Effect of Cellulose Characteristics on the Properties of the Wet-Spun Aerogel Fibers

Abstract

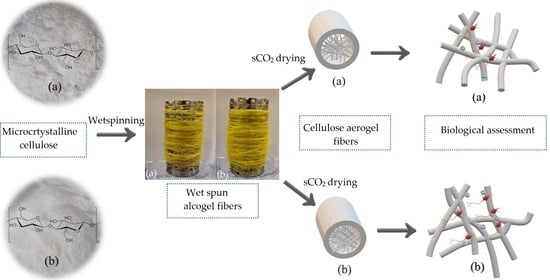

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Solution Preparation, Wet Spinning, and Washing

2.3. Supercritical CO2 Drying

2.4. Size Exclusion Chromatography (SEC)

2.5. Fourier Transforms Infrared Spectroscopy (FTIR)

2.6. X-ray Diffraction (XRD)

2.7. Thermal Stability Test

2.8. Imaging, Scanning Electron Microscope and X-ray Microtomography

2.9. N2 Adsorption-Desorption

2.10. Cytotoxicity Test

2.11. Statistical Analysis

3. Results

3.1. Properties of Microcrystalline Cellulose Powder and Fabricated Fibers

3.2. Fourier Transforms Infrared Spectroscopy (FTIR)

3.3. Wide-Angle X-ray Diffraction (WAXD)

3.4. Thermal Stability

3.5. Morphology and Textural Properties of the Aerogel Fibers

3.5.1. Imaging by Scanning Electron Microscope

3.5.2. X-ray Microtomography

3.5.3. N2 Adsorption-Desorption

3.6. Cytotoxicity

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Corrias, A.; Casula, M.; Aegerter, M.; Leventis, N.; Koebel, M.M. Aerogels containing metal, alloy and oxide nanoparticles in dielectric matrices. In Aerogel Handbook; Springer: New York, NY, USA, 2010. [Google Scholar]

- Montes, S.; Maleki, H. 12—Aerogels and their applications. In Colloidal Metal Oxide Nanoparticles; Thomas, S., Tresa Sunny, A., Velayudhan, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 337–399. [Google Scholar] [CrossRef]

- Budtova, T. Cellulose II aerogels: A review. Cellulose 2019, 26, 81–121. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Adnan, A.S.; Yahya, E.B.; Olaiya, N.G.; Safrida, S.; Hossain, M.S.; Balakrishnan, V.; Gopakumar, D.A.; Abdullah, C.K.; Oyekanmi, A.A.; et al. A Review on Plant Cellulose Nanofibre-Based Aerogels for Biomedical Applications. Polymers 2020, 12, 1759. [Google Scholar] [CrossRef] [PubMed]

- García-González, C.A.; Budtova, T.; Durães, L.; Erkey, C.; Del Gaudio, P.; Gurikov, P.; Koebel, M.; Liebner, F.; Neagu, M.; Smirnova, I. An Opinion Paper on Aerogels for Biomedical and Environmental Applications. Molecules 2019, 24, 1815. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, F. Starch based aerogels: Production, properties and applications. Trends Food Sci. Technol. 2019, 89, 1–10. [Google Scholar] [CrossRef]

- De Marco, I.; Reverchon, E. Starch aerogel loaded with poorly water-soluble vitamins through supercritical CO2 adsorption. Chem. Eng. Res. Des. 2017, 119, 221–230. [Google Scholar] [CrossRef]

- Long, L.-Y.; Weng, Y.-X.; Wang, Y.-Z. Cellulose Aerogels: Synthesis, Applications, and Prospects. Polymers 2018, 10, 623. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Jiang, H.; Xu, D.; Yang, Y. A facile method to prepare cellulose whiskers—Silica aerogel composites. J. Sol-Gel Sci. Technol. 2017, 83, 72–80. [Google Scholar] [CrossRef]

- Ribeiro, N.; Soares, G.C.; Santos-Rosales, V.; Concheiro, A.; Alvarez-Lorenzo, C.; García-González, C.A.; Oliveira, A.L. A new era for sterilization based on supercritical CO2 technology. J. Biomed. Mater. Res. Part B Appl. Biomater. 2020, 108, 399–428. [Google Scholar] [CrossRef]

- Champeau, M.; Thomassin, J.M.; Tassaing, T.; Jérôme, C. Drug loading of polymer implants by supercritical CO2 assisted impregnation: A review. J. Control. Release 2015, 209, 248–259. [Google Scholar] [CrossRef] [PubMed]

- Kistler, S.S. Coherent Expanded Aerogels and Jellies. Nature 1931, 127, 741. [Google Scholar] [CrossRef]

- Tewari, P.H.; Hunt, A.J.; Lofftus, K.D. Ambient-temperature supercritical drying of transparent silica aerogels. Mater. Lett. 1985, 3, 363–367. [Google Scholar] [CrossRef]

- van Bommel, M.J.; de Haan, A.B. Drying of silica gels with supercritical carbon dioxide. J. Mater. Sci. 1994, 29, 943–948. [Google Scholar] [CrossRef]

- Kikic, I.; Vecchione, F. Supercritical impregnation of polymers. Curr. Opin. Solid State Mater. Sci. 2003, 7, 399–405. [Google Scholar] [CrossRef]

- Vermerris, W.; Abril, A. Enhancing cellulose utilization for fuels and chemicals by genetic modification of plant cell wall architecture. Curr. Opin. Biotechnol. 2015, 32, 104–112. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Festucci-Buselli, R.A.; Otoni, W.C.; Joshi, C.P. Structure, organization, and functions of cellulose synthase complexes in higher plants. Braz. J. Plant Physiol. 2007, 19, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Chu, H.-Y.; Hong, J.-Y.; Huang, C.-F.; Wu, J.-Y.; Wang, T.-L.; Wu, T.-M.; Lee, R.-H. Enhanced photovoltaic properties of perovskite solar cells by the addition of cellulose derivatives to MAPbI3 based photoactive layer. Cellulose 2019, 26, 9229–9239. [Google Scholar] [CrossRef]

- Jyothibasu, J.P.; Kuo, D.-W.; Lee, R.-H. Flexible and freestanding electrodes based on polypyrrole/carbon nanotube/cellulose composites for supercapacitor application. Cellulose 2019, 26, 4495–4513. [Google Scholar] [CrossRef]

- Huang, X.; Liu, Y.; Deng, J.; Yi, B.; Yu, X.; Shen, P.; Tan, S. A novel polymer gel electrolyte based on cyanoethylated cellulose for dye-sensitized solar cells. Electrochim. Acta 2012, 80, 219–226. [Google Scholar] [CrossRef]

- Hoepfner, S.; Ratke, L. Open Porous Cellulose Aerogel Fibers; German Aerospace Center: Köln, Germany, 2008. [Google Scholar] [CrossRef]

- Hoepfner, S.; Ratke, L.; Milow, B. Synthesis and characterisation of nanofibrillar cellulose aerogels. Cellulose 2008, 15, 121–129. [Google Scholar] [CrossRef]

- Wu, Z.-Y.; Li, C.; Liang, H.-W.; Chen, J.-F.; Yu, S.-H. Ultralight, Flexible, and Fire-Resistant Carbon Nanofiber Aerogels from Bacterial Cellulose. Angew. Chem. Int. Ed. 2013, 52, 2925–2929. [Google Scholar] [CrossRef] [PubMed]

- Gavillon, R.; Budtova, T. Aerocellulose: New highly porous cellulose prepared from cellulose-NaOH aqueous solutions. Biomacromolecules 2008, 9, 269–277. [Google Scholar] [CrossRef] [PubMed]

- Sescousse, R.; Gavillon, R.; Budtova, T. Wet and dry highly porous cellulose beads from cellulose—NaOH—water solutions: Influence of the preparation conditions on beads shape and encapsulation of inorganic particles. J. Mater. Sci. 2011, 46, 759–765. [Google Scholar] [CrossRef]

- Mohamed, S.M.K.; Ganesan, K.; Milow, B.; Ratke, L. The effect of zinc oxide (ZnO) addition on the physical and morphological properties of cellulose aerogel beads. RSC Adv. 2015, 5, 90193–90201. [Google Scholar] [CrossRef]

- Fischer, S.; Leipner, H.; Thümmler, K.; Brendler, E.; Peters, J. Inorganic molten salts as solvents for cellulose. Cellulose 2003, 10, 227–236. [Google Scholar] [CrossRef]

- Jin, H.; Nishiyama, Y.; Wada, M.; Kuga, S. Nanofibrillar cellulose aerogels. Colloids Surf. A Physicochem. Eng. Asp. 2004, 240, 63–67. [Google Scholar] [CrossRef]

- Karadagli, I.; Schulz, B.; Schestakow, M.; Milow, B.; Gries, T.; Ratke, L. Production of porous cellulose aerogel fibers by an extrusion process. J. Supercrit. Fluids 2015, 106, 105–114. [Google Scholar] [CrossRef]

- Schulz, B.; Meinert, T.; Bierbüsse, D.; Busen, M.; Körtzinger, N.; Stankowski, M.; Seide, G. Cellulose Aerogel Fibers Tested on a REXUS 18 Rocket—The ACTOR Project. Chem. Ing. Tech. 2016, 88, 1501–1507. [Google Scholar] [CrossRef]

- Mroszczok, J.; Schulz, B.; Wilsch, K.; Frenzer, G.; Kasper, S.; Seide, G. Cellulose Aerogel Fibres for Thermal Encapsulation of Diesel Hybrid Engines for Fuel Savings in Cars. Mater. Today Proc. 2017, 4, S244–S248. [Google Scholar] [CrossRef]

- Valo, H.; Arola, S.; Laaksonen, P.; Torkkeli, M.; Peltonen, L.; Linder, M.B.; Serimaa, R.; Kuga, S.; Hirvonen, J.; Laaksonen, T. Drug release from nanoparticles embedded in four different nanofibrillar cellulose aerogels. Eur. J. Pharm. Sci. 2013, 50, 69–77. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Zhang, L.; Xu, Z.; Dai, H.; Wu, W. Nanocellulose/Gelatin Composite Cryogels for Controlled Drug Release. ACS Sustain. Chem. Eng. 2019, 7, 6381–6389. [Google Scholar] [CrossRef]

- Cai, H.; Sharma, S.; Liu, W.; Mu, W.; Liu, W.; Zhang, X.; Deng, Y. Aerogel Microspheres from Natural Cellulose Nanofibrils and Their Application as Cell Culture Scaffold. Biomacromolecules 2014, 15, 2540–2547. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Zhai, T.; Turng, L.-S. Aerogel microspheres based on cellulose nanofibrils as potential cell culture scaffolds. Cellulose 2017, 24, 2791–2799. [Google Scholar] [CrossRef]

- Matsuyama, K.; Morotomi, K.; Inoue, S.; Nakashima, M.; Nakashima, H.; Okuyama, T.; Kato, T.; Muto, H.; Sugiyama, H. Antibacterial and antifungal properties of Ag nanoparticle-loaded cellulose nanofiber aerogels prepared by supercritical CO2 drying. J. Supercrit. Fluids 2019, 143, 1–7. [Google Scholar] [CrossRef]

- Wang, X.; Cheng, F.; Liu, J.; Smått, J.-H.; Gepperth, D.; Lastusaari, M.; Xu, C.; Hupa, L. Biocomposites of copper-containing mesoporous bioactive glass and nanofibrillated cellulose: Biocompatibility and angiogenic promotion in chronic wound healing application. Acta Biomater. 2016, 46, 286–298. [Google Scholar] [CrossRef]

- Hattori, M.; Koga, T.; Shimaya, Y.; Saito, M. Aqueous Calcium Thiocyanate Solution as a Cellulose Solvent. Structure and Interactions with Cellulose. Polym. J. 1998, 30, 43. [Google Scholar] [CrossRef] [Green Version]

- Sjöholm, E. Size exclusion chromatography of cellulose and cellulose derivatives. In Handbook of Size Exclusion Chromatography and Related Techniques; CRC Press: Boca Raton, FL, USA, 2004; Volume 91, pp. 311–354. [Google Scholar]

- Poletto, M.; Pistor, V.; Zattera, A.J. Structural characteristics and thermal properties of native cellulose. Cellul. Fundam. Asp. 2013, 2, 45–68. [Google Scholar]

- Nelson, M.L.; O’Connor, R.T. Relation of certain infrared bands to cellulose crystallinity and crystal latticed type. Part I. Spectra of lattice types I, II, III and of amorphous cellulose. J. Appl. Polym. Sci. 1964, 8, 1311–1324. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Lang, Y.; Yu, M. Structural ATR-IR analysis of cellulose fibers prepared from a NaOH complex aqueous solution. IOP Conf. Ser. Mater. Sci. Eng. 2017, 213, 012039. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.; Shen, X. Solubility of bacteria cellulose in zinc chloride aqueous solutions. Carbohydr. Polym. 2011, 86, 239–244. [Google Scholar] [CrossRef]

- Driemeier, C.; Bragatto, J. Crystallite Width Determines Monolayer Hydration across a Wide Spectrum of Celluloses Isolated from Plants. J. Phys. Chem. B 2013, 117, 415–421. [Google Scholar] [CrossRef]

- Ye, S.; He, S.; Su, C.; Jiang, L.; Wen, Y.; Zhu, Z.; Shao, W. Morphological, Release and Antibacterial Performances of Amoxicillin-Loaded Cellulose Aerogels. Molecules 2018, 23, 2082. [Google Scholar] [CrossRef] [Green Version]

- Zhao, T.; Chen, Z.; Lin, X.; Ren, Z.; Li, B.; Zhang, Y. Preparation and characterization of microcrystalline cellulose (MCC) from tea waste. Carbohydr. Polym. 2018, 184, 164–170. [Google Scholar] [CrossRef] [PubMed]

- Reichenauer, G. Structural Characterization of Aerogels. In Aerogels Handbook; Aegerter, M.A., Leventis, N., Koebel, M.M., Eds.; Springer: New York, NY, USA, 2011; pp. 449–498. [Google Scholar] [CrossRef]

- Smirnova, I.; Gurikov, P. Aerogels in Chemical Engineering: Strategies toward Tailor-Made Aerogels. Annu. Rev. Chem. Biomol. Eng. 2017, 8, 307–334. [Google Scholar] [CrossRef]

- Phillips, G.O.; Williams, P.A. Handbook of Hydrocolloids; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- García-González, C.A.; Alnaief, M.; Smirnova, I. Polysaccharide-based aerogels—Promising biodegradable carriers for drug delivery systems. Carbohydr. Polym. 2011, 86, 1425–1438. [Google Scholar] [CrossRef]

- Bertini, I.; Sabatini, A. Infrared Spectra of Substituted Thiocyanate Complexes. The Effect of the Substituent on Bond Type. II. Inorg. Chem. 1966, 5, 1025–1028. [Google Scholar] [CrossRef]

- Chen, W.; Yu, H.; Li, Q.; Liu, Y.; Li, J. Ultralight and highly flexible aerogels with long cellulose I nanofibers. Soft Matter 2011, 7, 10360–10368. [Google Scholar] [CrossRef]

- Maleki, H.; Durães, L.; García-González, C.A.; del Gaudio, P.; Portugal, A.; Mahmoudi, M. Synthesis and biomedical applications of aerogels: Possibilities and challenges. Adv. Colloid Interface Sci. 2016, 236, 1–27. [Google Scholar] [CrossRef] [PubMed]

- Schestakow, M.; Karadagli, I.; Ratke, L. Cellulose aerogels prepared from an aqueous zinc chloride salt hydrate melt. Carbohydr. Polym. 2016, 137, 642–649. [Google Scholar] [CrossRef] [PubMed]

- Kampschulte, M.; Langheinirch, A.C.; Sender, J.; Litzlbauer, H.D.; Althöhn, U.; Schwab, J.D.; Alejandre-Lafont, E.; Martels, G.; Krombach, G.A. Nano-Computed Tomography: Technique and Applications. Rofo 2016, 188, 146–154. [Google Scholar] [CrossRef] [Green Version]

- Coenen, A.M.J.; Bernaerts, K.V.; Harings, J.A.W.; Jockenhoevel, S.; Ghazanfari, S. Elastic materials for tissue engineering applications: Natural, synthetic, and hybrid polymers. Acta Biomater. 2018, 79, 60–82. [Google Scholar] [CrossRef]

- Ozdemir, E.; Sendemir-Urkmez, A.; Yesil-Celiktas, O. Supercritical CO2 processing of a chitosan-based scaffold: Can implantation of osteoblastic cells be enhanced? J. Supercrit. Fluids 2013, 75, 120–127. [Google Scholar] [CrossRef]

- Lindman, B.; Karlström, G.; Stigsson, L. On the mechanism of dissolution of cellulose. J. Mol. Liq. 2010, 156, 76–81. [Google Scholar] [CrossRef]

- Jiang, F.; Hsieh, Y.-L. Dual Wet and Dry Resilient Cellulose II Fibrous Aerogel for Hydrocarbon–Water Separation and Energy Storage Applications. ACS Omega 2018, 3, 3530–3539. [Google Scholar] [CrossRef] [Green Version]

- Cervin, N.T.; Johansson, E.; Larsson, P.A.; Wågberg, L. Strong, Water-Durable, and Wet-Resilient Cellulose Nanofibril-Stabilized Foams from Oven Drying. ACS Appl. Mater. Interfaces 2016, 8, 11682–11689. [Google Scholar] [CrossRef] [PubMed]

| Sample | Mn (g·mol−1) | Mw (g·mol−1) | Mz (g·mol−1) | PDI |

|---|---|---|---|---|

| Cc | 61,760 | 163,500 | 404,220 | 2.647 |

| Cs | 78,700 | 565,630 | 1,942,200 | 7.187 |

| Sample | Average Pore Size (nm) | Minimum Size (nm) | Maximum Size (nm) |

|---|---|---|---|

| Fc | 3.398 ± 6.346 | 2.142 | 1546.107 |

| Fs | 3.657 ± 9.165 | 2.139 | 2116.107 |

| Sample | Total Porosity (%) | Closed Porosity (%) | Open Porosity (%) |

|---|---|---|---|

| Fc | 77.323 ± 2.331 | 0.00052 | 77.32263 |

| Fs | 71.649 ± 3.121 | 0.00575 | 71.64738 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rostamitabar, M.; Seide, G.; Jockenhoevel, S.; Ghazanfari, S. Effect of Cellulose Characteristics on the Properties of the Wet-Spun Aerogel Fibers. Appl. Sci. 2021, 11, 1525. https://doi.org/10.3390/app11041525

Rostamitabar M, Seide G, Jockenhoevel S, Ghazanfari S. Effect of Cellulose Characteristics on the Properties of the Wet-Spun Aerogel Fibers. Applied Sciences. 2021; 11(4):1525. https://doi.org/10.3390/app11041525

Chicago/Turabian StyleRostamitabar, Matin, Gunnar Seide, Stefan Jockenhoevel, and Samaneh Ghazanfari. 2021. "Effect of Cellulose Characteristics on the Properties of the Wet-Spun Aerogel Fibers" Applied Sciences 11, no. 4: 1525. https://doi.org/10.3390/app11041525