Study on the Leakage and Inter-Stage Pressure Drop Characteristics of Two-Stage Finger Seal

Abstract

:Featured Application

Abstract

1. Introduction

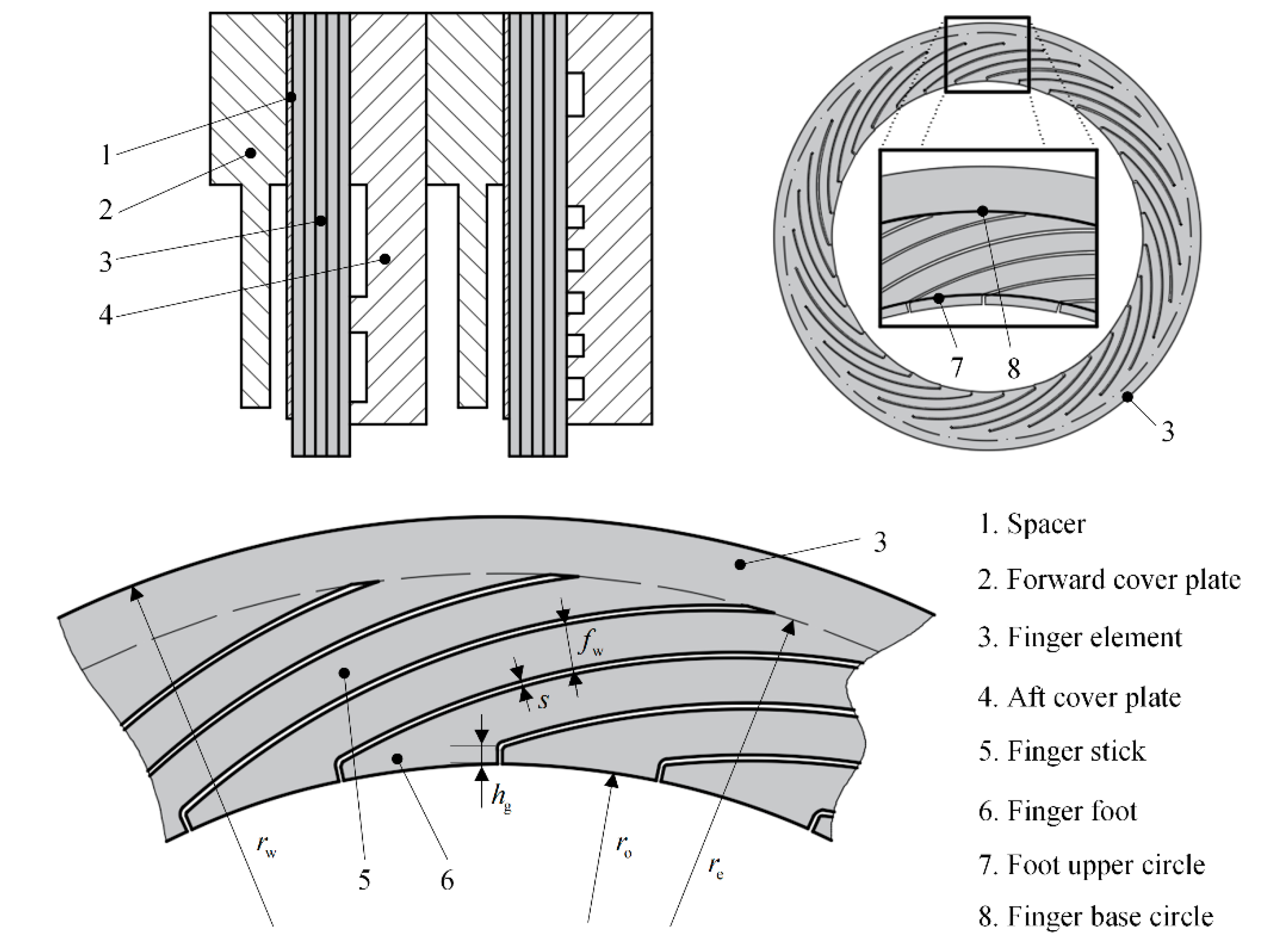

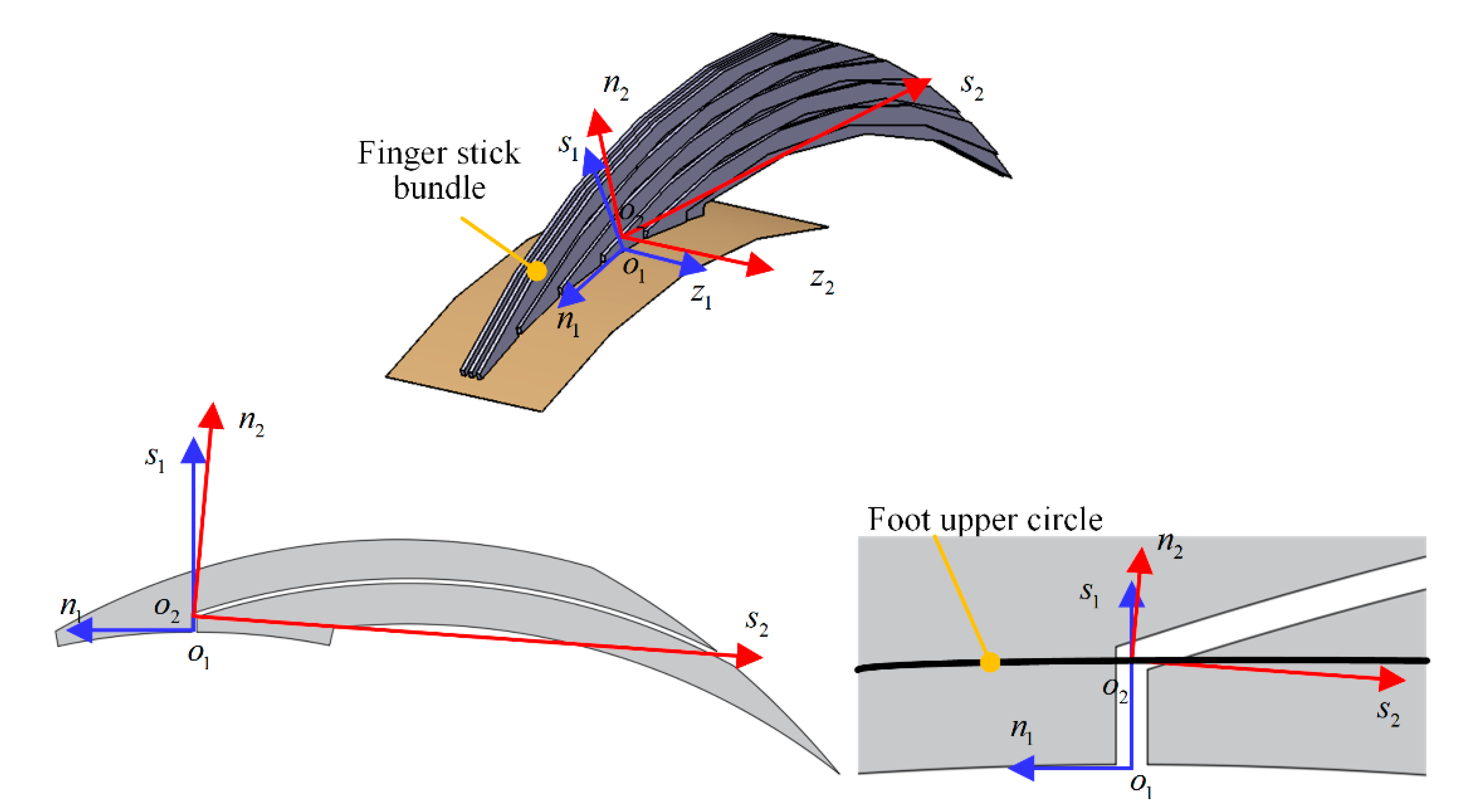

2. Two-Stage Finger Seal Geometry

3. Analysis Method of Two-Stage Finger Seal Based on FEM/CFD Coupling

3.1. Analysis Scheme

- (1)

- Specify the initial axial pressure difference of each 1SFS according to the total axial pressure difference of 2SFS (it is generally assumed that each 1SFS bears the same axial pressure difference).

- (2)

- Calculate the radial hysteresis clearance of each 1SFS and the resistance coefficients of each porous medium as input parameters of the CFD model of 2SFS.

- (3)

- Establish the CFD model of 2SFS including main leakage flow and side leakage flow, then calculate the leakage of 2SFS and the axial pressure difference of each 1SFS.

- (4)

- According to the axial pressure difference of each 1SFS acquired based on step (3), recalculate the radial hysteresis clearance of each 1SFS and the resistance coefficients of each porous medium, then modify the CFD model of 2SFS and recalculate the leakage of 2SFS and the axial pressure difference of each 1SFS.

- (5)

- Take that the relative error of leakage of 2SFS is less than 0.001 as the convergence criterion. If the convergence criterion is satisfied, the leakage of 2SFS and the axial pressure difference of each 1SFS can be acquired based on the last established CFD model of 2SFS; otherwise, return to step (4).

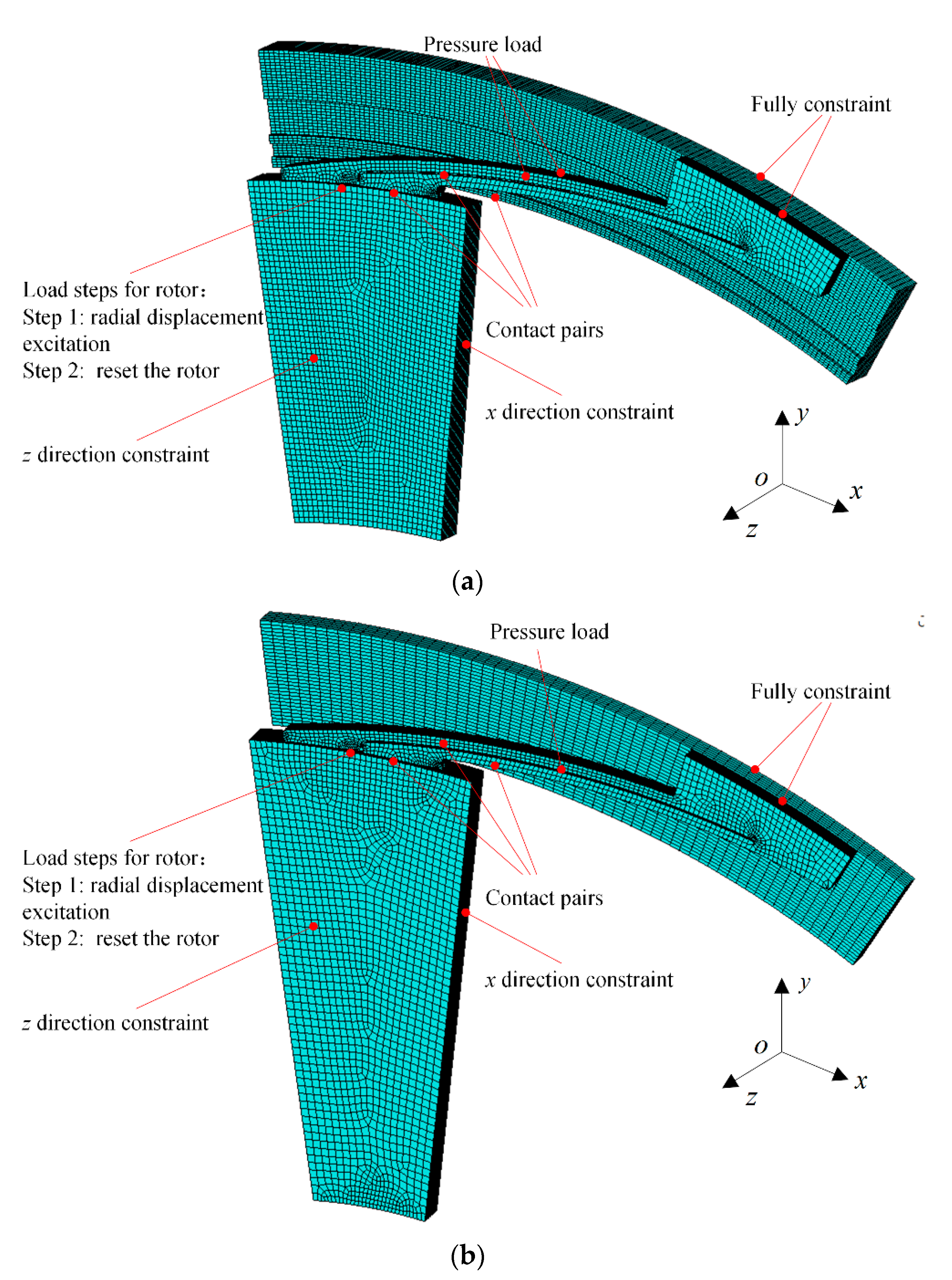

3.2. Finite Element Models of Finger Seal

3.3. CFD Model of Two-Stage Finger Seal

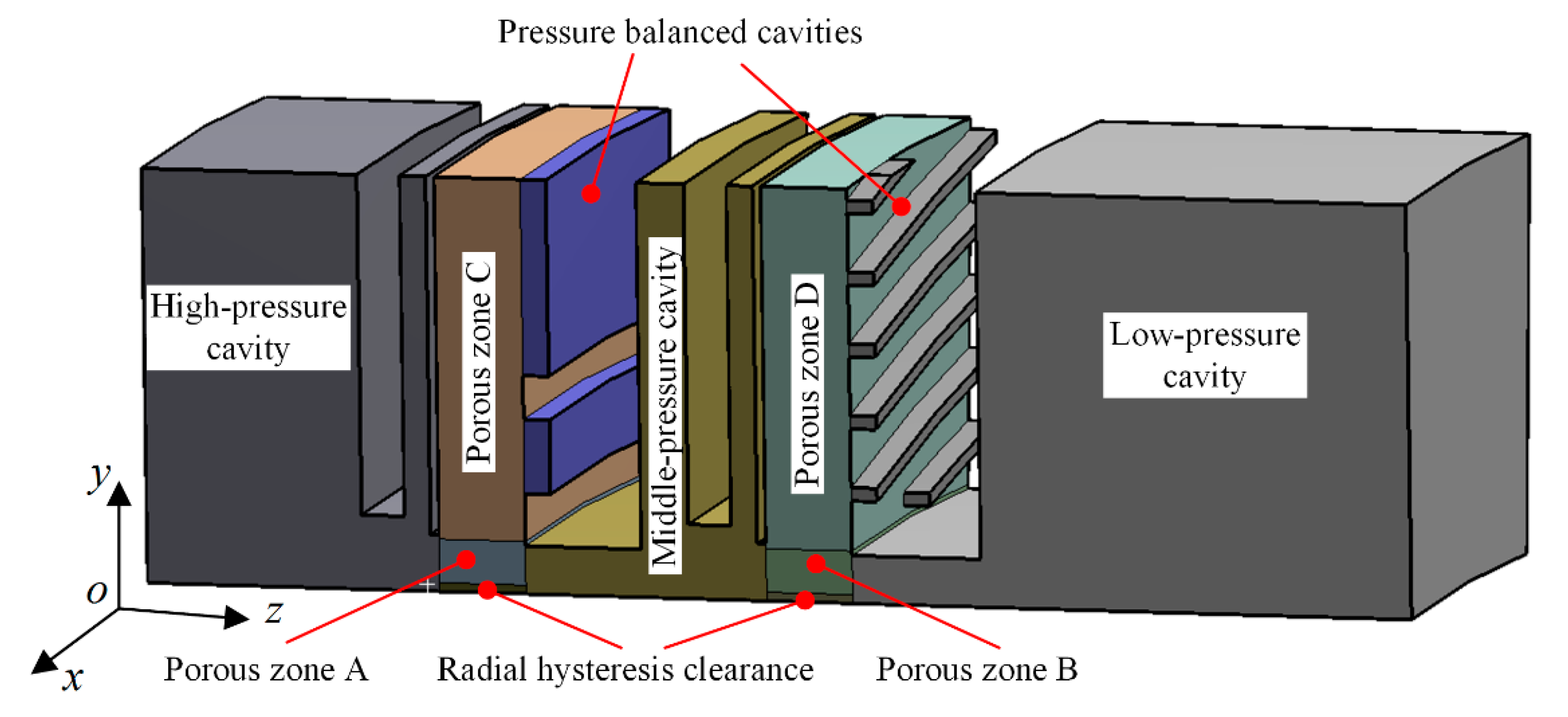

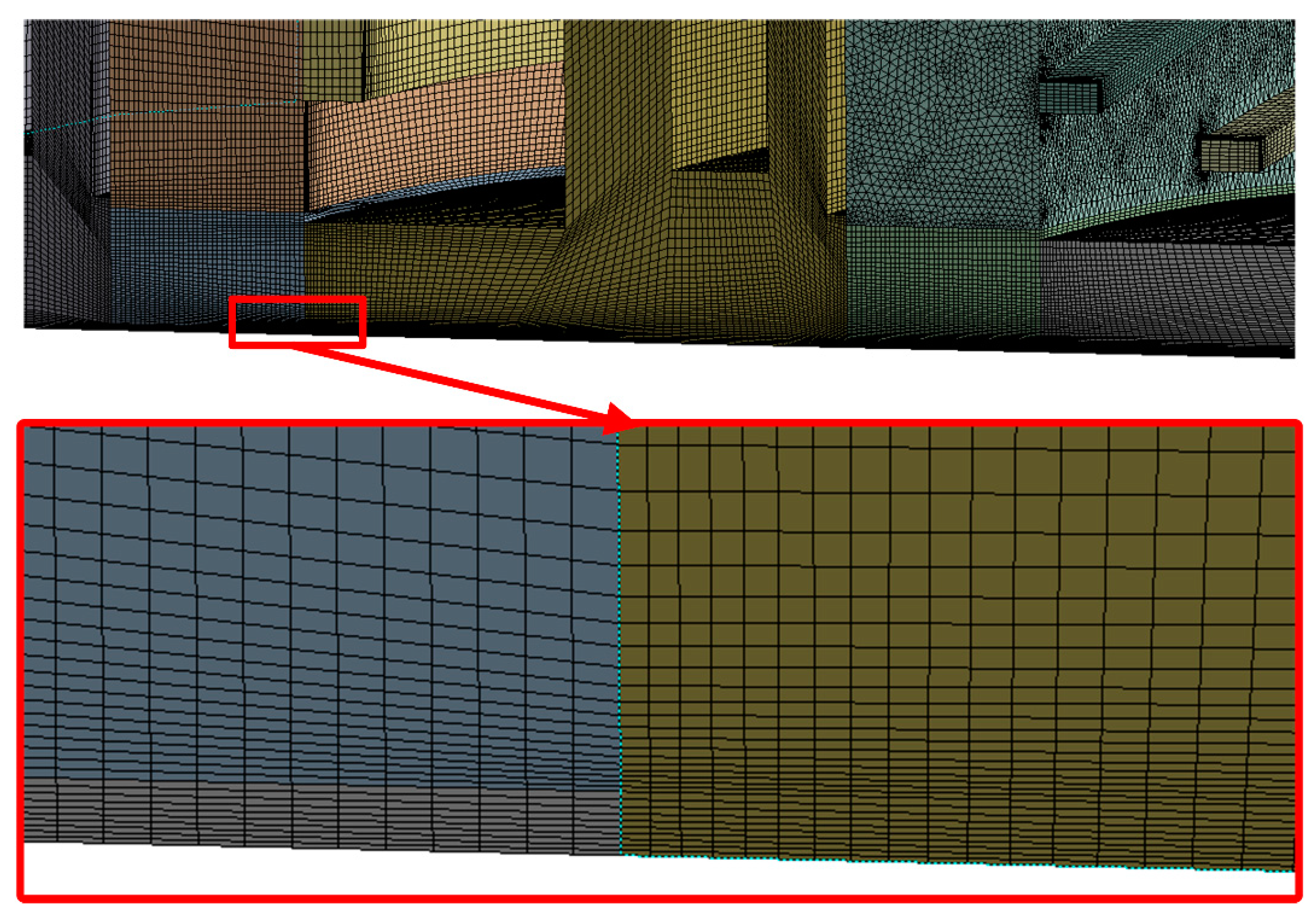

3.3.1. Numerical Model

3.3.2. Calculation of Resistance Coefficients of Porous Media

4. Validation Work on the Numerical Method

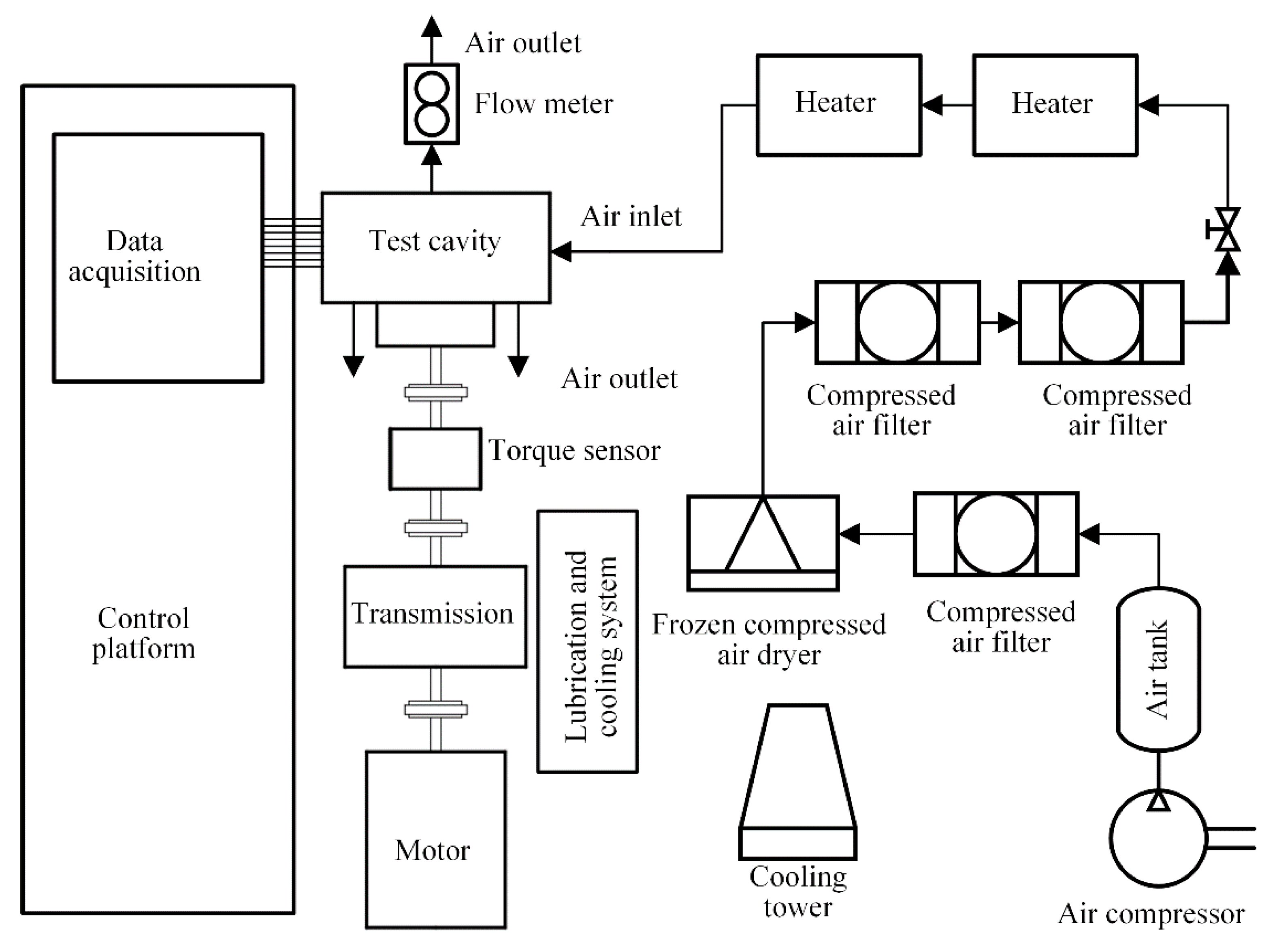

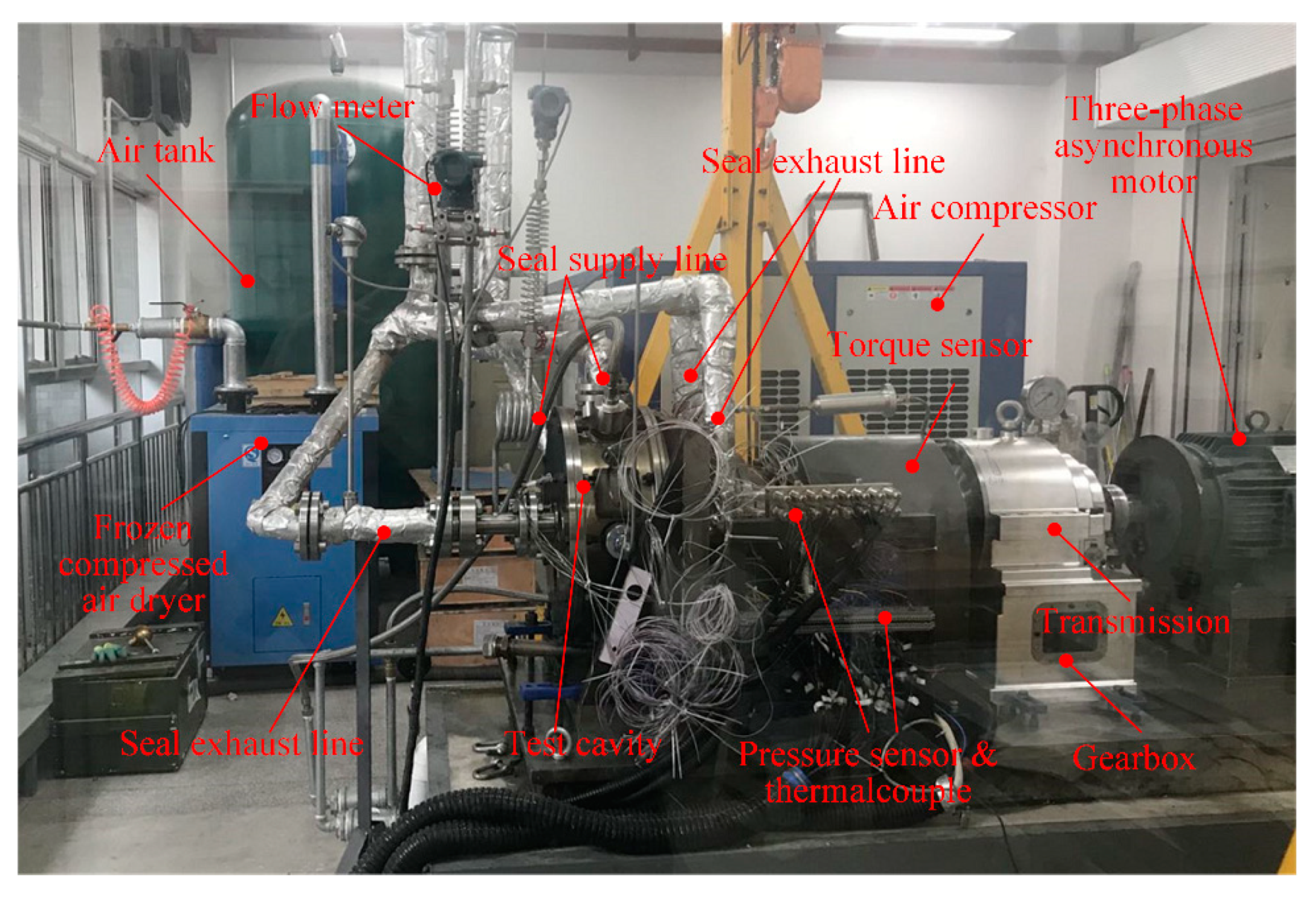

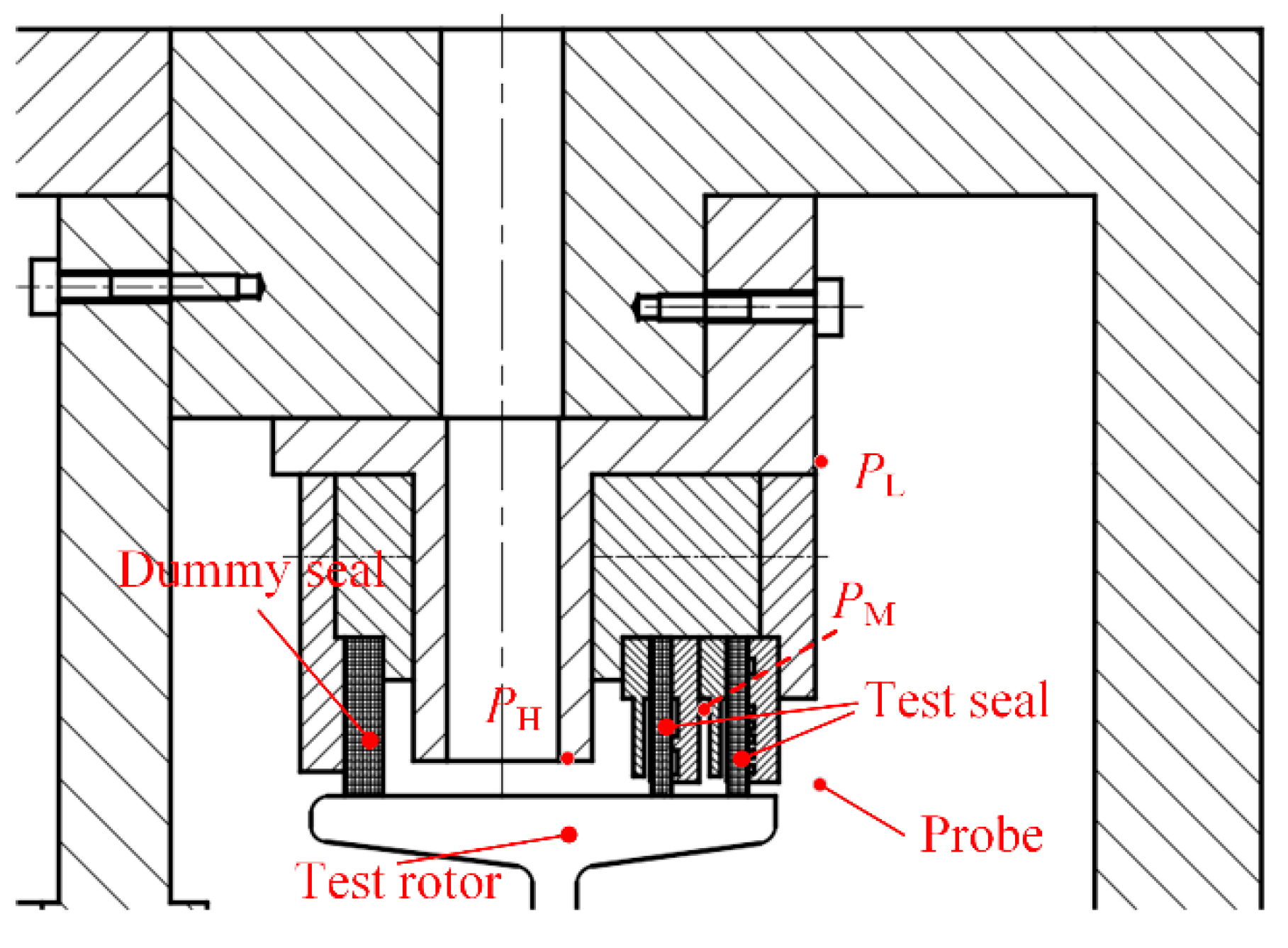

4.1. Test Rig

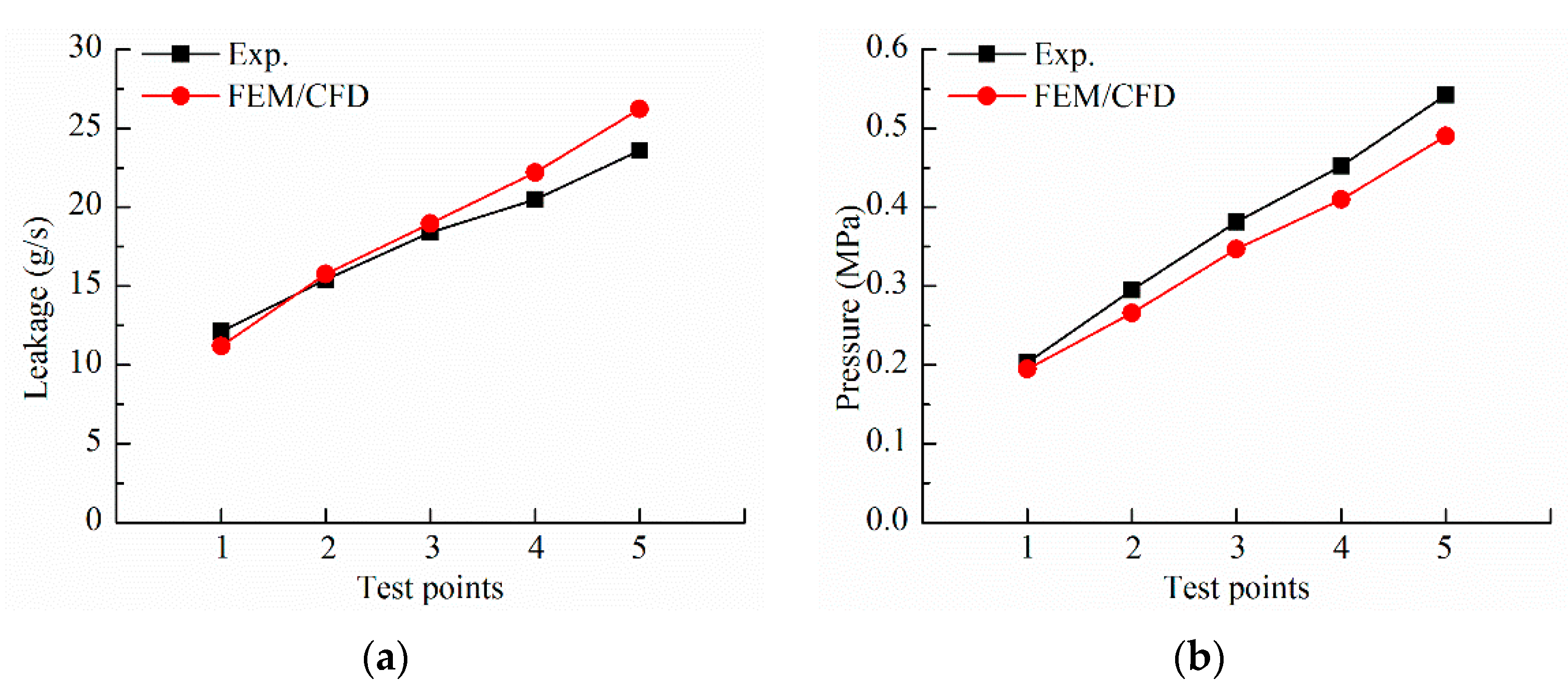

4.2. Comparison between Experimental Results and Numerical Results

5. Results and Discussion

5.1. Leakage Performance of Two-Stage Finger Seal

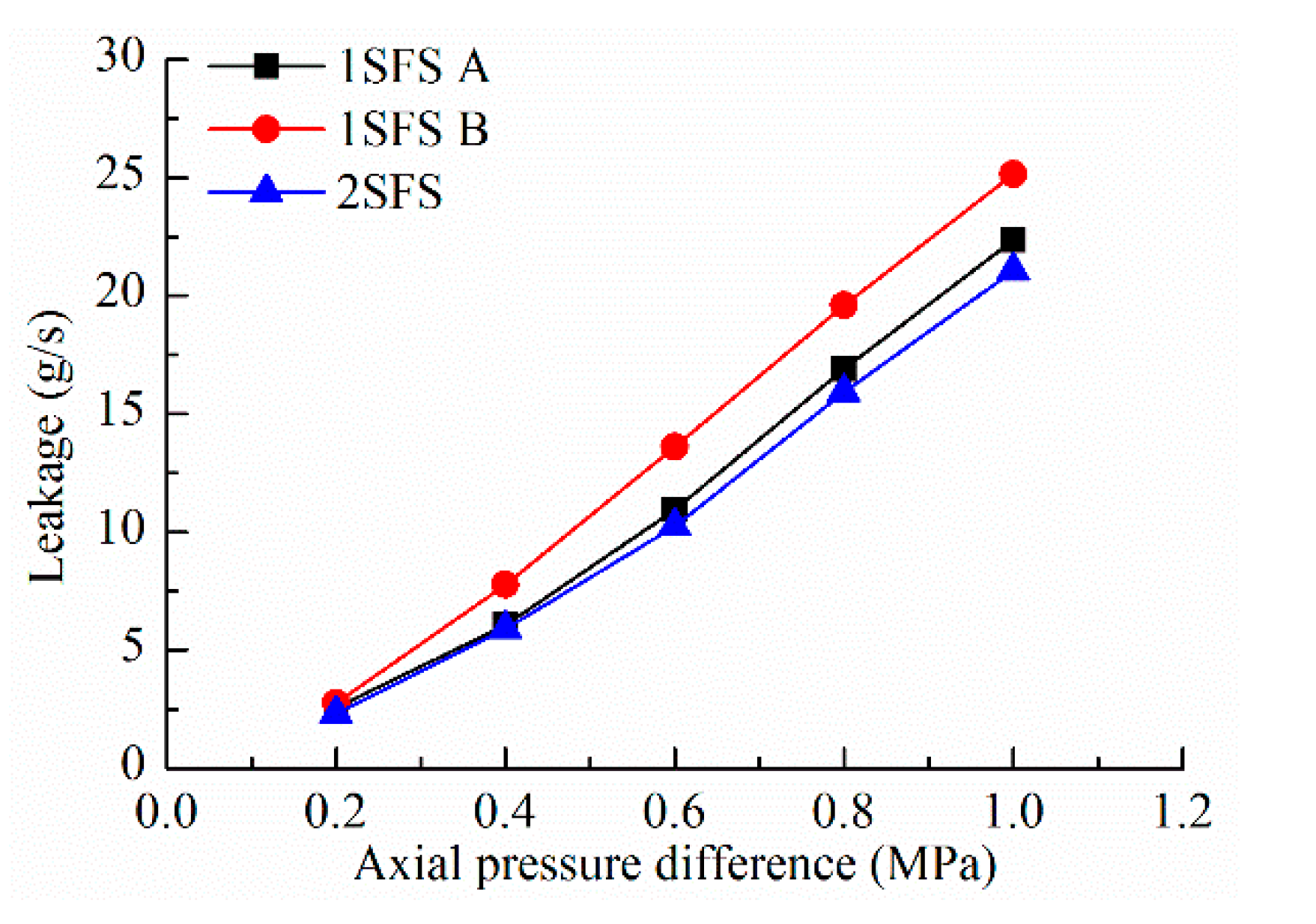

5.1.1. Comparison of One-Stage Finger Seal and Two-Stage Finger Seal

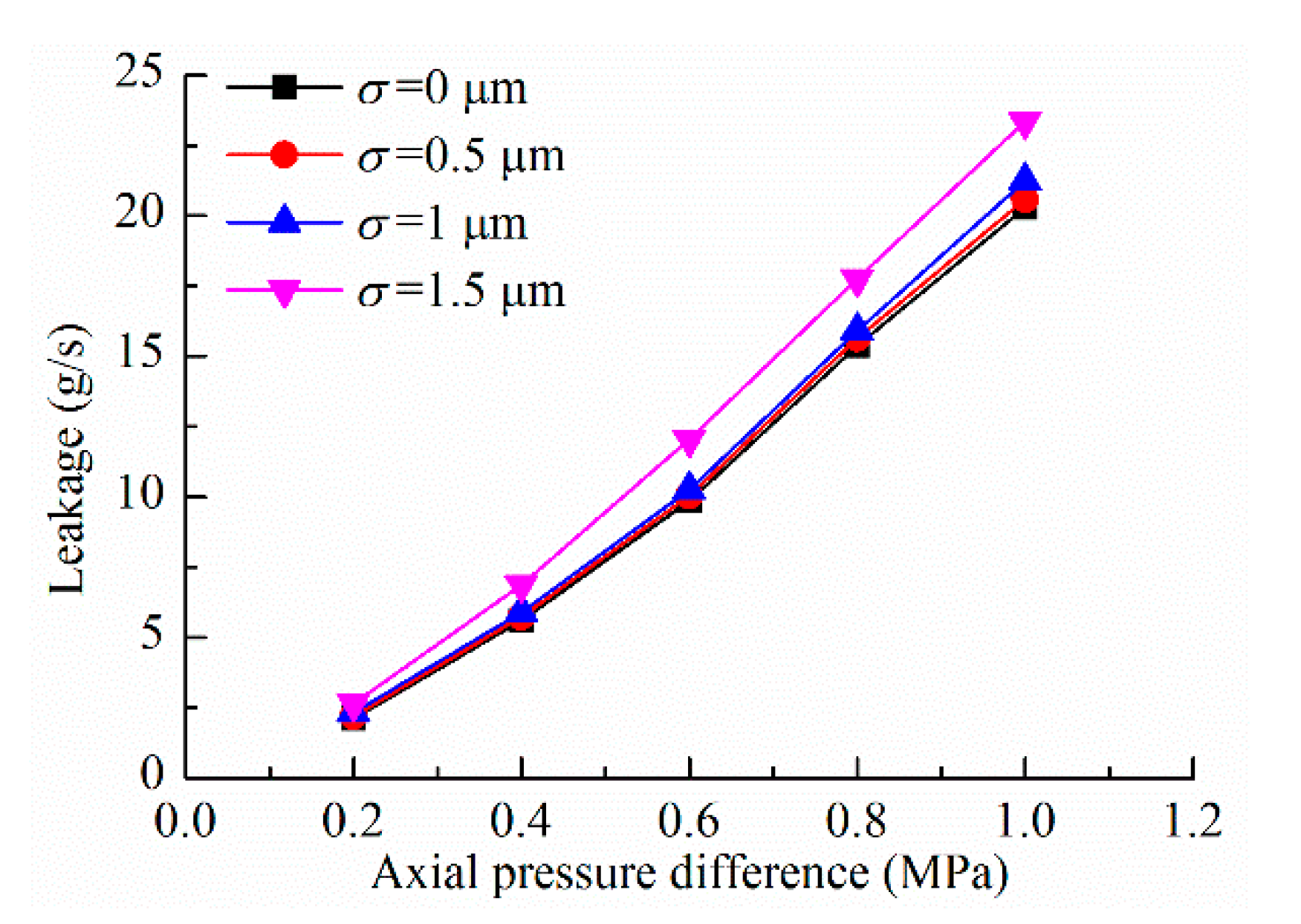

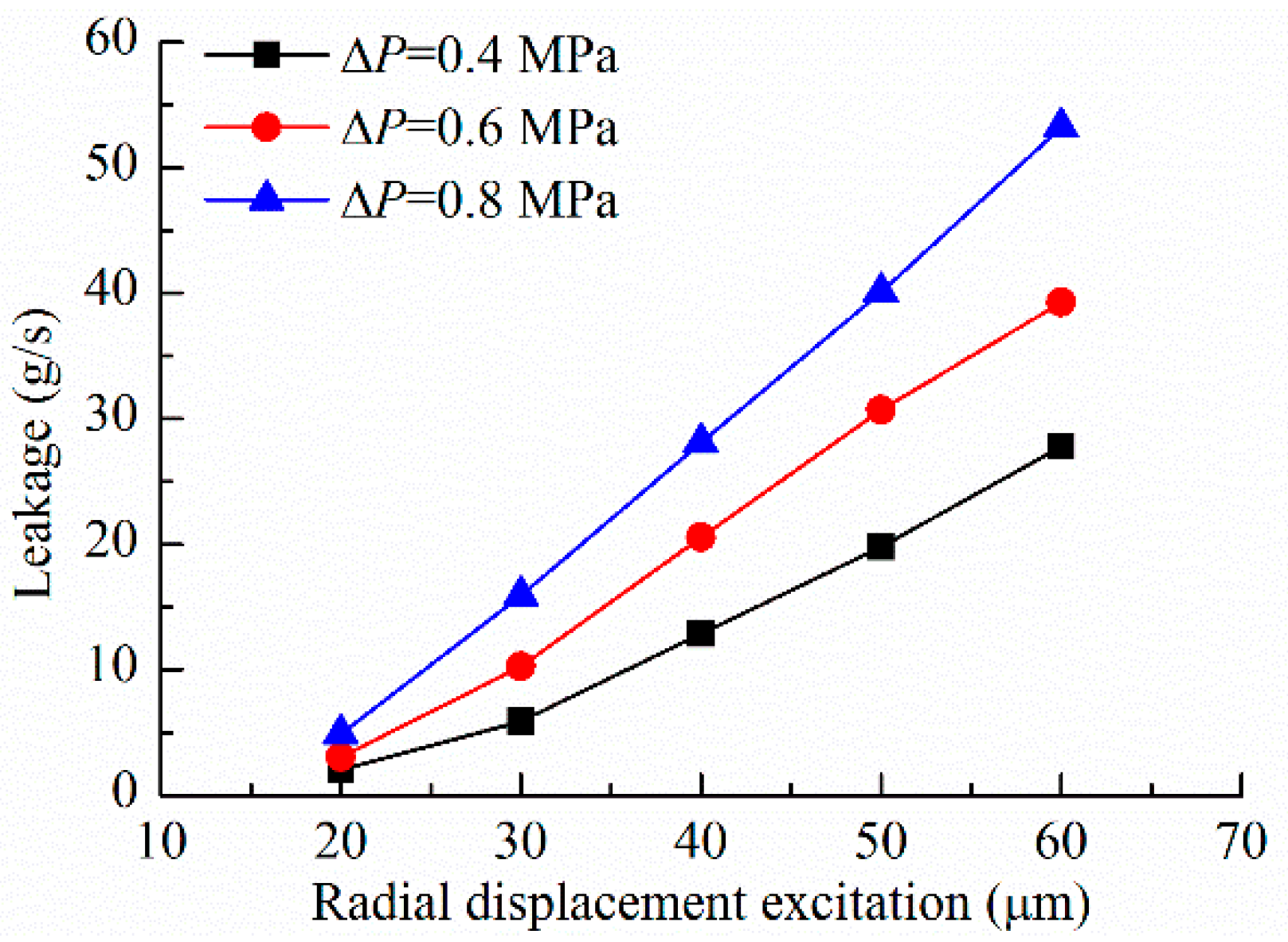

5.1.2. Factors Affecting the Leakage of Two-Stage Finger Seal

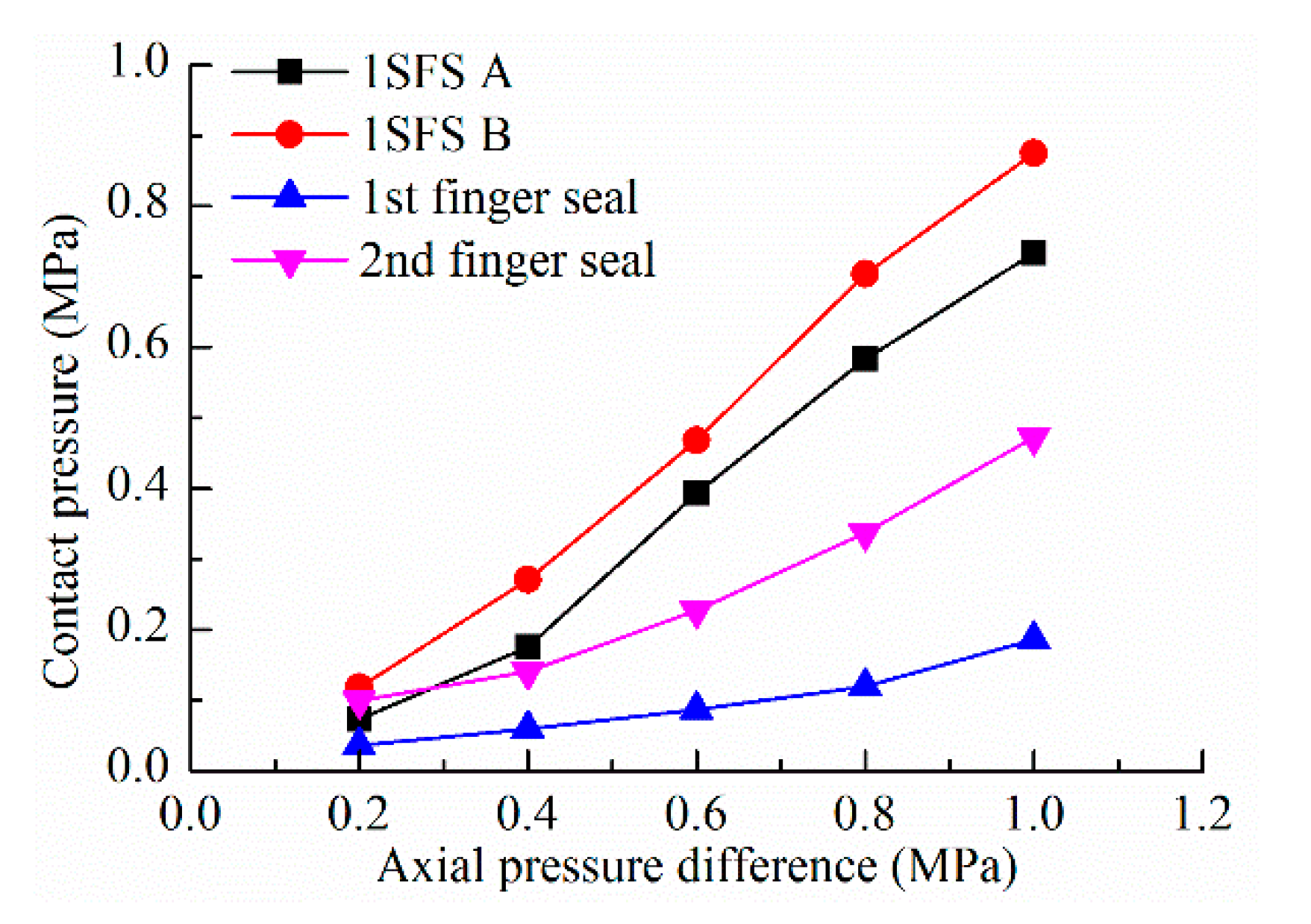

5.2. Inter-Stage Pressure Drop Characteristics of Two-Stage Finger Seal

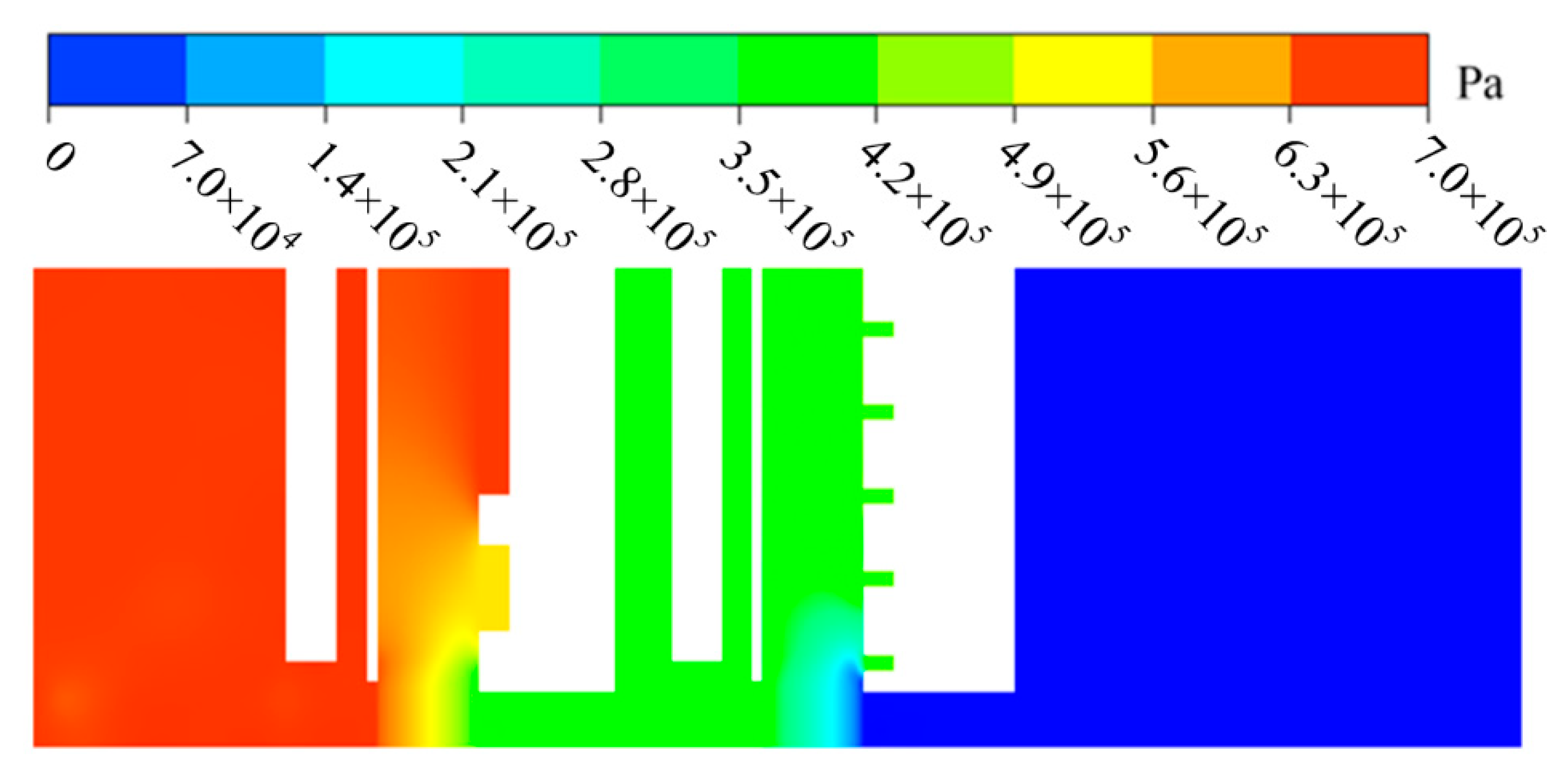

5.2.1. Pressure Distribution of Two-Stage Finger Seal

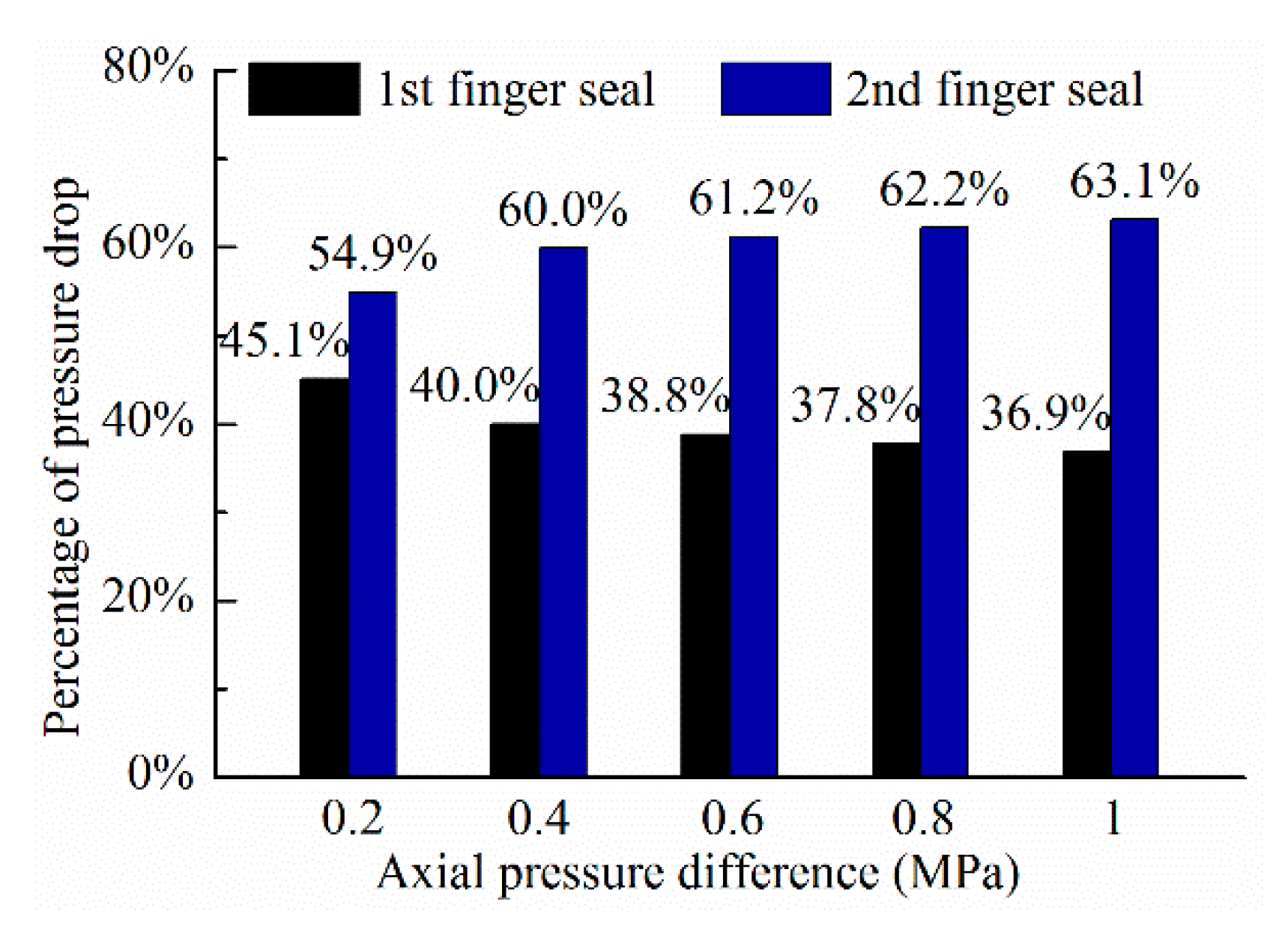

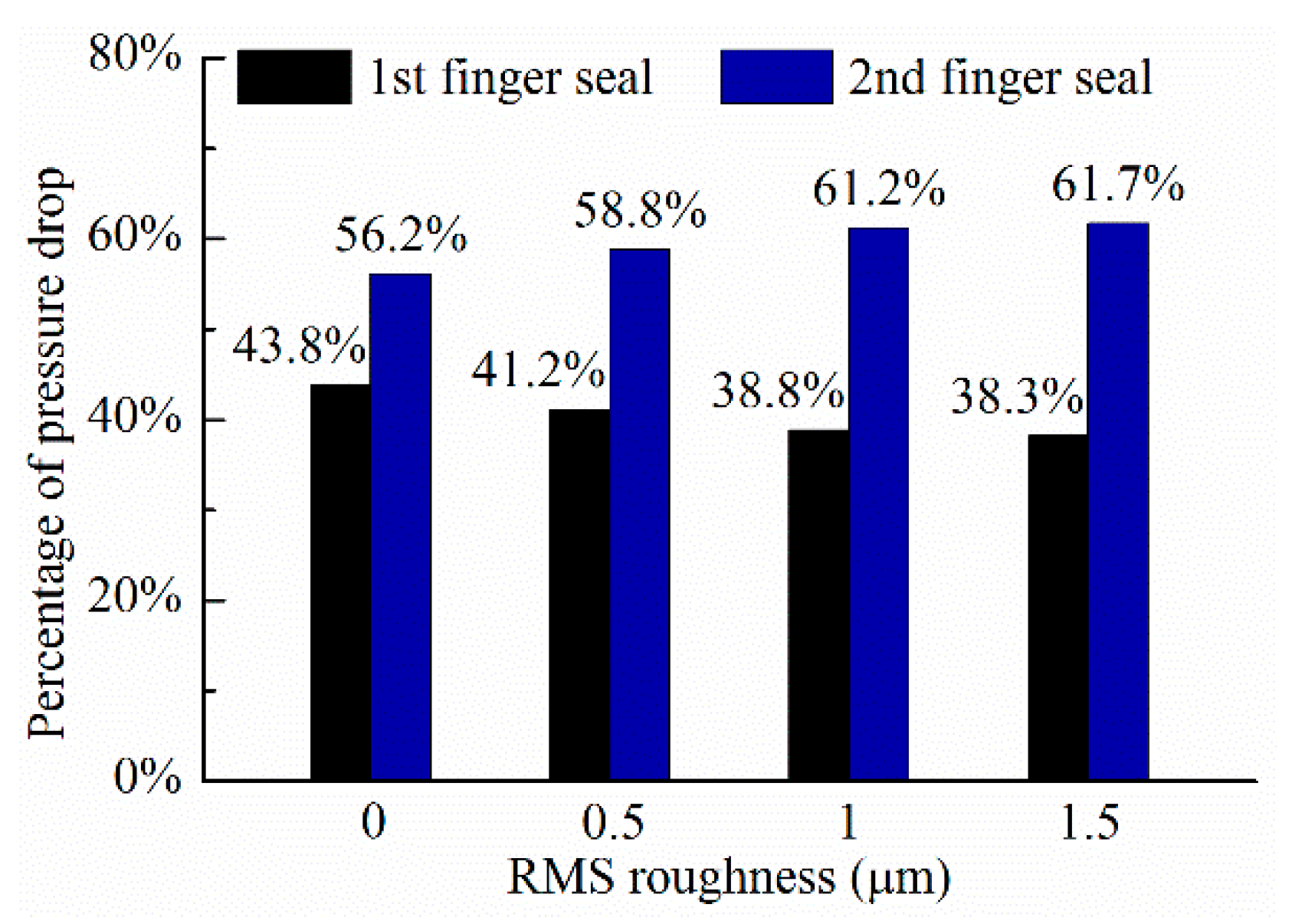

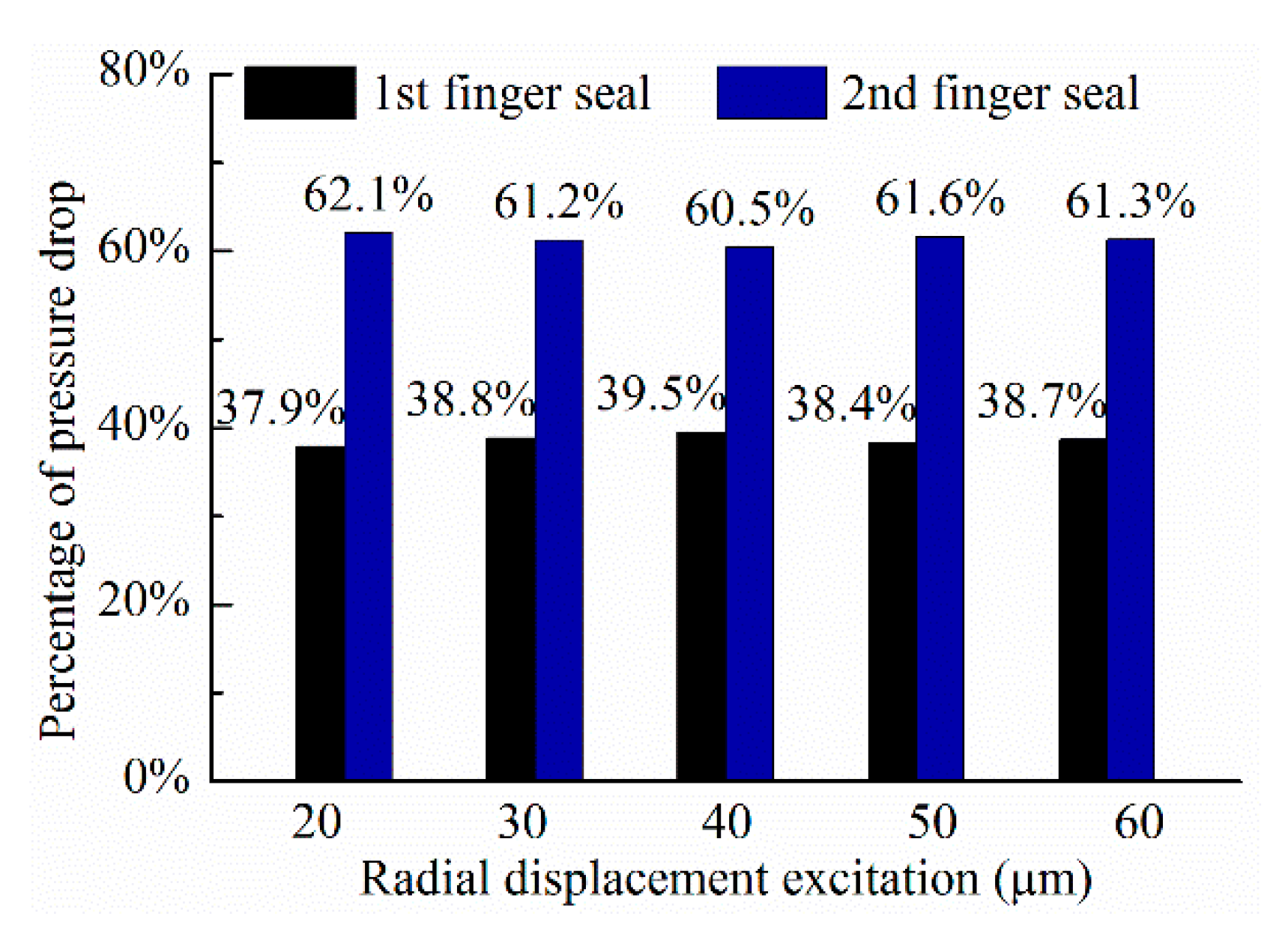

5.2.2. Factors Affecting the Inter-Stage Pressure Drop Characteristics of Two-Stage Finger Seal

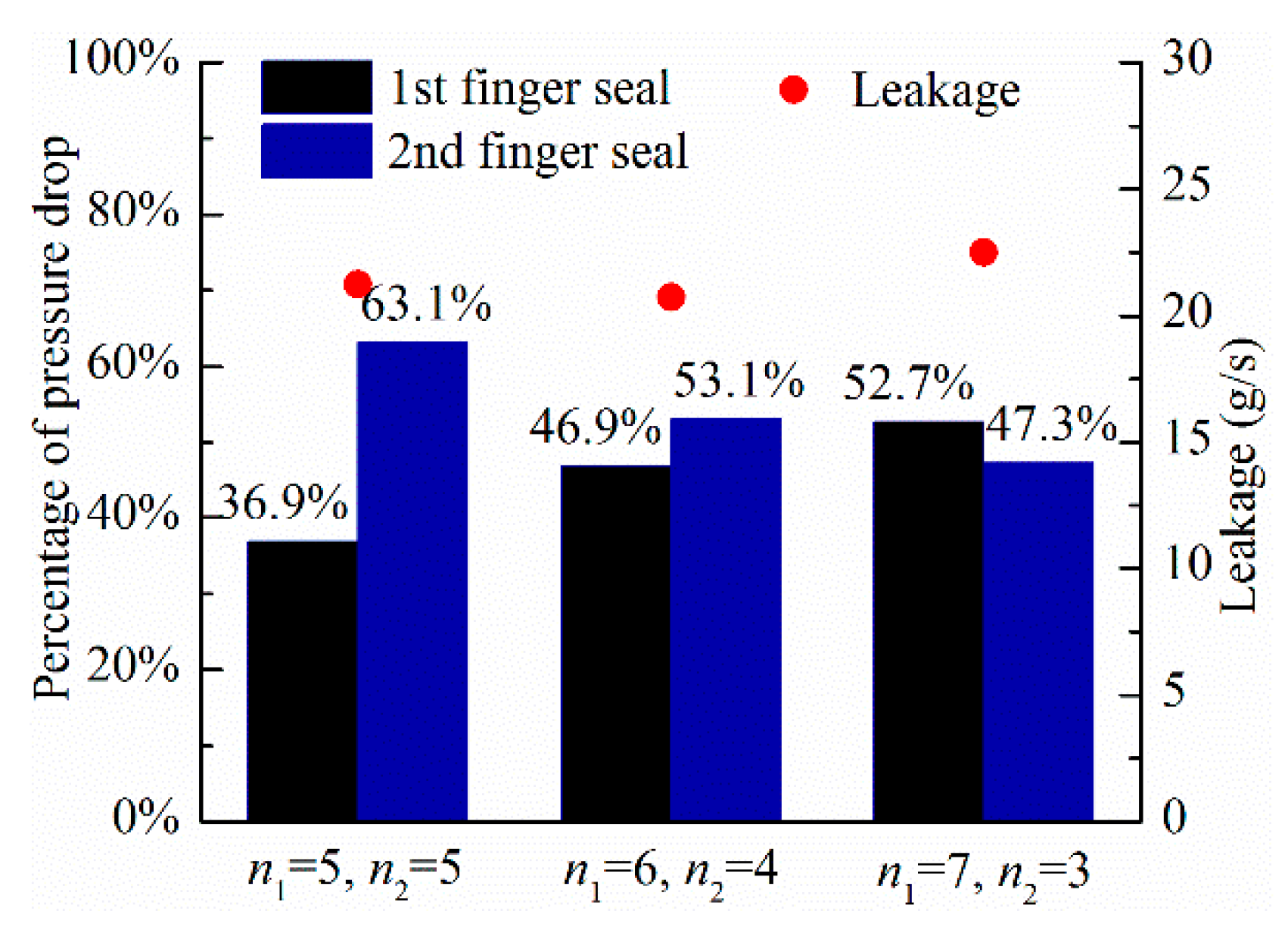

5.2.3. Improvement of the Inter-Stage Imbalance of Pressure Drop of Two-Stage Finger Seal

6. Conclusions

- (1)

- The difference in leakage between 2SFS and 1SFS increases with increasing axial pressure difference, and when the axial pressure difference increases from 0.2 MPa to 1 MPa, the contact pressure ratio of the 1st finger seal in 2SFS to the 1SFS A decreases from 0.49 to 0.25, the contact pressure ratio of the 2nd finger seal in 2SFS to the 1SFS B decreases from 0.84 to 0.54. So the 2SFS has better performance than the 1SFS, and the advantage of the 2SFS compared with the 1SFS is more significant under high axial pressure difference.

- (2)

- Compared with not considering side leakage flow, the leakage of 2SFS increases when the side leakage flow is considered. When the RMS roughness of finger elements is 1.5 μm, the relative increment of leakage of 2SFS is more than 15%.

- (3)

- There exists a phenomenon of inter-stage imbalance of pressure drop for 2SFS, and increasing axial pressure difference and the RMS roughness of finger elements will aggravate the imbalance of pressure drop between stages of 2SFS. The radial displacement excitation of rotor has little effect on the inter-stage pressure drop characteristics of 2SFS.

- (4)

- Increasing the number of finger elements of the 1st finger seal and decreasing the number of finger elements of the 2nd finger seal can improve the inter-stage imbalance of pressure drop of 2SFS with little change in leakage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chupp, R.E.; Nelson, P. Evaluation of brush seals for limited-life engines. J. Propuls. Power 1993, 9, 113–118. [Google Scholar] [CrossRef]

- Steinetz, B.M.; Hendricks, R.C. Engine seal technology requirements to meet NASA’s Advanced Subsonic Technology program goals. J. Propuls. Power 1996, 12, 786–793. [Google Scholar] [CrossRef] [Green Version]

- Marie, H. A study of Non-Contacting Passive-Adaptive Turbine Finger Seal Performance. Ph.D. Thesis, University of Akron, Akron, OH, USA, 2005. [Google Scholar]

- Pugachev, A.O.; Deckner, M. Experimental and theoretical rotordynamic stiffness coefficients for a three-stage brush seal. Mech. Syst. Signal Proc. 2012, 31, 143–154. [Google Scholar] [CrossRef]

- Chupp, R.E.; Hendricks, R.C.; Lattime, S.B.; Steinetz, B.M. Sealing in Turbomachinery. J. Propuls. Power 2006, 22, 313–349. [Google Scholar] [CrossRef]

- Li, H.M.; Braun, M.J. The sealing behavior and force analysis of a double-laminate single-padded finger seal. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007; pp. 1279–1290. [Google Scholar]

- Raben, M.; Friedrichs, J.; Flegler, J. Brush seal frictional heat generation: Test rig design and validation. ASME J. Eng. Gas Turbines Power 2017, 139, 032502. [Google Scholar] [CrossRef]

- Huang, S.; Suo, S.; Li, Y.; Wang, Y. Theoretical and experimental investigation on tip forces and temperature distributions of the brush seal coupled aerodynamic force. ASME J. Eng. Gas Turbines Power 2014, 136, 052502. [Google Scholar] [CrossRef]

- Pugachev, A.O. Aggregation of experimental and theoretical data for brush seal leakage evaluation. In Proceedings of the 50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Cleveland, OH, USA, 28–30 July 2014. [Google Scholar]

- Chen, G.D.; Wang, L.N.; Yu, Q.P.; Su, H. Dynamic analysis of C/C composite finger seal. Chin. J. Aeronaut. 2014, 27, 745–758. [Google Scholar] [CrossRef] [Green Version]

- Proctor, M.P.; Kumar, A.; Delgado, I.R. High-speed, high-temperature finger seal test results. J. Propuls. Power 2004, 20, 312–318. [Google Scholar] [CrossRef] [Green Version]

- Arora, G.K.; Proctor, M.P.; Steinetz, B.M.; Delgado, I.R. Pressure balanced, low hysteresis, finger seal test results. In Proceedings of the 35th Joint Propulsion Conference and Exhibit, Los Angeles, CA, USA, 20–24 June 2014. [Google Scholar]

- Li, G.Q.; Zhang, Q.; Guo, L.; Yu, Q.P.; Xu, G.; Zhu, J.Q. Leakage and wear characteristics of finger seal in hot/cold state for aero-engine. Tribol. Int. 2018, 127, 209–218. [Google Scholar]

- Lu, F.; Liu, J.; Lu, H. Experimental study on leakage and wear characteristics of C/C composite finger seal. Ind. Lubr. Tribol. 2020, 72, 1133–1138. [Google Scholar] [CrossRef]

- Braun, M.J. Finger seal: A compliant seal. In Encyclopedia of Tribology; Wang, Q.J., Chung, Y.W., Eds.; Springer: Boston, MA, USA, 2013; pp. 1106–1131. [Google Scholar]

- Gibson, N.; Takeuchi, D.; Hynes, T.; Malak, M. Second generation air-to-air mechanical seal design and performance. In Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, San Diego, CA, USA, 30 July–3 August 2014. [Google Scholar]

- Proctor, M.P.; Steinetz, B.M.; Delgado, I.R.; Hendricks, R.C. Turbine Seal Research at NASA GRC; Report No. E-663258; NASA: Cleverland, OH, USA, 2011.

- Zhao, H.; Jiao, Z.Z.; Sun, D.; Liu, Y.Q.; Zhan, P.; Xin, Q. Numerical and experimental research on interstage pressure drop distribution affecting factors of multi-stage brush seals. Acta Aeronaut. Astronaut. Sin. 2020, 41, 1–12. [Google Scholar]

- Zhao, H.; Su, H.; Chen, G. Analysis of total leakage of finger seal with side leakage flow. Tribol. Int. 2020, 150, 106371. [Google Scholar] [CrossRef]

- Dogu, Y.; Aksit, M.F.; Demiroglu, M.; Dinc, O.S. Evaluation of flow behavior for clearance brush seals. ASME J. Eng. Gas Turbines Power 2008, 130, 012507. [Google Scholar] [CrossRef]

- Makino, T.; Morohoshi, S.; Taniguchi, S. Application of average flow model to thin film gas lubrication. J. Tribol. 1993, 115, 185–190. [Google Scholar] [CrossRef]

- Patir, N. Effects of Surface Roughness on Partial Film Lubrication Using an Average Flow Model Based on Numerical Simulation. Ph.D. Thesis, Northwestern University, Evanston, IL, USA, 1978. [Google Scholar]

- Huang, S.Q. Research on the Flow Field and Bristles Tip Contact Heat Transfer Characteristics of Brush Seal. Ph.D. Thesis, Tsinghua University, Beijing, China, 2015. [Google Scholar]

| Parameters | Units | Values |

|---|---|---|

| Base radius of the involute/rb | mm | 20.5 |

| Radius of finger base circle/re | mm | 136 |

| Inner radius of finger seal/ro | mm | 126 |

| Outside radius of finger seal/rw | mm | 141 |

| Finger interstice width/s | mm | 0.3 |

| Height of finger foot/hg | mm | 1.25 |

| Thickness of finger element/t | mm | 0.4 |

| Number of finger elements of the 1st finger seal/n1 | - | 5 |

| Number of finger elements of the 2nd finger seal/n2 | - | 5 |

| Number of finger sticks/m | - | 72 |

| Seal/rotor radial clearance | μm | 0, 55 |

| RMS roughness of finger element/σ | μm | 0.5, 1, 1.5 |

| Test Points | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Pressure in high-pressure cavity/MPa | 0.350 | 0.445 | 0.530 | 0.618 | 0.698 |

| Pressure in low-pressure cavity/MPa | 0.150 | 0.195 | 0.230 | 0.268 | 0.298 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, H.; Su, H.; Chen, G.; Zhang, Y. Study on the Leakage and Inter-Stage Pressure Drop Characteristics of Two-Stage Finger Seal. Appl. Sci. 2021, 11, 2239. https://doi.org/10.3390/app11052239

Zhao H, Su H, Chen G, Zhang Y. Study on the Leakage and Inter-Stage Pressure Drop Characteristics of Two-Stage Finger Seal. Applied Sciences. 2021; 11(5):2239. https://doi.org/10.3390/app11052239

Chicago/Turabian StyleZhao, Hailin, Hua Su, Guoding Chen, and Yanchao Zhang. 2021. "Study on the Leakage and Inter-Stage Pressure Drop Characteristics of Two-Stage Finger Seal" Applied Sciences 11, no. 5: 2239. https://doi.org/10.3390/app11052239

APA StyleZhao, H., Su, H., Chen, G., & Zhang, Y. (2021). Study on the Leakage and Inter-Stage Pressure Drop Characteristics of Two-Stage Finger Seal. Applied Sciences, 11(5), 2239. https://doi.org/10.3390/app11052239