Decontamination of Powdery Foods Using an Intense Pulsed Light (IPL) Device for Practical Application

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

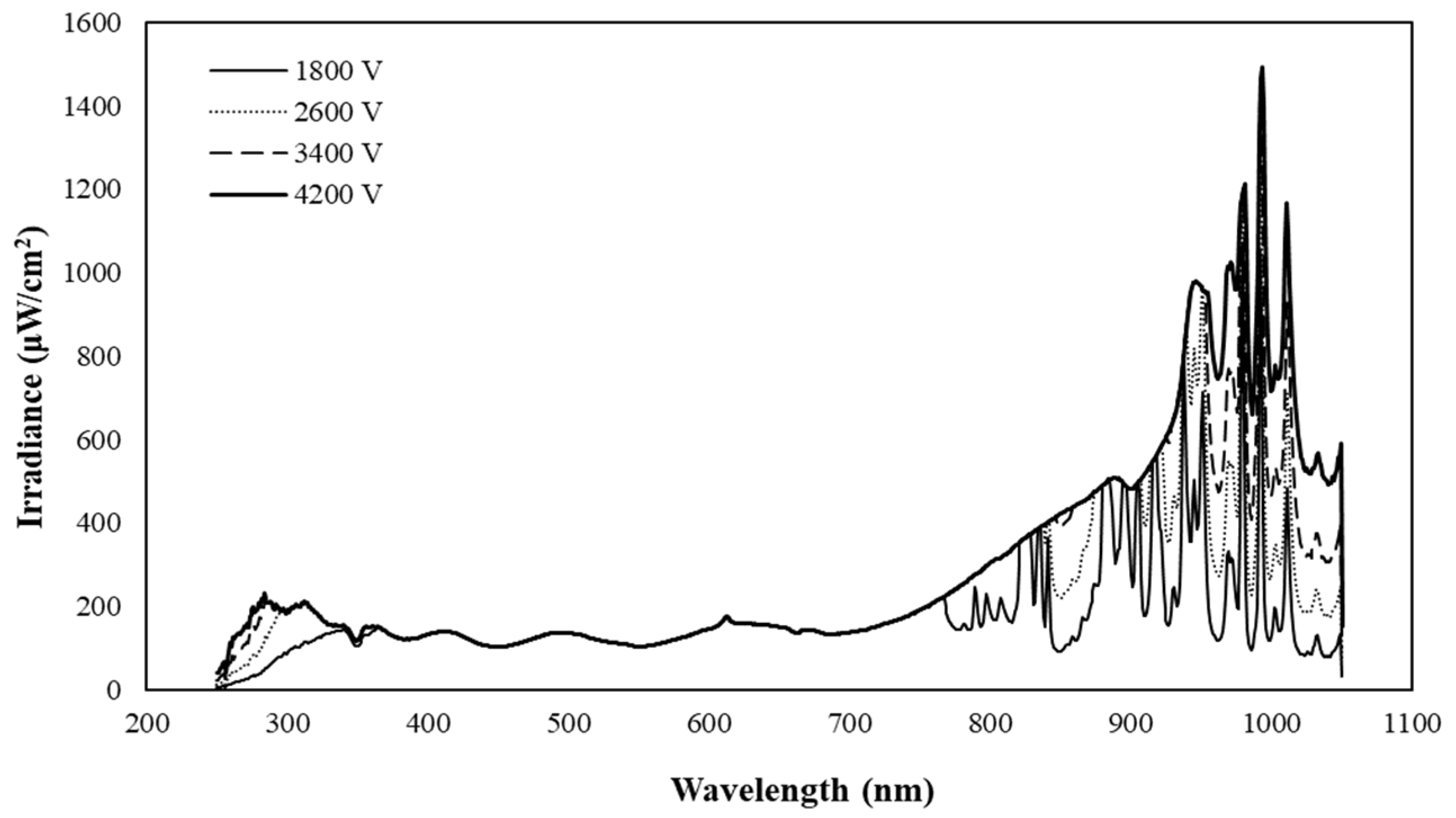

2.2. IPL Device

2.3. Treatment Conditions

2.4. Microorganism Counts

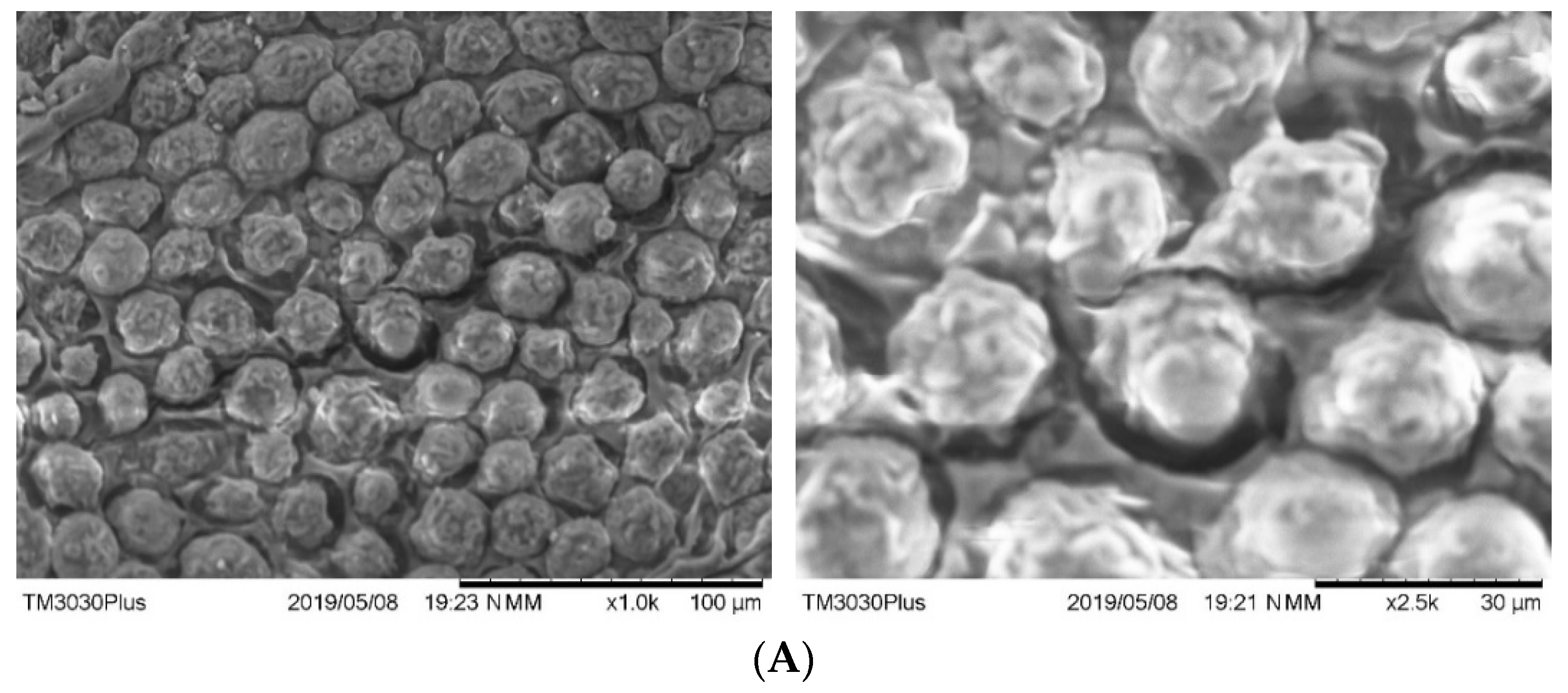

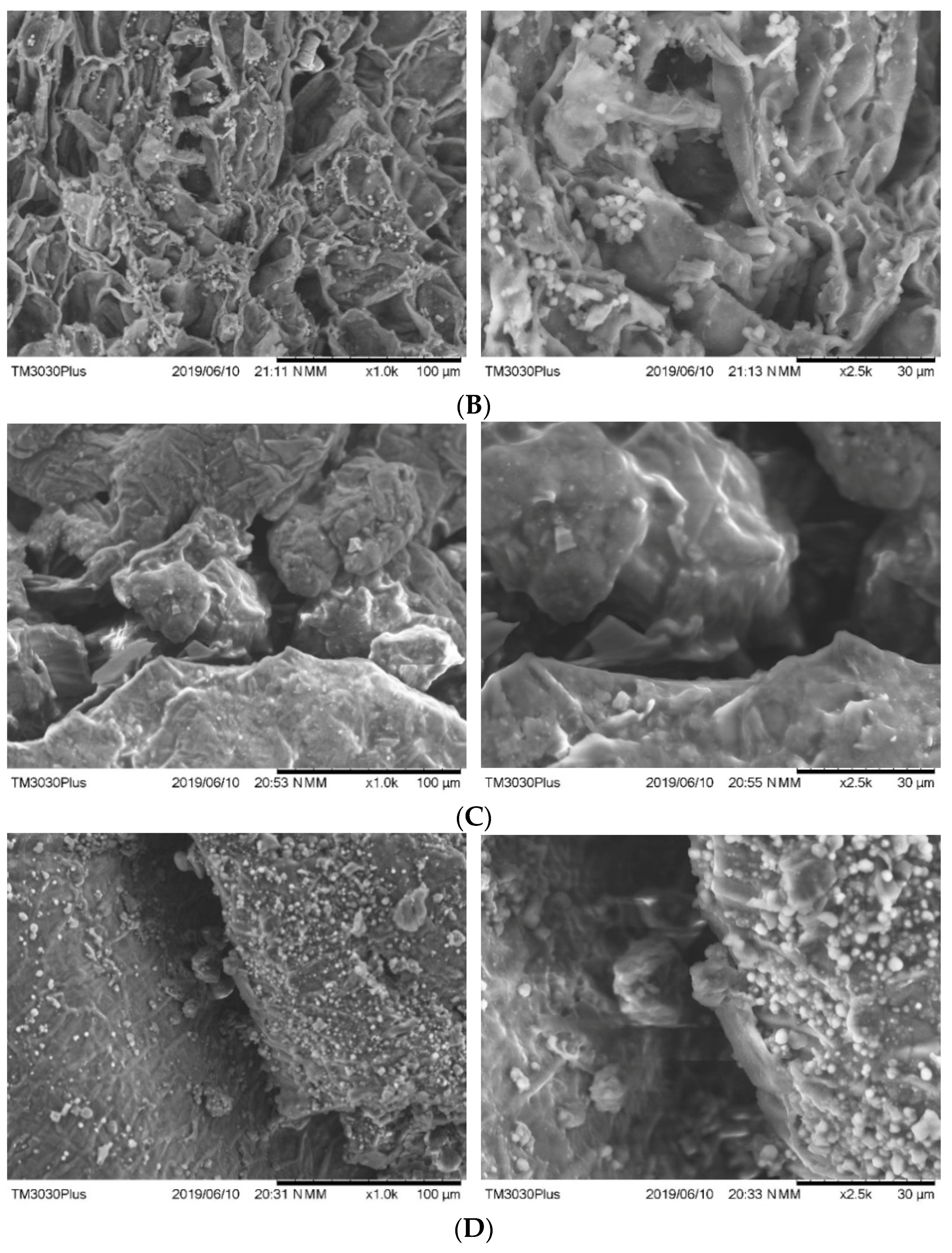

2.5. Scanning Electron Microscopy Measurements

2.6. Color Changes

2.7. Changes in Water Activity and Moisture Content

3. Results

3.1. Inactivation Effect of IPL Treatment on Seeds and Powdered Foods

3.2. Effects of Macroscopic Factors on Inactivation

3.3. Effects of Microscopic Factors on Inactivation

3.4. Measuring Changes in Physical Properties

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karsha, P.V.; Lakshmi, O.B. Antibacterial activity of black pepper (Piper nigrum Linn.) with special reference to its mode of action on bacteria. Indian J. Nat. Prod. Resour. 2010, 1, 213–215. [Google Scholar]

- Kim, S.T.; Wang, Y.; Kang, S.Y.; Kim, S.G.; Rakwal, R.; Kim, Y.C.; Kang, K.Y. Developing rice embryo proteomics reveals essential role for embryonic proteins in regulation of seed germination. J. Proteome Res. 2009, 8, 3598–3605. [Google Scholar] [CrossRef]

- [USFDA] Food and Drug Administration. Enforcement report. Recalls and Field Corrections: Foods–Class I; Recall Number F-535-1; USFDA: Silver Spring, MD, USA, 2001.

- Banerjee, M.; Sarkar, P.K. Microbiological quality of some retail spices in India. Food Res. Int. 2003, 36, 469–474. [Google Scholar] [CrossRef]

- Rendlen, M. Hygienic problems of phytogenic raw materials for food production with special emphasis to herbs and spices. Food Sci. Biotechnol. 2004, 13, 262–268. [Google Scholar]

- Oularbi, S.; Mansouri, B. Decontamination of black pepper and red pepper by gamma radiation. Radiat. Phys. Chem. 1996, 48, 386. [Google Scholar] [CrossRef]

- Fine, F.; Gervais, P. Efficiency of pulsed UV light for microbial decontamination of food powders. J. Food Prot. 2004, 67, 787–792. [Google Scholar] [CrossRef] [PubMed]

- Almela, L.; Nieto-Sandoval, J.M.; Fernández López, J.A. Microbial inactivation of paprika by a high-temperature short-X time treatment. Influence on color properties. J. Agric. Food. Chem. 2002, 50, 1435–1440. [Google Scholar] [CrossRef] [PubMed]

- Bhavya, M.L.; Umesh Hebbar, H. Pulsed light processing of foods for microbial safety. Food Qual. Saf. 2017, 1, 187–202. [Google Scholar] [CrossRef] [Green Version]

- Agüero, M.V.; Jagus, R.J.; Martín-Belloso, O.; Soliva-Fortuny, R. Surface decontamination of spinach by intense pulsed light treatments: Impact on quality attributes. Postharvest Biol. Technol. 2016, 121, 118–125. [Google Scholar] [CrossRef] [Green Version]

- Gómez-López, V.M.; Devlieghere, F.; Bonduelle, V.; Debevere, J. Factors affecting the inactivation of micro-organisms by intense light pulses. J. Appl. Microbiol. 2005, 99, 460–470. [Google Scholar] [CrossRef] [PubMed]

- Roberts, P.; Hope, A. Virus inactivation by high intensity broad spectrum pulsed light. J. Virol. Methods. 2003, 110, 61–65. [Google Scholar] [CrossRef]

- Wekhof, A. Disinfection with flash lamps. PDA J. Pharm. Sci. Technol. 2000, 54, 264–276. [Google Scholar]

- Cheon, H.L.; Shin, J.Y.; Park, K.H.; Chung, M.S.; Kang, D.H. Inactivation of foodborne pathogens in powdered red pepper (Capsicum annuum L.) using combined UV-C irradiation and mild heat treatment. Food Control 2015, 50, 441–445. [Google Scholar] [CrossRef]

- Fine, F.; Gervais, P. A new high temperature short time process for microbial decontamination of seeds and food powders. Powder Technol. 2005, 157, 108–113. [Google Scholar] [CrossRef]

- Hu, S.; Zhao, Y.; Hayouka, Z.; Wang, D.; Jiao, S. Inactivation kinetics for Salmonella typhimurium in red pepper powders treated by radio frequency heating. Food Control 2018, 85, 437–442. [Google Scholar] [CrossRef]

- Adhikari, A.; Syamaladevi, R.M.; Killinger, K.; Sablani, S.S. Ultraviolet-C light inactivation of Escherichia coli O157:H7 and Listeria monocytogenes on organic fruit surfaces. Int. J. Food Microbiol. 2015, 210, 136–142. [Google Scholar] [CrossRef] [PubMed]

- Ozer, N.P.; Demirci, A. Inactivation of Escherichia coli O157:H7 and Listeria monocytogenes inoculated on raw salmon fillets by pulsed UV-light treatment. Int. J. Food. Sci. Tech. 2006, 41, 354–360. [Google Scholar] [CrossRef]

- Jun, S.; Irudayaraj, J.; Demirci, A.; Geiser, D. Pulsed UV-light treatment of corn meal for inactivation of Aspergillus niger spores. Int. J. Food. Sci. Tech. 2003, 38, 883–888. [Google Scholar] [CrossRef]

- Woodling, S.E.; Moraru, C.I. Influence of surface topography on the effectiveness of pulsed light treatment for the inactivation of Listeria innocua on stainless-steel surfaces. J. Food Sci. 2005, 70, m345–m351. [Google Scholar] [CrossRef]

- Condón-Abanto, S.; Condón, S.; Raso, J.; Lyng, J.G.; Álvarez, I. Inactivation of Salmonella typhimurium and Lactobacillus plantarum by UV-C light in flour powder. Innov. Food Sci. Emerg. Technol. 2016, 35, 1–8. [Google Scholar] [CrossRef]

- Hong, H.J.; Kim, A.J.; Park, H.R.; Shin, J.K. Changes in physicochemical properties of paprika by intense pulsed light treatment. Korean J. Food Sci. Technol. 2013, 45, 339–344. [Google Scholar] [CrossRef] [Green Version]

- Esbelin, J.; Mallea, S.; Ram, A.F.; Carlin, F. Role of pigmentation in protecting Aspergillus niger conidiospores against pulsed light radiation. Photochem. Photobiol. 2013, 89, 758–761. [Google Scholar] [CrossRef] [PubMed]

- Proulx, J.; Hsu, L.C.; Miller, B.M.; Sullivan, G.; Paradis, K.; Moraru, C.I. Pulsed-light inactivation of pathogenic and spoilage bacteria on cheese surface. J. Dairy Sci. 2015, 98, 5890–5898. [Google Scholar] [CrossRef]

- Turtoi, M.; Nicolau, A. Intense light pulse treatment as alternative method for mould spores destruction on paper–polyethylene packaging material. J. Food Eng. 2007, 83, 47–53. [Google Scholar] [CrossRef]

- Driks, A. Maximum shields: The assembly and function of the bacterial spore coat. Trends Microbiol. 2002, 10, 251–254. [Google Scholar] [CrossRef]

- Melly, E.; Genest, P.; Gilmore, M.E.; Little, S.; Popham, D.L.; Driks, A.; Setlow, P. Analysis of the properties of spores of Bacillus subtilis prepared at different temperatures. J. Appl. Microbiol. 2002, 92, 1105–1115. [Google Scholar] [CrossRef]

- Artíguez, M.L.; de Marañón, I.M. Inactivation of spores and vegetative cells of Bacillus subtilis and Geobacillus stearothermophilus by pulsed light. Innov. Food Sci. Emerg. Technol. 2015, 28, 52–58. [Google Scholar] [CrossRef]

- Levy, C.; Aubert, X.; Lacour, B.; Carlin, F. Relevant factors affecting microbial surface decontamination by pulsed light. Int. J. Food Microbiol. 2012, 152, 168–174. [Google Scholar] [CrossRef] [PubMed]

- Nicorescu, I.; Nguyen, B.; Moreau-Ferret, M.; Agoulon, A.; Chevalier, S.; Orange, N. Pulsed light inactivation of Bacillus subtilis vegetative cells in suspensions and spices. Food Control 2013, 31, 151–157. [Google Scholar] [CrossRef]

- Elmnasser, N.; Guillou, S.; Leroi, F.; Orange, N.; Bakhrouf, A.; Federighi, M. Pulsed-light system as a novel food decontamination technology: A review. Can. J. Microbiol. 2007, 53, 813–821. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cserhalmi, Z.; Sass-Kiss, A.; Tóth-Markus, M.; Lechner, N. Study of pulsed electric field treated citrus juices. Innov. Food Sci. Emerg. Technol. 2006, 7, 49–54. [Google Scholar] [CrossRef]

- Hwang, H.J.; Cheigh, C.I.; Chung, M.S. Comparison of bactericidal effects of two types of pilot-scale intense-pulsed-light devices on cassia seeds and glutinous millet. Innov. Food Sci. Emerg. Technol. 2018, 49, 170–175. [Google Scholar] [CrossRef]

- Tomašević, I. The effect of intense light pulses on the sensory quality and instrumental color of meat from different animal breeds. Biotech. Anim. Husb. 2015, 31, 273–281. [Google Scholar] [CrossRef]

- Hierro, E.; Barroso, E.; De la Hoz, L.; Ordóñez, J.A.; Manzano, S.; Fernández, M. Efficacy of pulsed light for shelf-life extension and inactivation of Listeria monocytogenes on ready-to-eat cooked meat products. Innov. Food Sci. Emerg. Technol. 2011, 12, 275–281. [Google Scholar] [CrossRef]

| Control | After IPL Treatment | ΔE | |||||

|---|---|---|---|---|---|---|---|

| L | a | b | L | a | b | ||

| Sesame seeds | 57.78 ± 0.21 | 4.68 ± 0.06 | 17.3 ± 0.12 | 57.34 ± 0.21 | 4.03 ± 0.26 | 17.22 ± 0.30 | 0.79 |

| Ground black pepper | 41.00 ± 0.18 | 3.44 ± 0.08 | 14.14 ± 0.09 | 42.19 ± 0.62 | 3.03 ± 0.21 | 13.58 ± 0.49 | 1.38 |

| Ground red pepper | 28.54 ± 0.50 | 29.17 ± 0.11 | 23.04 ± 0.08 | 29.57 ± 0.52 | 28.61 ± 0.26 | 22.06 ± 0.04 | 1.53 |

| Embryo buds of rice | 63.52 ± 0.31 | 4.25 ± 0.09 | 23.95 ± 0.03 | 62.43 ± 0.18 | 4.21 ± 0.08 | 24.55 ± 0.402 | 1.26 |

| Water Content (%) | Water Activity | |||

|---|---|---|---|---|

| Control | Treated | Control | Treated | |

| Sesame seeds | 5.12 ± 0.21 a | 5.11 ± 0.10 a | 0.36 ± 0.01 a | 0.32 ± 0.01 a |

| Ground black pepper | 11.23 ± 0.19 a | 10.62 ± 0.30 a | 0.35 ± 0.05 a | 0.28 ± 0.05 ab |

| Ground red pepper | 13.34 ± 0.35 a | 12.82 ± 0.15 ab | 0.35 ± 0.00 a | 0.34 ± 0.01 ab |

| Embryo buds of rice | 8.34 ± 0.21 a | 8.03 ± 0.15 a | 0.35 ± 0.01 a | 0.34 ± 0.00 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, H.-J.; Yee, S.-Y.; Chung, M.-S. Decontamination of Powdery Foods Using an Intense Pulsed Light (IPL) Device for Practical Application. Appl. Sci. 2021, 11, 1518. https://doi.org/10.3390/app11041518

Hwang H-J, Yee S-Y, Chung M-S. Decontamination of Powdery Foods Using an Intense Pulsed Light (IPL) Device for Practical Application. Applied Sciences. 2021; 11(4):1518. https://doi.org/10.3390/app11041518

Chicago/Turabian StyleHwang, Hee-Jeong, So-Yoon Yee, and Myong-Soo Chung. 2021. "Decontamination of Powdery Foods Using an Intense Pulsed Light (IPL) Device for Practical Application" Applied Sciences 11, no. 4: 1518. https://doi.org/10.3390/app11041518