Conduction Transformation-Based Coordination Method for Conflict in Product Adaptive Design Driven by Functional Requirements

Abstract

:1. Introduction

2. Construction of Customer Requirement-Product Function Matching Mechanism

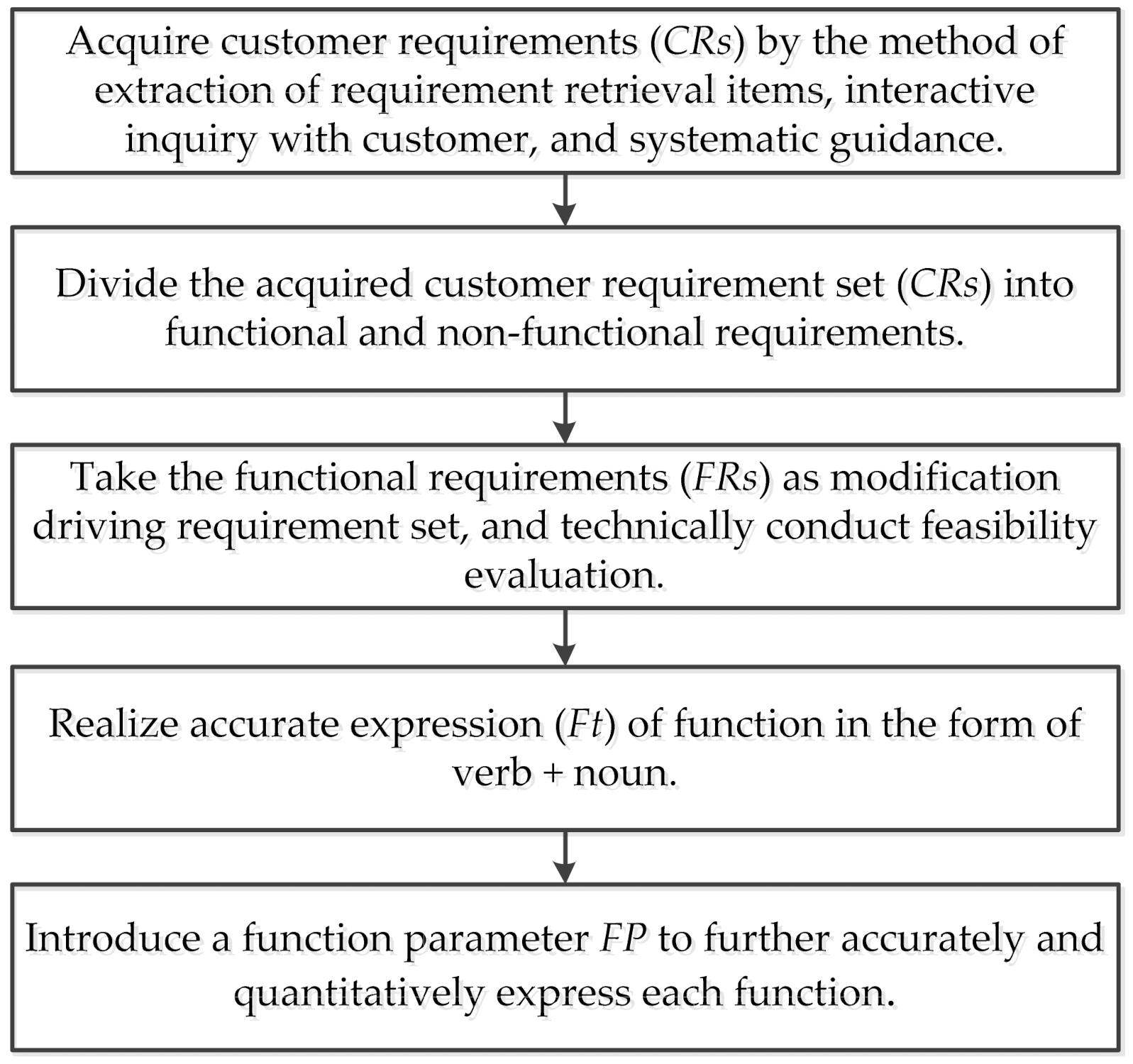

2.1. Analysis of Customer Functional Requirements and Delimiting of Extension Sets

2.2. Multi-Layer FBS Vertical Decomposition of Customer Requirement-Product Function

3. Analysis of Product Function-Structure Correlation

3.1. Analysis of Structure-Structure Correlation

3.2. Analysis of Structure-Function Correlation

4. Conduction Transformation-Based Coordination for Product Structure Modification

4.1. Creation of Extension Transformation Operation

4.2. Extraction of Conduction Transformation Trigger Unit

4.3. Judgment of Conduction Transformation Trigger Condition

- (1)

- Structure-structure conduction transformation effect

- (2)

- Structure-function conduction transformation effect

4.4. Creation of Conduction Transformation-Based Coordination Strategy

5. A Case Study

5.1. Customer Requirement-Product Function Mapping

- (1)

- FRs = {FR1 = <Automatically material loading and unloading>; FR2 = <Low working noise>; FR3 = <High cutting efficiency>; FR4 = <Less waste produced from cutting>; FR5 = <Low energy consumption>}

- (2)

- NFRs = {NFR1 = <Moderate price>; NFR2 = <Simple equipment operation>}

5.2. Analysis of Structure Layer of Product

5.3. Creation of Conduction Transformation-Based Coordination Strategy for Structure Layer of Product

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stone, R.B.; Wood, K.L. Development of a functional basis for design. J. Mech. Des. 2000, 122, 359–370. [Google Scholar] [CrossRef]

- Gu, P.; Hashemian, M.; Nee, A.Y.C. Adaptable design. CIRP Ann.–Manuf. Technol. 2004, 53, 539–557. [Google Scholar] [CrossRef]

- Xue, D.; Nee, A.Y.C. Adaptable design: Concepts, methods, and applications. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 1367–1387. [Google Scholar]

- Pahl, G.; Beitz, W. Engineering Design: A Systematic Approach; Springer: London, UK, 1996. [Google Scholar]

- Opran, C.G.; Pricop, M.; Teodorru, C. Research regarding adaptive design of gear pumps used for polymeric products engineering. Appl. Mech. Mater. 2015, 760, 601–606. [Google Scholar] [CrossRef]

- Wan, Y.J.; Li, Y.; Li, W.Q.; Yan, X.Q. Method and realization for product innovative design based on endogenous function requirements. Comput. Integ. Manuf. Syst. 2013, 19, 235–243. [Google Scholar]

- Liang, R.; Zhang, J.H.; Tan, R.H.; Li, Y. Design process model and application of the existing product function innovation. J. Mech. Eng. 2016, 52, 50–61. [Google Scholar] [CrossRef]

- Morris, A.; Halpern, M.; Setchi, R.; Prickett, P. Assessing the challenges of managing product design change through-life. J. Eng. Des. 2015, 27, 25–49. [Google Scholar] [CrossRef] [Green Version]

- Jarratt, T.A.W.; Eckert, C.M.; Caldwell, N.H.M.; Clarkson, P.J. Engineering change: An overview and perspective on the literature. Res. Eng. Des. 2010, 22, 103–124. [Google Scholar] [CrossRef]

- Ullah, I.; Tang, D.B.; Yin, L.L.; Hussain, I.; Wang, Q. Cost-effective propagation paths for multiple change requirements in the product design. Proc. Inst. Mech. Eng. C-J. Mech. 2018, 232, 1572–1585. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, W.; Tong, S. Simulation based scheduling of multiple change propagations in multistage product development processes. Expert Syst. Appl. 2017, 89, 1–19. [Google Scholar] [CrossRef]

- Zhang, H.Z.; Ding, G.F.; Li, R.; Qin, S.F.; Yan, K.Y. Design change model for effective scheduling change propagation paths. Chin. J. Mech. Eng. 2017, 30, 1081–1090. [Google Scholar] [CrossRef]

- Yang, F.; Duan, G.J. Developing a parameter linkage-based method for searching change propagation paths. Res. Eng. Des. 2011, 23, 353–372. [Google Scholar] [CrossRef]

- Tang, D.B.; Xu, R.H.; Tang, J.C.; He, R. Analysis of engineering change impacts based on design structure matrix. J. Mech. Eng. 2010, 46, 154–161. [Google Scholar] [CrossRef]

- You, C.F.; Yeh, S.C. Engineering change propagation system using STEP. Concurr. Eng.-Res. Appl. 2002, 10, 349–356. [Google Scholar] [CrossRef]

- Lee, J.; Hong, Y.S. Bayesian network approach to change propagation analysis. Res. Eng. Des. 2017, 28, 437–455. [Google Scholar] [CrossRef]

- Gong, Z.W.; Mo, R.; Yang, H.C.; Chen, T. Method for forecasting avalanche propagation of engineering change. Comput. Integr. Manuf. Syst. 2012, 18, 2619–2627. [Google Scholar]

- Masmoudi, M.; Leclaire, P.; Zolghadri, M.; Haddar, M. Change propagation prediction: A formal model for two-dimensional geometrical models of products. Concurr. Eng.-Res. Appl. 2017, 25, 174–189. [Google Scholar] [CrossRef]

- Hamraz, B.; Caldwell, N.H.M.; Clarkson, P.J. A Multidomain engineering change propagation model to support uncertainty reduction and risk management in design. J. Mech. Des. 2012, 134, 1–14. [Google Scholar] [CrossRef]

- Tavčar, J.; Duhovnik, J. Engineering change management in individual and mass production. Robot. Cim.-Int. Manuf. 2005, 21, 205–215. [Google Scholar] [CrossRef]

- Scholz-Reiter, B.; Hohns, H.; Kruse, A.; Konig, E. Hybrid product change management in the ramp-up phase of the automotive industry. Ind. Manag. 2004, 20, 21–24. [Google Scholar]

- Morris, A.; Setchi, R.; Prickett, P. Product change management and future information architectures. Smart. Innov. Syst. Tech. 2016, 52, 241–250. [Google Scholar]

- Koh, E.C.Y.; Caldwell, N.H.M.; Clarkson, P.J. A method to assess the effects of engineering change propagation. Res. Eng. Des. 2012, 23, 329–351. [Google Scholar] [CrossRef]

- Li, Y.L.; Lin, P.H. Parallel change propagation model of complex product. Comput. Integr. Manuf. Syst. 2017, 23, 737–743. [Google Scholar]

- Eisa, H.; Garstenauer, A.; Blackburn, T. Causes of engineering change propagation: An analysis during product lifecycle. Eng. Manag. J. 2018, 30, 3–13. [Google Scholar] [CrossRef]

- Eltaief, A.; Louhichi, B.; Remy, S. Associations management and change propagation in the CAD assembly. Comput. Ind. 2018, 98, 134–144. [Google Scholar] [CrossRef]

- Yang, C.Y.; Cai, W. Extenics: Theory, Method and Application; Science Press: Beijing, China, 2013. [Google Scholar]

- Tang, L.; Yang, C.Y.; Li, W.H. Adopting gene expression programming to generate extension strategies for incompatible problem. Neural. Comput. Appl. 2016, 28, 2649–2664. [Google Scholar] [CrossRef]

- Zhan, Y.W.; Su, N. Extension Design; Science Press: Beijing, China, 2010. [Google Scholar]

- Li, W.J.; Song, Z.H.; Mao, E.R.; Suh, S. Using Extenics to describe coupled solutions in Axiomatic design. J. Eng. Des. 2018, 30, 1–31. [Google Scholar] [CrossRef]

- Ren, S.D.; Gui, F.Z.; Zhao, Y.W.; Xie, Z.W.; Hong, H.H.; Wang, H.W. Accelerating preliminary low-carbon design for products by integrating TRIZ and Extenics methods. Adv. Mech. Eng. 2017, 9, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.W.; Hong, H.H.; Jiang, G.C.; Chen, W.G.; Wang, H.W. Conflict resolution for product performance requirements based on propagation analysis in the extension theory. Adv. Mech. Eng. 2014, 6, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.Q.; Zhao, Y.W.; Hong, H.H.; Wang, H.; Chen, W.G. Coordination method of extension conductive transformation for performance conflict based on requirement- driven. Comput. Integr. Manuf. Syst. 2013, 19, 1205–1215. [Google Scholar]

- Zhou, J.Q.; Zhao, Y.W.; Hong, H.H.; Wang, H.; He, L. Conduction cooperation method for product performance conflicts based on extension transformation. Chin. Mech. Eng. 2014, 25, 661–668. [Google Scholar]

- Tang, L.; Yang, C.Y. Conductive transformation under complicated basic-element correlative network. CAAI Trans. Intell. Syst. 2016, 11, 104–110. [Google Scholar]

- Gong, J.Z.; Qiu, J.; Li, G.X.; Li, W. Extension approach for product module variant design. Comput. Integr. Manuf. Syst. 2008, 14, 1256–1267. [Google Scholar]

- Chandrasegaran, S.K.; Ramani, K.; Sriram, R.D.; Horvath, I.; Bernard, A.; Harik, R.F.; Gao, W. The evolution, challenges, and future of knowledge representation in product design systems. Comput.-Aided Des. 2013, 45, 204–228. [Google Scholar] [CrossRef]

- Gero, J.S.; Kannengiesser, U. The situated function-behaviour-structure framework. Des. Stud. 2004, 25, 373–391. [Google Scholar] [CrossRef]

- He, R.; Tang, D.B.; Xue, J.B. Engineering change propagation based on design structure matrix. Comput. Integr. Manuf. Syst. 2008, 14, 656–660. [Google Scholar]

- Chen, L.; Zheng, Y.; Xi, J.T.; Li, S.Y. An analysis method for change propagation based on product feature network. Res. Eng. Des. 2020, 31, 491–503. [Google Scholar] [CrossRef]

- Zhang, J.H.; Wang, F.L.; Wang, C.K. Integrating case-based with rule-based reasoning in body-in-white fixture design. Int. J. Adv. Manuf. Technol. 2016, 85, 1807–1824. [Google Scholar] [CrossRef]

- Xie, Z.W.; Zhao, Y.W.; Ren, S.D.; Gui, F.Z. Study on functional-requirement oriented recognition method of product adaptive modification unit. Comput. Integr. Manuf. Syst. 2020, 26, 426–436. [Google Scholar]

- Tomiyama, T.; Gu, P.; Jin, Y.; Lutters, D.; Kind, C.; Kimura, F. Design methodologies: Industrial and educational applications. CIRP Ann.-Manuf. Technol. 2009, 58, 543–565. [Google Scholar] [CrossRef] [Green Version]

- Chechurin, L.; Borgianni, Y. Understanding TRIZ through the review of top cited publications. Comput. Ind. 2016, 82, 119–134. [Google Scholar] [CrossRef]

- Popoff, A.; Millet, D. Sustainable life cycle design using constraint satisfaction problems and quality function deployment. Proc. CIRP 2017, 61, 75–80. [Google Scholar] [CrossRef]

- Roldan Reyes, E.; Negny, S.; Cortes Robles, G.; Le Lann, J.M. Improvement of online adaptation knowledge acquisition and reuse in case-based reasoning: Application to process engineering design. Eng. Appl. Artif. Intell. 2015, 41, 1–16. [Google Scholar] [CrossRef]

| Transformation Operation Object | Symbol Expression | Selected Transformation Operations | Transformation Priority |

|---|---|---|---|

| Value transformation | T(v) | TE, TR, TY | I |

| Attribute transformation | T(c) | TC, TS, TY | II |

| Object transformation | T(O) | TI, TD, TC, TS, TY | III |

| No. | Process | Main Contents |

|---|---|---|

| 0 | Prepare | Arrange material, e.g., cloth, or leather, with a spreading mechanism, to form a patch with height of ~100 mm, and place the patch onto the cutting table. |

| 1 | Feed | Allow the feeding system to operate; stop feeding after one end of the material to be cut is delivered to the place near the material outlet. |

| 2 | Adsorb | 2.1 Cover film: Cover film onto the material to be cut so that the material is in relatively closed environment; 2.2 Depressurize (the cavity): Start the vacuum pump, to evacuate air from the cavity under the film, so that the cavity becomes low pressure environment, resulting in its inside-outside pressure difference, which makes the material to be cut adsorbed to the bristle bed. |

| 3 | Cut | Allow the cutter control system to operate so that the material is cut into the required shape by the cutter according to the path preset in the sample arrangement system. |

| 4 | Move out of window | 4.1 Raise pressure (in the cavity): After the material in the current window is cut, stop the cutting process, and reduce the air evacuating rate of the vacuum pump, so that the air pressure in the cavity rises slightly, making the material adsorbed to the bristle bed and easy to be moved. 4.2 Move material: Allow the feeding system to operate so that the cut cloth, etc. is delivered to the arranging table and the material to be cut is delivered to the cutting window. Next, repeat processes 1–4. |

| 5 | End | After all materials are cut, turn off the system. |

| Functional Parameter | Ideal Domain X0 (m/min) | Extended Domain X (m/min) | Optimal Point x0 (m/min) | Actual Value x (m/min) | Dependent Function Value k(x) |

|---|---|---|---|---|---|

| FP | (40,50) | (30,50) | 50 | 35 | 0.5 |

| M | M1-1 | M1-2 | M1-3 | M2-1 | M2-2 | M2-3 | M3-1 | M3-2 | M3-3 | M4-1 | M7-1 | M7-2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1-1 | – | (0,0,0, 0,0,0) | (1,0,0, 0,1,0) | (0,0,0, 0,0,0) | (0,0,0 ,0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) |

| M1-2 | (0,0,0, 0,0,0) | – | (1,0,0, 0,1,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) |

| M1-3 | (1,0,0,0,1,0) | (1,0,0, 0,1,0) | – | (0,0,0, 0,0,0) | (0,0,1, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) |

| M2-1 | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | – | (1,0,0, 0,1,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) |

| M2-2 | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,1, 0,0,0) | (1,0,0, 0,1,0) | – | (1,0,0, 0,1,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) |

| M2-3 | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (1,0,0, 0,1,0) | – | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) |

| M3-1 | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | – | (1,0,0, 0,1,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) |

| M3-2 | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (1,0,0, 0,1,0) | – | (1,0,0, 0,1,0) | (0,0,1, 0,0,1) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) |

| M3-3 | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (1,0,0, 0,1,0) | – | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) |

| M4-1 | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,1, 0,0,1) | (0,0,0, 0,0,0) | – | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) |

| M7-1 | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | – | (1,0,1, 0,1,0) |

| M7-2 | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (0,0,0, 0,0,0) | (1,0,1, 0,1,0) | – |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Xie, Z.; Ren, S.; Ye, D.; Zhan, M.; Zhao, Y. Conduction Transformation-Based Coordination Method for Conflict in Product Adaptive Design Driven by Functional Requirements. Appl. Sci. 2021, 11, 11757. https://doi.org/10.3390/app112411757

Zhou J, Xie Z, Ren S, Ye D, Zhan M, Zhao Y. Conduction Transformation-Based Coordination Method for Conflict in Product Adaptive Design Driven by Functional Requirements. Applied Sciences. 2021; 11(24):11757. https://doi.org/10.3390/app112411757

Chicago/Turabian StyleZhou, Jianqiang, Zhiwei Xie, Shedong Ren, Dongfen Ye, Min Zhan, and Yanwei Zhao. 2021. "Conduction Transformation-Based Coordination Method for Conflict in Product Adaptive Design Driven by Functional Requirements" Applied Sciences 11, no. 24: 11757. https://doi.org/10.3390/app112411757

APA StyleZhou, J., Xie, Z., Ren, S., Ye, D., Zhan, M., & Zhao, Y. (2021). Conduction Transformation-Based Coordination Method for Conflict in Product Adaptive Design Driven by Functional Requirements. Applied Sciences, 11(24), 11757. https://doi.org/10.3390/app112411757