Influence of Aeration Method on Gaseous Emissions and the Losses of the Carbon and Nitrogen during Cow Manure Composting

Abstract

:1. Introduction

2. Materials and Methods

2.1. Composting Materials

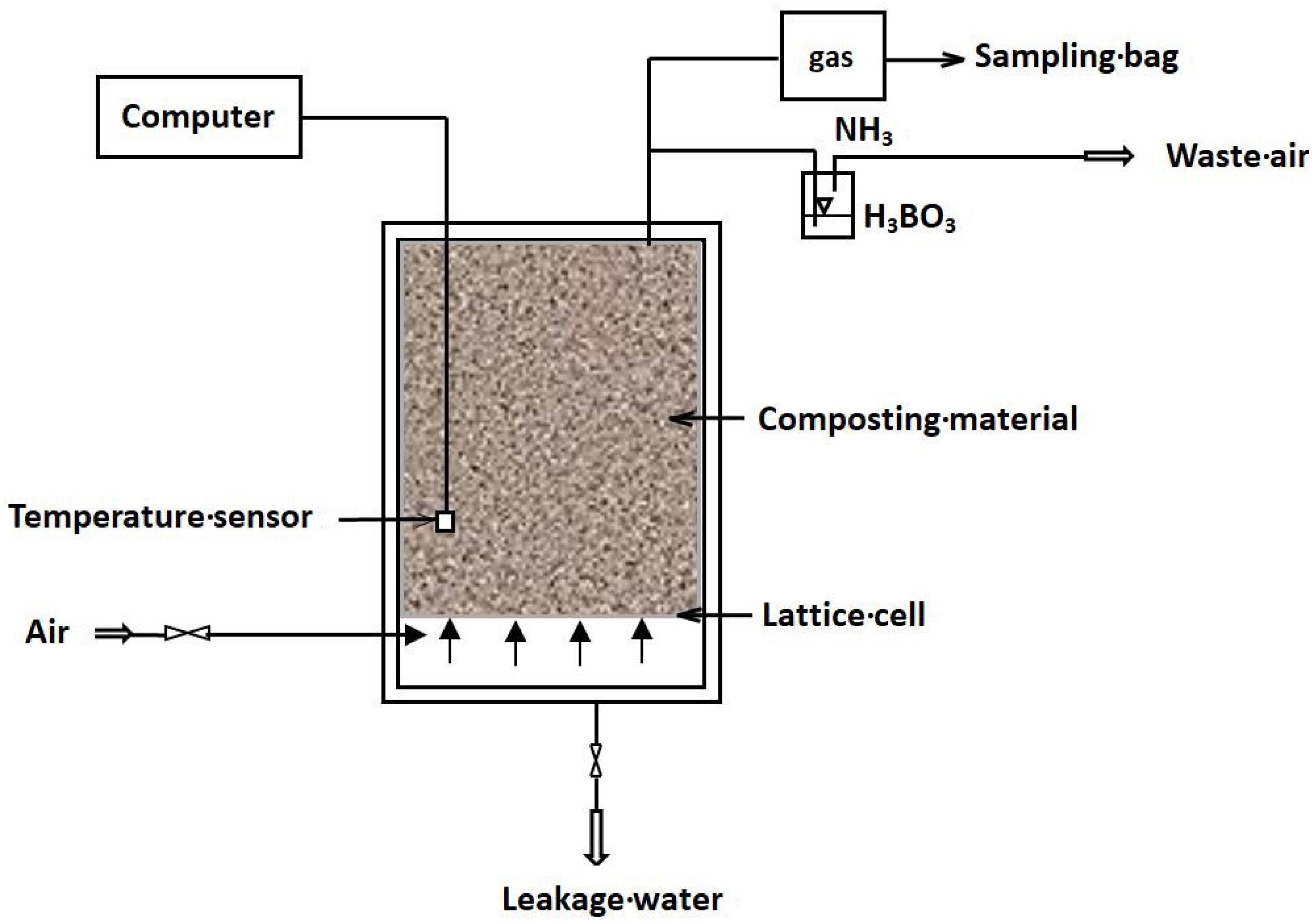

2.2. Experimental Equipment and Design

2.3. Sampling and Analysis Methods

2.4. Statistical Analysis

3. Results

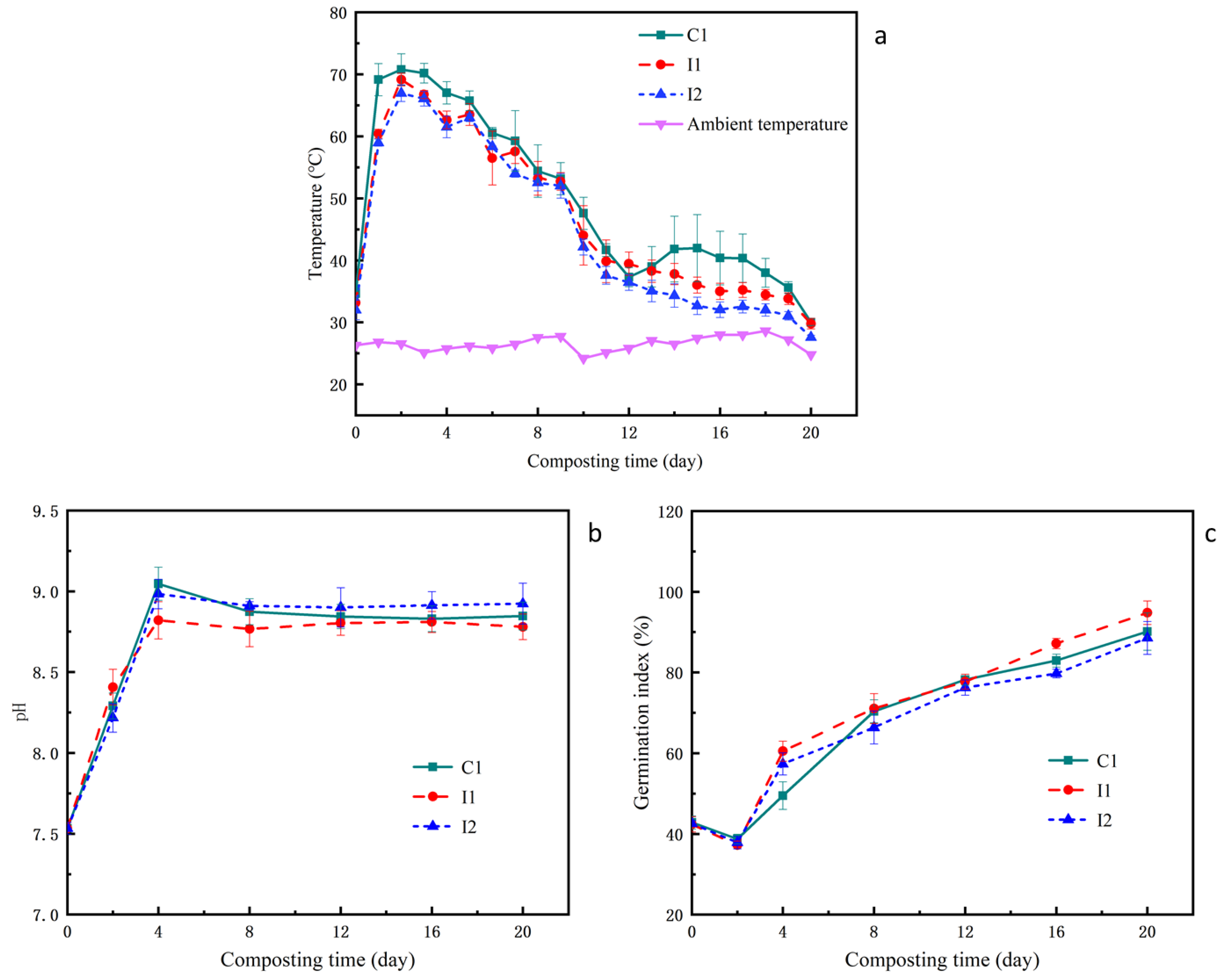

3.1. Variations in Temperature, pH, and GI during the Composting

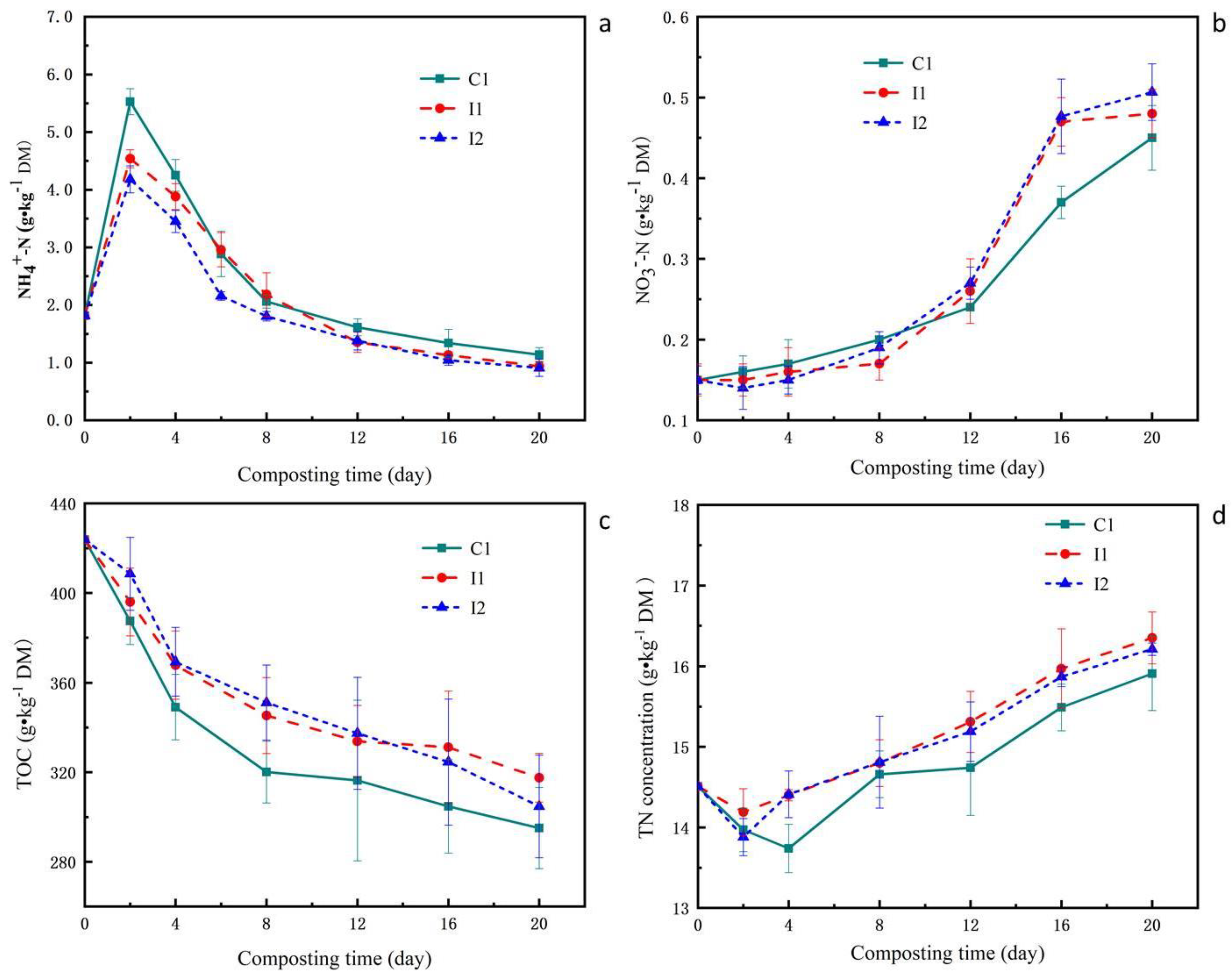

3.2. Variations in NH4+-N, NO3−-N, TN, and TOC during the Composting

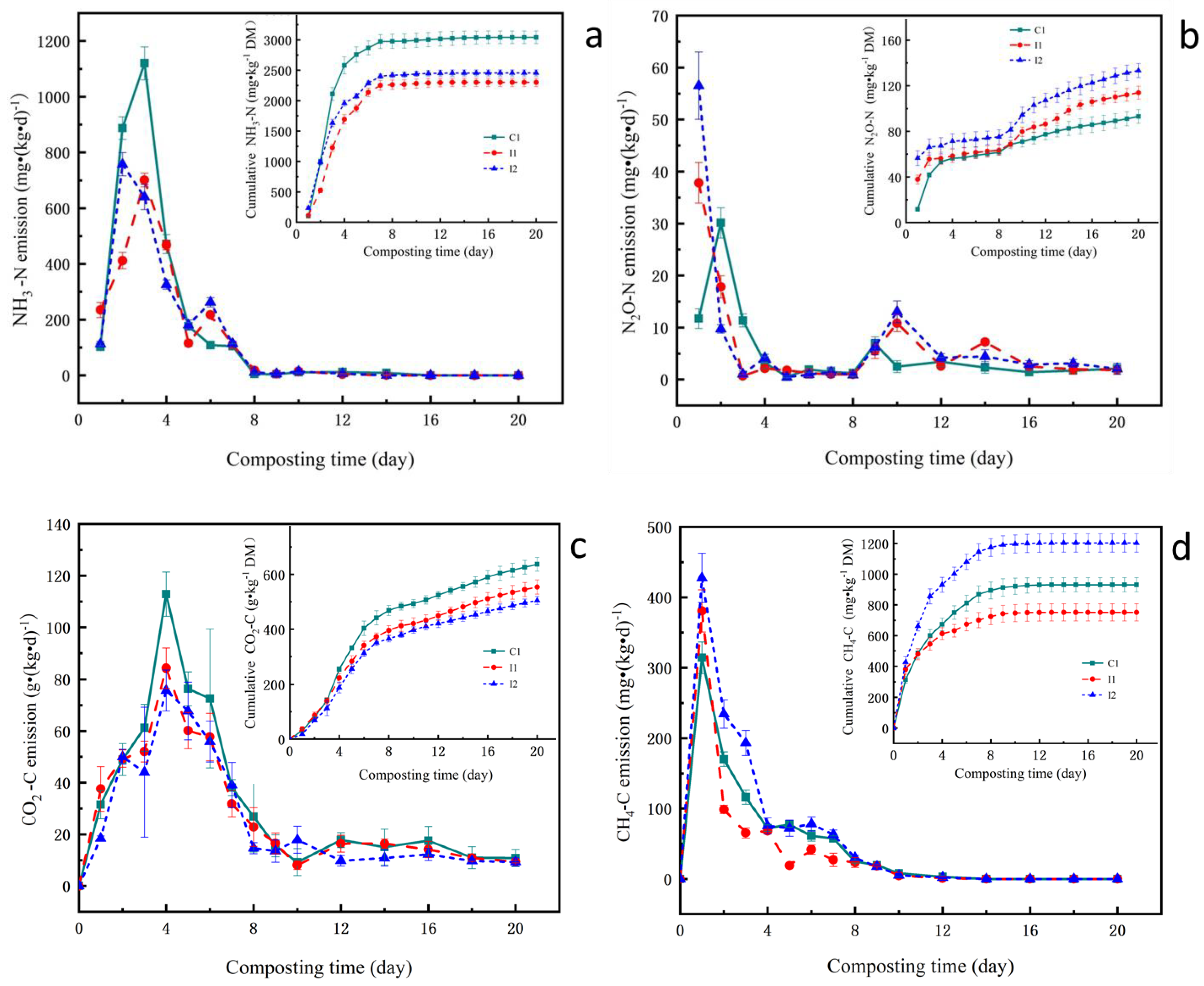

3.3. Emissions of NH3 and GHGs during the Composting

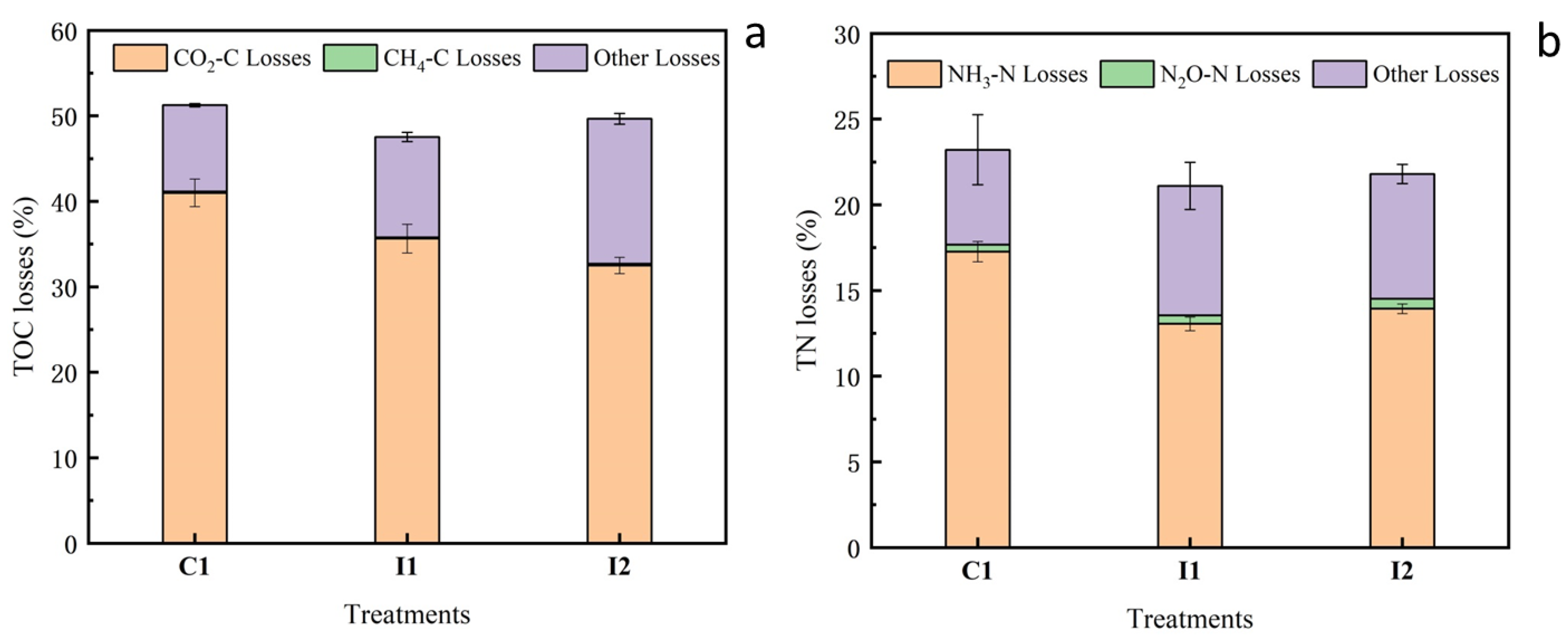

3.4. Carbon and Nitrogen Losses

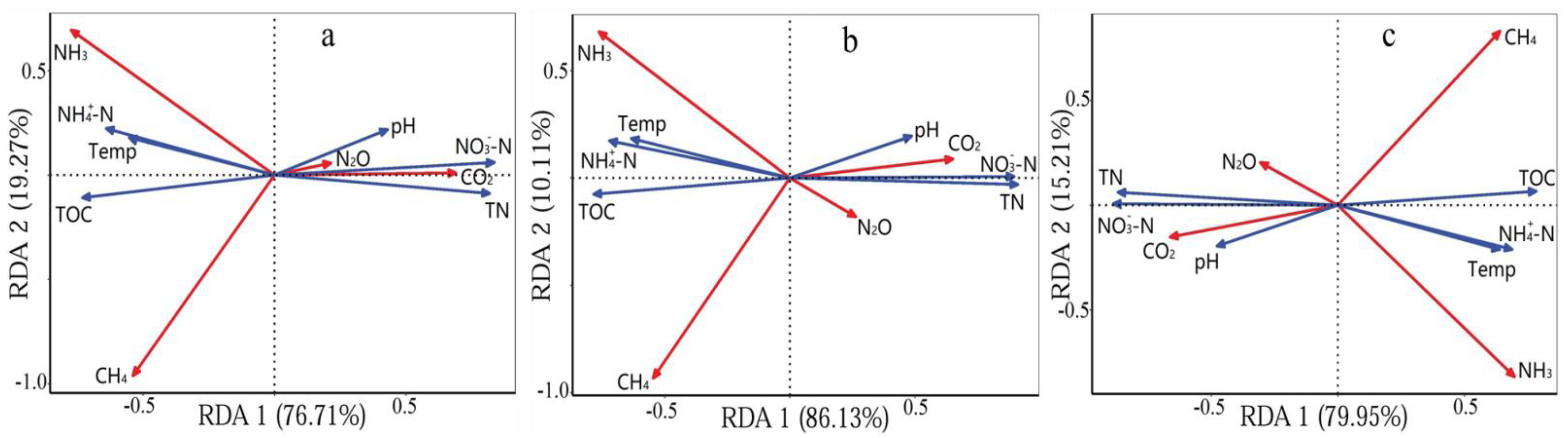

3.5. Redundancy Analysis (RDA) of Gaseous Emissions and Physicochemical Properties

4. Discussion

4.1. Temperature, pH and GI

4.2. NH4+-N, NO3−-N, TN, and TOC

4.3. Emissions of NH3 and GHGs

4.4. Carbon and Nitrogen Losses

4.5. Relationships between Gases and Physicochemical Indices

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, M.; Li, B.; Yu, A.; Liang, F.; Yang, L.; Sun, Y. The effect of aeration rate on forced-aeration composting of chicken manure and sawdust. Bioresour. Technol. 2010, 101, 1899–1903. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.J.; Awasthi, M.K.; Du, W.; Ren, X.N.; Lei, T.; Lv, J.L. Compost supplementation with nitrogen loss and greenhouse gas emissions during pig manure composting. Bioresour. Technol. 2020, 297, 122435. [Google Scholar] [CrossRef]

- Han, Z.; Sun, D.; Wang, H.; Li, R.; Bao, Z.; Qi, F. Effects of ambient temperature and aeration frequency on emissions of ammonia and greenhouse gases from a sewage sludge aerobic composting plant. Bioresour. Technol. 2018, 270, 457–466. [Google Scholar] [CrossRef] [PubMed]

- Yuan, J.; Chadwick, D.; Zhang, D.; Li, G.; Chen, S.; Luo, W.; Du, L.; He, S.; Peng, S. Effects of aeration rate on maturity and gaseous emissions during sewage sludge composting. Waste Manag. 2016, 56, 403–410. [Google Scholar] [CrossRef] [PubMed]

- Meng, L.; Li, W.; Zhang, S.; Wu, C.; Wang, K. Effects of sucrose amendment on ammonia assimilation during sewage sludge composting. Bioresour. Technol. 2016, 210, 160–166. [Google Scholar] [CrossRef] [PubMed]

- Jiang, T.; Ma, X.; Yang, J.; Tang, Q.; Yi, Z.; Chen, M.; Li, G. Effect of different struvite crystallization methods on gaseous emission and the comprehensive comparison during the composting. Bioresour. Technol. 2016, 217, 219–226. [Google Scholar] [CrossRef] [PubMed]

- Nakhshiniev, B.; Perera, C.; Biddinika, M.K.; Gonzales, H.B.; Sumida, H.; Yoshikawa, K. Reducing ammonia volatilization during composting of organic waste through addition of hydrothermally treated lignocellulose. Int. Biodeterior. Biodegrad. 2014, 96, 58–62. [Google Scholar] [CrossRef]

- Yuan, J.; Yang, Q.Y.; Zhang, Z.Y.; Li, G.X.; Luo, W.H.; Zhang, D.F. Use of additive and pretreatment to control odors in municipal kitchen waste during aerobic composting. J. Environ. Sci. 2015, 37, 83–90. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Chen, M.L.; Huang, Y.M.; Liu, H.J.; Xie, S.W.; Abbas, F. Impact of different nitrogen source on the compost quality and greenhouse gas emissions during composting of garden waste. Process. Saf. Environ. 2019, 124, 326–335. [Google Scholar] [CrossRef]

- Szanto, G.L.; Hamelers, H.M.; Rulkens, W.H.; Veeken, A.H.M. NH3, N2O and CH4 emissions during passively aerated composting of straw-rich pig manure. Bioresour. Technol. 2007, 98, 2659–2670. [Google Scholar] [CrossRef] [PubMed]

- Ermolaev, E.; Jarvis, A.; Sundberg, C.; Smars, S.; Pell, M.; Jonsson, H. Nitrous oxide and methane emissions from food waste composting at different temperatures. Waste Manag. 2015, 46, 113–119. [Google Scholar] [CrossRef]

- Jiang, T.; Ma, X.G.; Tang, Q.; Yang, J.; Li, G.X.; Schuchardt, F. Combined use of nitrification inhibitor and struvite crystallization to reduce the NH3 and N2O emissions during composting. Bioresour. Technol. 2016, 217, 210–218. [Google Scholar] [CrossRef]

- Zeng, J.; Yin, H.; Shen, X.; Liu, N.; Ge, J.; Han, L.; Huang, G. Effect of aeration interval on oxygen consumption and GHG emission during pig manure composting. Bioresour. Technol. 2018, 250, 214–220. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Wang, Q.; Huang, H.; Ren, X.N.; Lahori, A.H.; Mahar, A.; Ali, A.; Shen, F.; Li, R.H.; Zhang, Z.Q. Influence of zeolite and lime as additives on greenhouse gas emissions and maturity evolution during sewage sludge composting. Bioresour. Technol. 2016, 216, 172–181. [Google Scholar] [CrossRef] [PubMed]

- Hellmann, B.; Zelles, L.; Palojarvi, A.; Bai, Q.Y. Emission of climate-relevant trace gases and succession of microbial communities during open-window composting. Appl. Environ. Microbiol. 1997, 63, 1011–1018. [Google Scholar] [CrossRef] [Green Version]

- Chowdhury, M.A.; de Neergaard, A.; Jensen, L.S. Potential of aeration flow rate and bio-char addition to reduce greenhouse gas and ammonia emissions during manure composting. Chemosphere 2014, 97, 16–25. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, S.J.; Xue, W.T.; Guo, H.; Li, X.R.; Zou, G.Y.; Zhao, T.K.; Dong, H.M. The Characteristics of Carbon, Nitrogen and Sulfur Transformation During Cattle Manure Composting-Based on Different Aeration Strategies. Int. J. Environ. Res. Public Health 2019, 16, 3930. [Google Scholar] [CrossRef] [Green Version]

- Jiang, T.; Li, G.; Tang, Q.; Ma, X.; Wang, G.; Schuchardt, F. Effects of aeration method and aeration rate on greenhouse gas emissions during composting of pig feces in pilot scale. J. Environ. Sci. 2015, 31, 124–132. [Google Scholar] [CrossRef]

- NY525-2012. China Standard Method: Organic Fertilizer; Ministry of Agriculture of the People’s Republic of China: Beijing, China, 2012.

- Wang, X.; Bai, Z.H.; Yao, Y.; Gao, B.B.; Chadwick, D.; Chen, Q.; Hu, C.S.; Ma, L. Composting with negative pressure aeration for the mitigation of ammonia emissions and global warming potential. J. Clean. Prod. 2018, 195, 448–457. [Google Scholar] [CrossRef]

- Tong, B.X.; Wang, X.; Wang, S.Q.; Ma, L.; Ma, W.Q. Transformation of nitrogen and carbon during composting of manure litter with different methods. Bioresour. Technol. 2019, 293, 122046. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.B.; Zheng, Y.Q.; Gao, D.; Kong, J.S.; Luo, W. Variation of oxygen concentration during aerobic composting of pig manure. J. Appl. Ecol. 2004, 15, 2179–2183. [Google Scholar]

- Shen, Y.J.; Zhang, P.Y.; Zhao, L.X.; Cheng, H.S.; Zhou, H.B.; Zhang, X. Effects of ventilation modes on control of main odor substances in pig manure composting. Trans. Chin. Soc. Agric. Eng. 2019, 35, 203–209. [Google Scholar]

- NY/T1168-2006. Technical Requirement for Non-Hazardous Treatment of Animal Manure; Ministry of Agriculture of the People’s Republic of China: Beijing, China, 2006.

- Zhu, X.; Dong, W.; Wang, H.; Yan, C.; Liu, H.; Liu, E. Effects of cattle manure composting methods on greenhouse gas and ammonia emissions. Trans. Chin. Soc. Agric. Eng. 2017, 33, 258–264. [Google Scholar]

- Nie, E.; Zheng, G.; Gao, D.; Liu, X. Moderate intensity of ventilation can significantly reduce nitrogen loss during aerobic composting of chicken manure. J. Plant Nutr. Fertil. 2019, 25, 1773–1780. [Google Scholar]

- Rihani, M.; Malamis, D.; Bihaoui, B.; Etahiri, S.; Loizidou, M.; Assobhei, O. In-vessel treatment of urban primary sludge by aerobic composting. Bioresour. Technol. 2010, 101, 5988–5995. [Google Scholar] [CrossRef] [PubMed]

- Wong, J.W.; Mak, K.F.; Chan, N.W.; Lam, A.; Fang, M.; Zhou, L.X.; Wu, Q.T.; Liao, X.D. Co-composting of soybean residues and leaves in Hong Kong. Bioresour. Technol. 2001, 76, 99–106. [Google Scholar] [CrossRef]

- Meng, X.; Liu, B.; Xi, C.; Luo, X.; Yuan, X.; Wang, X.; Zhu, W.; Wang, H.; Cui, Z. Effect of pig manure on the chemical composition and microbial diversity during co-composting with spent mushroom substrate and rice husks. Bioresour. Technol. 2018, 251, 22–30. [Google Scholar] [CrossRef]

- Selim, S.M.; Zayed, M.S.; Atta, H.M. Evaluation of phytotoxicity of compost during composting process. Nat. Sci. 2012, 10, 69–77. [Google Scholar]

- Chen, M.L.; Wang, C.; Wang, B.R.; Bai, X.; Gao, H.; Huang, Y. Enzymatic mechanism of organic nitrogen conversion and ammonia formation during vegetable waste composting using two amendments. Waste Manag. 2019, 95, 306–315. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Li, G.; Jiang, T.; Schuchardt, F.; Chen, T.; Zhao, Y.; Shen, Y. Effect of aeration rate, C/N ratio and moisture content on the stability and maturity of compost. Bioresour. Technol. 2012, 112, 171–178. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Huang, H.Y.; Sun, J.J.; Wu, H.S.; Duan, H.Y.; Xu, Y.D.; Jin, H.M.; Chang, Z.Z. Effect of hyperthermerphilic pretreatment on transformation and losses of C and N during pig manure composting. China Environ. Sci. 2018, 38, 1792–1800. [Google Scholar]

- Awasthi, M.K.; Pandey, A.K.; Bundela, P.S.; Khan, J. Co-composting of organic fraction of municipal solid waste mixed with different bulking waste: Characterization of physicochemical parameters and microbial enzymatic dynamic. Bioresour. Technol. 2015, 182, 200–207. [Google Scholar] [CrossRef]

- Liu, N.; Zhou, J.; Ma, S.; Han, L.; Huang, G. Impacts of Biochar on Major Forms Contents and Conservation Mechanism of Nitrogen during Aerobic Composting of Chicken Manure. Trans. Chin. Soc. Agric. Mach. 2016, 47, 233–239. [Google Scholar]

- Yuan, J.; Li, Y.; Chen, S.; Li, D.; Tang, H.; Chadwick, D.; Li, S.; Li, W.; Li, G. Effects of phosphogypsum, superphosphate, and dicyandiamide on gaseous emission and compost quality during sewage sludge composting. Bioresour. Technol. 2018, 270, 368–376. [Google Scholar] [CrossRef] [PubMed]

- Santos, A.; Bustamante, M.A.; Tortosa, G.; Moral, R.; Bernal, M.P. Gaseous emissions and process development during composting of pig slurry: The influence of the proportion of cotton gin waste. J. Clean. Prod. 2016, 112, 81–90. [Google Scholar] [CrossRef]

- Pan, J.T.; Cai, H.Z.; Zhang, Z.Q.; Liu, H.B.; Li, R.H.; Mao, H.; Awasthi, M.K.; Wang, Q.; Zhai, L.M. Comparative evaluation of the use of acidic additives on sewage sludge composting quality improvement, nitrogen conservation, and greenhouse gas reduction. Bioresour. Technol. 2018, 270, 467–475. [Google Scholar] [CrossRef]

- Vuorinen, A.H.; Saharinen, M.H. Evolution of microbiological and chemical parameters during manure and straw co-composting in a drum composting system. Agric. Ecosyst. Environ. 1997, 66, 19–29. [Google Scholar] [CrossRef]

- Chan, M.T.; Selvam, A.; Wong, J.W.C. Reducing nitrogen loss and salinity during ’struvite’ food waste composting by zeolite amendment. Bioresour. Technol. 2016, 200, 838–844. [Google Scholar] [CrossRef] [PubMed]

- Luo, W.H.; Yuan, J.; Luo, Y.M.; Li, G.X.; Nghiem, L.D.; Price, W.E. Effects of mixing and covering with mature compost on gaseous emissions during composting. Chemosphere 2014, 117, 14–19. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, T.; Schuchardt, F.; Li, G.X.; Guo, R.; Luo, Y.M. Gaseous emission during the composting of pig feces from Chinese Ganqinfen system. Chemosphere 2013, 90, 1545–1551. [Google Scholar] [CrossRef]

- El Kader, N.A.; Robin, P.; Paillat, J.M.; Leterme, P. Turning, compacting and the addition of water as factors affecting gaseous emissions in farm manure composting. Bioresour. Technol. 2007, 98, 2619–2628. [Google Scholar] [CrossRef] [PubMed]

- Richardson, D.; Felgate, H.; Watmough, N.; Thomson, A.; Baggs, E. Mitigating release of the potent greenhouse gas N2O from the nitrogen cycle—Could enzymic regulation hold the key? Trends Biotechnol. 2009, 27, 388–397. [Google Scholar] [CrossRef] [PubMed]

- Tsutsui, H.; Fujiwara, T.; Matsukawa, K.; Funamizu, N. Nitrous oxide emission mechanisms during intermittently aerated composting of cattle manure. Bioresour. Technol. 2013, 141, 205–211. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, M.K.; Wang, M.J.; Chen, H.Y.; Wang, Q.; Zhao, J.C.; Ren, X.N.; Li, D.S.; Awasthi, S.K.; Shen, F.; Li, R.H.; et al. Heterogeneity of biochar amendment to improve the carbon and nitrogen sequestration through reduce the greenhouse gases emissions during sewage sludge composting. Bioresour. Technol. 2017, 224, 428–438. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Sun, X.; Awasthi, M.K.; Wang, Q.; Ren, X.; Li, R.; Chen, H.; Wang, M.; Liu, T.; Zhang, Z. Performance evaluation of gaseous emissions and Zn speciation during Zn-rich antibiotic manufacturing wastes and pig manure composting. Bioresour. Technol. 2018, 267, 688–695. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Ren, L.; Li, G.; Chen, T.; Guo, R. Influence of aeration on CH4, N2O and NH3 emissions during aerobic composting of a chicken manure and high C/N waste mixture. Waste Manag. 2011, 31, 33–38. [Google Scholar] [CrossRef] [PubMed]

- Tiquia, S.M.; Tam, N.F.Y. Fate of nitrogen during composting of chicken litter. Environ. Pollut. 2000, 110, 535–541. [Google Scholar] [CrossRef]

- Li, S.; Li, D.; Li, J.; Li, Y.; Li, G.; Zang, B.; Li, Y. Effect of spent mushroom substrate as a bulking agent on gaseous emissions and compost quality during pig manure composting. Environ. Sci. Pollut. Res. 2018, 25, 12398–12406. [Google Scholar] [CrossRef] [PubMed]

- Ghanney, P.; Qiu, H.; Anning, D.K.; Yang, H.; Wang, Y.; Kugbe, J.X. Moisture-Induced Pattern of Gases and Physicochemical Indices in Corn Straw and Cow Manure Composting. Appl. Sci. 2021, 11, 8493. [Google Scholar] [CrossRef]

| Materials | MC (%) | TOC (%) | TN (%) | C/N | pH |

|---|---|---|---|---|---|

| Dairy manure | 63.93 ± 0.49 | 40.83 ± 3.10 | 2.02 ± 0.21 | 20.30 ± 1.11 | 7.6 ± 0.17 |

| Corn stalks | 7.26 ± 0.22 | 43.75 ± 1.78 | 0.72 ± 0.04 | 60.78 ± 0.59 | 7.1 ± 0.10 |

| Initial composting mixture | 60.22 ± 1.18 | 42.38 ± 1.01 | 1.45 ± 0.13 | 29.35 ± 2.20 | 7.53 ± 0.04 |

| Treatments | Aeration Rate (L·kg−1 DM·min−1) | Aeration Flow (L/h) | Aeration Method |

|---|---|---|---|

| C1 | 0.21 | 100 | continuous |

| I1 | 0.42 (average 0.21) | 200 | Intermittent (aerate 10 min, stop 10 min) |

| I2 | 0.84 (average 0.21) | 400 | Intermittent (aerate 5 min, stop 15 min) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Qiu, H.; Li, M.; Ghanney, P. Influence of Aeration Method on Gaseous Emissions and the Losses of the Carbon and Nitrogen during Cow Manure Composting. Appl. Sci. 2021, 11, 11639. https://doi.org/10.3390/app112411639

Wang Y, Qiu H, Li M, Ghanney P. Influence of Aeration Method on Gaseous Emissions and the Losses of the Carbon and Nitrogen during Cow Manure Composting. Applied Sciences. 2021; 11(24):11639. https://doi.org/10.3390/app112411639

Chicago/Turabian StyleWang, Youling, Huizhen Qiu, Mengchan Li, and Philip Ghanney. 2021. "Influence of Aeration Method on Gaseous Emissions and the Losses of the Carbon and Nitrogen during Cow Manure Composting" Applied Sciences 11, no. 24: 11639. https://doi.org/10.3390/app112411639