Features of Acoustic Emission in Tensile Testing of Dissimilar Welded Joints of Pearlitic and Austenitic Steels

Abstract

:1. Introduction

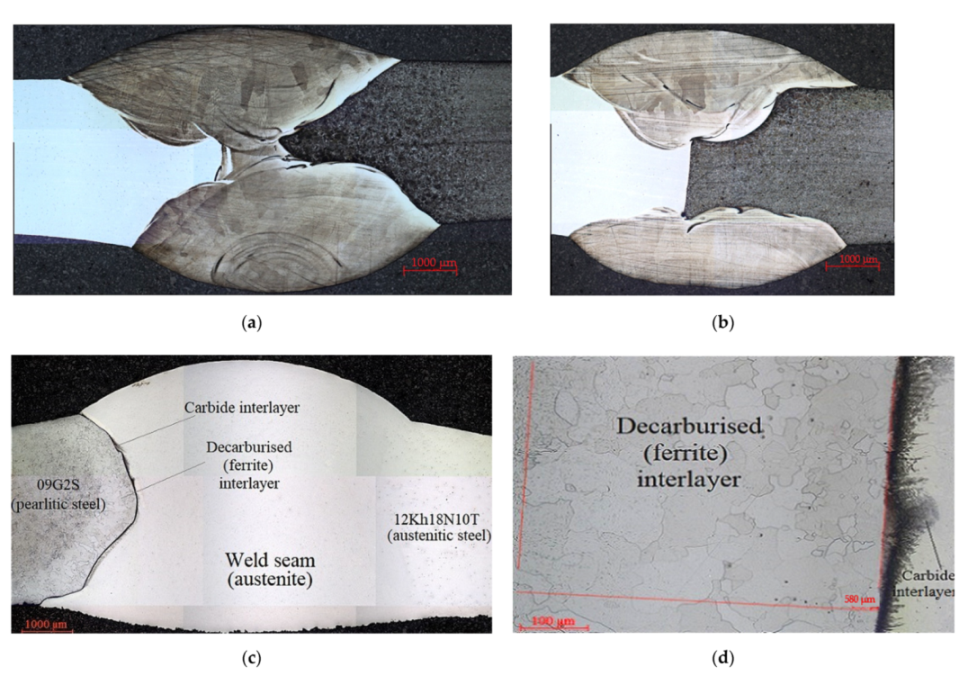

2. Materials and Methods

3. Results and Discussion

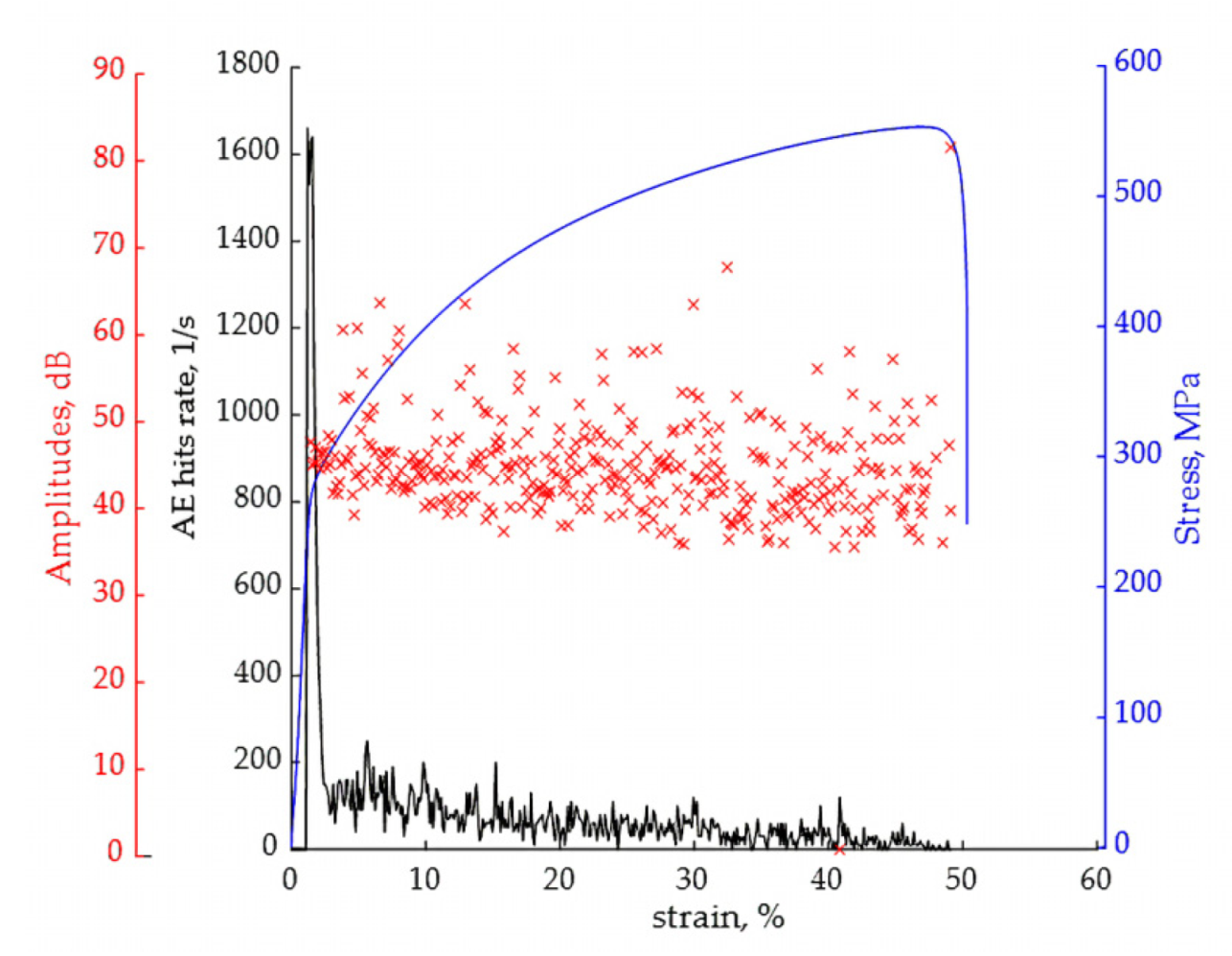

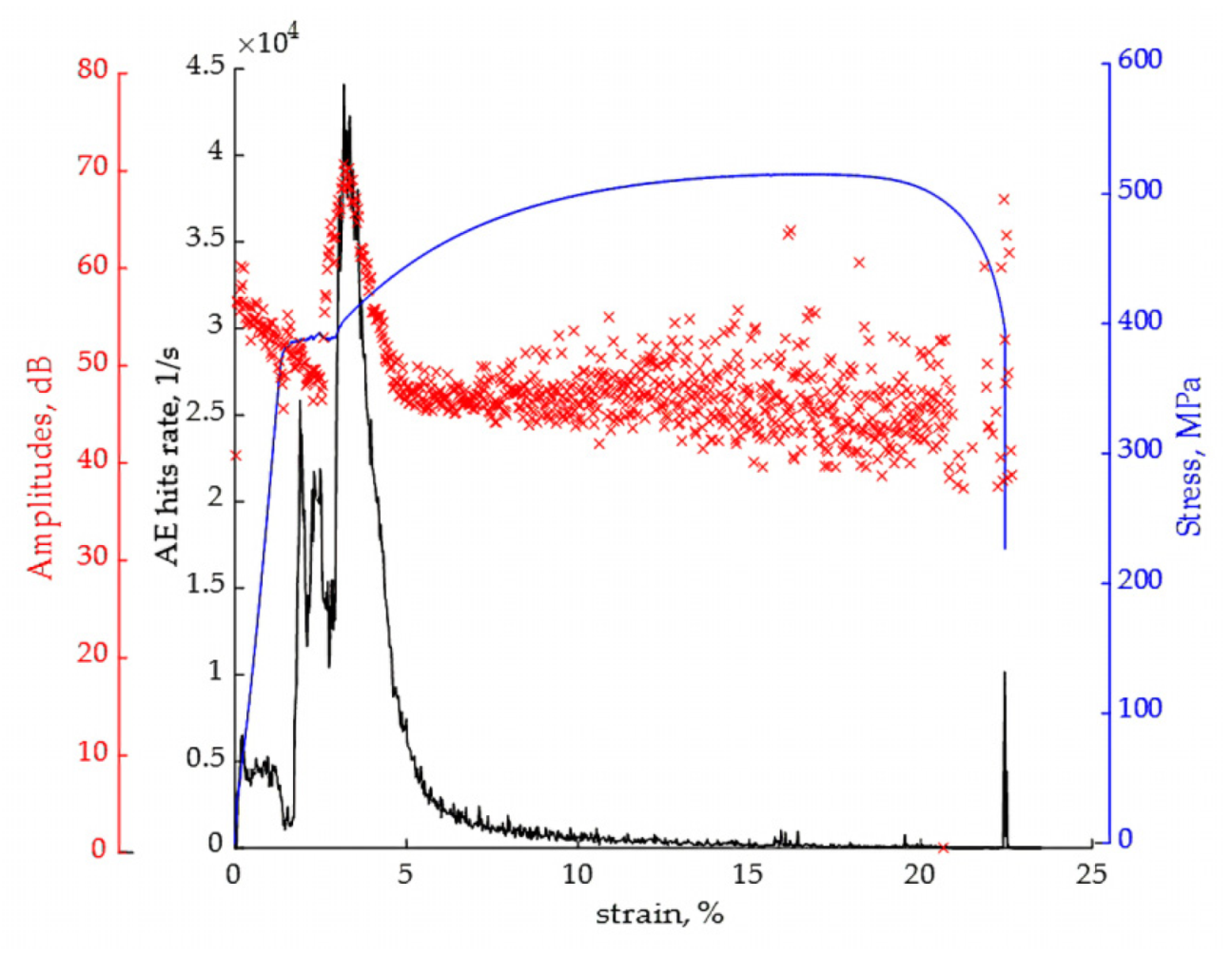

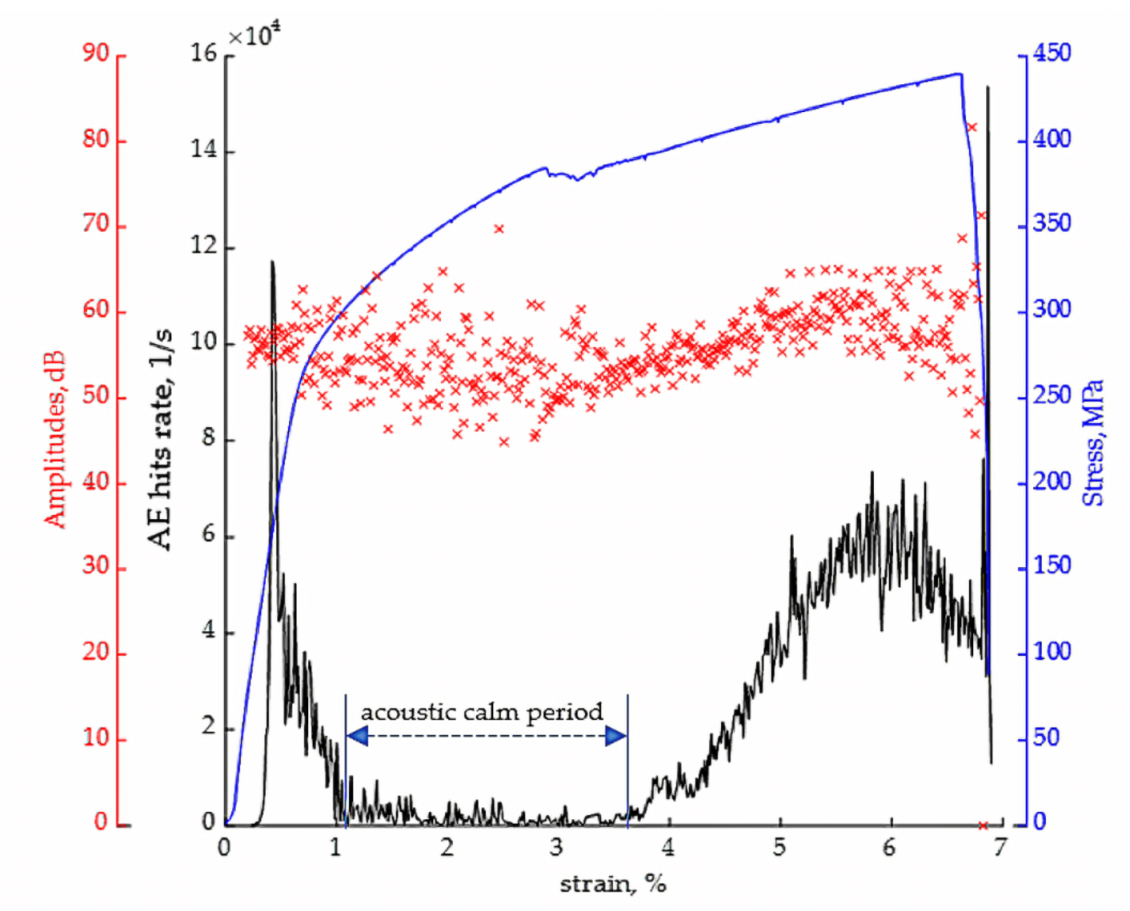

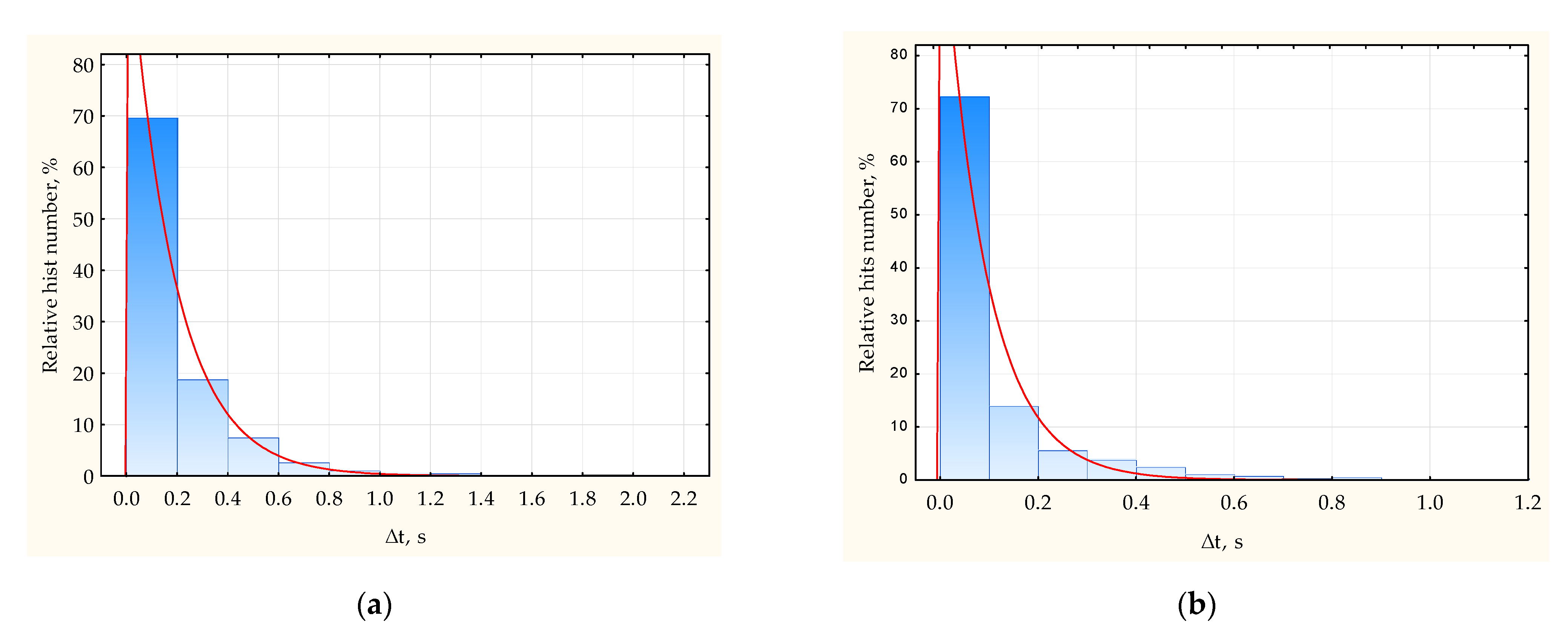

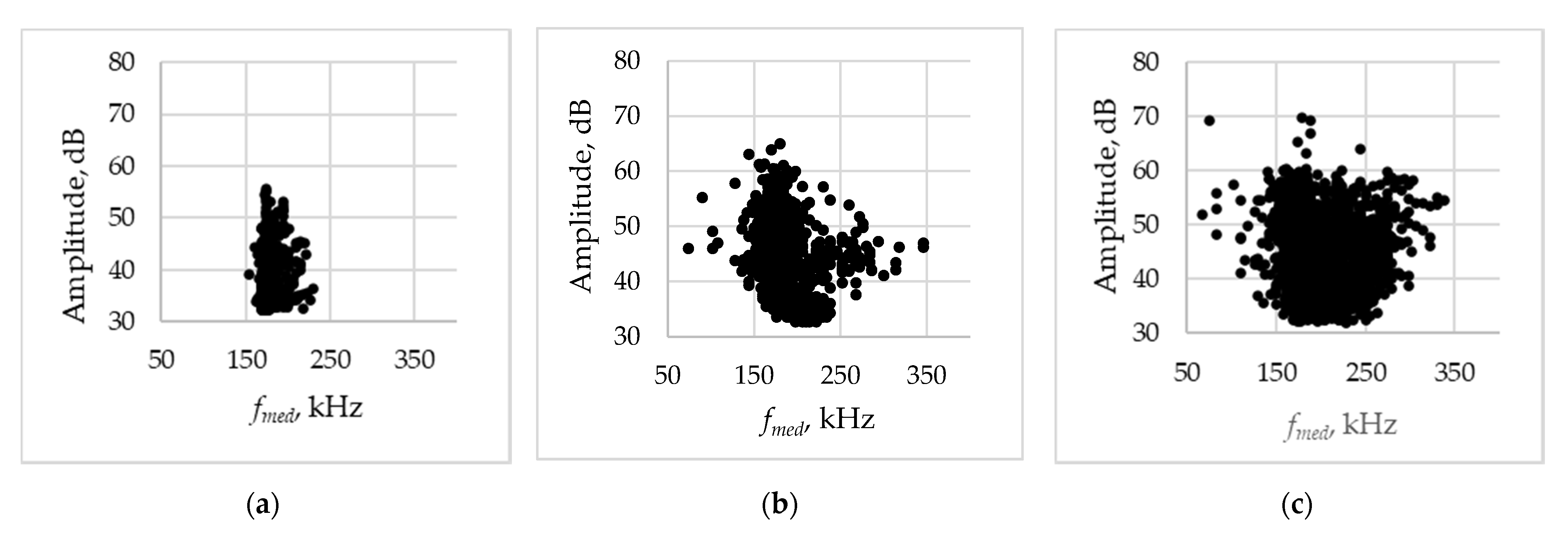

3.1. AE under Tension of the Specimens from 09G2S Steel and Specimens from 12Kh18N10T Steel

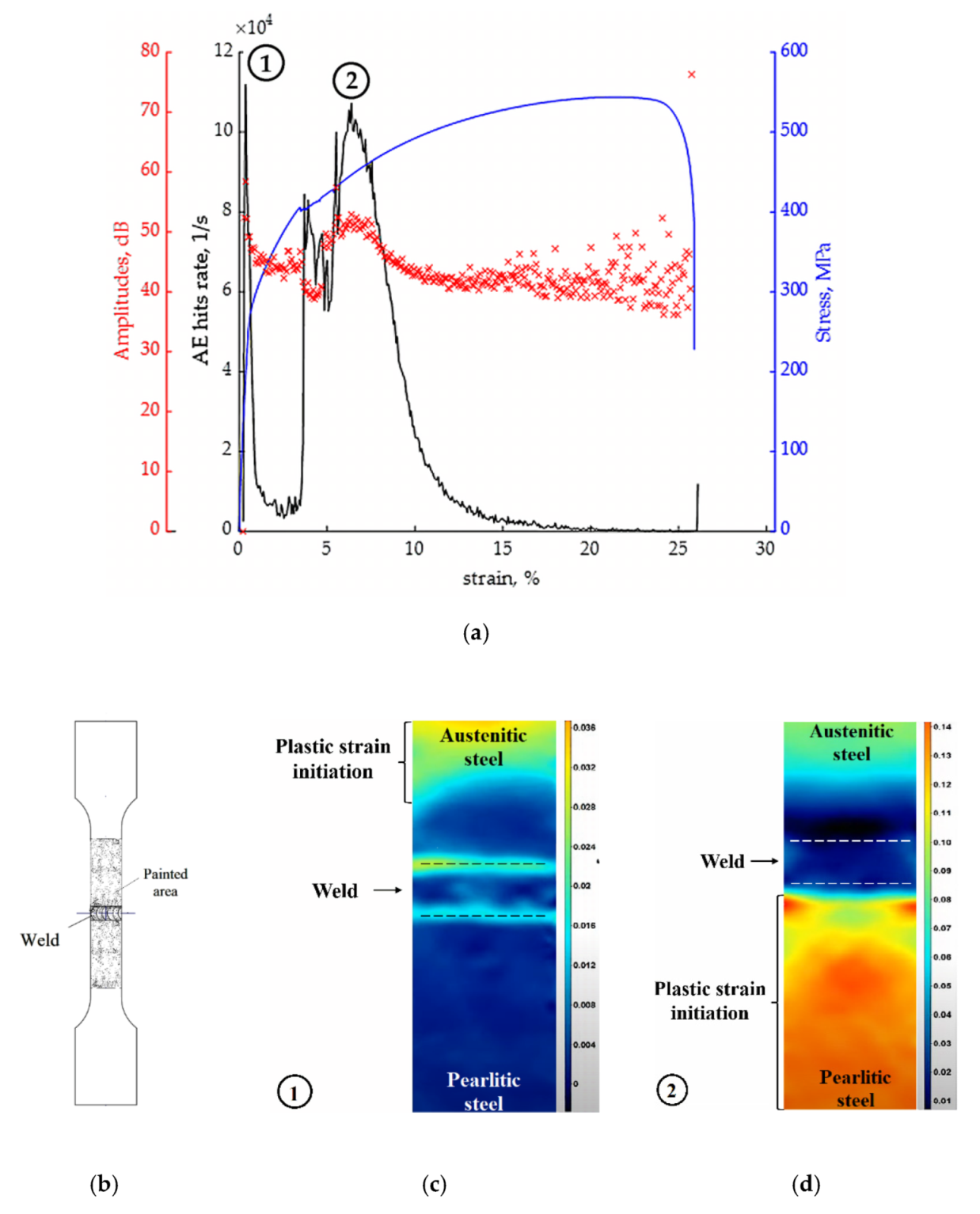

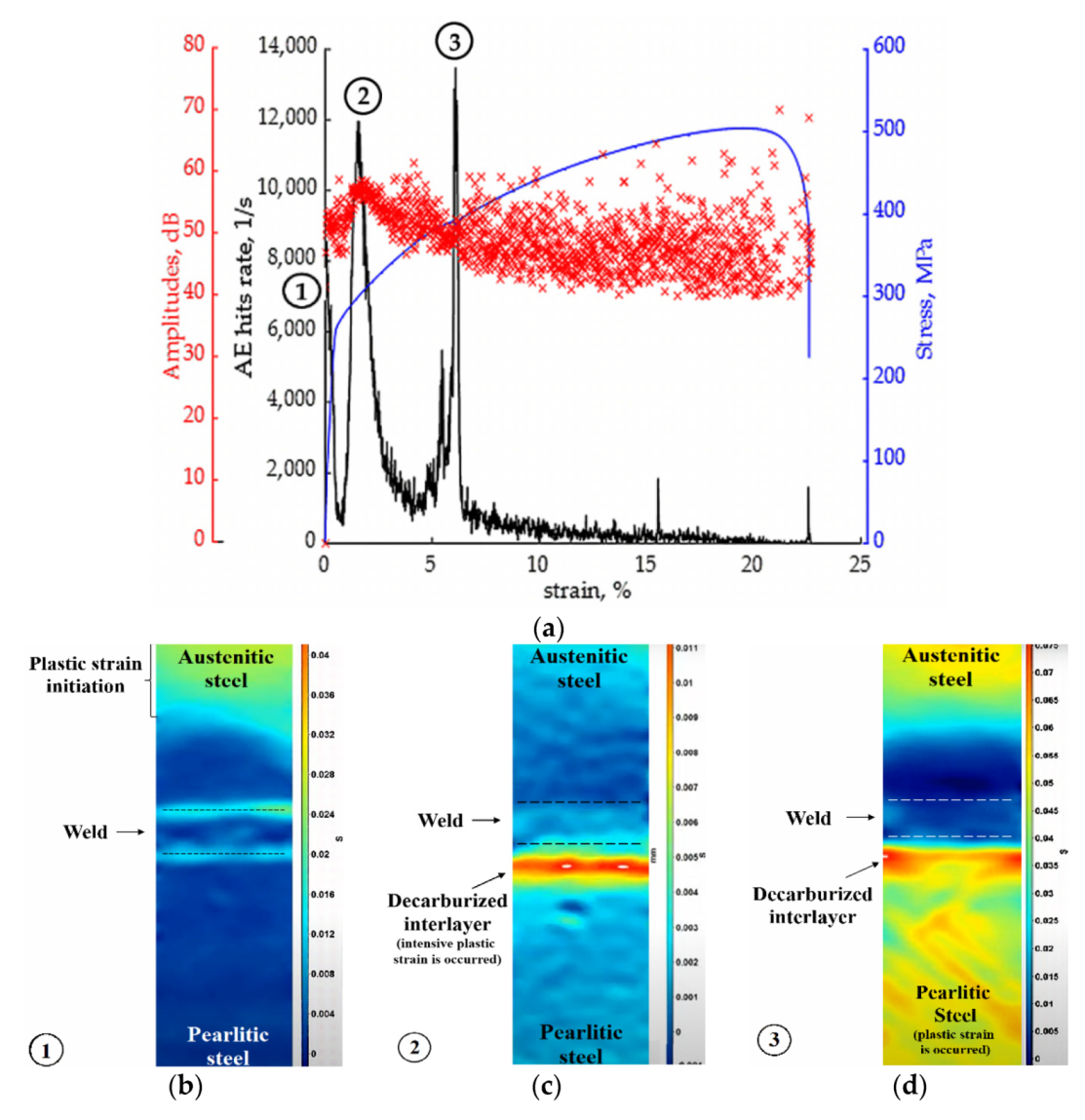

3.2. Investigation of AE under Tension of Specimens with Dissimilar Welded Joints

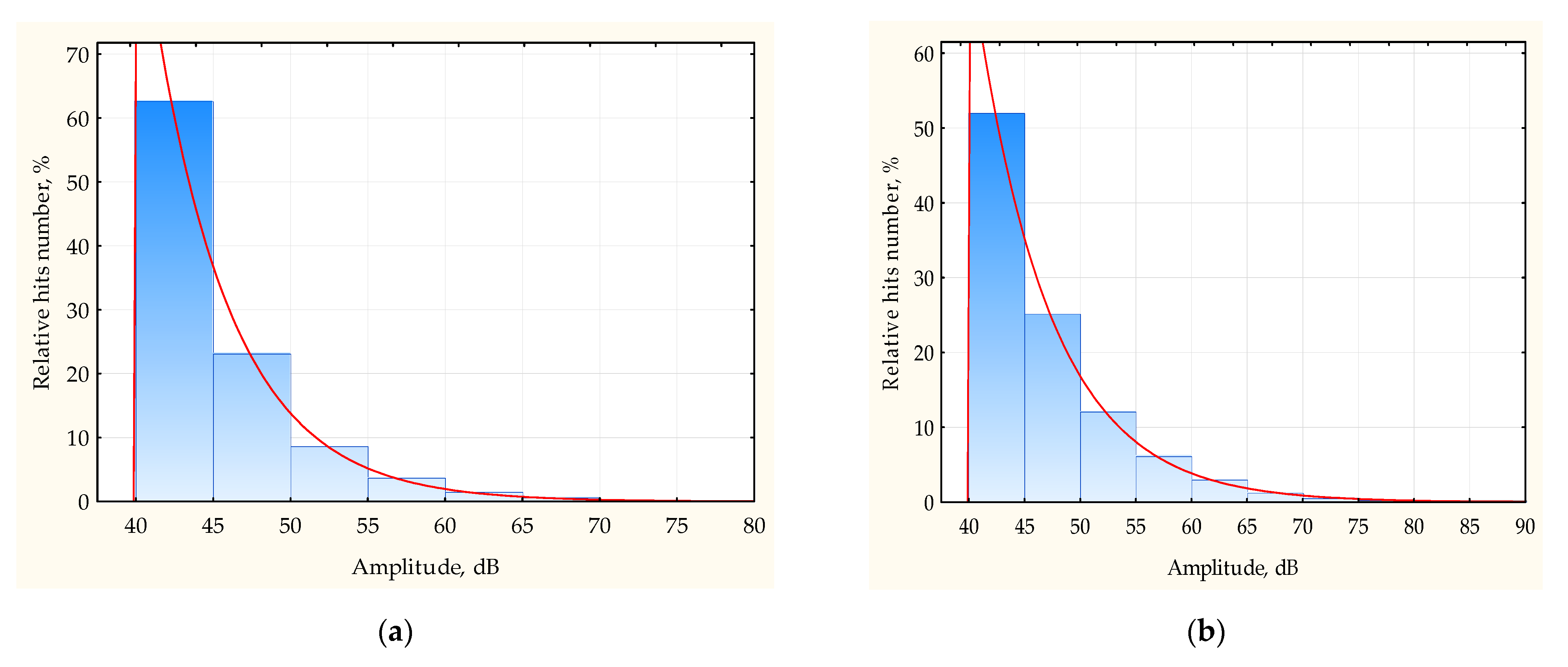

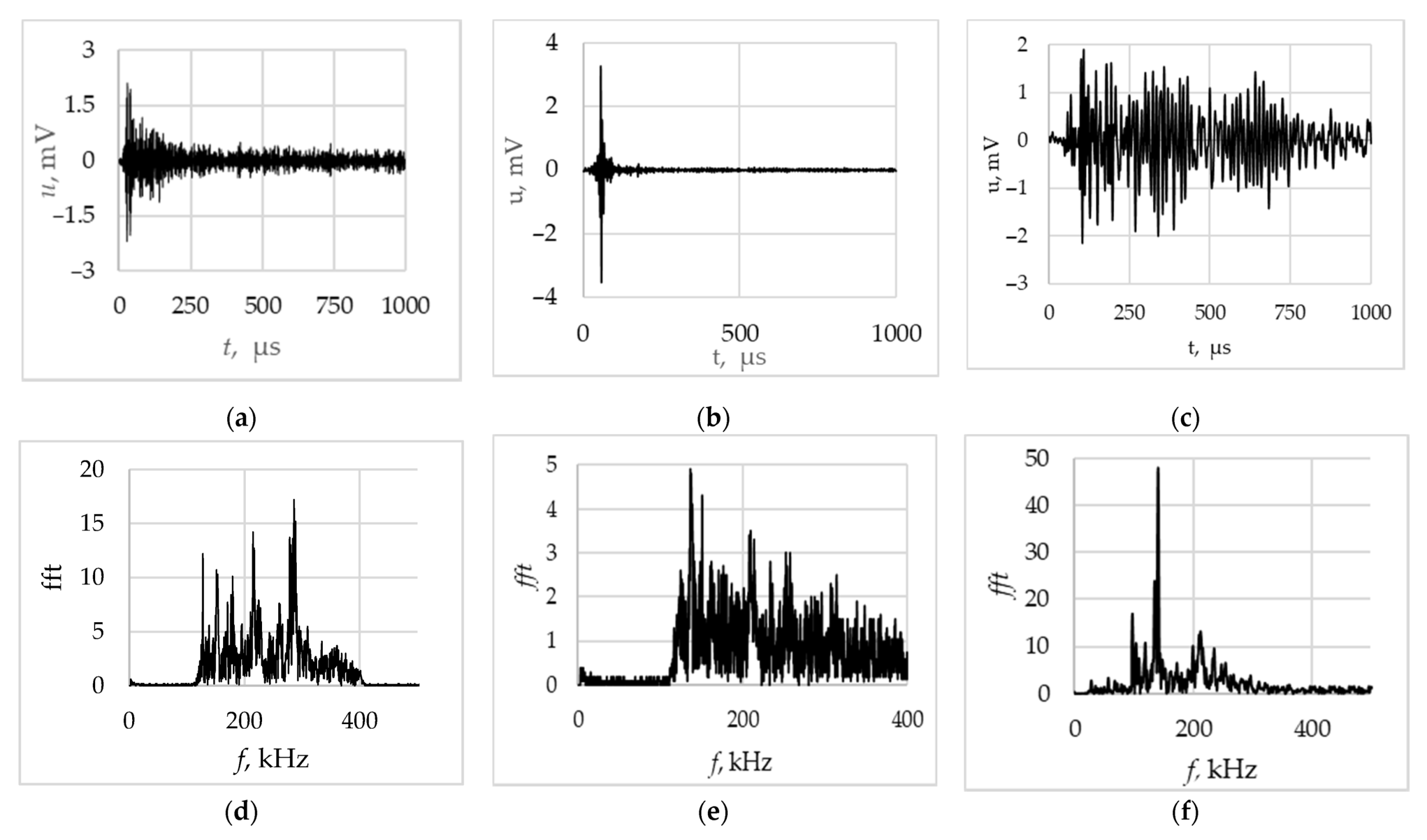

3.3. Investigation of AE Signals Waveform and Spectrum

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Manning, J.R. Diffusion Kinetics for Atoms in Crystals; Van Nostrand: Toronto, ON, Canada, 1968; p. 257. [Google Scholar]

- Rathod, D.W.; Pandey, S.; Singh, P.K.; Prasad, R. Experimental analysis of dissimilar metal weld joint: Ferritic to austenitic stainless steel. Mater. Sci. Eng. A 2015, 639, 259–268. [Google Scholar] [CrossRef]

- Khodakov, V.D.; Khodakov, D.V. Structure and mechanism of formation of dissimilar welded joints in nuclear power plant made of austenitic and pearlitic steels. Weld. Int. 2016, 30, 935–940. [Google Scholar] [CrossRef]

- Saini, M.; Arora, N.; Pandey, C.; Mehdi, H. Mechanical properties of bimetallic weld joint between SA 516 grade 65 carbon steel and SS 304 L for steam generator application. Int. J. Res. Eng. Technol. 2014, 3, 39–42. [Google Scholar]

- Dinesh, W.; Rathod, P.K.; Pandey, S.; Aravindan, S. Effect of buffer-layered buttering on microstructure and mechanical properties of dissimilar metal weld joints for nuclear plant application. Mater. Sci. Eng. A 2016, 666, 100–113. [Google Scholar] [CrossRef]

- Wang, W.K.; Liu, Y.; Zhang, Q.B.; Zhang, L.J.; Zhang, J.X. Microstructure and local mechanical properties of a dissimilar metal welded joint with buttering layer in steam turbine rotor. Mater. Sci. Eng. A 2019, 747, 244–254. [Google Scholar] [CrossRef]

- Goncharov, A.L.; Marchenkov, A.Y.; Terentyev, E.V.; Zhmurko, I.E.; Sliva, A.P. Study of structural non-homogeneity impact on mechanical properties of dissimilar weld joints of carbon steel 20 and corrosion-resistant austenitic 12Kh18N10T steel. Mater. Sci. Eng. 2019, 681, 012016. [Google Scholar] [CrossRef]

- ISO 17637:2016. Non-Destructive Testing of Welds—Visual Testing of Fusion-Welded Joints. Available online: https://www.iso.org/standard/67259.html (accessed on 11 November 2021).

- Moore, P.O. Radiographic Testing in Nondestructive Testing Handbook, 3rd ed.; American Society for NDT: Columbus, OH, USA, 2005; Volume 4. [Google Scholar]

- Bulavinov, A.; Kroning, M.; Walte, F.; Lui, J.; Reddy, K. Ultrasonic Inspection of Austenitic and Dissimilar Welds. In Proceedings of the IV Conferencia Panamericana de END, Buenos Aires, Argentina, 22–26 October 2007; p. 13. [Google Scholar]

- Eisazadeh, H.; Bunn, J.; Coules, H.E.; Achuthan, A.; Goldak, J.; Aidun, D.K. A Residual stress study in similar and dissimilar welds. Weld. Res. J. 2016, 95, 111–119. [Google Scholar]

- Han, T.; Schubert, F.; Hillmalnn, S.; Meyendorf, N. Phased Array Ultrasonic Testing of Dissimilar Metal Welds using Geometric Based Referencing Delay Law Technique. In Proceedings of the 7th International Workshop NDT in Progress: NDT of Lightweight Materials, Dresden, Germany, 7–8 November 2013; Volume 9439, p. 943904. [Google Scholar] [CrossRef]

- Bazulin, E.G. Allowing for Inhomogeneous Anisotropy of a Welded Joint when Reconstructing Reflector Images from Echo Signals Received by an Ultrasonic Antenna Array. Rus. J. Nondestr. Test. 2017, 53, 9–22. [Google Scholar] [CrossRef]

- Hwang, Y.; Park, J.; Kim, H.-J.; Song, S.-J.; Cho, Y.-S.; Kang, S.-S. Performance Comparison of Ultrasonic Focusing Techniques for Phased Array Ultrasonic Inspection of Dissimilar Metal Welds. Int. J. Precis. Eng. Manuf. 2019, 20, 525–534. [Google Scholar] [CrossRef]

- Juengert, A.; Dugan, S.; Homann, T.; Mitzscherling, S.; Prager, J.; Pudovikov, S.; Schwender, T. Advanced Ultrasonic Techniques for Nondestructive Testing of Austenitic and Dissimilar Welds in Nuclear Facilities. AIP Conf. Proc. 2018, 1949, 110002. [Google Scholar] [CrossRef]

- Sagaidak, A.I.; Elizarov, S.V. Acoustic emission parameters correlated with fracture and deformation processes of concrete members. Constr. Build. Mater. 2007, 21, 477–482. [Google Scholar] [CrossRef]

- Linderov, M.; Vinogradov, A.; Segel, C.; Weidner, A.; Biermann, H. Deformation mechanisms in austenitic TRIP/TWIP steels at room and elevated temperature investigated by acoustic emission and scanning electron microscopy. Mater. Sci. Eng. A 2014, 597, 183–193. [Google Scholar] [CrossRef]

- Muránsky, O.; Barnett, M.R.; Carr, D.G.; Vogel, S.C.; Oliver, E.C. Investigation of deformation twinning in a fine-grained and coarse-grained ZM20 Mg alloy: Combined in situ neutron diffraction and acoustic emission. Acta Mater. 2010, 58, 1503–1517. [Google Scholar] [CrossRef]

- Fukaura, K.; Yokoyama, Y.; Yokoi, D.; Tsujii, N.; Ono, K. Fatigue of cold-work tool steels: Effect of heat treatment and carbide morphology on fatigue crack formation, life, and fracture surface observations. Metall. Mater. Trans. A 2004, 35, 1289–1300. [Google Scholar] [CrossRef]

- Inamura, T.; Nagano, S.; Shimojo, M.; Takashima, K.; Higo, Y. Detection of pre-martensitic transformation phenomena in austenitic stainless steels using as acoustic emission technique. J. Acoust. Emiss. 2001, 19, 85–90. [Google Scholar]

- Wuriti, G.S.; Chaattopadhyaya, S.; Krolczyk, G. Comparison of Acoustic Emission Data Acquired During Tensile Deformation of Maraging Steel M250 Welded Specimens. Arch. Acoust. 2020, 45, 221–231. [Google Scholar]

- Chang, H. Acoustic Emission Study of Fatigue Crack Propagation of Weld Joint for X52 Pipeline Steel. Mater. Sci. Forum 2019, 960, 38–44. [Google Scholar] [CrossRef]

- Rastegaev, I.; Danyuk, A.; Afanas’yev, M.; Merson, D.; Berto, F.; Vinogradov, A. Acoustic Emission Assessment of Impending Fracture in a Cyclically Loading Structural Steel. Metals 2016, 6, 266. [Google Scholar] [CrossRef] [Green Version]

- Shamsudin, M.F.; Mares, C.; Johnston, C.; Lage, Y.; Edwards, G.; Gan, T.-H. Application of Bayesian estimation to structural health monitoring of fatigue cracks in welded steel pipe. Mech. Syst. Signal Process. 2019, 121, 112–123. [Google Scholar] [CrossRef]

- Chai, M.; Qin, M.; Zheng, Y.; Hou, X.; Zhang, Z.; Cheng, G.; Duan, Q. Acoustic Emission Detection during Welding Residual Stresses Release in 2.25Cr1Mo0.25V Steel Welds. Mater. Today Proc. 2018, 5, 13759–13766. [Google Scholar] [CrossRef]

- Kong, Y.S.; Cheepu, M.; Lee, J.-K. Evaluation of the Mechanical Properties of Inconel 718 to SCM 440 Dissimilar Friction Welding through Real-Time Monitoring of the Acoustic Emission System. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 1181–1190. [Google Scholar] [CrossRef]

- Venkatakrishna, A.; Lakshminarayanan, A.K.; Radhika, K.; Rajasekaran, R. Characterizing the Tensile Deformation Behavior of Friction Stir Welded Dissimilar Joints using Acoustic Emission Technique. In Trends in Manufacturing and Engineering Management; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Paventhan, R.; Lakshminarayanan, P.R.; Balasubramanian, V. Fatigue behavior of friction welded medium carbon steel and austenitic stainless steel dissimilar joints. Mater. Des. 2011, 32, 1888–1894. [Google Scholar] [CrossRef]

- Chen, G.; Luo, H.; Yang, H.; Han, Z.; Lin, Z.; Zhang, Z.; Su, Y. Effects of the welding inclusion and notch on the fracture behaviors of low-alloy steel. J. Mater. Res. Technol. 2019, 8, 447–456. [Google Scholar] [CrossRef]

- Russian State Standard GOST 19281-89 Rolled Steel with Increased Strength General Specifications; Standartinform: Moscow, Russia, 1989.

- Russian State Standard GOST 5582-75 Stainless and Heat-Resisting Sheet Specifications; Standartinform: Moscow, Russia, 1975.

- Ennaceur, C.; Beaugrand, V. Acoustic Emission Monitoring of Crack Growth in Dissimilar Joints for Corrosion Resistant Applications. In Proceedings of the 28th European Conference on Acoustic Emission Testing, Krakow, Poland, 17–19 September 2008; pp. 64–69. [Google Scholar]

- Vinogradov, A.Y.; Merson, D.L. The Nature of Acoustic Emission during Deformation Processes in Metallic Materials. Low Temp. Phys. 2018, 44, 930–937. [Google Scholar] [CrossRef]

- Kumar, J.; Sarmah, R.; Ananthakrishna, G. General Framework for Acoustic Emission during Plastic Deformation. Phys. Rev. B Condens. Matter Mater. Phys. 2015, 92, 14. [Google Scholar] [CrossRef] [Green Version]

- Builo, S.I. Diagnostics of the Predestruction State Based on Amplitude and Time Invariants of the Flow of Acoustic-Emission Acts. Russ. J. Nondestruct. Test. 2004, 40, 561–564. [Google Scholar] [CrossRef]

- Kumar, J.; Ananthakrishna, G. Modeling the Complexity of Acoustic Emission during Intermittent Plastic Deformation: Power Laws and Multifractal Spectra. Phys. Rev. E 2019, 97, 2018. [Google Scholar] [CrossRef] [Green Version]

- Vinogradov, A.; Yasnikov, I.S.; Merson, D.L. Phenomenological Approach Towards Modelling the Acoustic Emission due to Plastic Deformation in Metals. Scr. Mater. 2019, 170, 172–176. [Google Scholar] [CrossRef]

| C | Si | Mn | Ni | S | P | Cr | Cu | Ti | Fe | |

|---|---|---|---|---|---|---|---|---|---|---|

| 12Kh18N10T steel | ≤0.12 | ≤0.8 | ≤2 | 9–11 | ≤0.02 | ≤0.035 | 17–19 | ≤0.3 | 0.4–1 | ~67 |

| 09G2S steel | ≤0.12 | 0.5–0.8 | 1.3–1.7 | ≤0.3 | ≤0.04 | ≤0.035 | ≤0.3 | ≤0.3 | - | Balance |

| Sabaros SW146 wire | 0.10 | 0.80 | 8.5 | 8.5 | - | - | 18.5 | - | - | Balance |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barat, V.; Marchenkov, A.; Bardakov, V.; Karpova, M.; Zhgut, D.; Elizarov, S. Features of Acoustic Emission in Tensile Testing of Dissimilar Welded Joints of Pearlitic and Austenitic Steels. Appl. Sci. 2021, 11, 11892. https://doi.org/10.3390/app112411892

Barat V, Marchenkov A, Bardakov V, Karpova M, Zhgut D, Elizarov S. Features of Acoustic Emission in Tensile Testing of Dissimilar Welded Joints of Pearlitic and Austenitic Steels. Applied Sciences. 2021; 11(24):11892. https://doi.org/10.3390/app112411892

Chicago/Turabian StyleBarat, Vera, Artem Marchenkov, Vladimir Bardakov, Marina Karpova, Daria Zhgut, and Sergey Elizarov. 2021. "Features of Acoustic Emission in Tensile Testing of Dissimilar Welded Joints of Pearlitic and Austenitic Steels" Applied Sciences 11, no. 24: 11892. https://doi.org/10.3390/app112411892

APA StyleBarat, V., Marchenkov, A., Bardakov, V., Karpova, M., Zhgut, D., & Elizarov, S. (2021). Features of Acoustic Emission in Tensile Testing of Dissimilar Welded Joints of Pearlitic and Austenitic Steels. Applied Sciences, 11(24), 11892. https://doi.org/10.3390/app112411892