Enhancing SERS Intensity by Coupling PSPR and LSPR in a Crater Structure with Ag Nanowires

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Fabrication of Crater Structures

2.2. Spray Coating of Ag Nanowires (AgNWs)

2.3. Characterization

2.4. Finite-Difference Time Domain (FDTD) Simulations

3. Results and Discussion

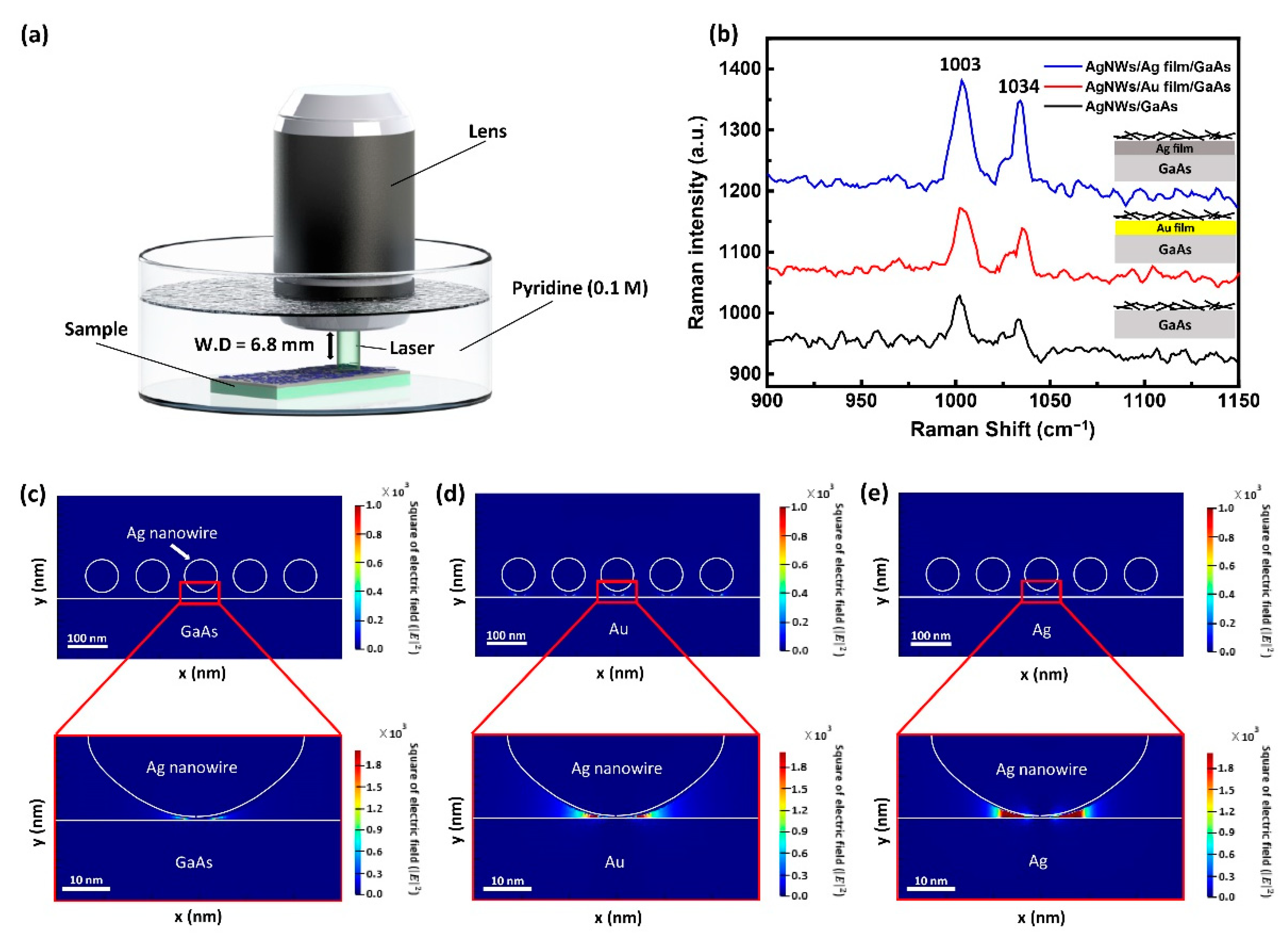

3.1. Finding a Metal with Excellent Surface-Enhanced Raman Scattering (SERS) Properties When Combined with AgNWs

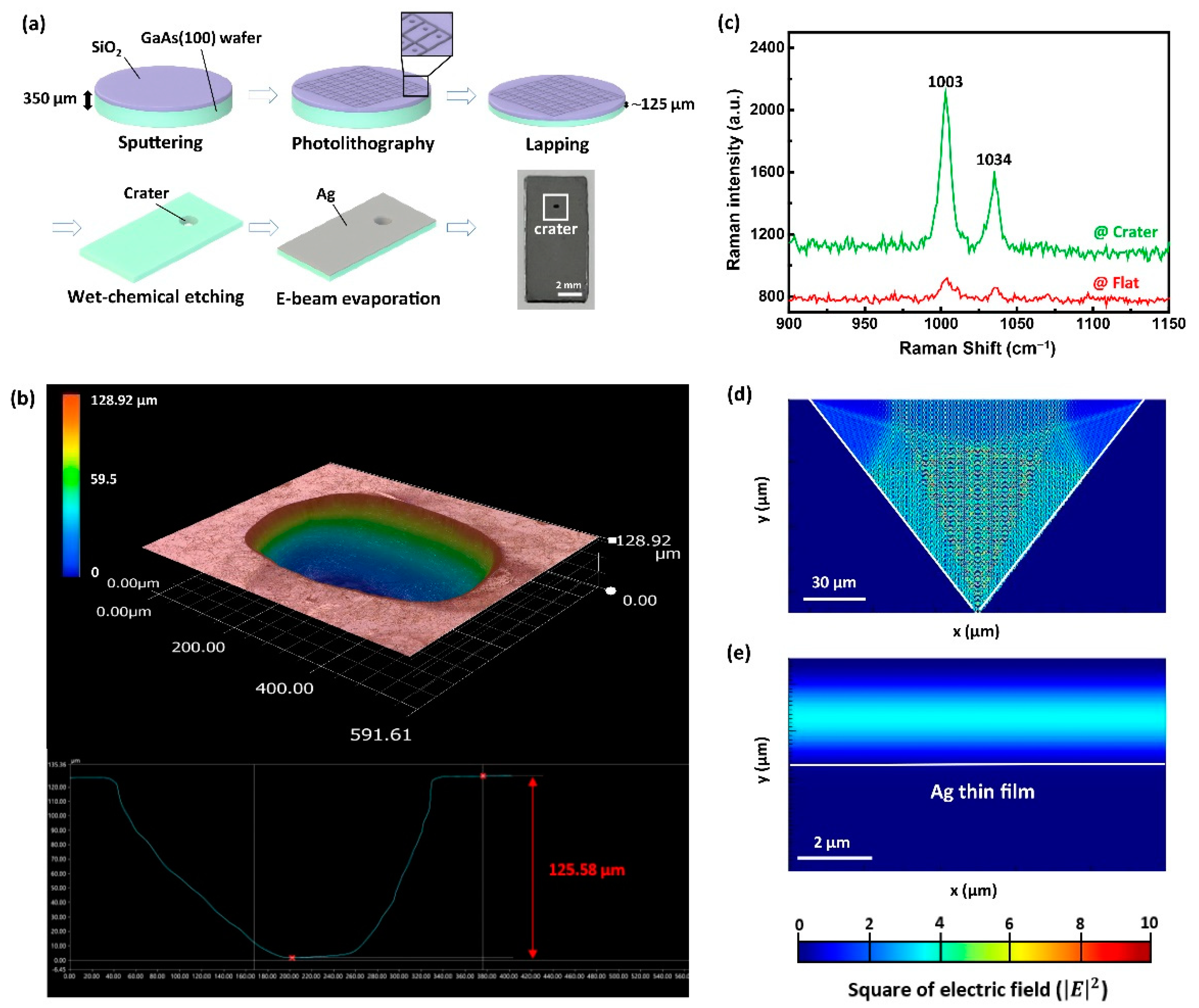

3.2. Fabrication of Ag Crater Structures and Characterization of SERS

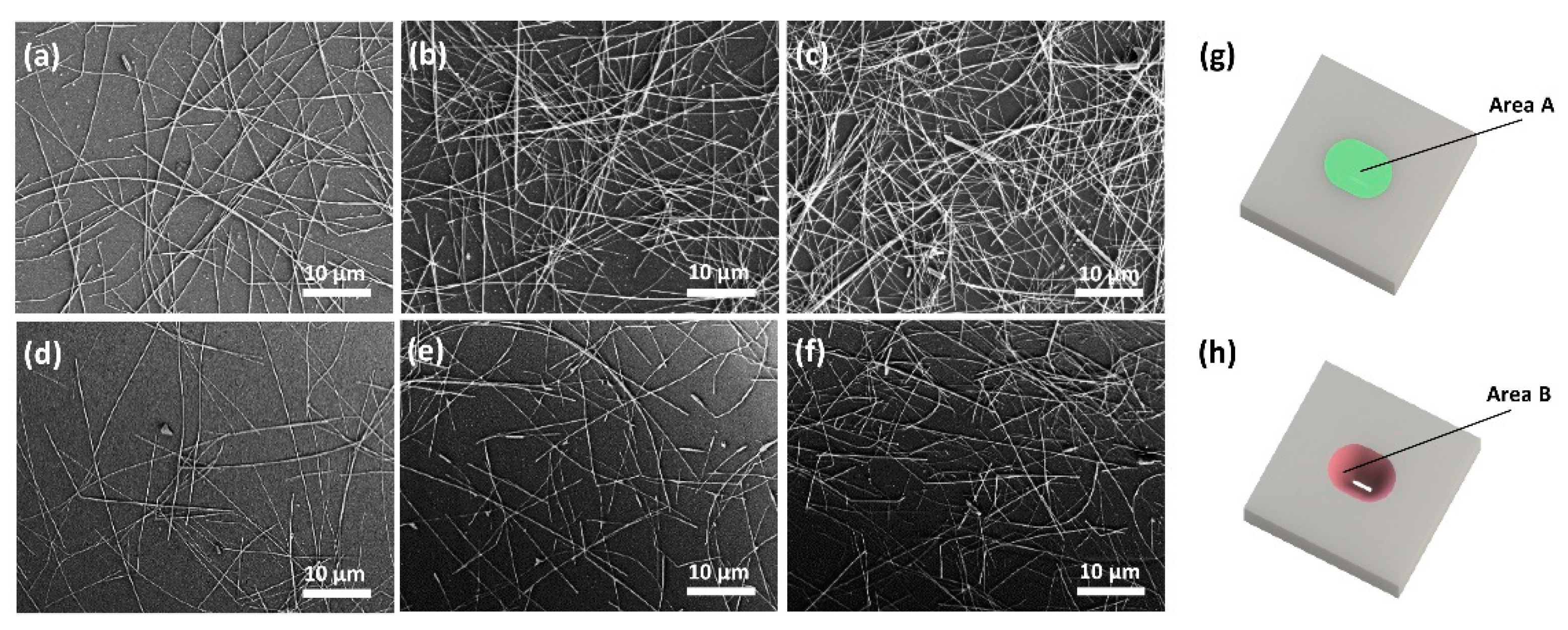

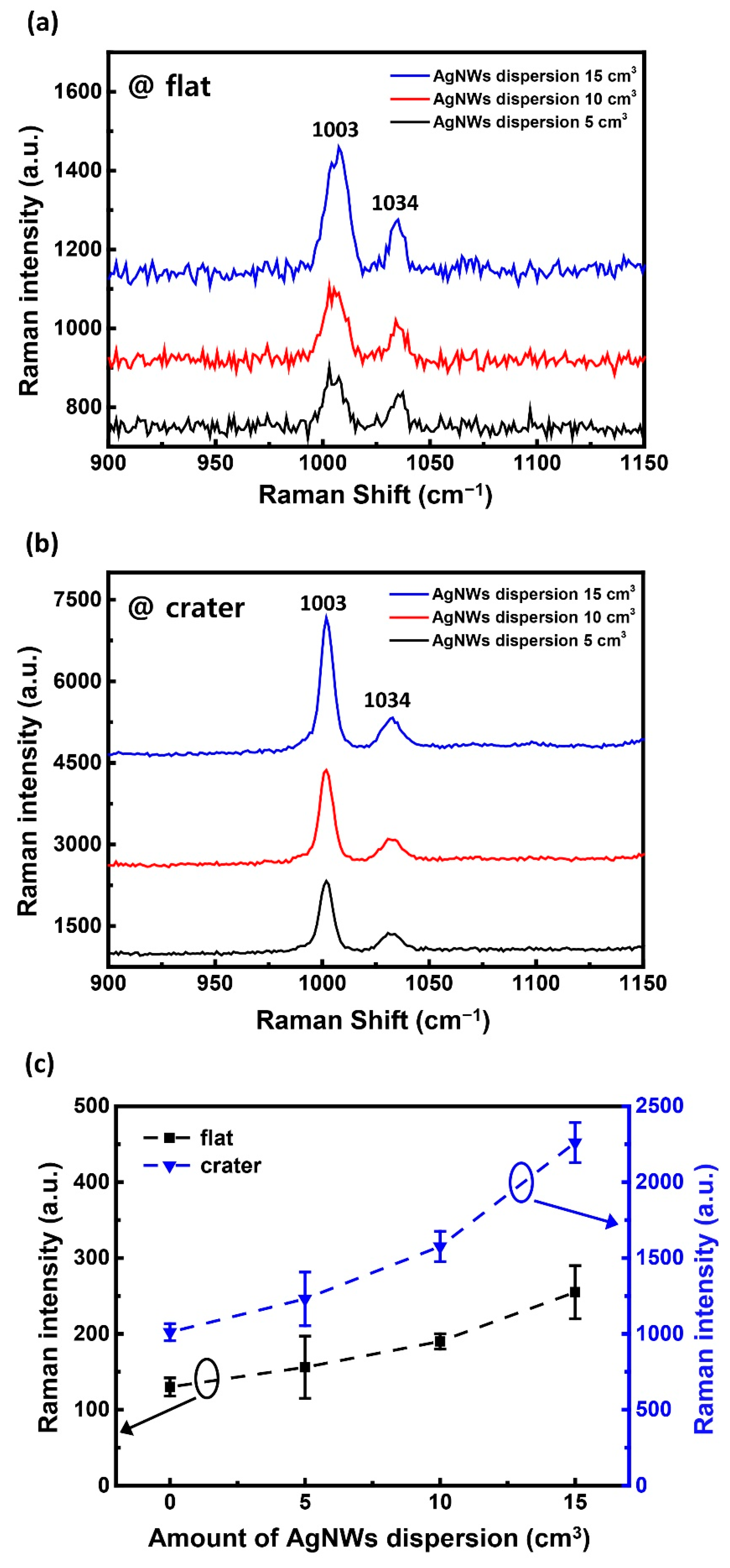

3.3. Coupling of the Ag Crater Structure and AgNWs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ritchie, R.H. Plasma Losses by Fast Electrons in Thin Films. Phys. Rev. 1957, 106, 874–881. [Google Scholar] [CrossRef]

- Homola, J.; Yee, S.S.; Gauglitz, G. Surface Plasmon Resonance Sensors: Review. Sens. Actuators B Chem. 1999, 54, 3–15. [Google Scholar] [CrossRef]

- Zhang, Z.L.; Fang, Y.R.; Wang, W.H.; Chen, L.; Sun, M.T. Propagating Surface Plasmon Polaritons: Towards Applications for Remote-Excitation Surface Catalytic Reactions. Adv. Sci. 2016, 3, 1500215. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Xu, B.; Bai, W.; Zhang, J.; Cai, L.; Hu, H.; Song, G. Multiple Surface Plasmon Resonances in Compound Structure with Metallic Nanoparticle and Nanohole Arrays. Plasmonics 2012, 7, 659–663. [Google Scholar] [CrossRef]

- Yi, Z.; Liu, M.; Luo, J.; Zhao, Y.; Zhang, W.; Yi, Y.; Yi, Y.; Duan, T.; Wang, C.; Tang, Y. Multiple Surface Plasmon Resonances of Square Lattice Nanohole Arrays in Au-SiO2-Au Multilayer Films. Opt. Commun. 2017, 390, 1–6. [Google Scholar] [CrossRef]

- Wei, H.; Xu, H. Hot Spots in Different Metal Nanostructures for Plasmon-Enhanced Raman Spectroscopy. Nanoscale 2013, 5, 10794–10805. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.B.; Luk’yanchuk, B.S.; Guo, W.; Edwardson, S.P.; Whitehead, D.J.; Li, L.; Liu, Z.; Watkins, K.G. The Influences of Particle Number on Hot Spots in Strongly Coupled Metal Nanoparticles Chain. J. Chem. Phys. 2008, 128, 94705. [Google Scholar] [CrossRef]

- Dick, L.A.; McFarland, A.D.; Haynes, C.L.; van Duyne, R.P. Metal Film over Nanosphere (MFON) Electrodes for Surface-Enhanced Raman Spectroscopy (SERS): Improvements in Surface Nanostructure Stability and Suppression of Irreversible Loss. J. Phys. Chem. B 2002, 106, 853–860. [Google Scholar] [CrossRef]

- Liu, K.; Bai, Y.; Zhang, L.; Yang, Z.; Fan, Q.; Zheng, H.; Yin, Y.; Gao, C. Porous Au-Ag Nanospheres with High-Density and Highly Accessible Hotspots for SERS Analysis. Nano Lett. 2016, 16, 3675–3681. [Google Scholar] [CrossRef] [PubMed]

- Jang, S.; Lee, J.; Nam, S.; Ko, H.; Chang, S.T. Large-Area, Highly Sensitive SERS Substrates with Silver Nanowire Thin Films Coated by Microliter-Scale Solution Process. Nanoscale Res. Lett. 2017, 12, 581. [Google Scholar] [CrossRef] [Green Version]

- Pandey, P.; Vongphachanh, S.; Yoon, J.; Kim, B.; Choi, C.J.; Sohn, J.I.; Hong, W.K. Silver Nanowire-Network-Film-Coated Soft Substrates with Wrinkled Surfaces for Use as Stretchable Surface Enhanced Raman Scattering Sensors. J. Alloy. Compd. 2021, 859, 157862. [Google Scholar] [CrossRef]

- Lee, J.; Hua, B.; Park, S.; Ha, M.; Lee, Y.; Fan, Z.; Ko, H. Tailoring Surface Plasmons of High-Density Gold Nanostar Assemblies on Metal Films for Surface-Enhanced Raman Spectroscopy. Nanoscale 2014, 6, 616–623. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, X.; Wu, Y.; Wen, X.; Zhu, J.; Bai, X.; Qi, Y.; Yang, H. Surface Plasmons and SERS Application of Au Nanodisk Array and Au Thin Film Composite Structure. Opt. Quantum Electron. 2020, 52, 238. [Google Scholar] [CrossRef]

- Abutoama, M.; Li, S.; Abdulhalim, I. Widening the Spectral Range of Ultrahigh Field Enhancement by Efficient Coupling of Localized to Extended Plasmons and Cavity Resonances in Grating Geometry. J. Phys. Chem. C 2017, 121, 27612–27623. [Google Scholar] [CrossRef]

- Nie, S.; Emory, S.R. Probing Single Molecules and Single Nanoparticles by Surface-Enhanced Raman Scattering. Science 1997, 275, 1102–1106. [Google Scholar] [CrossRef] [PubMed]

- Lane, L.A.; Qian, X.; Nie, S. SERS Nanoparticles in Medicine: From Label-Free Detection to Spectroscopic Tagging. Chem. Rev. 2015, 115, 10489–10529. [Google Scholar] [CrossRef]

- Lin, Z.; He, L. Recent Advance in SERS Techniques for Food Safety and Quality Analysis: A Brief Review. Curr. Opin. Food Sci. 2019, 28, 82–87. [Google Scholar] [CrossRef]

- Bonham, A.J.; Braun, G.; Pavel, I.; Moskovits, M.; Reich, N.O. Detection of Sequence-Specific Protein-DNA Interactions via Surface Enhanced Resonance Raman Scattering. J. Am. Chem. Soc. 2007, 129, 14572–14573. [Google Scholar] [CrossRef]

- Kim, J.A.; Wales, D.J.; Thompson, A.J.; Yang, G.-Z. Fiber-Optic SERS Probes Fabricated Using Two-Photon Polymerization For Rapid Detection of Bacteria. Adv. Opt. Mater. 2020, 8, 1901934. [Google Scholar] [CrossRef] [Green Version]

- Cao, C.; Li, P.; Liao, H.; Wang, J.; Tang, X.; Yang, L. Cys-Functionalized AuNP Substrates for Improved Sensing of the Marine Toxin STX by Dynamic Surface-Enhanced Raman Spectroscopy. Anal. Bioanal. Chem. 2020, 412, 4609–4617. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, H.; Ha, N.B.; Pfannkuche, J.; Amann, H.; Kronfeldt, H.D.; Kowalewska, G. Detection of PAHs in Seawater Using Surface-Enhanced Raman Scattering (SERS). Mar. Pollut. Bull. 2004, 49, 229–234. [Google Scholar] [CrossRef] [PubMed]

- Kim, A.; Won, Y.; Woo, K.; Kim, C.H.; Moon, J. Highly Transparent Low Resistance ZnO/Ag Nanowire/ZnO Composite Electrode for Thin Film Solar Cells. ACS Nano 2013, 7, 1081–1091. [Google Scholar] [CrossRef]

- Kwon, J.; Suh, Y.D.; Lee, J.; Lee, P.; Han, S.; Hong, S.; Yeo, J.; Lee, H.; Ko, S.H. Recent Progress in Silver Nanowire Based Flexible/Wearable Optoelectronics. J. Mater. Chem. C 2018, 6, 7445–7461. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, H.; Ge, Y.; Yang, S.; Wang, P.; Fang, Y. Surface-Nanostructured Single Silver Nanowire: A New One-Dimensional Microscale Surface-Enhanced Raman Scattering Interface. Langmuir 2018, 34, 15160–15165. [Google Scholar] [CrossRef] [PubMed]

- Kang, T.; Yoon, I.; Jeon, K.S.; Choi, W.; Lee, Y.; Seo, K.; Yoo, Y.; Park, Q.H.; Ihee, H.; Suh, Y.D.; et al. Creating Well-Defined Hot Spots for Surface-Enhanced Raman Scattering by Single-Crystalline Noble Metal Nanowire Pairs. J. Phys. Chem. C 2009, 113, 7492–7496. [Google Scholar] [CrossRef] [Green Version]

- Chen, M.; Phang, I.Y.; Lee, M.R.; Yang, J.K.W.; Ling, X.Y. Layer-by-Layer Assembly of Ag Nanowires into 3D Woodpile-like Structures to Achieve High Density “Hot Spots” for Surface-Enhanced Raman Scattering. Langmuir 2013, 29, 7061–7069. [Google Scholar] [CrossRef] [PubMed]

- Yoon, I.; Kang, T.; Choi, W.; Kim, J.; Yoo, Y.; Joo, S.W.; Park, Q.H.; Ihee, H.; Kim, B. Single Nanowire on a Film as an Efficient SERS-Active Platform. J. Am. Chem. Soc. 2009, 131, 758–762. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Guo, W.; He, L.; He, L.; Chen, Y.; Shen, X.; Wu, D. A New SERS Substrate of Self-Assembled Monolayer Film of Gold Nanoparticles on Silicon Wafer for the Rapid Detection of Polycyclic Aromatic Hydrocarbons. Mater. Chem. Phys. 2020, 250, 122994. [Google Scholar] [CrossRef]

- Cejkova, J.; Prokopec, V.; Brazdova, S.; Kokaislova, A.; Matejka, P.; Stepanek, F. Characterization of Copper SERS-Active Substrates Prepared by Electrochemical Deposition. Appl. Surf. Sci. 2009, 255, 7864–7870. [Google Scholar] [CrossRef]

- Han, J.; Lee, J.; Ju, S. Fabrication of Flexible Ultraviolet Photodetectors Using an All-Spray-Coating Process. AIP Adv. 2016, 6, 45218. [Google Scholar] [CrossRef] [Green Version]

- Lamprecht, B.; Krenn, J.R.; Schider, G.; Ditlbacher, H.; Salerno, M.; Felidj, N.; Leitner, A.; Aussenegg, F.R.; Weeber, J.C. Surface Plasmon Propagation in Microscale Metal Stripes. Appl. Phys. Lett. 2001, 79, 51–53. [Google Scholar] [CrossRef]

- Lee, H.Y.; Kwak, M.S.; Lim, K.W.; Ahn, H.S.; Yi, S.N. Fabrication and Time-Dependent Analysis of Micro-Hole in GaAs(100) Single Crystal Wafer Using Wet Chemical Etching Method. Korean J. Mater. Res. 2019, 29, 155–159. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryu, J.-H.; Lee, H.Y.; Lee, J.-Y.; Kim, H.-S.; Kim, S.-H.; Ahn, H.S.; Ha, D.H.; Yi, S.N. Enhancing SERS Intensity by Coupling PSPR and LSPR in a Crater Structure with Ag Nanowires. Appl. Sci. 2021, 11, 11855. https://doi.org/10.3390/app112411855

Ryu J-H, Lee HY, Lee J-Y, Kim H-S, Kim S-H, Ahn HS, Ha DH, Yi SN. Enhancing SERS Intensity by Coupling PSPR and LSPR in a Crater Structure with Ag Nanowires. Applied Sciences. 2021; 11(24):11855. https://doi.org/10.3390/app112411855

Chicago/Turabian StyleRyu, Jae-Hoon, Ha Young Lee, Jeong-Yeon Lee, Han-Sol Kim, Sung-Hyun Kim, Hyung Soo Ahn, Dong Han Ha, and Sam Nyung Yi. 2021. "Enhancing SERS Intensity by Coupling PSPR and LSPR in a Crater Structure with Ag Nanowires" Applied Sciences 11, no. 24: 11855. https://doi.org/10.3390/app112411855

APA StyleRyu, J.-H., Lee, H. Y., Lee, J.-Y., Kim, H.-S., Kim, S.-H., Ahn, H. S., Ha, D. H., & Yi, S. N. (2021). Enhancing SERS Intensity by Coupling PSPR and LSPR in a Crater Structure with Ag Nanowires. Applied Sciences, 11(24), 11855. https://doi.org/10.3390/app112411855