Experimental Study on Application of Tuned Mass Dampers for Chatter in Turning of a Thin-Walled Cylinder

Abstract

1. Introduction

2. Chatter Generated during Turning of a Thin-Walled Cylinder

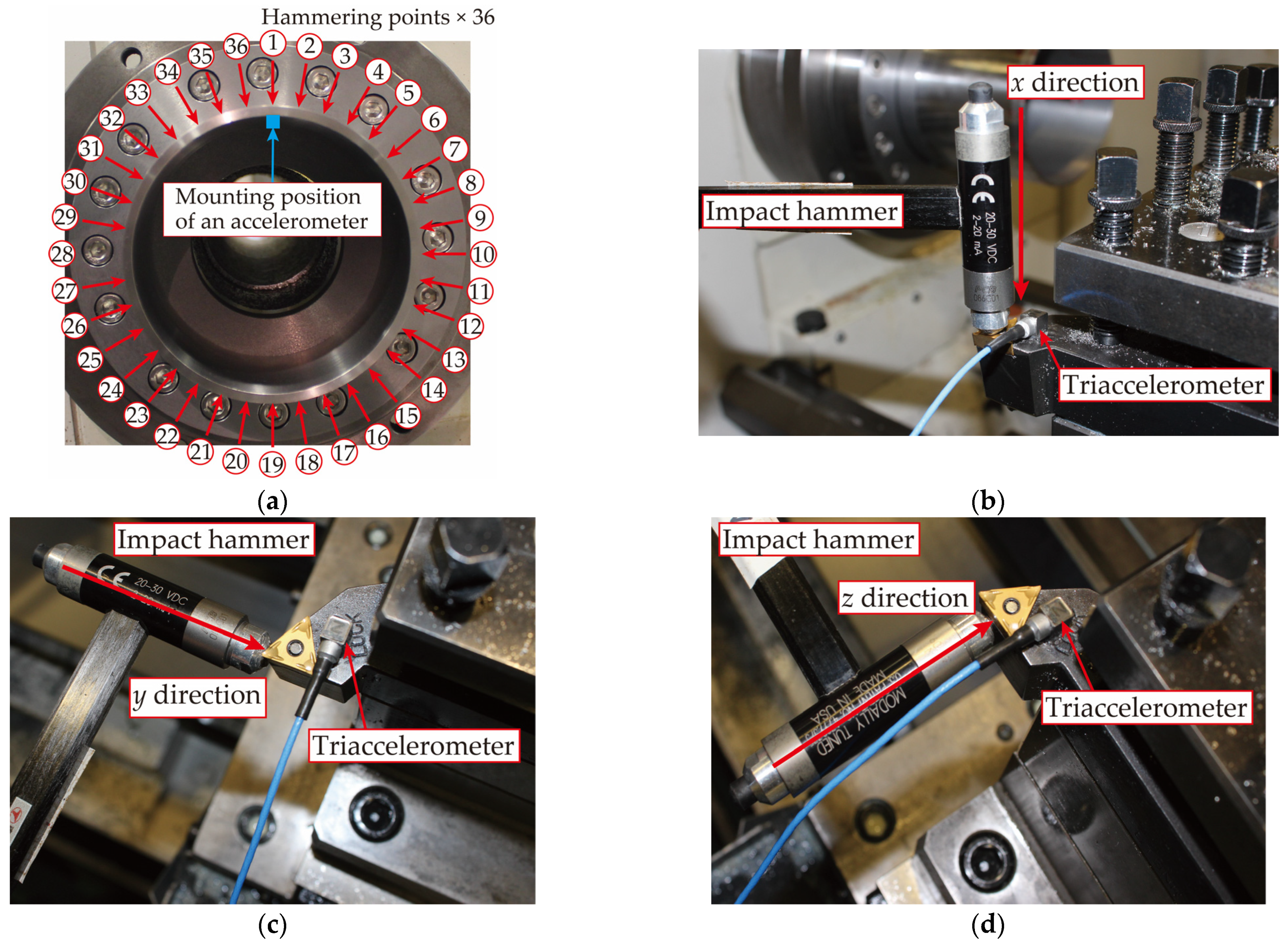

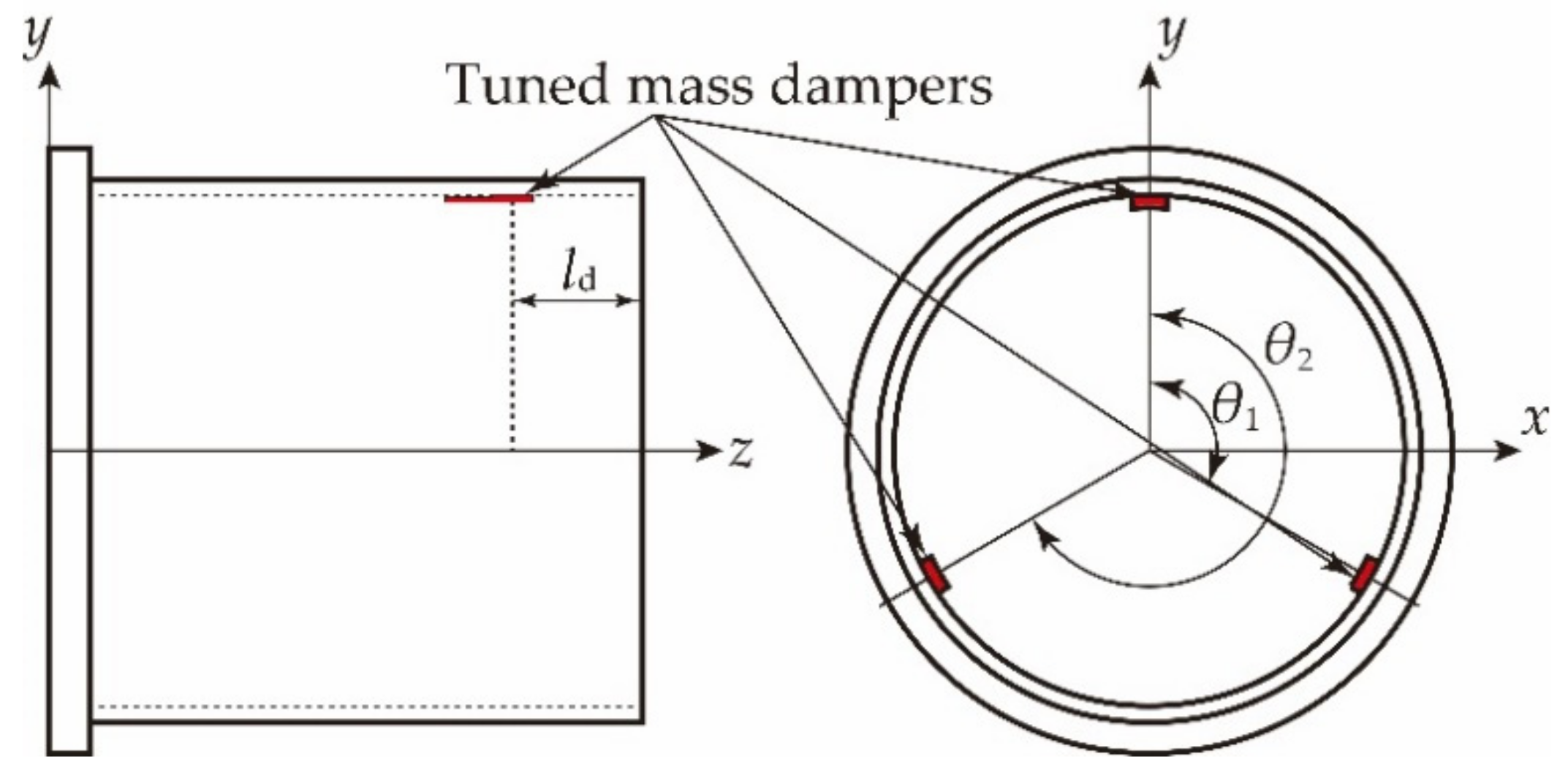

2.1. Thin-Walled Cylindrical Workpiece and Experimental Setup

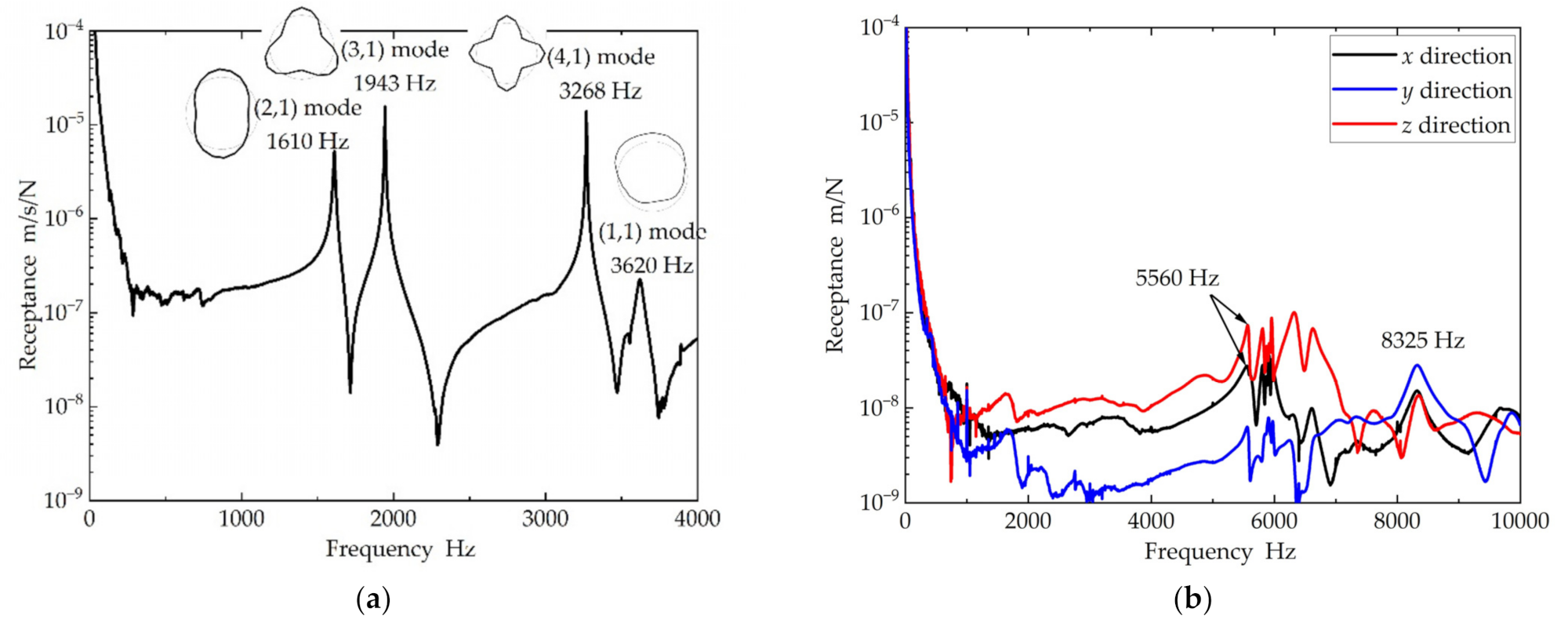

2.2. Frequency Characteristics of Thin-Walled Cylindrical Workpiece and Cutting Tool

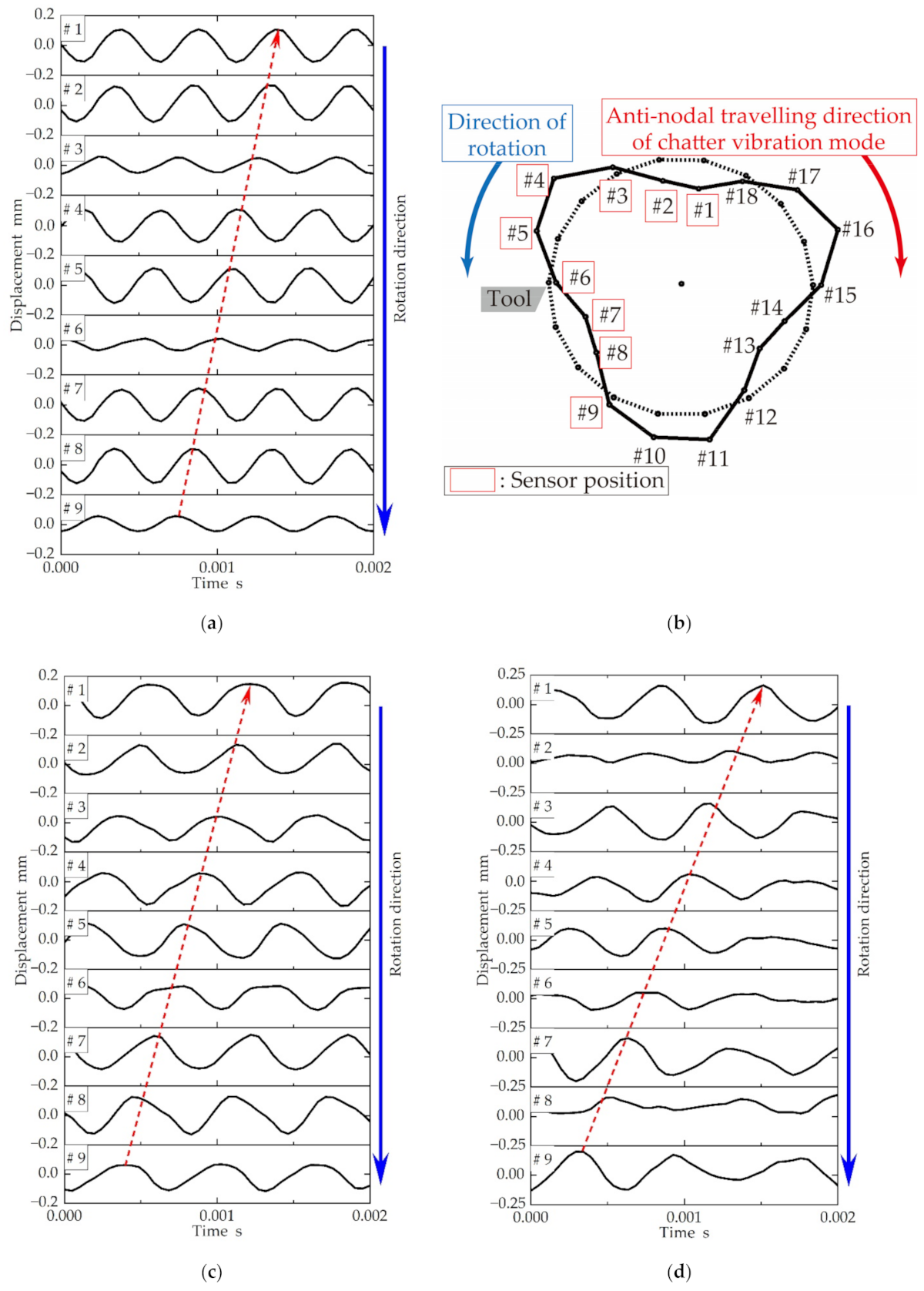

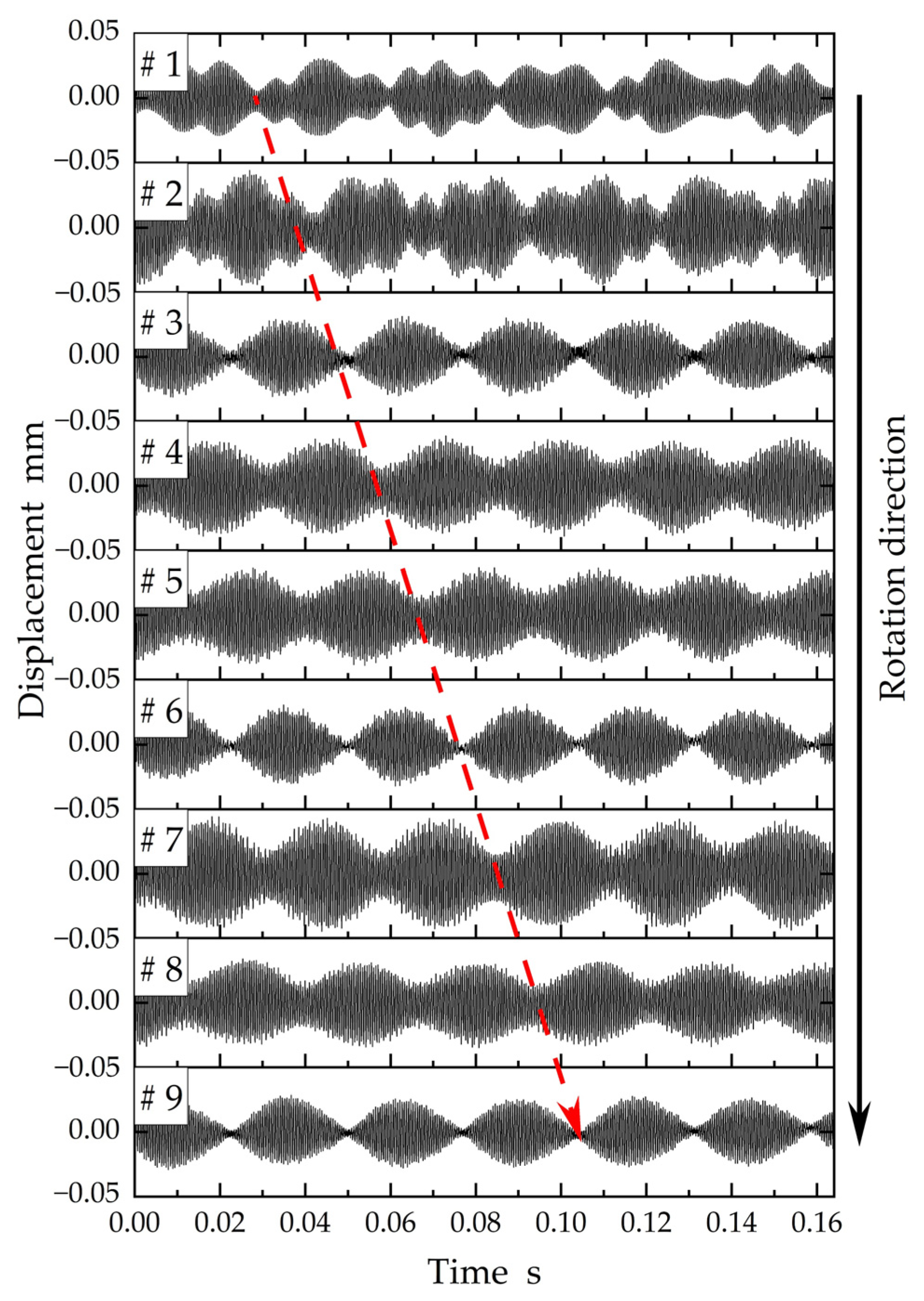

2.3. Chatter Vibration Mode

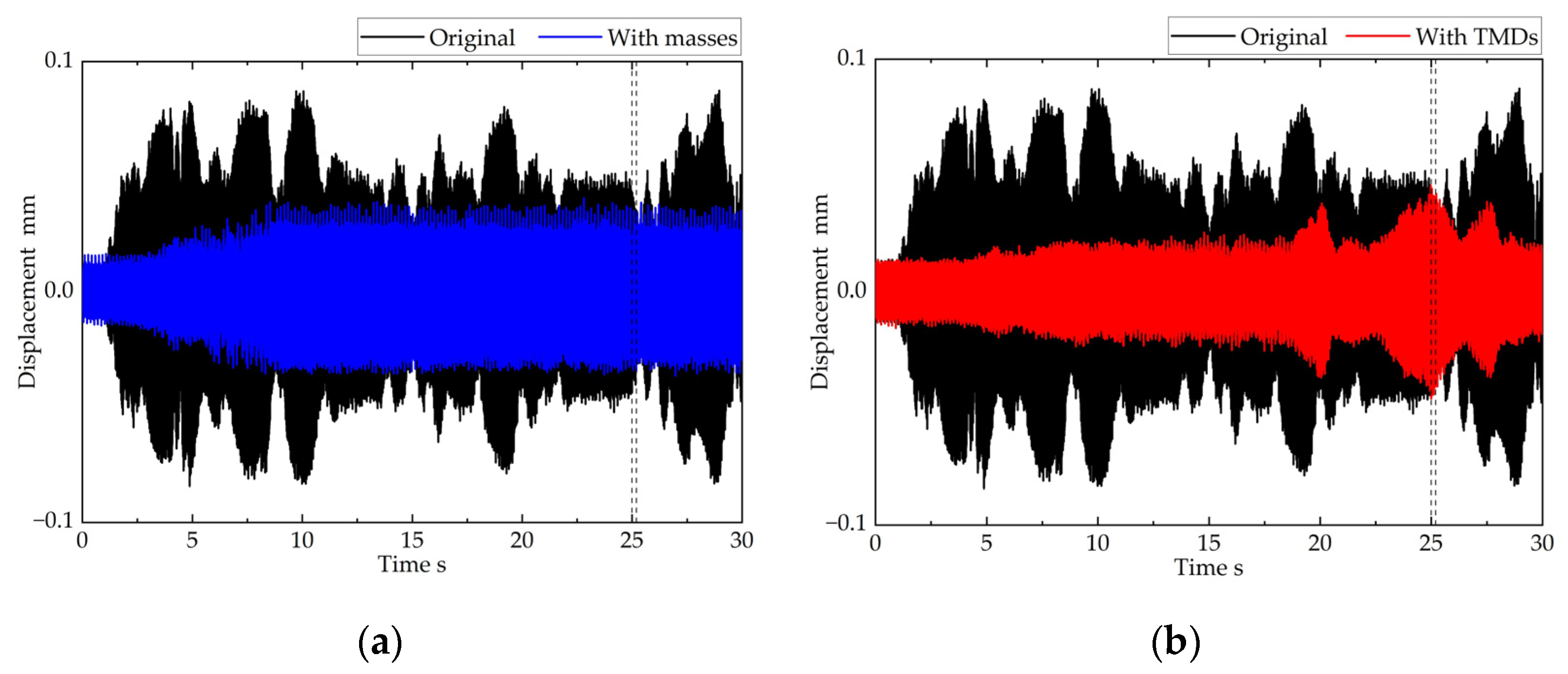

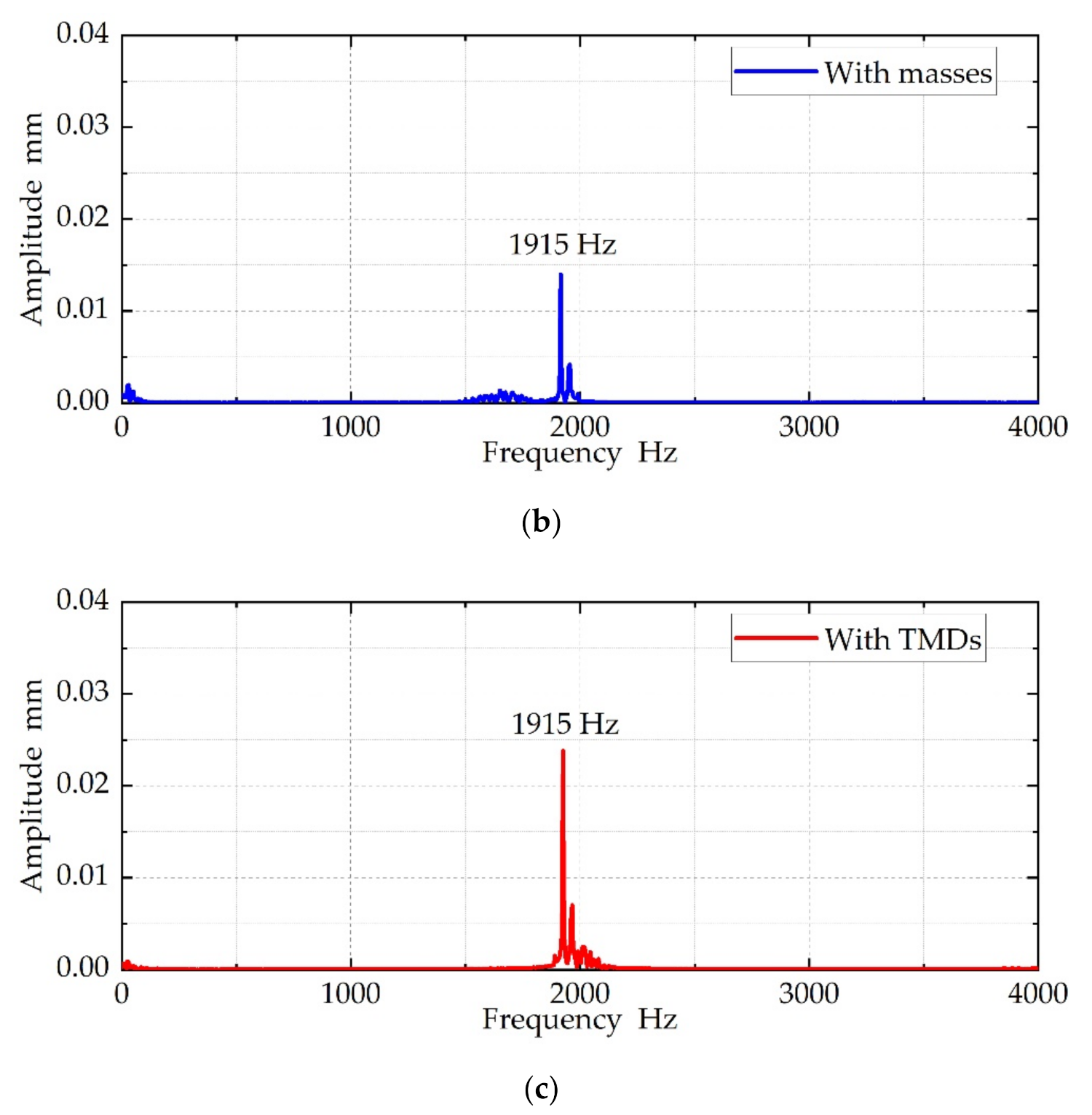

3. Experimental Verification of Chatter Suppression Effect with TMDs

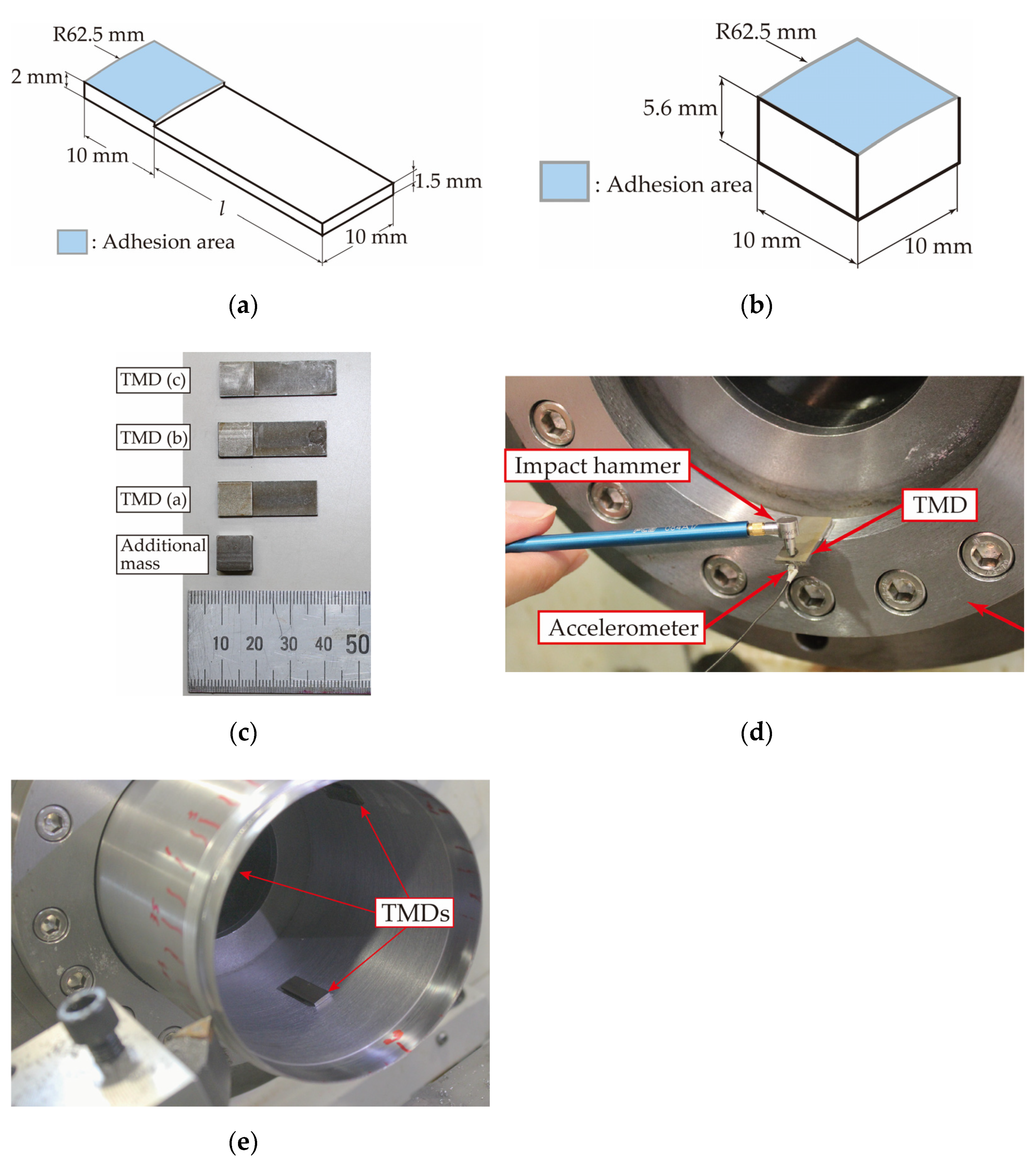

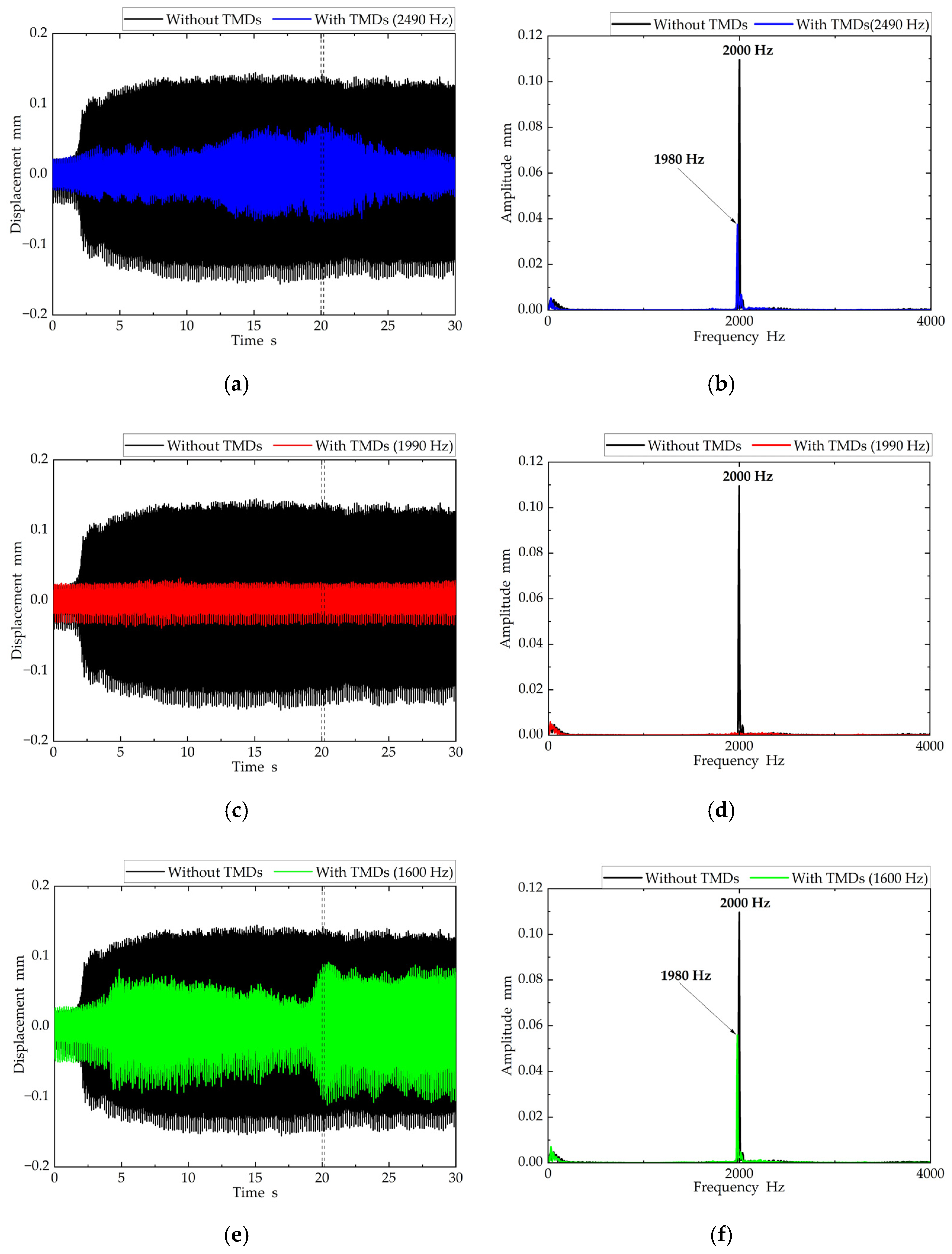

3.1. Specifications of TMD

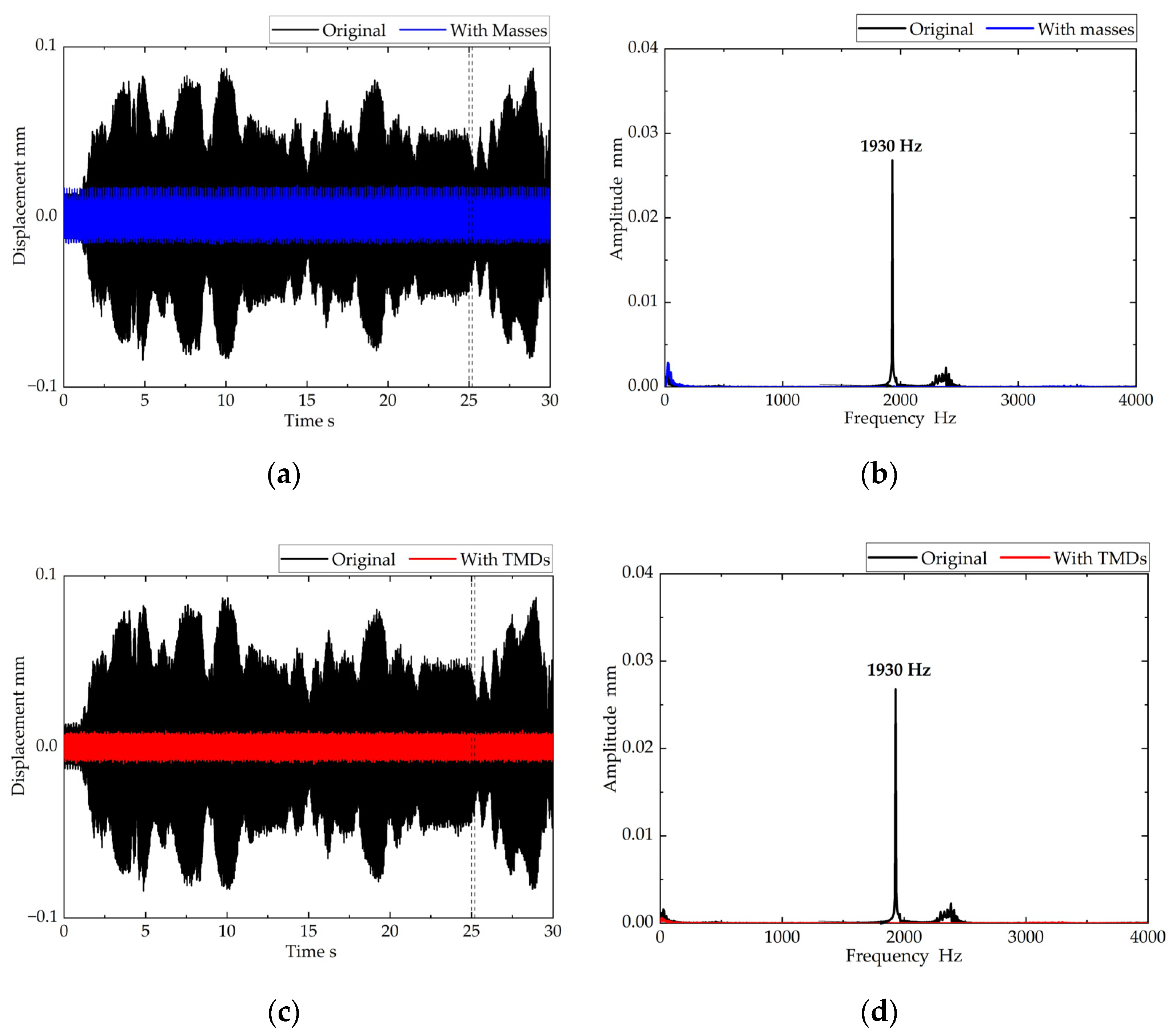

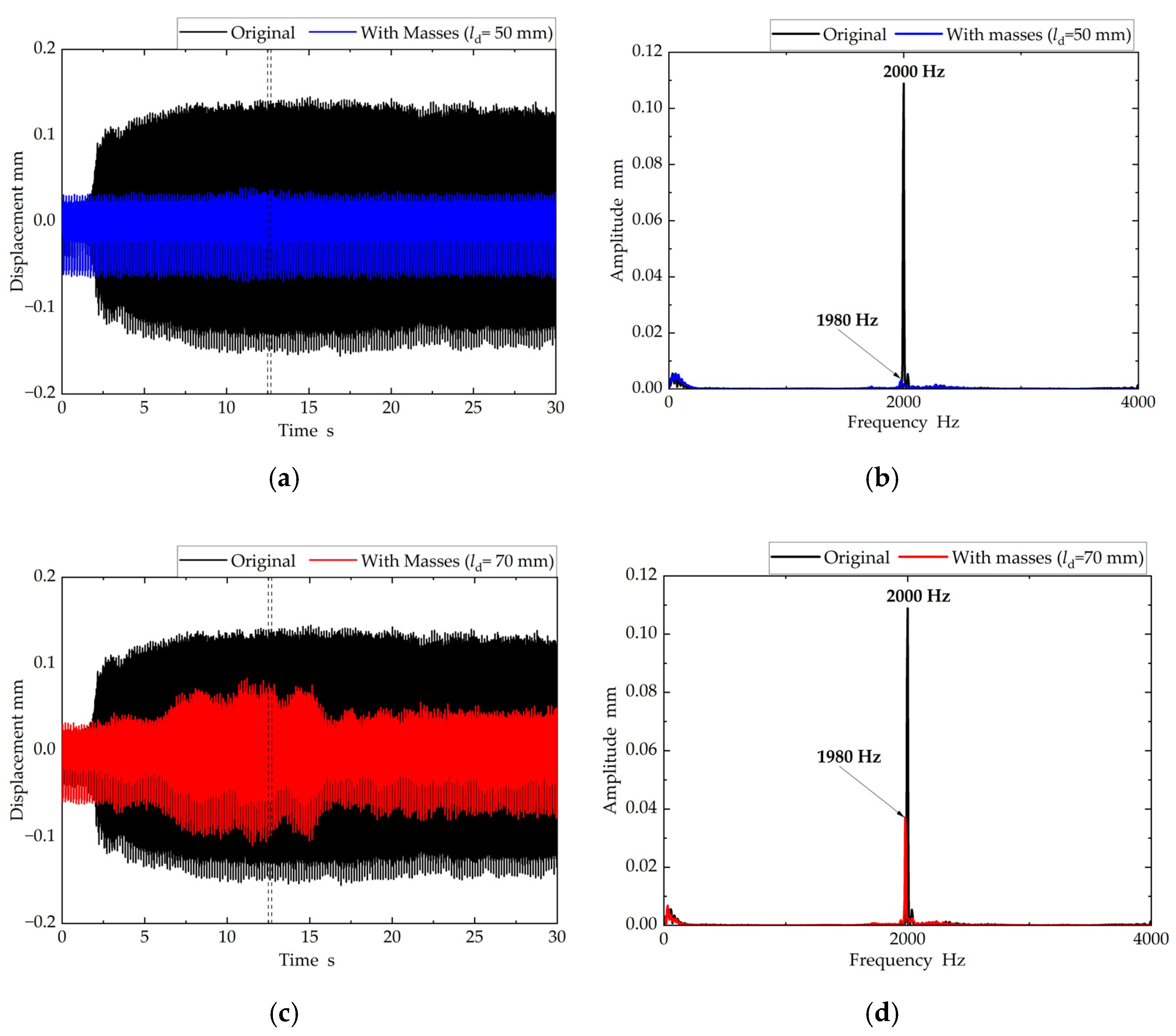

3.2. Effect of Various Circumferential Arrangements of TMDs on Chatter Suppression

3.3. Effect of Various Equivalent Mass Ratios of TMD on Chatter Suppression

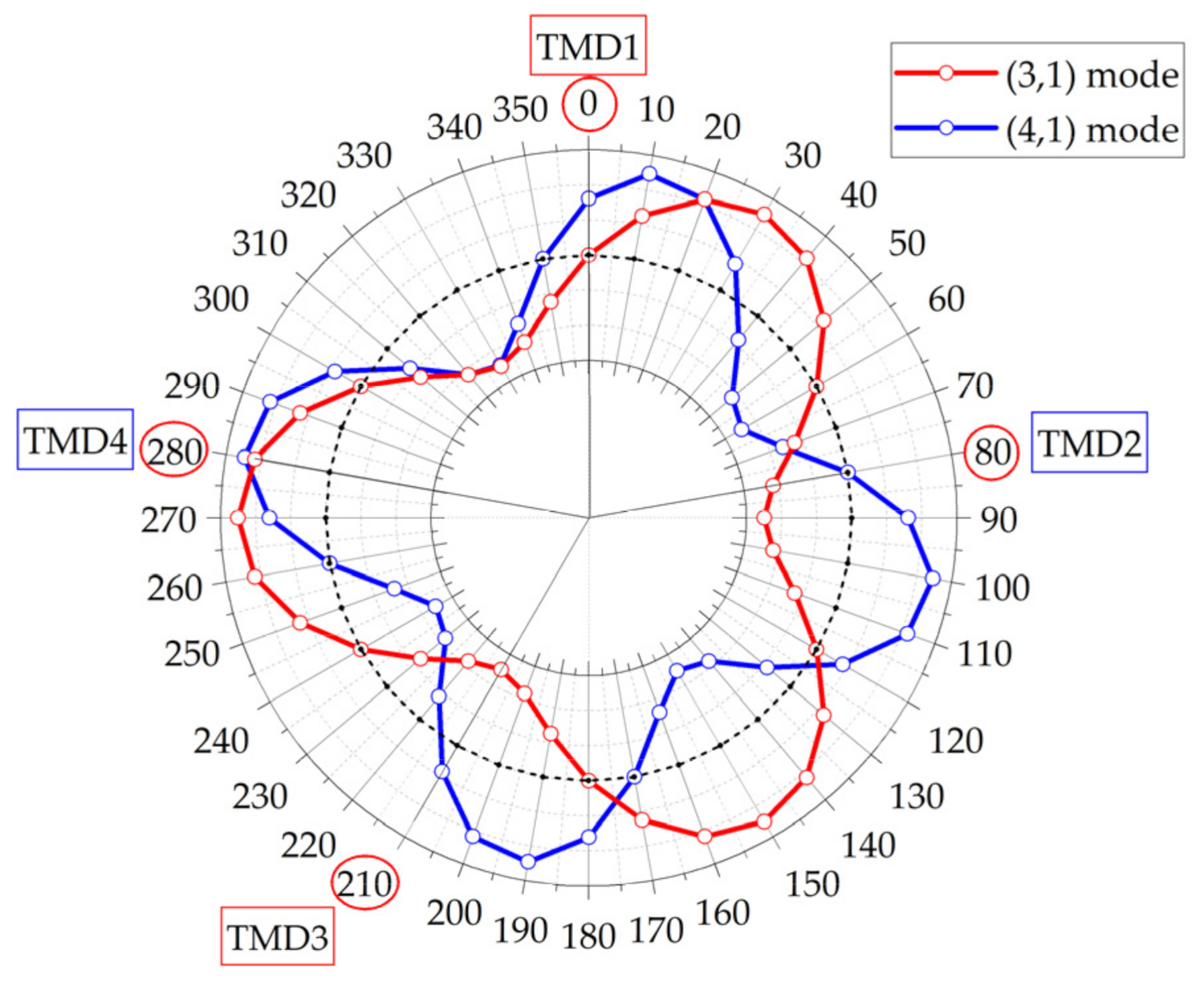

3.4. Design for TMDs in Case of Multiple Modes of Chatter Generation

4. Discussion

5. Conclusions

- (1)

- The chatter can be controlled if the masses or TMDs are attached to the workpiece such that their mounting arrangements do not coincide with the spacing of the nodes of the generated chatter vibration mode.

- (2)

- In case the TMDs are attached to the fixed end of the workpiece, the natural frequencies of the TMDs must be adjusted approximately to the chatter frequency for obtaining a sufficient chatter suppression effect.

- (3)

- To suppress multiple chatter modes using the TMDs, the TMDs ought to be placed at unequal intervals and at least two attached TMDs should be tuned for each chatter vibration mode.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kolluru, K.; Axinte, D. Coupled interaction of dynamic responses of tool and workpiece in thin wall milling. J. Mater. Process. Technol. 2013, 213, 1565–1574. [Google Scholar] [CrossRef]

- Chanda, A.; Fischer, A.; Eberhard, P.; Dwivedy, S.K. Stability analysis of a thin-walled cylinder in turning operation using the semi-discretization method. Acta Mech. Sin. 2014, 30, 214–222. [Google Scholar] [CrossRef]

- Song, Q.; Liu, Z.; Wan, Y.; Ju, G.; Shi, J. Application of Sherman–Morrison–Woodbury formulas in instantaneous dynamic of peripheral milling for thin-walled component. Int. J. Mech. Sci. 2015, 96–97, 79–90. [Google Scholar] [CrossRef]

- Gerasimenko, A.; Guskov, M.; Gouskov, A.; Lorong, P.; Shokhin, A. Analytical modeling of a thin-walled cylindrical workpiece during the turning process. Stability analysis of a cutting process. J. Vibroeng. 2017, 19, 5825–5841. [Google Scholar] [CrossRef]

- Irene, D.S.; Asuncion, R.; Norberto, L.L.L.; Juan, G.A. Thin-wall machining of light alloys: A review of models and industrial approaches. Materials 2019, 12, 2012. [Google Scholar] [CrossRef]

- Quintana, G.; Ciurana, J. Chatter in machining processes: A review. Int. J. Mach. Tools Manuf. 2011, 51, 363–376. [Google Scholar] [CrossRef]

- Munoa, J.; Beudaert, X.; Dombovari, Z.; Altintas, Y.; Budak, E.; Brecher, C.; Stepan, G. Chatter suppression techniques in metal cutting. CIRP Ann. Manuf. Technol. 2016, 65, 785–808. [Google Scholar] [CrossRef]

- Matsubara, A.; Taniyama, Y.; Wang, J.; Kono, D. Design of a support system with a pivot mechanism for suppressing vibrations in thin-wall milling. CIRP Ann. Manuf. Technol. 2017, 66, 381–384. [Google Scholar] [CrossRef]

- Fei, J.; Lin, B.; Xiao, J.; Ding, M.; Yan, S.; Zhang, X.; Zhang, J. Investigation of moving fixture on deformation suppression during milling process of thin-walled structures. J. Manuf. Process. 2018, 32, 403–411. [Google Scholar] [CrossRef]

- Croppi, L.; Grossi, N.; Scippa, A.; Campatelli, G. Fixture Optimization in Turning Thin-Wall Components. Machines 2019, 7, 68. [Google Scholar] [CrossRef]

- Guo, L.; Yang, F.; Li, T.; Zhou, M.; Tang, J. Vibration suppression of aeroengine casing during milling. Int. J. Adv. Manuf. Technol. 2021, 113, 295–307. [Google Scholar] [CrossRef]

- Zeng, S.; Wan, X.; Li, W.; Yin, Z.; Xiong, Y. A novel approach to fixture design on suppressing machining vibration of flexible workpiece. Int. J. Mach. Tools Manuf. 2012, 58, 29–43. [Google Scholar] [CrossRef]

- Fischer, A.; Eberhard, P. Simulation-Based Stability Analysis of a Thin-Walled Cylinder During Turning with Improvements Using an Adaptronic Turning Chisel. Arch. Mech. Eng. 2011, 58, 367–391. [Google Scholar] [CrossRef][Green Version]

- Ma, H.; Wu, J.; Yang, L.; Xiong, Z. Active chatter suppression with displacement-only measurement in turning process. J. Sound Vib. 2017, 401, 255–267. [Google Scholar] [CrossRef]

- Fallah, M.; Moetakef-Imani, B. Adaptive inverse control of chatter vibrations in internal turning operations. Mech. Syst. Signal Process. 2019, 129, 91–111. [Google Scholar] [CrossRef]

- Lu, X.; Chen, F.; Altintas, Y. Magnetic actuator for active damping of boring bars. CIRP Ann. Manuf. Technol. 2014, 63, 369–372. [Google Scholar] [CrossRef]

- Kishore, R.; Choudhury, S.K.; Orra, K. On-line control of machine tool vibration in turning operation using electro-magneto rheological damper. J. Manuf. Process. 2018, 31, 187–198. [Google Scholar] [CrossRef]

- Yigit, U.; Cigeroglu, E.; Budak, E. Chatter reduction in boring process by using piezoelectric shunt damping with experimental verification. Mech. Syst. Signal Process. 2017, 94, 312–321. [Google Scholar] [CrossRef]

- Falta, J.; Janota, M.; Sulitka, M. Chatter suppression in finish turning of thin-walled cylinder: Model of tool workpiece interaction and effect of spindle speed variation. Procedia CIRP 2018, 77, 175–178. [Google Scholar] [CrossRef]

- Otto, A.; Radons, G. Application of spindle speed variation for chatter suppression in turning. CIRP J. Manuf. Sci. Technol. 2013, 6, 102–109. [Google Scholar] [CrossRef]

- Beri, B.; Meszaros, G.; Stepan, G. Machining of slender workpieces subjected to time-periodic axial force: Stability and chatter suppression. J. Sound Vib. 2021, 504, 116114. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Z.; Song, Q.; Wang, B. Analysis and implementation of chatter frequency dependent constrained layer damping tool holder for stability improvement in turning process. J. Mater. Process. Technol. 2019, 266, 687–695. [Google Scholar] [CrossRef]

- Kolluru, K.; Axinte, D.; Becker, A. A solution for minimizing vibrations in milling of thin walled casings by applying dampers to workpiece surface. CIRP Ann. Manuf. Technol. 2013, 62, 415–418. [Google Scholar] [CrossRef]

- Tarng, Y.S.; Kao, J.Y.; Lee, E.C. Chatter suppression in turning operations with a tuned vibration absorber. J. Mater. Process. Technol. 2000, 105, 55–60. [Google Scholar] [CrossRef]

- Nakano, Y.; Takahara, H.; Kondo, E. Countermeasure against chatter in end milling operations using multiple dynamic ab-sorbers. J. Sound Vib. 2013, 332, 1626–1638. [Google Scholar] [CrossRef]

- Bansal, A.; Law, M. A receptance coupling approach to optimally tune and place absorbers on boring bars for chatter sup-pression. Procedia CIRP 2018, 77, 167–170. [Google Scholar] [CrossRef]

- Nakano, Y.; Kishi, T.; Takahara, H.; Croppi, L.; Scippa, A. Experimental Investigation on the Effect of Tuned Mass Damper on Mode Coupling Chatter in Turning Process of Thin-Walled Cylindrical Workpiece. In Proceedings of the 18th Asia-Pacific Vibration Conference, The University of Technology Sydney, Sydney, Australia, 18–20 November 2019. [Google Scholar]

- Seto, K.; Tominari, N. Effect of a Variable Stiffness-Type Dynamic Damper on Machine Tools with Long Overhung Ram. Bull. JSME 1976, 19, 1270–1277. [Google Scholar] [CrossRef]

- Wang, M.; Zan, T.; Yang, Y.; Fei, R. Design and implementation of nonlinear TMD for chatter suppression: An application in turning processes. Int. J. Mach. Tools Manuf. 2010, 50, 474–479. [Google Scholar] [CrossRef]

- Yang, Y.; Muñoa, J.; Altintas, Y. Optimization of multiple tuned mass dampers to suppress machine tool chatter. Int. J. Mach. Tools Manuf. 2010, 50, 834–842. [Google Scholar] [CrossRef]

- Sims, N.D. Vibration absorbers for chatter suppression: A new analytical tuning methodology. J. Sound Vib. 2007, 301, 592–607. [Google Scholar] [CrossRef]

- Chang, J.Y.; Lai, G.J.; Chen, M.F. A study on the chatter characteristics of the thin wall cylindrical workpiece. Int. J. Mach. Tools Manuf. 1994, 34, 489–498. [Google Scholar] [CrossRef]

- Kurita, Y.; Oura, Y.; Tanaka, T.; Kawata, M. Chatter vibration of workpiece deformation type in cutting thin-walled cylindrical workpiece (Generation mechanism of chatter vibration). Trans. JSME 2020, 86, 1–15. [Google Scholar] [CrossRef]

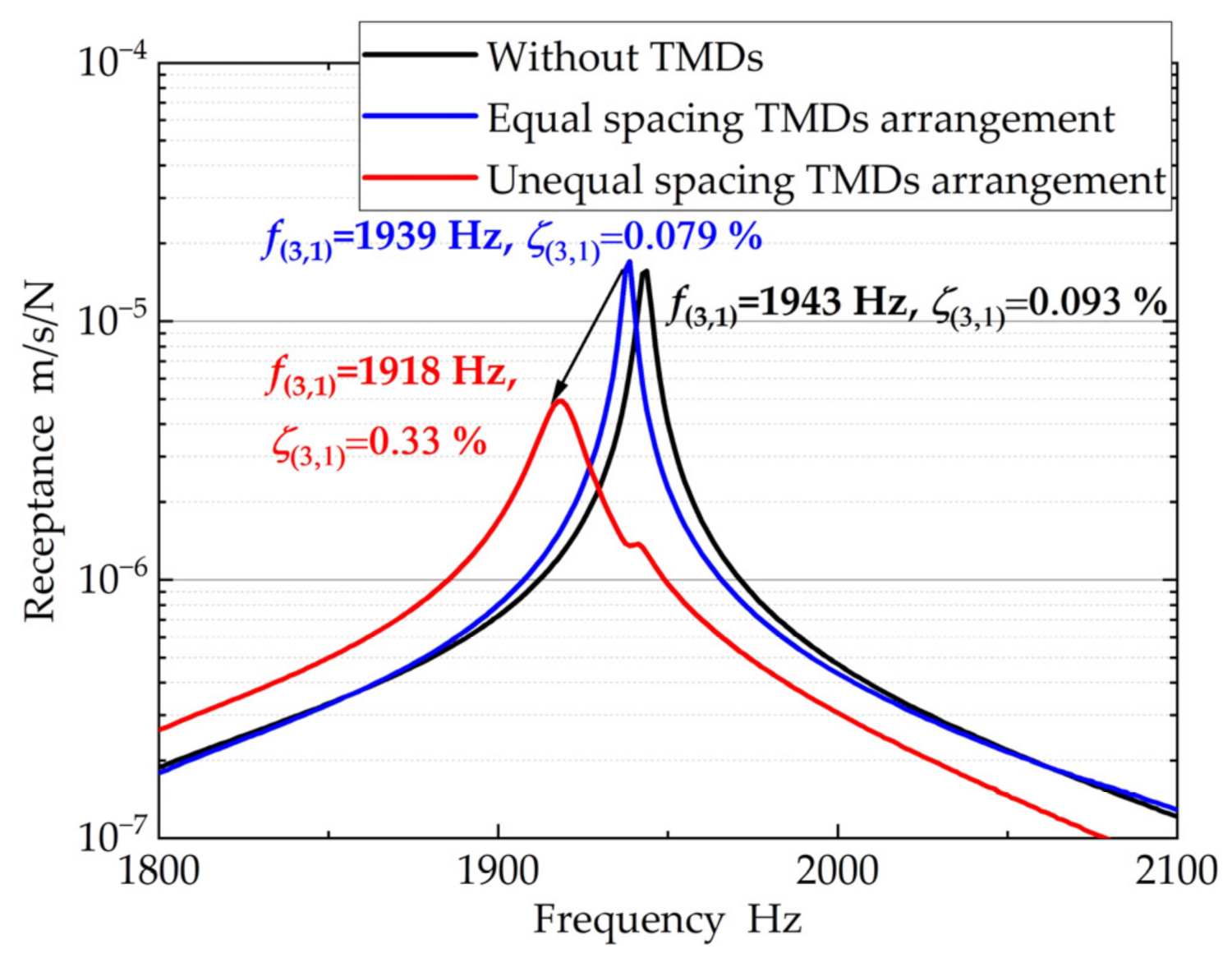

| Mode Number (m, n) | Natural Frequency (Hz) | Damping Ratio (%) |

|---|---|---|

| (2, 1) | 1610 | 0.31 |

| (3, 1) | 1943 | 0.093 |

| (4, 1) | 3268 | 0.049 |

| (1, 1) | 3620 | 0.51 |

| Rake Angle (°) | Clearance Angle (°) | Approach Angle (°) | Nose Radius of Insert (mm) |

|---|---|---|---|

| –5 | 5 | 91 | 0.4 |

| Wall Thickness (mm) | Chatter Frequency (Hz) | Mode | Chatter Frequency (Hz) | Mode |

|---|---|---|---|---|

| 4.0 | 1995 | (3, 1) | – | – |

| 2.6 | 1606 | (3, 1) | 2409 | (4, 1) |

| 1.5 | 1458 | (4, 1) | – | – |

| TMD | Length of Beam l (mm) | Natural Frequency fd (Hz) | Damping Ratio ζd (%) | Mass m (g) |

|---|---|---|---|---|

| (a) | 19 | 2490 | 7.0 | 4.0 |

| (b) | 21.5 | 1990 | 4.8 | 4.3 |

| (c) | 24 | 1600 | 4.5 | 4.5 |

| Mounting Arrangement A | Mounting Arrangement B | |||

|---|---|---|---|---|

| Natural Frequency (Hz) | Position (°) | Natural Frequency (Hz) | Position (°) | |

| TMD 1 | 1600 | 0 | 1600 | 0 |

| TMD 2 | 2490 | 140 | 2490 | 110 |

| TMD 3 | 2490 | 250 | 1600 | 270 |

| Mounting Arrangement C | ||

|---|---|---|

| Natural Frequency (Hz) | Position (°) | |

| TMD 1 | 1600 | 0 |

| TMD 2 | 2490 | 80 |

| TMD 3 | 1600 | 210 |

| TMD 4 | 2490 | 280 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakano, Y.; Kishi, T.; Takahara, H. Experimental Study on Application of Tuned Mass Dampers for Chatter in Turning of a Thin-Walled Cylinder. Appl. Sci. 2021, 11, 12070. https://doi.org/10.3390/app112412070

Nakano Y, Kishi T, Takahara H. Experimental Study on Application of Tuned Mass Dampers for Chatter in Turning of a Thin-Walled Cylinder. Applied Sciences. 2021; 11(24):12070. https://doi.org/10.3390/app112412070

Chicago/Turabian StyleNakano, Yutaka, Tsubasa Kishi, and Hiroki Takahara. 2021. "Experimental Study on Application of Tuned Mass Dampers for Chatter in Turning of a Thin-Walled Cylinder" Applied Sciences 11, no. 24: 12070. https://doi.org/10.3390/app112412070

APA StyleNakano, Y., Kishi, T., & Takahara, H. (2021). Experimental Study on Application of Tuned Mass Dampers for Chatter in Turning of a Thin-Walled Cylinder. Applied Sciences, 11(24), 12070. https://doi.org/10.3390/app112412070