Model-Driven Design and Development of Flexible Automated Production Control Configurations for Industry 4.0

Abstract

1. Introduction

2. Materials and Methods

2.1. Modeling of Flexible Automation Production Systems

- The Asset is a physical or a logical object owned by or under the custodial duties of an organization, having either a perceived or actual value to the organization.

- The Asset Administration Shell (AAS) is the digitalization of an asset. In other words, and AAS is the interface that connects the physical asset through I4.0 communications such as OPC Unified Architecture (OPC UA) [31]. It is also in charge of offering the I4.0 component’s services to the Industry 4.0 (e.g., [32] presents an AAS model able to represent International Electrotechnical Commission (IEC) 61131-3 standard compliant programs and the relevant relationships with Programmable Logic Controllers and each device of the controlled plant). According to the glossary of Platform Industrie 4.0 [33], the AAS concept can be directly related to the concept of Digital Twin (DT). However, several works in the literature apply the DT concept to refer exclusively to highly accurate simulation models. In the authors’ understanding, both meanings are correct as both, in different ways, are related to the Asset behavior. In this work, the first one applies.

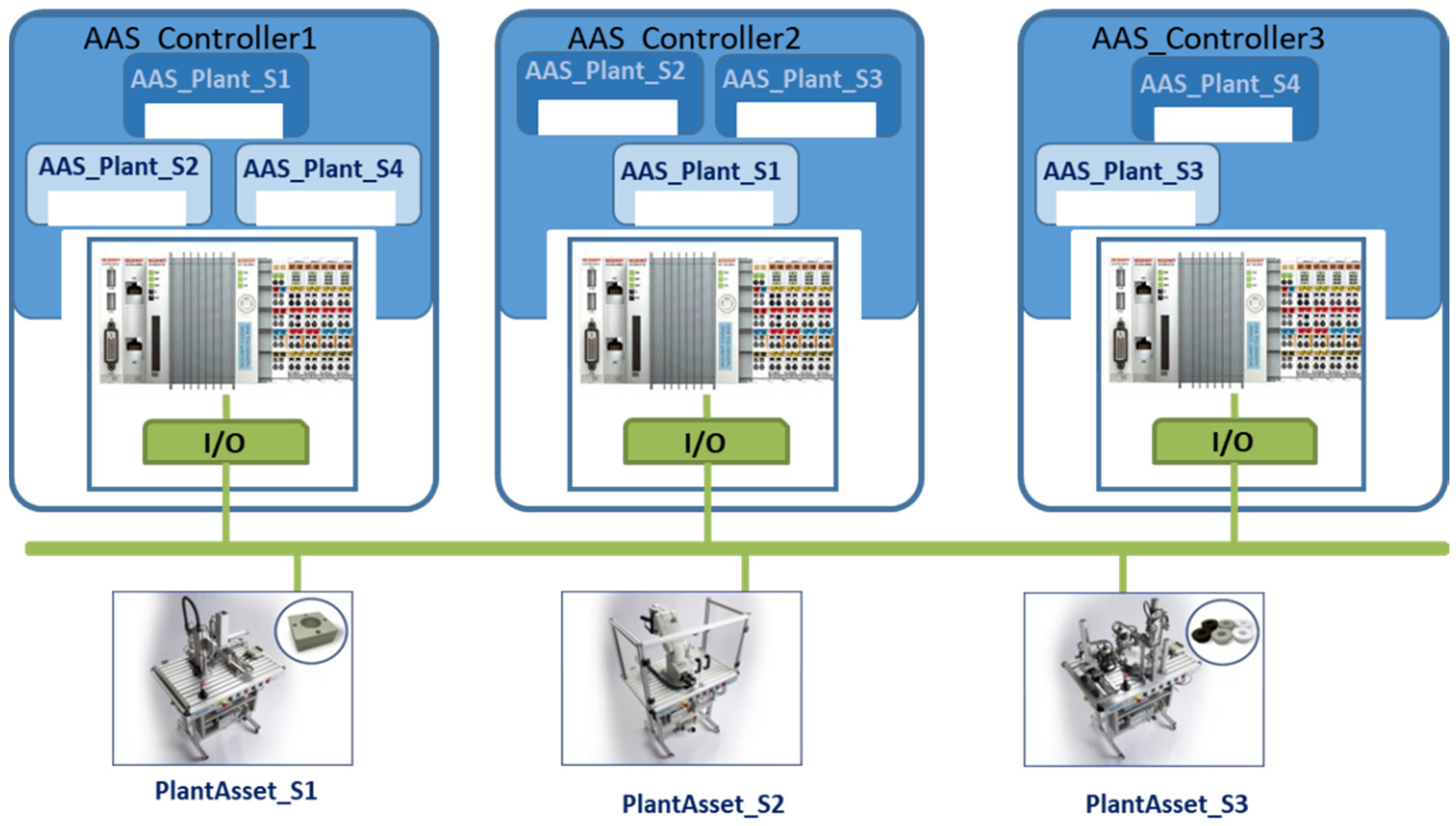

- Controller I4.0 Component:

- ○

- Asset (ControllerAsset): The Programmable Logic Controller (PLC), the primary controller for such type of systems, and the I/O boards;

- ○

- AAS (AAS_Controller): automatizes the production by means of its I/Os.

- Plant I4.0 Component:

- ○

- Asset (PlantAsset): physical station and the sensors and actuators connected to controller’s I/Os;

- ○

- AAS (AAS_Plant): offers a production service (which contains the control logic and data).

- non-critical situations: the automation system is aware of the current process state. Therefore, it is possible to activate ProductionServices in another PLC (after de-activation in the current controller or after a controller failure), using as their initial state the last known state of the interrupted ProductionService;

- critical situations: the automation system does not know exactly the current state of the ProductionServices. Therefore, as it can lead to unpredictable process behavior, the activation/de-activation of ProductionServices is inhibited in critical situations. For example, when a controller fails, it has to be analyzed if all its active ProductionServices can be recovered, on a tracking controller, in a previous known state (checkpoint). In the case of a non-recoverable situation, it is analyzed if the ProductionService must be safely stopped and the operator warned. Figure 3 depicts a simple but illustrative example of a ProductionService for the movement of a piece by a crane. While the crane is lifting, transporting or placing the piece, the ProductionService cannot be de-activated as the piece may be released which prevents the production from continuing. Therefore, the state of the ProductionService during these operations is denoted as critical and in such case, reconfiguration cannot be performed. The rest of the states are denoted as non-critical.

2.2. Flexible Automation Middleware (FAM)

- The Middleware Manager (MM) is the main orchestrator. It is a unique agent in charge of managing the System Repository (SR): a dynamic model that contains information about the current state of the automation application, which changes over time.

- The QoS Manager comprises a set of agents responsible for QoS fulfilment.

- QoS Monitor (QM) agents are responsible for monitoring the specific QoS to be handled, generating triggers if they detect QoS losses. Hence, there are as many QMs as QoS to be met.

- The Diagnosis & Decision (D&D) agent is unique in the system and it is responsible for launching diagnosis and decision algorithms as well as reconfiguration events.

- 3.

- The Plant_AAS Agent (APlant_AAS) manages the execution of the corresponding ProductionService’s actions as well as collects, transmits, stores and makes diagnosis on the current state of this. The Component Manager of a APlant_AAS is implemented by a Finite State Machine that represents the possible states of the ProductionService lifecycle (detailed description can be found in [26]). Although each ProductionService can be replicated in a number of controllers, at runtime only one controller will be executing the ProductionService and its corresponding APlant_AAS will be in active state. For the rest of the controllers, the ProductionService is not executing and their corresponding APlant_AASs will be in tracking state.

- 4.

- The Controller_AAS Agent (AController_AAS) registers its corresponding controller and the associated resources in the System Repository when the controller joins the system. It also registers itself in the Directory Facilitator of JADE offering as services the set of ProductionServices that can run in the controller. Finally, it launches its corresponding APlant_AASs. There are as many AController_AAS as controllers in the system.

2.3. Model Driven Engineering for Modeling Flexible Automation Production Systems

3. Results

3.1. FAPS Model Editor

- The System Unit Class Library indicates the concepts required to define a flexible automation system. It comprises the so-called System Unit Classes (SUC), which represent the elements of the meta-model. The SUCs are characterized by their attributes. As the elements in the system can be simple or complex (i.e., composed of internal elements), the SUCs representing them can be either simple or complex. The complex SUCs comprise instances of other previously defined SUCs.

- The Interface Class Library offers interfaces that enable the association of a SUC (simple or complex) to an element on an external file. This library provides a PLCopen interface included in AML which grants access to the POUs and variables within a PLCopen automation project. It also includes the hardware interface, a new interface added to allow the definition of the controllers and automation projects in PLCopen.

- The Role Class Library provides the different roles by which the elements can be organized in the model (choice, sequence, each and every role). The ramifications of the structures based on these roles is settled by means of their attributes minOccurs and maxOccurs.

3.2. Flexible Automation Projects Code Generator

- ProductionService_id: a program to control the execution of the Production Service (PS_id);

- SendStateService_id: a program that reads and serializes the state variables of the production service;

- ReceiveStateService_id: a program that de-serializes the received information and updates de state variables of the production service with new initialization values in case it changes from tracking to active in a controller.

3.2.1. Production Service Program

- isActive and wasActive: these boolean variables determine the activation/deactivation of the logic.

- recoveryAction: it is related to the coded actions required to manage a concrete critical situation if necessary.

- Action_CriticalSituationID: it identifies a specific recovery code (POU instance).

- Rule 1—Interface definition: It is applied to every InternalElement having RefBaseSystemUnitPath property with AAS_Plant value. The rule starts adding the common part with the fixed local variables at their initial values. After, it adds as many POU instance variables as actions defined in the CriticalSituation elements. For this, it searches those inherited InternalElements that have RefBaseSystemUnitPath property with Action, getting the value of its ExternalInterface. This will be the type of the new added variable. The name will be the same as the InternalElement’s name.

- Rule 2—Body: It is applied to every InternalElement having RefBaseSystemUnitPath property with AAS_Plant value. The common minimal structure is initially added (See Figure 9), changing PS_id() by the name of the ExternalElement in a POUInstance. Furthermore, this template applies Rule 3 to complete the list of the possible causes related to the activation of a Production Service.

- Rule 3—Recovery Actions: It is applied to InternalElements that have RefBaseSystemUnitPath property with CriticalSituation value. The code to add depends on the value of the recoveryType property (see Figure 9). The PS_id() is customized following the procedure commented above.

3.2.2. Serialization Programs

- Rule1—Interface Definition: It is applied to every InternalElement having RefBaseSystemUnitPath property with POUInstance. It initially calculates the number of bytes needed for defining the state (NumberOfBytes of Figure 11). For this, local and global variables as well as input and output parameters of the POU that implements the control logic of Production Service are identified. This POU is located in the name of the ExternalElement. Then, Rule 2 and Rule 3 are applied in order to generate the body of serialize or deserialize, respectively.

- Rule 2—Serialize Body. It requires the Production Service’s state and its corresponding variables (see Figure 11).

- Rule 3—De-Serialize Body: It also requires the state and the related variables, resulting in the writing of the new state (see Figure 11).

3.3. Application Dependant Agents Code Generator

3.3.1. APlant_AAS Template

- PS_ID: this parameter contains an identifier that can match the identifier of the automation project, and that identifies each Program Organization Unit.

- recoveryInfo: it contains the set of masks to be applied to each component to determine which type of operation must be applied at any moment. These masks, defined following the meta-model presented in Figure 14, allow to identify the critical situations of the Production System (e.g., the manufacturing steps 42–44 from Figure 3 are identified as critical situations based on the information in the recoveryInfo parameter). The Diagnosis XML file has been conceived to ease the generation and storage of such information with a predefined structure. This file stores information about the state variables (name and type), and the masks to perform both the diagnosis and the checkpoint. Note, that the diagnosis masks determine if it is a critical state type (checkpoint or unrecoverable) by filtering the state variables related to the condition to be diagnosed.

3.3.2. APlant_AAS Generation

- Rule 1—State characterization: It generates the set of variables conforming the state. To do this, every InternalElement having RefBaseSystemUnitPath property with RefVariable and the InternalElement having RefBaseSystemUnitPath property with POUinstance in AAS_Plant are processed.

- Rule 2—Critical Situation: It applies to the InternalElements that have RefBaseSystemUnitPath property with CriticalSituation in an AAS_Plant. As a result, the Critical Situation information stored in diagnosis XML file is generated.

- Rule 3—Diagnosis: It processes the Condition to identify which the state variables are required to determine the type of critical state at that situation. This rule applies to every InternalElement with RefBaseSystemUnitPath property having an Expression in a CriticalSituation.

- Rule 4—Checkpoint: It processes the CheckpointState to determine at which condition the AAS_Plant must be restarted. This rule applies to each InternalElement that have RefBaseSystemUnitPath property with CheckPointVariable in a Critical Interval.

3.3.3. AController_AAS Template

- ID, which identifies the agent in the system;

- A textual Description;

- CPUfactor, with respect to a reference controller;

- Memory resources;

- IP address;

- AssignedPS: a list of Production Services, whose control logic is executed in the controller.

4. Assessment

- Step 1—QoS Loss Detection: Registration of controller 2 unbalances the system as its current workload is too low. When the workload monitoring of controller 2 detects it, the AController_AAS2 (CA2 in Figure 16) triggers an event to notify the QM (“QoS_Loss_Event(lowerLimit_reach;CA2)” in Figure 16), that eventually leads to Production System reconfiguration (“QoS_Reconfiguration_Event (systemLoad;lowerLimit_recovery;CA2)” in Figure 16).

- Step 2—Diagnosis and Decision: The D&D receives the reconfiguration event and proceeds to initiate a negotiation among controllers to decide the new distribution. For simplicity, this negotiation process is encapsulated in the “Workload Optimization Process” block in Figure 16. The new distribution depends on the CPU factors of the AController_AASs (CA1 and CA2 in Figure 16), current distribution of the Production Services, and the CPU workload limits introduced by the Production Service software modules. When the negotiation concludes, the D&D launches the relocation of the Production Services).

- Step 3—Reconfiguration: Relocation is represented by the “for loop: PSs to be relocated” in Figure 16, which consists of the following steps. Firstly, the D&D forces the APlant_AASs (PSAi.j in Figure 16) of the affected production service software modules to move to wait decision state (wait in Figure 13). Similarly, the D&D also forces the former active APlant_AAS to stop in the next non-critical situation of the control code (“change_State(waitDecision;nonCriticalStop)” in Figure 16). At this point, the D&D commands the execution of the production service software modules from the last known state in their new locations (“change_State(active;direct)” in Figure 16).

5. Conclusions

- The definition of the critical intervals in the manufacturing process, which is essential to manage flexibility properly, has proved to be a difficult task. To that end, it is necessary to rely on someone with a great knowledge of the manufacturing process, who has also taken part in the design process of the code for the controllers. As far as authors know, other approaches do not contemplate this task, as they consider that the state represents the whole process, and thus any situation should be recoverable. Nevertheless, the reality is very different.

- The advantages of AutomationML for modeling and processing different types of data have been demonstrated. Interoperability is ensured with AutomationML as long as the integrators use PLCOpen, which is widely known and used by an increasing number of engineers and suppliers (e.g., Siemens allows to export hardware configuration to AutomationML). Despite it is a relatively new standard, it is receiving an increasing attention as exportation format for different types of data (information, code, etc.).

- The proposed approach eases the reconfiguration and scalability of the system, allowing the reconfiguration of the control system (by adding or removing controllers) without changing the configuration of the assets. In the same way, changes in the control of the process can be easily implemented thanks to automated code generation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AAS | Asset Administration Shell |

| AML | Automation ML |

| APS | Automation Production Systems |

| CAEX | Computer Aided Engineering eXchange |

| CL | Control Logic |

| D&D | Diagnosis & Decision |

| DT | Digital Twin |

| FAM | Flexible Automation Middleware |

| FAPS | Flexible Automation Production System |

| FAVA | Functional Application Design for Distributed Automation Systems |

| FB | Function Blocks |

| FSM | Finite State Machine |

| IE | Internal Element |

| JADE | Java Agent Development Framework |

| MM | Middleware Manager |

| MDD | Model Driven Design |

| MDE | Model Driven Engineering |

| M2M | Model to Model |

| M2T | Model to Text |

| MAS | Multi Agent Systems |

| PS | Production Service |

| PLCs | Programmable Logic Controllers |

| POU | Program Organization Unit |

| QoS | Quality of service |

| QM | QoS Monitor |

| RAMI 4.0 | Reference Architecture Model for Industry 4.0 |

| SysML | System Modeling Language |

| SR | System Repository |

| SUC | System Unit Classes |

| UML | Unified Modeling Language |

| XML | eXtensible Markup Language |

References

- European Commission. Research and Innovation. Factories of the Future PPP: Towards Competitive EU Manufacturing. Available online: https://ec.europa.eu/research/press/2013/pdf/ppp/fof_factsheet.pdf (accessed on 1 February 2021).

- Blanchet, M.; Rinn, T.; Von Thaden, G.; de Thieulloy, G. Industry 4.0 The New Industrial Revolution How Europe Will Succeed. Available online: http://www.iberglobal.com/files/Roland_Berger_Industry.pdf (accessed on 1 February 2021).

- National Science and Technology Council. ADVANCED MANUFACTURING: A Snapshot of Priority Technology Areas Across the Federal Government. Available online: https://www.mrs.org/docs/default-source/advocacy-policy/resources/advanced-manufacturing—A-snapshot-of-priority-technology-areas.pdf?sfvrsn=fb15e811_6 (accessed on 1 February 2021).

- Liao, Y.; Deschamps, F.; Loures, E.F.R.; Ramos, L.F.P. Past, present and future of Industry 4.0—A systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- European Commission; European Factories of the Future Research Association (EFFRA). Factories of the Future. Multi-Annual Roadmap for the Contractual PPP under Horizon 2020. Available online: https://www.effra.eu/sites/default/files/factories_of_the_future_2020_roadmap.pdf (accessed on 1 February 2021).

- Lindstrom, J.; Kyosti, P.; Birk, W.; Lejon, E. An initial model for zero defect manufacturing. Appl. Sci. 2020, 10, 4570. [Google Scholar] [CrossRef]

- Mourtzis, D. Simulation in the design and operation of manufacturing systems: State of the art and new trends. Int. J. Prod. Res. 2020, 58, 1927–1949. [Google Scholar] [CrossRef]

- Mourtzis, D.; Vlachou, E. A cloud-based cyber-physical system for adaptive shop-floor scheduling and condition-based maintenance. J. Manuf. Syst. 2018, 47, 179–198. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, X.; Wang, L. Smart manufacturing process and system automation—A critical review of the standards and envisioned scenarios. J. Manuf. Syst. 2020, 56, 312–325. [Google Scholar] [CrossRef]

- Cotrino, A.; Sebastián, M.A.; González-Gaya, C. Industry 4.0 roadmap: Implementation for small and medium-sized enterprises. Appl. Sci. 2020, 10, 8566. [Google Scholar] [CrossRef]

- Tay, S.I.; Malaysia, T.H.O.; Raja, P.; Pahat, B.; Hamid, N.A.A.; Ahmad, A.N.A. An overview of industry 4.0: Definition, components, and government initiatives. J. Adv. Res. Dyn. Control. Syst. 2018, 10, 1379–1387. [Google Scholar]

- Florescu, A.; Barabas, S.A. Modeling and simulation of a flexible manufacturing system—A basic component of industry 4.0. Appl. Sci. 2020, 10, 8300. [Google Scholar] [CrossRef]

- Shen, W.; Wang, L.; Hao, Q. Agent-based distributed manufacturing process planning and scheduling: A state-of-the-art survey. IEEE Trans. Syst. Part. C 2006, 36, 563–577. [Google Scholar] [CrossRef]

- Krupitzer, C.; Roth, F.M.; VanSyckel, S.; Schiele, G.; Becker, C. A survey on engineering approaches for self-adaptive systems. Pervasive Mob. Comput. 2015, 17, 184–206. [Google Scholar] [CrossRef]

- Wang, L.; Adamson, G.; Holm, M.; Moore, P. A review of function blocks for process planning and control of manufacturing equipment. J. Manuf. Syst. 2012, 31, 269–279. [Google Scholar] [CrossRef]

- Nouri, H. Development of a comprehensive model and BFO algorithm for a dynamic cellular manufacturing system. Appl. Math. Model. 2016, 40, 1514–1531. [Google Scholar] [CrossRef]

- Urban, T.L.; Chiang, W.-C. Designing energy-efficient serial production lines: The unpaced synchronous line-balancing problem. Eur. J. Oper. Res. 2016, 248, 789–801. [Google Scholar] [CrossRef]

- Legat, C.; Vogel-Heuser, B. A Multi-agent architecture for compensating unforeseen failures on field control level. In Service Orientation in Holonic and Multi-Agent Manufacturing and Robotics. Studies in Computational Intelligence; Borangiu, T., Trentesaux, D., Thomas, A., Eds.; Springer: Cham, Switzerland, 2014; Volume 544, pp. 195–208. [Google Scholar] [CrossRef]

- Ribeiro, L.; Barata, J.; Onori, M.; Hoos, J. Industrial agents for the fast deployment of evolvable assembly systems. In Industrial Agents; Leitão, P., Karnouskos, S., Eds.; Morgan Kaufmann: Boston, MA, USA, 2015; pp. 301–322. ISBN 9780128003411. [Google Scholar] [CrossRef]

- Rocha, A.; Di Orio, G.; Barata, J.; Antzoulatos, N.; Castro, E.; Scrimieri, D.; Ratchev, S. An agent based framework to support plug and produce. In Proceedings of the 2014 12th IEEE International Conference on Industrial Informatics (INDIN 2014), Porto Alegre, Brazil, 27–30 July 2014; pp. 504–510. [Google Scholar] [CrossRef]

- Botygin, I.A.; Tartakovsky, V.A. The development and simulation research of load balancing algorithm in network infra-structures. In Proceedings of the 2014 International Conference on Mechanical Engineering, Automation and Control Systems (MEACS 2014), Tomsk, Russia, 16–18 October 2014; pp. 1–5. [Google Scholar] [CrossRef]

- Guo, L.; Wang, B.; Wang, W. Research of energy-efficiency algorithm based on on-demand load balancing for wireless sensor networks. In Proceedings of the 2009 International Conference on Test and Measurement, Hong Kong, China, 5–6 December 2009; pp. 22–26. [Google Scholar] [CrossRef]

- Merz, M.; Frank, T.; Vogel-Heuser, B. Dynamic redeployment of control software in distributed industrial automation systems during runtime. In Proceedings of the 2012 IEEE International Conference on Automation Science and Engineering (CASE 2012), Seoul, Korea, 20–24 August 2012; pp. 863–868. [Google Scholar] [CrossRef]

- Streit, A.; Rösch, S.; Vogel-Heuser, B. Redeployment of control software during runtime for modular automation systems taking real-time and distributed I/O into consideration. In Proceedings of the 2014 IEEE Emerging Technology and Factory Automation (ETFA 2014), Barcelona, Spain, 16–19 September 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Salazar, L.A.C.; Mayer, F.; Schütz, D.; Vogel-Heuser, B. Platform independent multi-agent system for robust networks of production systems. IFAC PapersOnLine 2018, 51, 1261–1268. [Google Scholar] [CrossRef]

- Priego, R.; Iriondo, N.; Gangoiti, U.; Marcos, M. Agent Based Middleware Architecture for Reconfigurable Manufacturing Systems. Int. J. Adv. Manuf. Technol. 2017, 92, 1579–1590. [Google Scholar] [CrossRef][Green Version]

- International Electrotechnical Commission. Smart Manufacturing—Reference Architecture Model Industry 4.0 (RAMI4.0). IEC Standard PAS 63088: 2017(E). Available online: https://webstore.iec.ch/publication/30082 (accessed on 3 February 2021).

- Wang, H. Dynamic Fault Handling and Reconfiguration for Industrial Automation Systems. Available online: https://www.ias.uni-stuttgart.de/dokumente/publikationen/2019_Dynamic_Fault_Handling_and_Reconfiguration_for_Industrial_Automation_Systems.pdf (accessed on 3 February 2021).

- Lyu, G.; Fazlirad, A.; Brennan, R.W. Multi-agent modeling of cyber-physical systems for IEC 61499 based distributed automation. Procedia Manuf. 2020, 51, 1200–1206. [Google Scholar] [CrossRef]

- Fraile, F.; Sanchis, R.; Poler, R.; Ortiz, A. Reference models for digital manufacturing platforms. Appl. Sci. 2019, 9, 4433. [Google Scholar] [CrossRef]

- Cavalieri, S.; Salafia, M.G. Insights into mapping solutions based on OPC UA information model applied to the industry 4.0 asset administration shell. Computers 2020, 9, 28. [Google Scholar] [CrossRef]

- Cavalieri, S.; Giuseppe, M.G. Asset administration shell for PLC representation based on IEC 61131-3. IEEE Access 2020, 8, 142606–142621. [Google Scholar] [CrossRef]

- Glossary. Available online: https://www.plattform-i40.de/SiteGlobals/PI40/Forms/Listen/Glossar/EN/Glossary_Formular.html?queryResultId=null&pageNo=0&resourceId=1081500&pageLocale=en&input_=1081494&titlePrefix=Alle (accessed on 13 February 2021).

- International Electrotechnical Commission. IEC 61131–3:2013 Programmable Controllers—Part 3: Programming Languages. Available online: https://webstore.iec.ch/publication/4552 (accessed on 3 February 2021).

- The Structure of the Administration Shell: Trilateral Perspectives from France, Italy and Germany. Available online: https://www.plattform-i40.de/PI40/Redaktion/EN/Downloads/Publikation/hm-2018-trilaterale-coop.pdf?__blob=publicationFile&v=4 (accessed on 25 February 2021).

- Booch, G.; Rumbaugh, J.; Jacobson, I. The Unified Modeling Language User Guide, 2nd ed.; Addison-Wesley Professional: Boston, MA, USA, 2015; ISBN 0321267974. [Google Scholar]

- Estevez, E.; Marcos, M.; Gangoiti, U.; Orive, D. A Tool Integration Framework for Industrial Distributed Control Systems. In Proceedings of the 44th IEEE Conference on Decision and Control, Seville, Spain, 12–15 December 2005; pp. 8373–8378. [Google Scholar] [CrossRef]

- Hästbacka, D.; Vepsäläinen, T.; Kuikka, S. Model-driven development of industrial process control applications. J. Syst. Softw. 2011, 84, 1100–1113. [Google Scholar] [CrossRef]

- Thramboulidis, K.; Frey, G. Towards a model-driven IEC 61131-based development process in industrial automation. J. Softw. Eng. Appl. 2011, 4, 217–226. [Google Scholar] [CrossRef]

- Vyatkin, V.; Hanisch, H.-M.; Pang, C.; Yang, C.-H. Closed-loop modeling in future automation system engineering and validation. IEEE Trans. Syst. Part. C 2009, 39, 17–28. [Google Scholar] [CrossRef]

- SysML. The SysML Specification. Available online: http://www.sysml.org (accessed on 3 February 2021).

- Schütz, D.; Obermeier, M.; Vogel-heuser, B. SysML-based approach for automation software development—Explorative usability evaluation of the provided notation. In Design, User Experience, and Usability. Web, Mobile, and Product Design. DUXU 2013; Lecture Notes in Computer Science; Marcus, A., Ed.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 8015, pp. 568–574. [Google Scholar] [CrossRef]

- Fay, A.; Vogel-Heuser, B.; Frank, T.; Eckert, K.; Hadlich, T.; Diedrich, C. Enhancing a model-based engineering approach for distributed manufacturing automation systems with characteristics and design patterns. J. Syst. Softw. 2015, 101, 221–235. [Google Scholar] [CrossRef]

- Wehrmeister, M.A.; de Freitas, E.P.; Binotto, A.P.D.; Pereira, C.E. Combining aspects and object-orientation in model-driven engineering for distributed industrial mechatronics systems. Mechatronics 2014, 24, 844–865. [Google Scholar] [CrossRef]

- Marcos, M.; Estevez, E.; Perez, F.; Van der Wal, E. XML exchange of control programs. IEEE Ind. Electron. Mag. 2009, 3, 32–35. [Google Scholar] [CrossRef]

- Van der Wal, E. PLCopen. IEEE Ind. Electron. Mag. 2009, 3, 25. [Google Scholar] [CrossRef]

- Thramboulidis, K. The 3+1 SysML view-model in model integrated mechatronics. J. Softw. Eng. Appl. 2010, 3, 109–118. [Google Scholar] [CrossRef]

- Priego, R.; Armentia, A.; Estévez, E.; Marcos, M. Modeling techniques as applied to generating tool-independent automation projects. Automatisierungstechnik 2016, 64, 325–340. [Google Scholar] [CrossRef]

- Vogel-Heuser, B.; Schütz, D.; Frank, T.; Legat, C. Model-driven engineering of Manufacturing Automation Software Projects—A SysML-based approach. Mechatronics 2014, 24, 883–897. [Google Scholar] [CrossRef]

- Institute of Automation and Information Systems. Functional Application Design for Distributed Automation Systems (FAVA). Available online: https://www.ais.mw.tum.de/en/research/ (accessed on 3 February 2021).

- Vogel-Heuser, B.; Rösch, S. Integrated modeling of complex production automation systems to increase dependability. In Risk—A Multidisciplinary Introduction; Klüppelberg, C., Straub, D., Welpe, I., Eds.; Springer: Cham, Switzerland, 2014; pp. 363–385. [Google Scholar] [CrossRef]

- Cândido, G.; Colombo, A.W.; Barata, J.; Jammes, F. Service-oriented infrastructure to support the deployment of evolvable production systems. IEEE T. Ind. Inform. 2011, 7, 759–767. [Google Scholar] [CrossRef]

- Legat, C.; Schütz, D.; Vogel-Heuser, B. Automatic generation of field control strategies for supporting (re-)engineering of manufacturing systems. J. Intell. Manuf. 2014, 25, 1101–1111. [Google Scholar] [CrossRef]

- Selic, B. The pragmatics of model-driven development. IEEE Softw. 2003, 20, 19–25. [Google Scholar] [CrossRef]

- Binder, C.; Neureiter, C.; Lastro, G. Towards a MDA process for developing industry 4.0 applications. Int. J. Model. Opt. 2019, 9, 1–6. [Google Scholar] [CrossRef]

- Lüder, A.; Estévez, E.; Hundt, L.; Marcos, M. Automatic transformation of logic models within engineering of embedded mechatronical units. Int. J. Adv. Manuf. Technol. 2011, 54, 1077–1089. [Google Scholar] [CrossRef]

- AutomationML. Available online: http://www.automationml.org/ (accessed on 3 February 2021).

- Schmidt, D.C. Guest editor’s introduction: Model-driven engineering. Computer 2006, 39, 25–31. [Google Scholar] [CrossRef]

- Estévez, E.; Marcos, M. Model-based validation of industrial control systems. IEEE Trans. Ind. Inform. 2012, 8, 302–310. [Google Scholar] [CrossRef]

- Fedai, M.; Drath, R. CAEX—A neutral data exchange format for engineering data. ATP Int. Autom. Technol. 2005, 1, 43–51. [Google Scholar]

- Hergenhahn, T. LIBNODAVE—Exchange Data with Siemens PLCs. Available online: http://libnodave.sourceforge.net/ (accessed on 3 February 2021).

- Heiser, D.; Croes, M.; Schlameuß, R. S7netplus. Available online: https://github.com/S7NetPlus/s7netplus (accessed on 11 January 2021).

- Beckhoff. Automation Device Specification (ADS). Available online: https://infosys.beckhoff.com/english.php?content=../content/1033/tcadscommon/html/tcadscommon_intro.htm&id= (accessed on 3 February 2021).

| PSAs | Dist. Alg. | 1st Reconf | 2nd Reconf | 3rd Reconf | 4th Reconf | 5th Reconf | 6th Reconf | 7th Reconf | 8th Reconf |

|---|---|---|---|---|---|---|---|---|---|

| 2 | 5.29 | 610.04 | 1214.79 | ||||||

| 3 | 6.14 | 610.66 | 1216.09 | 1822.70 | |||||

| 4 | 8.36 | 612.20 | 1221.51 | 1830.35 | 2437.00 | ||||

| 5 | 11.67 | 616.58 | 1236.59 | 1843.65 | 2450.43 | 3056.97 | |||

| 6 | 12.72 | 617.41 | 1222.53 | 1827.60 | 2432.38 | 3065.81 | 3687.38 | ||

| 7 | 16.98 | 625.51 | 1230.31 | 1837.61 | 2444.37 | 3050.74 | 3657.21 | 4262.64 | |

| 8 | 17.49 | 622.99 | 1242.58 | 1851.25 | 2456.50 | 3062.99 | 3667.54 | 4275.75 | 4880.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gangoiti, U.; López, A.; Armentia, A.; Estévez, E.; Marcos, M. Model-Driven Design and Development of Flexible Automated Production Control Configurations for Industry 4.0. Appl. Sci. 2021, 11, 2319. https://doi.org/10.3390/app11052319

Gangoiti U, López A, Armentia A, Estévez E, Marcos M. Model-Driven Design and Development of Flexible Automated Production Control Configurations for Industry 4.0. Applied Sciences. 2021; 11(5):2319. https://doi.org/10.3390/app11052319

Chicago/Turabian StyleGangoiti, Unai, Alejandro López, Aintzane Armentia, Elisabet Estévez, and Marga Marcos. 2021. "Model-Driven Design and Development of Flexible Automated Production Control Configurations for Industry 4.0" Applied Sciences 11, no. 5: 2319. https://doi.org/10.3390/app11052319

APA StyleGangoiti, U., López, A., Armentia, A., Estévez, E., & Marcos, M. (2021). Model-Driven Design and Development of Flexible Automated Production Control Configurations for Industry 4.0. Applied Sciences, 11(5), 2319. https://doi.org/10.3390/app11052319