Comparative Analysis of Surface Pressure Fluctuations of High-Speed Train Running in Open-Field and Tunnel Using LES and Wavenumber-Frequency Analysis

Abstract

:1. Introduction

2. Computational Methods and Model

2.1. Large Eddy Simulation

2.2. Wavenumber-Frequency Analysis

2.3. Target Model and Details on Simulation

3. Unsteady Flow Analysis

4. Main Aerodynamic Noise Sources

4.1. Bogies

4.2. Pantograph

4.3. HVAC Box

5. Decomposition of Surface Pressure Fields

6. Comparison of Decomposed Surface Pressure Fields between Open-Field and Tunnel

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Undecomposed Pressure Fluctuations [Unit: dB] | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Car Type | Section | Left Sidewall | Roof Wall | Right Sidewall | |||||||||||

| C | 1 | 2 | 3 | 4 | 5 | 1 | 2 | 3 | 1 | 2 | 3 | 4 | 5 | ||

| R | Case | ||||||||||||||

| TC1 | 1 | O | 111.0 | 109.8 | 107.0 | 109.2 | - | 120.2 | 109.8 | 109.1 | 109.3 | 108.3 | 107.5 | 110.4 | - |

| T | 109.5 | 110.8 | 108.5 | 110.1 | - | 120.0 | 108.9 | 107.0 | 109.3 | 110.0 | 108.2 | 111.7 | - | ||

| 2 | O | 106.3 | 106.3 | 106.1 | 106.3 | - | 120.6 | 112.3 | 108.2 | 106.3 | 106.2 | 106.5 | 107.6 | - | |

| T | 108.4 | 108.8 | 108.6 | 109.3 | - | 121.7 | 112.3 | 107.3 | 107.2 | 108.3 | 107.4 | 109.4 | - | ||

| 3 | O | 106.7 | 104.8 | 104.6 | 105.2 | - | 115.4 | 110.6 | 107.7 | 106.1 | 105.1 | 105.2 | 106.6 | - | |

| T | 109.4 | 108.6 | 108.4 | 108.3 | - | 116.5 | 112.1 | 109.2 | 108.0 | 108.5 | 107.0 | 108.3 | - | ||

| M1 | 1 | O | 116.2 | 111.2 | 111.7 | 111.1 | 116.6 | 121.1 | 119.1 | 117.7 | 113.0 | 113.4 | 111.6 | 110.1 | 110.4 |

| T | 112.9 | 113.4 | 111.1 | 111.7 | 114.9 | 121.3 | 117.0 | 116.3 | 112.7 | 112.1 | 114.2 | 112.5 | 111.6 | ||

| 2 | O | 112.1 | 110.2 | 111.1 | 108.9 | 109.0 | 121.6 | 117.3 | 114.3 | 109.6 | 110.1 | 107.7 | 108.4 | 108.3 | |

| T | 110.5 | 110.9 | 111.6 | 109.0 | 112.1 | 122.3 | 114.5 | 113.8 | 109.0 | 110.3 | 110.6 | 108.2 | 107.7 | ||

| 3 | O | 107.7 | 107.0 | 107.4 | 109.2 | 107.3 | 122.7 | 117.0 | 113.0 | 108.4 | 108.0 | 107.2 | 107.4 | 106.0 | |

| T | 111.2 | 109.8 | 110.1 | 108.8 | 110.4 | 121.5 | 117.6 | 114.0 | 109.4 | 108.6 | 108.5 | 110.0 | 106.9 | ||

| M’3 | 1 | O | 113.4 | 111.4 | 112.5 | 110.9 | 109.6 | 118.2 | 113.5 | 109.7 | 113.7 | 116.6 | 112.9 | 108.6 | 110.9 |

| T | 115.0 | 113.1 | 110.8 | 111.8 | 111.3 | 118.0 | 115.4 | 111.5 | 118.8 | 117.7 | 115.2 | 109.8 | 108.9 | ||

| 2 | O | 110.8 | 109.4 | 109.9 | 108.7 | 108.8 | 115.3 | 112.5 | 112.4 | 110.9 | 112.6 | 110.6 | 110.7 | 110.7 | |

| T | 112.4 | 112.0 | 109.5 | 112.6 | 109.5 | 115.9 | 111.5 | 109.5 | 117.2 | 114.8 | 113.1 | 108.3 | 108.0 | ||

| 3 | O | 110.7 | 107.7 | 106.9 | 105.3 | 106.8 | 115.9 | 112.8 | 114.4 | 109.5 | 107.9 | 108.5 | 109.0 | 108.7 | |

| T | 110.6 | 108.2 | 107.9 | 108.2 | 110.7 | 113.3 | 112.7 | 113.3 | 112.7 | 109.8 | 109.5 | 106.9 | 107.0 | ||

| TC2 | 1 | O | 118.4 | 114.1 | 111.5 | 110.8 | - | 119.1 | 112.9 | 109.5 | 113.2 | 116.1 | 112.2 | 109.9 | - |

| T | 114.9 | 117.1 | 116.3 | 115.4 | - | 118.2 | 115.6 | 114.6 | 119.1 | 119.2 | 113.4 | 110.0 | - | ||

| 2 | O | 115.2 | 113.0 | 109.3 | 109.6 | - | 115.6 | 113.0 | 108.6 | 111.0 | 111.4 | 111.3 | 108.8 | - | |

| T | 113.3 | 114.6 | 117.0 | 114.2 | - | 118.2 | 113.0 | 111.3 | 116.9 | 116.7 | 113.8 | 109.3 | - | ||

| 3 | O | 110.7 | 108.9 | 108.6 | 108.8 | - | 118.2 | 115.0 | 112.5 | 109.2 | 107.8 | 108.5 | 109.6 | - | |

| T | 110.0 | 113.7 | 113.5 | 114.4 | - | 119.9 | 113.8 | 111.2 | 111.1 | 112.7 | 109.0 | 107.1 | - | ||

| Incompressible Pressure Fluctuations [Unit: dB] | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Car Type | Section | Left Sidewall | Roof Wall | Right Sidewall | |||||||||||

| C | 1 | 2 | 3 | 4 | 5 | 1 | 2 | 3 | 1 | 2 | 3 | 4 | 5 | ||

| R | Case | ||||||||||||||

| TC1 | 1 | O | 110.8 | 109.5 | 106.4 | 108.7 | - | 120.2 | 109.8 | 109.0 | 109.0 | 108.1 | 107.1 | 109.8 | - |

| T | 108.1 | 109.8 | 107.2 | 108.6 | - | 120.0 | 108.4 | 105.8 | 108.2 | 108.7 | 106.7 | 110.5 | - | ||

| 2 | O | 105.8 | 105.9 | 105.5 | 105.7 | - | 120.5 | 112.3 | 108.1 | 105.9 | 106.0 | 106.0 | 106.8 | - | |

| T | 105.9 | 107.0 | 106.8 | 107.7 | - | 121.7 | 111.9 | 106.3 | 104.2 | 105.6 | 105.5 | 107.2 | - | ||

| 3 | O | 106.4 | 104.4 | 104.0 | 104.8 | - | 115.4 | 110.5 | 107.6 | 105.8 | 104.8 | 104.7 | 106.3 | - | |

| T | 107.9 | 107.0 | 106.6 | 106.2 | - | 116.4 | 111.7 | 108.4 | 105.7 | 105.8 | 105.5 | 106.0 | - | ||

| M1 | 1 | O | 115.9 | 111.0 | 111.4 | 110.7 | 116.1 | 121.0 | 119.0 | 117.5 | 112.8 | 113.2 | 111.4 | 109.9 | 109.9 |

| T | 112.4 | 113.0 | 110.6 | 111.0 | 114.1 | 121.1 | 116.6 | 115.7 | 112.4 | 111.6 | 113.8 | 112.1 | 111.1 | ||

| 2 | O | 111.9 | 110.0 | 111.0 | 108.5 | 108.5 | 121.5 | 117.1 | 114.1 | 109.2 | 109.8 | 107.5 | 108.2 | 108.0 | |

| T | 109.4 | 109.9 | 110.5 | 107.9 | 110.6 | 122.1 | 114.1 | 113.4 | 108.2 | 109.3 | 109.8 | 107.2 | 106.7 | ||

| 3 | O | 107.5 | 106.7 | 107.1 | 109.0 | 106.9 | 122.7 | 116.8 | 112.5 | 108.0 | 107.7 | 107.0 | 107.3 | 105.8 | |

| T | 110.2 | 108.6 | 108.7 | 107.8 | 108.9 | 121.4 | 117.2 | 113.7 | 108.5 | 107.3 | 107.2 | 109.2 | 105.5 | ||

| M’3 | 1 | O | 112.8 | 111.1 | 112.3 | 110.7 | 109.1 | 118.1 | 113.4 | 109.6 | 113.5 | 116.1 | 112.6 | 108.4 | 110.0 |

| T | 114.4 | 112.9 | 110.3 | 111.3 | 110.8 | 117.7 | 115.1 | 111.2 | 118.0 | 117.3 | 114.9 | 109.4 | 107.9 | ||

| 2 | O | 110.3 | 108.8 | 109.7 | 108.6 | 108.5 | 115.2 | 112.3 | 112.2 | 110.6 | 112.0 | 110.3 | 110.4 | 110.0 | |

| T | 111.6 | 111.3 | 108.8 | 111.5 | 109.1 | 115.6 | 111.0 | 109.0 | 116.5 | 113.6 | 112.7 | 107.4 | 106.8 | ||

| 3 | O | 110.3 | 107.3 | 106.7 | 105.0 | 106.5 | 115.7 | 112.5 | 114.3 | 109.3 | 107.2 | 108.2 | 108.8 | 108.2 | |

| T | 110.1 | 107.4 | 106.4 | 107.0 | 110.3 | 113.1 | 112.3 | 113.0 | 111.9 | 108.4 | 108.4 | 105.6 | 105.4 | ||

| TC2 | 1 | O | 117.5 | 113.3 | 110.7 | 110.3 | - | 119.0 | 112.6 | 109.4 | 112.7 | 115.4 | 111.9 | 109.4 | - |

| T | 114.2 | 116.0 | 115.9 | 113.9 | - | 117.9 | 115.3 | 114.2 | 118.2 | 118.8 | 112.8 | 109.2 | - | ||

| 2 | O | 114.3 | 112.2 | 109.0 | 109.2 | - | 115.6 | 112.9 | 108.4 | 110.7 | 110.6 | 110.6 | 108.3 | - | |

| T | 112.6 | 113.4 | 116.6 | 112.8 | - | 118.1 | 112.7 | 110.9 | 115.8 | 116.1 | 113.4 | 108.2 | - | ||

| 3 | O | 110.1 | 108.3 | 108.0 | 108.5 | - | 118.1 | 114.8 | 112.2 | 108.9 | 107.2 | 108.0 | 108.9 | - | |

| T | 108.8 | 112.2 | 112.7 | 113.4 | - | 119.7 | 113.6 | 110.6 | 109.7 | 111.5 | 108.3 | 106.0 | - | ||

| Compressible Pressure Fluctuations [Unit: dB] | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Car Type | Section | Left Sidewall | Roof Wall | Right Sidewall | |||||||||||

| C | 1 | 2 | 3 | 4 | 5 | 1 | 2 | 3 | 1 | 2 | 3 | 4 | 5 | ||

| R | Case | ||||||||||||||

| TC1 | 1 | O | 97.7 | 96.5 | 98.3 | 99.7 | - | 96.9 | 90.5 | 91.7 | 97.1 | 95.7 | 97.5 | 101.9 | - |

| T | 104.1 | 104.1 | 102.9 | 104.6 | - | 98.2 | 99.3 | 101.0 | 102.7 | 104.3 | 102.8 | 105.6 | - | ||

| 2 | O | 97.1 | 95.4 | 97.5 | 97.2 | - | 100.3 | 94.1 | 92.2 | 95.6 | 94.2 | 97.4 | 100.0 | - | |

| T | 104.6 | 104.2 | 104.1 | 104.2 | - | 101.7 | 101.8 | 100.7 | 104.1 | 105.1 | 102.8 | 105.4 | - | ||

| 3 | O | 95.5 | 93.8 | 95.5 | 94.8 | - | 94.9 | 90.2 | 92.1 | 94.0 | 92.4 | 95.1 | 97.1 | - | |

| T | 104.2 | 103.6 | 103.7 | 104.1 | - | 100.6 | 101.9 | 101.1 | 104.0 | 105.0 | 101.6 | 104.6 | - | ||

| M1 | 1 | O | 103.6 | 97.2 | 100.3 | 99.6 | 106.7 | 106.5 | 103.5 | 102.6 | 100.3 | 99.3 | 97.2 | 95.0 | 100.6 |

| T | 103.3 | 102.8 | 101.2 | 103.4 | 107.3 | 108.2 | 105.6 | 107.5 | 101.2 | 102.2 | 104.0 | 102.5 | 102.2 | ||

| 2 | O | 98.4 | 94.8 | 97.2 | 98.1 | 98.8 | 106.3 | 104.7 | 100.8 | 99.2 | 97.7 | 93.9 | 95.3 | 96.3 | |

| T | 103.9 | 104.1 | 104.7 | 102.5 | 106.8 | 108.5 | 103.4 | 102.6 | 101.2 | 103.5 | 102.8 | 101.1 | 101.0 | ||

| 3 | O | 94.8 | 94.2 | 94.8 | 96.4 | 95.6 | 103.5 | 102.3 | 103.2 | 96.9 | 95.1 | 92.1 | 93.1 | 93.4 | |

| T | 104.1 | 103.7 | 104.3 | 101.9 | 104.9 | 104.4 | 106.2 | 102.5 | 102.1 | 102.8 | 102.8 | 102.6 | 101.1 | ||

| M’3 | 1 | O | 104.0 | 99.9 | 97.4 | 98.6 | 100.2 | 101.7 | 96.7 | 94.1 | 101.3 | 107.7 | 101.1 | 96.7 | 103.4 |

| T | 105.8 | 100.1 | 101.3 | 102.0 | 101.5 | 105.2 | 104.2 | 100.2 | 111.0 | 107.8 | 104.5 | 99.6 | 102.2 | ||

| 2 | O | 100.7 | 100.5 | 96.1 | 94.0 | 97.4 | 99.7 | 98.6 | 97.9 | 98.3 | 103.8 | 98.4 | 99.1 | 102.8 | |

| T | 104.3 | 103.8 | 101.2 | 106.2 | 98.9 | 103.2 | 102.1 | 100.1 | 108.8 | 108.6 | 102.6 | 100.9 | 101.8 | ||

| 3 | O | 99.4 | 97.0 | 93.8 | 93.4 | 95.7 | 103.1 | 100.2 | 97.3 | 94.6 | 99.5 | 97.7 | 94.8 | 99.4 | |

| T | 100.6 | 100.6 | 102.6 | 101.9 | 100.6 | 101.0 | 102.1 | 101.0 | 104.5 | 104.3 | 102.8 | 100.9 | 101.7 | ||

| TC2 | 1 | O | 111.1 | 106.5 | 103.8 | 100.8 | - | 98.3 | 99.8 | 92.9 | 102.8 | 107.8 | 101.2 | 100.5 | - |

| T | 106.2 | 110.7 | 106.0 | 109.9 | - | 106.2 | 102.7 | 104.5 | 111.6 | 108.8 | 104.4 | 102.0 | - | ||

| 2 | O | 107.7 | 105.1 | 98.2 | 98.5 | - | 98.4 | 95.2 | 94.7 | 99.4 | 103.4 | 103.2 | 99.3 | - | |

| T | 105.1 | 108.3 | 106.2 | 108.6 | - | 103.3 | 101.2 | 101.0 | 110.6 | 107.9 | 103.1 | 102.8 | - | ||

| 3 | O | 101.2 | 100.1 | 99.7 | 97.0 | - | 100.6 | 101.6 | 100.8 | 97.3 | 99.0 | 99.3 | 101.0 | - | |

| T | 103.8 | 108.2 | 105.5 | 107.9 | - | 105.5 | 101.2 | 102.2 | 105.5 | 106.5 | 101.0 | 100.6 | - | ||

References

- Talotte, C. Aerodynamic noise: A critical survey. J. Sound Vib. 2000, 231, 549–562. [Google Scholar] [CrossRef]

- Mellet, C.; Létourneaux, F.; Poisson, F.; Talotte, C. High speed train noise emission: Latest investigation of the aerodynamic/rolling noise contribution. J. Sound Vib. 2006, 293, 535–546. [Google Scholar] [CrossRef]

- Thompson, D.J. Railway Noise and Vibration: Mechanisms, Modelling and Means of Control, 1st ed.; Elsevier: Oxford, UK, 2008. [Google Scholar]

- Palmer, F.S. Aeroacoustics in High Speed Train. Ph.D. Thesis, Escuela Técnica Superior de Ingeniería, Aeronáuticos (UPM), Madrid, Spain, 2014. [Google Scholar]

- Noh, H. Noise-Source identification of a high-speed train by noise source level analysis. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016, 231, 717–728. [Google Scholar] [CrossRef]

- Iglesias, E.L. Component-Based Model for Aerodynamic Noise of High-Speed Trains. Ph.D. Thesis, University of Southampton, Southampton, UK, 2015. [Google Scholar]

- Myouken, M.; Kuribayasi, K.; Saito, T. Noise Evaluation of Developed egg Shaped Sound-Proofing Wall for High Speed Railway by Field Test; InterNoise: Madrid, Spain, 2019. [Google Scholar]

- Iglesias, E.L.; Thompson, D.J.; Smith, M.; Kitagawa, T.; Yamazaki, N. Anechoic wind tunnel tests on high-speed train bogie aerodynamic noise. Int. J. Rail Transp. 2017, 5, 78–109. [Google Scholar]

- Thompson, D.J.; Iglesias, E.L.; Liu, X.; Zhu, J.; Hu, Z. Recent developments in the prediction and control of aerodynamic noise from high-speed trains. Int. J. Rail Transp. 2015, 3, 119–150. [Google Scholar] [CrossRef]

- Zhu, J. Aerodynamic Noise of High-Speed Train Bogies. Ph.D. Thesis, University of Southampton, Southampton, UK, 2015. [Google Scholar]

- Paradot, N.; Masson, E.; Poisson, F.; Grégoire, R.; Guilloteau, E.; Touil, H.; Sagaut, P. Aero-acoustic methods for high-speed train noise prediction. In Proceedings of the World Congress on Railway Research, Seoul, Korea, 18–22 May 2008. [Google Scholar]

- Andreini, A.; Bianchini, C.; Facchini, B.; Giusti, A.; Bellini, D.; Chiti, F.; Federico, G. Large eddy simulation for train aerodynamic noise predictions. In Proceedings of the World Congress on Railway Research, Lille, France, 22–26 May 2011. [Google Scholar]

- Yu, H.H.; Li, J.C.; Zhang, H.Q. On aerodynamic noises radiated by the pantograph system of high-speed trains. Acta Mech. Sin. 2013, 29, 399–410. [Google Scholar] [CrossRef] [Green Version]

- Meskine, M.; Pérot, F.; Kim, M.; Freed, D.; Senthooran, S.; Sugiyama, Z.; Polidoro, F.; Gautier, S. Community noise prediction of digital high speed train using LBM. In Proceedings of the 19th AIAA/CEAS Aeroacoustics Conference, Berlin, Germany, 27–29 May 2013. [Google Scholar]

- Lee, S.; Cheong, C.; Kim, J.; Kim, B. Numerical analysis and characterization of surface pressure fluctuations of high-speed trains using wavenumber-frequency analysis. Appl. Sci. 2019, 9, 4924. [Google Scholar] [CrossRef] [Green Version]

- Shin, D.C. Recent Experience of and Prospects for High-Speed Rail in Korea: Implications of a Transport System and Regional Development from a Global Perspective; Working paper 2005-02; Ministry of Transport: Seoul, Korea, 2005.

- Lee, S.; Cheong, C.; Lee, S.; Kim, J.; Son, D.; Sim, G. Investigation into influence of sound absorption block on interior noise of high speed train in tunnel. J. Acoust. Soc. Korea 2018, 37, 223–231. [Google Scholar]

- ANSYS Fluent Theory Guide, Release 15.0, Section 4.12.2.1., ANSYS Inc. Available online: http://www.ansys.com (accessed on 4 December 2021).

- Lee, S.; Cheong, C. Prediction and Analysis of Vehicle Interior Noise according to Incompressible and Compressible External Surface Pressure Fluctuations Due to External Flow; InterNoise: Seoul, Korea, 23–26 August 2020. [Google Scholar]

- Van Herpe, F.; Bordji, M.; Baresh, D.; Lafon, P. Wavenumber-frequency analysis of the wall pressure fluctuations in the wake of a car side mirror. In Proceedings of the 17th AIAA/CEAS Aeroacoustics Conference, Portland, OR, USA, 5–8 June 2011. [Google Scholar]

- Hartmann, M.; Ocker, J.; Lemke, T.; Mutzke, A.; Schwarz, V.; Tokuno, H.; Toppinga, R.; Unterlechner, P.; Wickern, G. Wind noise caused by the A-pillar and the side mirror flow of a generic vehicle model. In Proceedings of the 18th AIAA/CEAS Aeroacoustics Conference, American Institute of Aeronautics and Astronautics, Colorado Springs, CO, USA, 4–6 June 2012. [Google Scholar]

- Zhu, C.; Hemida, H.; Flynn, D.; Baker, C.; Liang, X.; Zhou, D. Numerical simulation of the slipstream and aeroacoustic field around a High-Speed Train. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016, 231, 740–756. [Google Scholar] [CrossRef]

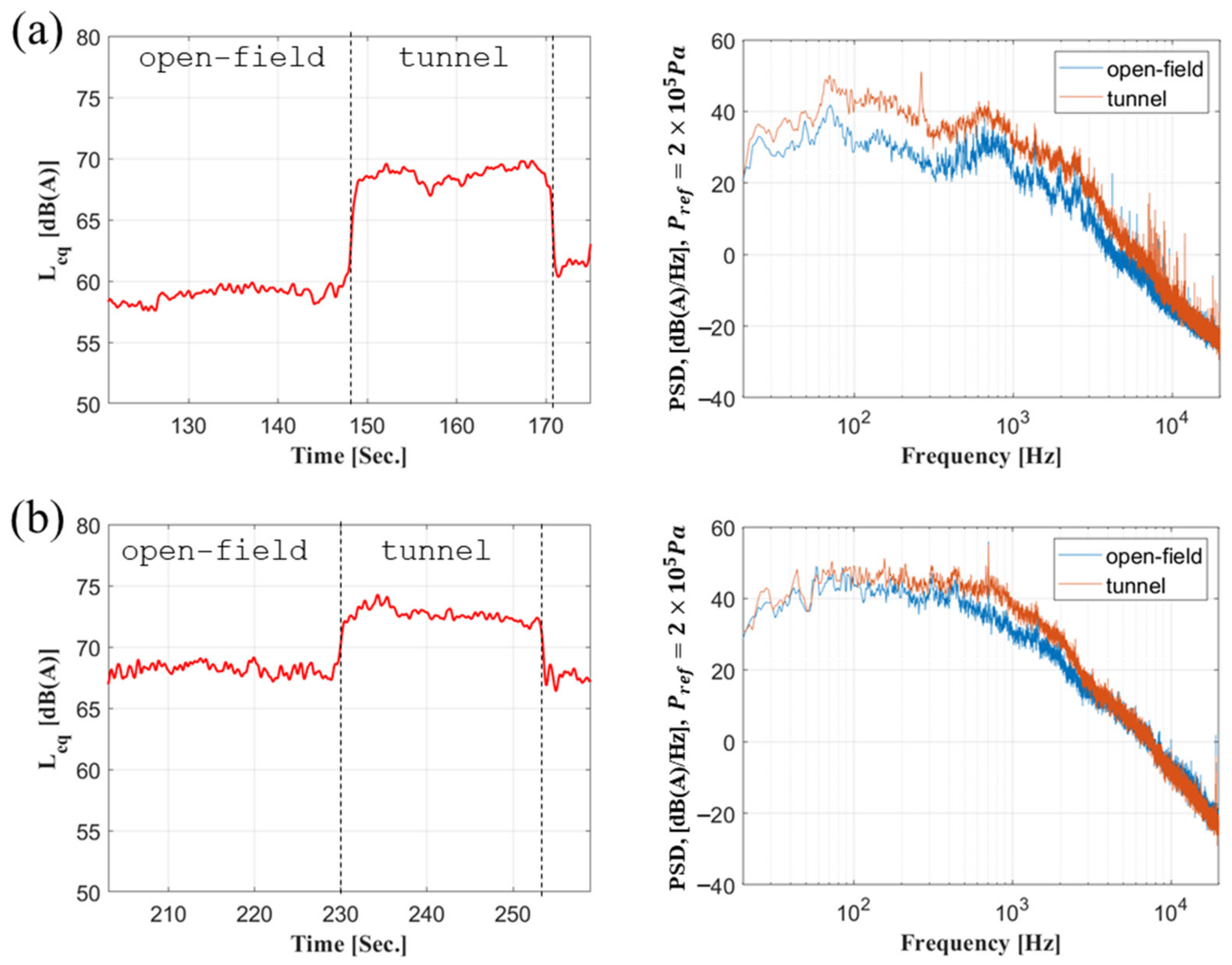

| Vehicle | Running Conditions | Running Speed [km/h] | Noise Level [dB(A)] |

|---|---|---|---|

| KTX | Open-field | 187 | 59.3 |

| Tunnel | 217 | 68.1 | |

| HEMU-430X | Open-field | 192 | 68.5 |

| Tunnel | 205 | 72.9 |

| Equations | Discretization Method |

|---|---|

| Pressure | Second order |

| Momentum | Bounded central differencing |

| Energy | Second-order upwind |

| Transient formulation | Second-order implicit |

| Case | Boundary Type | Setting | Remarks |

|---|---|---|---|

| O/T | Inlet boundary | Velocity inlet | 83.33 m/s, non-reflecting |

| O/T | Outlet boundary | Pressure outlet | 101,325 Pa, non-reflecting |

| O/ | Side and upper boundary | Pressure far field | 101,325 Pa, Ma = 0.24 |

| /T | Tunnel wall | Moving wall | 83.33 m/s |

| O/T | Ground | Moving wall | 83.33 m/s |

| O/T | EMU surfaces | No-slip wall | |

| O/T | Rail | Moving wall | 83.33 m/s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Cheong, C.; Kim, B.; Kim, J. Comparative Analysis of Surface Pressure Fluctuations of High-Speed Train Running in Open-Field and Tunnel Using LES and Wavenumber-Frequency Analysis. Appl. Sci. 2021, 11, 11702. https://doi.org/10.3390/app112411702

Lee S, Cheong C, Kim B, Kim J. Comparative Analysis of Surface Pressure Fluctuations of High-Speed Train Running in Open-Field and Tunnel Using LES and Wavenumber-Frequency Analysis. Applied Sciences. 2021; 11(24):11702. https://doi.org/10.3390/app112411702

Chicago/Turabian StyleLee, Songjune, Cheolung Cheong, Byunghee Kim, and Jaehwan Kim. 2021. "Comparative Analysis of Surface Pressure Fluctuations of High-Speed Train Running in Open-Field and Tunnel Using LES and Wavenumber-Frequency Analysis" Applied Sciences 11, no. 24: 11702. https://doi.org/10.3390/app112411702

APA StyleLee, S., Cheong, C., Kim, B., & Kim, J. (2021). Comparative Analysis of Surface Pressure Fluctuations of High-Speed Train Running in Open-Field and Tunnel Using LES and Wavenumber-Frequency Analysis. Applied Sciences, 11(24), 11702. https://doi.org/10.3390/app112411702