Probabilistic Linear Time-Dependent Stress Beam Analysis and Its Stress-Strength Reliability

Abstract

:Featured Application

Abstract

1. Introduction

2. Theoretical Background of the Equivalent Stress

2.1. Elastic Stress Analysis

2.2. Time-Dependent Stress Analysis Based on the Linear Viscoelastic Approach

2.3. Strength Analysis

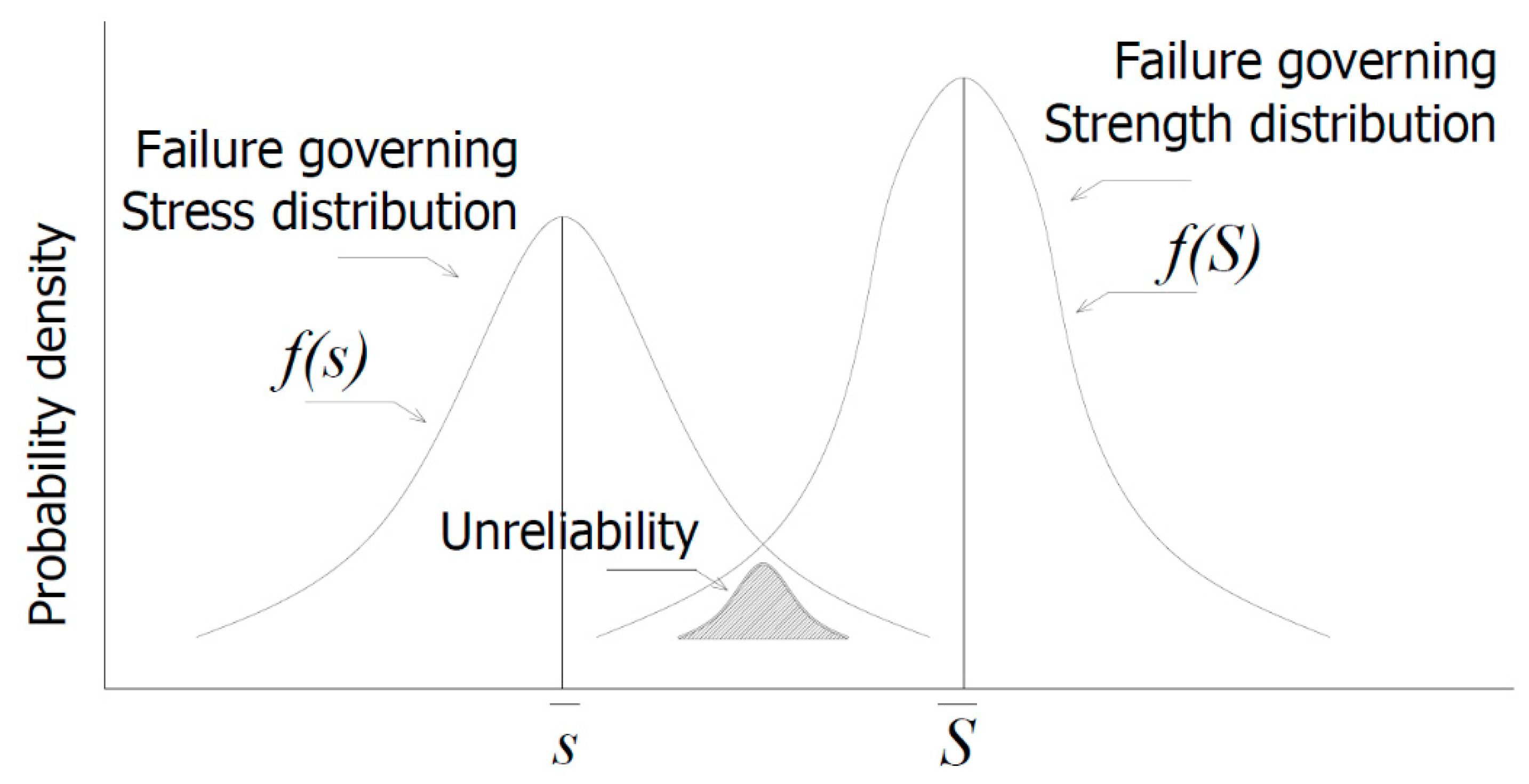

2.4. Stress-Strength Reliability Analysis

3. Proposed Stress-Strength Method

3.1. Steps to Determine the Stress Distribution

- Step 1.

- For the application case, determine its static properties, perform the corresponding static analysis, and after validating the principal’s critical variables select the corresponding structural element.

- Step 2.

- Based on the performed static analysis, by using the corresponding equation determine the maximum deflection of the bending beam.

- Step 3.

- By using the static analysis, estimate the corresponding normal stress values generated on the weakest area.

- Step 4.

- Determine the corresponding principal stress values (.

- Step 5.

- Define the time-dependent strain and its corresponding time-dependent stress .

- Step 6.

- Define the stress-strain analysis. Then, based on the defined stress-strain values, determine the true stress and the true strain values.

- Step 7.

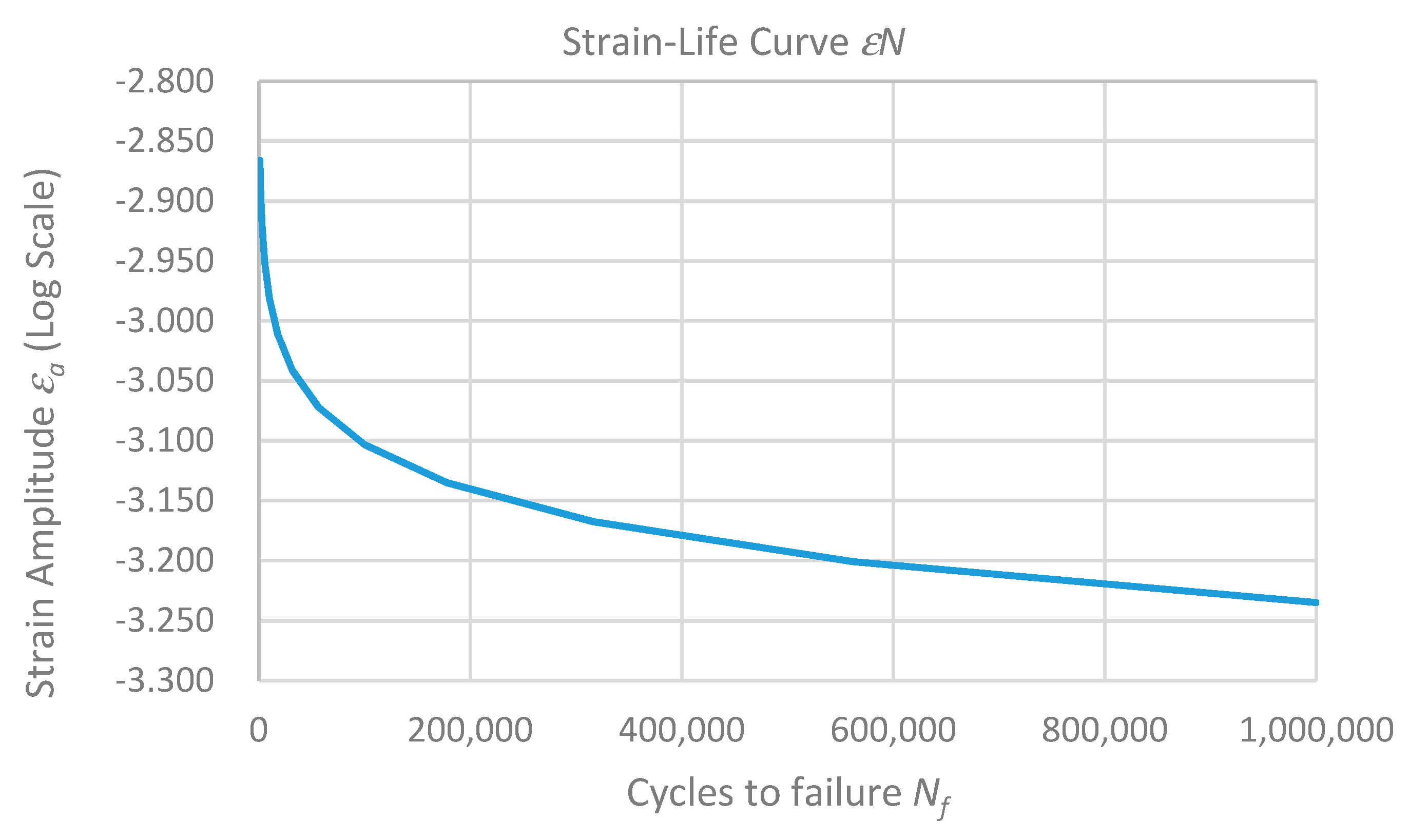

- Estimate the strain-life curve .

- Step 7.1.

- Step 7.2.

- Based on the determined stress amplitudes to cycles, determine the corresponding maximum and minimum strains ().

- Step 7.3.

- By using the estimated data given in step 7.2, determine the strain and its components elastic and plastic strain amplitudes (), and its corresponding constant value that defines the strain-life curve .

- Step 8.

- Compare the time-dependent strain determined in step 5 with the maximum strain which represents the desired strain at cycles to failure .

- Step 9.

- By using the estimated equivalent stress , determine its corresponding normal distribution parameters .

3.2. Stress-Strength Analysis

- Step 10.

- For the selected material, determine its principal strength values and determine its corresponding normal distribution parameters .

- Step 11.

- By using Equation (17), determine the Z value.

- Step 12.

- Take the probability that the Z value estimated in step 11 represents the reliability index of the analyzed element.

3.3. Numerical Application of the Proposed Method

3.3.1. Stress Distribution Based on the Time-Dependent Stress

- Step 1.

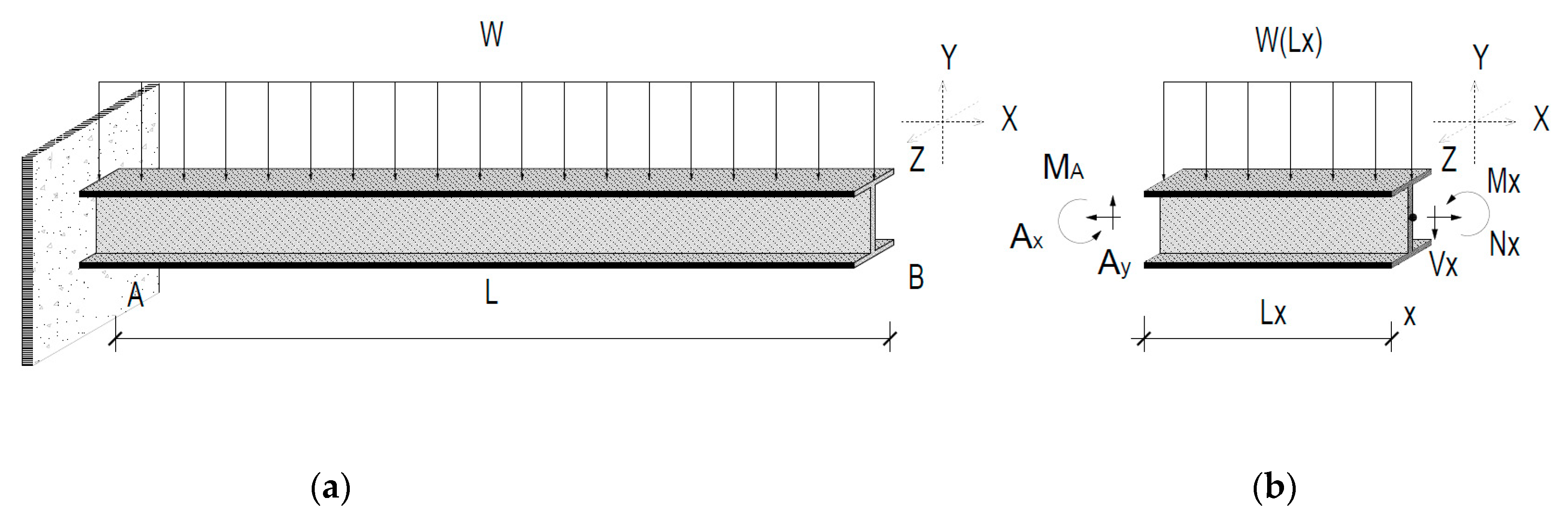

- In this case, the beam is supposed to be continuously braced, and for the analysis, the variables are the clear length 9.00 m, and the uniform load 49.25 kN/m. The selected beam is the W33X291, and in the analysis, its weight was added. Now, based on Figure 2, the reaction force at point A is 443.22 kN.

- Step 2.

- Based on the application case, the deflection of the bending beam is determined as

- Step 3.

- For the application case, the formulated analysis for the normal and shear stresses are

- Step 4.

- Based on data from step 3, from Equation (5), 86.60 MPa; from Equation (2), 105.84 MPa; from Equation (3), 67.37 MPa, and; from Equation (4), 19.23 MPa.

- Step 5.

- By incorporating the value of the maximum principal stress as in Equation (8), the effect of the elastic modulus through time is determined. Similarly, by using the time-dependent elastic modulus () values in Equation (13), the corresponding time-dependent stress value is determined. In Equation (8), the used viscoelastic parameter was 9.5 × 1010 GPa⋅s, which according with Sun et al. [16] corresponds to 20 . The corresponding analysis is given in the Table 2.

- Step 6.

- Step 7.

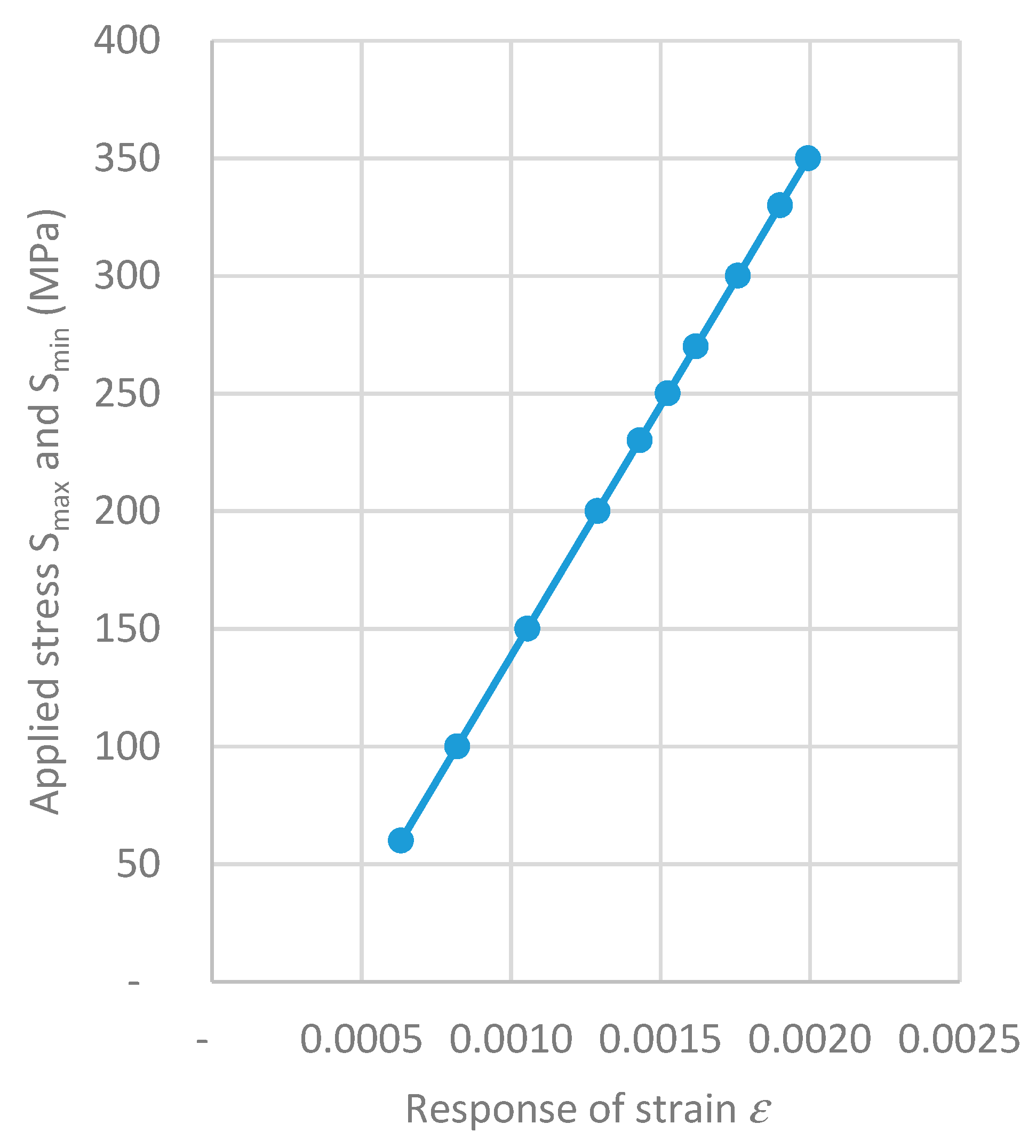

- Based on the true stress-true strain values given in Table 3, the strain-life curve analysis is as follows.

- Step 7.1.

- Based on the true stress-true strain values, the stress amplitude and the constant b value are determined as follows:

- Step 7.2.

- By using the values and by taking the minimum stress , the estimated values of the maximum and minimum strain () that define the hysteresis loops given in Figure 3 are:

- Step 7.3.

- By using both the plastic strain amplitude data and the defined cycles to failure values, the log-linear analysis constant c value is 0.3643. The generated strain-life curve is shown in Figure 4.

- Step 8.

- As the objective is to define the cycles to failure that correspond with the strain of 0.000864, then the determined value of the strain given in Table 2 of step 5 0.000864 was interpolated. To this interpolated value, the corresponding time-dependent stress, as shown in Table 2 is 74.28 MPa. Nevertheless, because the time-dependent stress represents the generated maximum principal stress at , then the equivalent supposed load that generates the determined deflection at this time can be estimated as

- Step 9.

- By using the equivalent stress 184.03 MPa value as a mean of the normal distribution and its estimated standard deviation 18.40 value, the normal stress distribution parameters are (184.03, 18.40).

3.3.2. Stress-Strength Analysis

- Step 10.

- By using the tensile strength = 119.89 MPa value as the mean of the normal distribution and its estimated standard deviation 11.98 value, the normal strength distribution parameters are (119.89, 11.98).

- Step 11.

- Based on the stress (184.03, 18.40) and the strength (119.89, 11.98) distributions parameters, from Equation (17), −0.0013.

- Step 12.

- From the Z value, the reliability of the stress-strength function for the W beam 33X291, is R(t) = 1%.

4. Conclusions

- (1)

- Because the generated internal stresses are always related to the bending beam, and since the proposed method uses these stress values to determine the stress distribution, then the reliability of any structural element can always be determined by applying the proposed method.

- (2)

- Because the applied stresses are independent of the material strength, then the proposed method can be used as a complement to the classic design methodology of structural elements based on the reliability index to discriminate among the possible addressed alternatives.

- (3)

- Because the proposed method can be performed for any desired cycles, from the element selection to the reliability determination, then it can be used as a guideline in any structural analysis. Although here the analysis was performed at 106 cycles (or at the value), it can be performed at any desired cycles.

- (4)

- Note that as in Table 5, when the value is lower than the expected equivalent stress , then both the plastic and fracture of cracked mechanical components analysis should be performed.

- (5)

- Note because the less used modified factors the higher the value, then for environments where fewer modifier factors are needed, the designed beam reliability index will be higher.

- (6)

- As the principal stress values on which the proposed method is based are the eigenvalues of a quadratic form represented by the stress matrix, the proposed method can be used to determine the reliability of an analyzed element in any field where the eigenvalues are known. As is the case for a principal components analysis and a quality analysis where they are performed using a second-order polynomial model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brinson, H.F.; Brinson, L.C. Polymer Engineering Science and Viscoelasticity: An Introduction; Springer: Boston, MA, USA, 2008. [Google Scholar]

- Dowling, N.E. Mechanical Behavior of Materials: Engineering Methods for Deformation, Fracture, and Fatigue; Pearson: Boston, MA, USA, 2013. [Google Scholar]

- Weibull, W. A Statistical Theory of Strength of Materials. In Generalstabens Lotografiska Anstalts Förlag; Centraltrycheriet: Stockholm, Sweden, 1939; pp. 5–10. [Google Scholar]

- Duffy, S.F.; Gyekenyesi, J.P. Time Dependent Reliability Model Incorporating Continuum Damage Mechanics for High-Temperature Ceramics. NTRS. 1989. Available online: https://ntrs.nasa.gov/citations/19890015116 (accessed on 9 April 2021).

- McCormac, J. Diseño de Estructuras de Acero; Alfaomega Grupo Editor S.A. de C.V.: Mexico City, Mexico, 2016. [Google Scholar]

- Design, A.S. Specification for Structural Steel Buildings; AISC: Chicago, IL, USA, December 1999; Volume 27. [Google Scholar]

- Zadeh, H.J.; Nanni, A. Reliability Analysis of Concrete Beams Internally Reinforced with Fiber-Reinforced Polymer Bars. Struct. J. 2013, 110, 1023–1032. [Google Scholar]

- Baji, H.; Ronagh, H.R. Reliability-Based Study on Ductility Measures of Reinforced Concrete Beams in ACI 318. Struct. J. 2016, 113, 373. [Google Scholar] [CrossRef]

- Xue, W.; Peng, F.; Xue, W. Reliability-Based Design Provisions for Flexural Strength of Fiber-Reinforced Polymer Prestressed Concrete Bridge Girders. Struct. J. 2020, 116, 04020086. [Google Scholar]

- Eryilmaz, S. On Stress-Strength Reliability with a Time-Dependent Strength. J. Qual. Reliab. Eng. 2013, 2013, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Piña-Monarrez, M.R. Weibull stress distribution for static mechanical stress and its stress/strength analysis. Qual. Reliab. Eng. Int. 2017, 34, 229–244. [Google Scholar] [CrossRef]

- Barraza-Contreras, J.M.; Piña-Monarrez, M.R.; Molina, A. Fatigue-Life Prediction of Mechanical Element by Using the Weibull Distribution. Appl. Sci. 2020, 10, 6384. [Google Scholar] [CrossRef]

- Alrubaie, M.A.A.; Gardner, D.J.; Lopez-Anido, R.A. Modeling the Long-Term Deformation of a Geodesic Spherical Frame Structure Made from Wood Plastic Composite Lumber. Appl. Sci. 2020, 10, 5017. [Google Scholar] [CrossRef]

- Asyraf, M.; Ishak, M.; Sapuan, S.; Yidris, N. Influence of Additional Bracing Arms as Reinforcement Members in Wooden Timber Cross-Arms on Their Long-Term Creep Responses and Properties. Appl. Sci. 2021, 11, 2061. [Google Scholar] [CrossRef]

- Wang, B.; Huang, W.; Zheng, S. Study on Restoring Force Performance of Corrosion Damage Steel Frame Beams under Acid Atmosphere. Appl. Sci. 2018, 9, 103. [Google Scholar] [CrossRef] [Green Version]

- Sun, Y.; Maciejewski, K.; Ghonem, H. Simulation of Viscoplastic Deformation of Low Carbon Steel Structures at Elevated Temperatures. J. Mater. Eng. Perform. 2011, 21, 1151–1159. [Google Scholar] [CrossRef] [Green Version]

- Gere, J.M.; Timoshenko, S. Mechanics of Materials; Brooks/Cole: Pacific Grove, CA, USA, 2001; pp. 815–839. [Google Scholar]

- Timoshenko, S. Resistencia de Materiales, Segunda Parte; Espasa-Calpe Sa: Madrid, Spain, 1957. [Google Scholar]

- Ugural, A.C.; Fenster, S.K. Advanced Mechanics of Materials and Applied Elasticity, 5th ed; Prentice Hall: Englewood Cliffs, NJ, USA, 2011. [Google Scholar]

- Arasaratnam, P.; Sivakumaran, K.S.; Tait, M.J. True Stress-True Strain Models for Structural Steel Elements. ISRN Civ. Eng. 2011, 656401. [Google Scholar] [CrossRef] [Green Version]

- Budynas, R.G.; Nisbett, J.K. Shigley’s Mechanical Engineering Design; McGraw-Hill: New York, NY, USA, 2008; Volume 8. [Google Scholar]

- Lee, Y.-L.; Pan, J.; Hathaway, R.; Barkey, M. Fatigue Testing and Analysis: Theory and Practice; Elsevier Butterworth-Heinemann: Burlington, MA, USA, 2005; Volume 13. [Google Scholar]

- Kececioglu, D. Robust Engineering Design-by-Reliability with Emphasis on Mechanical Components & Structural Reliability; DEStech Publications, Inc.: Pennsylvania, PA, USA, 2003. [Google Scholar]

- Baro, M.; Monarrez, M.R.P.; Villa, B. Stress-Strength Weibull Analysis with Different Shape Parameter β and Probabilistic Safety Factor. Dyna 2020, 87, 28–33. [Google Scholar] [CrossRef]

- Zhang, J.; Li, W.; Dai, H.; Liu, N.; Lin, J. Study on the Elastic–Plastic Correlation of Low-Cycle Fatigue for Variable Asymmetric Loadings. Materials 2020, 13, 2451. [Google Scholar] [CrossRef] [PubMed]

- Molina, A.; Piña-Monarrez, M.R.; de la Cruz-Cháidez, S.T. Análisis metodológico del esfuerzo normal σyy basado en deflexión elástica. Rev. Ciencias Tecnológicas 2019, 2, 166–180. [Google Scholar] [CrossRef]

| Limits of Its Mechanical Properties. | (Psi/ MPa) |

|---|---|

| Yield tensile strength | 61,391 (427) |

| Ultimate tensile strength | 83,831 (578) |

| Time f(t) | Time t = i (s) | E (t = i) Equation (8) | δmax Equation (14) | ε(t=i) Equation (7) | σ1(i) Equation (13) | σeq-i Step 8 |

|---|---|---|---|---|---|---|

| 0.00 | 0 | 213.00 | 0.0227465 | 0.0004969 | 105.84 | |

| 30 days | 2,592,000 | 211.77 | 0.0228782 | 0.0004998 | 105.24 | |

| 0.5 year | 15,768,000 | 205.75 | 0.0235472 | 0.0005144 | 102.36 | |

| 1 year | 31,536,000 | 198.99 | 0.0243478 | 0.0005319 | 99.31 | |

| 5 years | 157,680,000 | 157.54 | 0.0307527 | 0.0006718 | 83.98 | |

| 10 years | 315,360,000 | 125.00 | 0.0387589 | 0.0008467 | 74.90 | |

| 10.50 years | 330,976,627 | 122.49 | 0.0395518 | 0.0008640 | 74.28 | 184.03 |

| 25 years | 788,400,000 | 77.17 | 0.0627775 | 0.0013714 | 64.63 | |

| 50 years | 1,576,800,000 | 47.12 | 0.1028084 | 0.0022459 | 59.50 |

| Tested Stress | Tested Strain | True Strain | True Stress | ||

|---|---|---|---|---|---|

| 398.0000 | 0.002002 | 0.002000 | 398.0000 | ||

| 427.0000 | 0.004008 | 0.004000 | 427.0000 | ||

| 578.0000 | 0.163113 | 0.151100 | 681.0000 | ||

| 488.0000 | 0.220200 | 0.199015 | 709.5745 |

| 1 | 665.2646 | |||||

| 1000 | 349.8785 | 0.001993 | 0.000632 | 0.001361 | 0.000810 | 0.000551 |

| 10,000 | 282.4174 | 0.001351 | 0.000307 | 0.001044 | 0.000654 | 0.000390 |

| 100,000 | 227.9637 | 0.001072 | 0.000284 | 0.000789 | 0.000528 | 0.000261 |

| 1,000,000 | 184.0094 | 0.000864 | 0.000282 | 0.000582 | 0.000426 | 0.000156 |

| 10,000,000 | 148.5300 | 0.000700 | 0.000282 | 0.000416 | 0.000344 | 0.000072 |

| 100,000,000 | 119.8915 | 0.000560 | 0.000282 | 0.000281 | 0.000278 | 0.000004 |

| Summary of W Beams Data | W Beam Selection | W Beam Selection | W Beam Selection |

|---|---|---|---|

| DATA | 30X357 | 33X291 | 33X318 |

| Step 1. Supported reaction Ay (kN) | 451.89 | 443.22 | 446.77 |

| Step 1. Maximum bending moment (kN⋅m) | 2033.51 | 1994.50 | 2010.45 |

| Step 2 (in) | 0.8192 | 0.8955 | 0.8030 |

| Step 3 (MPa) | 91.17 | 105.74 | 95.91 |

| Step 3 (MPa) | 64.84 | 67.47 | 68.79 |

| Step 3 (MPa) | 1.98 | 1.94 | 1.95 |

| Step 4 (MPa) | 78.00 | 86.61 | 82.35 |

| Step 4 (MPa) | 13.16 | 19.14 | 13.56 |

| Step 4 (MPa) | 91.31 | 105.84 | 96.05 |

| Step 4. Principal stress (MPa) | 64.69 | 67.37 | 68.65 |

| Step 4 (MPa) | 13.31 | 19.23 | 13.70 |

| Step 5. (GPa) | 107.44 | 122.49 | 111.98 |

| Step 5. | 0.000849 | 0.000864 | 0.0008577 |

| Step 5 (m) | 0.04112 | 0.03955 | 0.03879 |

| Step 5. Defined time analysis i (years) | 13.95 | 10.50 | 10.50 |

| Step 6. Fatigue strength limit (MPa) | 117.30 | 119.89 | 118.74 |

| Step 5. Equivalent stress (MPa) | 181.01 | 184.03 | 182.69 |

| Step 10. Stress-strength reliability | 0.15% | 0.17% | 0.16% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Molina, A.; Piña-Monarrez, M.R.; Barraza-Contreras, J.M.; de la Cruz-Cháidez, S.T. Probabilistic Linear Time-Dependent Stress Beam Analysis and Its Stress-Strength Reliability. Appl. Sci. 2021, 11, 3459. https://doi.org/10.3390/app11083459

Molina A, Piña-Monarrez MR, Barraza-Contreras JM, de la Cruz-Cháidez ST. Probabilistic Linear Time-Dependent Stress Beam Analysis and Its Stress-Strength Reliability. Applied Sciences. 2021; 11(8):3459. https://doi.org/10.3390/app11083459

Chicago/Turabian StyleMolina, Alejandro, Manuel R. Piña-Monarrez, Jesús M. Barraza-Contreras, and Servio T. de la Cruz-Cháidez. 2021. "Probabilistic Linear Time-Dependent Stress Beam Analysis and Its Stress-Strength Reliability" Applied Sciences 11, no. 8: 3459. https://doi.org/10.3390/app11083459

APA StyleMolina, A., Piña-Monarrez, M. R., Barraza-Contreras, J. M., & de la Cruz-Cháidez, S. T. (2021). Probabilistic Linear Time-Dependent Stress Beam Analysis and Its Stress-Strength Reliability. Applied Sciences, 11(8), 3459. https://doi.org/10.3390/app11083459