Non-Hertzian Elastohydrodynamic Contact Stress Calculation of High-Speed Ball Screws

Abstract

:1. Introduction

2. Materials and Methods

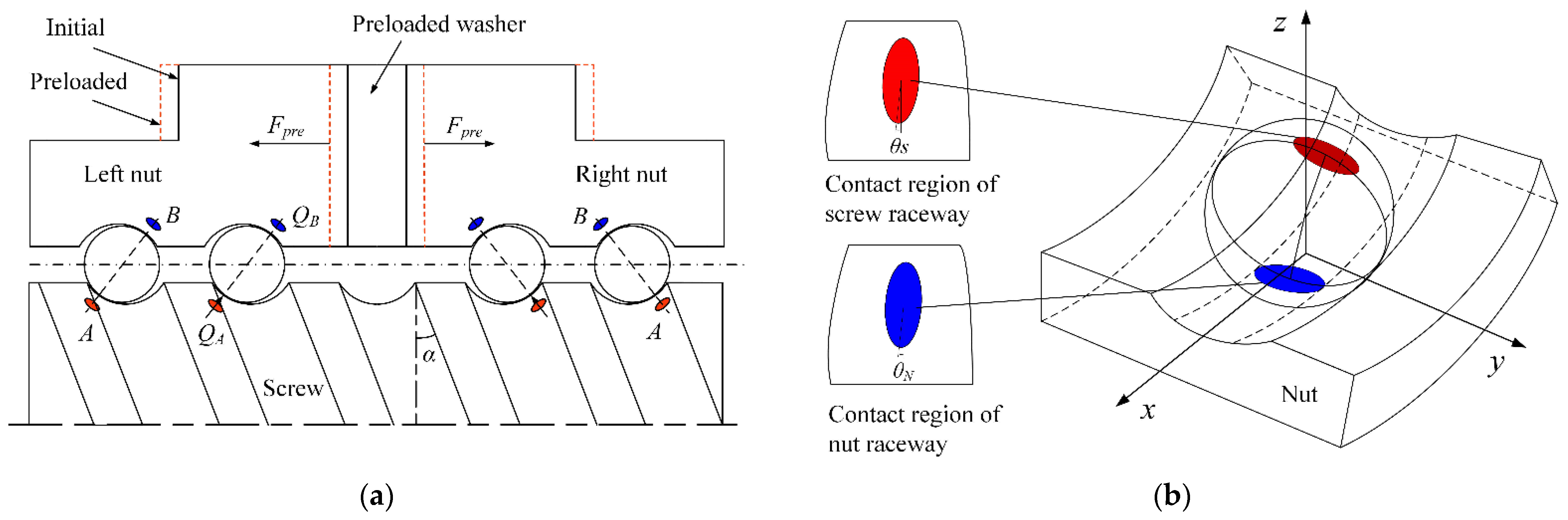

2.1. Analysis of Force and Motion

2.2. Non-Hertzian Normal Contact Stress Calculation

- The initial normal contact stress P is given, pi,j ≥ 0. The normal contact stress distribution pi,j is also satisfied in the mesh region.

- The discretized normal contact deformation V is determined by Equation (4).

- The contact gap c between the two contact surfaces is calculated by Equations (3)–(6), and the contact gap is satisfied with the boundary condition.

- According to the variational principle, the contact in Equation (7) can be transformed by the conditional extremum of the quadratic function, the normal contact stress pi,j is modified by Equation (10) satisfying the boundary condition in Equation (11).

- The current relative error is determined by:

- If ε ≥ ε0, the iteration solution process of the non-Hertzian contact stress continues from steps (2)–(5), otherwise the iteration solution process ends.

2.3. Non-Hertzian Elastohydrodynamic Contact Stress Calculation

- The lubricant and the solid are isothermal, and the contact stress and the film thickness do not vary with time.

- The curvature radius of the solid surface is much larger than the lubricant film thickness.

- No relative sliding between the lubricant film and solid surface at the common interface.

- Compared with the film shear stress, the inertial force and other bulk forces of the lubricant film are negligible.

- Due to the lubricant film thickness being very thin, it can be assumed that the film contact stress remains constant along the film thickness direction, namely no squeeze film effect.

- The inlet of the contact region is flooded fully by the lubricant film.

- The lubricant is the Newtonian fluid and obeys Newton’s law of viscosity.

3. Experiments and Verification

3.1. Experiments Procedures

3.2. Experimental Results

4. Results Analysis and Discussion

4.1. Comparison of the Normal Contact Stress between Hertzian Solution and Non-Hertzian Solution

4.2. Analysis of the Non-Hertzian Contact Stress with Different Helix Angles

4.3. Analysis of the Elastohydrodynamic Contact Stress with Different Helix Angles

4.4. Effect of the Elastohydrodynamic Contact Stress under Different Screw Speeds

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Glossary

| a | Major axis of the elliptical contact region/mm |

| b | Minor axis of the elliptical contact region/mm |

| c | Contact gap between the two contact surfaces/mm |

| d | Approaching distance of the contact surface/mm |

| h | Lubricant film thickness/μm |

| n | Number of the working ball |

| p | Normal contact stress/MPa |

| r | Radius/mm |

| u | Entrainment velocity/(mm/s) |

| x, y, z | Coordinates in ball screws |

| A | Area/(μm2) |

| D | Fractal dimension |

| E | Elasticity modulus/MPa |

| F | Force/N |

| G | Scale parameters |

| K | Deformation influence coefficient/(mm/N) |

| I, J | Total number in the x or y direction |

| L | Pitch of the screw/mm |

| M | Torque/(N/mm) |

| Q | Load/N |

| R | The ratio of the asperity bearing stress |

| ROU | Profile of the rough surface/μm |

| V | Contact deformation/mm |

| W | Quadratic function |

| α | Helix angle/° |

| β | Contact angle/° |

| ε | Iteration precision |

| θ | Deflection angle of the contact region/° |

| υ | Poisson ratio |

| τ | Lubricant film shear stress/MPa |

| ρ | Lubricant film density/(kg/m3) |

| η | Lubricant film viscosity/(Pa·s) |

| μ | Friction coefficient |

| Ω’ | Screw speed/(mm/s) |

Nomenclature

| 0 | Initial value |

| 1, 2 | The two contact surfaces |

| a | Asperity bearing |

| bb | Ball |

| f | Lubricant film bearing |

| g | Contact gap |

| h | Mesh region |

| i, j | Column or row number |

| pre | Preload |

| t, n, b | Coordinates in OHtnb |

| o, e | Entrance and exit coordinates of the contact region |

| A | Contact point between ball and screw raceway |

| AH | Contact point between ball and screw raceway with Hertzian contact |

| B | Contact point between ball and nut raceway |

| BH | Contact point between ball and nut raceway with Hertzian contact |

| IH | Inertia |

| S | Screw |

| SA | Friction between ball and screw raceway |

| SB | Friction between ball and nut raceway |

| N | Nut |

Abbreviations

| BSs | Ball screws |

| DNBSs | Double-nut ball screws |

| EHL | Elastohydrodynamic lubrication |

| NC | Numerical control |

Appendix A

The Finite Difference Method

References

- Zhang, G.; Jin, H.; Lin, Y.-J. Attaining Ultraprecision Machining by Feed Drive System Stability Control with Piezoelectric Preloading Actuators. Appl. Sci. 2021, 11, 8491. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, C.; Li, Z.; Lu, Z. Analysis on Dynamic Contact Characteristics and Dynamic Stiffness Estimating Method of Single Nut Ball Screw Pair Based on the Whole Rolling Elements Model. Appl. Sci. 2020, 10, 5795. [Google Scholar] [CrossRef]

- Liu, J.; Feng, H.; Zhou, C. Static load distribution and axial static contact stiffness of a preloaded double-nut ball screw considering geometric errors. Mech. Mach. Theory 2022, 167, 104460. [Google Scholar] [CrossRef]

- Lin, B.; Okwudire, C.E.; Wou, J.S. Low Order Static Load Distribution Model for Ball Screw Mechanisms Including Effects of Lateral Deformation and Geometric Errors. J. Mech. Des. 2018, 140, 12. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, C.; Meng, X.; Wen, B. Static load distribution analysis of ball screws with nut position variation. Mech. Mach. Theory 2020, 151, 103893. [Google Scholar] [CrossRef]

- Huang, Y.-C.; Kao, C.-H.; Chen, S.-J. Diagnosis of the Hollow Ball Screw Preload Classification Using Machine Learning. Appl. Sci. 2018, 8, 1072. [Google Scholar] [CrossRef] [Green Version]

- Zhen, N.; An, Q. Analysis of stress and fatigue life of ball screw with considering the dimension errors of balls. Int. J. Mech. Sci. 2018, 137, 68–76. [Google Scholar] [CrossRef]

- Miura, T.; Matsubara, A.; Kono, D.; Otaka, K.; Hoshide, K. Design of high-precision ball screw based on small-ball concept. Precis. Eng. 2017, 47, 452–458. [Google Scholar] [CrossRef]

- Bertolino, A.C.; Jacazio, G.; Mauro, S.; Sorli, M. Investigation on the ball screws no-load drag torque in presence of lubrication through MBD simulations. Mech. Mach. Theory 2021, 161, 104328. [Google Scholar] [CrossRef]

- Su, J.; Song, H.-X.; Ke, L.-L. Elastohydrodynamic lubrication line contact in couple-stress elasticity. Math. Mech. Solids 2021, 26, 1053–1073. [Google Scholar] [CrossRef]

- Pei, J.; Han, X.; Tao, Y.; Feng, S. Mixed elastohydrodynamic lubrication analysis of line contact with Non-Gaussian surface roughness. Tribol. Int. 2020, 151, 106449. [Google Scholar] [CrossRef]

- Clarke, A.; Jamali, H.; Sharif, K.; Evans, H.; Frazer, R.; Shaw, B. Effects of profile errors on lubrication performance of helical gears. Tribol. Int. 2017, 111, 184–191. [Google Scholar] [CrossRef]

- Sharif, K.J.; Evans, H.P.; Snidle, R.W.; Barnett, D.; Egorov, I.M. Effect of elastohydrodynamic film thickness on a wear model for worm gears. In Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology; SAGE Publications: Southend Oaks, CA, USA, 2006; Volume 220, pp. 295–306. [Google Scholar]

- Sharif, K.; Evans, H.; Snidle, R. Prediction of the wear pattern in worm gears. Wear 2006, 261, 666–673. [Google Scholar] [CrossRef]

- Wei, C.C.; Lin, J.F.; Horng, J.-H. Analysis of a ball screw with a preload and lubrication. Tribol. Int. 2009, 42, 1816–1831. [Google Scholar] [CrossRef]

- Otsu, T.; Komatsu, K.; Hashimura, S.; Imado, K. Shear properties under the starved condition of polyisobutylene lubricant for use in screw tightening-effect of operating condition on lubrication properties. Tribol. Int. 2018, 122, 133–142. [Google Scholar] [CrossRef]

- Fleischer, J.; Spohrer, A.; Leberle, U.; Dosch, S. Adaptive and Adequate Lubrication for Highest Component-lifetimes in Feed Drive Axes with Ball Screws. Procedia CIRP 2015, 29, 335–340. [Google Scholar] [CrossRef]

- Xie, Z.; Xue, Q.; Wu, J.; Gu, L.; Wang, L.; Song, B. Mixed-lubrication analysis of planetary roller screw. Tribol. Int. 2019, 140, 105883. [Google Scholar] [CrossRef]

- Oh, K.-J.; Cao, L.; Chung, S.-C. Explicit modeling and investigation of friction torques in double-nut ball screws for the precision design of ball screw feed drives. Tribol. Int. 2020, 141, 105841. [Google Scholar] [CrossRef]

- Zhou, H.-X.; Zhou, C.-G.; Feng, H.-T.; Ou, Y. Theoretical and experimental analysis of the preload degradation of double-nut ball screws. Precis. Eng. 2020, 65, 72–90. [Google Scholar] [CrossRef]

- Wang, W.; Hu, Y.; Wang, H. Numerical solution of dry contact problem based on fast Fourier transform and conjugate gradient method. Chin. J. Mech. Eng. 2006, 42, 14–18. [Google Scholar] [CrossRef]

- Brandt, A.; Lubrecht, A. Multilevel matrix multiplication and fast solution of integral equations. J. Comput. Phys. 1990, 90, 348–370. [Google Scholar] [CrossRef]

- Wang, M.; Sun, T.; Dong, Z.; Kong, D.; Gao, X. Non-Hertzian Contact Stress Calculation of High-speed Ball Screw Mechanism. Adv. Eng. Sci. 2021, 53, 178–186. [Google Scholar]

- Hu, Y.-Z.; Zhu, D. A Full Numerical Solution to the Mixed Lubrication in Point Contacts. J. Tribol. 1999, 122, 1–9. [Google Scholar] [CrossRef]

- Gao, X.-S.; Wang, M.; Liu, X.-B. Modeling and application of thermal contact resistance of ball screws. J. Central South Univ. 2019, 26, 168–183. [Google Scholar] [CrossRef]

- Roelands, C.J.A. Correlation aspect of the viscosity-temperature-pressure relation of lubrication oil. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1966. [Google Scholar]

- Dowson, D.; Higginson, G.R. Elastohydrodynamic Lubrication; Pergamon Press: Oxford, UK, 1966. [Google Scholar]

- Ausloos, M.; Berman, D.H. A multivariate Weierstrass–Mandelbrot function. In Proceedings of the Royal Society of London Series A, Mathematical and Physical Sciences; Royal Society: London, UK, 1985; Volume 400, pp. 331–350. [Google Scholar] [CrossRef]

- Zhu, D.; Wang, Q.J. Effect of Roughness Orientation on the Elastohydrodynamic Lubrication Film Thickness. J. Tribol. 2013, 135, 031501. [Google Scholar] [CrossRef]

- Wang, W.-Z.; Liu, Y.-C.; Wang, H.; Hu, Y.-Z. A Computer Thermal Model of Mixed Lubrication in Point Contacts. J. Tribol. 2004, 126, 162–170. [Google Scholar] [CrossRef]

- Hu, J.; Wang, M.; Zan, T. The kinematics of ball-screw mechanisms via the slide–roll ratio. Mech. Mach. Theory 2014, 79, 158–172. [Google Scholar] [CrossRef]

- Han, Y. Research on Identification and Control Compensation of Friction in Sero Feed System of CNC Machine Tool; Harbin Institute of Technology: Harbin, China, 2017. (In Chinese) [Google Scholar]

- Bair, S. Actual Eyring Models for Thixotropy and Shear-Thinning: Experimental Validation and Application to EHD. J. Tribol. 2004, 126, 728–732. [Google Scholar] [CrossRef]

- Wang, W.-Z.; Wang, S.; Shi, F.; Wang, Y.-C.; Chen, H.-B.; Wang, H.; Hu, Y.-Z. Simulations and Measurements of Sliding Friction between Rough Surfaces in Point Contacts: From EHL to Boundary Lubrication. J. Tribol. 2007, 129, 495–501. [Google Scholar] [CrossRef]

| Screw radius, r (mm) | 16 | Ball radius, rb (mm) | 2.9765 |

| Radius of the normal section on the screw raceway, rS (mm) | 3.215 | Radius of the normal section on the nut raceway, rN (mm) | 3.215 |

| Helix angle, α (°) | 5.68 | Pitch, L0 (mm) | 10 |

| Initial contact angle β0 (°) | 40.26 | Preload, Fpre (N) | 1500 |

| Screw speed, Ω’ (mm/s) | 83 | Number of working balls, nbb | 168 |

| Young’s modulus, E1 = E2 (GPa) | 200 | Density ρ0 (kg/m3) | 970 |

| Poisson’s ratio, υ1 = υ2 | 0.3 | Viscosity η0 (Pa·s) | 0.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, T.; Wang, M.; Gao, X.; Zhao, Y. Non-Hertzian Elastohydrodynamic Contact Stress Calculation of High-Speed Ball Screws. Appl. Sci. 2021, 11, 12081. https://doi.org/10.3390/app112412081

Sun T, Wang M, Gao X, Zhao Y. Non-Hertzian Elastohydrodynamic Contact Stress Calculation of High-Speed Ball Screws. Applied Sciences. 2021; 11(24):12081. https://doi.org/10.3390/app112412081

Chicago/Turabian StyleSun, Tiewei, Min Wang, Xiangsheng Gao, and Yingjie Zhao. 2021. "Non-Hertzian Elastohydrodynamic Contact Stress Calculation of High-Speed Ball Screws" Applied Sciences 11, no. 24: 12081. https://doi.org/10.3390/app112412081

APA StyleSun, T., Wang, M., Gao, X., & Zhao, Y. (2021). Non-Hertzian Elastohydrodynamic Contact Stress Calculation of High-Speed Ball Screws. Applied Sciences, 11(24), 12081. https://doi.org/10.3390/app112412081