Evaluation of Structural Performance of Post-Installed Anchors Embedded in Cracked Concrete in Power Plant Facilities

Abstract

1. Introduction

1.1. Background

1.2. Fixation Unit Anchor System

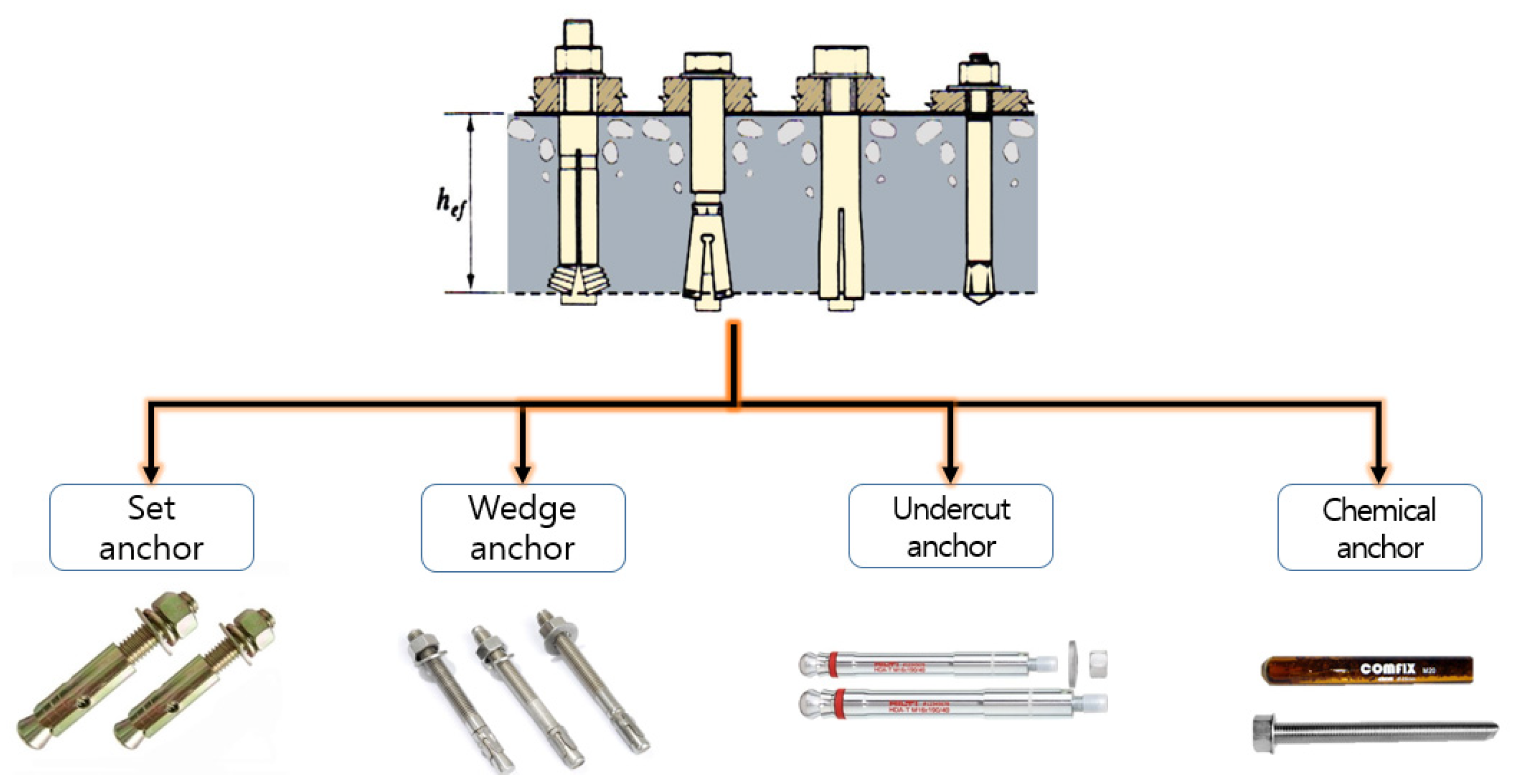

1.2.1. Types of Post-Installed Anchor Bolts

1.2.2. Design Standards and Failure Modes for Concrete-Embedded Anchor Bolts

2. Overseas Seismic Performance Evaluation Criteria

3. Experiment Overview

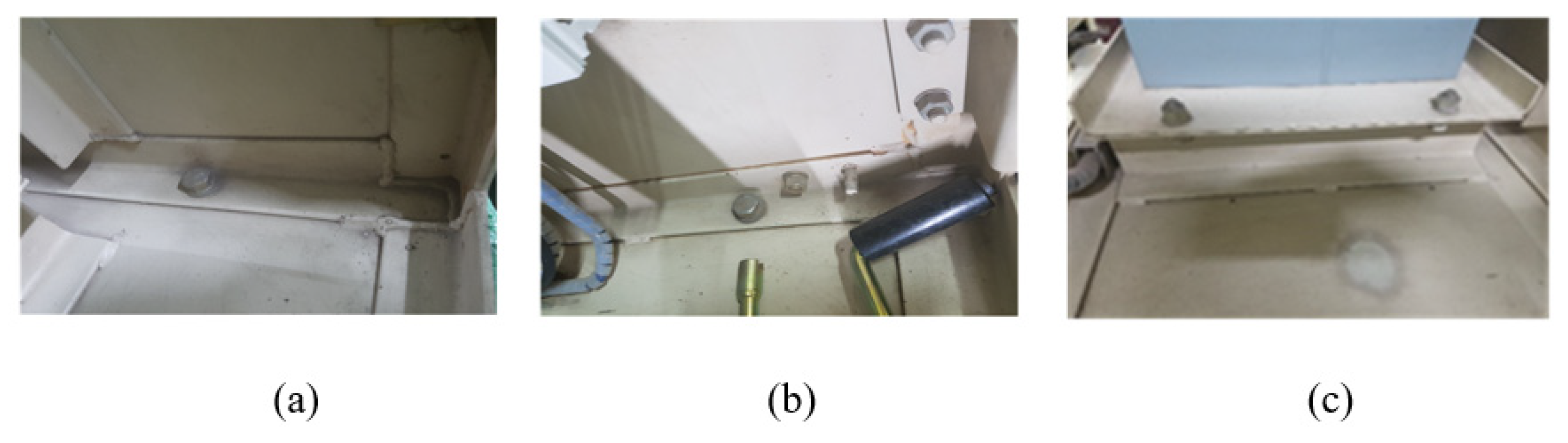

3.1. Selection of Test Targets through a Field Survey

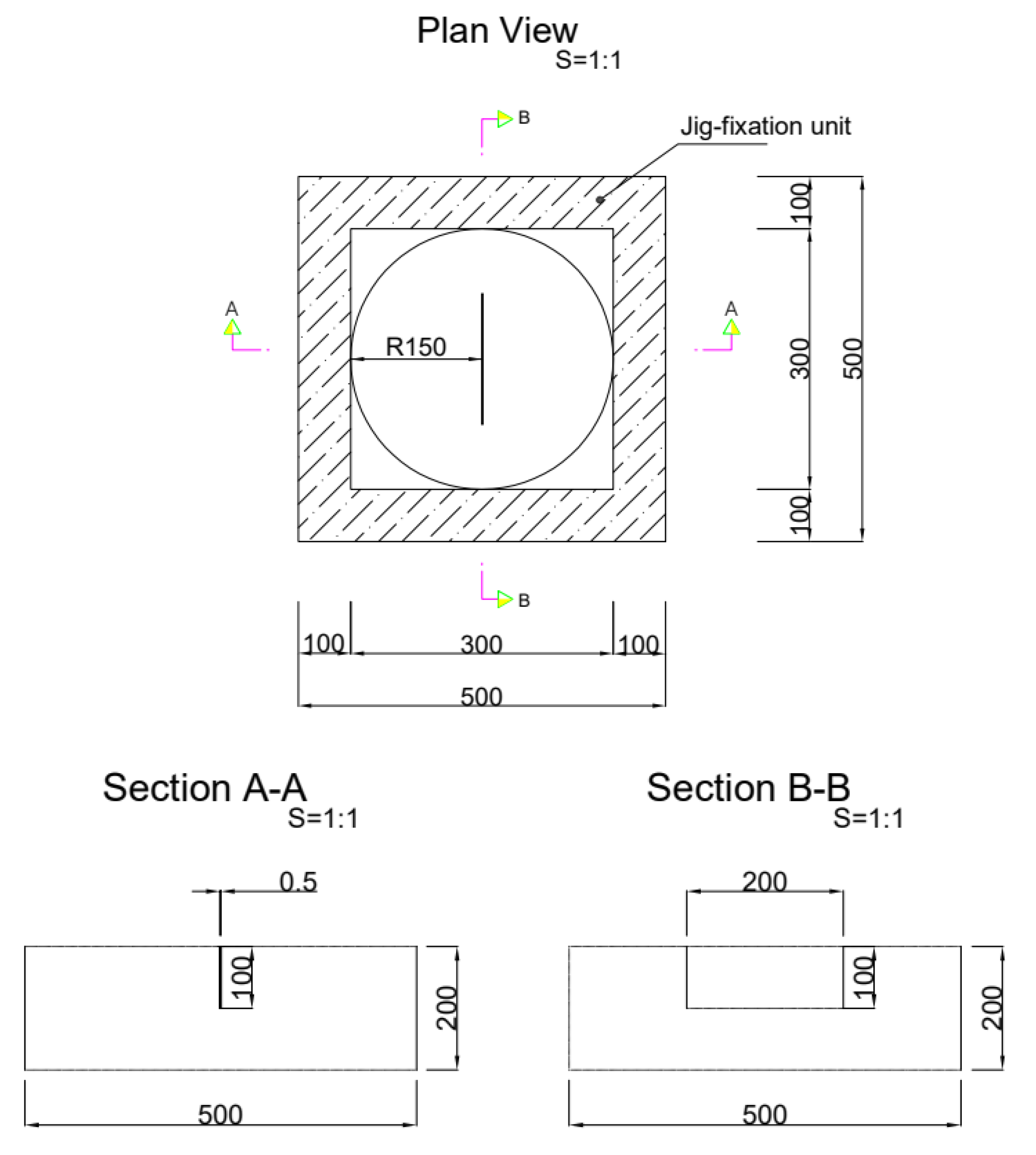

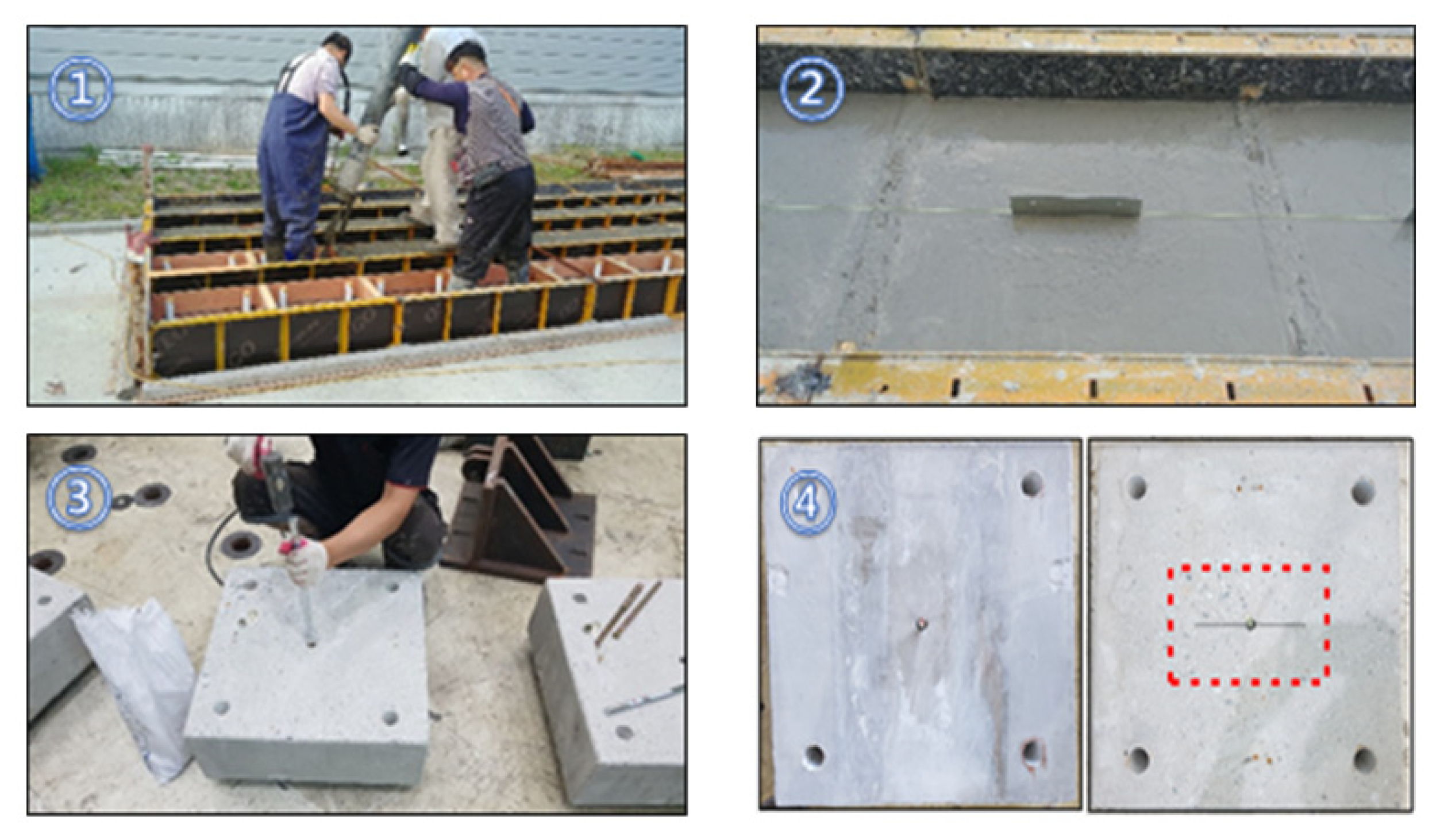

3.2. Specimen Design and Fabrication

3.2.1. Non-Cracked Concrete

3.2.2. Cracked Concrete

4. Performance Evaluation of Post-Installed Anchors

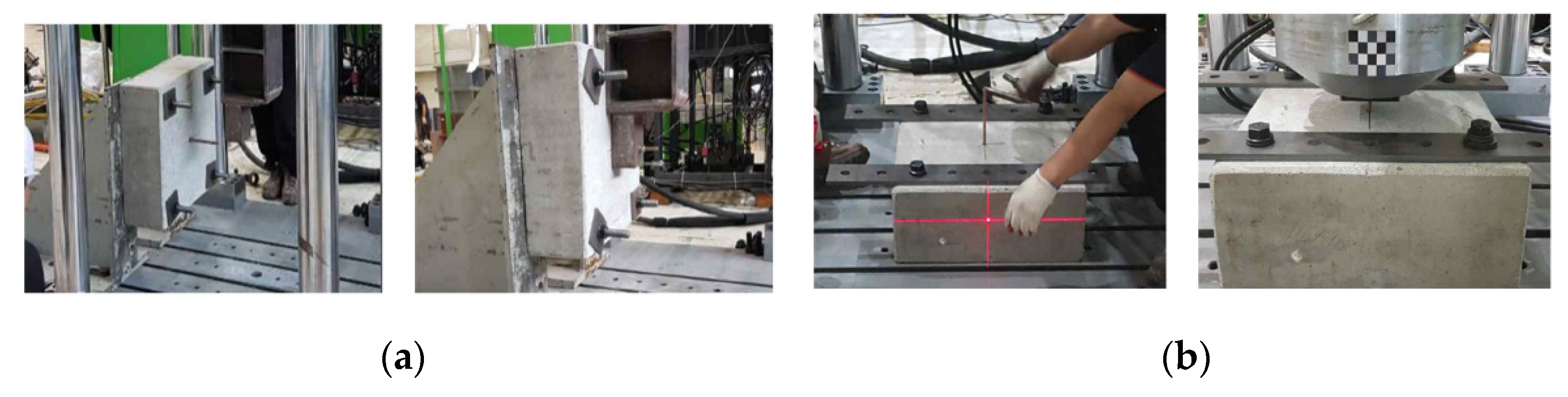

4.1. Static Loading Test

4.1.1. Experimental Method

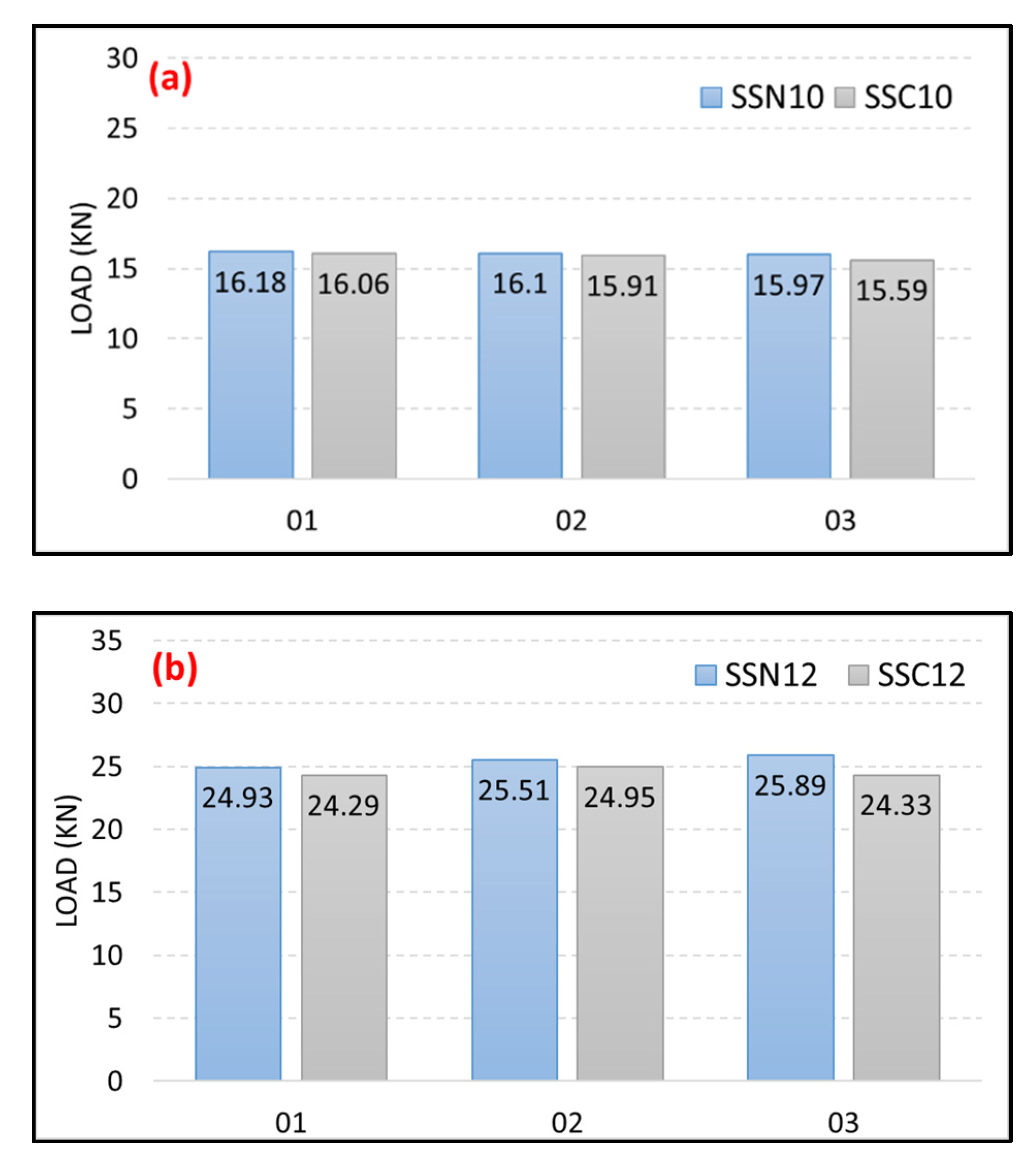

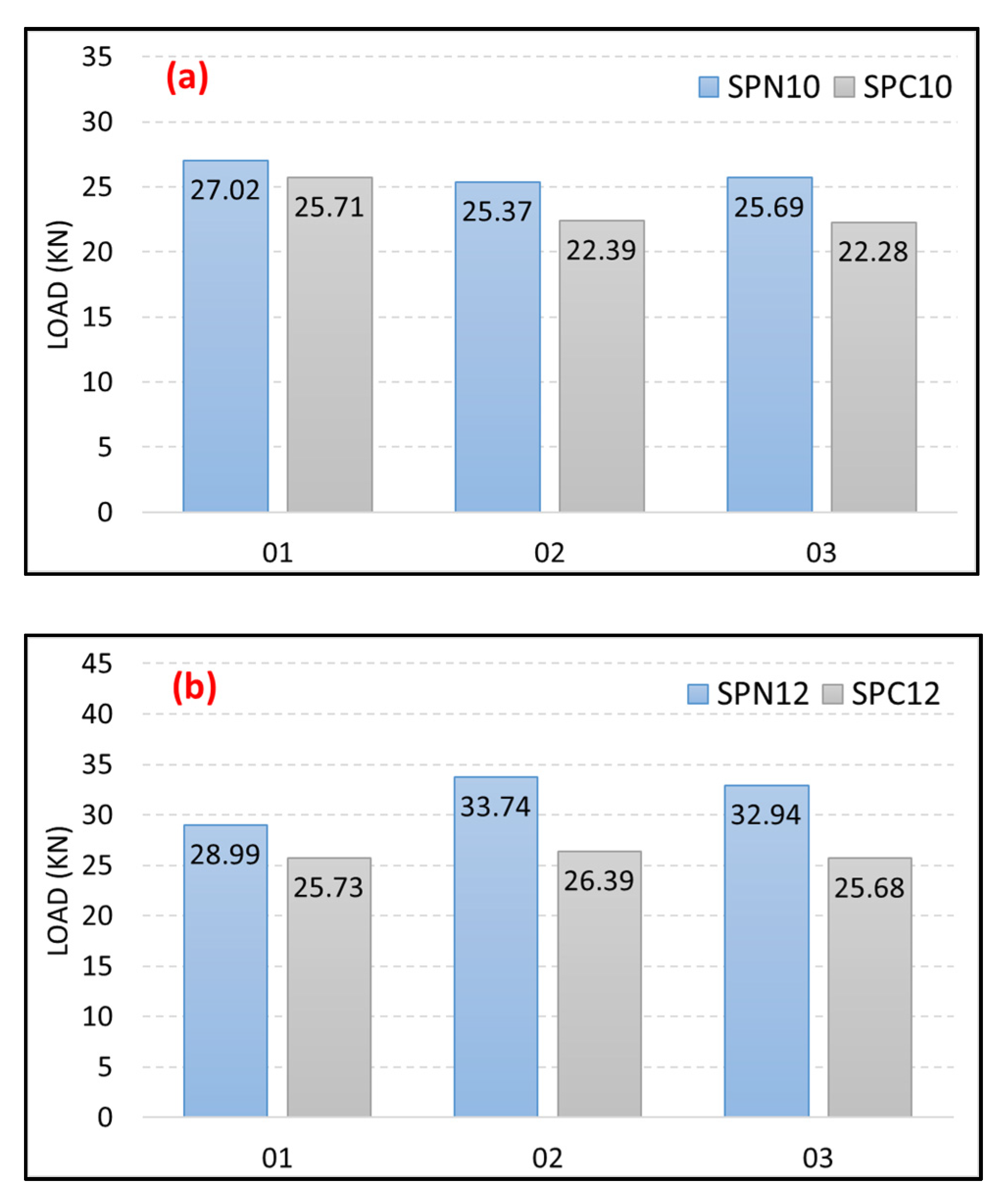

4.1.2. Shear Performance Evaluation

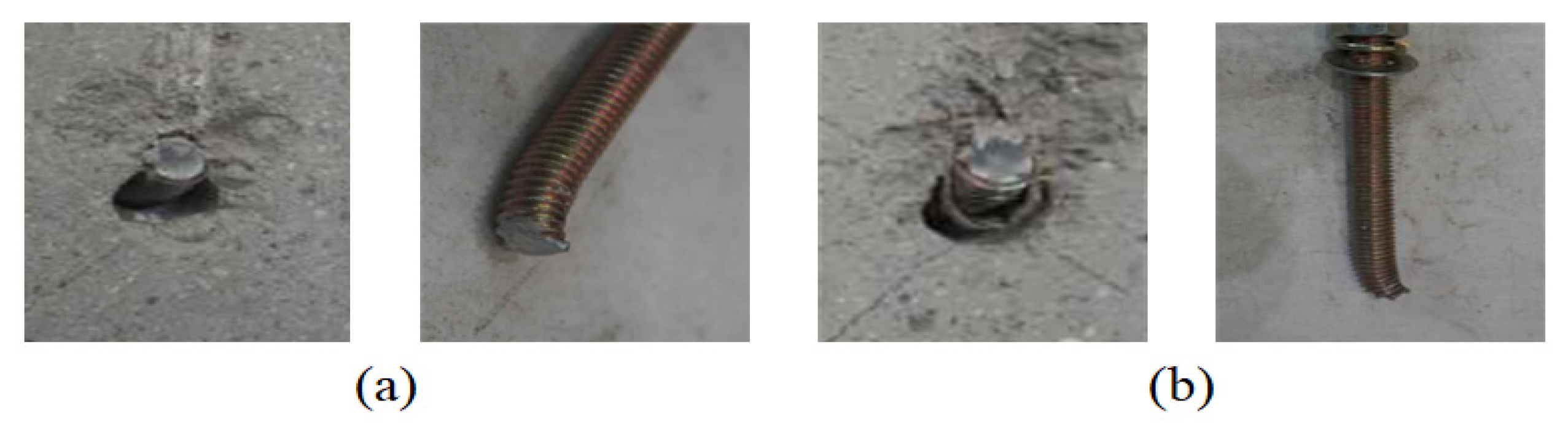

4.1.3. Pull-Out Performance Evaluation

4.2. Dynamic Loading Test

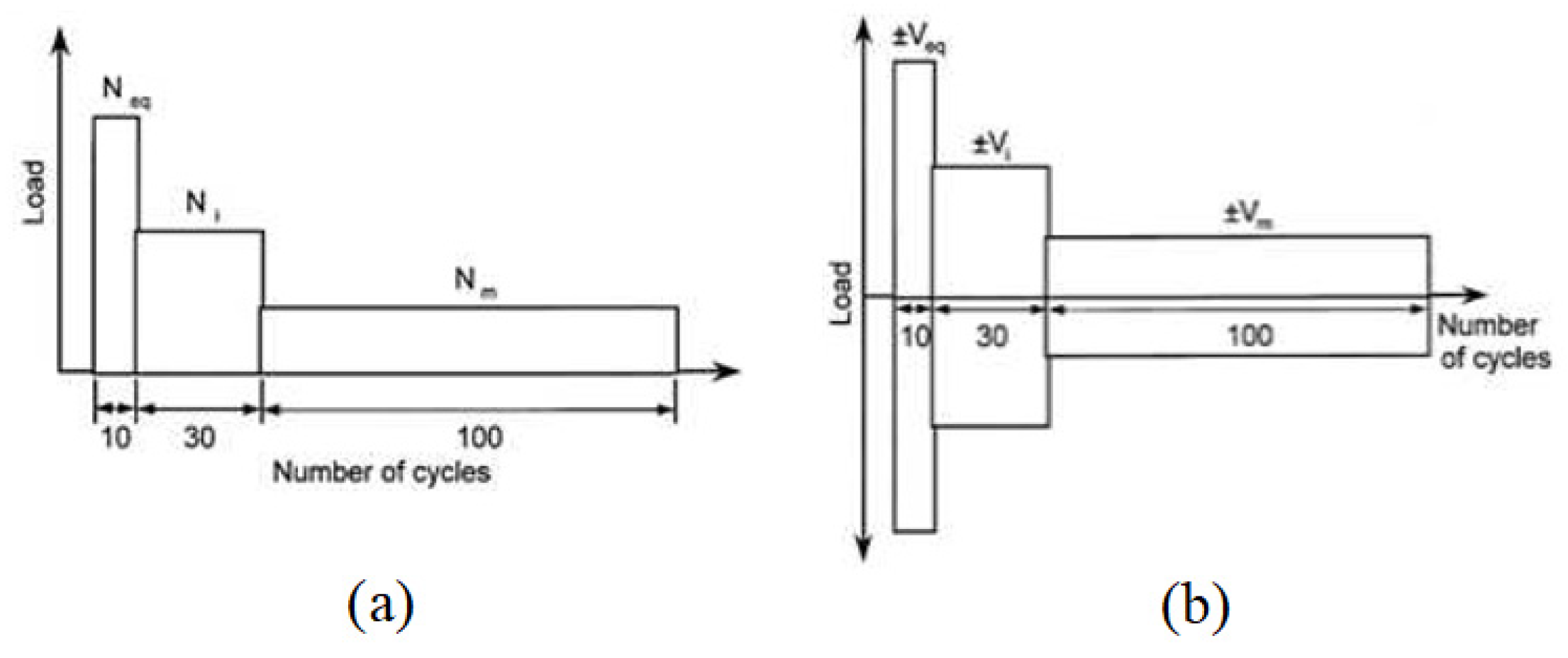

4.2.1. Presentation of Dynamic Load Protocol

4.2.2. Experimental Methods

4.2.3. Shear Performance Evaluation

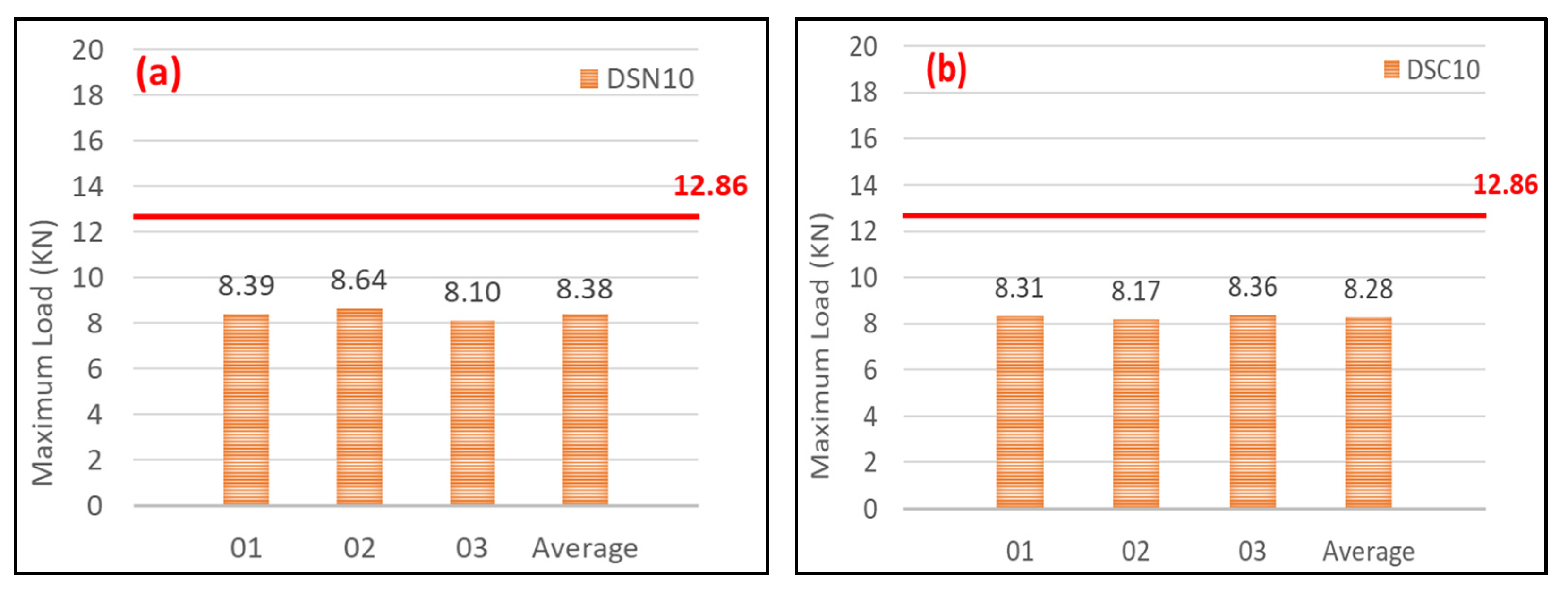

- DSN10 and DSC10

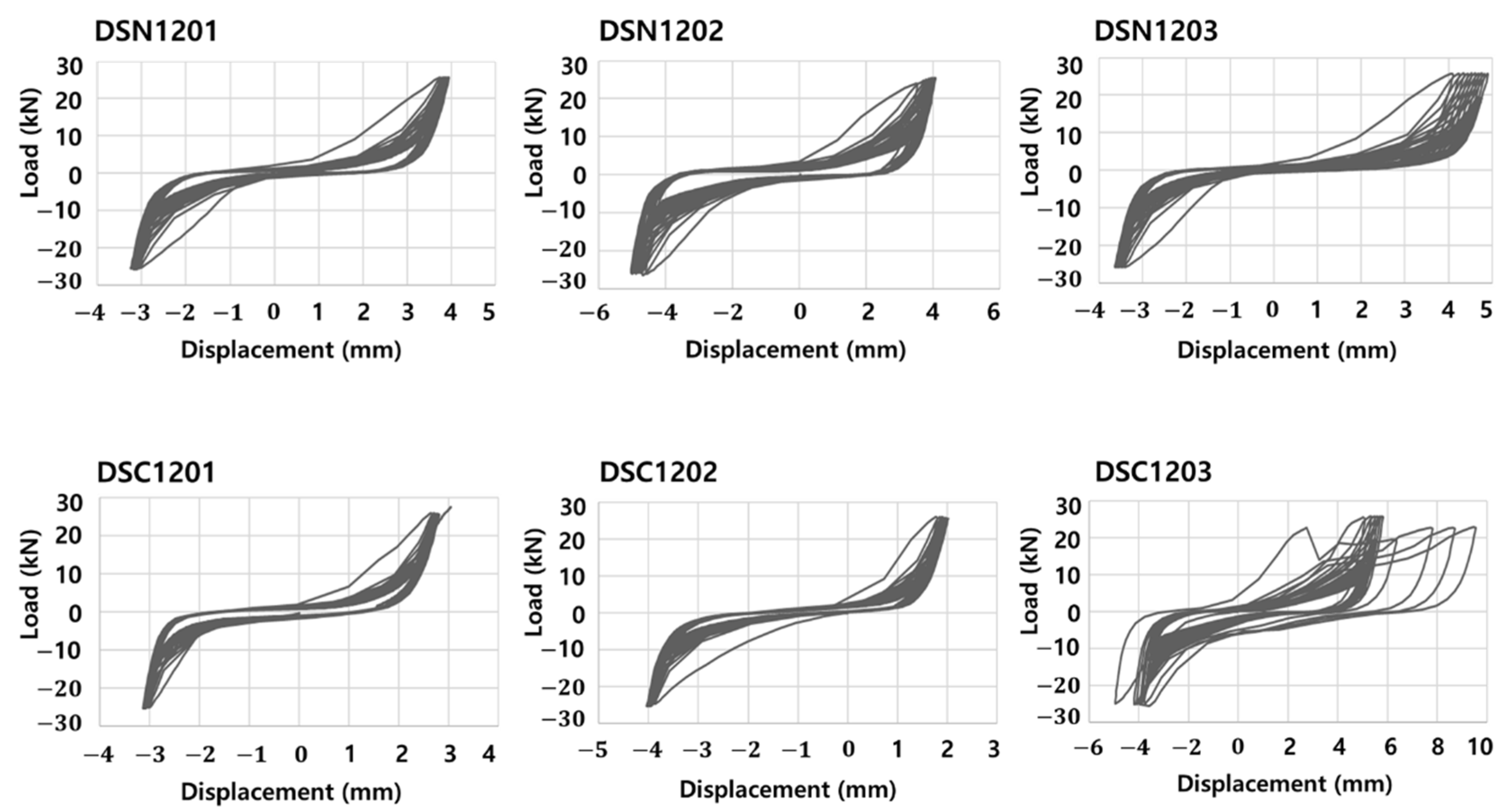

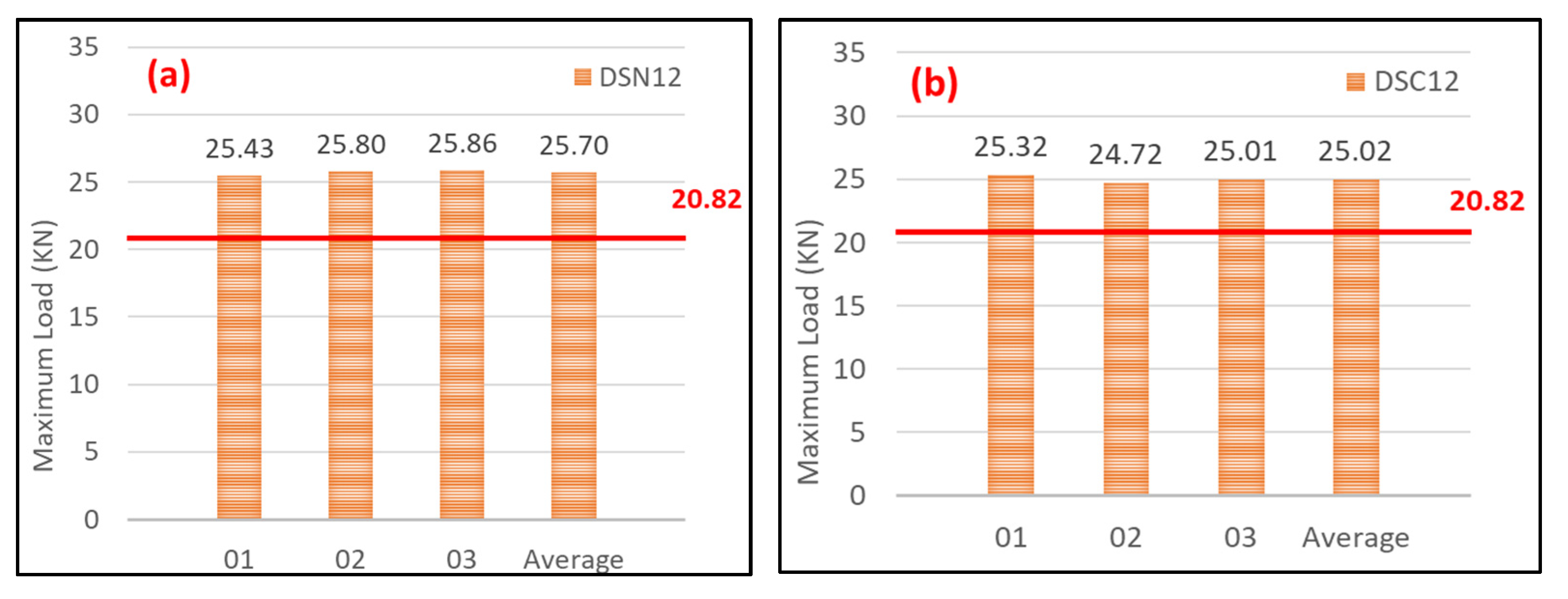

- DSN12 and DSC12

4.2.4. Pull-Out Performance Evaluation

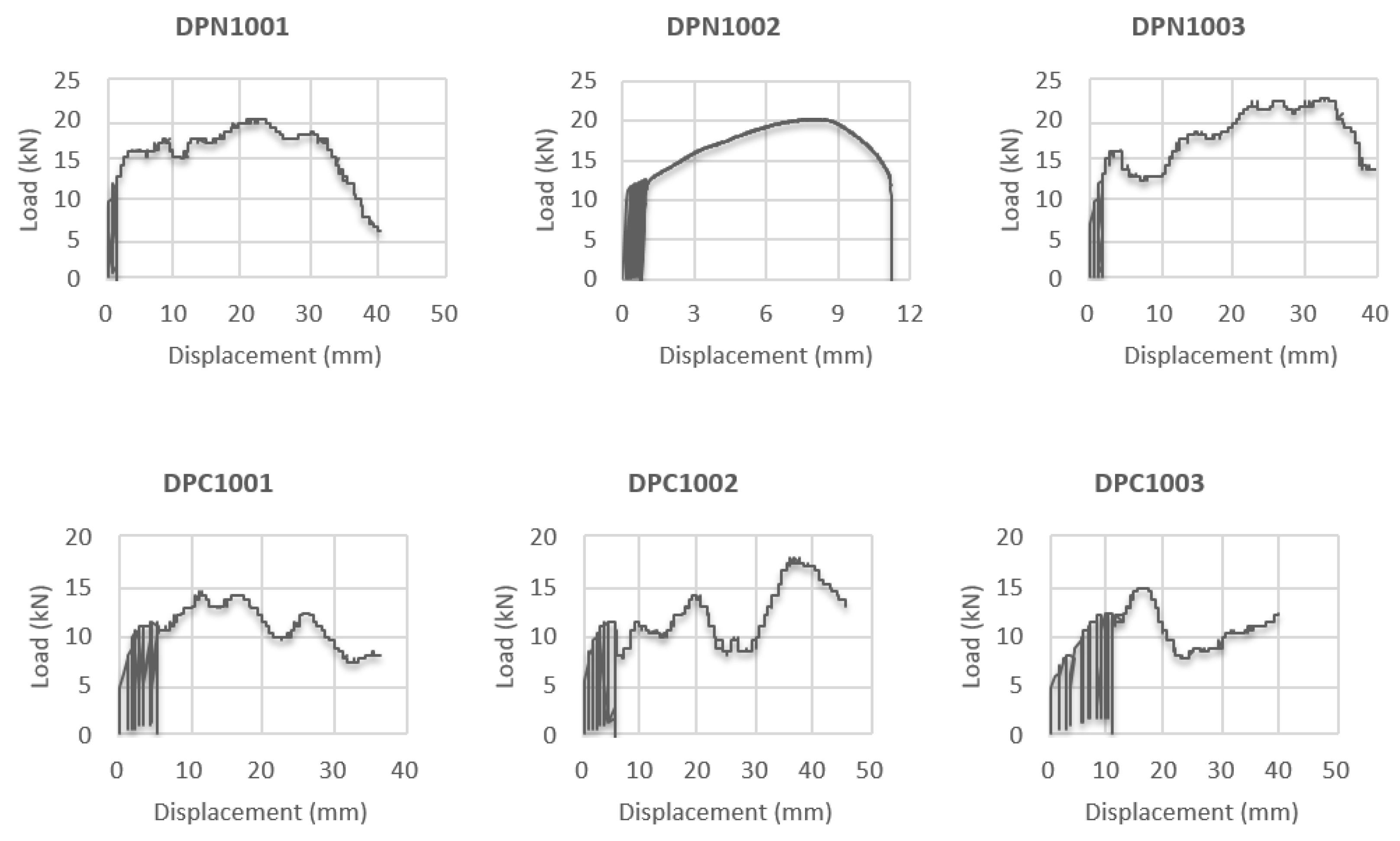

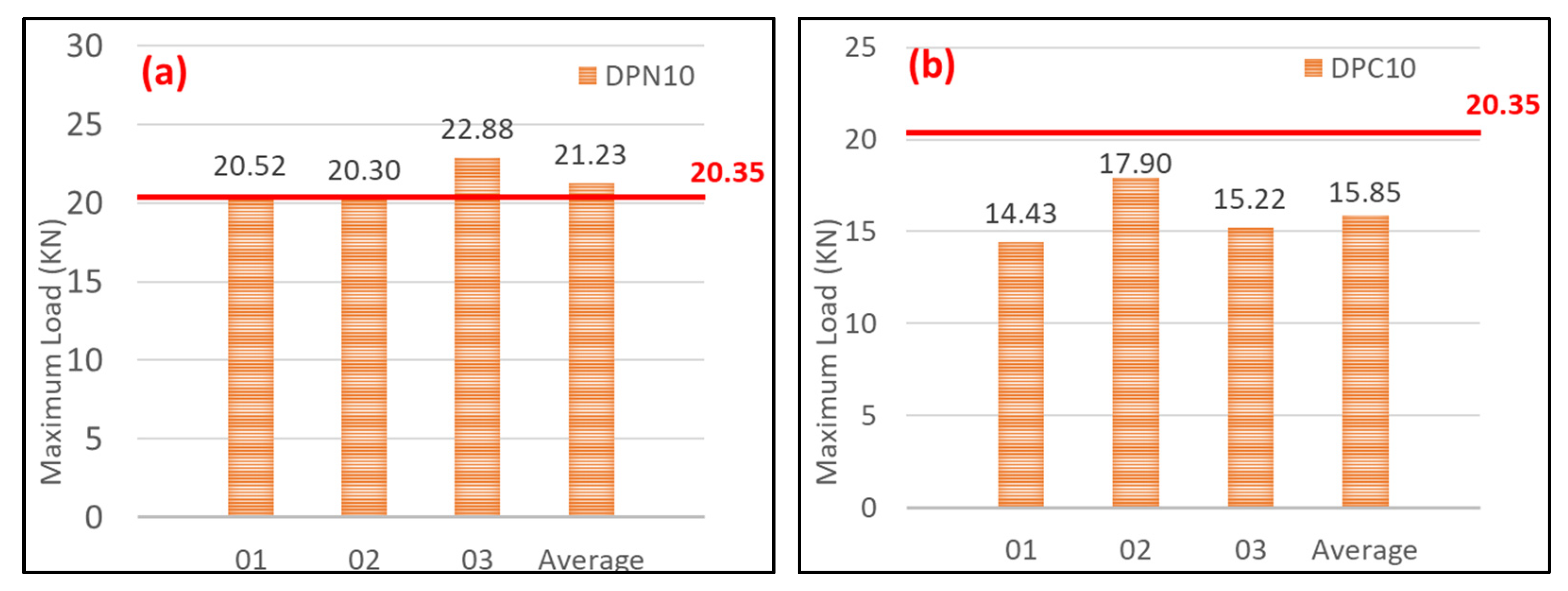

- DPN10 and DPC10

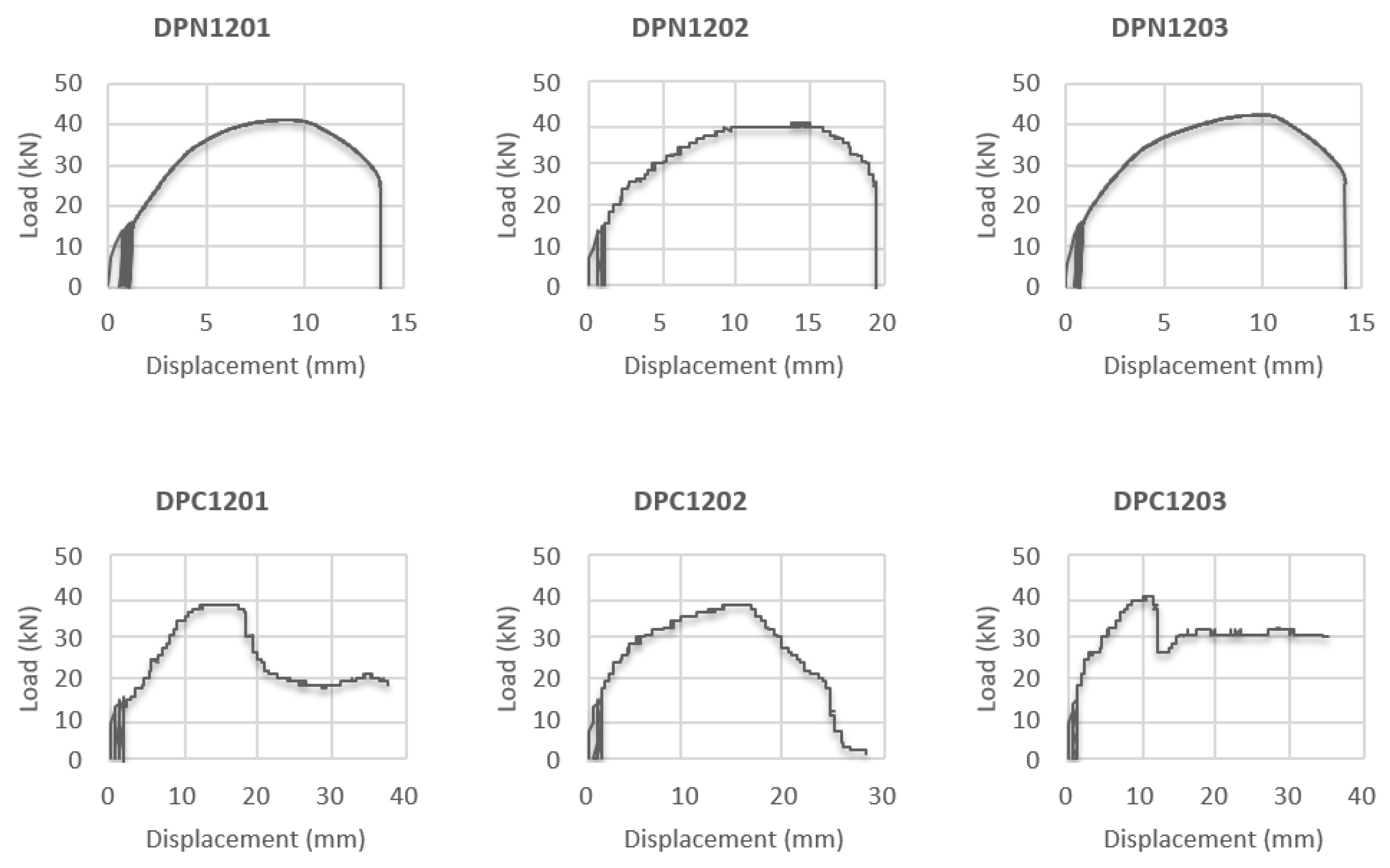

- DPN12 and DPC12

5. Conclusions

- In this study, the average maximum loads of post-installed anchors were calculated by evaluating the static performance of two concrete types (non-cracked and cracked concrete), based on which a dynamic load protocol was presented. A dynamic performance evaluation was conducted using this protocol to evaluate the seismic safety of concrete-embedded anchor bolts.

- The static shear test results of the M10 and M12 set anchors showed that steel failure occurred in both the cracked and non-cracked concrete. It appears that the anchor failure occurred before the load affected the concrete, owing to the sufficient bearing capacity of the concrete for the anchor bolt installed at the center of the concrete specimen and because of the concrete–anchor distance generated during the anchor installation.

- In the static pull-out test results, the M10 set anchor exhibited an anchor steel failure in both the cracked and non-cracked concrete. The M12 set anchor showed a concrete cone failure by the concrete–anchor adhesive force, owing to its slightly increased diameter. As with the M10 set anchor, the maximum pull-out load in the cracked concrete specimens was smaller than that in the non-cracked concrete specimens, owing to a reduction in the concrete–anchor adhesive force.

- In the dynamic shear test results of the M10 and M12 set anchors, both anchors exhibited steel failure. The M12 set anchor met the seismic performance verification criterion (80% of the static performance), but the M10 set anchor could not because its dynamic performance was reduced, owing to the cyclic loading.

- The results of the dynamic pull-out test showed that the M10 anchor met the seismic performance verification criterion in a non-cracked state, i.e., at the time of installation, but could not meet the criterion when cracks occurred, owing to aging and other loads. In the case of the M12 set anchor, the maximum pull-out loads under dynamic loads were found to be higher than those of the static tests. This appears to be because the clearance between the concrete and the set anchor, which existed at the time of the set anchor installation, contributed to the concrete–anchor frictional force generated by vibrations under the application of cyclic loading.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jung, W.; Kwon, M.; Kim, J.; Ju, B. Performance Evaluation of the Post-Installed Anchor for Sign Structure. Int. J. Civ. Environ. Eng. 2012, 6, 1097–1102. [Google Scholar]

- Lee, S.M.; Jung, W.Y. Evaluation of anchorage performance of the switchboard cabinet under seismic loading condition. Adv. Mech. Eng. 2020, 12, 1687814020926309. [Google Scholar] [CrossRef]

- Reducing the Risks of Nonstructural Earthquake Damage—A Practical Guide; FEMA E-74; FEMA: Washington, DC, USA, 2012.

- Oh, S.H.; Park, H.Y.; Choi, K.K. Seismic Damage Status and Characteristics of Non-structural Elements. Korean Soc. Noise Vib. Eng. 2018, 28, 71–77. [Google Scholar]

- Park, Y.M.; Jeon, M.; Lee, K.J.; Kim, C.H. A Study on the Concrete Breakout Capacity Evaluation of Medium-to-Large size CIP Anchor Bolts under Tension Loading. J. Korean Soc. Steel Constr. 2011, 23, 493–501. [Google Scholar]

- Building Code Requirements for Structural Concrete (ACI 318-11) and Commentary; ACI Committee 318; ACI: Farmington Hills, MI, USA, 2011; 503p.

- Jang, J.B.; Suh, Y.P.; Lee, J.R. A Study on the Evaluation of Concrete Breakout Strength for Cast-In-Place Anchor with Crack. J. Korean Soc. Civ. Eng. 2004, 24, 647–652. [Google Scholar]

- Park, Y.M.; Ju, H.J.; Kim, D.H.; Kang, M.K.; Lee, J.H. Static Shear Resistance of Cast-In-Place Anchors in Cracked Concrete. J. Korean Soc. Steel Constr. 2015, 27, 87–97. [Google Scholar] [CrossRef]

- Evaluating the Performance of Post-Installed Mechanical Anchors in Concrete, Reported by ACI Committee 355; ACI 355.2-01; ACI: Farmington Hills, MI, USA, 2002.

- Mahrenholtz, C.; Eligehausen, R.; Hutchinson, T.C.; Hoehler, M.S. Behavior of post-installed anchors tested by stepwise increasing cyclic crack protocols. ACI Struct. J. 2017, 114, 623. [Google Scholar] [CrossRef]

- Post-Installed Fasteners in Concrete under Seismic Action; EOTA TR 049; EOTA: Brussels, Belgium, 2016.

- Kim, S.-Y.; Yu, C.-S.; Yoon, Y.-S. Sleeve-type expansion anchor behavior in cracked and uncracked concrete. Nucl. Eng. Des. 2004, 228, 273–281. [Google Scholar] [CrossRef]

- Standard Test Methods for Strength of Anchors in Concrete and Masonry Elements; ASTM E 488-96; ASTM: West Conshohocken, PA, USA, 2003.

| Division | Tensile Strength | Shear Strength |

|---|---|---|

| Steel Failure | Nsa | Vsa |

| Pullout | Npn | |

| Side-Face Blowout | Nsb | |

| Concrete Breakout | Ncb | Vcb |

| Concrete Splitting | ||

| Concrete Pryout | Vcp |

| Division | Diameter (mm) | Length (mm) | Embedded Depth (mm) |

|---|---|---|---|

| Anchor | Φ10 | 250 | 100 |

| Φ12 | 250 | 100 |

| Specimen Name | Test Method | Remark (Specimen Test Classification) |

|---|---|---|

| SSN1001–03 | T-01 | Test No. 01 to 03 (static_shear_non-cracked_10Ø) |

| SSC1001–03 | Test No. 01 to 03 (static_shear_cracked_10Ø) | |

| SSN1201–03 | Test No. 01 to 03 (static_shear_non-cracked_12Ø) | |

| SSC1201–03 | Test No. 01 to 03 (static_shear_cracked_12Ø) | |

| SPN1001–03 | Test No. 01 to 03 (static_pull-out_non-cracked_10Ø) | |

| SPC1001–03 | Test No. 01 to 03 (static_pull-out_cracked_10Ø) | |

| SPN1201–03 | Test No. 01 to 03 (static_pull-out_non-cracked_12Ø) | |

| SPC1201–03 | Test No. 01 to 03 (static_pull-out_cracked_12Ø) |

| Specimen Test Classification | Max. Average Load | ||

|---|---|---|---|

| Shear tests | Φ10 | Non-cracked concrete | 16.08 kN |

| Cracked concrete | 15.85 kN | ||

| Φ12 | Non-cracked concrete | 25.44 kN | |

| Cracked concrete | 24.52 kN | ||

| Specimen Test Classification | Max. Average Load | ||

|---|---|---|---|

| Pull-out tests | Φ10 | Non-cracked concrete | 26.03 kN |

| Cracked concrete | 23.46 kN | ||

| Φ12 | Non-cracked concrete | 31.89 kN | |

| Cracked concrete | 25.93 kN | ||

| Anchor | Test | Applied Load (kN) | Static Max. Average Load (kN) (Refer to Table 4 and Table 5) | ||

|---|---|---|---|---|---|

| 50% (10 Times) | 37.5% (30 Times) | 25% (100 Times) | |||

| Φ10 | Shear | 8 | 6 | 4 | 16.08 |

| Pull-out | 13 | 9.5 | 6.4 | 26.03 | |

| Φ12 | Shear | 13 | 9.8 | 6.5 | 25.44 |

| Pull-out | 16 | 12 | 8 | 31.89 | |

| Specimen Name | Test Method | Remark (Specimen Test Classification) |

|---|---|---|

| DSN1001–03 | T-01 | Test No. 01 to 03 (dynamic_shear_non-cracked_10Ø) |

| DSC1001–03 | Test No. 01 to 03 (dynamic_shear_cracked_10Ø) | |

| DSN1201–03 | Test No. 01 to 03 (dynamic_shear_non-cracked_12Ø) | |

| DSC1201–03 | Test No. 01 to 03 (dynamic_shear_cracked_12Ø) | |

| DPN1001–03 | Test No. 01 to 03 (dynamic_pull-out_non-cracked_10Ø) | |

| DPC1001–03 | Test No. 01 to 03 (dynamic_pull-out_cracked_10Ø) | |

| DPN1201–03 | Test No. 01 to 03 (dynamic_pull-out_non-cracked_12Ø) | |

| DPC1201–03 | Test No. 01 to 03 (dynamic_pull-out_cracked_12Ø) |

| Anchor | Concrete | Test No.01 (kN) | Test No.02 (kN) | Test No.03 (kN) | Criteria 80% (Refer to Table 6) |

|---|---|---|---|---|---|

| Φ10 | Non-crack | 8.39 | 8.64 | 8.10 | 12.86 kN |

| Crack | 8.31 | 8.17 | 8.36 | ||

| Φ12 | Non-crack | 25.43 | 25.80 | 25.86 | 20.82 kN |

| Crack | 25.32 | 24.72 | 25.01 |

| Anchor | Concrete | Test No.01 (kN) | Test No.02 (kN) | Test No.03 (kN) | Criteria 80% (Refer to Table 6) |

|---|---|---|---|---|---|

| Φ10 | Non-crack | 20.52 | 20.30 | 22.88 | 20.35 kN |

| Crack | 14.43 | 17.90 | 15.22 | ||

| Φ12 | Non-crack | 42.47 | 41.25 | 40.39 | 25.51 kN |

| Crack | 39.15 | 38.95 | 40.70 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Jung, W. Evaluation of Structural Performance of Post-Installed Anchors Embedded in Cracked Concrete in Power Plant Facilities. Appl. Sci. 2021, 11, 3488. https://doi.org/10.3390/app11083488

Lee S, Jung W. Evaluation of Structural Performance of Post-Installed Anchors Embedded in Cracked Concrete in Power Plant Facilities. Applied Sciences. 2021; 11(8):3488. https://doi.org/10.3390/app11083488

Chicago/Turabian StyleLee, Sangmoon, and Wooyoung Jung. 2021. "Evaluation of Structural Performance of Post-Installed Anchors Embedded in Cracked Concrete in Power Plant Facilities" Applied Sciences 11, no. 8: 3488. https://doi.org/10.3390/app11083488

APA StyleLee, S., & Jung, W. (2021). Evaluation of Structural Performance of Post-Installed Anchors Embedded in Cracked Concrete in Power Plant Facilities. Applied Sciences, 11(8), 3488. https://doi.org/10.3390/app11083488