1. Introduction

In a competitive environment of manufacturing, production control, including the scheduling operations via modules associated with a variety of management tools, must reflect both customer’s demands, and, on the other hand, the production capability, sustainability, and profit. The effective scheduling in a sense of achievement of a high production performance leads to generating benefits in the form of shortening processing time and reduction of costs. To ensure the changing requirements effectively and to generate suitable production schedules, implementation of heuristics, simulation, analytical models [

1,

2], artificial intelligence techniques [

3], or dispatching rules, especially in case of dynamic scheduling [

4,

5], can be employed in this type of decision-making.

In the production sector, scheduling can be in a wider perspective defined as “a process of arranging, controlling, and optimizing work or workloads” [

1]. With regard to finding the optimal schedule for a specific structure and production system conditions, the scheduling is considered as a complex combinatorial optimization problem [

4], mostly proved of NP-hard type [

1]. Exact optimization methods are mainly used only for the systems which have a specific topology where very strong simplifying assumptions must be used [

6], so they are not too applicable in a real-world scenario for more complex systems. In that case, approximate optimization methods and metaheuristics [

7] based on stochastic local search approach, machine learning techniques, especially artificial neural networks (ANN), fuzzy logic methods, and expert systems, are at the center of research interest to find optimal or near-optimal solutions [

8,

9] instead of exact mathematical optimization models.

In contrast to other methods, dispatching rules (we also use the term priority rules throughout the following text) represent the valuable practical and dominant approach of the shop floor control in the complex industry environment [

10,

11], such as, e.g., in semiconductor manufacturing for solving complex scheduling problems in real-time [

12]. Priority rules are popular because they are characterized by the simplicity of implementation, satisfactory performance, and a substantially reduced computational requirement [

2,

11,

13]. Nevertheless, the choice of appropriate dispatching rules is not a trivial task and depends on the relevant key performance indicators [

11].

When considering the application of specific priority rule in production control, a question appears on how the selection of priority rule influences the production performance objectives. Years of research on the field of priority rules have shown that in general, no rule outperforms the others, whereas there are different system configurations, operating conditions, and production performance indicators [

14,

15]. This is understandable, considering that the rules are developed for a specific category of system configurations involving a specific set of performance objectives, therefore they generally do not work well in an environment where they were not intended [

15].

The impacts generated by the selected priority rule are mostly difficult to explain by analytical methods [

1], thus the simulation is used very often to evaluate the schedule efficiency in the complex scheduling problem [

10,

16]. As an illustration, in the simulation study, Vinod and Sridharan [

13] evaluated the performance measures based on flow time and tardiness of jobs for the different combinations of due-date assignment methods and seven scheduling decision rules applied in a dynamic job shop system. Xanthopoulos et al. [

5] compared seventeen dispatching rules in the study focused on stochastic dynamic scheduling problems with sequence-dependent setups. Performance measures were mean work-in-progress (WIP), mean cycle time, mean tardiness, and a fraction of tardy jobs.

In opposition to the simulation, the optimization approach offers to find the optimal or near-optimal scheduling concerning one or more desired objectives. Specifically, simulation-based optimization uses metaheuristics to determine nearly optimal parameter configurations for simulations, and it can solve even complex stochastic combinatorial optimization problems. Simulation-based optimization with genetic algorithm applyication has been successfully applied in the work of Vieira et al. [

17]. Freitag and Hildebrandt [

18] applied simulation-based optimization employing multi-objective genetic programming to solve the complex problem of automated design of scheduling rules for short-term scheduling in a semiconductor manufacturing environment. The authors investigated seven standard rules: FIFO (First In First Out), ERD (Earliest Release Date), EDD (Earliest Due Date), ODD (Operation Due Date), MOD (Modified Operation Due Date), SPT (Shortest Processing Time), and CR (Critical Ratio). Additionally, the ODD+ rule was used. Kuck et al. [

11] proposed an adaptive simulation-based optimization approach to select suitable dispatching rules including FIFO, EDD, FASFS (First Arrival in the System First Served), CR, ODD, SPT, and MOD rules for each machine in the production system with different strategies to react to system changes. Solutions obtained via genetic algorithm were evaluated by applying a discrete-event simulation model.

In the related literature, research performed to investigate the impact of priority rules on production results in job shop systems has focused mostly on one or two optimization objectives, such as tardiness, makespan (completion time), mean flowtime, or proportion of tardy jobs, with one priority rule applied to all the machines on the shop floor. Zahmani et al. [

16] presented a simulation model for makespan minimization using different priority rules for each machine on the shop floor. Obtained experimental results served for learning base construction, which was utilized for developing an inference model for the selection of the most suitable priority rule. In the work of Demir and Erden [

19], Genetic Algorithm (GA) and Ant Colony Optimization (ACO) were used together to obtain the best combination of dispatching rule, due date assignment rule, and route of all jobs to minimize earliness, tardiness, and due dates of each job.

We can find a lot of literature that mainly tackles single and bi-criteria job shop scheduling problems [

20], and more objectives are taken into account rather exceptionally. The reason is that when reflecting many aspects of production evaluation concurrently, multi-criteria optimization is needs to be considered to obtain satisfying results for production parameters setting. An identification of optimal solution is not trivial in this case because there is no single solution, but a set of possible optimal solutions, all equivalent in a mathematical sense. The individual solutions in this set form the so-called Pareto front (or Pareto frontier) in the objective space [

21]. Methods for finding optimal solutions to the multi-criteria problem are still in progress nowadays, concerning an improvement in finding very accurate and highly diverse solutions for an approximation of true Pareto front to offer design-makers a diverse range of design options [

22].

In this study, based on preliminary experiments with single-objective optimization performed for a flexible job shop production system with partially interchangeable workstations, we focused on solving the multi-objective problem to evaluate and compare production results with respect to the priority rule applied for operations scheduling. The simulation-based optimization of five contradictory production objectives: Average flowtime, average machine utilization, average work in progress, average number of products, and an average costs per part unit is connected to the discrete-event simulation model of one-piece flow type when applying three specific well-known and often studied priority rules [

5]. The rules are FIFO, which considers the order of incoming parts, EDD, which selects an operation of a part with the closest due date, and STR (Slack Time Remaining), where an operation of a part with the lowest time reserve is favored. We choose the FIFO priority rule as the most common one and simplest to implement. The reason for selection of another standard and very known EDD and STR scheduling principles was that they outperform other rules in a shortening flow time. It is important for the production of the type of make-to-order typical for flexible job shops and a lean production concept. Additionally, EDD and STR were involved in this investigation because they are widely used in the literature as benchmarks for metrics related to due date [

5,

23]. Two types of scalarization methods (Weighted Sum Method and Weighted Product Method) in a priori arrangement are applied for the definition of multi-objective function in the optimization model of the production system.

Compared with other related works, the main contribution of this study is considering more interesting conflicting performance production indicators of various types to offer the complex view to production results via multi-criteria evaluating many objectives simultaneously when employing a selected priority rule in scheduling operations. In addition, based on results of scalar multi-criteria simulation optimization, the global effective solutions can be recommended as support for decision-making in production control. Additionally, when solving a multi-criteria optimization problem (MOP), we have experimented with a modified approach in the transformation of individual objective functions in a scalar multi-criteria objective function comparing to works in the related literature. In this context, the most relevant publication to this work is the paper by Marler and Arora [

24] dealing with practical aspects of multi-criteria methods usage and transformations for scalar multi-criteria objective function that inspired us to employ them in this work.

The main structure of the paper is as follows. Firstly, we briefly describe the problem of scheduling operations when priority rules are applied in the scheduling process. In the next part, a concept of Pareto-optimality in multi-criteria optimization and applied methods are mentioned. The part concerning the methodology of experiments introduces the simulation and optimization model and the design of optimization experiments. Finally, in the last section, we present and compare the obtained results focusing on the practical aspect of production control.

4. Experimental Study

The effect of linking priority rules and multi-criteria optimization methods on optimization of production goals in the studied production system was explored via simulation-based optimization experiments performed in two phases. At first, single objective experiments were needed to find reference points for the transformation of production objectives. Secondly, multi-objective optimization according to general formulation (2) was conducted to determined MOP solutions for both WSM and WPM methods applied in definitions of multi-criteria objective functions in an optimization model (Equations (3) and (4)) when three different priority rules were consequently applied.

4.1. Simulation Model

The discrete-event simulation model in this study represents a hypothetical partially flexible job-shop production system adopted from [

46]. It can be categorized as such a class of production systems that produce smaller numbers of different types of products according to several routings in a one-piece flow way, especially following the lean production concept. Regarding to its flexibility, some operations are only achievable on part of the available machines.

The model system has been built to maintain the main characteristics of FJS, which are mentioned in the

Section 2.1. It meets the typical demands regarding the jobs and machines assumed in the deterministic flexible job shop scheduling problem [

5,

20,

27]:

All machines and all jobs are available at time t = 0.

The number of jobs and machines are assumed to be finite;

a job cannot be processed by two machines at the same time;

each machine is always accessible for production, i.e., no machine breakdowns or order cancelations are supposed;

the machine can execute only one operation at a time on any job;

an operation of a job cannot be performed until its preceding operations are completed;

once started operation must not be interrupted;

operation is processed by any machine from a given set;

the model does not include any assembly operations.

The studied model system consisted of six partially interchangeable machines with their input and output buffer [

46]. A total of seven types of operations (A, B, C, D, E, F, G) were performed in the production system. The system manufactured four types of products, each with the specified determination of the sequence of four operations (that cannot be interchanged) defined in

Table 1.

Transportation of parts between buffers was ensured by conveyors with sensors that allow identifying every coming part. If the appropriate attribute of a part was detected, then the part was accepted for the next processing. The interchangeability of workplaces according to the operations possible to perform at individual machines in the system is shown in

Table 2.

In this study, we implemented consequently selected priority rules FIFO, EDD, and STR to define the order in which the individual operations will be done. This order was determined by the calculated priority with respect to the rule performing. When implementing priority rule EDD into the simulation model, the priority key for the operation associated with a given job was updated with respect to the earliest due date information. In the case of the STR priority rule, Equation (1) was used for the calculation of the priority. Based on the determined priority rule, the machine always selected the operation that had the highest priority of all. If multiple operations had the same priority, these operations were grouped randomly. If the next operation can be done on different machines, the machine with minimal setup costs was selected to process it.

The simulation model was designed and built in such a way that it involved the possibility of choice of priority rule at the start of simulation. After selecting the priority rule by the user, the studied system was fully deterministic. Neither breakdowns due to order cancellations nor machine failures were allowed. All internal parameters, such like operation and setup times, and all costs items were keeping as constants during experiments, too. Most of operation times slightly differed due to the type of processing operation and type of product. Every machine was set up when the type of operation was changed. To simplify the investigated problem, the question of the impact of the different range of operating times was not included in the design of simulation experiments. The detailed information about operation times and costs for individual operation is given in

Table 3.

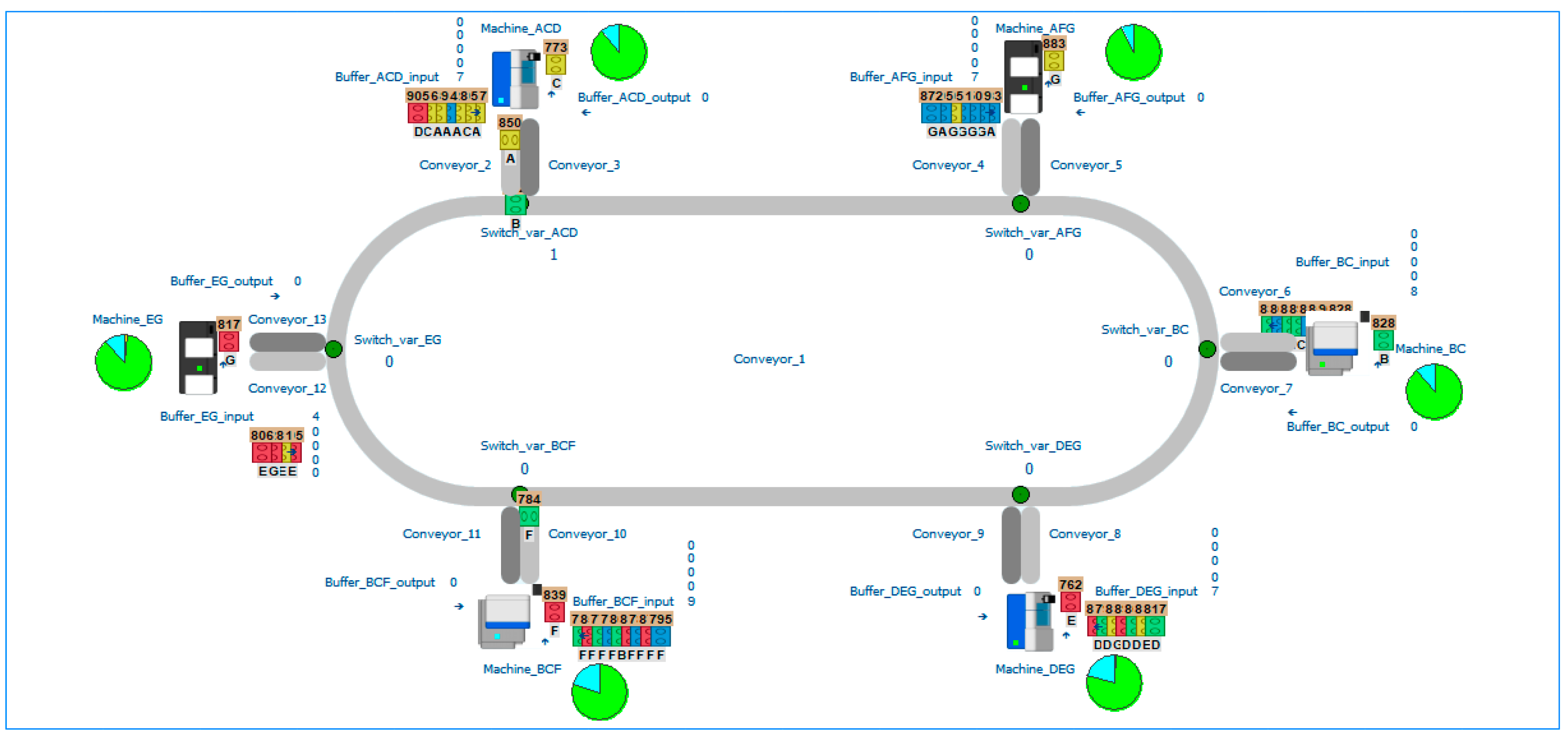

The model of the production system was created in simulation software Witness Horizon ver. 22, developed by Lanner. Simulation environment of Witness Horizon is designed for modelling, simulation, predictive analytics, and optimization of production and logistic processes, or services with the aim to verify consequences of different scenarios in the virtual world via simulation, or to find an effective set of system parameters. We used it for simulation and optimization experiments in the presented study. The discrete-event simulation model is depicted in

Figure 1.

4.2. Preliminary Simulation Experiments

Conditions of optimization experiments were proposed on the base of preliminary simulation experiments performed on the presented simulation model for three priority rules consequently in Witness simulator. The experiments served for understanding the simulation model’s behavior under different loadings and its limits associated with production results.

Different loadings were modelled by changing the time between arrivals (inter-arrival time) for the entry of each of four parts in the range 1 min to 20 min. Each of the parts entered in one piece lot size to the system.

Simulation runs lasted 1440 min, which represented standard period of 1 day covering three shifts. The warm-up period of 90 min was found out as the period which is needed to produce one product of each four types using simulation.

As system response, we observed values of five production indicators: Average flowtime (min.), average machine utilization (%), average work in progress (pcs), average number of products (pcs), and the average costs per part unit (€) as outputs from simulation runs. These experiments showed production limits according to the design variables and rules setting.

4.3. Optimization Model

When considering the avoidance of the extreme situations in production, which mean too few processed products and, on the other hand, the system overload, the space of design variables for optimization was determined as a four-dimensional domain defined by time between arrivals for the entry of each of four products in a reasonable range of 8 min to 16 min, based on the simulation results for this system. In this case, the modelled system showed acceptable values of production goals for all three priority rules.

Based on observed production results, the suitable values of constraints of production goals for optimization model were also suggested. As for the machine utilization constraints, from the practical point of view referring to [

35], the decision was influenced by the fact that the machine utilization more than 80% generally corresponds to moderate and heavy shop load level in job shops. The constraints concerning production objectives applied in all optimization experiments are specified in

Table 4.

The optimization objectives represented five selected aforementioned key performance indicators: Average flowtime, average machine utilization, average work in progress, average number of products, and the average costs per part unit. For MOP solving, they were combined into two types of scalar multi-criteria objective functions. This scalarization procedure generating multi-criteria objective function based on WSM and WPM methods (Equations (3) and (4)) is described in detail in the following paragraphs.

4.3.1. Transformation (Normalization) of Production Objectives

When applying a weighted sum approach or other types of scalarization, it is reasonable to normalize individual objectives

Fi entering the scalar multi-objective function to avoid the scaling effects and thus ensure their comparable impact in the objective function expression. We utilized the transformation which represented a robust min-max type of normalization. It can also be referred to as the upper-lower-bound transformation in the literature [

47]. This transformation and many other potential ones are provided in a survey by Marler and Arora [

24] in a comprehensive overview. The applied robust transformation was in this study implemented in a form (5) involving two so-called reference points as maximal and minimal values of the individual objective functions

.

Here, the transformation (5) includes a component of an ideal point [

38] vector

(maybe replaced the point, referred also as a utopia point [

23]) and a component of the worst point vector

. They represent the unreachable solution for individual production objectives as the best (ideal), and as the worst one. The ideal point vector

is determined as the optimum of the single-criterion function according to the optimization goal regardless of other objectives. Vector

is composed of the worst values of production goals, obtained from single-optimization experiments. Value

Fi in the expression (5) represents the individual objective value, resulted from the simulation run. The transformation scheme ensures the same range and magnitude for all objectives within the range between 0 and 1. Comparing to works [

24,

47] where the distance between solution

Fi and utopia point is minimized, we modified the transformation scheme to (5) and maximized the distance between solution

Fi and the worst point.

4.3.2. Single-Objective Optimizations

The presented approach demanded to find the minimum and maximum value for each of five selected production goals with respect to constraints presented in

Table 4. We used a set of single-objective optimizations for this purpose instead of an estimation [

24,

38]. The objective functions for obtaining ideal and worst points were optimized according to the type of production objective. The objective functions and target of optimization for each of them are shown in

Table 5.

Simulation environment Witness Horizon includes the optimization module Experimenter with its Advanced Mode for the performance of simulation-based optimization. Implemented optimization algorithms comprise Random solutions, Hill Climb, Min/Mid/Max, and All Combinations algorithms, and metaheuristic, such as Adaptive Thermostatistical Simulated Annealing (SA). The optimum of the individual objective functions representing production goals was obtained via simulation-based optimization in two steps. Firstly, employing a metaheuristic algorithm briefly explored the design space with respect to the local optima at the beginning of optimization process. None of the values reached by SA represented global optimum, only local ones, therefore we did not present them. Secondly, we used the Brute Force algorithm All Combinations, which runs all constrained combinations of design parameters. The optimization process via the All Combinations algorithm was time consuming, but with the guarantee that the optimal solution will be found. For all experiments, the length of the one simulation run was set up to 1440 min and the warm-up period was 90 min. We used one replication for one simulation run due to the deterministic nature of the model. The resulted values of the ideal and worst points are listed in

Table 6.

4.3.3. The Formation of Scalar Multi-Criteria Objective Functions and Conditions of Optimization

After the determination of all reference ideal and worst points necessary for the transformation of production goals, further experiments based on respecting all five production goals simultaneously are carried out under the same conditions. The scalar multi-criteria objective functions for each of the three priority rules were built on WSM and WPM methods.

Multi-objective

UWSM function (6) was formed on the base of the Weighted Sum Method (defined by Equation (3)) as the linear combination of the normalized individual objectives

expressed by (5) using the weight vector

w.

All components wi were equal to the value 0.2 to not give priority to any of five production goals. Due to the normalization of objectives given by (5), the structure of the proposed scalar objective function UWSM demands the maximization of (6) to lead to the single preferred Pareto optimal solution finding.

When adopting the Weighted Product Method (defined by Equation (4)) with the same settings of weights,

UWPM function is defined by Equation (7), and, on the contrary, the minimization of (7) yields the Pareto optimal solution.

The objectives that need to be maximized were transformed using a reciprocal of (5).

Box 1 and

Box 2 contain an example of code which shows the transformation in WSM and WPM-based multi-criteria objective functions for EDD priority rule, written in the versatile WITNESS Action Language. (WITNESS also supports external code libraries written in common languages such as C++, C#, and VB.net).

Box 1. A code in a body of Weighted Sum Method (WSM)-based objective function using EDD priority rule in simulator.

IF Number_of_products >= 400 AND Flow_Time <= 180 AND Machine_utilization >= 80

RETURN 0.2 * ((Number_of_products − 429)/(482 − 429)) + 0.2 * ((Work_in_progress − 22.109)/(2.637 − 22.109)) + 0.2 * ((Flow_Time − 179.527)/(45.128 − 179.527)) + 0.2 * ((Machine_utilization − 82.096)/(89.283 − 82.096)) + 0.2 * ((Costs_per_part_unit − 37.297)/(31.410 − 37.297))

ELSE

RETURN 0.2 * ((Number_of_products − 429)/(482 − 429)) + 0.2 * ((Work_in_progress − 22.109)/(2.637 − 22.109)) + 0.2 * ((Flow_Time − 179.527)/(45.128 − 179.527)) + 0.2 * ((Machine_utilization − 82.096)/(89.283 − 82.096)) + 0.2 * ((Costs_per_part_unit − 37.297)/(31.410 − 37.297)) – 10

ENDIF

Box 2. A code in a body of Weighted Product Method (WPM)-based objective function using EDD priority rule in simulator.

IF Number_of_products >= 400 AND Flow_Time <= 180 AND Machine_utilization >= 80

RETURN ((482 − 429)/(Number_of_products − 429)) ** 0.2 * ((Work_in_progress − 22.109)/(2.637 − 22.109)) ** 0.2 * ((Flow_Time − 179.527)/(45.128 − 179.527)) ** 0.2 * ((89.283 − 82.096)/(Machine_utilization − 82.096)) ** 0.2 * ((Costs_per_part_unit − 37.297)/(31.41 − 37.297)) ** 0.2

ELSE

RETURN ((482 − 429)/(Number_of_products − 429)) ** 0.2 * ((Work_in_progress − 22.109)/(2.637 − 22.109)) ** 0.2 * ((Flow_Time − 179.527)/(45.128 − 179.527)) ** 0.2 * ((89.283 − 82.096)/(Machine_utilization − 82.096)) ** 0.2 * ((Costs_per_part_unit − 37.297)/(31.41 − 37.297)) ** 0.2 + 10

ENDIF

For other rules, the form of body function was created analogically, with corresponding ideal and worst points shown in

Table 6. In all cases, the same weights of 0.2 were used as parameters expressed a priori articulated decision-maker´s preferences. Independently on the type of objective function, the key optimization idea was to ensure the maximization of a distance between the solution and the worst point. As can be seen in

Box 1 and

Box 2, all objective functions were constrained by the values presented in

Table 4. For these optimization experiments, simulation-based optimization with All Combinations algorithm was applied with one replication for one simulation run lasting 1440 min, with the warm-up period 90 min to find global optimum.

5. Experimental Results

The performed optimization experiments were of two categories. Firstly, the single-objective optimizations exploring 4096 scenarios for each of the three priority rules were conducted to find the reference points involved in the robust transformation of production objectives (with the aims given in

Table 5). All results were obtained under the same conditions, which are described in previous section with respect to design space, objective functions, constraints, and conditions of simulation runs.

The column graph in

Figure 2 shows a comparison of ideal point values when applying different priority rules.

Analogically,

Figure 3 depicts a comparison of obtained values of the worst point. All data were presented in

Table 6 above.

Secondly, the experiments focused on multi-criteria optimization carried out to acquire the optimal daily production results according to given a priori preferences. When applying the WPM method, the minimization of objective function regarding the best and worst values of production performance, introduced in

Box 2 and subjected to constraints, was performed. On the contrary, the objective function built via WSM scalarization method presented in

Box 1 was maximized. In contrast to the approach in the works of Marler and Arora [

24] or Xiang et al. [

47], where the distance of the solution to the ideal point was minimized, we modified the structure of scalar objective function so that the maximization of the distance between solution and the worst point was needed.

The individual values of five production objectives for obtained optimal solutions in objective space applying WSM and WPM methods linked to three selected scheduling principles are shown in

Table 7.

The graphical comparison of production goals obtained employing WSM and WPM methods for three different priority rules is presented in

Figure 4a–e.

On the basis of obtained production goals as nondominated solutions in objective space presented in

Table 7, the four design variables—the times between arrivals for entry of each of four parts P1, P2, P3, and P4 (the inter-arrival times (IATP1—IATP4)) were identified as effective solutions in the design space. They are presented for both methods and three priority rules in

Table 8.

In this work, we address not only solving multi-objective optimization problem in scheduling itself, but also the way, how to evaluate the impact of the applied priority rule to the production results via obtaining the trade-off solution, and comparing it to the best values of many production goals determined by limits of the studied system. To compare the obtained trade-off solutions, simple ordering based on obtained optimization results presented in

Table 7 from the best one (1.) to the worst (5.) according to the optimization target for each of the production objectives was assigned. In addition, an average of the order values was calculated to evaluation the less is better, as it is presented in

Table 9.

On the base of average values relating to the ordering given in

Table 9, we assigned the final ranking to each of the applied methods in the conjunction with the evaluated priority rule to determine the best performance result. A ranking “1” was given to the rule with the method that provided the best performance, i.e., to the summarized evaluation with the smallest average value. A ranking “2” to the next one, etc. The result of the final evaluation is introduced in

Figure 5.

Finally, we compared the obtained compromise solution for the best evaluated scheduling to the coordinates of an unfeasible ideal point when the EDD priority rule was employed in production control. The differences due to the compromise character of the solution are presented in

Figure 6.

6. Discussion

The obtained experimental outcomes reflect the dynamical structure of the system determined by applied priority rule. As the precise analytical expression of the transformation of input parameters (time between arrivals for the entry of the parts) to the outputs (production goals) is not known, all objective function values were determined by simulation in a simulation-based optimization process.

The results of experiments related to single-objective optimization of production objectives, which are presented in

Table 6 and compared in

Figure 2 and

Figure 3, show that priority rules EDD and STR provided the comparable ideal and worst values for almost all production objectives in the studied model system. That means the daily production limits of the investigated production system according to both rules were similar, therefore the reference points would have to influence the MOP solution only insignificantly. The ideal and the worst values were applied in the robust transformation involved in both employed multi-criteria optimization methods in the next step.

The following optimization experiments were conducted with the focus on comparing results of multi-criteria optimization with the relation to the evaluation of reached production goals, respecting the implemented specific priority rule. The results presented in

Table 9 demonstrate that there does not exist a single dispatching rule that achieves the highest ranking in the connection to applied multicriteria methods according to all observed performance objectives. As can be seen in

Figure 5, according to the type of scalar objective function used in the multi-criteria optimization, the best ranking overall was obtained for the WSM when the EDD priority rule was applying. Very similar although slightly worse results were achieved by the WSM using the STR rule. Both scalarization methods in the presence of the FIFO priority rule achieved the worst results with a relatively large loss. The result has confirmed what, e.g., Kemppainen [

23] states, that the FIFO rule is not recommended for manufacturing operations since it is usually overcome by any other priority rule.

The presented findings point to that employing the EDD and STR rule brought similar production performance results in the context of the complex view to obtained compromise solutions in the studied production system. The relatively long inter-arrival times for EDD rule presented as effective solutions in design space in

Table 8 are in consonance with the fact that due date based dispatching rules are expected to work well at low utilization levels [

35], and outperformed other rules under light load and smaller job shop configurations [

23].

Based on the findings of this investigation, a practical suggestion for production how to set up the input arrival time of each of four entering parts into the system under the specific rule can be proposed. It is determined by design variables presented in

Table 8. When utilizing the EDD rule and WSM method, the effective solution is following the values of the design vector (12; 15; 14; 9), determined in minutes. Comparing to the unreachable best results determined by ideal point, the loss of production performance is 2.07% for an average number of manufactured products, 25.26% for an average flow time, 1.52% for average machine utilization, 40.78% for average work in progress, and 0.52% for average cost per part unit, respectively.

As for the recommendation of input arrival times when utilizing the STR rule with WSM, it is the design vector (14; 13; 13; 9), determined in minutes. The loss when comparing the compromise solution to the best values in case of setting relating to the WSM+STR rule, is 0.84% for an average number of manufactured products, 25.98% for an average flow time, 1.58% for average machine utilization, 45.06% for average work in progress, and 1.48% for average cost per part unit.

For the setup of design variables going up from the WPM + STR rule, the suggested design vector is (15; 12; 15; 10), determined in minutes. The corresponding loss is 5.01% for an average number of manufactured products, 3.25% for average flow time, 5.74% for average machine utilization, 1.12% for average work in progress, and 2.26% for average cost per part unit, respectively, all in the relation to the values of ideal point.

Despite the weights in scalar objective function were the same, we can notice that in contrast to WSM methods that prioritized some of the production objectives, the compromise solution yielded by WPM is in a relative evaluation more balanced. In this context, the results confirmed that the scalarization methods applying in a priori arrangement bring the problem with the precise reflection of the weights to desired Pareto optimal solutions [

24]. The coordinates of the weight vector serve as the model parameters in a multi-objective function and influence the location of Pareto front points.

When exploring the compromise solutions found in the objective space from the perspective of the production goals control, we can see a noticeable impact of the applied scalarization method on the evaluation of production results. The comparison of the reached results in

Figure 4a–e shows that all production goals that we wish to maximize, such as the number of products and machine utilization, were substantially higher in the case of the WSM method employed, regardless of the applied priority rule. On the contrary, the WPM method provided better results for production goal values that need to be minimized. As we can see in

Figure 4, the production objectives, such as the average flow time and the average work in progress, achieved smaller values in comparison to results yielded by the WSM method. Finally, in the case of the average costs per part unit, we can notice very similar and comparable results for all applied methods.

Working with many contradictory objectives assumes that they are not completely independent, and a correlation can appear between some of them. As can be noticed in the results introduced in

Figure 4, there exist two pairs of objectives which are correlated. We can observe the positive correlation between the number of products and machine utilization (

Figure 4a,b), as well as between flow time and work-in-progress (

Figure 4c,d). We supposed that correlations, applied transformation of production objectives, and different expressions defining the structure of objective function themselves could explain the obtained results significantly. To evaluate the direct influence of correlations on optimization results will need further experiments with a reduced set of objectives.

The rankings of priority rules strongly depend on selected performance measures involved in evaluation and the structure of the production system model itself. The interesting different approach, how to optimize multiple objectives in flexible job shop system, is introduced in a comparative study in the work of Sels et al. [

48]. They conducted single-objective optimizations for five individual objectives in the presence of 30 priority rules consequently to evaluate the individual performance objective with respect to the scheduling principle. The observed objectives were makespan, mean flow time, proportion of tardy jobs, mean tardiness, and maximum tardiness. As for ranking of rules, each priority rule’s performance was measured as the percentage deviation from the best performing priority rule. Based on the best results via ranking, they constructed the hybrid scheduling rule to ensure optimization of all five objectives simultaneously. EDD and Slack (called STR in our study) rules were the part of the hybrid priority rules in the top 5 of the priority rules that performed best on the five objective functions. Their experiments showed that an integrated optimization approach outperforms the hierarchical approach when solving the flexible job shop scheduling problem [

48].

7. Conclusions

In this study, we presented the results of the wider investigation of common priority rules FIFO, EDD, and STR applied in the partially flexible job shop system in terms of several conflicting production performance indicators evaluated simultaneously. We employed scalar multi-criteria simulation-based optimization in a priori arrangement to identify the impact of applied priority rule to production results. From this perspective, the evaluation of the influence of the applied priority rule and system loading to daily production for five selected production objectives at the same time based on MOP solving offers the possibility to find effective settings of external input parameters with respect to the scheduling principle, and it can support decision-making in production control.

Combination of metaheuristic algorithm Simulated Annealing and full combinatorial analysis in the final phase of the optimization process yielded a global solution of defined MOPs for each of the selected priority rules. The experimental results demonstrated that the found compromise solutions strongly depended on a selected scalar multi-criteria method and applied priority rule. Although the weights in the scalar objective function were the same, based on the performed experiments, we can conclude that results for production goals which need to be minimized were better when the WPM method was applied, in contrast to WSM, which developed the values of other production objectives, regardless of the employed priority rule. EDD and STR priority rules were shown as more suitable than the FIFO rule, both with comparable production performance.

Despite these facts, from the complex point of view, all effective solutions in the design space resulted from scalar multi-criteria simulation-based optimization obtained independently from the applied rule and applied optimization method, and were situated in the area connected to the lower production system load. For the modelled production system, the recommended settings for inter-arrival time of entering part for four types of manufactured products were presented to obtain acceptable values of production goals.

Future research will be focused on other multi-criteria method applications, and the question of the effect of other priority rules is still open. The evaluation of stochastic system performance will be in the center of interest, too.