Contact-Area-Changeable CMP Conditioning for Enhancing Pad Lifetime

Abstract

:1. Introduction

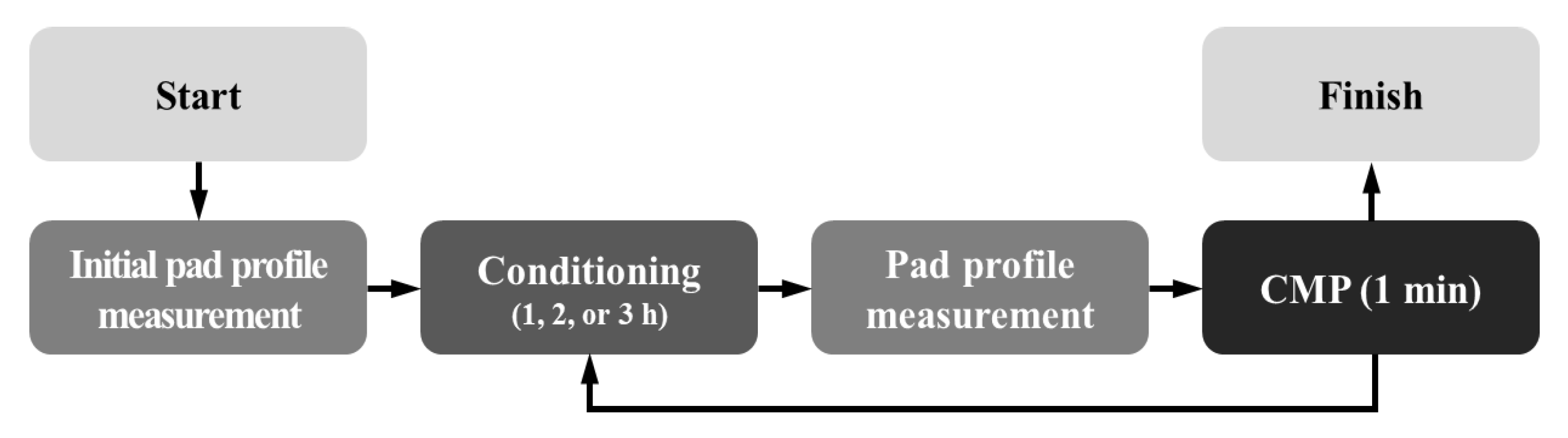

2. Experimental Set-Up

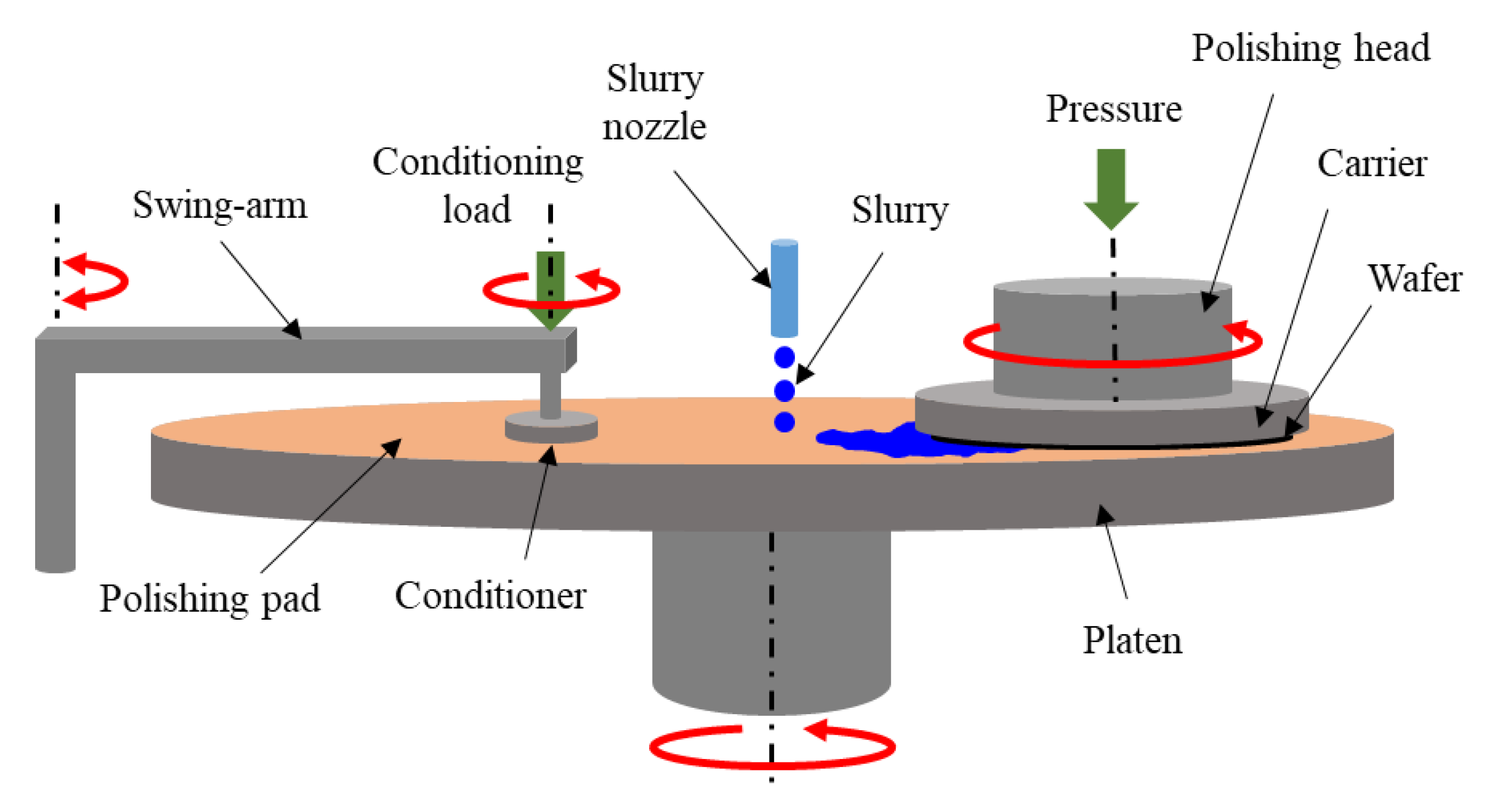

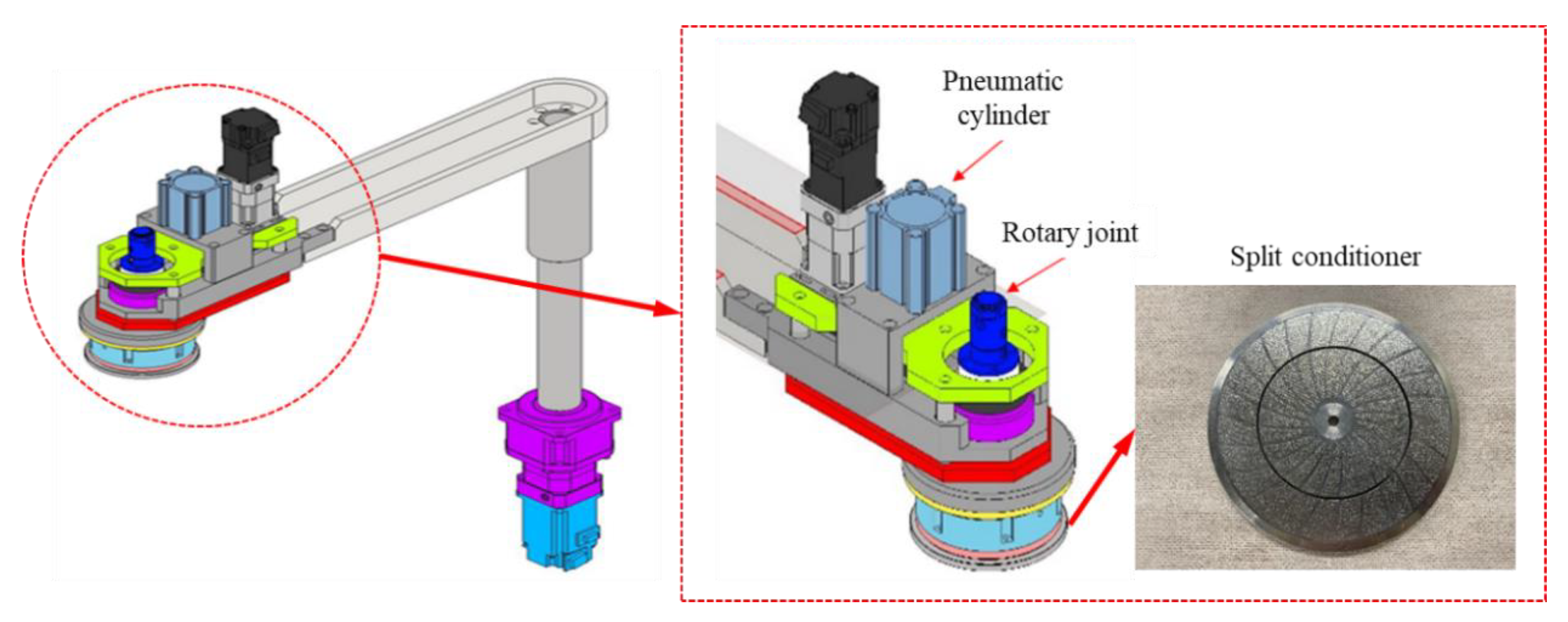

2.1. CMP Conditioning System and Condition

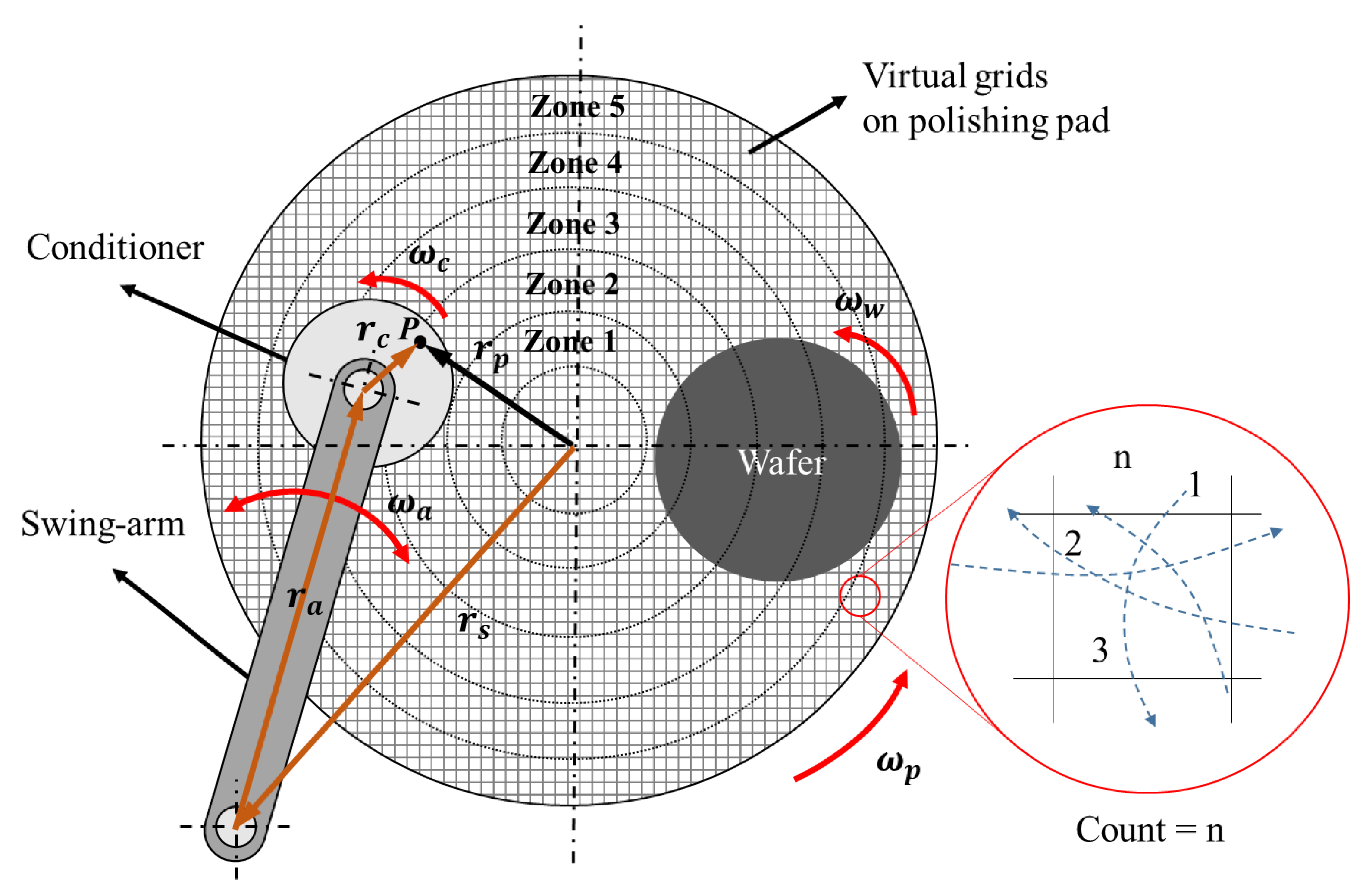

2.2. Pad Wear Simulation

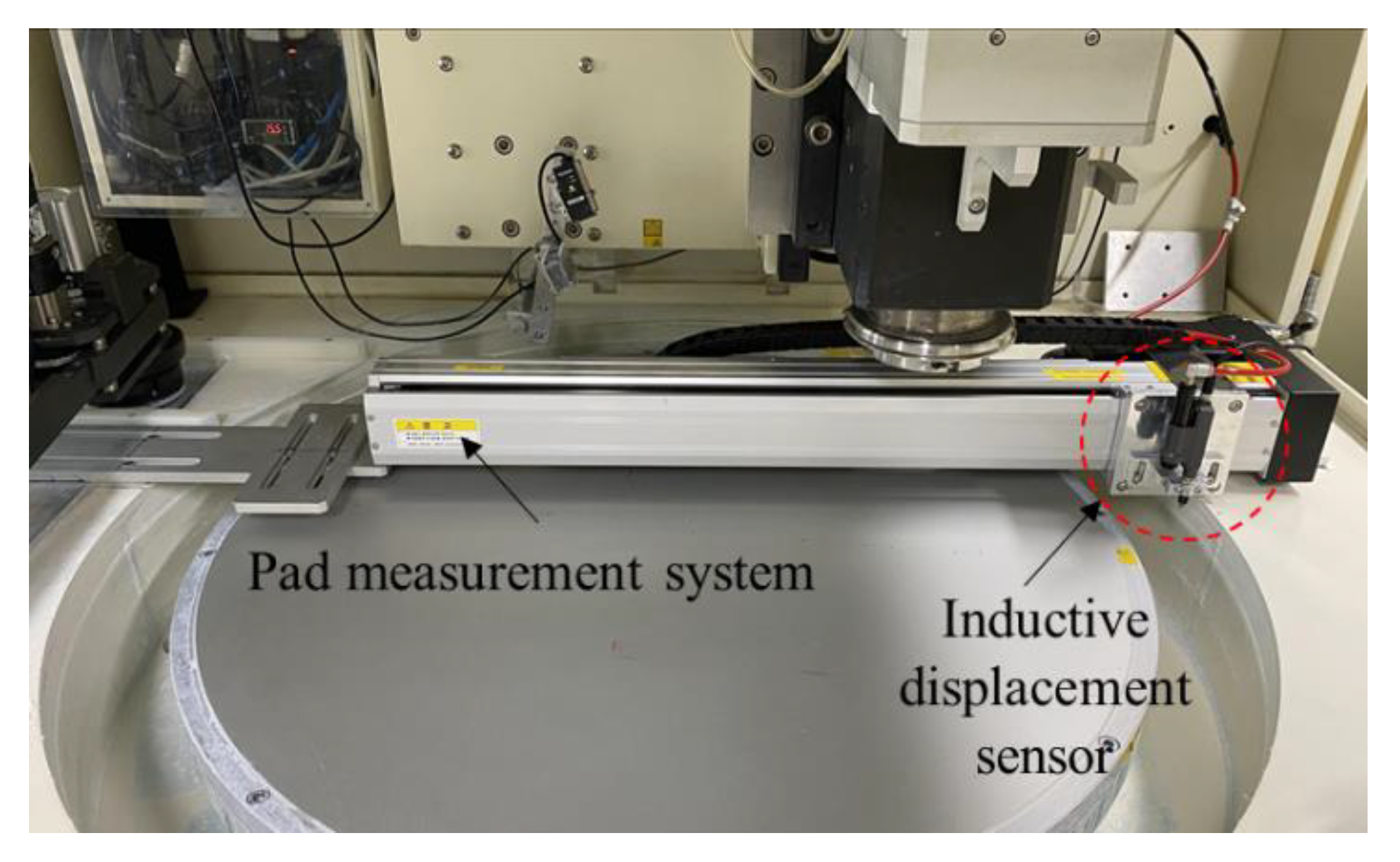

2.3. CMP Experiment and Pad Profile Measurement

3. Result and Discussion

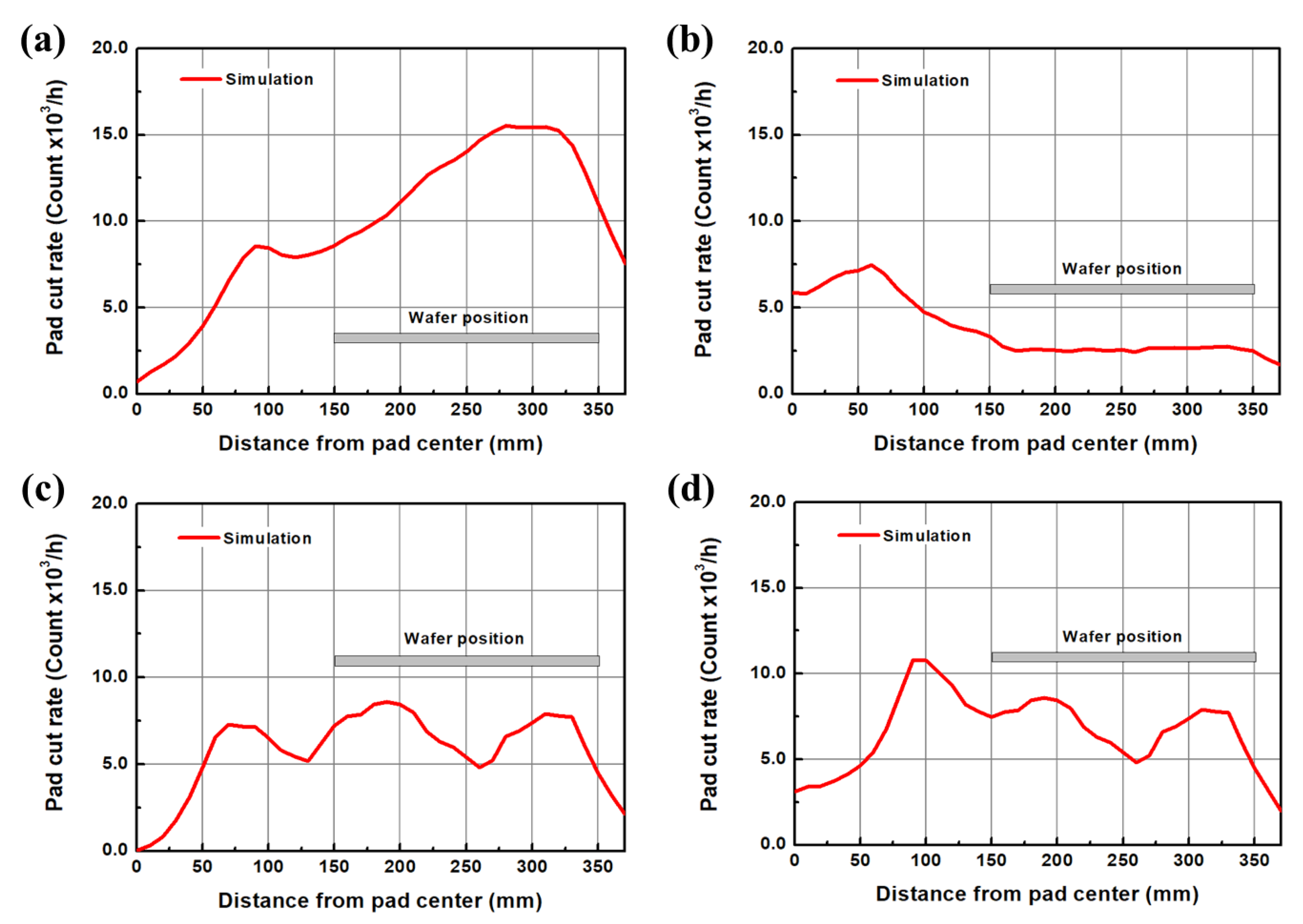

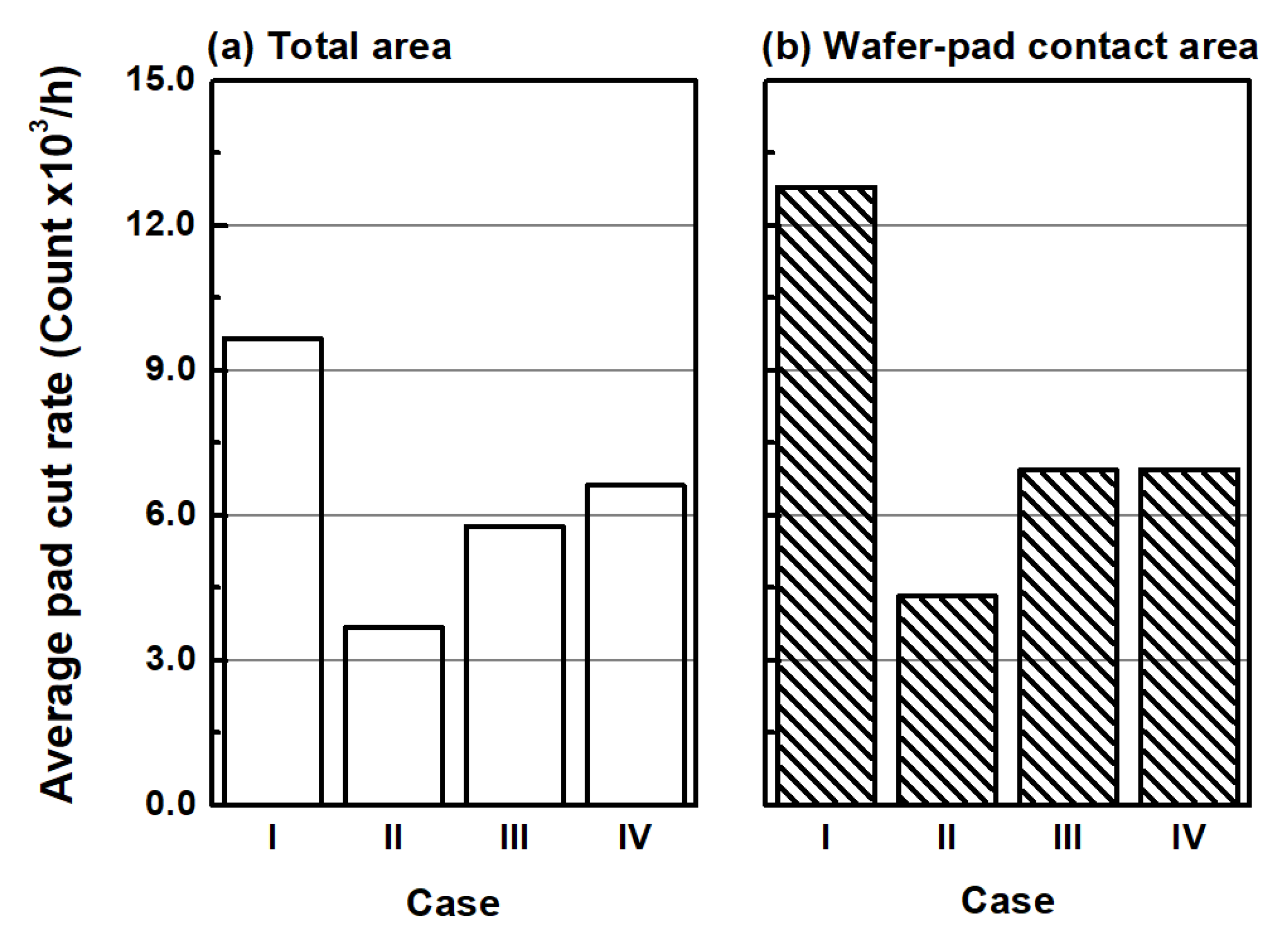

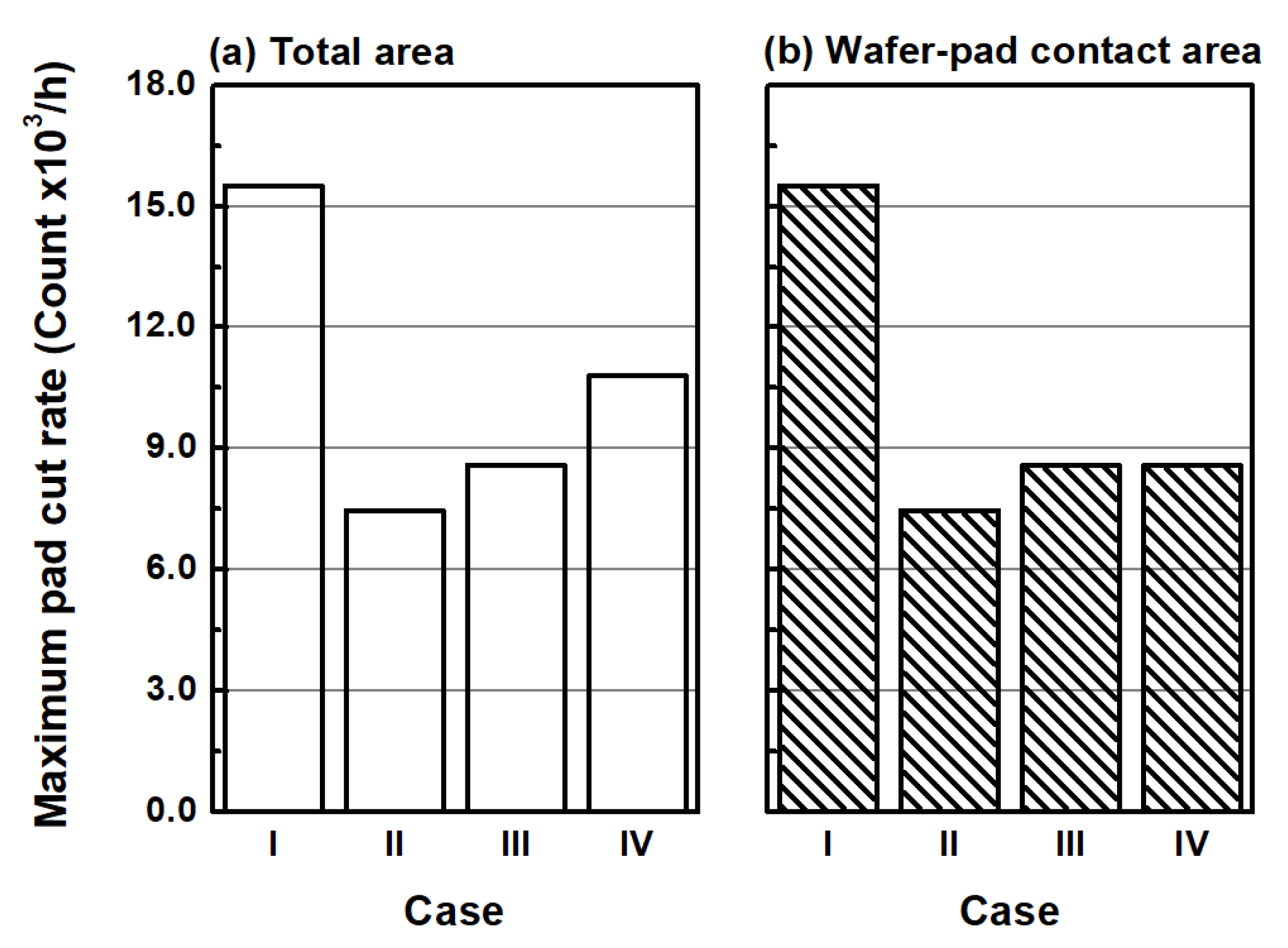

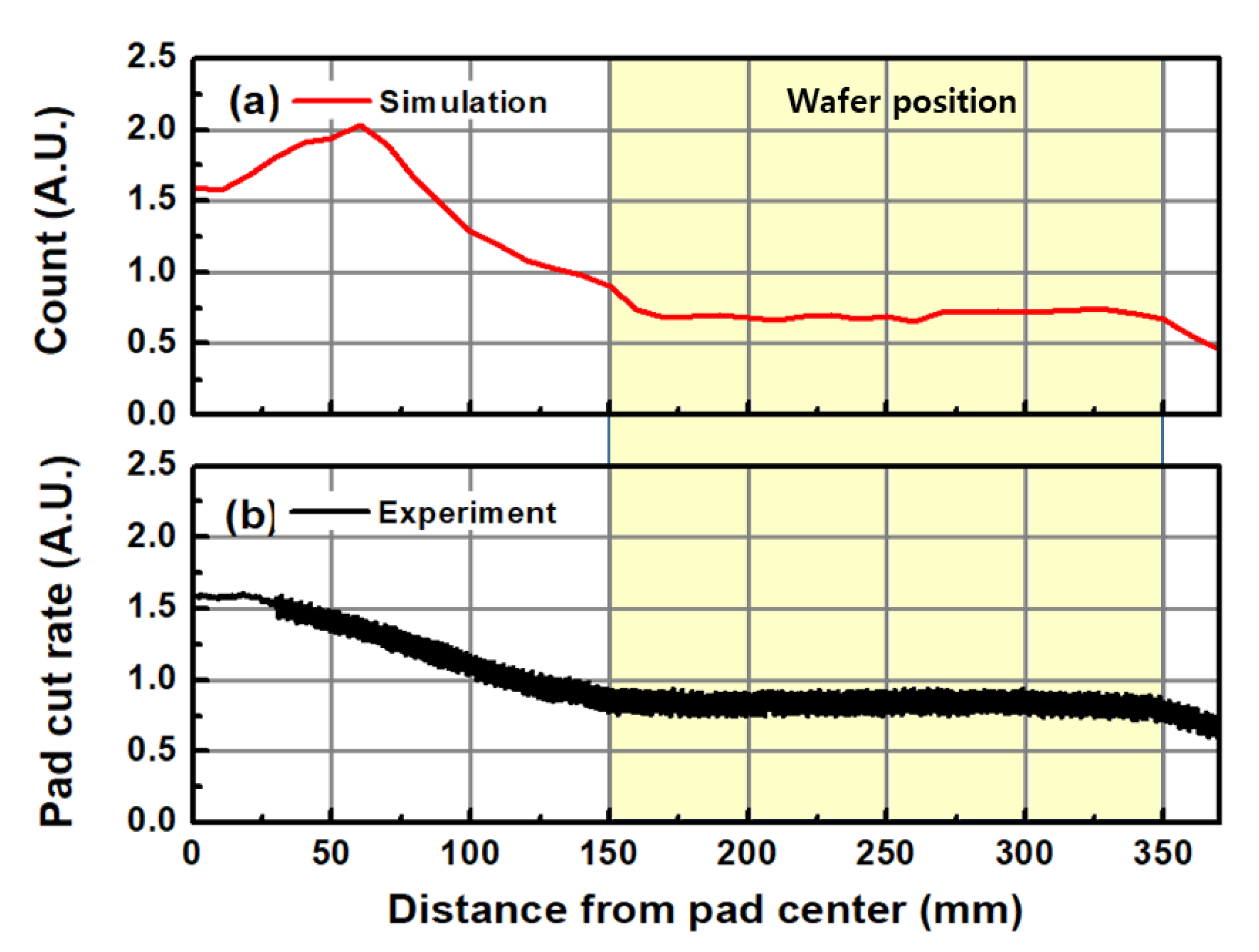

3.1. Simulation Results of Pad Cut Rate Distribution

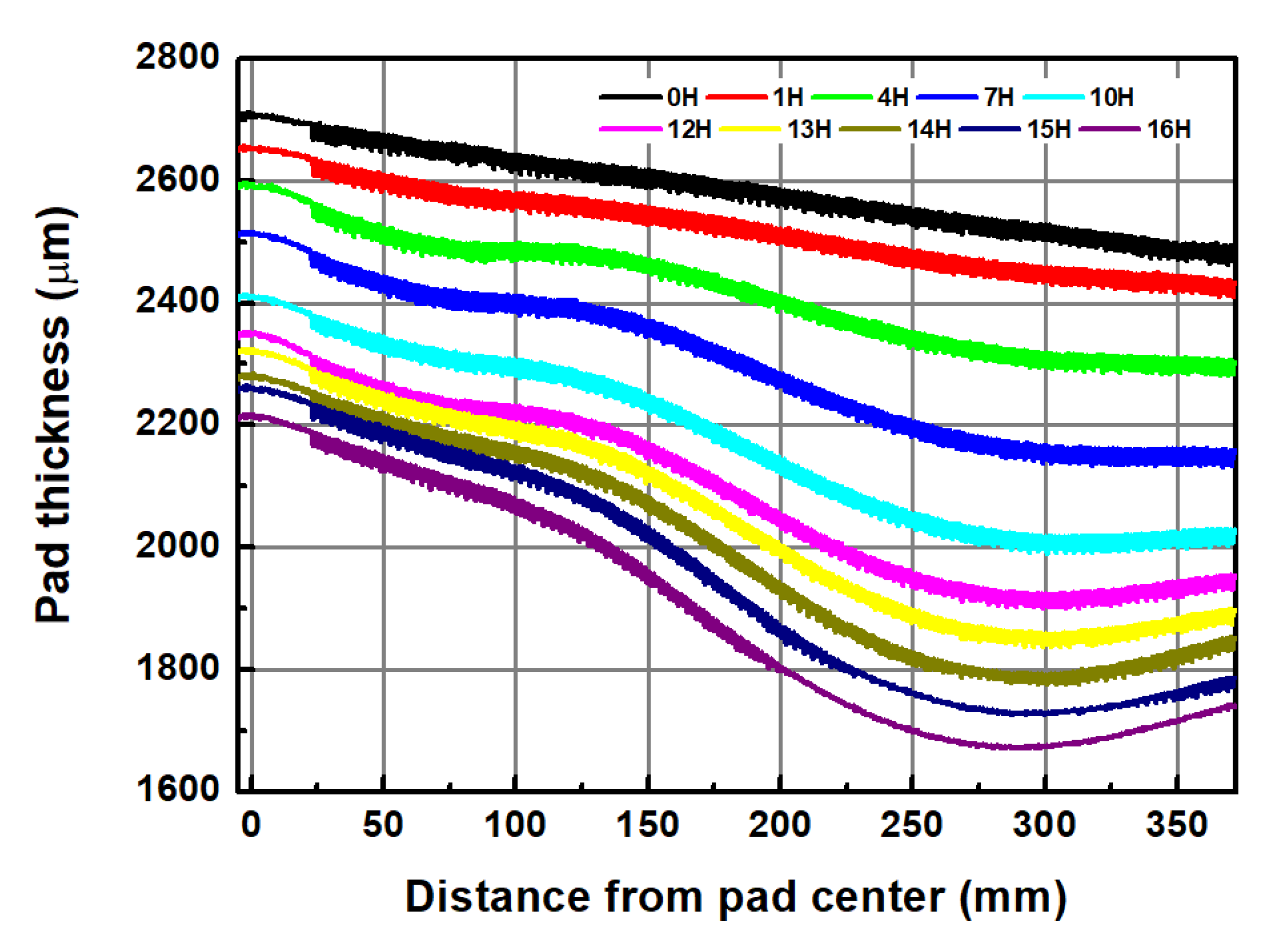

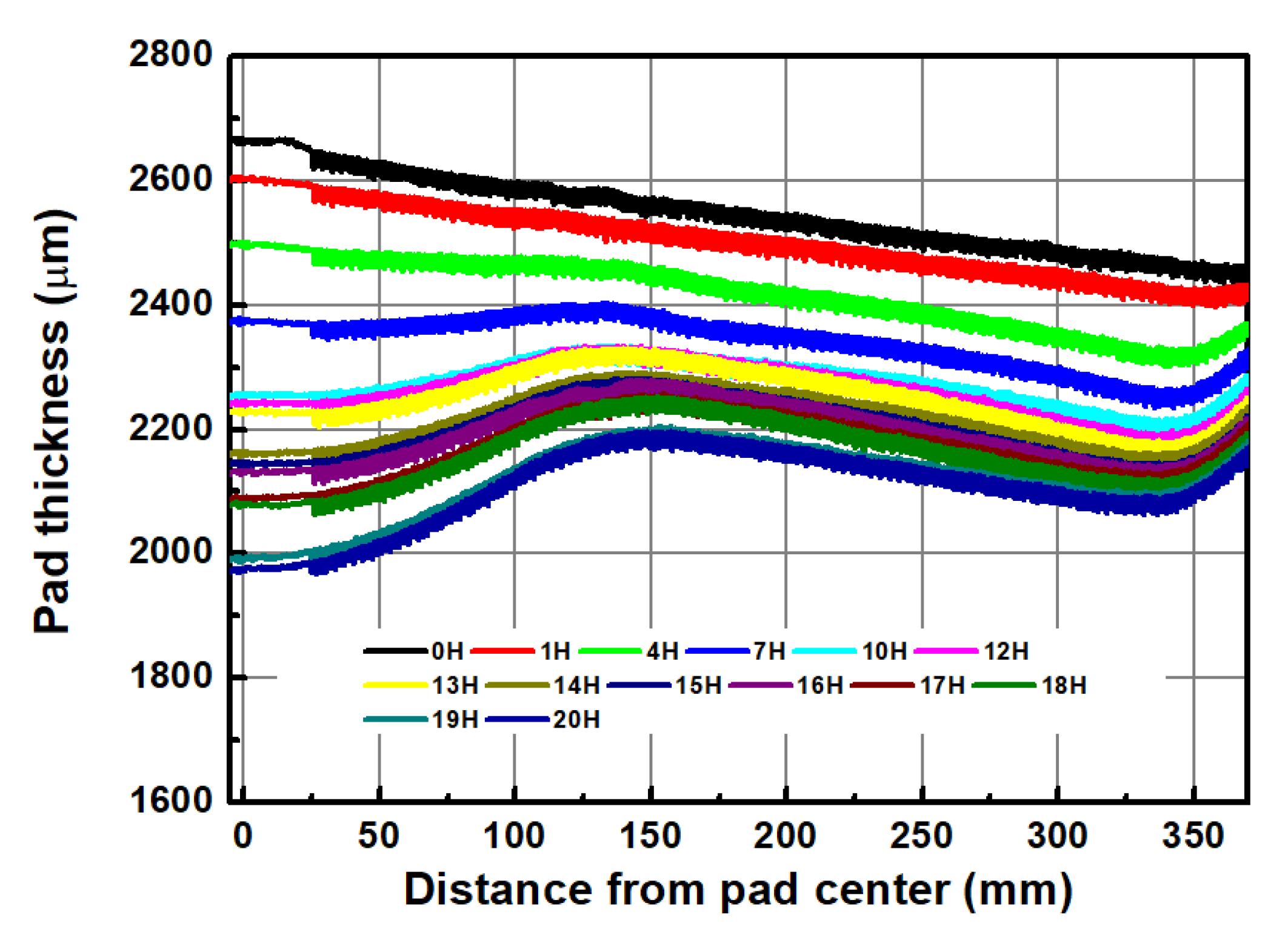

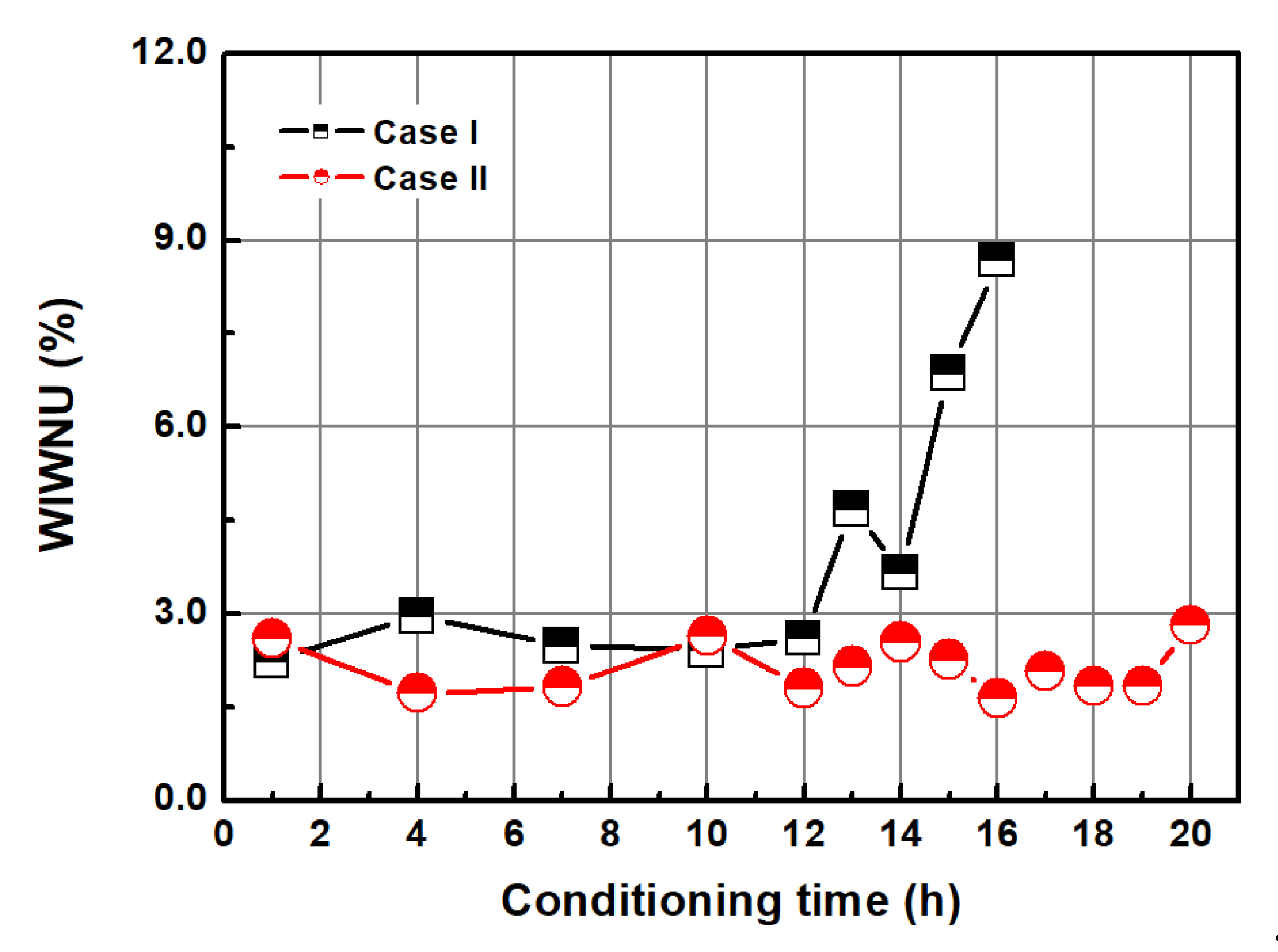

3.2. Comparison of Pad Lifetimes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Verkatesh, V.C.; Inasaki, I.; Toenshof, H.K.; Nakagawa, T.; Marinescu, I.D. Observations on Polishing and Ultraprecision Machining of Semiconductor Substrate Materials. CIRP Ann. Manufact. Technol. 1995, 44, 611–618. [Google Scholar] [CrossRef]

- Zhao, G.; Wei, Z.; Wang, W.; Feng, D.; Xu, A.; Liu, W.; Song, Z. Review on modeling and application of chemical mechanical polishing. Nanotechnol. Rev. 2020, 9, 182–189. [Google Scholar] [CrossRef] [Green Version]

- Zantye, P.B.; Kumar, A.; Sikder, A.K. Chemical mechanical planarization for microelectronics applications. Mater. Sci. Eng. R Rep. 2004, 45, 89–220. [Google Scholar] [CrossRef]

- Krishnan, M.; Nalaskowski, J.W.; Cook, L.M. Chemical Mechanical Planarization: Slurry chemistry, Materials, and Mechanism. Chem. Rev. 2010, 110, 178–204. [Google Scholar] [CrossRef] [PubMed]

- Jeong, S.; Jeong, K.; Choi, J.; Jeong, H. Analysis of Correlation between Pad Temperature and Asperity angle in Chemical Mechanical Planarization. Appl. Sci. 2021, 11, 1507. [Google Scholar] [CrossRef]

- Huang, D.; Babu, S.V.; Wang, L.; Moser, T. Effect of CMP Pad and Slurry to STI and ILD Polishing. ECS Trans. 2010, 33, 23. [Google Scholar] [CrossRef]

- Guo, D.M.; Liu, R.H.; Kang, R.K.; Jin, Z.J. Study on Adhesion Removal Model in CMP SiO2 ILD. Key Eng. Mater. 2008, 389–390, 475–480. [Google Scholar] [CrossRef]

- Bengochea, L.V.; Smapuruno, T.; Kavaljer, M.; Johnston, R.; Philipossian, A. Characterization of CMP Slurries Using Densitometry and Refractive Index Measurements. Micromachines 2018, 9, 542. [Google Scholar] [CrossRef] [Green Version]

- Chang, S.-H. A dishing model for STI CMP process. Microelectron. Eng. 2005, 82, 136–142. [Google Scholar] [CrossRef]

- Xie, X.; Park, T.; Boning, D.; Smith, A.; Allard, P.; Patel, N. Characterizing STI CMP Processes with an STI Test Mask Having Realistic Geometric Shapes. MRS Online Proc. Libr. 2004, 816, 941–948. [Google Scholar] [CrossRef]

- Ryan, J.G.; Geffken, R.M.; Poulin, N.R.; Paraszczak, J.R. The evolution of interconnection technology at IBM. IBM J. Res. Dev. 1995, 39, 371–381. [Google Scholar] [CrossRef]

- Fayolle, M.; Romagna, F. Copper CMP evaluation: Planarization issue. Microelectron. Eng. 1997, 37–38, 135–141. [Google Scholar] [CrossRef]

- Wenbio, R.; Lan, C.; Zhigang, L.; Tuanchun, Y. Effects of pattern characteristics on copper CMP. J. Semicond. 2009, 30, 046001. [Google Scholar] [CrossRef]

- Ein-Eli, Y.; Starosvetsky, D. Review on copper chemical-mechanical polishing (CMP) and post-CMP cleaning in ultra large system integrated (ULSI)—An electrochemical perspective. Electrochim. Acta 2007, 52, 1825–1838. [Google Scholar] [CrossRef]

- Lee, W.-S.; Kim, S.-Y.; Seo, Y.-J.; Lee, J.-K. An optimization of tungsten plug chemical mechanical polishing (CMP) using different consumables. J. Mater. Sci. Mater. Electron. 2001, 12, 63–68. [Google Scholar] [CrossRef]

- Fayolle, M.; Sicurani, E.; Morand, Y. W CMP process integration: Consumables evaluation-electrical results and end point detection. Microelectron. Eng. 1997, 37–38, 347–352. [Google Scholar] [CrossRef]

- Tseng, W.-T.; Mohan, K.; Hull, R.; Hagan, J.; Truong, C.; Lehuu, D.K.; Muradian, D. A Microreplicated Pad for Tungsten Chemical-Mechanical Planarization. ECS J. Solid State Sci. Technol. 2016, 5, P546. [Google Scholar] [CrossRef] [Green Version]

- Seo, J. A review on chemical and mechanical phenomena at the wafer interface during chemical mechanical planarization. J. Mater. Res. 2020, 36, 235–257. [Google Scholar] [CrossRef]

- Lee, H. Semi-empirical Material Removal Model with Modified Real Contact Area for CMP. Int. J. Precis. Eng. Manufact. 2019, 20, 1325–1332. [Google Scholar] [CrossRef]

- Banerjee, G.; Rhoades, L. Chemical Mechanical Planariaation–Historical Review and Future Direction. ECS Trans. 2008, 13, 1–19. [Google Scholar] [CrossRef]

- Borucki, L.J.; Witelski, T.; Plwase, C.; Kramer, P.R.; Schwedeman, D. A theory of pad conditioning for chemical–mechanical polishing. J. Eng. Math. 2004, 50, 1–24. [Google Scholar] [CrossRef]

- Lee, W.J.; Park, H.S.; Shin, H.C. Enhancement of CMP pad lifetime for shallow trench isolation process using profile simulation. Curr. Appl. Phys. 2009, 9, S134–S137. [Google Scholar] [CrossRef]

- Sun, T.; Borucki, L.; Zhuang, Y.; Philipossian, A. Investigating the effect of diamond size and conditioning force on chemical mechanical planarization pad topography. Microelectron. Eng. 2010, 87, 553–559. [Google Scholar] [CrossRef]

- Tsai, M.Y.; Peng, J.D. Investigation of a novel diamond disk’s effect on pad topography in oxide chemical mechanical polishing. Mater. Manuf. Proc. 2010, 25, 1440–1448. [Google Scholar] [CrossRef]

- Tso, P.L.; Ho, S.Y. Factors influencing the dressing rate of chemical mechanical polishing pad conditioning. Int. J. Adv. Manuf. Technol. 2007, 33, 720–724. [Google Scholar] [CrossRef]

- Jeong, H.D.; Park, K.H.; Cho, K.K. CMP Pad Break-in Time Reduction in Silicon Wafer Polishing. CIRP-Ann. 2007, 56, 357–360. [Google Scholar] [CrossRef]

- Tso, P.-L.; Huang, Z.-H.; Chou, S.-W.; Shih, C.-Y. Study on the CMP Pad Life with Mechanical Properties. Key Eng. Mater. 2009, 389–390, 481–486. [Google Scholar] [CrossRef]

- Kim, N.-H.; Seo, Y.-J.; Lee, W.-S. Temperature effects of pad conditioning process on oxide CMP: Polishing pad, slurry characteristics, and surface reactions. Microelectron. Eng. 2006, 83, 362–370. [Google Scholar] [CrossRef]

- Tsai, M.-Y. Polycrystalline diamond shaving conditioner for CMP pad conditioning. J. Mater. Proc. Technol. 2010, 210, 1095–1102. [Google Scholar]

- Li, Z.C.; Baisie, E.A.; Zhang, X.H. Diamond disc pad conditioning in chemical mechanical planarization (CMP): A surface element method to predict pad surface shape. Precis. Eng. 2012, 36, 356–363. [Google Scholar] [CrossRef]

- Yeh, H.M.; Chen, K.S. Development of a pad conditioning simulation module with a diamond dresser for CMP applications. Int. J. Adv. Manuf. Technol. 2010, 50, 1–12. [Google Scholar] [CrossRef]

- Chang, O.; Kim, H.; Park, K.; Seo, H.; Jeong, H. Mathematical modeling of CMP conditioning process. Microelectron. Eng. 2007, 84, 577–583. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Yu, C.-C.; Shen, S.-H.; Ho, M. Operational Aspects of Chemical Mechanical Polishing Polish Pad Profile Optimization. J. Electrochem. Soc. 2000, 147, 3922–3930. [Google Scholar] [CrossRef]

- Zhou, Y.Y.; Davis, E.C. Variation of polish pad shape during pad dressing. Mater. Sci. Eng. B 1999, 68, 91–98. [Google Scholar] [CrossRef]

- Lee, S.; Jeong, S.; Park, K.; Kim, H.; Jeong, H. Kinematical modeling of pad profile variation during conditioning in chemical mechanical polishing. Jpn. J. Appl. Phys. 2009, 48, 126502. [Google Scholar] [CrossRef]

- Lee, H.; Lee, S. Investigation of pad wear in CMP with swing-arm conditioning and uniformity of material removal. Precis. Eng. 2017, 49, 85–91. [Google Scholar] [CrossRef]

- Lee, D.; Lee, K.; Jeong, S.; Kim, H.; Cho, H.; Jeong, H. Effect of Diamond Abrasive Shape of CMP Conditioner on Polishing Pad Surface Control. Tribol. Lubr. 2019, 35, 330–336. [Google Scholar]

- Tyan, F. Pad Conditioning Density Distribution in CMP Process with Diamond Dresser. In Proceedings of the 2005 American Control Conference, Portland, OR, USA, 8–10 June 2005. ThA09.6. [Google Scholar]

- Chen, C.-C.A.; Li, J.-C.; Liao, W.-C.; Ciou, Y.-J.; Chen, C.-C. Dynamic Pad Surface Metrology Monitoring by Swing-Arm Chromatic Confocal System. Appl. Sci. 2021, 11, 179. [Google Scholar] [CrossRef]

| Condition (Unit) | Value |

|---|---|

| Rotational speed of platen (rpm) | 93 |

| Rotational speed of conditioner (rpm) | 101 |

| Conditioning load (kgf) | 4 |

| Sweep per minute (sweep/min) | 9 |

| Swing start radius (mm) | 370 |

| Swing end radius (mm) | 50 |

| Conditioning Zone | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Range (mm, from pad’s center) | 50–114 | 114–178 | 178–242 | 242–306 | 306–370 |

| Conditioner duration time (%) | 20 | 20 | 20 | 20 | 20 |

| Conditioning Zone | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Case I (reference) | Full contact | Full contact | Full contact | Full contact | Full contact |

| Case II | Full contact | Inner | Inner | Inner | Inner |

| Case III | Inner | Outer ring | Inner | Outer ring | Inner |

| Case IV | Outer ring | Inner | Outer ring | Inner | Outer ring |

| Condition | Value |

|---|---|

| Rotational speed of polishing head | 87 rpm |

| Rotational speed of platen | 93 rpm |

| Wafer pressure | 34.3 kPa |

| Retaining-ring pressure | 44.1 kPa |

| Slurry flow rate | 150 mL/min |

| Polishing time | 60 s |

| Polishing pad | KONI pad |

| Slurry | TSO-12 |

| Wafer | SiO2 wafer (200 mm) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, J.; Lee, H. Contact-Area-Changeable CMP Conditioning for Enhancing Pad Lifetime. Appl. Sci. 2021, 11, 3521. https://doi.org/10.3390/app11083521

Son J, Lee H. Contact-Area-Changeable CMP Conditioning for Enhancing Pad Lifetime. Applied Sciences. 2021; 11(8):3521. https://doi.org/10.3390/app11083521

Chicago/Turabian StyleSon, Jungyu, and Hyunseop Lee. 2021. "Contact-Area-Changeable CMP Conditioning for Enhancing Pad Lifetime" Applied Sciences 11, no. 8: 3521. https://doi.org/10.3390/app11083521

APA StyleSon, J., & Lee, H. (2021). Contact-Area-Changeable CMP Conditioning for Enhancing Pad Lifetime. Applied Sciences, 11(8), 3521. https://doi.org/10.3390/app11083521