Interpretation of Frequency Response Analysis for Fault Detection in Power Transformers

Abstract

1. Introduction

2. Transformer Frequency Response Analysis

3. Fault Extent Methodology

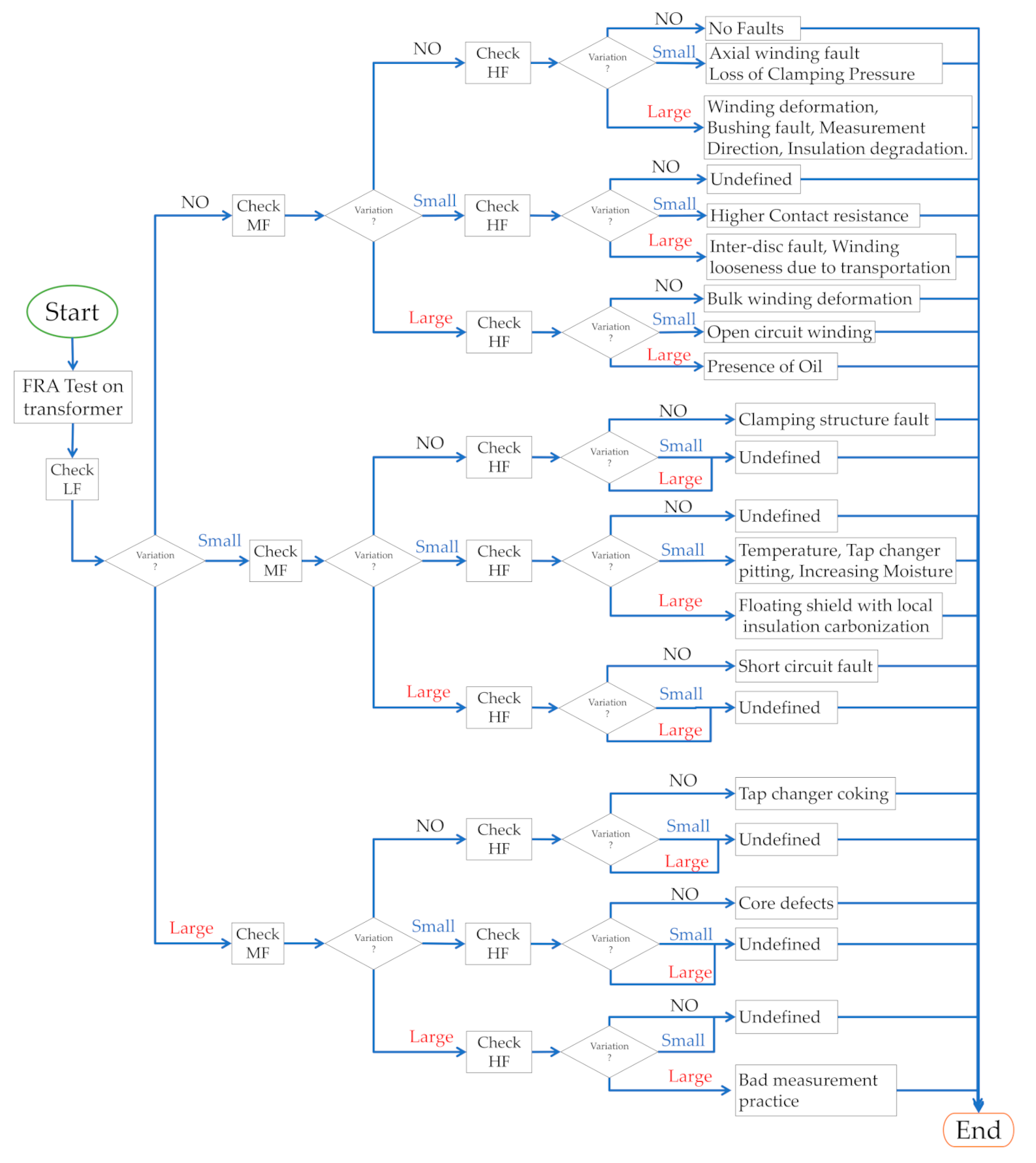

4. Proposed Fault Identification Guidelines

5. Case Study: Short Circuit Fault

6. Conclusions

- The proposed guidelines are established based on the review of previous extensive research presented in the literature, along with various FRA international standards.

- The flowchart is developed based on three frequency regions and three levels of variations based on CC calculation.

- The characteristic table is presented graphically with arrows to provide a simple interpretation scheme for an inexperienced user.

- An experimental case study conducted on an 11/0.433 kV 500 kVA transformer with normal and short circuit faults is presented to verify the feasibility of the proposed guidelines.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEEE. C57.149-2012—Guide for the Application and Interpretation of Frequency Response Analysis for Oil-Immersed Transformers; IEEE: Piscataway Township, NJ, USA, 2012. [Google Scholar] [CrossRef]

- Picher, P. Mechanical Condition Assessment of Transformer Windings Using Frequency Response Analysis (Fra). Cigre Eval. 2008, 26, 30–34. Available online: https://www.scribd.com/doc/207245891/CiGRE-342-2008 (accessed on 2 October 2020).

- IEC 60076-18 Ed. 1. Power Transformers—Part 18: Measurement of Frequency Response. 2012. Available online: https://webstore.iec.ch/publication/597 (accessed on 2 October 2020).

- Frequency Response Analysis on Winding Deformation of Power Transformers. DL/T911-2016, (In Chinese), People Republic China, Electricity Power Industry Stand. 2016. Available online: https://www.codeofchina.com/standard/DLT911-2016.html (accessed on 2 October 2020).

- Alsuhaibani, S.; Khan, Y.; Beroual, A.; Malik, N.H. A Review of Frequency Response Analysis Methods for Power Transformer Diagnostics. Energies 2016, 9, 879. [Google Scholar] [CrossRef]

- Senobari, R.K.; Sadeh, J.; Borsi, H. Frequency response analysis (FRA) of transformers as a tool for fault detection and location: A review. Electr. Power Syst. Res. 2018, 155, 172–183. [Google Scholar] [CrossRef]

- Secue, J.; Mombello, E. Sweep frequency response analysis (SFRA) for the assessment of winding displacements and deformation in power transformers. Electr. Power Syst. Res. 2008, 78, 1119–1128. [Google Scholar] [CrossRef]

- Sant’Ana, W.C.; Salomon, C.P.; Lambert-Torres, G.; da Silva, L.E.B.; Bonaldi, E.L.; Oliveira, L.E.D.L.D.; da Silva, J.G.B. A survey on statistical indexes applied on frequency response analysis of electric machinery and a trend based approach for more reliable results. Electr. Power Syst. Res. 2016, 137, 26–33. [Google Scholar] [CrossRef]

- Banaszak, S.; Kornatowski, E.; Szoka, W. The Influence of the Window Width on FRA Assessment with Numerical Indices. Energies 2021, 14, 362. [Google Scholar] [CrossRef]

- Cheng, B.; Wang, Z.; Crossley, P. Using Lumped Element Equivalent Network Model to Derive Analytical Equations for Interpretation of Transformer Frequency Responses. IEEE Access 2020, 8, 179486–179496. [Google Scholar] [CrossRef]

- Zhao, Z.; Yao, C.; Tang, C.; Li, C.; Yan, F.; Islam, S. Diagnosing Transformer Winding Deformation Faults Based on the Analysis of Binary Image Obtained From FRA Signature. IEEE Access 2019, 7, 40463–40474. [Google Scholar] [CrossRef]

- Al-Ameri, S.; Yousof, M.F.M.; Azis, N.; Avinash, S.; Talib, M.A.; Salem, A.A. Modeling frequency response of transformer winding to investigate the influence of RLC. Indones. J. Electr. Eng. Comput. Sci. 2019, 14, 219–229. [Google Scholar] [CrossRef]

- Abu-Siada, A.; Hashemnia, N.; Islam, S.; Masoum, M.A. Understanding power transformer frequency response analysis signatures. IEEE Electr. Insul. Mag. 2013, 29, 48–56. [Google Scholar] [CrossRef]

- Murthy, A.S.; Azis, N.; Jasni, J.; Othman, M.L.; Yousof, M.F.M.; Talib, M.A. Extraction of winding parameters for 33/11 kV, 30 MVA transformer based on finite element method for frequency response modelling. PLoS ONE 2020, 15, e0236409. [Google Scholar] [CrossRef]

- Abu-Siada, A.; Mosaad, M.I.; Kim, D.W.; El-Naggar, M.F. Estimating Power Transformer High Frequency Model Parameters Using Frequency Response Analysis. IEEE Trans. Power Deliv. 2019, 35, 1267–1277. [Google Scholar] [CrossRef]

- Aljohani, O.; Abu-Siada, A. Application of Digital Image Processing to Detect Short-Circuit Turns in Power Transformers Using Frequency Response Analysis. IEEE Trans. Ind. Informatics 2016, 12, 2062–2073. [Google Scholar] [CrossRef]

- Gonzales, J.C.; Mombello, E.E. Fault Interpretation Algorithm Using Frequency-Response Analysis of Power Transformers. IEEE Trans. Power Deliv. 2015, 31, 1034–1042. [Google Scholar] [CrossRef]

- Trela, K.; Gawrylczyk, K.M. FEM Modelling of the Influence of the Remaining Windings on the Frequency Response of the Power Transformer. Appl. Sci. 2020, 10, 7633. [Google Scholar] [CrossRef]

- Areu, O.H.; Menendez, A.M.G.; Sanchez, J.I.H.; Valdes, E.S. Diagnosis of faults in power transformers through the interpretation of FRA testing with artificial intelligence. In Proceedings of the 2018 IEEE International Autumn Meeting on Power, Electronics and Computing (ROPEC), Ixtapa, Mexico, 14–16 November 2018. [Google Scholar] [CrossRef]

- Gutten, M.; Korenciak, D.; Kucera, M.; Janura, R.; Glowacz, A.; Kantoch, E. Frequency and time fault diagnosis methods of power transformers. Meas. Sci. Rev. 2018, 18, 162–167. [Google Scholar] [CrossRef]

- Abu-Siada, A.; Radwan, I.; Abdou, A.F. 3D approach for fault identification within power transformers using frequency response analysis. IET Sci. Meas. Technol. 2019, 13, 903–911. [Google Scholar] [CrossRef]

- Tahir, M.; Tenbohlen, S. A Comprehensive Analysis of Windings Electrical and Mechanical Faults Using a High-Frequency Model. Energies 2019, 13, 105. [Google Scholar] [CrossRef]

- Banaszak, S.; Szoka, W. Cross Test Comparison in Transformer Windings Frequency Response Analysis. Energies 2018, 11, 1349. [Google Scholar] [CrossRef]

- Yousof, M.F.M.; Al-Ameri, S.; Ahmad, H.; Illias, H.A.; Arshad, S.N.M. A New Approach for Estimating Insulation Condition of Field Transformers Using FRA. Adv. Electr. Comput. Eng. 2020, 20, 35–42. [Google Scholar] [CrossRef]

- Omicron, F.P. Interpretation of Sweep Frequency Response Analysis (SFRA) Measurement Results; OMICRON Energy: Bundoora, Australia, 2016; pp. 1–26. Available online: https://www.ee.co.za/article/interpreting-sweep-frequency-response-analysis-measurements.html (accessed on 15 October 2020).

- Bustamante, S.; Manana, M.; Arroyo, A.; Laso, A.; Martinez, R. Determination of Transformer Oil Contamination from the OLTC Gases in the Power Transformers of a Distribution System Operator. Appl. Sci. 2020, 10, 8897. [Google Scholar] [CrossRef]

- Murthy, A.S.; Azis, N.; Al-Ameri, S.; Yousof, M.F.M.; Jasni, J.; Talib, M.A. Investigation of the Effect of Winding Clamping Structure on Frequency Response Signature of 11 kV Distribution Transformer. Energies 2018, 11, 2307. [Google Scholar] [CrossRef]

- Al-Ameri, S.; Alawady, A.A.; Yousof, M.F.M.; Ahmad, H.; Salem, A.A.; Talib, M.A. Frequency response analysis for transformer tap changer damage detection. Int. J. Power Electron. Drive Syst. (IJPEDS) 2020, 11, 350–358. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, Z.; Tang, C.; Yao, C.; Li, C.; Islam, S. Classifying Transformer Winding Deformation Fault Types and Degrees Using FRA Based on Support Vector Machine. IEEE Access 2019, 7, 112494–112504. [Google Scholar] [CrossRef]

- Zhao, Z.; Tang, C.; Yao, C.; Zhou, Q.; Xu, L.; Gui, Y.; Islam, S. Improved Method to Obtain the Online Impulse Frequency Response Signature of a Power Transformer by Multi Scale Complex CWT. IEEE Access 2018, 6, 48934–48945. [Google Scholar] [CrossRef]

- Omicron. Performing reliable and reproducible frequency response measurements on power transformers. Transform. Mag. 2018, 5, 1–12. [Google Scholar]

- Ćalasan, M.; Mujičić, D.; Rubežić, V.; Radulović, M. Estimation of Equivalent Circuit Parameters of Single-Phase Transformer by Using Chaotic Optimization Approach. Energies 2019, 12, 1697. [Google Scholar] [CrossRef]

- Banaszak, S.; Gawrylczyk, K.M.; Trela, K. Frequency Response Modelling of Transformer Windings Connected in Parallel. Energies 2020, 13, 1395. [Google Scholar] [CrossRef]

- Bagheri, M.; Nezhivenko, S.; Phung, B.T.; Blackburn, T. Air Core Transformer Winding Disk Deformation: A Precise Study on Mutual Inductance Variation and Its Influence on Frequency Response Spectrum. IEEE Access 2017, 6, 7476–7488. [Google Scholar] [CrossRef]

- Bigdeli, M.; Siano, P.; Alhelou, H.H. Intelligent Classifiers in Distinguishing Transformer Faults Using Frequency Response Analysis. IEEE Access 2021, 9, 13981–13991. [Google Scholar] [CrossRef]

- Kennedy, G.; McGrail, A.; Lapworth, J. Transformer sweep frequency response analysis (SFRA). Energize 2007, 28–33. Available online: https://www.ee.co.za/wp-content/uploads/legacy/Transformer_.pdf (accessed on 25 October 2020).

- Yousof, M.F.M.; Ekanayake, C.; Saha, T.K. Frequency response analysis to investigate deformation of transformer winding. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2359–2367. [Google Scholar] [CrossRef]

- Rahimpour, E.; Christian, J.; Feser, K.; Mohseni, H. Transfer function method to diagnose axial displacement and radial deformation of transformer windings. IEEE Trans. Power Deliv. 2003, 18, 493–505. [Google Scholar] [CrossRef]

- Liu, S.; Liu, Y.; Li, H.; Lin, F. Diagnosis of transformer winding faults based on FEM simulation and on-site experiments. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3752–3760. [Google Scholar] [CrossRef]

- Hashemnia, N.; Abu-Siada, A.; Masoum, M.A.S.; Islam, S.M. Characterization of transformer FRA signature under various winding faults. In Proceedings of the 2012 IEEE International Conference on Condition Monitoring and Diagnosis, Bali, Indonesia, 23–27 September 2012; pp. 446–449. [Google Scholar] [CrossRef]

- Reykherdt, A.A.; Davydov, V. Case studies of factors influencing frequency response analysis measurements and power transformer diagnostics. IEEE Electr. Insul. Mag. 2011, 27, 22–30. [Google Scholar] [CrossRef]

- Al-Ameri, S.; Yousof, M.F.M.; Ahmad, H.; Alsubari, M.; Talib, M.A. Examining faulty transformer tap changer using frequency response analysis. In Proceedings of the International Symposium on Electrical Insulating Materials, Toyohashi City, Japan, 11–15 September 2017. [Google Scholar] [CrossRef]

- Yousof, M.F.M.; Ekanayake, C.; Saha, T.K. Examining the ageing of transformer insulation using FRA and FDS techniques. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1258–1265. [Google Scholar] [CrossRef]

- Aljohani, O.; Abu-Siada, A. Identification of the minimum detection of transformer bushing failure based on Frequency Response Analysis (FRA). In Proceedings of the 2016 IEEE 2nd Annual Southern Power Electronics Conference (SPEC), Auckland, New Zealand, 5–8 December 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Bagheri, M.; Phung, B.; Blackburn, T. Influence of moisture content variation on Frequency Response Analysis of transformer winding. In Proceedings of the 2014 IEEE Electrical Insulation Conference (EIC), Philadelphia, PA, USA, 8–11 June 2014; pp. 333–337. [Google Scholar] [CrossRef]

| Proposed Methods | Advantages | Disadvantages |

|---|---|---|

| Statistical indicators [6,7,8,9] |

|

|

| FRA modeling equivalent circuit [13,14,15] |

|

|

| Mathematical models [16,17,18] |

|

|

| ANNs [19,20,21] |

|

|

| Proposed guidelines in this study |

|

|

| CC Value | Variation Level |

|---|---|

| 0.98–1.00 | No Variation |

| 0.96–0.97 | Small Variation |

| ≤0.95 | Large Variation |

| NO | Sensitivity to Fault | Test Type | LF | MF | HF | Reference |

|---|---|---|---|---|---|---|

| 1 | Radial winding deformation | Short circuit test | No | Small | Large | [1,3] |

| 2 | Axial winding deformation | Short circuit test | No | Small | Small | [1,3,38,39] |

| 3 | Bulk winding deformation | Open circuit test | No | Large | No | [1,3,36] |

| 4 | Core defects | Open circuit test | Large | Small | No | [1,2,3,36] |

| 5 | Higher contact resistance | Open circuit test | No | Small | Small | [1,36] |

| 6 | Short circuit fault | Short circuit test | Small | Large | No | [1,2,36] |

| 7 | Inter-disc fault | Short circuit test | No | Small | Large | [22] |

| 8 | Open circuit winding | Open circuit test | No | Large | Small | [1,39] |

| 9 | Winding looseness due to transportation | Open circuit test | No | Small | Large | [1] |

| 10 | Floating shield with local insulation | Open circuit test | Small | Small | Large | [1,2] |

| 11 | Presence of oil | Open circuit test | No | Large | Large | [2,40,41] |

| 12 | Measurement direction | Open circuit test | No | No | Large | [3] |

| 13 | Effect of temperature | Open circuit test | Small | Small | Small | [3,41] |

| 14 | Loss of clamping pressure | Short circuit test | No | No | Small | [13] |

| 15 | Tap changer coking | Open circuit test | Large | No | No | [42] |

| 16 | Tap changer pitting | Open circuit test | Small | Small | Small | [42] |

| 17 | Winding insulation degradation | Open circuit test | No | No | Large | [43,44] |

| 18 | Clamping structure damage | Open circuit test | No | Small | No | [36] |

| 19 | High voltage bushing fault | Short circuit test | No | Small | Small | [5,39,40,44] |

| 20 | Increasing moisture content | Short circuit test | Small | Small | Small | [41,43,45] |

| 21 | Bad measurement practice | Open and short test | Large | Large | Large | [3] |

| 22 | No faults | Open and short test | No | No | No | Obvious |

| Faults | Test Type | Magnitude | Shifting Frequency | ||||

|---|---|---|---|---|---|---|---|

| LF | MF | HF | LF | MF | HF | ||

| Radial winding deformation | Short circuit test | - | - | ↑ | - | - | → |

| Axial winding deformation | Short circuit test | - | - | ↑ | - | - | ← |

| Bulk winding deformation | Open circuit test | - | - | - | - | → | - |

| Core defects | Open circuit test | ↓ | ↓ | - | ← | - | - |

| Higher contact resistance | Open circuit test | - | ↑ | ↑ | - | ← | ← |

| Short circuit fault | Short circuit test | ↑ | ↑ | - | → | → | - |

| Inter-disc fault | Short circuit test | - | ↑ | ↑ | - | → | → |

| Open circuit winding | Open circuit test | - | ↓ | ↓ | - | ← | ← |

| Winding looseness | Open circuit test | - | - | ↑ | - | → | → |

| Floating shield with local insulation | Open circuit test | - | - | ↓ | - | → | → |

| Presence of oil | Open circuit test | - | - | - | - | ← | ← |

| Measurement direction | Open circuit test | - | - | ↓ | - | - | - |

| Effect of high temperature | Open circuit test | - | - | - | ← | ← | ← |

| Loss of clamping pressure | Short circuit test | - | - | ↓ | - | - | - |

| Tap changer coking | Open circuit test | ↓ | ˗ | ˗ | ˗ | ˗ | ˗ |

| Tap changer pitting | Open circuit test | ˗ | ˗ | ˗ | → | → | → |

| Winding insulation degradation | Open circuit test | ˗ | ˗ | ˗ | ˗ | ˗ | ← |

| Clamping structure damage | Open circuit test | ↓ | - | - | - | - | - |

| High voltage bushing fault | Short circuit test | - | - | ↑ | - | - | - |

| Increasing moisture content | Short circuit test | - | - | - | ← | ← | ← |

| Bad measurement practice | Open and short test | ↓↑ | ↓↑ | ↓↑ | ← → | ← → | ← → |

No variation.

No variation.  Small variation.

Small variation.  Large variation.

Large variation.| Tap | HV Rating | Tap Connection | LV Rating | V-Ratio Normal | V-Ratio Fault |

|---|---|---|---|---|---|

| 1 | 11,550 | 4–5 | 433 | 46.201 | 42.772 |

| Frequency Range | CC Value |

|---|---|

| 20 Hz–2 kHz | 0.9842 |

| 2 kHz–20 kHz | 0.6483 |

| 20 kHz–2 MHz | 0.9965 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Ameri, S.M.; Kamarudin, M.S.; Yousof, M.F.M.; Salem, A.A.; Siada, A.A.; Mosaad, M.I. Interpretation of Frequency Response Analysis for Fault Detection in Power Transformers. Appl. Sci. 2021, 11, 2923. https://doi.org/10.3390/app11072923

Al-Ameri SM, Kamarudin MS, Yousof MFM, Salem AA, Siada AA, Mosaad MI. Interpretation of Frequency Response Analysis for Fault Detection in Power Transformers. Applied Sciences. 2021; 11(7):2923. https://doi.org/10.3390/app11072923

Chicago/Turabian StyleAl-Ameri, Salem Mgammal, Muhammad Saufi Kamarudin, Mohd Fairouz Mohd Yousof, Ali A. Salem, A. Abu Siada, and Mohamed I. Mosaad. 2021. "Interpretation of Frequency Response Analysis for Fault Detection in Power Transformers" Applied Sciences 11, no. 7: 2923. https://doi.org/10.3390/app11072923

APA StyleAl-Ameri, S. M., Kamarudin, M. S., Yousof, M. F. M., Salem, A. A., Siada, A. A., & Mosaad, M. I. (2021). Interpretation of Frequency Response Analysis for Fault Detection in Power Transformers. Applied Sciences, 11(7), 2923. https://doi.org/10.3390/app11072923