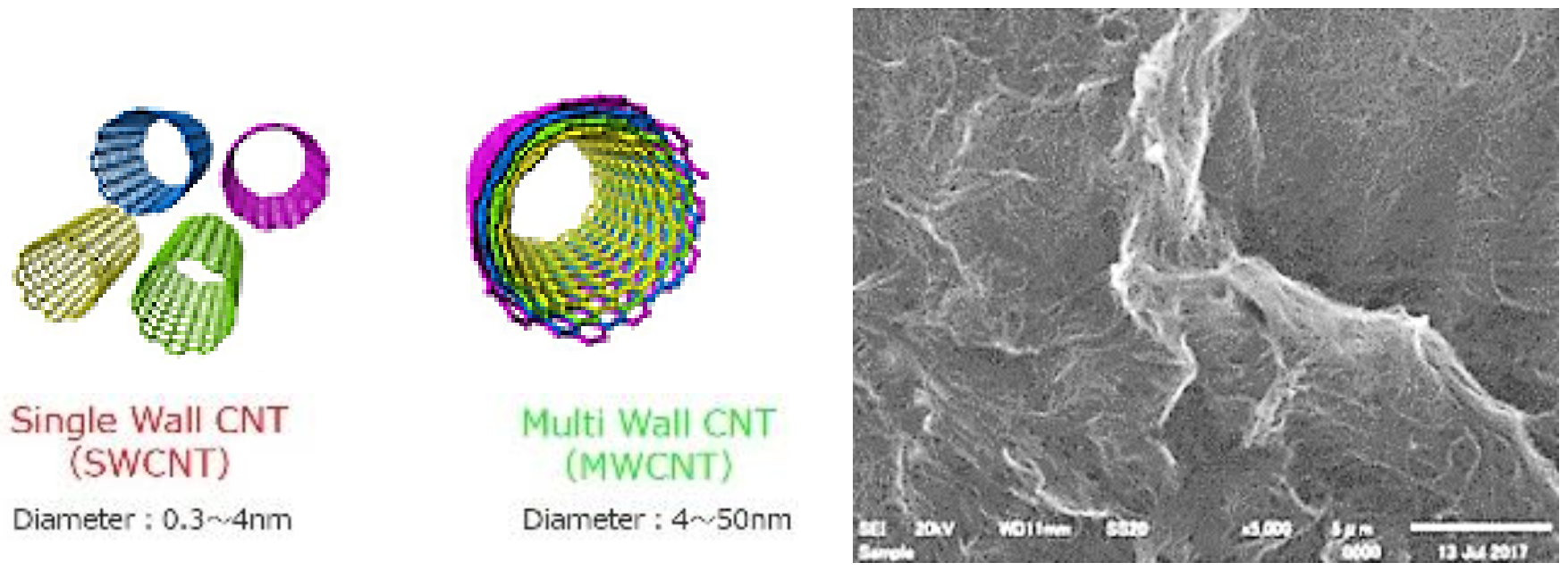

3.2. Sample Preparation

3.3. Equipment for Verifying Radio Wave Absorption Effect

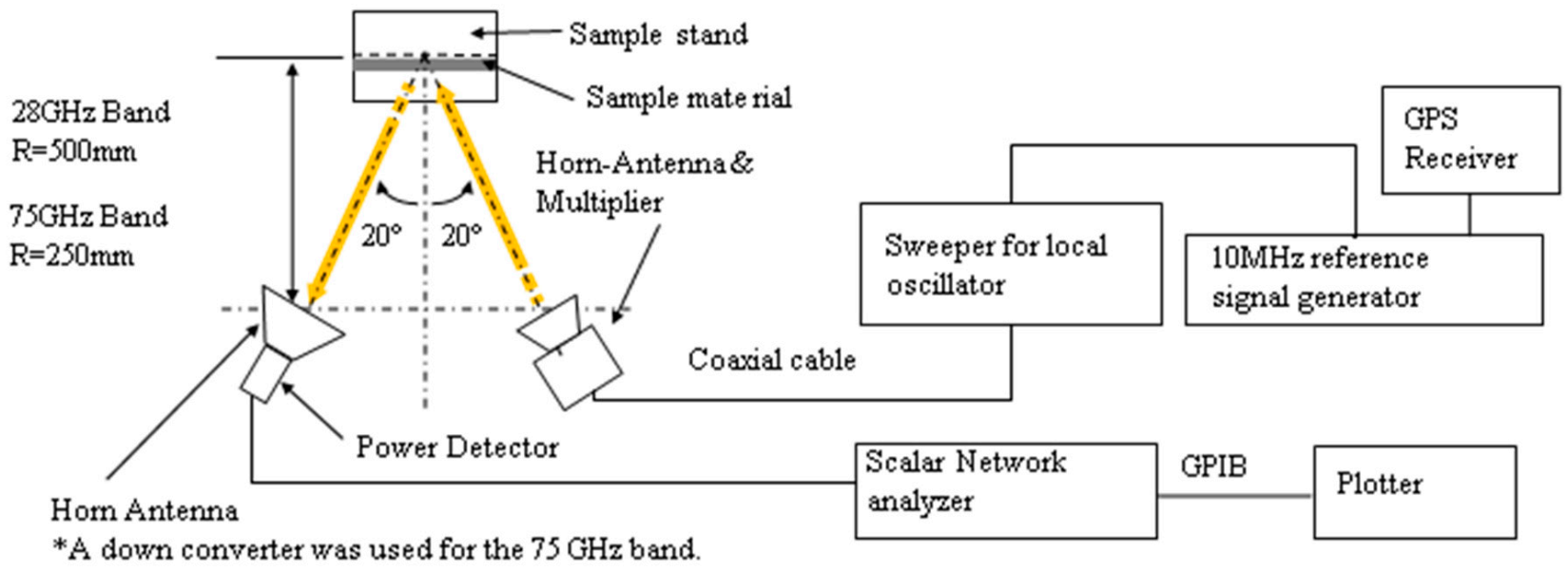

3.3.1. Outline of the Radio Wave Absorption Verification System

3.3.2. Antenna Installation Position

3.3.3. Outline of Antenna for 28 GHz Band

3.3.4. Outline of the Verification System for the Amount of Radio Wave Absorption for the 75 GHz Band

3.3.5. Sample Stand

4. Measurement Result of Radio Wave Absorption

4.1. 28 GHz Band Radio Wave Absorption

4.2. 75 GHz Band Radio Wave Absorption

5. Discussion

5.1. Measurement of 28 GHz Band

5.2. 75 GHz Band Measurement

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- What is Millimeter-Wave Radar that Expands the Possibilities of Autonomous Driving and Industrial Machinery. Available online: https://www.hitachi-solutions-create.co.jp (accessed on 2 November 2021).

- Roudbari, M.; Jorshari, T.; Lü, C.; Ansari; Kouzani, A.; Amabili, M. A review of size-dependent continuum mechanics models for micro- and nano-structures. Thin-Walled Struct. 2022, 170, 108562. [Google Scholar] [CrossRef]

- Chiba, S.; Waki, M.; Takeshita, M.; Uejima, M.; Arakawa, K. Dielectric elastomer using CNT as an electrode. Int. Soc. Opt. Photonics 2020, 11375, 113751C. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, C.; Li, H.; Pang, F.; Zou, T.; Wang, H.; Wang, N. Analysis of functionally graded carbon nanotube-reinforced composite structures. Nanotechnol. Rev. 2020, 9, 1408–1426. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Sabaruddin, F.A.; Kamarudin, S.; Ahmado, S.H.; Mahat, A.M.; Lee, C.L.; Aisyah, H.A.; et al. Fabrication, functionalization, and application of carbon nanotube-reinforced polymer composite: An overview. Polymers 2021, 13, 1047. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Internal Affairs and Communications. Main Applications and Radio Wave Characteristics for Each Frequency Band. Available online: https://www.tele.soumu.go.jp›freq›myuse›summary (accessed on 2 November 2021).

- Ministry of Environment. About Electromagnetic Field around Us. Available online: http://www.env.go.jp/chemi/electric/mate-rial/minomawari.pdf (accessed on 2 November 2021).

- Association of Radio Industries and Business. Radio Waves in Daily Life. Available online: http://www.arib-emf.org›denpa01-01 (accessed on 2 November 2021).

- First Electronic Development Co., Ltd. Do Electromagnetic Waves Affect the Human Body? Available online: https://www.first-ele.co.jp/den-ziha.html (accessed on 2 November 2021).

- Otsu, A. EMI Noise Problems and Regulations. J. Surf. Finish. Soc. Jpn. 1991, 42, 2–12. [Google Scholar] [CrossRef]

- Hashimoto, O. Radio wave propagation and wave absorption technology in 5G. Eng. Mater. 2021, 69, 18–20. [Google Scholar]

- Sugiyama, A.; Yoshino, M. Plating for Electro-magnetic Shielding. J. Surf. Finish. Soc. Jpn. 2017, 68, 191–195. [Google Scholar] [CrossRef] [Green Version]

- Yamamoto, S.; Hatakeyama, K. Design and evaluation of radio wave absorbers and electromagnetic shielding materials that use artificial materials. In Proceedings of the BI-4-1 (The Society Conference) Institute of Electronics Information and Communication Engineers (IEICE), Tokyo, Japan, 11 September 2019. [Google Scholar]

- Zhao, B.; Zhang, R. Electromagnetic Wave Absorption Properties of Core-Shell Ni-Based Composites. In Electromagnetic Materials and Devices; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef] [Green Version]

- Hayashi, O. Latest Developments in Electromagnetic Wave Absorbers and Shielding Materials-Design and Performance Enhancement for 5G; CMC Publishing Co.: Tokyo, Japan, 2020; pp. 1–318. ISBN 978-4-7813-1513-3. [Google Scholar]

- Koyo Sangyo Co. Ltd. Thickness and Weight Reduction That Could Not Be Achieved with Conventional Radio Wave Absorbers. Available online: https://premium.ipros.jp/koyoweb/catalog/detail/505729/ (accessed on 2 November 2021).

- Kashihara, K.; Fujita, N.; Hashimoto, H.; Ijiri, Y.; Hosono, K.; Mitsui, T.; Kudo, T. Development of the Sheet-Type Electromagnetic Wave Absorber for ETC/DSRC. Mitsubishi Cable Ind. Rev. 2002, 99, 69–77. Available online: https://www.mitsubishi-cable.co.jp/jihou/pdf/95/01.pdf (accessed on 2 November 2021).

- Ishino, K.; Watanabe, T.; Hashimoto, Y. Radio wave absorbers and those applications. Jpn. Soc. Appl. Phys. 1974, 43, 1157–1163. [Google Scholar]

- Toyo Ink SC Holdings. Millimeter-Wave Radio Wave Absorption Compound that Can Be Injection-Molded for in-Vehicle Radar Housing. Available online: https://newswitch.jp/p/27163#:~:te (accessed on 2 November 2021).

- Japan Radio Absorber Co., Ltd. Millimeter Wave Noise Absorption Sheet (CPE/silicon). Available online: https://mwa.co.jp/product/adas/ (accessed on 2 November 2021).

- Sekisui Chemical Co., Ltd. Radio Wave Absorption Sheet (ADAS). Available online: https://www.sekisui-automotive.com›adas.html (accessed on 2 November 2021).

- Maxell Co. Ltd. Electromagnetic Wave Absorption Rubber Sheets. Available online: https://biz.maxell.com/ja/adhesive_tapes_inks_functional_films/electromagnetic_wave_suppression_sheet2.html (accessed on 2 November 2021).

- Kansai Paint, Co. Ltd. For Millimeter Waves for the Purpose of Preventing Automatic Driving Malfunction. Available online: https://www.kansai.co.jp›sites›files›new›press18 (accessed on 2 November 2021).

- Chiba, S. Super flexible electrode for a DE made with CNT spray. In Proceedings of the SPIE 11375, Electroactive Polymer Actuators and Devices (EAPAD) XXII, Anaheim, CA, USA, 22 April–9 May 2020. [Google Scholar] [CrossRef]

- Chiba, S.; Waki, M.; Takeshita, M.; Yoshizawa, T. Improvement Measurement for Dielectric Elastomers for Heavy Duty Uses Such as Robots and Power assist Devices. Adv. Theor. Comput. Phys. 2021, 4, 241. [Google Scholar] [CrossRef]

- Chiba, S.; Waki, M.; Takeshita, M.; Uejima, M.; Arakawa, K. Single-wall CNT spray for easy creation of DE electrodes (Conference Presentation). In Proceedings of the SPIE 11375, Electroactive Polymer Actuators and Devices (EAPAD) XXII, Anaheim, CA, USA, 22 April–9 May 2020. [Google Scholar] [CrossRef]

- Chiba, S.; Waki, M.; Takeshita, M.; Uejima, M.; Arakawa, H.; Ohyama, K.; Yoshizawa, T.; Yoshizawa, S.; Yoshizawa, Y. Electromagnetic Wave Leakage Absorption Film Using CNT Spray. In Proceedings of the SPIE 11745, Passive and Active Millimeter-Wave Imaging XXIV, online, 12–17 April 2021. [Google Scholar] [CrossRef]

- Tenent, R.; Barnes, T.; Bergeson, J.; Ferguson, A.; To, B.; Gedvilas, L.; Heben, M.; Blackburn, J. Ultrasmooth, Large-Area, High-Uniformity, Conductive Transparent Single-Wall-Carbon-Nanotube Films for Photovoltaics Produced by Ultrasonic Spraying. Adv. Mater. 2009, 21, 3210–3216. [Google Scholar] [CrossRef]

- Chen, Z.; Qiao, N.; Yang, Y.; Ye, H.; Liu, S.; Wang, W.; Wang, Y. Enhanced Broadband Electromagnetic Absorption in Silicon Film with Photonic Crystal Surface and Random Gold Grooves Reflector. Sci. Rep. 2015, 5, 12794. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- The Japanese Industrial Standards Committee (JISC). Japanese Industrial Standards (JIS) Search Site. Available online: https://www.jisc.go.jp/app/jis/general/GnrJISSearch.html (accessed on 2 November 2021).

- Fukoku Co. Ltd. Available online: http://www.fukoku-rubber.co.jp/ (accessed on 2 November 2021).

- Chiba, S.; Waki, M.; Ono, K.; Hatano, R.; Taniyama, Y.; Tanaka, S.; Okada, E.; Ohyama, K. Challenge of creating high performance dielectric elastomers. In Proceedings of the SPIE2021 (Smart Structures and Materials Symposium and its 23rd Electroactive Polymer Actuators and Devices (EAPAD) Conference), Anaheim, CA, USA, 22–27 March 2021; pp. 1157–1162. [Google Scholar] [CrossRef]

- Chiba, S. Development and application of dielectric elastomers (0.15g DE can lift 8 kg weight). Funct. Mater. 2021, 41, 33–39. [Google Scholar]

| Coating Thickness (μm) | ||||

|---|---|---|---|---|

| 16 | 35 | 76 | ||

| Radio wave absorption (dB) | CNT spray paint | 0.52 | 5.91 | 3.29 |

| Carbon black paint | 3.29 | 2.32 | 1.62 | |

| Graphite paint | 1.27 | 1.44 | 0.57 | |

| Coating Thickness (μm) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 35 | 76 | ||||||||

| Upper Part | Lower Part | Average Value | Upper Part | Lower Part | Average Value | Upper Part | Lower Part | Average Value | ||

| Radio wave absorption (dB) | CNT spray paint | 6.78 | 7.14 | 6.96 | 1.45 | 1.18 | 1.32 | 2.26 | 3.76 | 3.01 |

| Carbon black paint | 1.25 | 1.32 | 1.29 | 3.03 | 2.96 | 3.00 | 1.47 | 1.40 | 1.44 | |

| Graphite paint | 0.77 | 0.61 | 0.69 | 0.89 | 0.93 | 0.91 | 0.71 | 0.67 | 0.69 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiba, S.; Waki, M. Verification of the Radio Wave Absorption Effect in the Millimeter Wave Band of SWCNTs and Conventional Carbon-Based Materials. Appl. Sci. 2021, 11, 11490. https://doi.org/10.3390/app112311490

Chiba S, Waki M. Verification of the Radio Wave Absorption Effect in the Millimeter Wave Band of SWCNTs and Conventional Carbon-Based Materials. Applied Sciences. 2021; 11(23):11490. https://doi.org/10.3390/app112311490

Chicago/Turabian StyleChiba, Seiki, and Mikio Waki. 2021. "Verification of the Radio Wave Absorption Effect in the Millimeter Wave Band of SWCNTs and Conventional Carbon-Based Materials" Applied Sciences 11, no. 23: 11490. https://doi.org/10.3390/app112311490

APA StyleChiba, S., & Waki, M. (2021). Verification of the Radio Wave Absorption Effect in the Millimeter Wave Band of SWCNTs and Conventional Carbon-Based Materials. Applied Sciences, 11(23), 11490. https://doi.org/10.3390/app112311490