Research on O-ring Dimension Measurement Algorithm Based on Cubic Spline Interpolation

Abstract

:1. Introduction

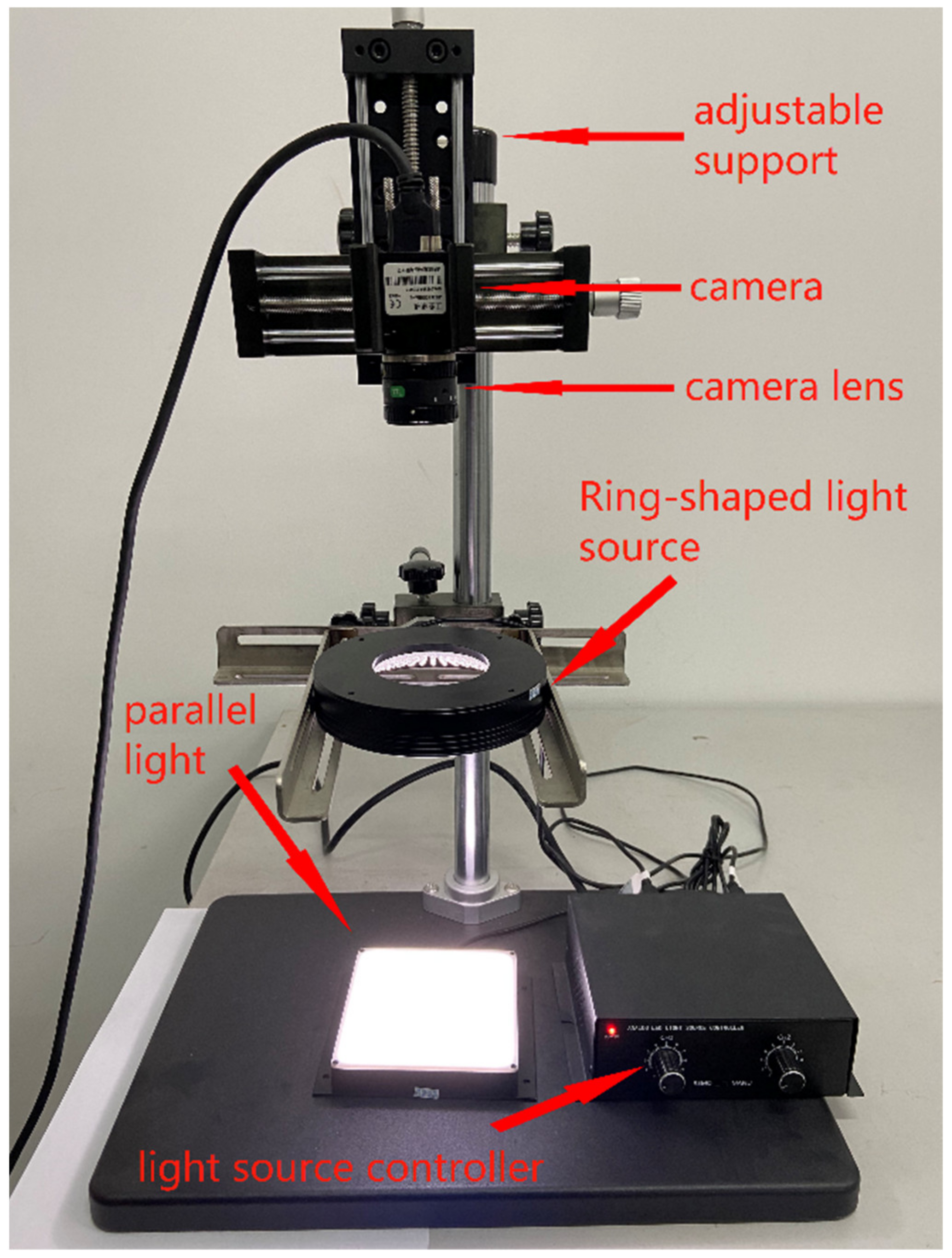

2. Image Acquisition System Design

3. O-Ring Dimension Measurement Algorithm Design

3.1. Pixel-Level Edge Algorithm Based on Noise-Resistant Mathematical Morphology

3.2. Sub-Pixel Level Edge Measurement Algorithm Based on Cubic Spline Interpolation

- (1)

- , i.e., ,, is continuous on ;

- (2)

- is a cubic polynomial over each small interval ;

- (3)

- (1)

- and the positive and negative signs on both sides of are not equal.

- (2)

- If there are multiple inflection points for the second order derivative , choose the minimal value point on the first order derivative.

3.3. Least Square Method for Circle Fitting

4. Experiments and Discussion

4.1. Calibration Experiments

4.2. Measurement Experiments

4.3. Analysis of Results

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Davies, P.; Le Gac, P.Y.; Ciausu, V.; Gallois, H. Testing of nitrile rubber joints for a deep submergence vehicle. Polym. Test. 2020, 90, 106630. [Google Scholar] [CrossRef]

- Koemmling, A.; Jaunich, M.; Goral, M.; Wolff, D. Insights for lifetime predictions of O-ring seals from five-year long-term aging tests. Polym. Degrad. Stab. 2020, 179, 109278. [Google Scholar] [CrossRef]

- Mo, Y.-M.; Gong, Y.; Yang, Z.-G. Failure analysis on the O-ring of radial thrust bearing room of main pump in a nuclear power plant. Eng. Fail. Anal. 2020, 115, 104673. [Google Scholar] [CrossRef]

- Oskoei, M.A.; Hu, H. A Survey on Edge Detection Methods; University of Essex: Colchester, UK, 2010; p. 33. [Google Scholar]

- Zhang, H.; Meng, C.; Bai, X.; Li, Z. Rock-ring detection accuracy improvement in infrared satellite image with sub-pixel edge detection. IET Image Process. 2019, 13, 729–735. [Google Scholar] [CrossRef]

- Hu, H.; Zhang, B.; Xu, D.; Xia, G. Battery Surface and Edge Defect Inspection Based on Sub-Regional Gaussian and Moving Average Filter. Appl. Sci. 2019, 9, 3418. [Google Scholar] [CrossRef] [Green Version]

- Peng, G.; Zhang, Z.; Li, W. Computer vision algorithm for measurement and inspection of O-rings. Measurement 2016, 94, 828–836. [Google Scholar] [CrossRef]

- Liu, J.; Du, H.; Du, Q. Improvement of sub-pixel morphological anti-aliasing algorithm. J. Comput. Appl. 2017, 37, 2871–2874. [Google Scholar]

- Ezekiel, S.; Lang, M. Edge Detection Using Minmax Measures; ACTA Press: Calgary, AB, Canada, 2003. [Google Scholar]

- Zhang, H.; Jin, X. A Method for New Energy Electric Vehicle Charging Hole Detection and Location Based on Machine Vision. In Proceedings of the 2016 5th International Conference on Environment, Materials, Chemistry And Power Electronics, Zhengzhou, China, 11–12 April 2016; pp. 392–399. [Google Scholar]

- Jishen, S.; Edward, J.D. The analysis of morphological filters with multiple structuring elements. Comput. Vis. Graph. Image Process. 1990, 50, 308–328. [Google Scholar]

- Maragos, P. Differential morphology and image processing. IEEE Trans. Image Process. 1996, 5, 922–937. [Google Scholar] [CrossRef]

- Zheng, L.; Lawlor, B.; Katko, B.J.; McGuire, C.; Zanteson, J.; Eliasson, V. Image Processing and Edge Detection Techniques to Quantify Shock Wave Dynamics Experiments. Exp. Tech. 2020. [Google Scholar] [CrossRef]

- Qiaoming, W.; Lei, W.; Hui, L.; Chun, L. Correction of Systematic Error in Sub-pixel Edge Location. In Proceedings of the 2020 IEEE 14th International Conference on Anti-Counterfeiting, Security, and Identification (ASID), Xiamen, China, 30 October–1 November 2020. [Google Scholar]

- Huang, C.; Jin, W.; Xu, Q.; Liu, Z.; Xu, Z. Sub-Pixel Edge Detection Algorithm Based on Canny-Zernike Moment Method. J. Circuits Syst. Comput. 2020, 29, 2050238. [Google Scholar] [CrossRef]

- Wang, G.; Xiao, L.; Jiang, Z.; Song, Y.; He, A. Sub-pixel multifractal method for image processing application. Acta Opt. Sin. 2006, 26, 1345–1349. [Google Scholar]

- Touqir, I.; Saleem, M.; Siddiqui, A.M. Novel wavelet based edge detection. Wseas Trans. Signal Process. 2006, 2, 1248–1253. [Google Scholar]

- Wang, G. A sub-pixel circle detection algorithm combined with improved RHT and fitting. Multimed. Tools Appl. 2020, 79, 29825–29843. [Google Scholar] [CrossRef]

- Feng, Y.; Yang, T.; Niu, Y. Subpixel Computer Vision Detection Based on Wavelet Transform. IEEE Access 2020, 8, 88273–88281. [Google Scholar] [CrossRef]

- Kanchanatripop, P.; Zhang, D. Adaptive Image Edge Extraction Based on Discrete Algorithm and Classical Canny Operator. Symmetry 2020, 12, 1749. [Google Scholar] [CrossRef]

- Chen, Y.-Q.; Zhu, X.-J.; Wang, Y.-H.; Guo, J.-J.; Chen, L.-Q. Subpixel edge detection of image for industrial thin sheet parts based on fuzzy clustering. Modul. Mach. Tool Autom. Manuf. Tech. 2014, 10, 66–68. [Google Scholar]

- Li, B.; Hu, H.-B.; Zhuang, T.-G. Contours embellishment using adaptive cubic B-spline in image segmentation. J. Infrared Millim. Waves 2001, 20, 401–405. [Google Scholar] [CrossRef]

- Xie, X.; Ge, S.; Xie, M.; Hu, F.; Jiang, N. An improved industrial sub-pixel edge detection algorithm based on coarse and precise location. J. Ambient Intell. Humaniz. Comput. 2020, 11, 2061–2070. [Google Scholar] [CrossRef]

- Di, Y.; Li, M.-Y.; Qiao, T.; Lu, N. Edge detection and mathematic fitting for corneal surface with Matlab software. Int. J. Ophthalmol. 2017, 10, 336–342. [Google Scholar]

- Gu, Y.; Lu, Y.; Yang, H.; Huo, J. Concentric Circle Detection Method Based on Minimum Enveloping Circle and Ellipse Fitting. In Proceedings of the 2019 IEEE 10th International Conference on Software Engineering And Service Science, Beijing, China, 18–20 October 2009; pp. 523–527. [Google Scholar]

- Tao, W.; Zhong, H.; Chen, X.; Selami, Y.; Zhao, H. A new fitting method for measurement of the curvature radius of a short arc with high precision. Meas. Sci. Technol. 2018, 29, 075014. [Google Scholar] [CrossRef]

- Hagara, M.; Kulla, P. Edge Detection with Sub-pixel Accuracy Based on Approximation of Edge with Erf Function. Radioengineering 2011, 20, 516–524. [Google Scholar]

- Chang, W.-T.; Su, C.-H.; Guo, D.-X.; Tang, G.-R.; Shiou, F.-J. Automated optical inspection for the runout tolerance of circular saw blades. Int. J. Adv. Manuf. Technol. 2013, 66, 565–582. [Google Scholar] [CrossRef]

| No. | Sub-Pixel Values for 17 mm Standard Block Diameter (Pixel) | K Value (mm/Pixel) |

|---|---|---|

| 1 | 451.9374 | 0.037616 |

| 2 | 451.956 | 0.037614 |

| 3 | 451.8846 | 0.03762 |

| 4 | 451.7348 | 0.037633 |

| 5 | 451.8928 | 0.03762 |

| 6 | 452.1574 | 0.037598 |

| 7 | 451.925 | 0.037617 |

| 8 | 451.5642 | 0.037647 |

| 9 | 451.9922 | 0.037611 |

| 10 | 451.8948 | 0.037619 |

| 11 | 451.702 | 0.037635 |

| 12 | 452.0722 | 0.037605 |

| 13 | 451.8054 | 0.037627 |

| 14 | 451.7554 | 0.037631 |

| 15 | 451.6664 | 0.037638 |

| 16 | 451.7822 | 0.037629 |

| 17 | 451.7796 | 0.037629 |

| 18 | 451.9564 | 0.037614 |

| 19 | 451.9132 | 0.037618 |

| 20 | 451.7258 | 0.037633 |

| Algorithm of This Paper | Sobel Algorithm | Canny Algorithm | ||||

|---|---|---|---|---|---|---|

| No. | Outer Diameter | Wire Diameter | Outer Diameter | Wire Diameter | Outer Diameter | Wire Diameter |

| 1 | 20.062 | 2.286 | 19.847 | 2.260 | 19.906 | 2.267 |

| 2 | 20.063 | 2.293 | 19.841 | 2.261 | 19.899 | 2.266 |

| 3 | 20.064 | 2.285 | 19.840 | 2.262 | 19.899 | 2.268 |

| 4 | 20.054 | 2.289 | 19.837 | 2.260 | 19.896 | 2.268 |

| 5 | 20.065 | 2.289 | 19.855 | 2.265 | 19.913 | 2.271 |

| 6 | 20.070 | 2.287 | 19.848 | 2.261 | 19.907 | 2.269 |

| 7 | 20.076 | 2.292 | 19.860 | 2.264 | 19.920 | 2.269 |

| 8 | 20.067 | 2.290 | 19.852 | 2.264 | 19.912 | 2.271 |

| 9 | 20.058 | 2.291 | 19.840 | 2.260 | 19.899 | 2.266 |

| 10 | 20.068 | 2.279 | 19.856 | 2.262 | 19.915 | 2.269 |

| 11 | 20.068 | 2.289 | 19.853 | 2.262 | 19.912 | 2.268 |

| 12 | 20.062 | 2.286 | 19.844 | 2.261 | 19.899 | 2.267 |

| 13 | 20.066 | 2.290 | 19.847 | 2.261 | 19.905 | 2.267 |

| 14 | 20.077 | 2.293 | 19.861 | 2.264 | 19.920 | 2.273 |

| 15 | 20.074 | 2.290 | 19.852 | 2.262 | 19.907 | 2.266 |

| 16 | 20.069 | 2.289 | 19.847 | 2.261 | 19.901 | 2.268 |

| 17 | 20.066 | 2.289 | 19.843 | 2.261 | 19.896 | 2.264 |

| 18 | 20.079 | 2.289 | 19.861 | 2.263 | 19.917 | 2.269 |

| 19 | 20.082 | 2.291 | 19.863 | 2.265 | 19.916 | 2.269 |

| 20 | 20.085 | 2.292 | 19.860 | 2.265 | 19.914 | 2.271 |

| Average value | 20.069 | 2.289 | 19.850 | 2.262 | 19.908 | 2.268 |

| Mean Square Error | 0.00480 | 0.000132 | 0.02246 | 0.00143 | 0.00858 | 0.00101 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haibing, H.; Zheng, X.; Yin, J.; Wang, Y. Research on O-ring Dimension Measurement Algorithm Based on Cubic Spline Interpolation. Appl. Sci. 2021, 11, 3716. https://doi.org/10.3390/app11083716

Haibing H, Zheng X, Yin J, Wang Y. Research on O-ring Dimension Measurement Algorithm Based on Cubic Spline Interpolation. Applied Sciences. 2021; 11(8):3716. https://doi.org/10.3390/app11083716

Chicago/Turabian StyleHaibing, Hu, Xipeng Zheng, Jiajie Yin, and Yueyan Wang. 2021. "Research on O-ring Dimension Measurement Algorithm Based on Cubic Spline Interpolation" Applied Sciences 11, no. 8: 3716. https://doi.org/10.3390/app11083716

APA StyleHaibing, H., Zheng, X., Yin, J., & Wang, Y. (2021). Research on O-ring Dimension Measurement Algorithm Based on Cubic Spline Interpolation. Applied Sciences, 11(8), 3716. https://doi.org/10.3390/app11083716