Characterization of Superplastic Deformation Behavior for a Novel Al-Mg-Fe-Ni-Zr-Sc Alloy: Arrhenius-Based Modeling and Artificial Neural Network Approach

Abstract

1. Introduction

2. Materials and Methods

- -

- Ei, and Pi are the experimental and modeled flow stress,

- -

- and are the mean values of the experimental and modeled flow stress, and

- -

- N is the sample size.

3. Results and Discussion

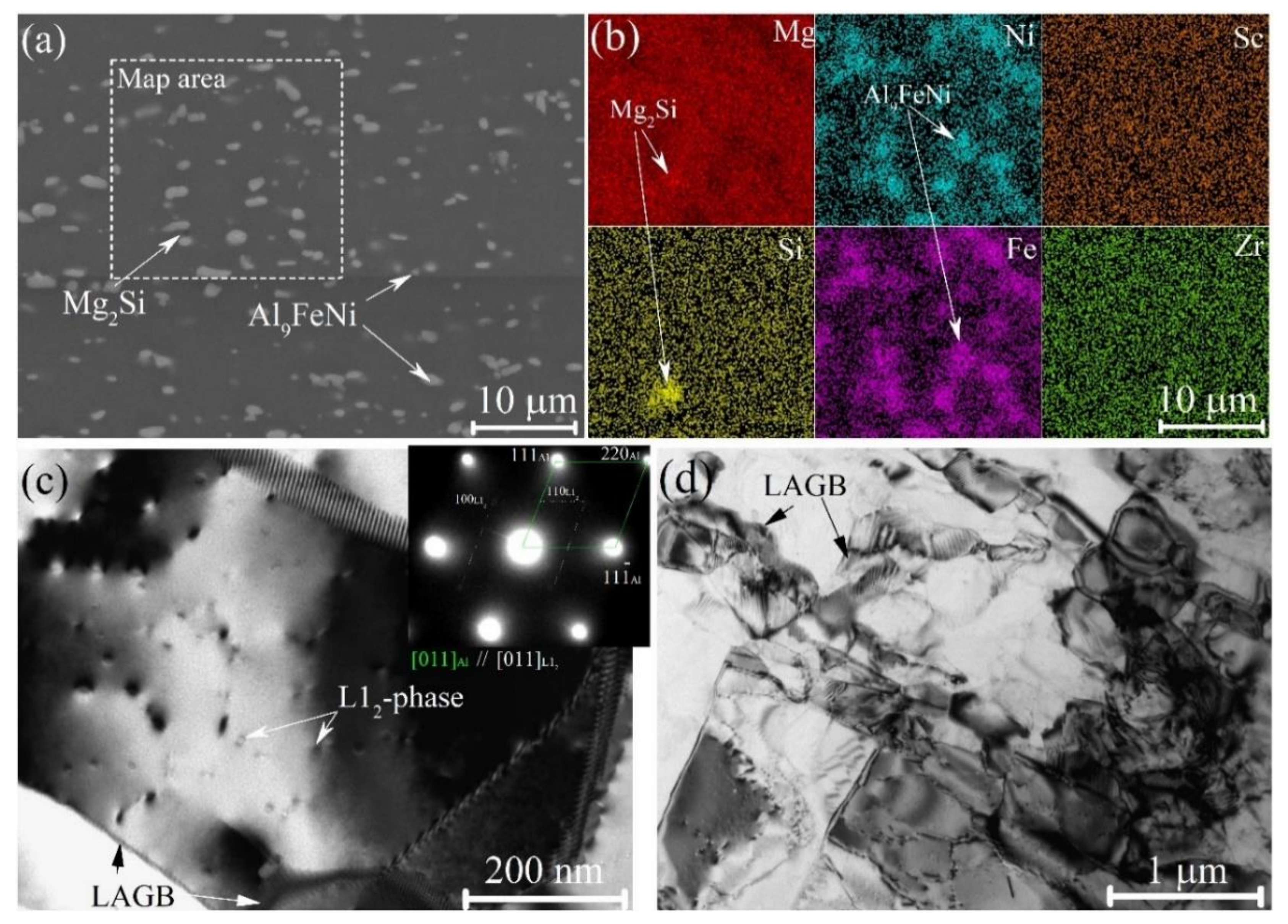

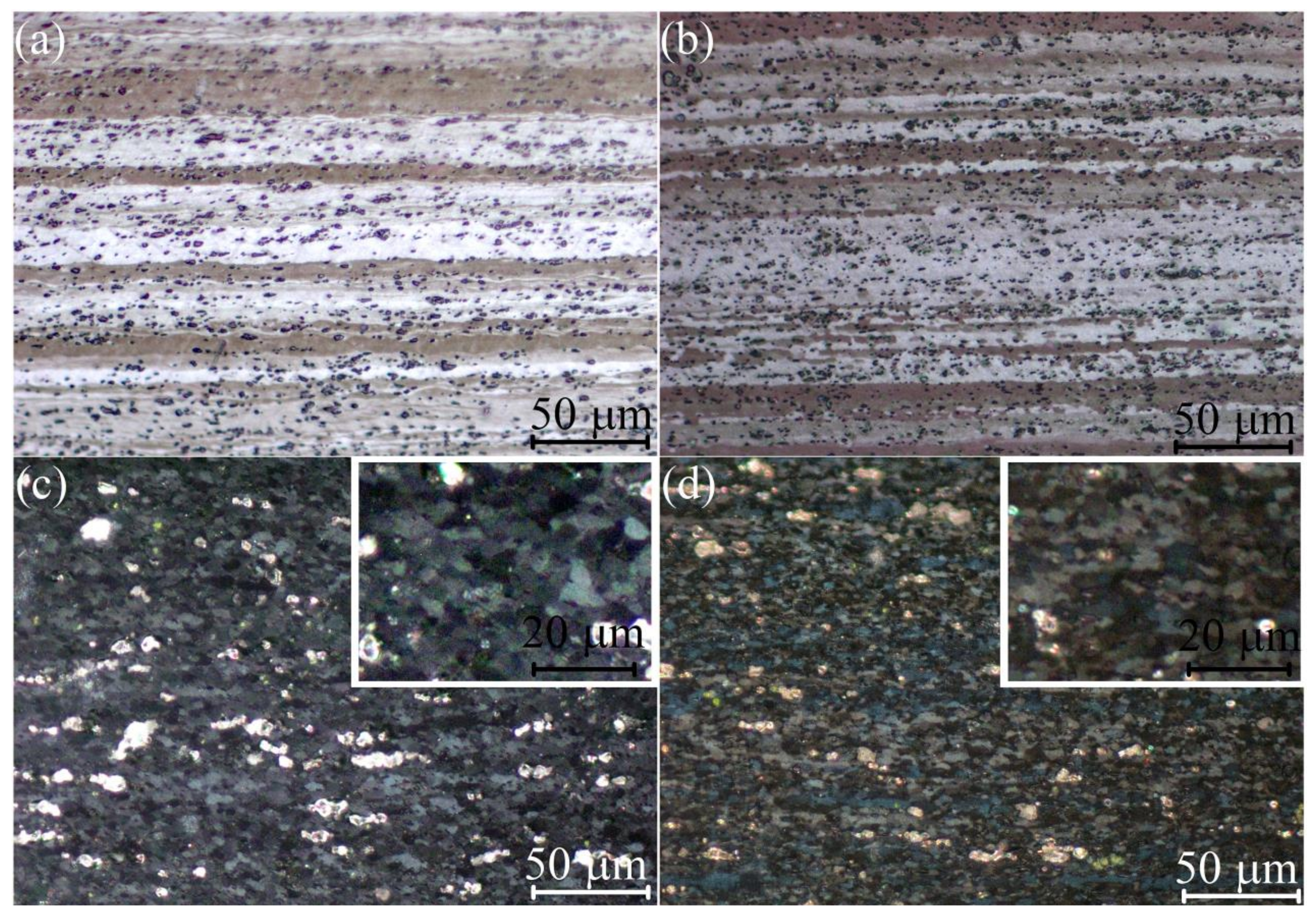

3.1. Microstructural Parameters of the Alloy Studied

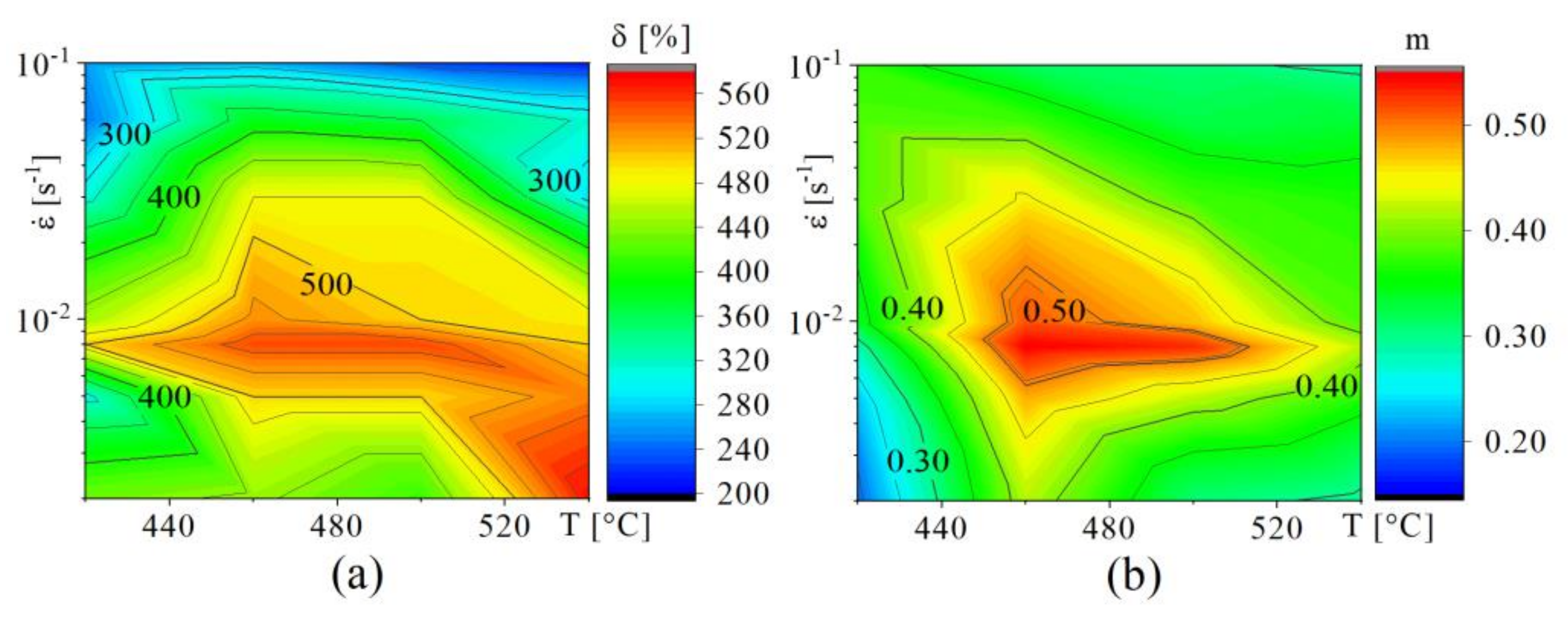

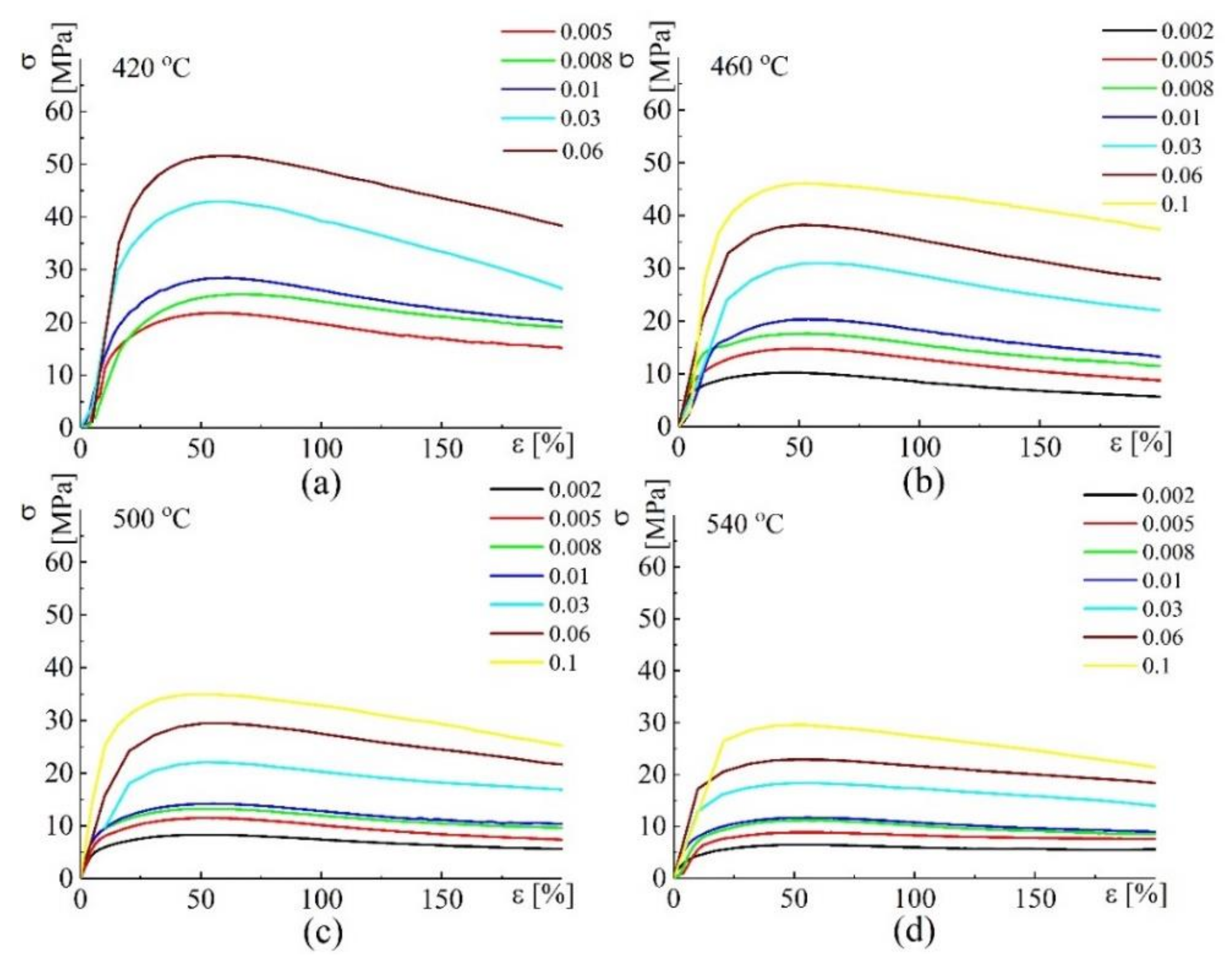

3.2. Tensile Test Results

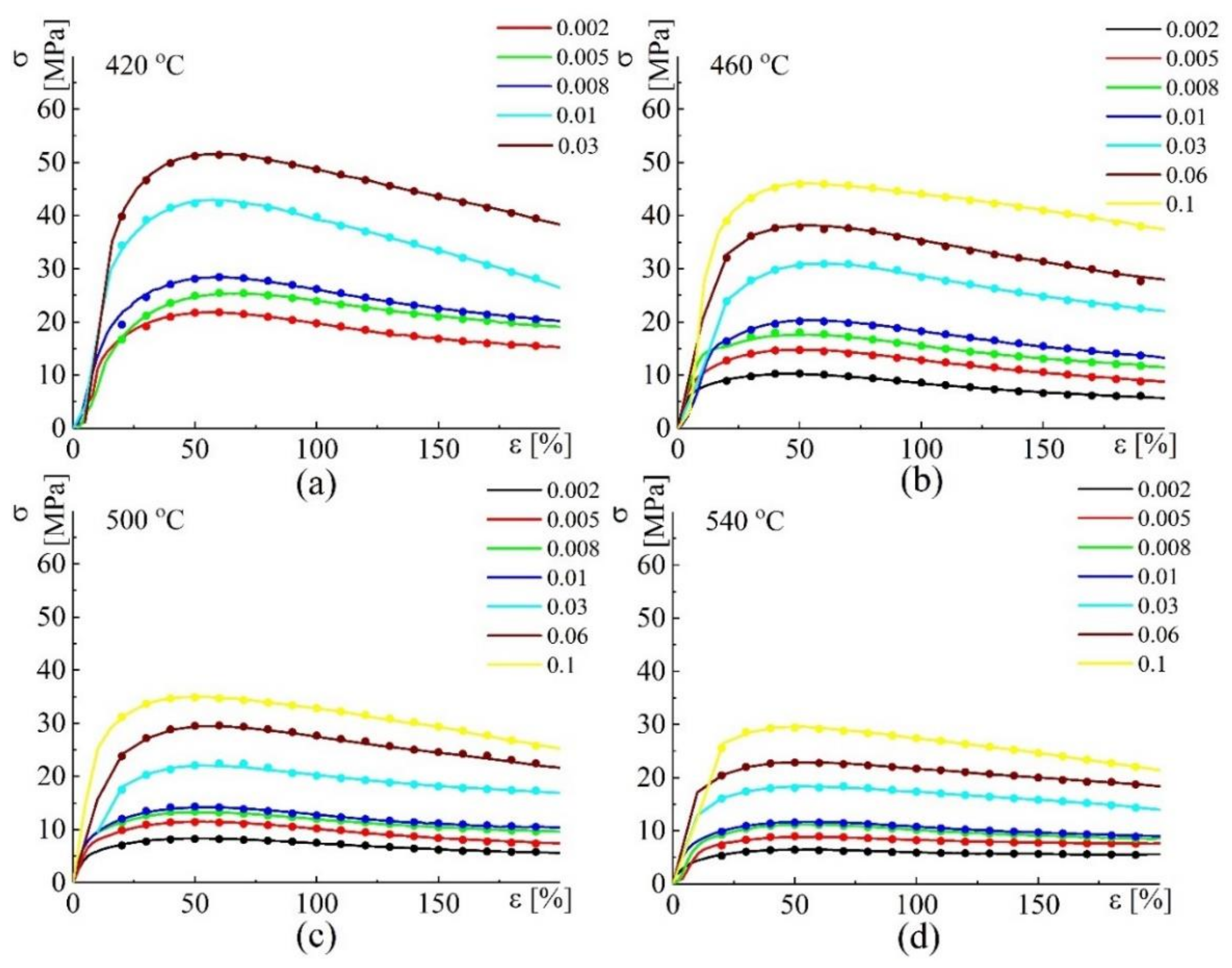

3.3. Flow Stress Behavior Modeling Experiments

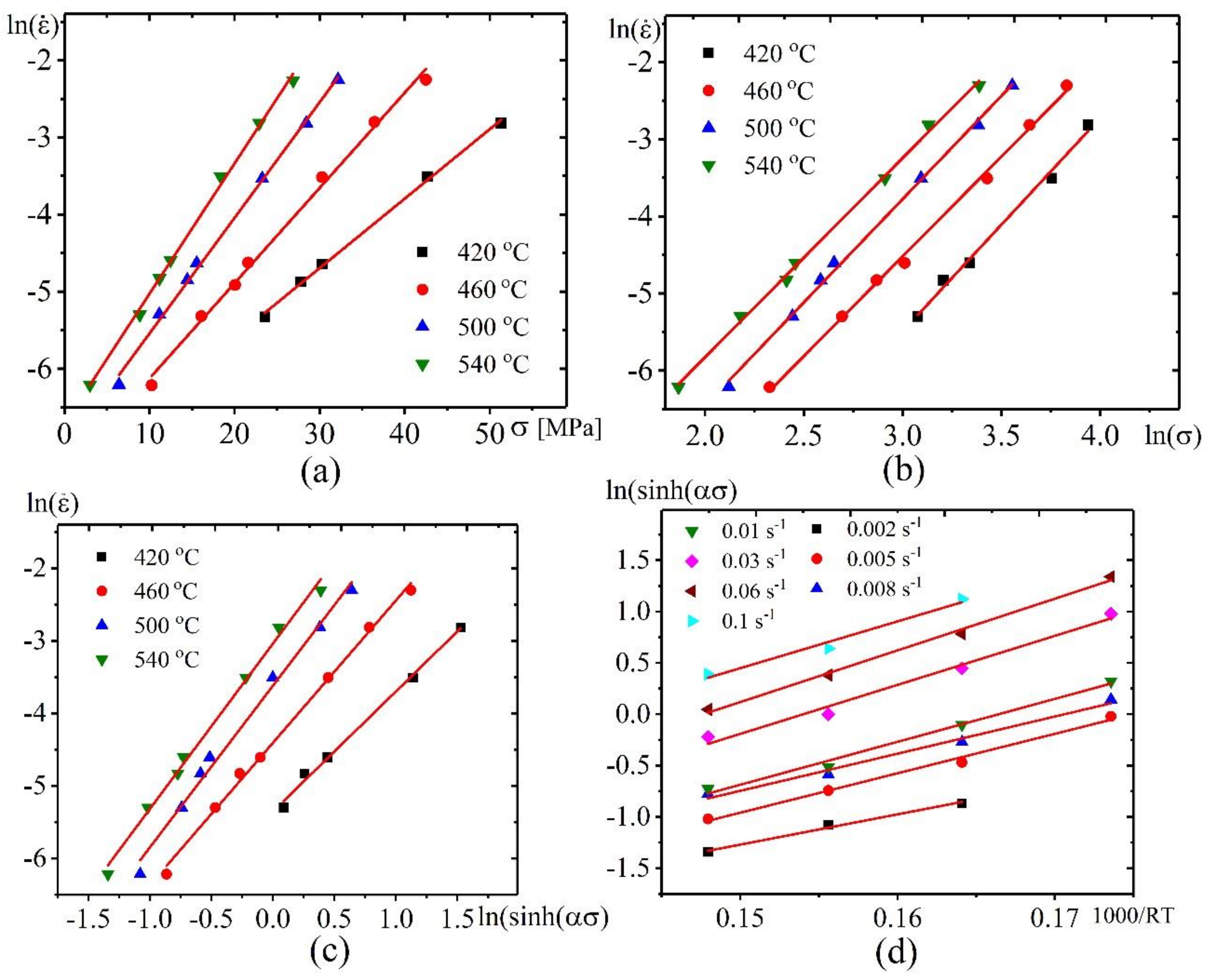

3.3.1. ACE Model

Constants Determination

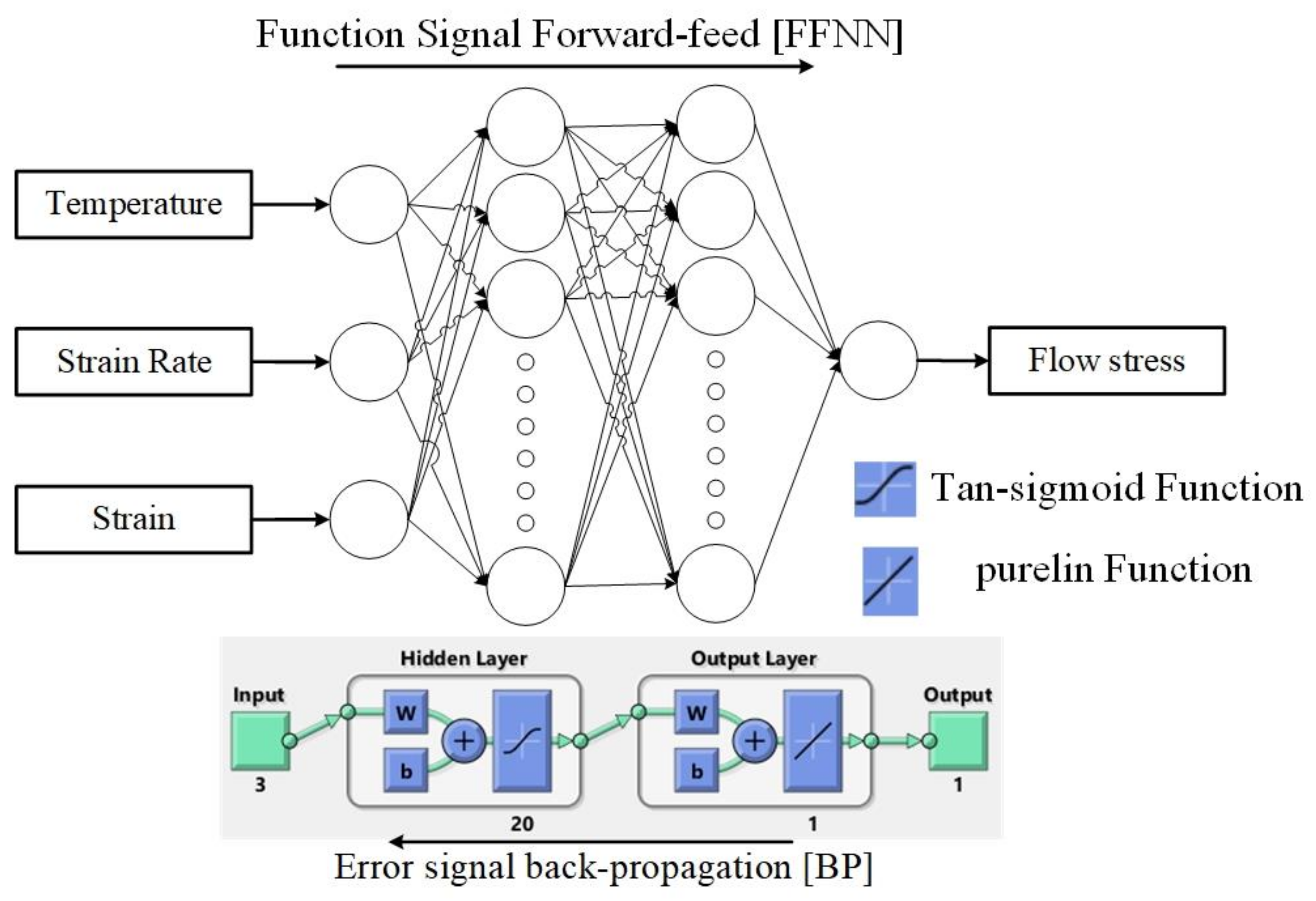

3.3.2. ANN Model

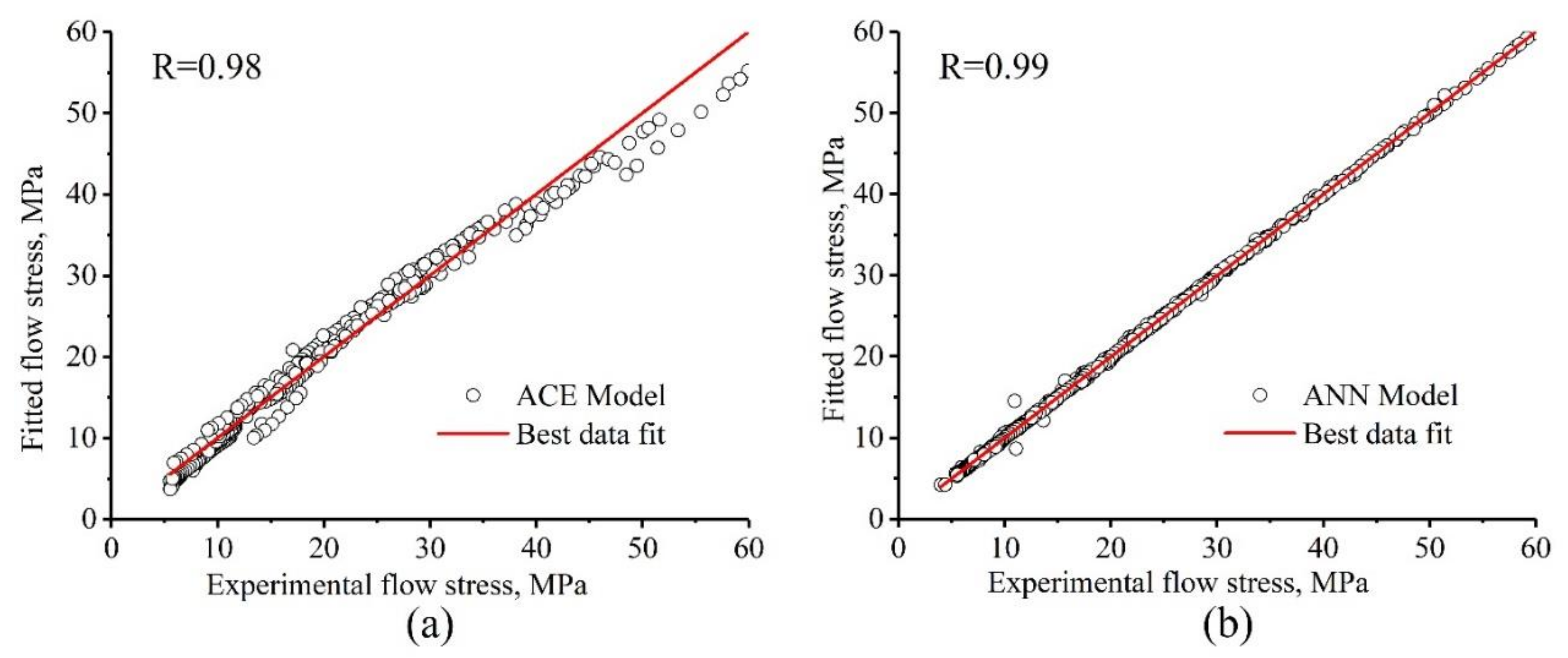

3.3.3. Verification of the Proposed Models

3.3.4. Models Cross-validation

4. Conclusions

- A

- The alloy studied containing coarse Al9FeNi particles of crystallization origin and fine L12-structured Al3Zr dispersoids exhibited a non-recrystallized grain structure before the start of the superplastic deformation. Due to dynamic recrystallization, a fine-grained structure was formed during deformation, which provided high-strain-rate superplasticity with elongation-to-failure above 500%. A higher strain rate provided a finer grain size for the alloy.

- B

- The effective activation energy of the superplastic deformation suggested that the alloy deformation was controlled by the grain boundary self-diffusion of aluminum. The strain-rate-sensitivity coefficient m values suggested that the grain boundary sliding mechanism was predominant and its contribution increased with increasing strain in the studied strain range.

- C

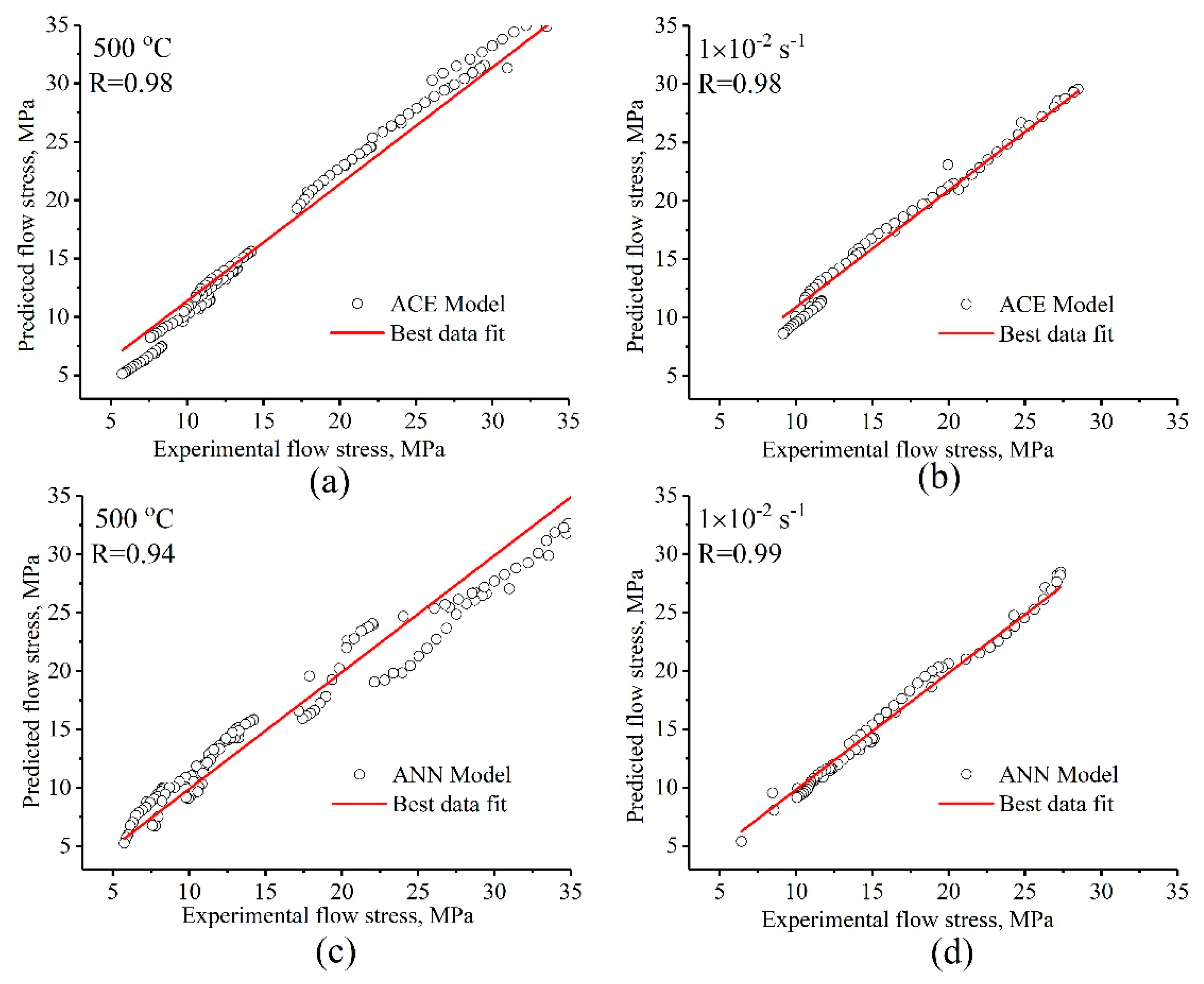

- The Arrhenius-based model and the three-layer artificial neural network were developed. The hidden layer of the used artificial neural network contained 20 neutrons that exhibited a minimum error level. In fitting and approximating the hot deformation behavior of the investigated alloy, the two constructed models demonstrated good performance. For the unmodeled deformation conditions, the cross-validation approach verified good predictability of the established models. However, relative to the artificial neural network model, the Arrhenius-based model demonstrated better predictability with a lower error level.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, W.; Gao, Y.; Feng, Z.; Wang, X.; Zhang, S.; Huang, L.; Huang, Z.; Jiang, L. Ductility limit diagrams for superplasticity and forging of high temperature polycrystalline materials. Acta Mater. 2020, 194, 378–386. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities and issues in the application of titanium alloys for aerospace components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Aksenov, S.; Sorgente, D. Determination of biaxial stress–strain curves for superplastic materials by means of bulge forming tests at constant stress. CIRP J. Manuf. Sci. Technol. 2020, 31, 618–627. [Google Scholar] [CrossRef]

- Aksenov, S.; Mikolaenko, V. The effect of material properties on the accuracy of superplastic tensile test. Metals 2020, 10, 1353. [Google Scholar] [CrossRef]

- Jarrar, F.; Sorgente, D.; Aksenov, S.A.; Enikeev, F. On the Challenges and Prospects of the Superplastic Forming Process. Mater. Sci. Forum 2019, 941, 2343–2348. [Google Scholar] [CrossRef]

- Grimes, R. 11—Superplastic forming of aluminium alloys. In Superplastic Forming of Advanced Metallic Materials; Woodhead Publishing Series in Metals and Surface Engineering; Giuliano, G., Ed.; Woodhead Publishing: Cambridge, UK, 2011; pp. 247–271. ISBN 9781845697532. Available online: https://www.sciencedirect.com/science/article/pii/B978184569753250011X (accessed on 6 July 2020). [CrossRef]

- XING, H.; Wang, C.; Zhang, K.; Wang, Z. Recent development in the mechanics of superplasticity and its applications. J. Mater. Process. Technol. 2004, 151, 196–202. [Google Scholar] [CrossRef]

- Hirsch, J. Aluminium in innovative light-weight car design. Mater. Trans. 2011, 52, 818–824. [Google Scholar] [CrossRef]

- Fereshteh-Saniee, F.; Fakhar, N.; Mahmudi, R. Influence of Combined Severe Plastic Deformation and Sheet Extrusion Process on the Superplastic Formability of AA 5083 Aluminum Alloy Assessed by Free Bulge Test. J. Mater. Eng. Perform. 2019, 28, 6682–6691. [Google Scholar] [CrossRef]

- Dunwoody, B.J. The Production of Automotive Body Panels in 5083 SPF Aluminium Alloy. Mater. Sci. Forum 2001, 357–359, 59–64. [Google Scholar] [CrossRef]

- Hefti, L.D. Commercial Airplane Applications of Superplastically Formed AA5083 Aluminum Sheet. J. Mater. Eng. Perform. 2007, 16, 136–141. [Google Scholar] [CrossRef]

- Wang, X.G.; Li, Q.S.; Wu, R.R.; Zhang, X.Y.; Ma, L. A Review on Superplastic Formation Behavior of Al Alloys. Adv. Mater. Sci. Eng. 2018, 2018. [Google Scholar] [CrossRef]

- Sorgente, D.; Tricarico, L. Characterization of a superplastic aluminium alloy ALNOVI-U through free inflation tests and inverse analysis. Int. J. Mater. Form. 2014, 7, 179–187. [Google Scholar] [CrossRef]

- Kudo, T.; Goto, A.; Saito, K. High Strain Rate Blow Formability of Newly Developed Al-Mg-High-Mn Alloy. Mater. Sci. Forum 2013, 735, 271–277. [Google Scholar] [CrossRef]

- Cleveland, R.M.; Ghosh, A.K.; Bradley, J.R. Comparison of superplastic behavior in two 5083 aluminum alloys. Mater. Sci. Eng. A 2003, 351, 228–236. [Google Scholar] [CrossRef]

- Kishchik, A.A.; Mikhaylovskaya, A.V.; Kotov, A.D.; Rofman, O.V.; Portnoy, V.K. Al-Mg-Fe-Ni based alloy for high strain rate superplastic forming. Mater. Sci. Eng. A 2018, 718, 190–197. [Google Scholar] [CrossRef]

- Yakovtseva, O.A.; Sitkina, M.N.; Kotov, A.D.; Rofman, O.V.; Mikhaylovskaya, A.V. Experimental study of the superplastic deformation mechanisms of high-strength aluminum-based alloy. Mater. Sci. Eng. A 2020, 788, 139639. [Google Scholar] [CrossRef]

- Bian, Z.; Liu, Y.; Dai, S.; Chen, Z.; Wang, M.; Chen, D.; Wang, H. Regulating microstructures and mechanical properties of Al–Fe–Ni alloys. Prog. Nat. Sci. Mater. Int. 2020, 30, 54–62. [Google Scholar] [CrossRef]

- Shirinkina, I.G.; Brodova, I.G. Annealing-Induced Structural–Phase Transformations in an Al–Zn–Mg–Fe–Ni Alloy after High Pressure Torsion. Phys. Met. Metallogr. 2020, 121, 344–351. [Google Scholar] [CrossRef]

- Belov, N.A. Sparingly alloyed high-strength aluminum alloys: Principles of optimization of phase composition. Met. Sci. Heat Treat. 2012, 53, 420–427. [Google Scholar] [CrossRef]

- Yakovtseva, O.A.; Kotov, A.D.; Sitkina, M.N.; Irzhak, A.V.; Mikhaylovskaya, A.V. Mechanisms of Superplastic High-Rate Deformation in the Al–Mg–Zn–Fe–Ni–Zr–Sc Alloy. Phys. Met. Metallogr. 2019, 120, 1014–1020. [Google Scholar] [CrossRef]

- Kotov, A.D.; Mikhaylovskaya, A.V.; Borisov, A.A.; Yakovtseva, O.A.; Portnoy, V.K. High-strain-rate superplasticity of the Al–Zn–Mg–Cu alloys with Fe and Ni additions. Phys. Met. Metallogr. 2017, 118, 913–921. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Yakovtseva, O.A.; Cheverikin, V.V.; Kotov, A.D.; Portnoy, V.K. Superplastic behaviour of Al-Mg-Zn-Zr-Sc-based alloys at high strain rates. Mater. Sci. Eng. A 2016, 659, 225–233. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Kishchik, A.A.; Kotov, A.D.; Rofman, O.V.; Tabachkova, N.Y. Precipitation behavior and high strain rate superplasticity in a novel fine-grained aluminum based alloy. Mater. Sci. Eng. A 2019, 760, 37–46. [Google Scholar] [CrossRef]

- Churyumov, A.Y.; Mikhaylovskaya, A.V.; Bazlov, A.I.; Tsarkov, A.A.; Kotov, A.D.; Aksenov, S.A. Influence of Al3Ni crystallisation origin particles on hot deformation behaviour of aluminium based alloys. Philos. Mag. 2017, 97, 572–590. [Google Scholar] [CrossRef]

- Rollett, A.; Humphreys, F.; Rohrer, G.S.; Hatherly, M. Recrystallization and Related Annealing Phenomena: Second Edition, 1st ed.; Pergamon: London, UK, 2004; ISBN 9780080441641. [Google Scholar] [CrossRef]

- Nes, E.; Wert, J.A. Modeling of recrystallization in alloys with a bimodal particle size distribution. Scr. Metall. 1984, 18, 1433–1438. [Google Scholar] [CrossRef]

- Humphreys, F.J. The nucleation of recrystallization at second phase particles in deformed aluminium. Acta Metall. 1977, 25, 1323–1344. [Google Scholar] [CrossRef]

- Bate, P.S.; Humphreys, F.J.; Ridley, N.; Zhang, B. Microstructure and texture evolution in the tension of superplastic Al-6Cu-0.4Zr. Acta Mater. 2005, 53, 3059–3069. [Google Scholar] [CrossRef]

- Bate, P. The effect of deformation on grain growth in Zener pinned systems. Acta Mater. 2001, 49, 1453–1461. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, G.; Yang, Z.; Xu, G. Microstructure characteristics and mechanical properties of new aerospace Al-Mg-Mn alloys with Al3(Sc1−xZrx) or Al3(Er1−xZrx) nanoparticles. Mater. Charact. 2019, 153, 79–91. [Google Scholar] [CrossRef]

- Miyake, Y.; Sato, Y.; Teranishi, R.; Kaneko, K. Effect of heat treatments on the microstructure and formability of Al–Mg–Mn–Sc–Zr alloy. Micron 2017, 101, 151–155. [Google Scholar] [CrossRef] [PubMed]

- Maeng, D.Y.; Lee, J.H.; Hong, S.I. The effect of transition elements on the superplastic behavior of Al–Mg alloys. Mater. Sci. Eng. A 2003, 357, 188–195. [Google Scholar] [CrossRef]

- PENG, Y.; YIN, Z.; NIE, B.; ZHONG, L. Effect of minor Sc and Zr on superplasticity of Al-Mg-Mn alloys. Trans. Nonferrous Met. Soc. China 2007, 17, 744–750. [Google Scholar] [CrossRef]

- Chuvil’deev, V.N.; Shadrina, I.S.; Nokhrin, A.V.; Kopylov, V.I.; Bobrov, A.A.; Gryaznov, M.Y.; Shotin, S.V.; Tabachkova, N.Y.; Chegurov, M.K.; Melekhin, N.V. An investigation of thermal stability of structure and mechanical properties of Al-0.5Mg–Sc ultrafine-grained aluminum alloys. J. Alloys Compd. 2020, 831, 154805. [Google Scholar] [CrossRef]

- Sitdikov, O.; Garipova, R.; Avtokratova, E.; Mukhametdinova, O.; Markushev, M. Effect of temperature of isothermal multidirectional forging on microstructure development in the Al-Mg alloy with nano-size aluminides of Sc and Zr. J. Alloys Compd. 2018, 746, 520–531. [Google Scholar] [CrossRef]

- Sitdikov, O.S.; Avtokratova, E.V.; Mukhametdinova, O.E.; Garipova, R.N.; Markushev, M.V. Effect of the Size of Al3(Sc,Zr) Precipitates on the Structure of Multi-Directionally Isothermally Forged Al-Mg-Sc-Zr Alloy. Phys. Met. Metallogr. 2017, 118, 1215–1224. [Google Scholar] [CrossRef]

- Michi, R.A.; Toinin, J.P.; Seidman, D.N.; Dunand, D.C. Ambient- and elevated-temperature strengthening by Al3Zr-Nanoprecipitates and Al3Ni-Microfibers in a cast Al-2.9Ni-0.11Zr-0.02Si-0.005Er (at.%) alloy. Mater. Sci. Eng. A 2019, 759, 78–89. [Google Scholar] [CrossRef]

- Mochugovskiy, A.G.; Mikhaylovskaya, A.V.; Zadorognyy, M.Y.; Golovin, I.S. Effect of heat treatment on the grain size control, superplasticity, internal friction, and mechanical properties of zirconium-bearing aluminum-based alloy. J. Alloys Compd. 2021, 856, 157455. [Google Scholar] [CrossRef]

- Nokhrin, A.; Shadrina, I.; Chuvil’deev, V.; Kopylov, V. Study of Structure and Mechanical Properties of Fine-Grained Aluminum Alloys Al-0.6wt.%Mg-Zr-Sc with Ratio Zr:Sc = 1.5 Obtained by Cold Drawing. Materials 2019, 12, 316. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Mishra, R.S.; Mahoney, M.W.; Grimes, R. High strain rate superplasticity in friction stir processed Al–Mg–Zr alloy. Mater. Sci. Eng. A 2003, 351, 148–153. [Google Scholar] [CrossRef]

- Mochugovskiy, A.G.; Mikhaylovskaya, A.V.; Tabachkova, N.Y.; Portnoy, V.K. The mechanism of L12 phase precipitation, microstructure and tensile properties of Al-Mg-Er-Zr alloy. Mater. Sci. Eng. A 2019, 744, 195–205. [Google Scholar] [CrossRef]

- Kishchik, A.A.; Kotov, A.D.; Mikhaylovskaya, A.V. The Microstructure and High-Strain-Rate Superplasticity of the Al–Mg–Ni–Fe–Mn–Cr–Zr Alloy. Phys. Met. Metallogr. 2019, 120, 1006–1013. [Google Scholar] [CrossRef]

- Zang, Q.; Yu, H.; Lee, Y.S.; Kim, M.S.; Kim, H.W. Hot deformation behavior and microstructure evolution of annealed Al-7.9Zn-2.7Mg-2.0Cu (wt%) alloy. J. Alloys Compd. 2018, 763, 25–33. [Google Scholar] [CrossRef]

- Ren, X.; Jia, L.; Zhang, K. Stress-strain relation during superplastic uniaxial tension at constant tension velocity. Eng. Res. Express 2019, 1, 015035. [Google Scholar] [CrossRef]

- Shen, J.; Hu, L.; Sun, Y.; Wan, Z.; Feng, X.; Ning, Y. A Comparative Study on Artificial Neural Network, Phenomenological-Based Constitutive and Modified Fields–Backofen Models to Predict Flow Stress in Ti-4Al-3V-2Mo-2Fe Alloy. J. Mater. Eng. Perform. 2019, 28, 4302–4315. [Google Scholar] [CrossRef]

- REZAEI ASHTIANI, H.R.; SHAHSAVARI, P. Constitutive modeling of flow behavior of precipitation-hardened AA7022-T6 aluminum alloy at elevated temperature. Trans. Nonferrous Met. Soc. China Engl. Ed. 2020, 30, 2927–2940. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, G.; Yu, J.; Zhang, W. Constitutive analysis of homogenized 7005 aluminum alloy at evaluated temperature for extrusion process. Mater. Des. 2015, 66, 129–136. [Google Scholar] [CrossRef]

- Dong, Y.; Zhang, C.; Zhao, G.; Guan, Y.; Gao, A.; Sun, W. Constitutive equation and processing maps of an Al-Mg-Si aluminum alloy: Determination and application in simulating extrusion process of complex profiles. Mater. Des. 2016, 92, 983–997. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, G.; Xu, X.; Chen, X.; Zhang, C. Constitutive modeling, processing map establishment and microstructure analysis of spray deposited Al-Cu-Li alloy 2195. J. Alloys Compd. 2019, 779, 735–751. [Google Scholar] [CrossRef]

- Feng, D.; Zhang, X.M.; Liu, S.D.; Deng, Y.L. Constitutive equation and hot deformation behavior of homogenized Al-7.68Zn-2.12Mg-1.98Cu-0.12Zr alloy during compression at elevated temperature. Mater. Sci. Eng. A 2014, 608, 63–72. [Google Scholar] [CrossRef]

- Rasaee, S.; Mirzaei, A.H.; Almasi, D. Constitutive modelling of Al7075 using the Johnson–Cook model. Bull. Mater. Sci. 2020, 43, 1–8. [Google Scholar] [CrossRef]

- Mimaroglu, A.; Yenihayat, O.F. Modelling the superplastic deformation process of 2024 aluminium alloys under constant strain rate: Use of finite element technique. Mater. Des. 2003, 24, 189–195. [Google Scholar] [CrossRef]

- Cao, F.R.; Zhou, B.J.; Bin, Y.I.N.; Xue, G.Q.; Zhu, X.T.; Xu, G.M. Modeling of deformation energy at elevated temperatures and its application in Mg–Li–Al–Y alloy. Trans. Nonferrous Met. Soc. China Engl. Ed. 2017, 27, 2434–2442. [Google Scholar] [CrossRef]

- Yakovtseva, O.; Sitkina, M.; Mosleh, A.O.; Mikhaylovskaya, A. High strain rate superplasticity in Al-Zn-Mg-based alloy: Microstructural design, deformation behavior, and modeling. Materials 2020, 13, 2098. [Google Scholar] [CrossRef]

- Li, J.; Li, F.; Cai, J.; Wang, R.; Yuan, Z.; Xue, F. Flow behavior modeling of the 7050 aluminum alloy at elevated temperatures considering the compensation of strain. Mater. Des. 2012, 42, 369–377. [Google Scholar] [CrossRef]

- Mondolfo, L.F. Aluminum Alloys Structure and Properties; Elsevier Ltd.: Amsterdam, The Netherlands, 1976; ISBN 978-0-408-70932-3. [Google Scholar]

- Belov, N.A.; Eskin, D.G.; Aksenov, A.A. Multicomponent Phase Diagrams, Chapter 7—Alloys with Nickel; Elsevier: Amsterdam, The Netherlands, 2005; pp. 223–256. ISBN 9780080445373. Available online: https://www.sciencedirect.com/science/article/pii/B978008044537350007X (accessed on 6 July 2020). [CrossRef]

- Mochugovskiy, A.G.; Mikhaylovskaya, A.V. Comparison of precipitation kinetics and mechanical properties in Zr and Sc-bearing aluminum-based alloys. Mater. Lett. 2020, 275, 128096. [Google Scholar] [CrossRef]

- Fuller, C.B.; Murray, J.L.; Seidman, D.N. Temporal evolution of the nanostructure of Al(Sc,Zr) alloys: Part i—Chemical compositions of Al3(Sc1-xZrx) precipitates. Acta Mater. 2005, 53, 5401–5413. [Google Scholar] [CrossRef]

- Belov, N.A.; Alabin, A.N.; Eskin, D.G.; Istomin-Kastrovskii, V.V. Optimization of hardening of Al-Zr-Sc cast alloys. J. Mater. Sci. 2006, 41, 5890–5899. [Google Scholar] [CrossRef]

- Barkov, R.Y.; Mikhaylovskaya, A.V.; Yakovtseva, O.A.; Loginova, I.S.; Prosviryakov, A.S.; Pozdniakov, A.V. Effects of thermomechanical treatment on the microstructure, precipitation strengthening, internal friction, and thermal stability of Al–Er-Yb-Sc alloys with good electrical conductivity. J. Alloys Compd. 2021, 855, 157367. [Google Scholar] [CrossRef]

- Lefebvre, W.; Danoix, F.; Hallem, H.; Forbord, B.; Bostel, A.; Marthinsen, K. Precipitation kinetic of Al3(Sc,Zr) dispersoids in aluminium. J. Alloys Compd. 2009, 470, 107–110. [Google Scholar] [CrossRef]

- Nieh, T.G.; Wadsworth, J.; Sherby, O.D. Superplasticity in Metals and Ceramics; Cambridge University Press: Cambridge, UK, 1997; ISBN 9780521561051. [Google Scholar]

- Langdon, T.G. Seventy-five years of superplasticity: Historic developments and new opportunities. J. Mater. Sci. 2009, 44, 5998–6010. [Google Scholar] [CrossRef]

- Bhatta, L.; Pesin, A.; Zhilyaev, A.P.; Tandon, P.; Kong, C.; Yu, H. Recent development of superplasticity in aluminum alloys: A review. Metals 2020, 10, 77. [Google Scholar] [CrossRef]

- Sellars, C.M.; McTegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of strain rate upon plastic flow of steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Mosleh, A.O.; Mikhaylovskaya, A.V.; Kotov, A.D.; Portnoy, V.K. Arrhenius-Type Constitutive Equation Model of Superplastic Deformation Behaviour of Different Titanium Based Alloys. In Defect and Diffusion Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2018. [Google Scholar]

- Ruano, O.A.; Sherby, O.D. On constitutive equations for various diffusion-controlled creep mechanisms. Rev. Phys. Appliquée 1988, 23, 625–637. [Google Scholar] [CrossRef]

- Kawasaki, M.; Balasubramanian, N.; Langdon, T.G. Flow mechanisms in ultrafine-grained metals with an emphasis on superplasticity. Mater. Sci. Eng. A 2011, 528, 6624–6629. [Google Scholar] [CrossRef]

- Mosleh, A.; Mikhaylovskaya, A.; Kotov, A.; Pourcelot, T.; Aksenov, S.; Kwame, J.; Portnoy, V. Modelling of the Superplastic Deformation of the Near-α Titanium Alloy (Ti-2.5Al-1.8Mn) Using Arrhenius-Type Constitutive Model and Artificial Neural Network. Metals 2017, 7, 568. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Mosleh, A.O.; Kotov, A.D.; Kwame, J.S.; Pourcelot, T.; Golovin, I.S.; Portnoy, V.K. Superplastic deformation behaviour and microstructure evolution of near-α Ti-Al-Mn alloy. Mater. Sci. Eng. A 2017, 708, 469–477. [Google Scholar] [CrossRef]

- Dai, Q.S.; Deng, Y.L.; Tang, J.G.; Wang, Y. Deformation characteristics and strain-compensated constitutive equation for AA5083 aluminum alloy under hot compression. Trans. Nonferrous Met. Soc. China Engl. Ed. 2019, 29, 2252–2261. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Roostaei, M.; Parsa, M.H.; Mahmudi, R. Rate controlling mechanisms during hot deformation of Mg-3Gd-1Zn magnesium alloy: Dislocation glide and climb, dynamic recrystallization, and mechanical twinning. Mater. Des. 2015, 68, 228–231. [Google Scholar] [CrossRef]

- Kotov, A.D.; Mikhailovskaya, A.V.; Mosleh, A.O.; Pourcelot, T.P.; Prosviryakov, A.S.; Portnoi, V.K. Superplasticity of an Ultrafine-Grained Ti–4% Al–1% V–3% Mo Alloy. Phys. Met. Metallogr. 2019, 120, 60–68. [Google Scholar] [CrossRef]

- Kotov, A.D.; Mikhaylovskaya, A.V.; Kishchik, M.S.; Tsarkov, A.A.; Aksenov, S.A.; Portnoy, V.K. Superplasticity of high-strength Al-based alloys produced by thermomechanical treatment. J. Alloys Compd. 2016, 688, 336–344. [Google Scholar] [CrossRef]

- Duan, Y.L.; Tang, L.; Deng, Y.; Cao, X.W.; Xu, G.F.; Yin, Z.M. Superplastic behavior and microstructure evolution of a new Al-Mg-Sc-Zr alloy subjected to a simple thermomechanical processing. Mater. Sci. Eng. A 2016, 669, 205–217. [Google Scholar] [CrossRef]

- Kotov, A.D.; Mikhaylovskaya, A.V.; Portnoy, V.K. Effect of the solid-solution composition on the superplasticity characteristics of Al-Zn-Mg-Cu-Ni-Zr Alloys. Phys. Met. Metallogr. 2014, 115, 730–735. [Google Scholar] [CrossRef]

- Yan, J.; Pan, Q.L.; Li, A.D.; Song, W.B. Flow behavior of Al–6.2Zn–0.70Mg–0.30Mn–0.17Zr alloy during hot compressive deformation based on Arrhenius and ANN models. Trans. Nonferrous Met. Soc. China Engl. Ed. 2017, 27, 638–647. [Google Scholar] [CrossRef]

- Haghdadi, N.; Zarei-Hanzaki, A.; Khalesian, A.R.; Abedi, H.R. Artificial neural network modeling to predict the hot deformation behavior of an A356 aluminum alloy. Mater. Des. 2013, 49, 386–391. [Google Scholar] [CrossRef]

| A1,2,3, α (α = β/n1), β, n1, n2 | the material constants that vary with the strain |

| Q1,2,3 | the activation energy of the deformation, J/mol |

| T | the absolute temperature, K |

| R | the universal gas constant, 8.314 J/(mol.K) |

| ln(A1) | n1/m * | Q1 [KJ/mol] | ln(A2) | β [MPa−1] | Q2 [kJ/mol] | α | ln(A3) | n2 | Q3 [kJ/mol] |

|---|---|---|---|---|---|---|---|---|---|

| 1.6 | 2.6/0.4 | 86 ± 5 | 6.1 | 0.11 | 80 ± 5 | 0.04 | 9.4 | 1.99 | 86 ± 5 |

| α | ||||

|---|---|---|---|---|

| a | 0.07 | 52.5 | 4.33 | 2.69 |

| b | −0.001 | 1.62 | 0.26 | 6.91 × 10−4 |

| c | 2.42 × 10−5 | −0.02 | −0.004 | 4.30 × 10−5 |

| d | −1.99 × 10−7 | 1.59 × 10−4 | 2.61 × 10−5 | −1.26 × 10−6 |

| e | 7.94 × 10−10 | −4.88 × 10−7 | −8.22 × 10−8 | 8.49 × 10−9 |

| f | −1.22 × 10−12 | 5.75 × 10−10 | 1.00 × 10−10 | −1.74 × 10−11 |

| R2 | 0.997 | 0.999 | 0.998 | 0.997 |

| R | RMSE | AARE (%) | |

|---|---|---|---|

| ACE | 0.98 | 1.42 | 6.54% |

| ANN | 0.99 | 0.27 | 0.91% |

| R | RMSE | AARE (%) | ||||

|---|---|---|---|---|---|---|

| 500 °C | 1 × 10−2 s−1 | 500 °C | 1 × 10−2 s−1 | 500 °C | 1 × 10−2 s−1 | |

| ACE | 0.98 | 0.98 | 1.92 | 1.2 | 9.5% | 7% |

| ANN | 0.94 | 0.99 | 1.87 | 0.7 | 10.5% | 5% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mosleh, A.O.; Kotov, A.D.; Kishchik, A.A.; Rofman, O.V.; Mikhaylovskaya, A.V. Characterization of Superplastic Deformation Behavior for a Novel Al-Mg-Fe-Ni-Zr-Sc Alloy: Arrhenius-Based Modeling and Artificial Neural Network Approach. Appl. Sci. 2021, 11, 2208. https://doi.org/10.3390/app11052208

Mosleh AO, Kotov AD, Kishchik AA, Rofman OV, Mikhaylovskaya AV. Characterization of Superplastic Deformation Behavior for a Novel Al-Mg-Fe-Ni-Zr-Sc Alloy: Arrhenius-Based Modeling and Artificial Neural Network Approach. Applied Sciences. 2021; 11(5):2208. https://doi.org/10.3390/app11052208

Chicago/Turabian StyleMosleh, Ahmed O., Anton D. Kotov, Anna A. Kishchik, Oleg V. Rofman, and Anastasia V. Mikhaylovskaya. 2021. "Characterization of Superplastic Deformation Behavior for a Novel Al-Mg-Fe-Ni-Zr-Sc Alloy: Arrhenius-Based Modeling and Artificial Neural Network Approach" Applied Sciences 11, no. 5: 2208. https://doi.org/10.3390/app11052208

APA StyleMosleh, A. O., Kotov, A. D., Kishchik, A. A., Rofman, O. V., & Mikhaylovskaya, A. V. (2021). Characterization of Superplastic Deformation Behavior for a Novel Al-Mg-Fe-Ni-Zr-Sc Alloy: Arrhenius-Based Modeling and Artificial Neural Network Approach. Applied Sciences, 11(5), 2208. https://doi.org/10.3390/app11052208