Seismic Resistance and Parametric Study of Building under Control of Impulsive Semi-Active Mass Damper

Abstract

1. Introduction

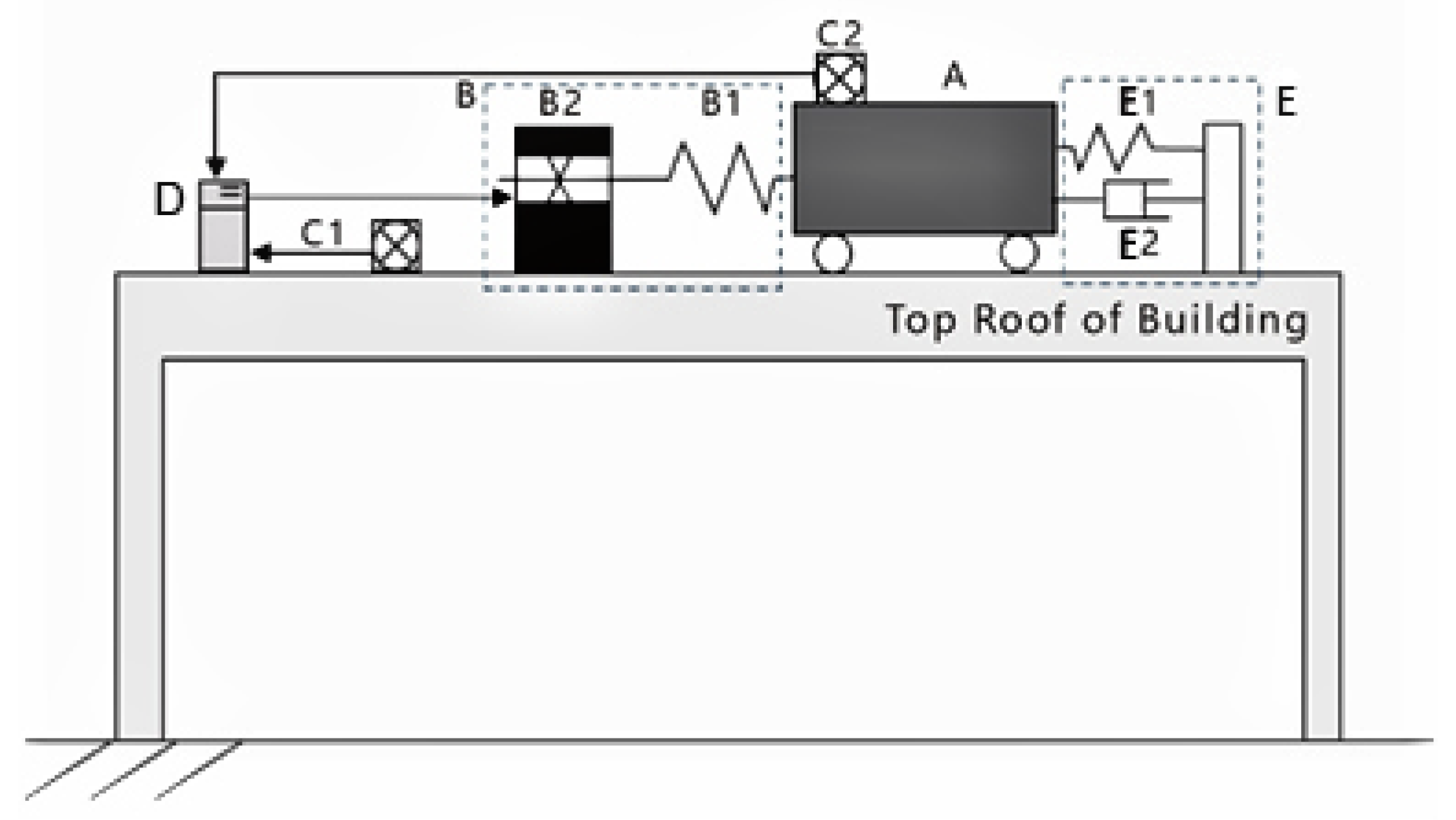

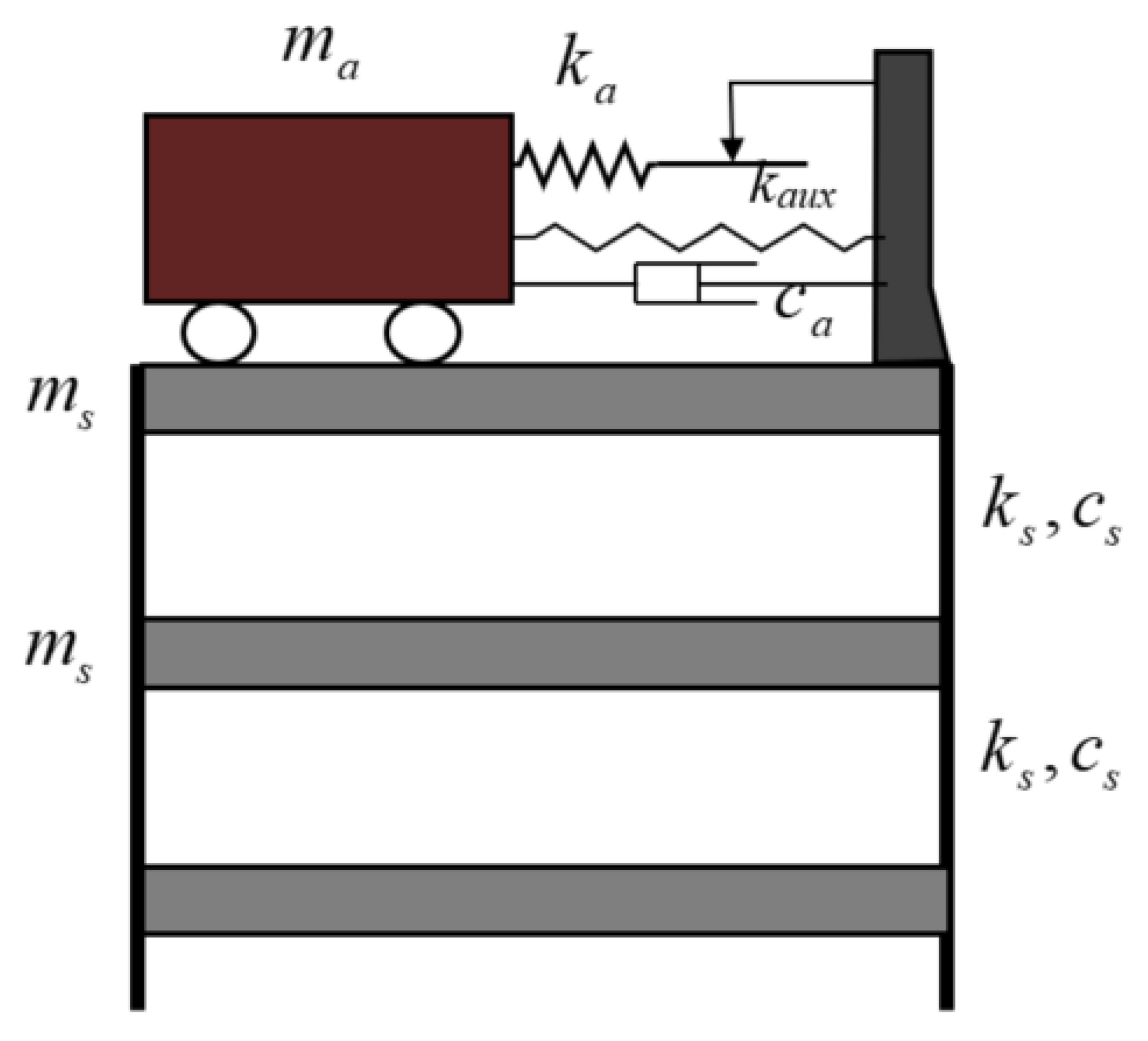

2. Concept of the ISAMD

- (1)

- Motion of the structural floor and the control mass block is detected by motion sensors (accelerometers, C1 and C2). The signal is actively retrieved by the controller.

- (2)

- The controller converts the acceleration signal to velocity and displacement signals.

- (3)

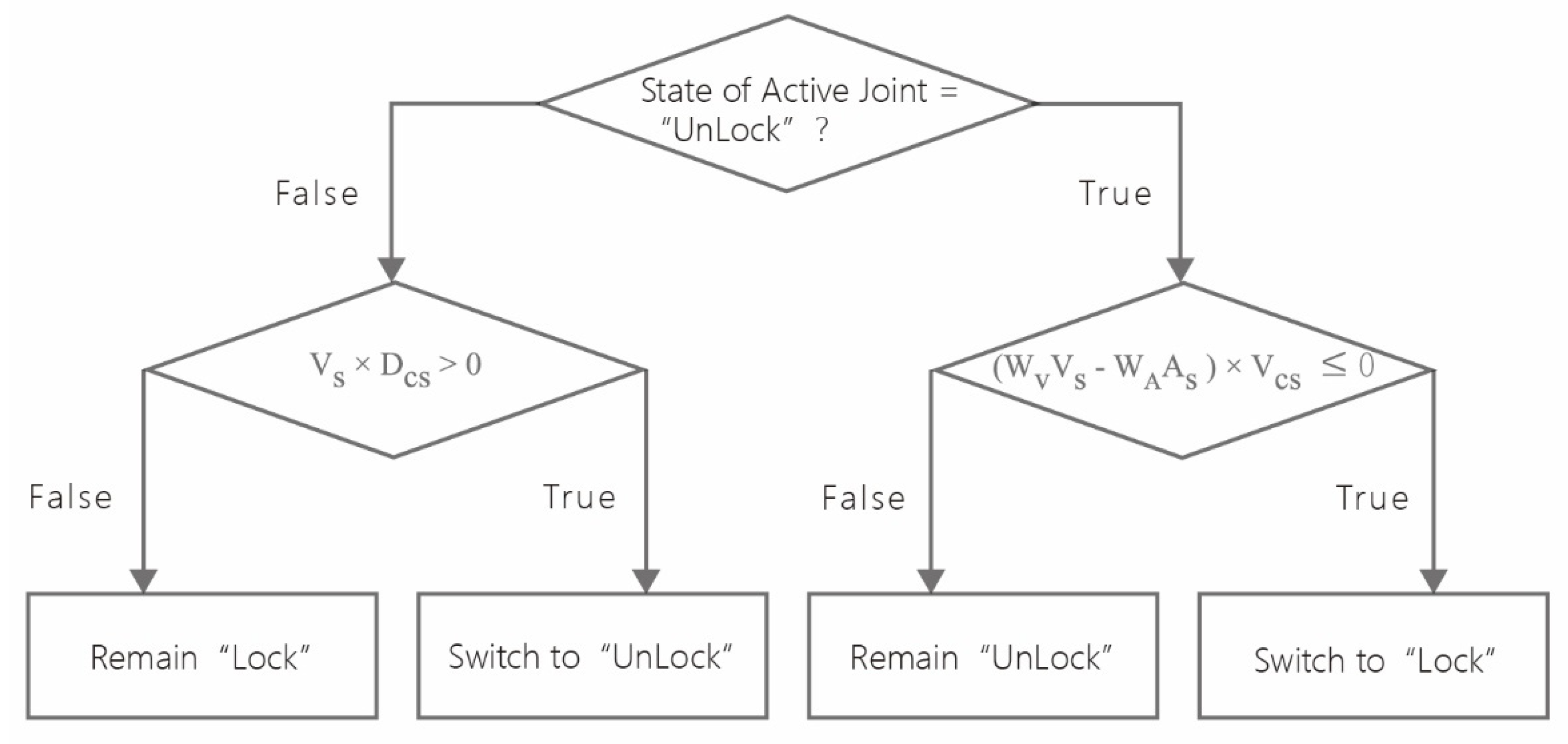

- The controller determines whether to “Unlock” or “Lock” the active joint according to the control law and outputs the control signal to the active joint.

- (4)

- The active joint (B2) releases or captures the switching spring (B1) according to the control signal from the controller.

- (5)

- Steps (1)–(5) are repeated.

- (1)

- Lock to Unlock: When the inner force of the switching spring (B1) begins to do positive work on the structure, the ISAMD switches to the “Unlock” status and the structure and the control mass become separated.

- (2)

- Unlock to Lock: When the ISAMD switches to the “Lock” status, the switching spring (B1) performs negative work on the structure. Then, the controller (D) sends a “Lock” command to the active joint (B2) to reconnect the main structure and control mass with the switching spring.

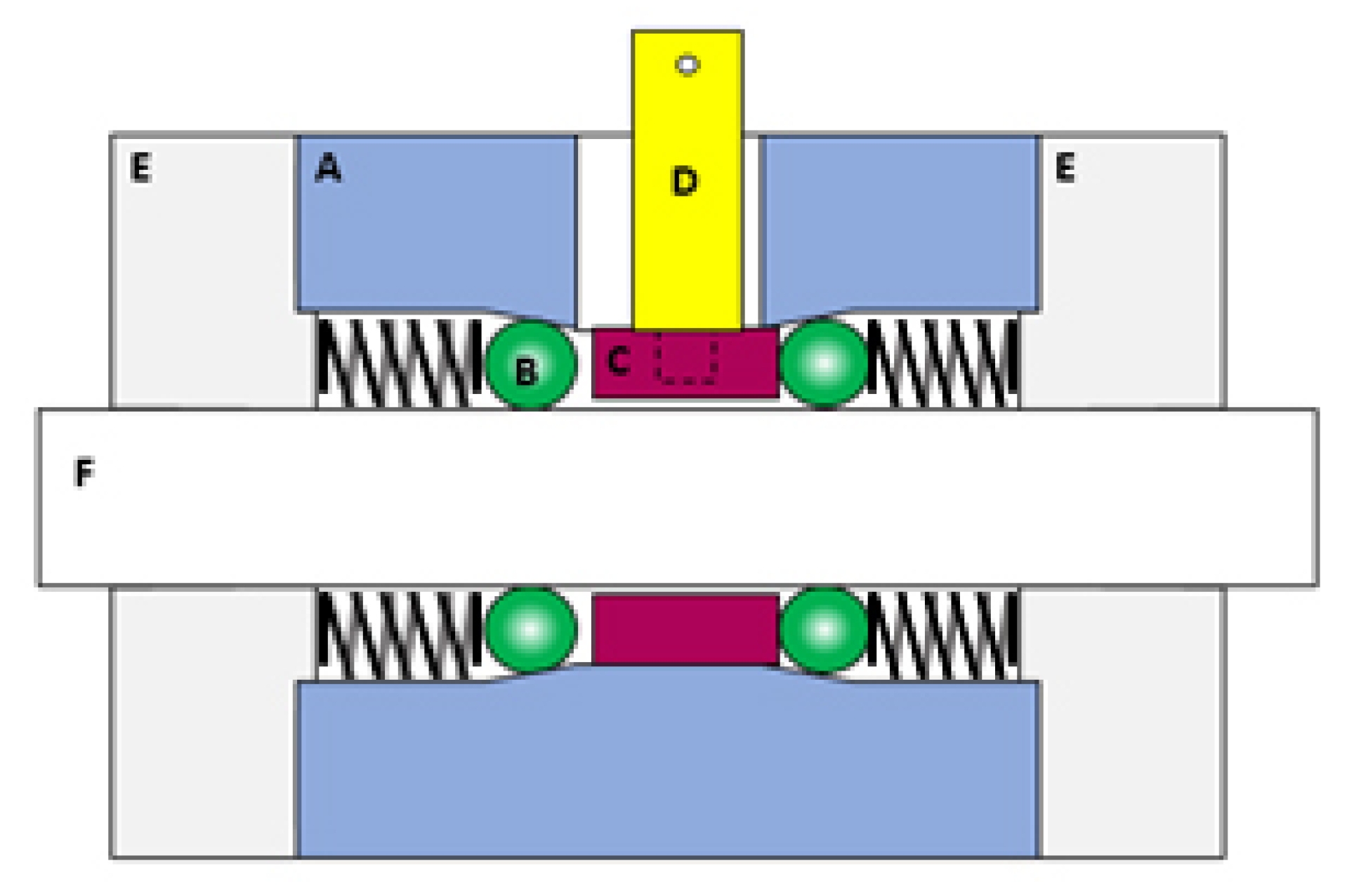

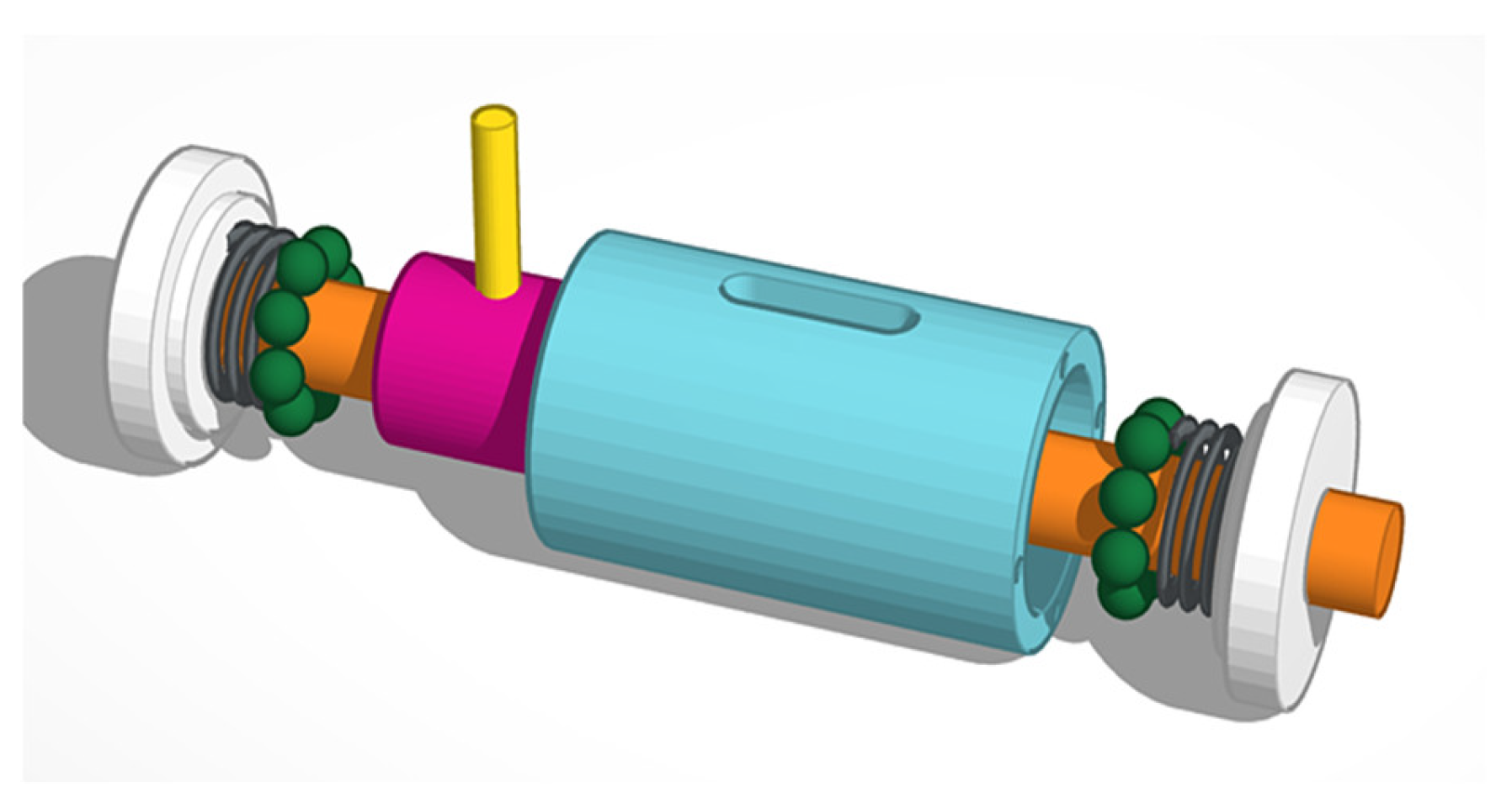

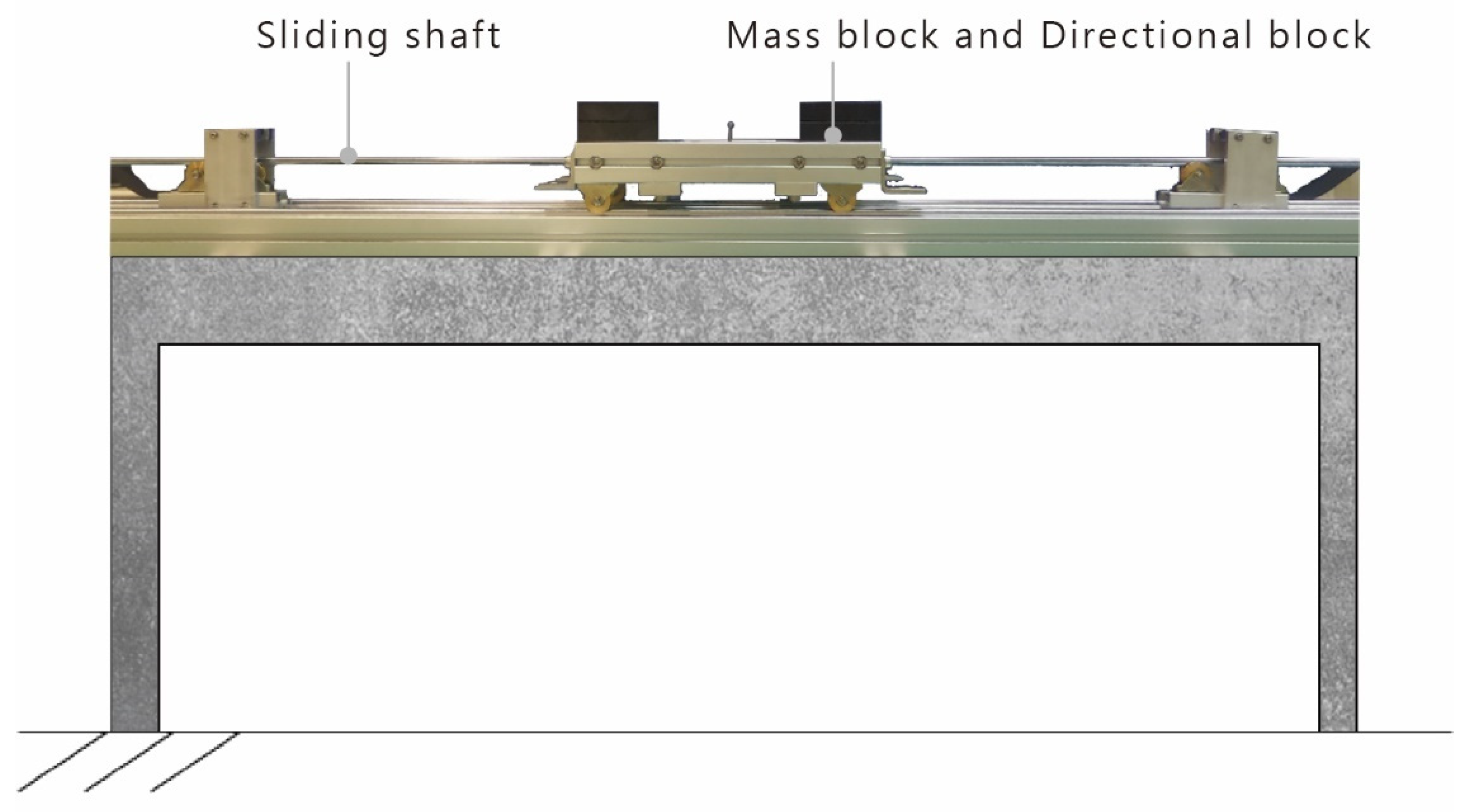

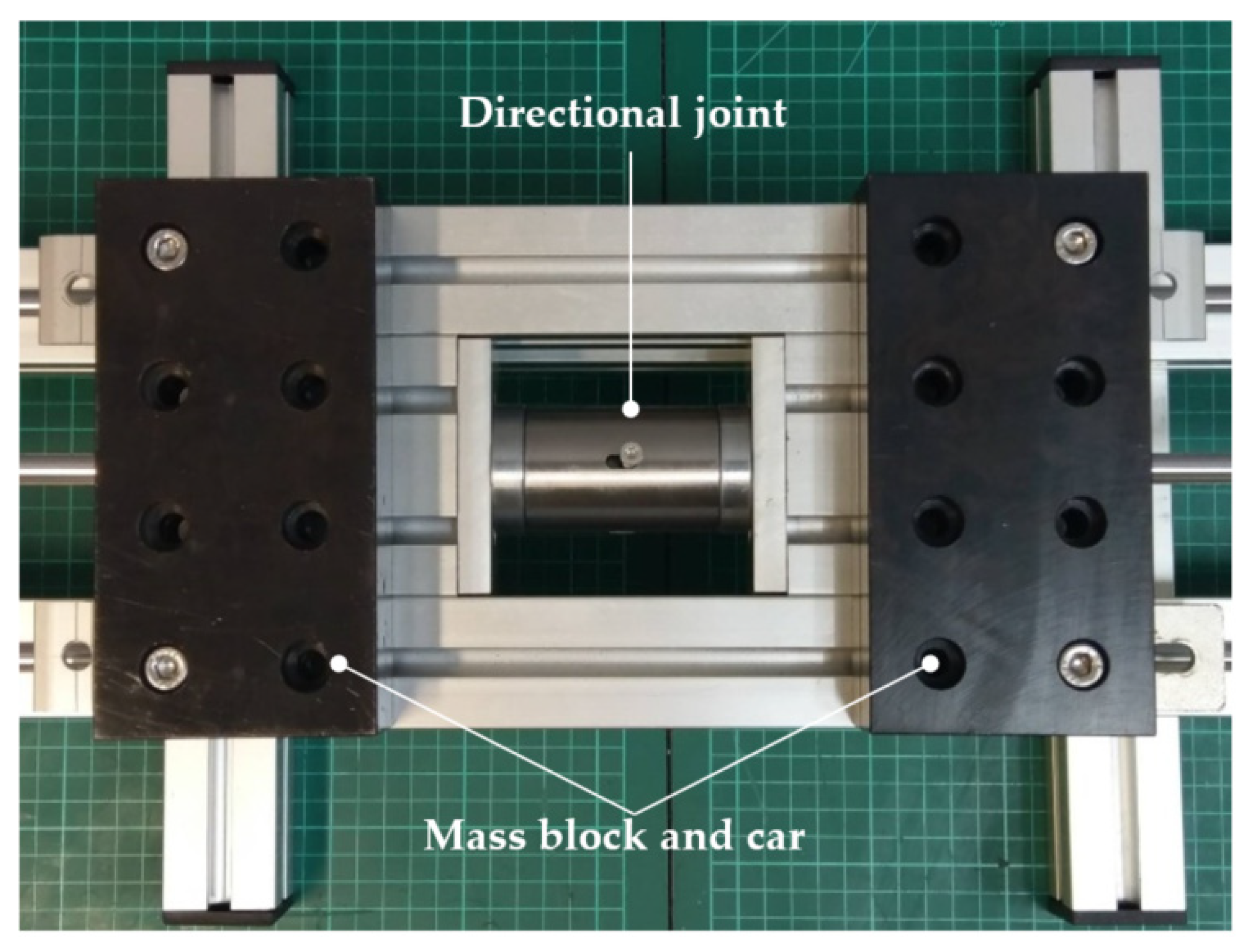

3. Developing Directional Joint of the ISAMD

4. Analysis Model

4.1. Control Law of the ISAMD

4.2. One-Dimensional Vector Form Instinct Finite Element Method, VFIFE

5. Setting of the Analysis Model for the Shock Absorption Effect of a 10-Story Building with the ISAMD

5.1. Analysis Setting

5.1.1. Main Structure Parameters

5.1.2. Control Parameters of the ISAMD

5.1.3. Control Parameters of the TMD

5.1.4. Earthquake Records

5.2. Indices of Control Performance

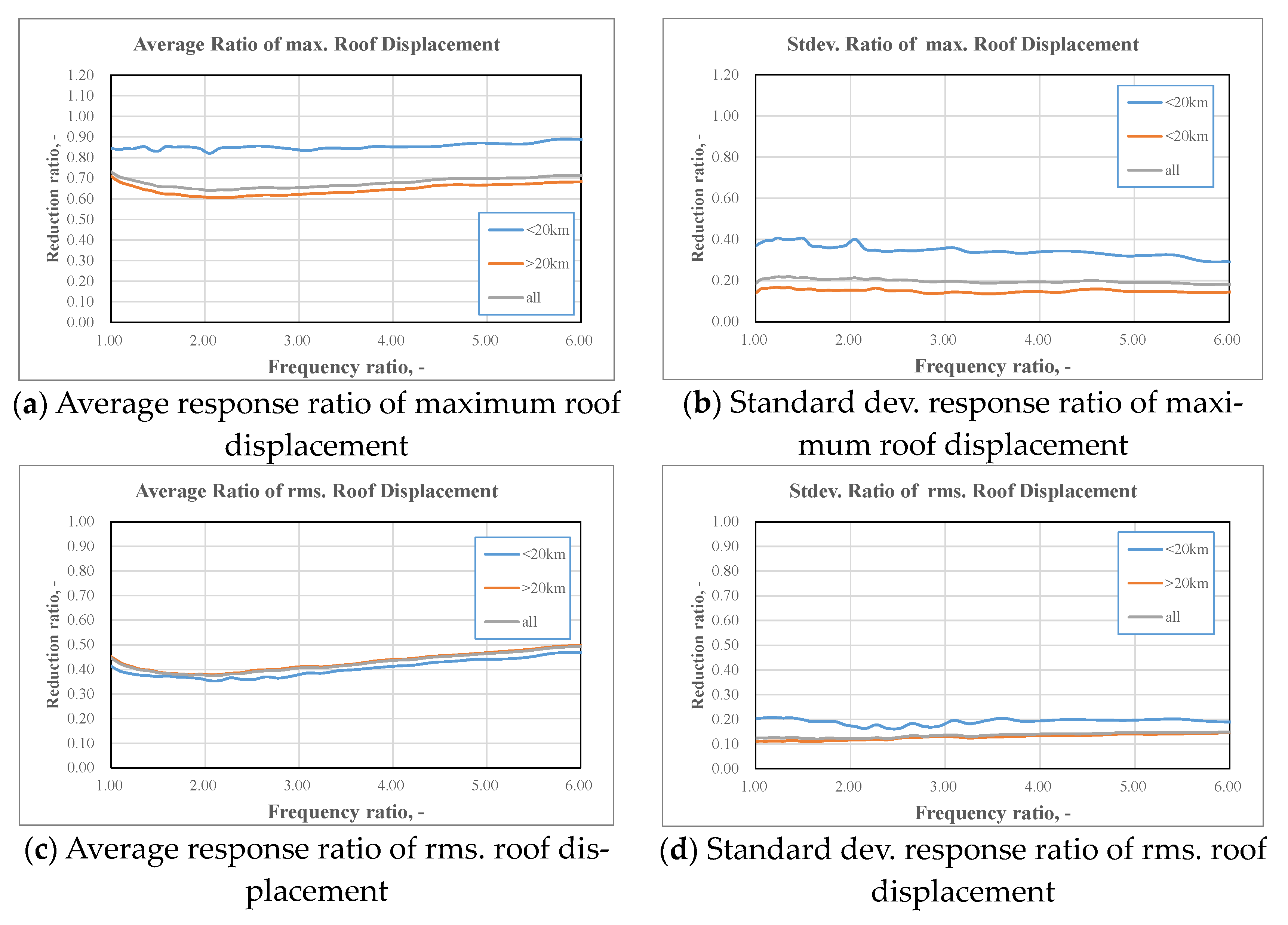

- (1)

- Average ratio of the maximum roof displacement reaction ():

- (2)

- Standard deviation of the maximum roof displacement reaction ratio ():

- (3)

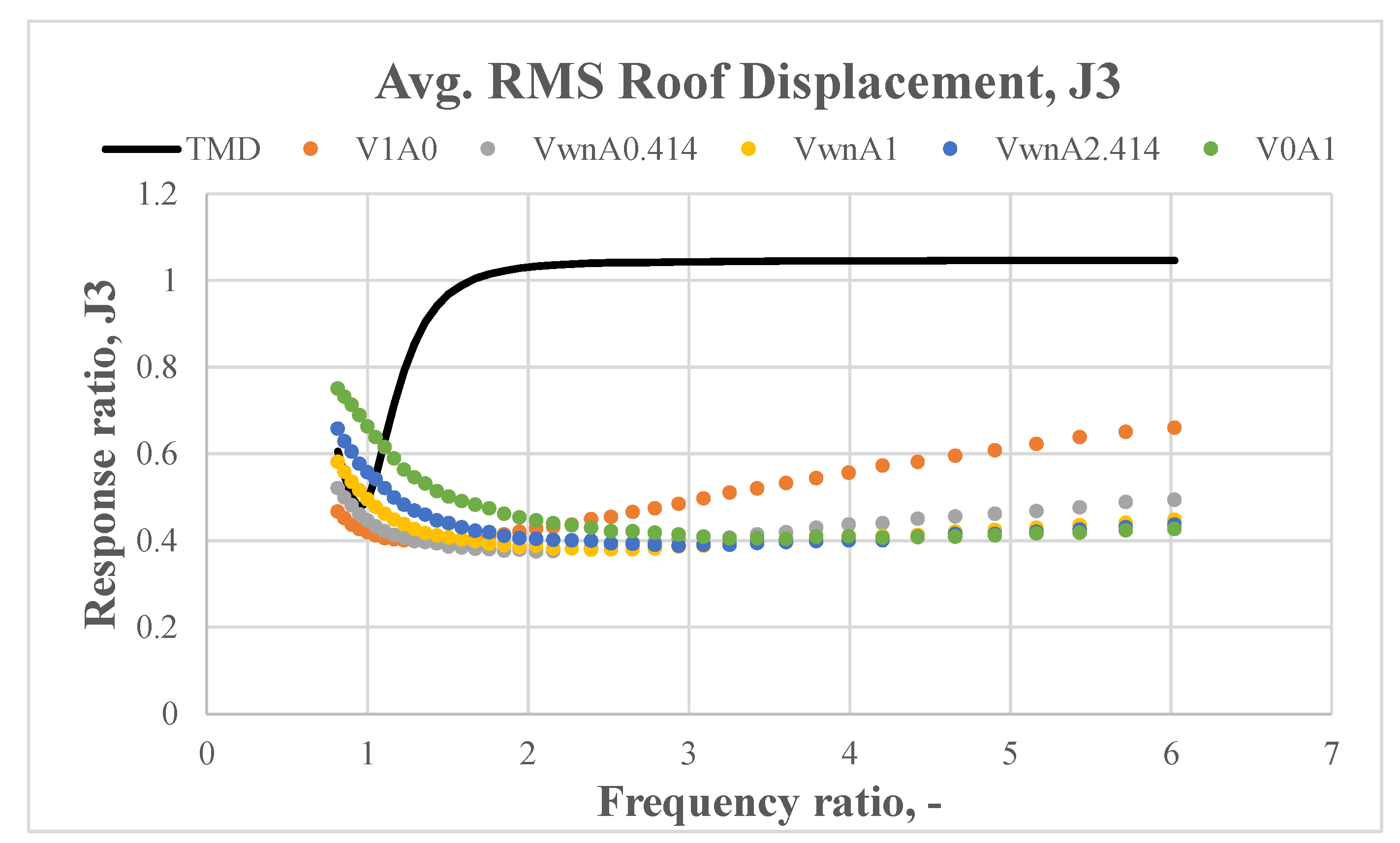

- Average Root Mean Square, RMS ratio of the roof displacement reaction ():

- (4)

- Standard deviation of the average RMS ratio of the roof displacement reaction ():

- (5)

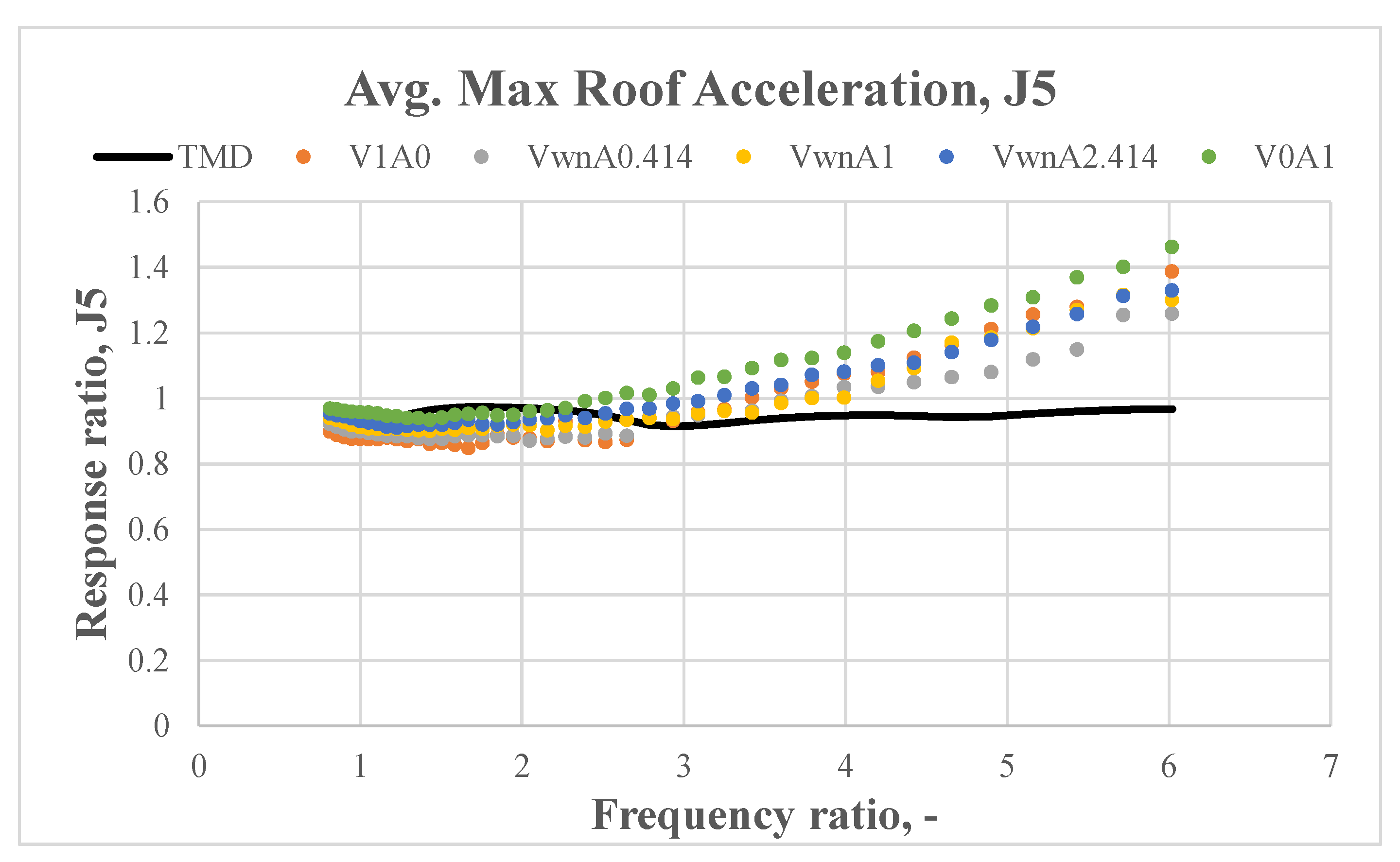

- Average ratio of the roof maximum absolute acceleration reaction ()

- (6)

- Average ratio of the maximum displacement of the control mass block ():

6. Results and Discussion

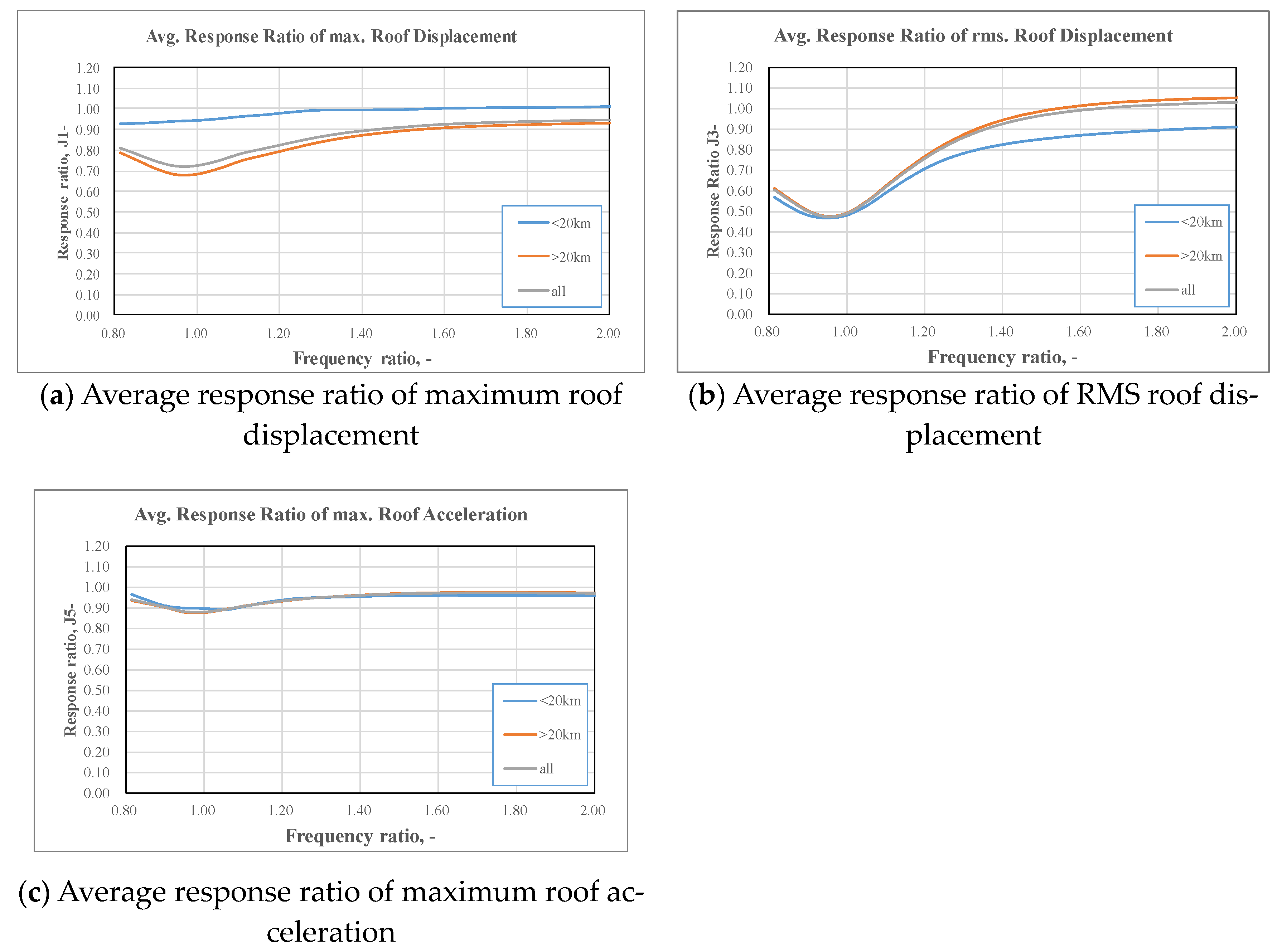

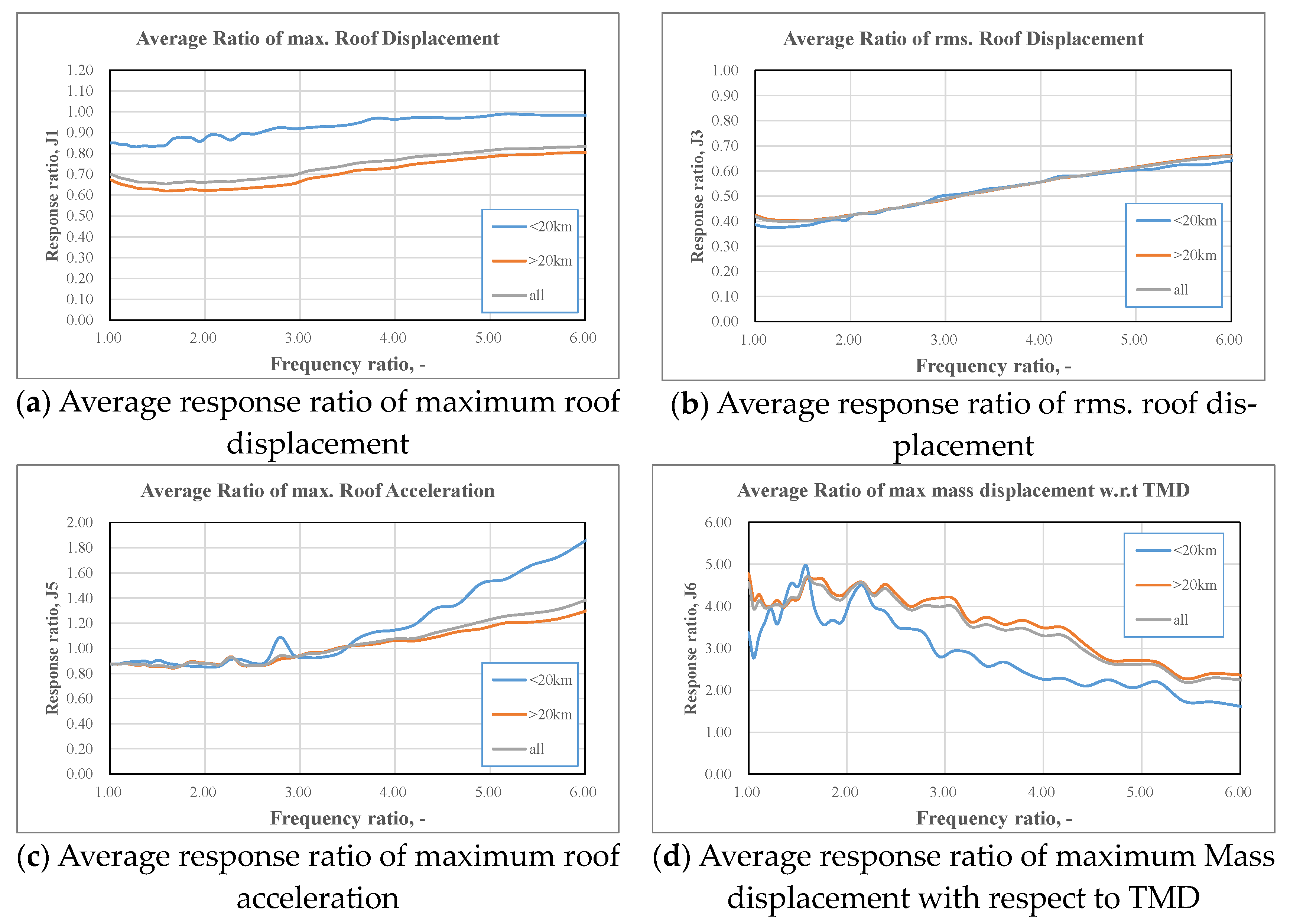

6.1. Analysis Results

6.2. Discussion

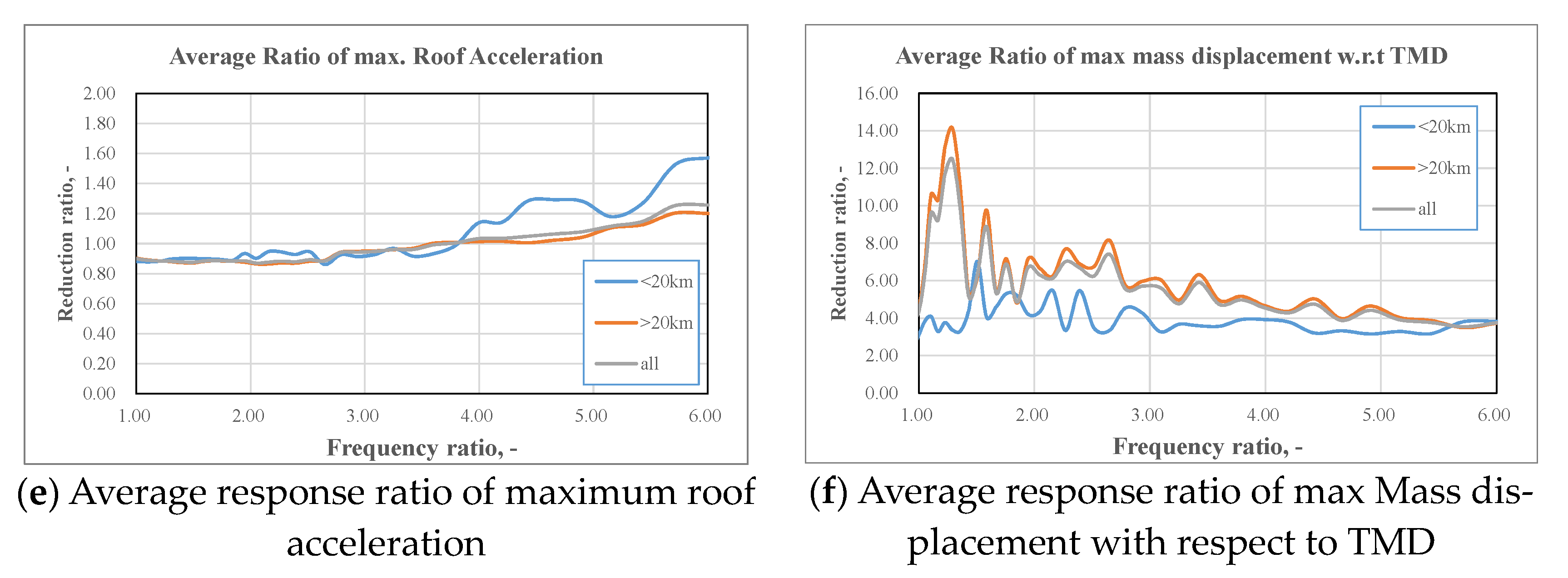

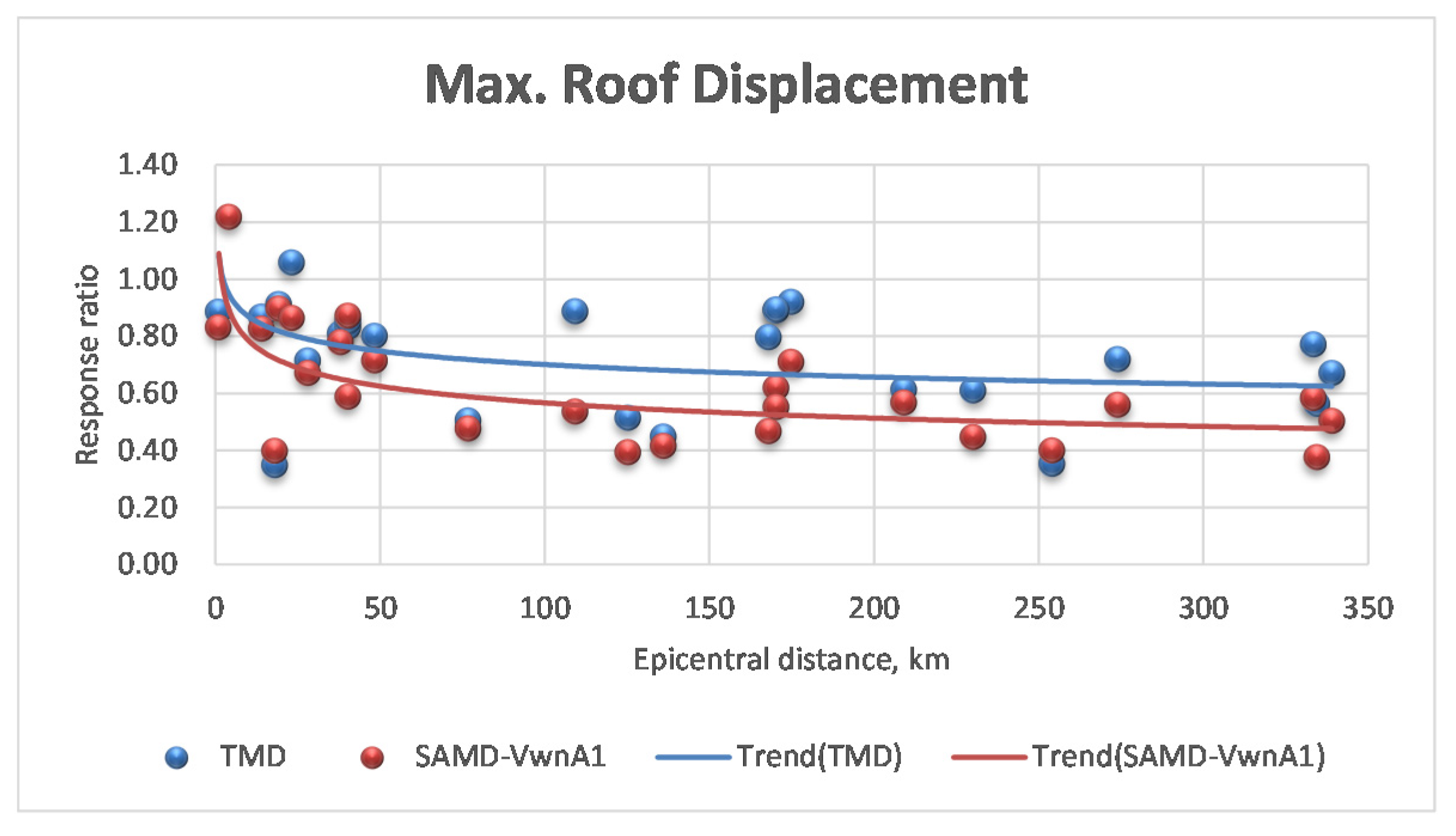

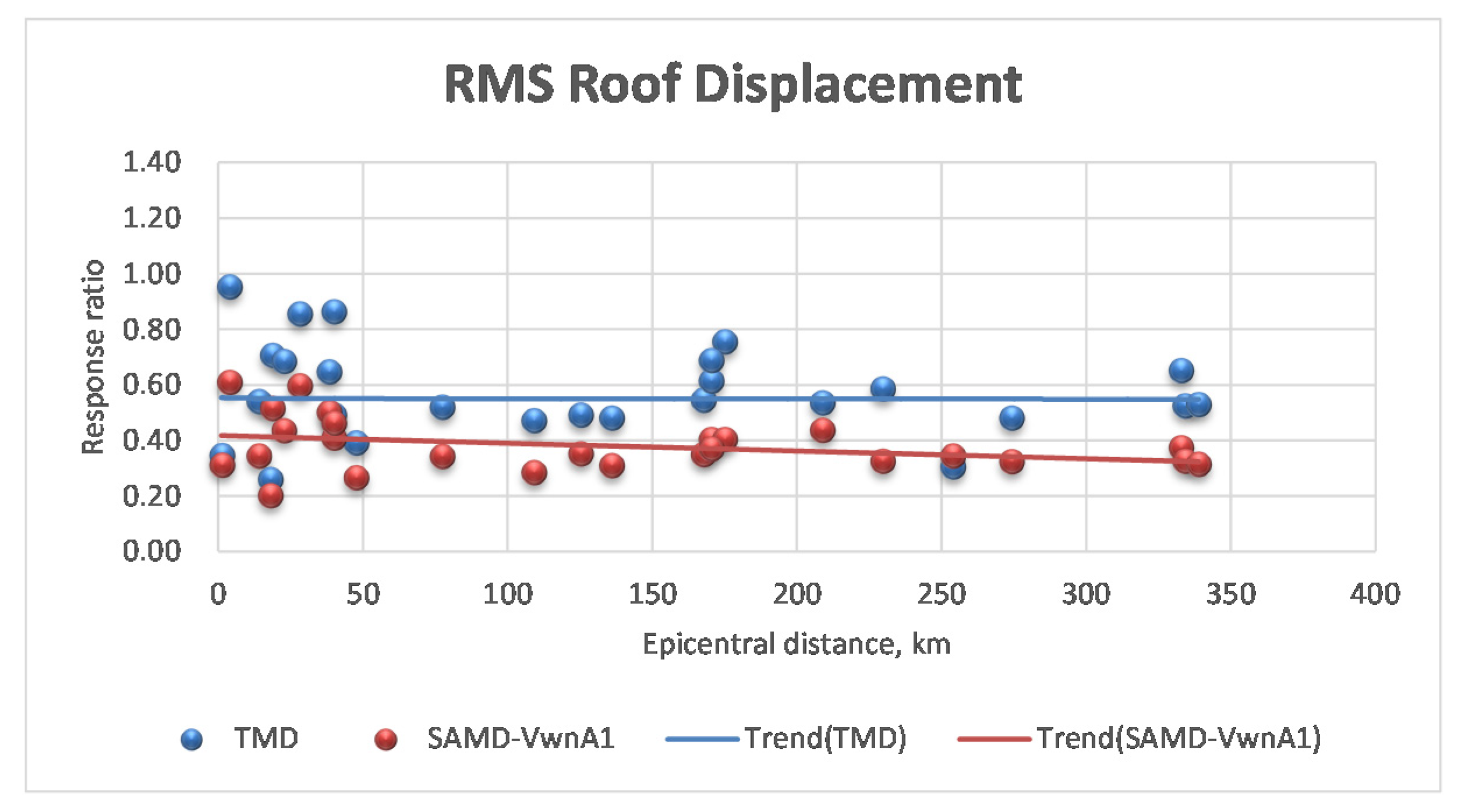

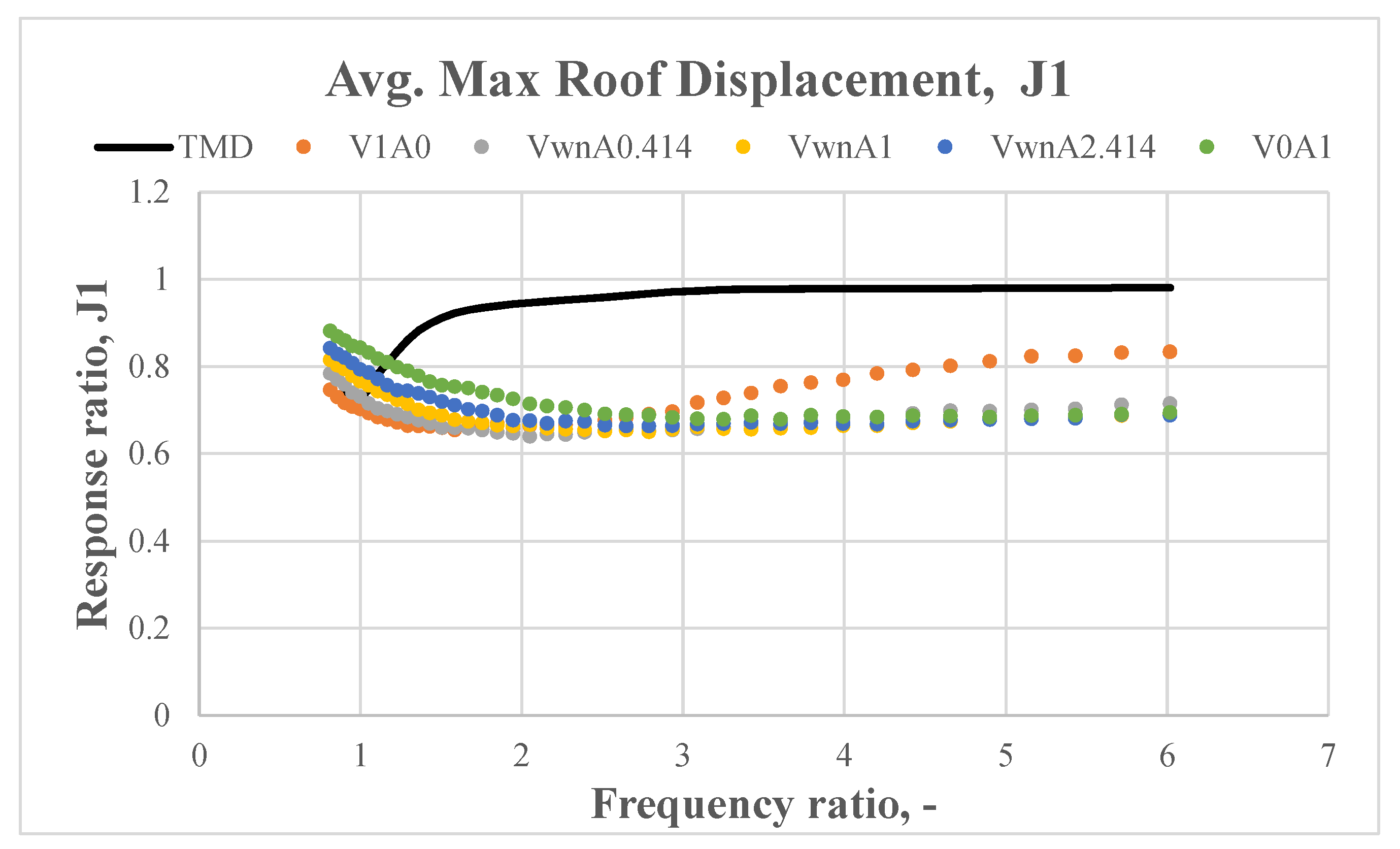

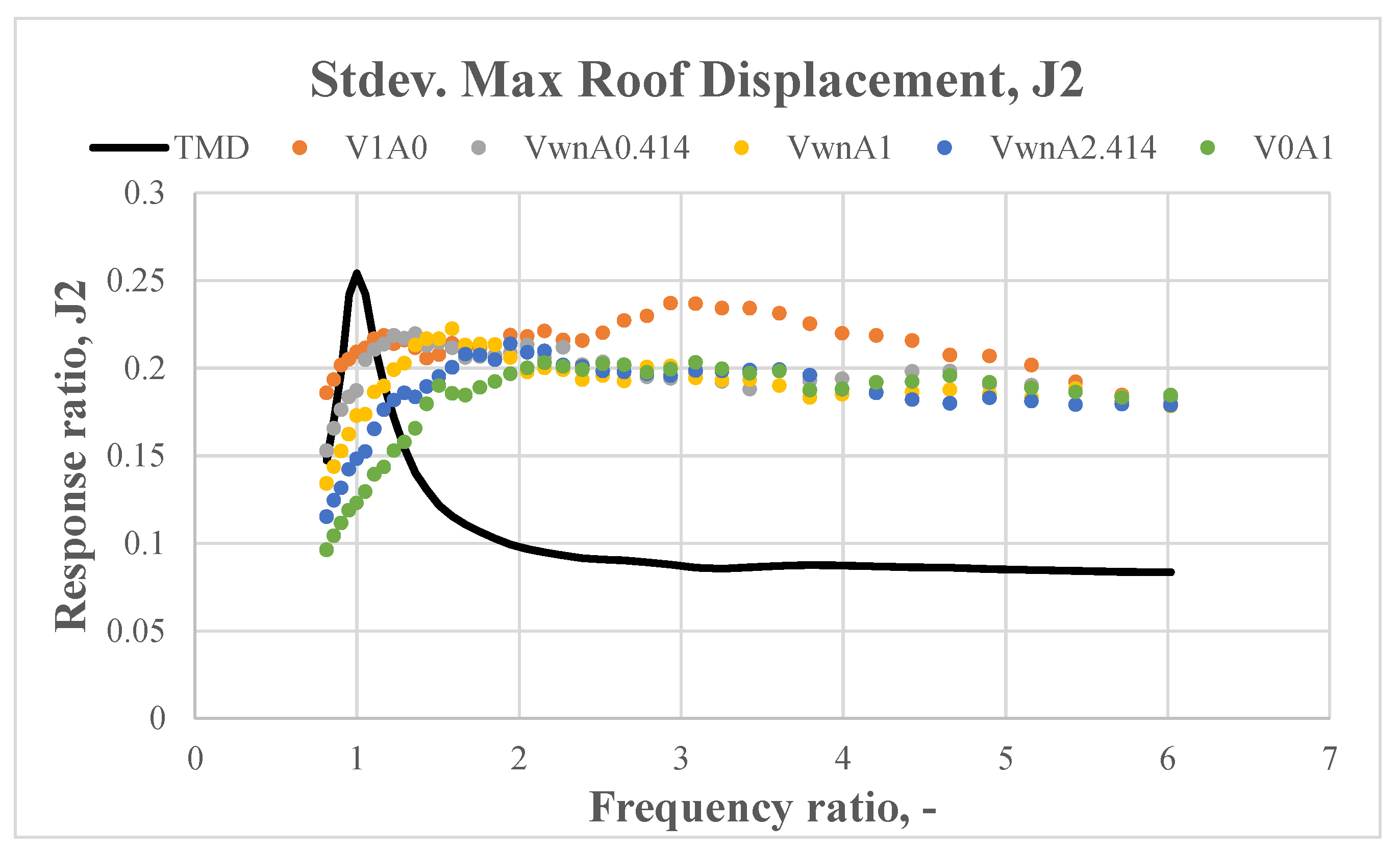

6.2.1. The Maximum Roof Displacement and Root Mean Square Displacement of the Structure

6.2.2. Influence of WV:WA on the Control Performance of the ISAMD

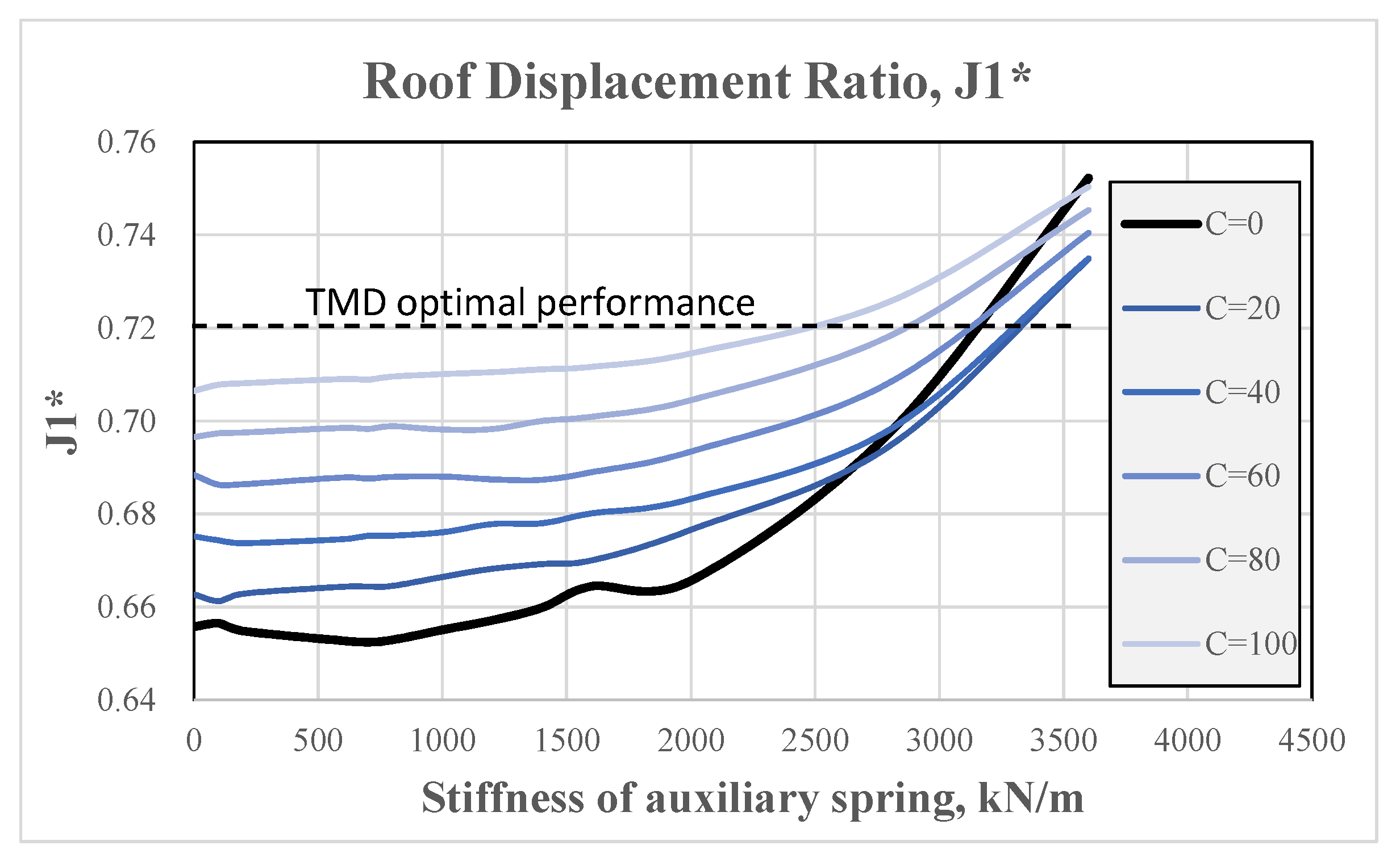

6.2.3. Seismic Resistance and Mass Block Displacement Influence of the ISAMD with Auxiliary Damper and Spring

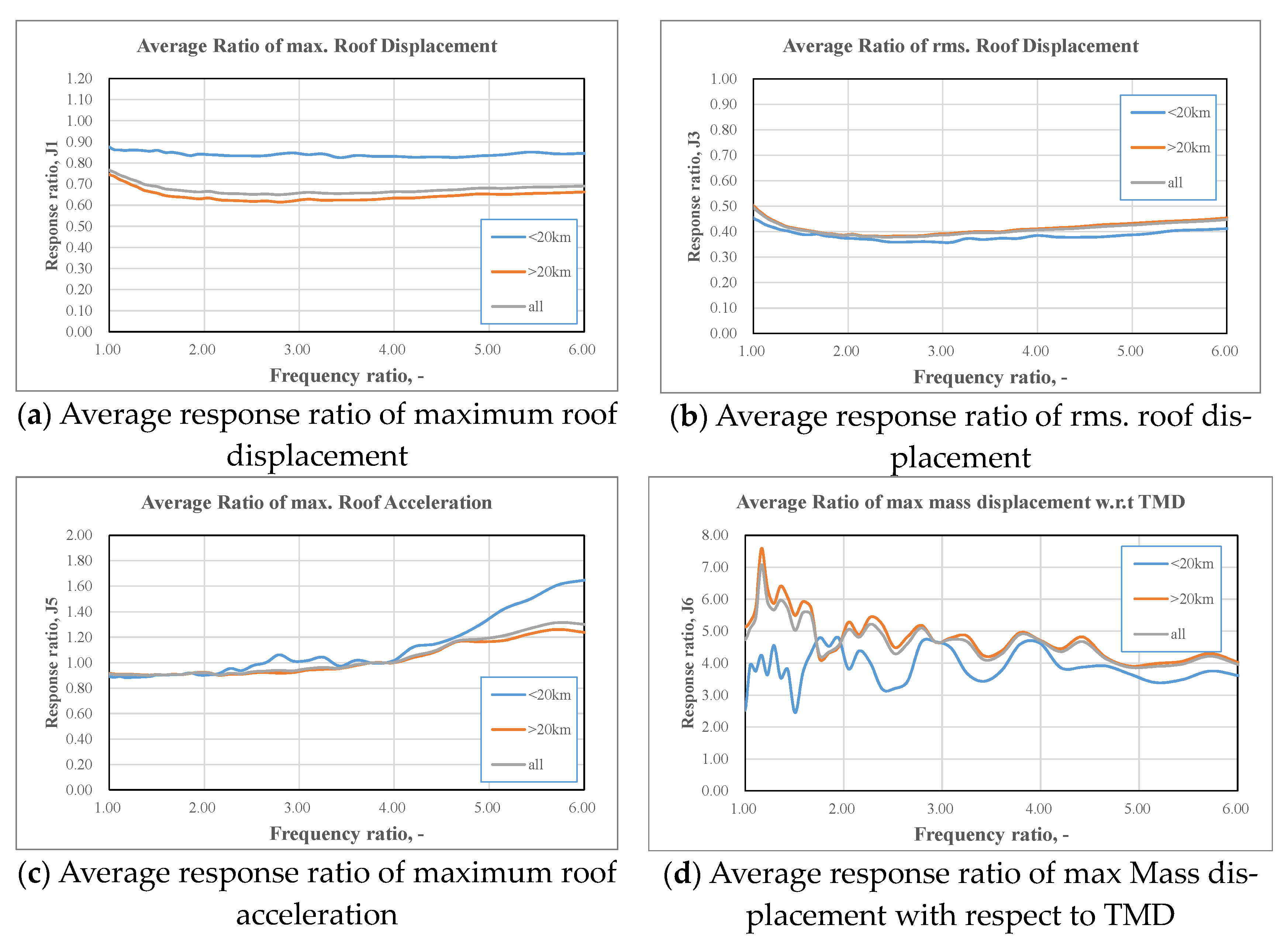

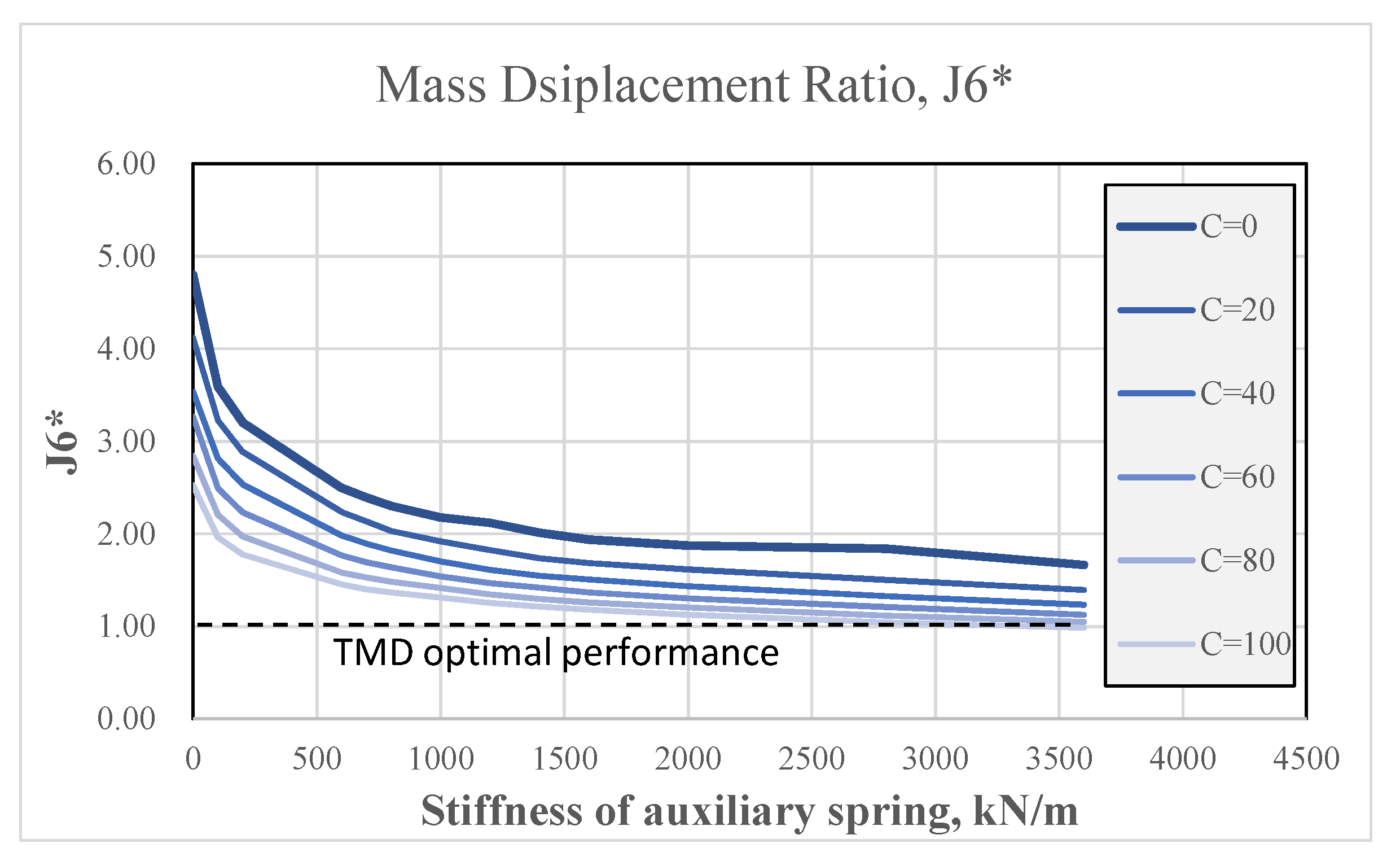

- (1)

- Figure 25 shows that, when the spring stiffness is up to 1000 kN/m, equivalent to one-quarter of the optimal stiffness of the TMD, the mass block displacement is reduced to twice that of the TMD. The displacement of mass blocks is effectively controlled with a reduction rate of about 60% compared to the original displacement reaction.

- (2)

- When the stiffness of the auxiliary spring is less than 1500 kN/m, the change in the displacement control effect for the maximum structural displacement reaction of the roof is less than 1%.

- (3)

- The auxiliary spring reduces the mass block displacement without affecting the control of structural acceleration; structural acceleration at the roof is even slightly lower than that without the auxiliary spring.

- (4)

- The ISAMD with an auxiliary damper has a more significant effect on reducing the mass block displacement than that of the ISAMD with the auxiliary spring. When the ISAMD is paired with auxiliary spring stiffness of 1000 kN/m, the damping coefficient is 80 kN·s/m, equivalent to the optimal damping coefficient of the TMD, and the mass block displacement is only 1.31 times that of the TMD. Nevertheless, the control effect index of the structural displacement reaction of the roof, J1*, is 0.70, indicating a 4% loss in seismic resistance.

- (5)

- The ISAMD with the auxiliary damper obviously magnifies the structural displacement of the roof. The ISAMD with the auxiliary spring should be preferred to reduce the displacement of the mass block.

- (6)

- The sensitivity of the ISAMD control indices to the frequency ratio of the main spring can be further reduced by the ISAMD with the auxiliary damper.

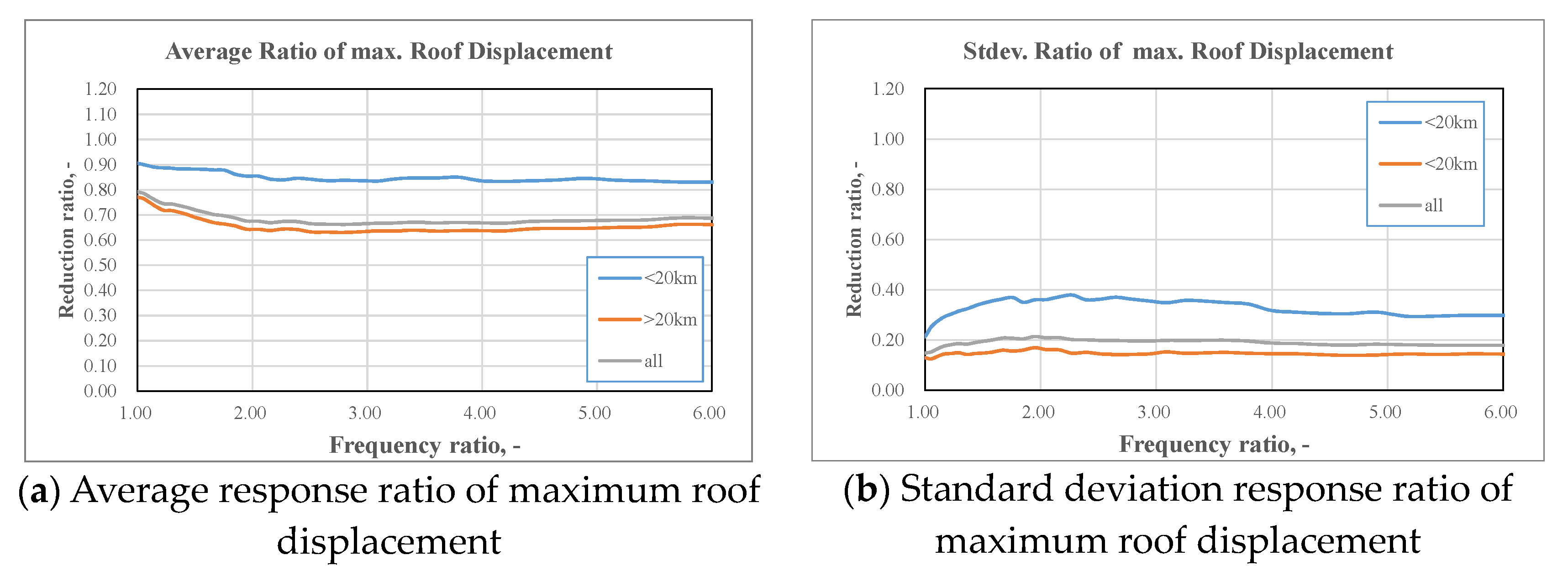

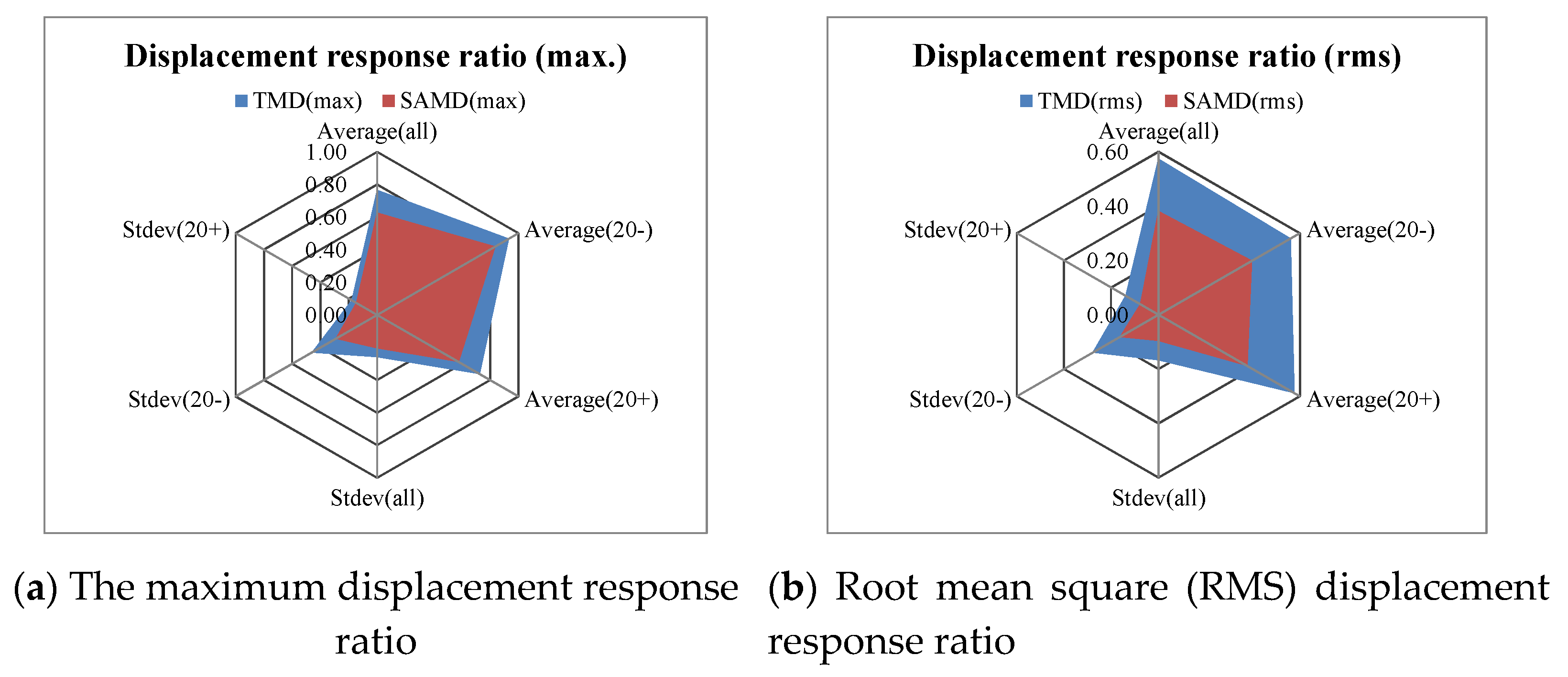

6.3. Influence of Near-Fault and Far-Field Ground Motion

7. Conclusions

- The maximum displacement reduction effect of the ISAMD is only slightly better than that of the TMD, reducing the maximum displacement responses of the roof by 4–10%. The optimal control efficiency indices of the TMD control system happen at a frequency ratio of 0.95. When the frequency ratio is slightly offset, the seismic resistance of the TMD is extremely limited due to the detuning effect. The sensitivity of the control indices of the ISAMD to the frequency ratio is very low, so detuning does not occur.

- The maximum roof displacement reaction of the structure with the ISAMD has a reduction ratio above 30%, and the root mean square of displacement reaction indicates greater than 60% seismic resistance. The control mass block displacement of the ISAMD is 2–4 times greater than that of the TMD. The installation space of the ISAMD must therefore be large. However, when the control mass frequency ratio of the ISAMD is relatively high, the installation space does not need to be excessively large.

- The frequency ratio should be around 2–4 for the structure with the ISAMD under different weight ratios to achieve a stable shock absorption effect. The average seismic resistance ratio is about 33–35%. The shock absorption effect of the root mean square of the roof structural displacement of the structure with the ISAMD is better than that of the maximum structural displacement reaction. The average seismic proof effect is consistently around 60%. Therefore, the ISAMD provides a very good damping effect. Nevertheless, the weight ratio of the ISAMD should avoid V1A0, as the control effect is slightly inferior to those of other weights.

- The control mass block displacement of the ISAMD can be reduced effectively by increasing the stiffness of the auxiliary spring. The gradient of the control mass block displacement on the stiffness of the auxiliary spring has a decreasing tendency with lower stiffness.

- The seismic resistance of the TMD changes greatly with the seismic load. However, the shock absorption effect of the ISAMD is stable, and the reliability of the structural displacement control effect of the structure with the ISAMD is better than that of the TMD, regardless of earthquake distance.

- The design criteria of the proposed ISAMD should consider a frequency ratio and weight ratio of around 2–4 and less than natural frequency, respectively.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Basharkah, M.A.; Yao, J.T.P. Reliability Aspects of Structural Control; Structural Engineering (Technical Report); Purdue University, School of Civil Engineering: West Lafayette, IN, USA, 1982. [Google Scholar]

- Choi, K.-M.; Jung, H.-J.; Lee, H.-J.; Cho, S.-W. Seismic protection of base-isolated building with nonlinear isolation system using smart passive control strategy. Struct. Control Health Monit. 2008, 15, 785–796. [Google Scholar] [CrossRef]

- Chen, Y.; Cao, T.; Ma, L.; Luo, C. Structural vibration passive control and economic analysis of a high-rise building in Beijing. Earthq. Eng. Eng. Vib. 2009, 8, 561–568. [Google Scholar] [CrossRef]

- Jung, H.-J.; Jang, D.-D.; Lee, H.-J.; Lee, I.-W.; Cho, S.-W. Feasibility Test of Adaptive Passive Control System Using MR Fluid Damper with Electromagnetic Induction Part. J. Eng. Mech. 2010, 136, 254–259. [Google Scholar] [CrossRef]

- Murase, M.; Tsuji, M.; Takewaki, I. Smart passive control of buildings with higher redundancy and robustness using base-isolation and inter-connection. Earthq. Struct. 2013, 4, 649–670. [Google Scholar] [CrossRef]

- Zhang, Z.; Balendra, T. Passive control of bilinear hysteretic structures by tuned mass damper for narrow band seismic motions. Eng. Struct. 2013, 54, 103–111. [Google Scholar] [CrossRef]

- Cacciola, P.; Tombari, A. Vibrating barrier: A novel device for the passive control of structures under ground motion. Proc. R. Soc. A Math. Phys. Eng. Sci. 2015, 471, 20150075. [Google Scholar] [CrossRef]

- Fisco, N.; Adeli, H. Smart structures: Part I—Active and semi-active control. Sci. Iran. 2011, 18, 275–284. [Google Scholar] [CrossRef]

- Liu, K.; Chen, L.-X.; Cai, G.-P. Active control of a nonlinear and hysteretic building structure with time delay. Struct. Eng. Mech. 2011, 40, 431–451. [Google Scholar] [CrossRef]

- Liu, K.; Chen, L.-X.; Cai, G.-P. Active control of buildings with bilinear hysteresis and time delay. Int. J. Struct. Stab. Dyn. 2013, 13. [Google Scholar] [CrossRef]

- Xinfa, Z.; Zhenbin, P.; Lian-Guang, M.; Yu, S. Active Control Based on Prediction of Structural Vibration Feedback. In Proceedings of the 2014 Fifth International Conference on Intelligent Systems Design and Engineering Applications, Hunan, China, 15–16 June 2014; pp. 123–127. [Google Scholar]

- Shih, M.-H.; Sung, W.-P.; Go, C.G. Development of accumulated semi-active hydraulic damper. Exp. Tech. 2002, 26, 29–32. [Google Scholar] [CrossRef]

- Shih, M.-H.; Sung, W.-P. A design concept of autonomous controller for improving seismic proof capability of semi-active control device. Exp. Tech. 2009, 34, 20–26. [Google Scholar] [CrossRef]

- Palacios-Quiñonero, F.; Rubió-Massegú, J.; Rossell, J.M.; Karimi, H.R. Semi-active-passive structural vibration control strategy for adjacent structures under seismic excitation. J. Frankl. Inst. 2012, 349, 3003–3026. [Google Scholar] [CrossRef]

- Hiramoto, K.; Matsuoka, T.; Sunakoda, K. Simultaneous optimal design of the structural model for the semi-active control design and the model-based semi-active control. Struct. Control Health Monit. 2014, 21, 522–541. [Google Scholar] [CrossRef]

- Shih, M.-H.; Sung, W.-P. Development of semi-active hydraulic damper as active interaction control device to withstand external excitation. Sadhana 2014, 39, 123–138. [Google Scholar] [CrossRef]

- Available online: https://en.wikipedia.org/wiki/Citigroup_Center (accessed on 22 January 2021).

- Available online: https://en.wikipedia.org/wiki/CN_Tower (accessed on 22 January 2021).

- Available online: https://en.wikipedia.org/wiki/John_Hancock_Tower (accessed on 22 January 2021).

- Available online: https://en.wikipedia.org/wiki/Taipei_101 (accessed on 22 January 2021).

- Sadek, F.; Mohraz, B.; Taylor, A.W.; Chung, R.M. A method of estimating the parameters of tuned mass dampers for seismic applications. Earthq. Eng. Struct. Dyn. 1997, 26, 617–635. [Google Scholar] [CrossRef]

- Lin, C.-C.; Ueng, J.-M.; Huang, T.-C. Seismic response reduction of irregular buildings using passive tuned mass dampers. Eng. Struct. 2000, 22, 513–524. [Google Scholar] [CrossRef]

- Bakre, S.V.; Jangid, R.S. Optimum parameters of tuned mass damper for damped main system. Struct. Control Health Monit. 2007, 14, 448–470. [Google Scholar] [CrossRef]

- Wang, J.-F.; Lin, C.-C.; Lian, C.-H. Two-stage optimum design of tuned mass dampers with consideration of stroke. Struct. Control Health Monit. 2009, 16, 55–72. [Google Scholar] [CrossRef]

- Soong, T.; Spencer, B. Supplemental energy dissipation: State-of-the-art and state-of-the-practice. Eng. Struct. 2002, 24, 243–259. [Google Scholar] [CrossRef]

- Lin, C.C.; Wang, J.F.; Chen, B.L. Train-Induced Vibration Control of High-Speed Railway Bridges Equipped with Multiple Tuned Mass Dampers. J. Bridg. Eng. 2005, 10, 398–414. [Google Scholar] [CrossRef]

- Robinson, J.K.; Gamble, S.L.; Myslimaj, B.M. Supplemental damping and using tuned sloshing dampers. Struct. Mag. 2007, 6, 14–18. [Google Scholar]

- Yamamoto, M.; Sone, T. Behavior of active mass damper (AMD) installed in high-rise building during 2011 earthquake off Pacific coast of Tohoku and verification of regenerating system of AMD based on monitoring. Struct. Control Health Monit. 2014, 21, 634–647. [Google Scholar] [CrossRef]

- Alkhatib, R.; Golnaraghi, M.F. Active Structural Vibration Control: A Review. Shock. Vib. Dig. 2003, 35, 367–383. [Google Scholar] [CrossRef]

- Abe, M. Semi-active tuned mass dampers for seismic protection of civil structures. Earthq. Eng. Struct. Dyn. 1996, 25, 743–749. [Google Scholar] [CrossRef]

- Aldemir, U. Optimal control of structures with semi-active tuned mass dampers. J. Sound Vib. 2003, 266, 847–874. [Google Scholar] [CrossRef]

- Cai, C.S.; Wu, W.J.; Araujo, M. Cable Vibration Control with a TMD-MR Damper System: Experimental Exploration. J. Struct. Eng. 2007, 133, 629–637. [Google Scholar] [CrossRef]

- Lin, C.-C.; Lin, G.-L.; Wang, J.-F. Protection of seismic structures using semi-active friction TMD. Earthq. Eng. Struct. Dyn. 2009, 39, 635–659. [Google Scholar] [CrossRef]

- Lin, G.-L.; Lin, C.-C.; Lu, L.-Y.; Ho, Y.-B. Experimental verification of seismic vibration control using a semi-active friction tuned mass damper. Earthq. Eng. Struct. Dyn. 2011, 41, 813–830. [Google Scholar] [CrossRef]

- Nagarajaiah, S.; Sonmez, E. Structures with semi-active variable stiffness single/multiple tuned mass dampers. J. Struct. Eng. 2007, 133, 67–77. [Google Scholar] [CrossRef]

- Nagarajaiah, S. Adaptive passive, semiactive, smart tuned mass dampers: Identification and control using empirical mode decomposition, hilbert transform, and short-term fourier transform. Struct. Control Health Monit. 2009, 16, 800–841. [Google Scholar] [CrossRef]

- Chey, M.-H.; Chase, J.G.; Mander, J.B.; Carr, A.J. Semi-active tuned mass damper building systems: Design. Earthq. Eng. Struct. Dyn. 2009, 39, 119–139. [Google Scholar] [CrossRef]

- Chey, M.-H.; Chase, J.G.; Mander, J.B.; Carr, A.J. Semi-active tuned mass damper building systems: Application. Earthq. Eng. Struct. Dyn. 2009, 39, 69–89. [Google Scholar] [CrossRef]

- Spencer, B.F.; Nagarajaiah, S. State of the Art of Structural Control. J. Struct. Eng. 2003, 129, 845–856. [Google Scholar] [CrossRef]

- Lin, C.C. Semi-Active Resettable Variable Stiffness TMD for Seismic Protection; Research Report; NSC-100-2221-E-005-054; National Science Council: Taipei, Taiwan, 2012. [Google Scholar]

- Soto-Brito, R.; Ruiz, S.E. Influence of ground motion intensity on the effectiveness of tuned mass dampers. Earthq. Eng. Struct. Dyn. 1999, 28, 1255–1271. [Google Scholar] [CrossRef]

- Lukkunaprasit, P.; Wanitkorkul, A. Inelastic buildings with tuned mass dampers under moderate ground motions from distant earthquakes. Earthq. Eng. Struct. Dyn. 2001, 30, 537–551. [Google Scholar] [CrossRef]

- Chen, G.; Wu, J. Experimental study on multiple tuned mass dampers to reduceseismic responses of a three-storey building structure. Earthq. Eng. Struct. Dyn. 2003, 32, 793–810. [Google Scholar] [CrossRef]

- Pinkaew, T.; Lukkunaprasit, P.; Chatupote, P. Seismic effectiveness of tuned mass dampers for damage reduction of structures. Eng. Struct. 2003, 25, 39–46. [Google Scholar] [CrossRef]

- Shih, M.-H.; Sung, W.-P. Development of semi-active mass damper with impulsive reaction. Sadhana 2020, 45, 1–11. [Google Scholar] [CrossRef]

- Shih, M.-H.; Sung, W.-P. Structural Control Effect and Performance of Structure Under Control of Impulse Semi-active Mass Control Mechanism. Iran. J. Sci. Technol. Trans. Civ. Eng. 2020, 1–16. [Google Scholar] [CrossRef]

- Shih, M.H.; Sung, W.P. Parametric Study of Impulse Semi-Active Mass Damper with Developing Directional Active Joint. Arab. J. Sci. Eng. 2021, in press. [Google Scholar]

- Lin, C.; Hu, C.; Wang, J.; Hu, R. Vibration control effectiveness of passive tuned mass dampers. J. Chin. Inst. Eng. 1994, 17, 367–376. [Google Scholar] [CrossRef]

| Analysis Parameter Category | Parameter Range |

|---|---|

| Parameters of main structure | Structure type: 10DOF shear building Story mass: = 500 tn Inter-story stiffness: = 883,645 Inter-story damping: = 2813 First modal frequency: = 1.0 Hz First modal damping ratio: = 0.01 |

| Control Parameters of the ISAMD | Mass ratio: = 0.02 Freq. ratio: = 0.8145~6.0 @rate = 0.95 Damping ratio: = 0.01~0.10 Weight ratio: |

| Control Parameters of the TMD | Mass ratio: = 0.02 Freq. ratio: = 0.8145~1.2277@rate = 0.95 Detuning rate: = 18.55%~22.77% Damping ratio: = 0.071~0.10 |

| Seismic waves | 26 records of ground acceleration of earthquakes with epicentral distance = 1–339 km (see Table 2) |

| No. | Earthquake | Year | Station | Epi. Dist. (km) | Dir. | PGA (g) |

|---|---|---|---|---|---|---|

| 1 | Kobe, Japan | 1995 | KJMA | 1 | NS | 8.21 |

| 2 | Northridge, USA | 1994 | Tarzana | 4 | EW | 17.45 |

| 3 | Santa Barbara, USA | 1978 | UCSB Goleta | 14 | NS | 3.40 |

| 4 | Chi-Chi, Taiwan | 1999 | TCU075 | 18 | NS | 2.57 |

| 5 | Northridge, USA | 1994 | Newhall | 19 | EW | 5.72 |

| 6 | Northridge, USA | 1994 | S_Monica | 23 | EW | 8.66 |

| 7 | Norcialtaly, Italy | 2016 | St_Angelo | 28 | - | 2.06 |

| 8 | Northridge, USA | 1994 | LA | 38 | EW | 3.48 |

| 9 | Northridge, USA | 1994 | SF bay | 40 | - | 1.64 |

| 10 | Norcialtaly, Italy | 2016 | Colfiolito | 40 | - | 2.55 |

| 11 | Loma Prieta, USA | 1989 | S_Cruz | 48 | NS | 3.62 |

| 12 | Calexico, USA | 2010 | Sierra | 77 | EW | 4.91 |

| 13 | Chile | 2010 | CCSP | 109 | EW | 5.94 |

| 14 | Sumatra, Indonesia | 2007 | PSKI | 125 | EW | 1.24 |

| 15 | Chile | 2016 | LL06 | 136 | - | 2.24 |

| 16 | Chile | 2010 | VA03 | 168 | - | 2.68 |

| 17 | Chile | 2010 | GO01 | 170 | EW | 2.32 |

| 18 | Chile | 2010 | CUR | 170 | EW | 4.66 |

| 19 | Chile | 2010 | GO04 | 175 | EW | 2.34 |

| 20 | Chile | 1980 | ANGO | 209 | NS | 6.84 |

| 21 | Chile | 1980 | MAT | 230 | NS | 3.37 |

| 22 | Alaska, USA | 2016 | HNE | 254 | EW | 2.07 |

| 23 | Chile | 1980 | LLO | 274 | NS | 3.19 |

| 24 | Chile | 2010 | S_Jose | 333 | NS | 4.61 |

| 25 | Chile | 2010 | S_Lucia | 334 | NS | 2.39 |

| 26 | Chile | 2010 | ColegioLasAmericas | 339 | NS | 3.02 |

| Parameter | J1 | J3 | J5 | J6 | |

|---|---|---|---|---|---|

| TMD | Value | 0.72 | 0.48 | 0.88 | N.A. |

| min. at rf | 0.95 | 0.95 | 0.95 | N.A. | |

| ISAMD WV:WA = 1:0 | Value | 0.65 | 0.40 | 0.85 | 5.43 |

| min. at rf | 1.59 | 1.43 | 1.67 | 2.19 | |

| ISAMD WV:WA = : | Value | 0.62 | 0.38 | 0.91 | 3.79 |

| min. at rf | 2.1 | 2.1 | 1.45 | 5.78 | |

| ISAMD WV:WA = :1 | Value | 0.65 | 0.38 | 0.91 | 3.87 |

| min. at rf | 2.79 | 2.27 | 1 | 4.90 | |

| ISAMD WV:WA = : | Value | 0.67 | 0.38 | 0.93 | 3.98 |

| min. at rf | 2.79 | 2.90 | 1.2 | 2.12 | |

| ISAMD WV:WA = 0:1 | Value | 0.68 | 0.4 | 0.94 | 3.71 |

| min. at rf | 3.25 | 3.25 | 1.36 | 3.42 | |

| Response | TMD (max) | ISAMD (max) | TMD (rms) | ISAMD (rms) |

|---|---|---|---|---|

| Average (overall) | 0.77 | 0.63 | 0.57 | 0.38 |

| Average (<20 km) | 0.93 | 0.84 | 0.56 | 0.40 |

| Average (>20 km) | 0.73 | 0.58 | 0.58 | 0.38 |

| Stdev. (overall) | 0.26 | 0.20 | 0.17 | 0.10 |

| Stdev. (<20 km) | 0.46 | 0.29 | 0.28 | 0.16 |

| Stdev. (>20 km) | 0.18 | 0.15 | 0.14 | 0.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shih, M.-H.; Sung, W.-P. Seismic Resistance and Parametric Study of Building under Control of Impulsive Semi-Active Mass Damper. Appl. Sci. 2021, 11, 2468. https://doi.org/10.3390/app11062468

Shih M-H, Sung W-P. Seismic Resistance and Parametric Study of Building under Control of Impulsive Semi-Active Mass Damper. Applied Sciences. 2021; 11(6):2468. https://doi.org/10.3390/app11062468

Chicago/Turabian StyleShih, Ming-Hsiang, and Wen-Pei Sung. 2021. "Seismic Resistance and Parametric Study of Building under Control of Impulsive Semi-Active Mass Damper" Applied Sciences 11, no. 6: 2468. https://doi.org/10.3390/app11062468

APA StyleShih, M.-H., & Sung, W.-P. (2021). Seismic Resistance and Parametric Study of Building under Control of Impulsive Semi-Active Mass Damper. Applied Sciences, 11(6), 2468. https://doi.org/10.3390/app11062468