Assimilation of Dynamic Combined Finite Discrete Element Methods Using the Ensemble Kalman Filter

Abstract

1. Introduction

2. Description of the Model

3. SHPB Experiment and HOSS Model Setup

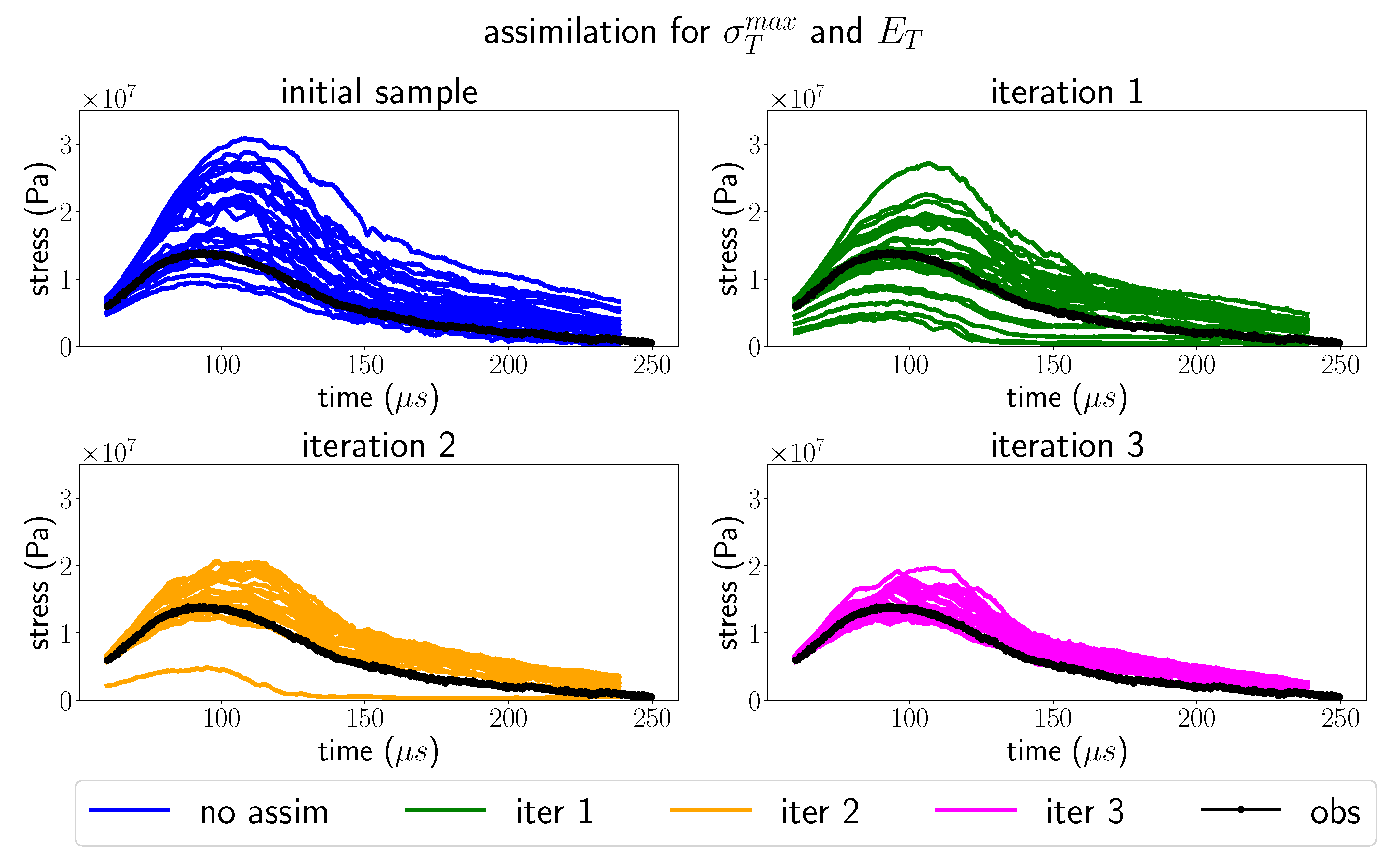

4. Data Assimilation

Ensemble Kalman Filter

- Initialization: An ensemble of parameter values , is provided by the latin hypercube sampling strategy, where ;

- Simulation: For each ensemble member simulate HOSS for the SHPB experiment, where the output is a stress versus time curve ( for );

- Cycle: Feedback the updated parameter values to HOSS and repeat Steps 2 and 3 until we see convergence of the error between the HOSS output and SHPB experiment (, where is the ensemble average);

- Forecast: Once convergence is achieved, perform a “forecast” of the HOSS model (best simulation with estimated parameter values).

5. Assimilation Results

5.1. Data Assimilation Simulation Setup

5.2. Data Assimilation Validation Experiments

5.3. Results with SHPB Observations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Brief FDEM Overview and HOSS Model Parameters

Model Parameters

References

- Munjiza, A. Discrete Elements in Transient Dynamics of Fractured Media. Ph.D. Thesis, Swansea University, Swansea, UK, 1992. [Google Scholar]

- Munjiza, A. The Combined Finite-Discrete Element Method; John Wiley and Sons Ltd.: New York, NY, USA, 2004. [Google Scholar]

- Lisjak, A.; Grasselli, G. A review of discrete modeling techniques for fracturing processes in discontinuous rock masses. J. Rock Mech. Geotech. Eng. 2014, 6, 301–314. [Google Scholar] [CrossRef]

- Tatone, B.; Lisjak, A.; Mahabadi, O.; Grasselli, G.; Donnelly, C. A preliminary evaluation of the combined finite element-discrete element method as a tool to assess gravity dam stability. In Proceedings of the CDA 2010 Annual Conference, Niagara Falls, ON, Canada, 2–7 October 2010. [Google Scholar]

- Lisjak, A.; Grasselli, G. Combined finite-discrete element analysis of rock slope stability under dynamic loading. In Proceedings of the Pan-Am CGS Geotechnical Conference, Toronto, ON, Canada, 2–6 October 2011. [Google Scholar]

- Carey, J.W.; Lei, Z.; Rougier, E.; Mori, H.; Viswanathan, H. Fracture-permeability behavior of shale. J. Unconv. Oil Gas Resour. 2015, 11, 27–43. [Google Scholar] [CrossRef]

- Hyman, J.D.; Jiménez-Martínez, J.; Viswanathan, H.S.; Carey, J.W.; Porter, M.L.; Rougier, E.; Karra, S.; Kang, Q.; Frash, L.; Chen, L.; et al. Understanding hydraulic fracturing: A multi-scale problem. Philos. Trans. R. Soc. Lond. A Math. Phys. Eng. Sci. 2016, 374. [Google Scholar] [CrossRef] [PubMed]

- Rougier, E.; Knight, E.; Munjiza, A. Fluid Driven Rock Deformation via the Combined FEM/DEM Methodology. In Proceedings of the 46th US Rock Mechanics/Geomechanics Symposium, Chicago, IL, USA, 24–27 June 2012; American Rock Mechanics Association: Alexandria, VA, USA, 2012. [Google Scholar]

- Moore, B.A.; Rougier, E.; O’Malley, D.; Srinivasan, G.; Hunter, A.; Viswanathan, H. Predictive modeling of dynamic fracture growth in brittle materials with machine learning. Comput. Mater. Sci. 2018, 148, 46–53. [Google Scholar] [CrossRef]

- Euser, B.; Rougier, E.; Lei, Z.; Knight, E.; Frash, L.; Carey, J.; Viswanathan, H.; Munjiza, A. Simulation of fracture coalescence in granite via the combined finite-discrete element method. Rock Mech. Rock Eng. 2019, 52, 3213–3227. [Google Scholar] [CrossRef]

- Elmo, D.; Stead, D. An integrated numerical modelling–discrete fracture network approach applied to the characterisation of rock mass strength of naturally fractured pillars. Rock Mech. Rock Eng. 2010, 43, 3–19. [Google Scholar] [CrossRef]

- Okubo, K.; Bhat, H.S.; Rougier, E.; Lei, Z.; Knight, E.E.; Klinger, Y. Dynamic fracture network around faults: Implications for earthquake ruptures, ground motion and energy budget. In Proceedings of the AGU Fall Meeting Abstracts, New Orleans, LA, USA, 11–15 December 2017. [Google Scholar]

- Okubo, K.; Bhat, H.S.; Rougier, E.; Marty, S.; Schubnel, A.; Lei, Z.; Knight, E.E.; Klinger, Y. Dynamics, Radiation, and Overall Energy Budget of Earthquake Rupture With Coseismic Off-Fault Damage. J. Geophys. Res. Solid Earth 2019, 124, 11771–11801. [Google Scholar] [CrossRef]

- Klinger, Y.; Okubo, K.; Vallage, A.; Champenois, J.; Delorme, A.; Rougier, E.; Lei, Z.; Knight, E.E.; Munjiza, A.; Satriano, C.; et al. Earthquake Damage Patterns Resolve Complex Rupture Processes. Geophys. Res. Lett. 2018, 45, 10279–10287. [Google Scholar] [CrossRef]

- Gao, K.; Euser, B.J.; Rougier, E.; Guyer, R.A.; Lei, Z.; Knight, E.E.; Carmeliet, J.; Johnson, P.A. Modeling of Stick-Slip Behavior in Sheared Granular Fault Gouge Using the Combined Finite-Discrete Element Method. J. Geophys. Res. Solid Earth 2018, 123, 5774–5792. [Google Scholar] [CrossRef]

- Gao, K.; Guyer, R.A.; Rougier, E.; Johnson, P.A. Plate motion in sheared granular fault system. Earth Planet. Sci. Lett. 2020, 548, 116481. [Google Scholar] [CrossRef]

- Godinez, H.; Rougier, E.; Osthus, D.; Lei, Z.; Knight, E.; Srinivasan, G. Fourier amplitude sensitivity test applied to dynamic combined finite-discrete element methods–based simulations. Int. J. Numer. Anal. Methods Geomech. 2019, 43, 30–44. [Google Scholar] [CrossRef]

- Osthus, D.; Godinez, H.; Rougier, E.; Srinivasan, G. Calibrating the stress-time curve of a combined finite-discrete element method to a Split Hopkinson Pressure Bar experiment. Int. J. Rock. Mech. Min. 2018, 106, 278–288. [Google Scholar] [CrossRef]

- Kalnay, E. Atmospheric Modeling, Data Assimilation, and Predictability; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Daley, R. Atmospheric Data Analysis; Cambridge University Press: Cambridge, UK, 1991. [Google Scholar]

- Asch, M.; Bocquet, M.; Nodet, M. Data Assimilation: Methods, Algorithms, and Applications; SIAM: Philadelphia, PA, USA, 2016. [Google Scholar]

- Smoljanović, H.; Živaljić, N.; Željana, N. A combined finite-discrete element analysis of dry stone masonry structures. Eng. Struct. 2013, 52, 89–100. [Google Scholar] [CrossRef]

- Pulatsu, B.; Erdogmus, E.; Lourenço, P.B.; Lemos, J.V.; Tuncay, K. Simulation of the in-plane structural behavior of unreinforced masonry walls and buildings using DEM. Structures 2020, 27, 2274–2287. [Google Scholar] [CrossRef]

- Knight, E.E.; Rougier, E.; Lei, Z. Hybrid Optimization Software Suite (HOSS)—Educational Version; Technical Report, LA-UR-15-27013; Los Alamos National Laboratory: Los Alamos, NM, USA, 2015.

- Rougier, E.; Knight, E.E.; Munjiza, A. LANL-CSM: HOSS—MUNROU Technology Overview; Presentation, LA-UR-13-23422; Los Alamos National Laboratory: Los Alamos, NM, USA, 2013.

- Knight, E.E.; Rougier, E.; Munjiza, A. LANL-CSM: Consortium Proposal for the Advancement of HOSS; Presentation, LA-UR-13-23409; Los Alamos National Laboratory: Los Alamos, NM, USA, 2013.

- Knight, E.E.; Rougier, E.; Lei, Z.; Euser, B.; Chau, V.; Boyce, S.H.; Gao, K.; Okubo, K.; Froment, M. HOSS: An implementation of the combined finite-discrete element method. Comput. Part. Mech. 2020, 7, 765–787. [Google Scholar] [CrossRef]

- Munjiza, A.; Knight, E.; Rougier, E. Computational Mechanics of Discontinua; John Wiley and Sons Ltd.: Chishester, UK, 2011. [Google Scholar]

- Munjiza, A.; Rougier, E.; Knight, E. Large Strain Finite Element Method: A Practical Course; John Wiley and Sons: New York, NY, USA, 2015. [Google Scholar]

- Rougier, E.; Knight, E.; Broome, S.; Sussman, A.; Munjiza, A. Validation of a three-dimensional Finite-Discrete Element Method using experimental results of the Split Hopkinson Pressure Bar test. Int. J. Numer. Meth. Eng. 2014, 70, 101–108. [Google Scholar] [CrossRef]

- Cukier, R.; Fortuin, C.; Shuler, K.; Petschek, A.; Schaibly, J. Study of the sensitivity of coupled reaction systems to uncertainties in rate coefficients. I. Theory. J. Chem. Phys. 1973, 59, 3873–3878. [Google Scholar] [CrossRef]

- Cukier, R.; Schaibly, J.; Shuler, K.E. Study of the sensitivity of coupled reaction systems to uncertainties in rate coefficients. III. Analysis of the approximations. J. Chem. Phys. 1975, 63, 1140–1149. [Google Scholar] [CrossRef]

- Brynson, J. Impact Response of Polyurethane. Ph.D. Thesis, School of Mechanical and Materials Engineering, Washington State University, Pullman, WA, USA, 2009. [Google Scholar]

- Chen, W.; Song, B. Split Hopkinson (Kolsky) Bar: Design, Testing and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Broome, S.T.; Lee, M.Y. Dynamic Brazilian Tension Results on Core from Borehole U-15n NNSS in Support of SPE; Technical Report SAND2018-13771R; Sandia National Lab.: Albuquerque, NM, USA, 2018.

- Le Dimet, F.; Talagrand, O. Variational algorithms for analysis and assimilation of meteorological observations: Theoretical aspects. Tellus 1986, 38A, 97–110. [Google Scholar] [CrossRef]

- Kalman, R. A new approach to linear filtering and prediction problems. Trans. ASME Ser. D J. Basic Eng. 1960, 82, 35–45. [Google Scholar] [CrossRef]

- Metropolis, N.; Ulam, S. The Monte Carlo Method. J. Am. Stat. Assoc. 1949, 44, 335–341. [Google Scholar] [CrossRef]

- Jazwinski, A. Stochastic Processes and Filtering Theory; Academic Press: Cambridge, MA, USA, 1970. [Google Scholar]

- Doucet, A.; de Freitas, N.; Gordon, N. Sequential Monte Carlo Methods in Practice; Springer: Berlin, Germany, 2001. [Google Scholar]

- Evensen, G. Sequential data assimilation with a nonlinear quasi-geostrophic model using Monte Carlo methods to forecast error statistics. J. Geophys. Res. 1994, 99, 10143–10162. [Google Scholar] [CrossRef]

- Evensen, G. The ensemble Kalman filter for combined state and parameter estimation. IEEE Control Syst. Mag. 2009, 29, 83–104. [Google Scholar] [CrossRef]

- Evensen, G. The ensemble Kalman filter: Theoretical formulation and practical implementation. Ocean Dyn. 2003, 53, 343–367. [Google Scholar] [CrossRef]

- Houtekamer, P.; Mitchell, H. Data assimilation using an ensemble Kalman filter technique. Mon. Weather Rev. 1998, 126, 796–811. [Google Scholar] [CrossRef]

- Hamill, T.; Whitaker, J.; Snyder, C. Distance-Dependent Filtering of Background Error Covariance Estimates in an Ensemble Kalman Filter. Mon. Weather Rev. 2001, 129, 2776–2790. [Google Scholar] [CrossRef]

- Evensen, G.; van Leeuwen, P. An Ensemble Kalman Smoother for Nonlinear Dynamics. Mon. Weather Rev. 2000, 128, 1852–1867. [Google Scholar] [CrossRef]

- Gu, Y.; Oliver, D.S. An iterative ensemble Kalman filter for multiphase fluid flow data assimilation. SPE J. 2007, 12, 438–446. [Google Scholar] [CrossRef]

- Emerick, A.A.; Reynolds, A.C. History matching time-lapse seismic data using the ensemble Kalman filter with multiple data assimilations. Comput. Geosci. 2012, 16, 639–659. [Google Scholar] [CrossRef]

- Emerick, A.A.; Reynolds, A.C. Ensemble smoother with multiple data assimilation. Comput. Geosci. 2013, 55, 3–15. [Google Scholar] [CrossRef]

- Iman, R.L.; Conover, W. Small sample sensitivity analysis techniques for computer models. with an application to risk assessment. Commun. Stat. Theory Methods 1980, 9, 1749–1842. [Google Scholar] [CrossRef]

- Rougier, E.; Munjiza, A. MRCK 3D Contact Detection Algorithm. In Proceedings of the Discrete Element Methods: 5th International Conference on Discrete Element Methods, London, UK, 25–26 August 2010; Munjiza, A., Ed.; [Google Scholar]

- Munjiza, A.; Andrews, K.; White, J. Combined single and smeared crack model in combined finite-discrete element analysis. Int. J. Numer. Meth. Eng. 1999, 44, 41–57. [Google Scholar] [CrossRef]

| Parameter | Description | Units | Value |

|---|---|---|---|

| E | Young’s Modulus | GPa | 35.0 |

| Poisson’s ratio | - | 0.16 | |

| Density | kg/m | 2550.0 |

| Parameter | Description | Units | Interval | Reference val. (Validation) |

|---|---|---|---|---|

| shear strength | Pa | 4.5 | ||

| specific energy in tangential direction | J/m 2 | 5.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Godinez, H.C.; Rougier, E. Assimilation of Dynamic Combined Finite Discrete Element Methods Using the Ensemble Kalman Filter. Appl. Sci. 2021, 11, 2898. https://doi.org/10.3390/app11072898

Godinez HC, Rougier E. Assimilation of Dynamic Combined Finite Discrete Element Methods Using the Ensemble Kalman Filter. Applied Sciences. 2021; 11(7):2898. https://doi.org/10.3390/app11072898

Chicago/Turabian StyleGodinez, Humberto C., and Esteban Rougier. 2021. "Assimilation of Dynamic Combined Finite Discrete Element Methods Using the Ensemble Kalman Filter" Applied Sciences 11, no. 7: 2898. https://doi.org/10.3390/app11072898

APA StyleGodinez, H. C., & Rougier, E. (2021). Assimilation of Dynamic Combined Finite Discrete Element Methods Using the Ensemble Kalman Filter. Applied Sciences, 11(7), 2898. https://doi.org/10.3390/app11072898