Abstract

Patterned surfaces have proven to be a valuable design to enhance adhesion, increasing hysteresis and the detachment stress at pull-off. To obtain high adhesive performance, soft materials are commonly, used, which easily conform to the countersurface, such as soft polymers and elastomers. Such materials are viscoelastic; i.e., they show rate-dependent properties. Here, the detachment of two half spaces is studied, one being flat and the other having a dimple in the limit of short range adhesion and a power law rate-dependent work of adhesion, as observed by several authors. Literature results have suggested that the dimpled surface would show pressure-sensitive adhesion, showing two possible adhered states, one weak, in partial contact, and one strong when full contact is achieved. By accounting for a power law rate-dependent work of adhesion, the “weak state” may be much stronger than it was in the purely elastic case, and hence the interface may be much more tough to separate. We study the pull-off detachment stress of the dimpled surface, showing that it weakly depends on the preload, but it is strongly affected by the dimensionless unloading rate. Finally, possible implications of the presented results in the detachment of soft materials from rough substrates are discussed.

1. Introduction

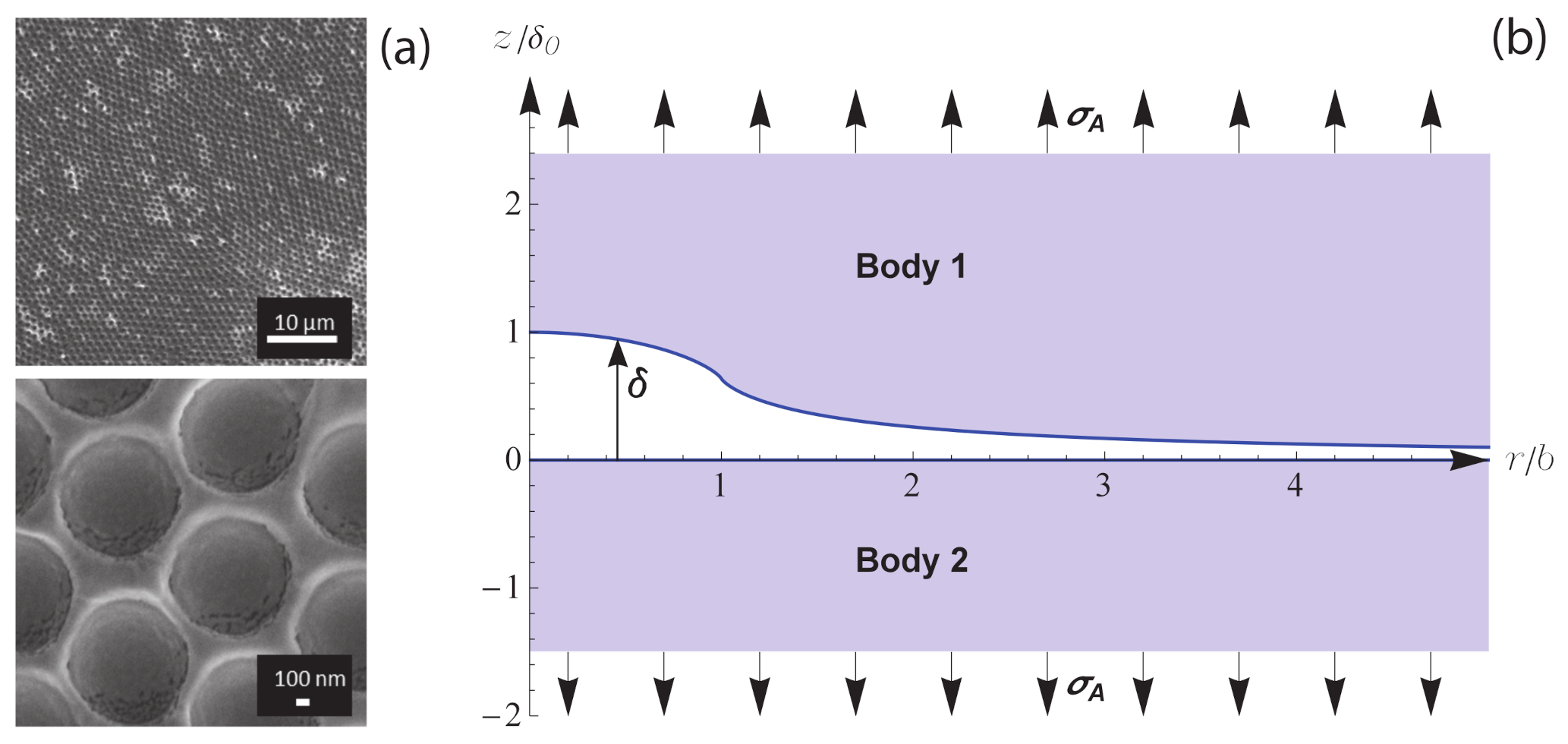

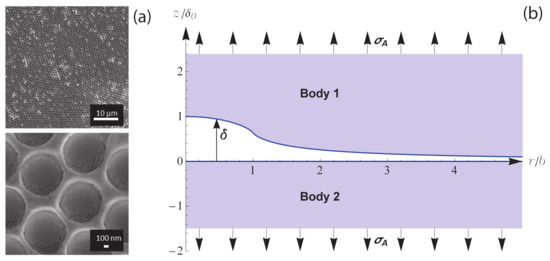

Tribology is a very active field of research of utmost importance in several engineering applications, ranging from automotive [1] to aerospace [2] and bio-engineering [3]. In automotive, for example, the role of adhesion and viscoelasticity is crucial in determining tires’ adherence and performance [4]. Adhesion due to van der Waals interactions is commonly exploited in nature, in which very efficient strategies have been developed to adhere to almost any kind of surface [5,6]. Lizardw, geckos and insects in general in most cases outperform the most advanced human designed adhesive technologies, and the topic still has far to go. Geckos for example have developed a multiscale hierarchical structure, so that the “macroscopic” foot splits in several lamellae, which branch in the setae and finally in fine spatulae of the size of nanometers [7,8]. Inspired by nature, several adhesive strategies have been pursued, among the others, that of fabricating patterned surfaces [9] present in mushroom pillars [10] or depressions (“dimples”) [9] (see Figure 1a) and have been shown to be able to reach far higher adhesive stress with respect to the smooth case. Nevertheless, simple criteria to discern sticky from unsticky surfaces are still unavailable [11,12,13], except maybe the criterion introduced by Dalquist at 3M, who suggested that a strong adhesive tape should have a Young’s modulus lower than 0.3 MPa to be able to conform well to the harder counterpart [14], which, only recently, has received some support from a theoretical perspective [11,12].

Figure 1.

(a) SEM images of a surface pattered with dimples (adapted from [9]). (b) Geometry of the dimple surface considered in this study. The model is axysimmetric.

Over the years, several authors have conceived of contact mechanics models to ascertain how the enhancement is originated and possibly indicate routes for further development or better performance [15,16,17]. A very elegant model for the detachment of a halfspace with a dimple from a flat substrate was proposed by McMeeking et al. [17], who developed a contact mechanics model in the limit of short range adhesion (the so-called “JKR limit” from Johnson, Kendall, and Roberts’ seminal paper [18]) and showed that the dimple surface behaved as a pressure-sensitive adhesive: detaching the dimple from its equilibrium position would lead to “weak adhesion” in partial contact, but upon application of a compressive pressure, a full-contact state would be achieved that would require a (theoretically) infinite tensile traction to be detached (“strong adhesion”). In this respect, the finding recalls the seminal work of Johnson [19], who considered the contact of a halfplane with sinusoidal waviness. Johnson had to postulate the presence of a flaw at the interface (air trapping, contaminants, fine scale roughness...), which would guarantee the possibility to separate the two surfaces. Zhou et al. [15] have applied the McMeeking et al. [17] model to study the adhesion capabilities of both cockroach pads (Nauphoeta cinerea) and dock beetles pads (Gastrophysa viridula), showing that they are strongly influenced by the geometric features of the interfacial pattern, and Cañas et al. [20] adopted the McMeeking et al. [17] model to fit experimental results of adhesion of biomimetic polydimethylsiloxane (PDMS) surfaces patterned with pillars with mushroom-shaped tips.

Recently, Papangelo and Ciavarella [21] generalized the “dimple” model of McMeeking et al. [17] by using a cohesive Maugis–Dugdale model, which introduces two new parameters, i.e., the theoretical strength of the material and the range of interaction of the adhesive tractions, and allowed investigation of the detachment performance of the dimple ranging from soft to hard materials as a function of a dimensionless parameter that is similar to that introduced by Tabor for the sphere [21,22]. It was shown that the dimple adhesive performance, particularly the “strong adhesive state”, becomes rapidly degraded, moving towards the rigid limit; hence for the dimple to effectively work as a pressure-sensitive mechanism, soft materials should be employed.

The above studies have considered the work of adhesion (the work needed to separate two flat surfaces from their equilibrium position up to infinity) as a constant that depends on the contact pair. Nevertheless, it is well-known that soft materials show rate-dependent properties. In particular, the dependence of the work of adhesion w on the velocity of the peeling (the velocity at the crack tip) is well documented both experimentally [23,24] and theoretically [25,26]. Although with some variants in the nomenclature, most of the authors agree that the dependence of the work of adhesion on the peeling velocity is well captured by a power law form (Reference [27])

where is the adiabatic (or thermodynamic) work of adhesion for vanishing peeling velocity, while and n are material properties with a reference velocity, and n an exponent usually in a range from to for realistic materials. Here, we revise the model of McMeeking et al. [17] by accounting for the effect of the rate at which the external load is applied. It will be shown that the dimple still behaves as a pressure-sensitive adhesive, but the “weak” adhesive state is strongly influenced by the unloading rate so that the pull-off stress in partial contact and the interfacial toughness can largely increase for high unloading velocity. The enhancement effect is greatly dependent on the exponent n, larger exponents leading to larger strengthening of the interface, but it is only marginally affected by the level of preload.

2. Griffith Equilibrium Solution for a Dimple

2.1. Elastic Problem

Here, the model introduced by McMeeking et al. [17] for the detachment of two elastic half-spaces is summarized. The geometry consists of two elastic bodies (see Figure 1b), with Young’s modulus and Poisson’s ratio and , one of those flat while the other with an axysimmetric dimple, whose geometry is defined by (see Figure 1b)

where r is the radial coordinate, is the dimple amplitude, b is the dimple radius, and are, respectively, the complete elliptical integral of first and second kind with argument . Johnson [28] has shown that a uniform axisymmetric pressure of magnitude p applied over a region on the surface of a half-space produces surface displacements as in Equation (2); hence, to make the two half-spaces conform to each other, one would need within the dimple a tensile traction T equal to [28]

where is the composite elastic modulus. Hence, if a remote stress (>0, when tensile) is applied, the stress at the interface of the two half-spaces will be

The combination of the remote stress applied and the inner (constant) stress within the dimple can be easily studied in the framework of the Linear Elastic Fracture Mechanics (LEFM) theory, as the dimple behaves as an axisymmetric crack under internal pressure [29]. Let us define, for a crack of radius c, the auxiliary function ([29], 3.114a)

Then, Equation (3.117) in [29] gives the stress intensity factor as , or equivalently, the energy release per unit area

Hence McMeeking et al. [17] apply the classical Griffith energetic argument that the energy release per unit area G should be equal to the surface energy of the contact pair (the “toughness”), leading to their LEFM model [17]. The equilibrium curves that link the remote tension to the crack radius are written in dimensionless form as

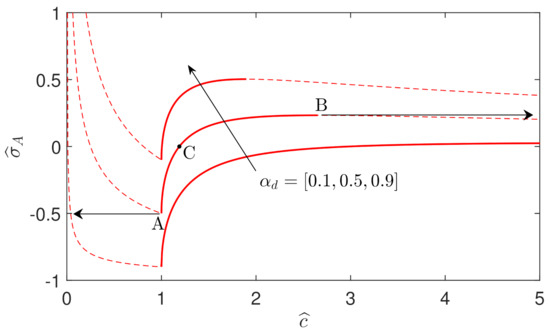

where we have introduced the following dimensionless parameters

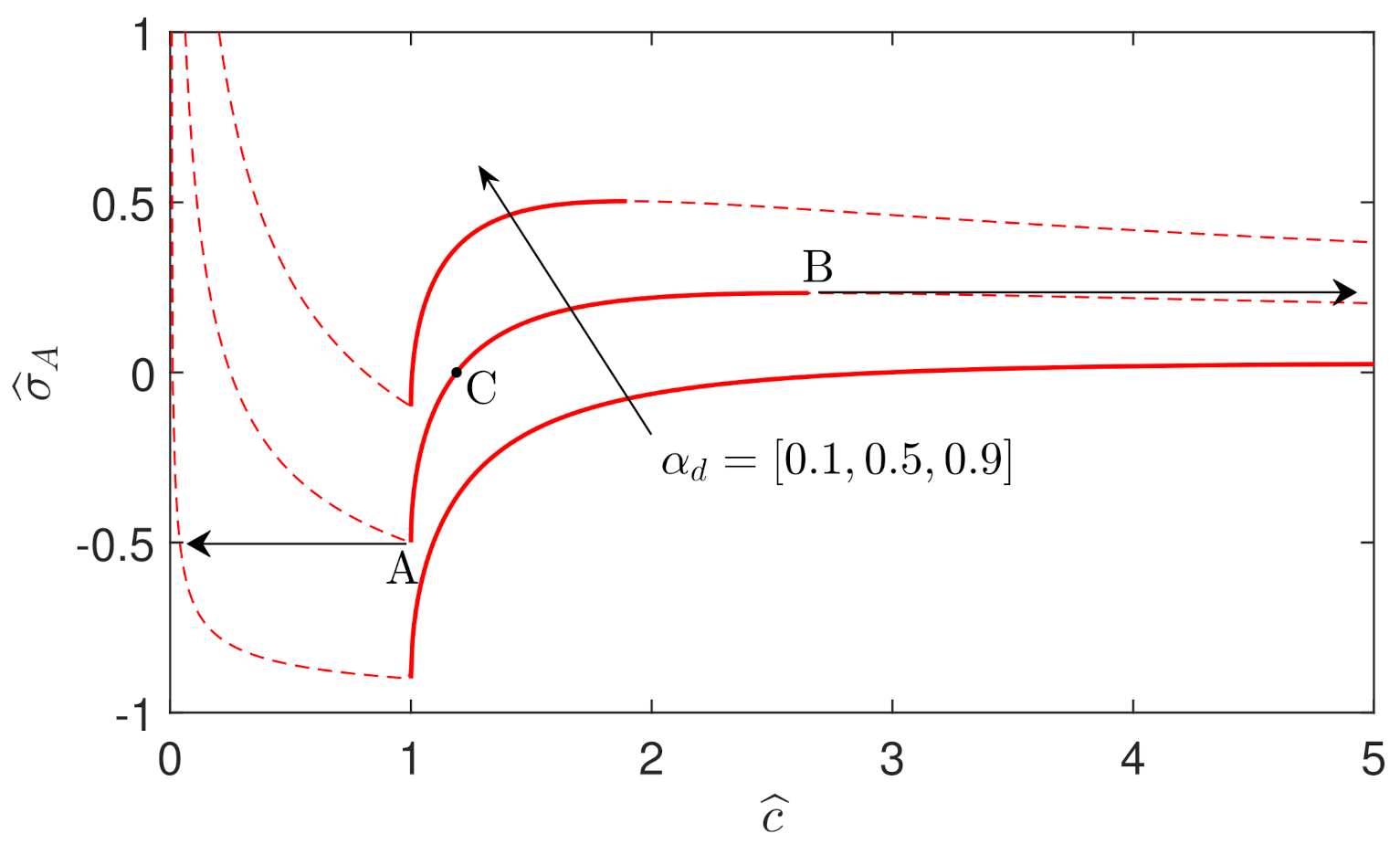

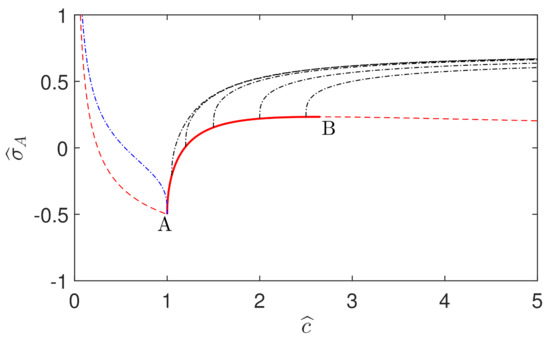

Notice that is analogous to the parameter that Johnson defined for the sinusoid [28] as it is proportional to the ratio between the adiabatic work of adhesion and the strain elastic energy to flatten the dimple. Figure 2 shows the equilibrium solutions for where we used a solid (dashed) line to identify the stable (unstable) branches of the curve. For the curve , we have labelled some noteworthy points. The system is in equilibrium under vanishing remote stress at the point “C”, which corresponds also to a certain radius (not null) of the crack . If a tensile stress is applied, the crack radius increases and detachment takes place at point “B” in partial contact (Reference [21] reports at pull-off), which will be referred to as the “weak” adhered state. If, from the equilibrium position “C”, a compressive pressure is applied below , the dimple jumps from point “A” to a full contact state (the branch below is unstable); hence, the crack shrinks, and theoretically an infinite tensile pressure will be needed to separate the two bodies. In practice, there may be flaws, contaminants, air trapping or simply the two surfaces will be detached when the theoretical strength is reached (see [21] for a detailed analysis).

Figure 2.

Remote stress versus the crack radius in the McMeeking et al. [17] elastic model for For the curve point “C” determines the equilibrium position , point “B” the “weak” adhesive state, while point A is the point where the jump to full contact happens.

2.2. Effect of a Rate-Dependent Work of Adhesion

We have introduced above the McMeeking et al. [17] LEFM elastic model for the detachment a dimpled half-space from a flat substrate. Nevertheless, soft matter has viscoelastic behavior; hence, we here extend the McMeeking et al. [17] model to account for a rate-dependent work of adhesion. According to Equation (1), the effective work of adhesion is a power-law function of the peeling velocity (t is the time), i.e., the velocity at the crack tip, which can be written as

where [Pa/s] is the externally imposed unloading rate and the “+” (“−”) sign holds when the crack advances or retracts (). Hence, using (1), (6) and (9) and imposing the Griffith equilibrium concept, one obtains

which in dimensionless notation reads

where the dimensionless unloading rate has been introduced. The ordinary differential equations in (11) are of first order and can be easily solved numerically using as a starting point a solution of the elastic problem in Equation (7). Clearly, physically admissible starting points are those on the stable branch AB in Figure 2; hence, as we shall see later, a rate-dependent work of adhesion will not affect the “strong” adhesive state, but only the “weak” one. In the next section we shall investigate the effects of the various parameters on the detachment stress in partial contact (“weak” state).

3. Results

3.1. Detachment Curves

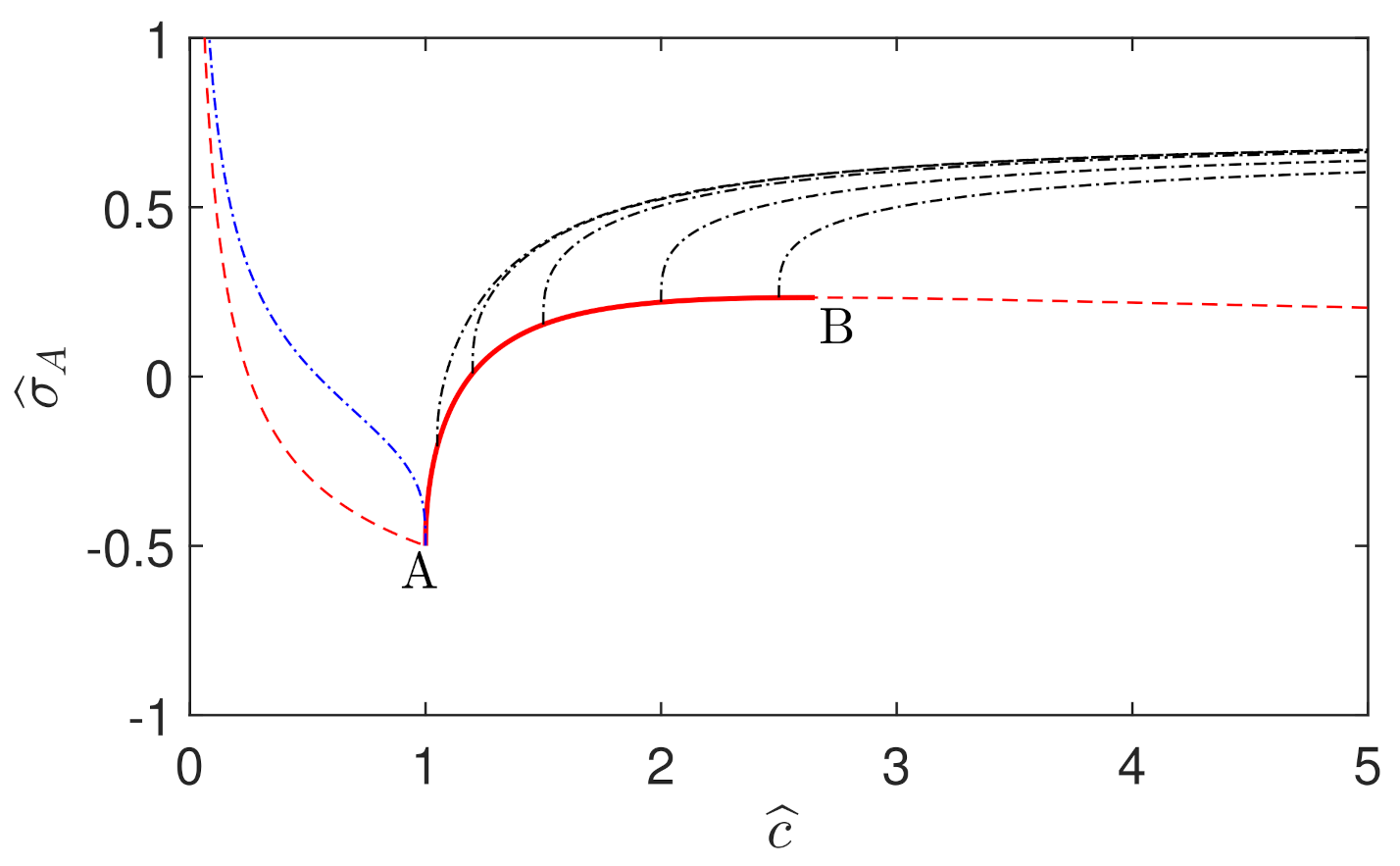

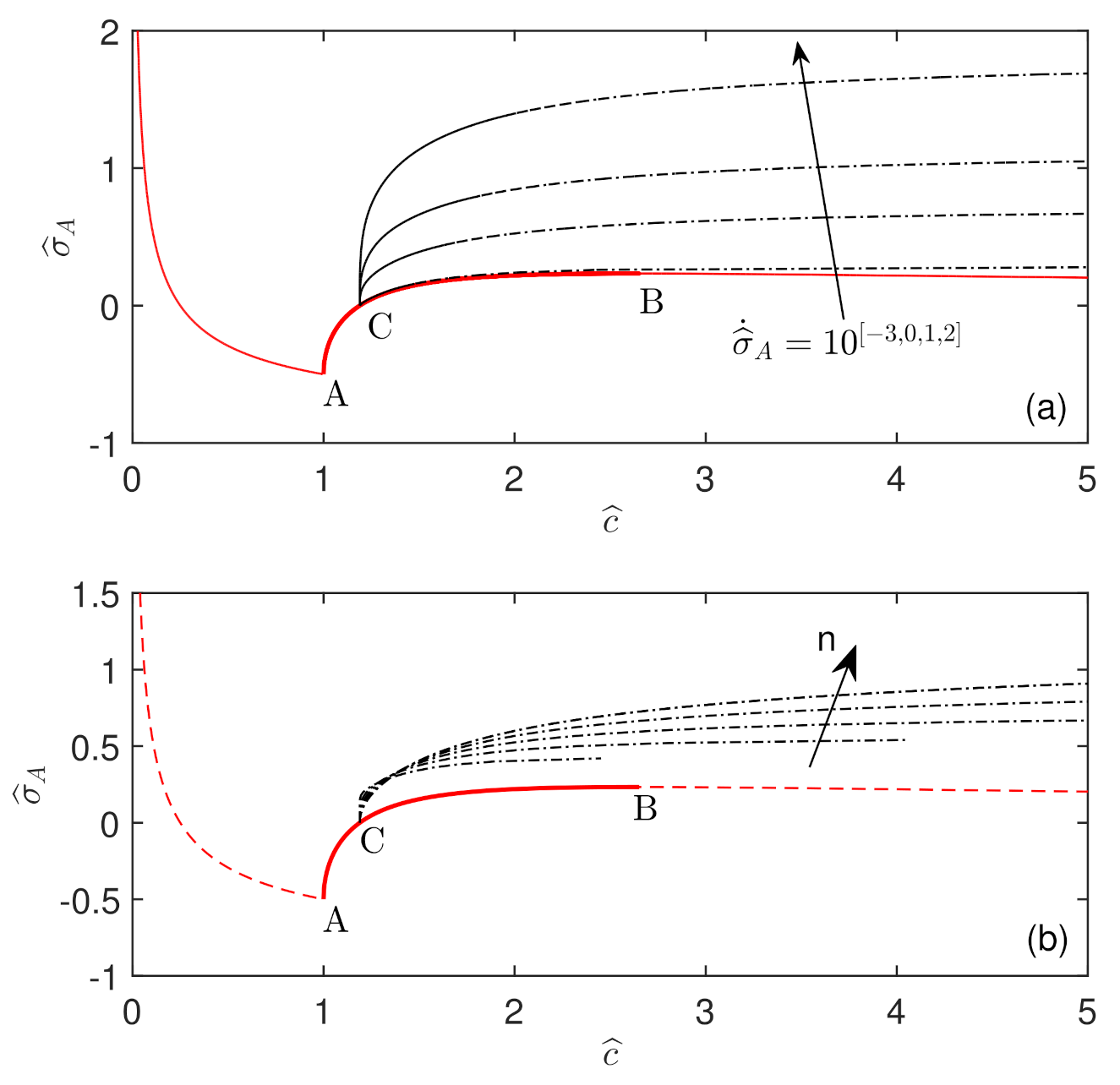

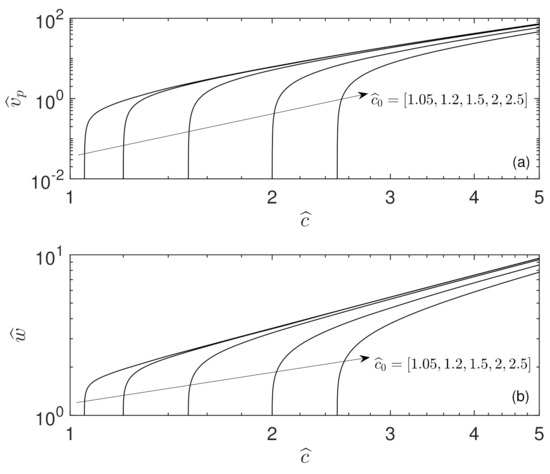

Let us investigate first the effect that a rate-dependent work of adhesion has on the detachment curve of the dimple by solving Equation (11). Figure 3 shows the unloading curves for the rate-dependent model (Equation (11), black dot-dashed curves) starting from different initial conditions on the branch AB (Figure 2) for , and . The red curve (solid for the stable, dashed for the unstable branches) shows the Griffith elastic reference solution [17]. Clearly, the rate-dependence of the work of adhesion has a toughening effect (dot-dashed black curves). Figure 4a shows the dimensionless peeling velocity as it changes during the detachment process, while panel (b) shows the corresponding dimensionless work of adhesion , while the crack propagates. The peeling process starts with a vanishing velocity; i.e., instantaneously, the remote stress increases without change of the crack radius , and this can be easily checked if one substitutes a solution of the Griffith elastic model (Equation (7)) into the rate-dependent model (Equation (11)). By further unloading the dimple surface , the peeling velocity increases with a power law behavior, and so does the interfacial toughness. Notice that the slope of the curve is inversely proportional to the peeling velocity; hence, the latter decays with a power law. We define the pull-off detachment stress as . Furthermore, Figure 3 shows the crack retraction curve, when the dimple is forced into the unstable regime ( blue dot-dashed curve). Apart from a different transient behavior, similarly to the elastic solution, the rate-dependent solution will jump into a full contact strong adhesive state. Figure 3 shows that the effect of the initial preload on the detachment stress is marginal, particularly in light of the dependencies on the parameters that we will show in the following. From now on, we will consider as initial condition only the more “likely” situation of unloading the dimple from its equilibrium position , which belongs to the stable branch AB for (otherwise for , the dimple naturally jumps into the full-contact strong adhesive state).

Figure 3.

Unloading curves of the dimpled surface starting from different initial conditions for , and Red lines for the Griffith elastic solution, dot-dashed black lines for the rate-dependent model unloading curves.

Figure 4.

(a) Dimensionless peeling velocity and (b) corresponding apparent work of adhesion for the unloading curves in Figure 3.

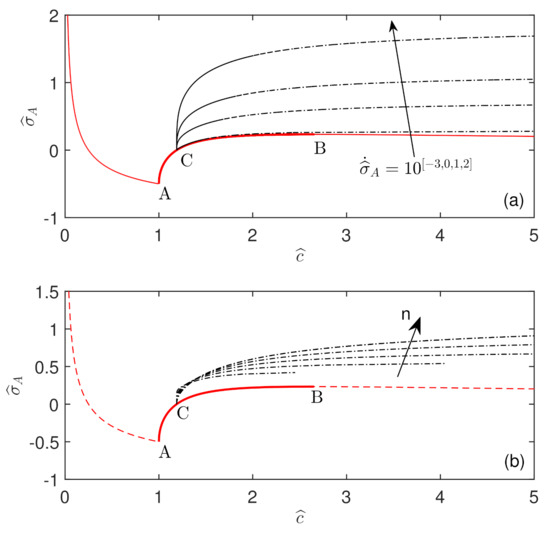

Let us look at the influence of the exponent n and of the unloading rate on the dimple detachment curves. Figure 5a shows that starting from the dimple equilibrium position “C” for , and , where black dot-dashed curves indicate the rate-dependent solutions, while the red curves show the reference elastic solution. Figure 5a shows that the unloading rate has a strong influence on the detachment stress and that the elastic solution is approached only for the very low unloading rate . Notice that, in this particular case, for the reference elastic solution, we have , while in the a rate-dependent case at , which gives a detachment stress increased by a factor . Finally panel (b) shows that for the same unloading rate , the pull-off stress increases with the exponent as for the increasing of the effective surface energy w (see Equation (1)).

Figure 5.

(a) Unloading curves of the dimpled surface starting from for , and Red lines for the Griffith elastic solution, dot-dashed black lines for the a rate-dependent unloading curves. (b) As panel (a) but for and .

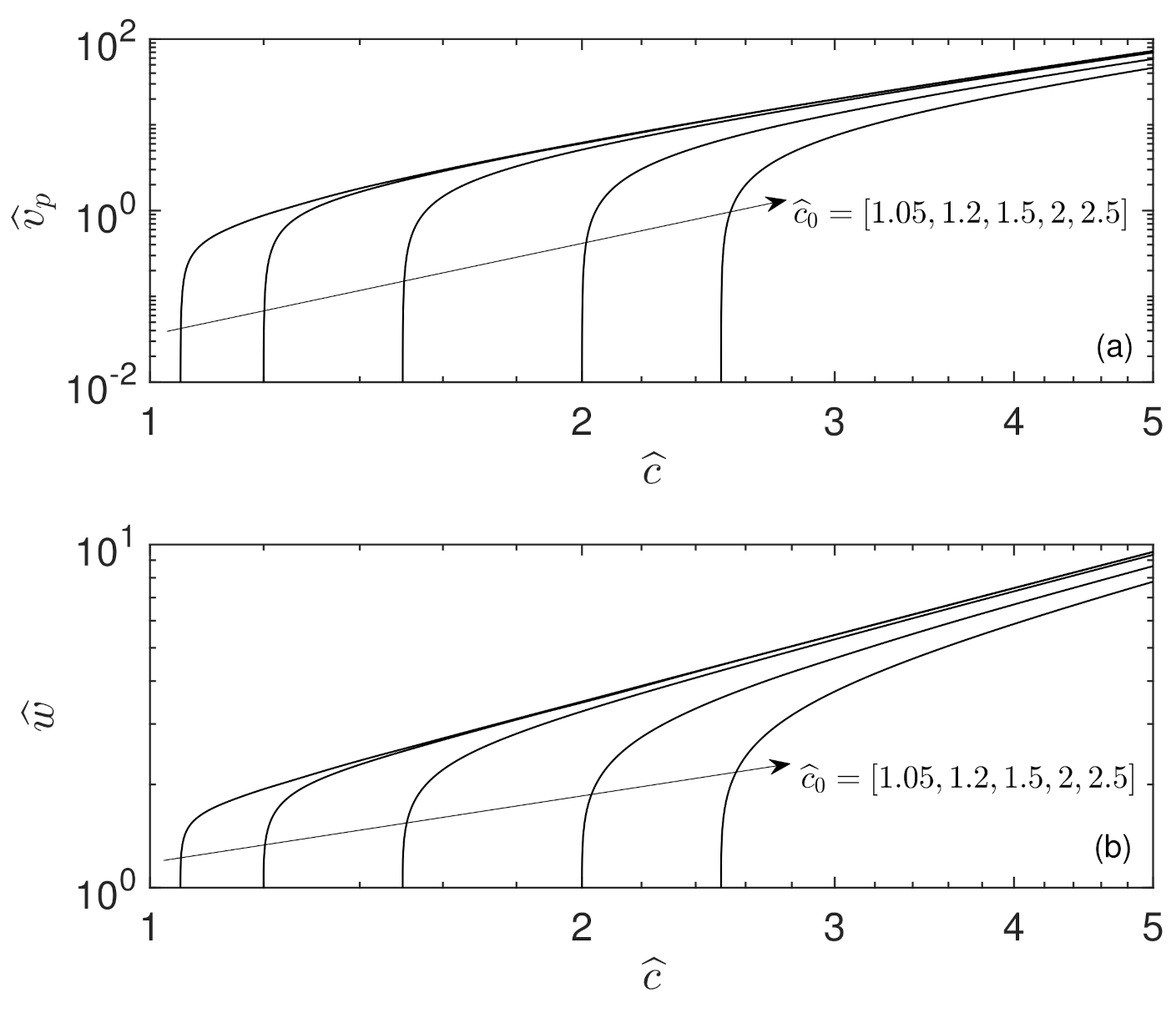

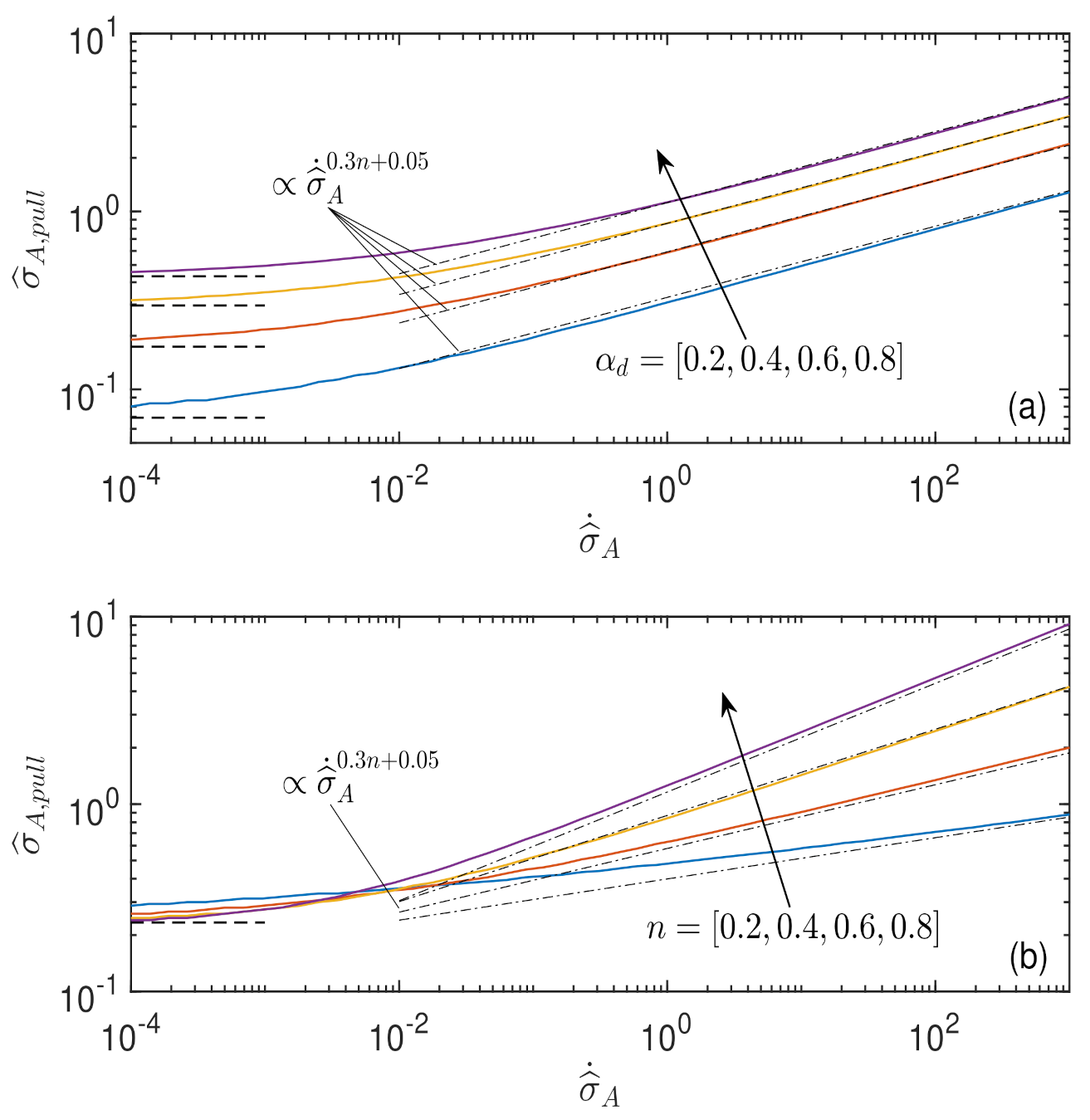

3.2. Pull-Off Detachment Stress

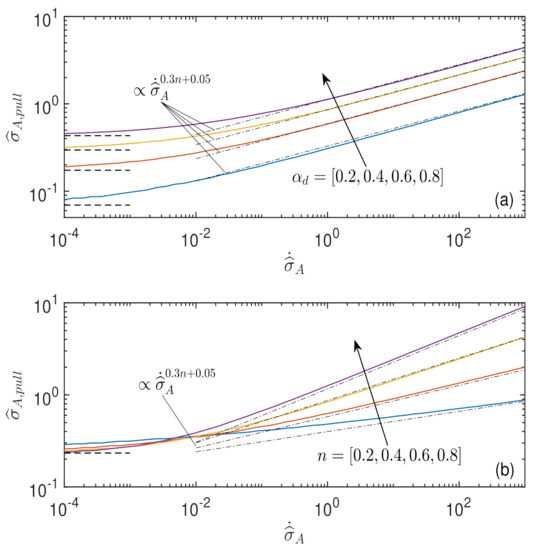

We have investigated the effect of the unloading rate and of the exponent n on the detachment curves of a dimple from an elastic substrate with rate-dependent work of adhesion. Here we give a closer look at the dependence of the pull-off stress on the unloading rate by varying and n. Figure 6a shows the pull-off stress as a function of the dimensionless unloading rate for and . Panel (a) shows that the the pull-off stress approaches the elastic value (obtained from Equation (7)) only at very low unloading rate , while it increases considerably when is increased, or by increasing . In the regime of high unloading rate, the pull-off stress dependence on is well captured by a power law behavior, while that on is linear. For and , a very good fit of the pull-off stress is given by the power law

whose predictions are given by dot-dashed black lines (almost indistinguishable from the solid curves obtained numerically). Panel (b) shows that for a fixed , the pull-off stress increases with the exponent n. At low , all the curves start from the same elastic solution (black dashed lines) as the pull-off stress depends only on and then increases for larger unloading rates with a power law behavior whose slope is very well fitted by a power law . (For , an estimate of the pull-off stress as a function of and n can be obtained by , where we found this to be more accurate close to and .) Notice that typically ; hence, the increase of the pull-off stress with the unloading rate is sublinear.

Figure 6.

(a) Pull-off detachment stress as a function of the dimensionless unloading rate for and . (b) Pull-off detachment stress as a function of the dimensionless unloading rate for For all the curves, the initial condition is . In both panels, the black dashed lines indicate the Griffith equilibrium solution from Equation (7). Black dot-dashed lines serve as a guide to the eye.

4. Conclusions

In this work, the detachment of a surface with an axisymmetric dimple from an elastic substrate with rate-dependent work of adhesion has been studied in the limit of short-range adhesion. Previous elastic model with constant work of adhesion has shown that the dimpled surface has two adhered states, one “strong” in full contact, one “weak” in partial contact. The rate dependence of the work of adhesion has been accounted for by adopting a power law dependence (with exponent n) of the effective work of adhesion on the pealing velocity as it is commonly observed in experiments [27]. Notice that, in this analysis, we have neglected bulk effects (we used the relaxed modulus of the viscoelastic material , with being the excitation frequency of the material); hence, the results presented should be representative for not too high peeling velocity. It has been shown that a rate-dependent work of adhesion does not affect the “strong” adhesive state, but it strongly influences the detachment pull-off stress in partial contact, resulting in a strong toughening of the interface. In this respect, we have shown that for a given unloading rate, after a transient, the peeling velocity increases with a power law behavior during the detachment process, and so does the effective work of adhesion. Furthermore, it has been shown that the pull-off stress (in partial contact) does not depend much on the particular initial condition chosen to unload the dimple. Instead, the pull-off stress depends on three dimensionless parameters; i.e., it increases by increasing the unloading rate, the exponent “n” or the dimensionless parameter . Clearly, for a real viscoelastic material, the interfacial toughening will not increase to infinity but will be limited by the ratio , which is known to vary anyway by orders of magnitude with the excitation frequency [26]. In this respect, for a real material, the curves in Figure 4 will be bounded. In conclusion, the presented results suggest that viscoelasticity may play a strong role in determining the apparent interfacial toughness in patterned interfaces. In particular, when soft rough substrates are considered, it may be very difficult to recognize other sources of toughening, such as those due to the increase of contact area due to roughness [30] or due the local jump instabilities as in the Guduru problem [31], unless an extremely low unloading rate is adopted as indeed recently attempted by Dalvi and coauthors [32].

Funding

A.P. acknowledges the support by the Italian Ministry of Education, University and Research under the Programme Department of Excellence Legge 232/2016 (Grant No. CUP-D94I 18000260001). A.P. is thankful to the DFG (German Research Foundation) for funding the project PA 3303/1-1. A.P. acknowledges support from “PON Ricerca e Innovazione 2014-2020-Azione I.2”–D.D. n. 407, 27/02/2018, bando AIM (Grant No. AIM1895471). AP acknowledges support for the Open Access fees by Hamburg University of Technology (TUHH) in the funding programme Open Access Publishing.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The author declares no conflict of interest.

References

- Hong, S.; Erdogan, G.; Hedrick, K.; Borrelli, F. Tyre–road friction coefficient estimation based on tyre sensors and lateral tyre deflection: Modelling, simulations and experiments. Veh. Syst. Dyn. 2013, 51, 627–647. [Google Scholar] [CrossRef]

- Yu, P.; Zhang, D.; Ma, Y.; Hong, J. Dynamic modeling and vibration characteristics analysis of the aero-engine dual-rotor system with Fan blade out. Mech. Syst. Signal Process. 2018, 106, 158–175. [Google Scholar] [CrossRef]

- Li, X.; Tao, D.; Lu, H.; Bai, P.; Liu, Z.; Ma, L.; Tian, Y. Recent developments in gecko-inspired dry adhesive surfaces from fabrication to application. Surf. Topogr. Metrol. Prop. 2019, 7, 023001. [Google Scholar] [CrossRef]

- Genovese, A.; Farroni, F.; Papangelo, A.; Ciavarella, M. A discussion on present theories of rubber friction, with particular reference to different possible choices of arbitrary roughness cutoff parameters. Lubricants 2019, 7, 85. [Google Scholar] [CrossRef]

- Ciavarella, M.; Joe, J.; Papangelo, A.; Barber, J.R. The role of adhesion in contact mechanics. J. R. Soc. 2019, 16, 20180738. [Google Scholar] [CrossRef] [PubMed]

- Kamperman, M.; Kroner, E.; del Campo, A.; McMeeking, R.M.; Arzt, E. Functional adhesive surfaces with “gecko” effect: The concept of contact splitting. Adv. Mater. 2010, 12, 335–348. [Google Scholar] [CrossRef]

- Huber, G.; Gorb, S.; Hosoda, N.; Spolenak, R.; Arzt, E. Influence of surface roughness on gecko adhesion. Acta Biomater 2007, 3, 607–610. [Google Scholar] [CrossRef]

- Pugno, N.M.; Lepore, E. Observation of optimal gecko’s adhesion on nanorough surfaces. Biosystems 2008, 94, 218–222. [Google Scholar] [CrossRef] [PubMed]

- Akerboom, S.; Appel, J.; Labonte, D.; Federle, W.; Sprakel, J.; Kamperman, M. Enhanced adhesion of bioinspired nanopatterned elastomers via colloidal surface assembly. J. R. Interface 2015, 12, 20141061. [Google Scholar] [CrossRef] [PubMed]

- Paretkar, D.; Kamperman, M.; Martina, D.; Zhao, J.; Creton, C.; Lindner, A.; Arzt, E. Preload-responsive adhesion: Effects of aspect ratio, tip shape and alignment. J. R. Soc. 2013, 10, 20130171. [Google Scholar] [CrossRef]

- Violano, G.; Afferrante, L.; Papangelo, A.; Ciavarella, M. On stickiness of multiscale randomly rough surfaces. J. Adhesion 2019, 1–19. [Google Scholar] [CrossRef]

- Ciavarella, M. Universal features in “stickiness” criteria for soft adhesion with rough surfaces. Tribol. Int. 2020, 146, 106031. [Google Scholar] [CrossRef]

- Tiwari, A.; Wang, J.; Persson, B.N.J. Adhesion paradox: Why adhesion is usually not observed for macroscopic solids. Phys. Rev. E 2020, 102, 042803. [Google Scholar] [CrossRef] [PubMed]

- Dahlquist, C.A. Treatise on Adhesion and Adhesives; Patrick, R.L., Ed.; Marcel Dekker: New York, NY, USA, 1969; p. 244. [Google Scholar]

- Zhou, Y.; Robinson, A.; Steiner, U.; Federle, W. Insect adhesion on rough surfaces: Analysis of adhesive contact of smooth and hairy pads on transparent microstructured substrates. J. R. Interface 2014, 11, 20140499. [Google Scholar] [CrossRef]

- Kern, M.D.; Qi, Y.; Long, R.; Rentschler, M.E. Characterizing adhesion between a micropatterned surface and a soft synthetic tissue. Langmuir 2017, 33, 854–864. [Google Scholar] [CrossRef]

- McMeeking, R.M.; Ma, L.; Arzt, E. Bi-Stable Adhesion of a Surface with a Dimple. Adv. Eng. Mater. 2010, 12, 389–397. [Google Scholar] [CrossRef]

- Johnson, K.L.; Kendall, K.; Roberts, A.D. Surface energy and the contact of elastic solids. Proc. R. Soc. Lond. A 1971, 324, 1558. [Google Scholar]

- Johnson, K.L. The adhesion of two elastic bodies with slightly wavy surfaces. Int. Solids Struct. 1995, 32, 423–430. [Google Scholar] [CrossRef]

- Cañas, N.; Kamperman, M.; Völker, B.; Kroner, E.; McMeeking, R.M.; Arzt, E. Effect of nano-and micro-roughness on adhesion of bioinspired micropatterned surfaces. Acta Biomater. 2012, 8, 282–288. [Google Scholar] [CrossRef]

- Papangelo, A.; Ciavarella, M. A Maugis–Dugdale cohesive solution for adhesion of a surface with a dimple. J. R. Soc. Interface 2017, 14, 20160996. [Google Scholar] [CrossRef]

- Tabor, D. Surface forces and surface interactions. J. Colloid Interface Sci. 1977, 58, 2. [Google Scholar] [CrossRef]

- Waters, J.F.; Guduru, P.R. Mode-mixity-dependent adhesive contact of a sphere on a plane surface. Proc. R. A Math. Phys. Eng. Sci. 2010, 466, 1303–1325. [Google Scholar] [CrossRef]

- Barquins, M.; Maugis, D.; Blouet, J.; Courtel, R. Contact area of a ball rolling on an adhesive viscoelastic material. Wear 1978, 51, 375–384. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Johnson, K.L. The mechanics of adhesion of viscoelastic solids. Philos. Mag. A 1981, 43, 697–711. [Google Scholar] [CrossRef]

- Persson, B.N.J.; Brener, E.A. Crack propagation in viscoelastic solids. Phys. Rev. E 2005, 71, 036123. [Google Scholar] [CrossRef] [PubMed]

- Gent, A.N.; Schultz, J. Effect of wetting liquids on the strength of adhesion of viscoelastic material. J. Adhes. 1972, 3, 281–294. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar]

- Maugis, D. Contact, Adhesion and Rupture of Elastic Solids (Volume 130); Springer: New York, NY, USA, 2000. [Google Scholar]

- Persson, B.N.J.; Tosatti, E. The effect of surface roughness on the adhesion of elastic solids. J. Chem. Phys. 2001, 115, 5597–5610. [Google Scholar] [CrossRef]

- Guduru, P.R. Detachment of a rigid solid from an elastic wavy surface: Theory. J. Mech. Phys. Solids 2007, 55, 473–488. [Google Scholar] [CrossRef]

- Dalvi, S.; Gujrati, A.; Khanal, S.R.; Pastewka, L.; Dhinojwala, A.; Jacobs, T.D. Linking energy loss in soft adhesion to surface roughness. Proc. Natl. Acad. Sci. USA 2019, 116, 25484–25490. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).