Design of the Class-E Power Amplifier with Finite DC Feed Inductance under Maximum-Rating Constraints

Abstract

:1. Introduction

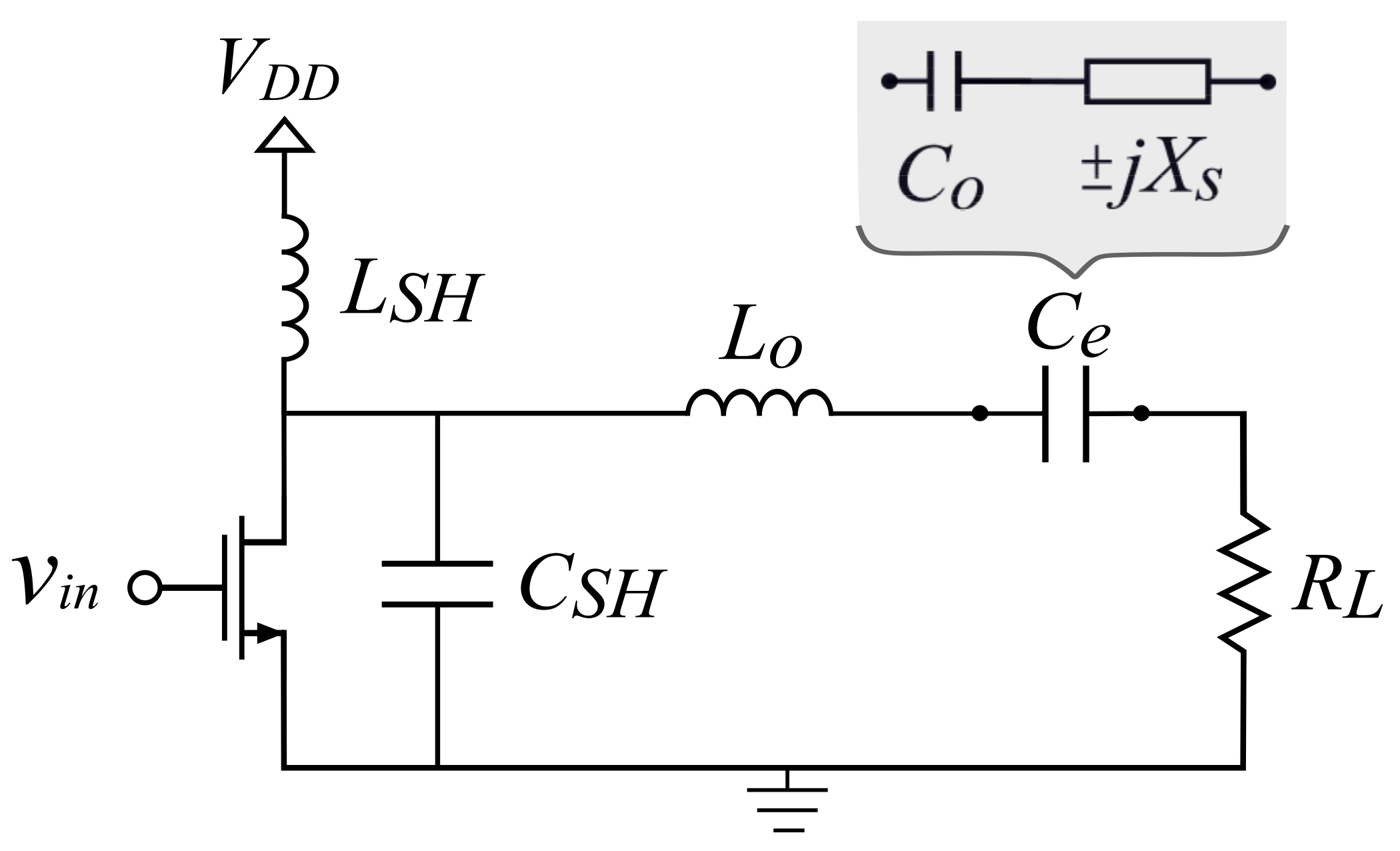

2. Ideal Class-E PA with FDI Model

3. Basic Design set of the Ideal Class-E PA with FDI Model

4. Proposed Analytical Expressions of the Maximum-Rating Constraints

4.1. Average Supply Current

4.2. Peak Load Voltage

4.3. Peak Load Current

4.4. Maximum Voltage Supported by the Switch

4.5. Maximum Current Supported by the Switch

4.6. RMS Current Supported by the Switch

4.7. Maximum Voltage Supported by and

4.8. Maximum Voltage Supported by

4.9. RMS Current Supported by

5. Accuracy of the Proposed Expressions of the Maximum-Rating Constrains

6. Conclusions

7. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PA | Power Amplifier |

| RF | Radio-Frequency |

| ZVS | Zero Voltage Switching |

| ZVDS | Zero Voltage Derivative Switching |

| FDI | Finite DC-Feed Inductance |

| VLSI | Very Large-Scale Integration |

| MAPE | Mean Absolute Percentage Error |

| RMS | Root Mean Square |

References

- Liu, S.; Liu, M.; Han, S.; Zhu, X.; Ma, C. Tunable Class E2 DC–DC Converter with High Efficiency and Stable Output Power for 6.78-MHz Wireless Power Transfer. IEEE Trans. Power Electron. 2018, 33, 6877–6886. [Google Scholar] [CrossRef]

- Qaragoez, Y.M.; Ali, I.; Kim, S.J.; Lee, K. A 5.8 GHz 9.5 dBm Class-E Power Amplifier for DSRC Applications. In Proceedings of the 2019 International SoC Design Conference (ISOCC), Jeju Island, Korea, 6–9 October 2019; pp. 202–203. [Google Scholar]

- Silva-Pereira, M.; Caldinhas Vaz, J. A Single-Ended Modified Class-E PA with HD2 Rejection for Low-Power RF Applications. IEEE Solid-State Circuits Lett. 2018, 1, 22–25. [Google Scholar] [CrossRef]

- Gorain, C.; Sadhu, P.K.; Raman, R. Analysis of High-Frequency Class E Resonant Inverter and its Application in an Induction Heater. In Proceedings of the 2018 2nd International Conference on Power, Energy and Environment: Towards Smart Technology (ICEPE), Shillong, India, 1–2 June 2018; pp. 1–6. [Google Scholar]

- Mangkalajan, S.; Ekkaravarodome, C.; Jirasereeamornkul, K.; Thounthong, P.; Higuchi, K.; Kazimierczuk, M.K. A Single-Stage LED Driver Based on ZCDS Class-E Current-Driven Rectifier as a PFC for Street-Lighting Applications. IEEE Trans. Power Electron. 2018, 33, 8710–8727. [Google Scholar] [CrossRef]

- Acar, M.; Annema, A.J.; Nauta, B. Analytical Design Equations for Class-E Power Amplifiers. IEEE Trans. Circuits Syst. I Reg. Pap. 2007, 54, 2706–2717. [Google Scholar] [CrossRef] [Green Version]

- Fajardo, A.; de Sousa, F.R. Integrated CMOS class-E power amplifier for self-sustaining wireless power transfer system. In Proceedings of the 2016 29th Symposium on Integrated Circuits and Systems Design (SBCCI), Belo Horizonte, Brazil, 29 August–3 September 2016; pp. 1–6. [Google Scholar] [CrossRef] [Green Version]

- Casallas, I.; Paez-Rueda, C.I.; Perilla, G.; Pérez, M.; Fajardo, A. Design Methodology of the Class-E Power Amplifier with Finite Feed Inductance—A Tutorial Approach. Appl. Sci. 2020, 10, 8765. [Google Scholar] [CrossRef]

- Acar, M.; Annema, A.; Nauta, B. Generalized Design Equations for Class-E Power Amplifiers with Finite DC Feed Inductance. In Proceedings of the 36th European Microwave Conference, Manchester, UK, 10–15 September 2006; pp. 1308–1311. [Google Scholar] [CrossRef] [Green Version]

- Ewing, G.D. High-Efficiency Radio-Frequency Power Amplifiers. Ph.D. Thesis, Oregon State University, Corvallis, OR, USA, 1964. [Google Scholar]

- Kreißig, M.; Ellinger, F. Extended analysis of idealized class-E operation with finite DC-feed inductance and preservation of zero volt switching at variable load. In Proceedings of the 2017 14th International Conference on Synthesis, Modeling, Analysis and Simulation Methods and Applications to Circuit Design (SMACD), Taormina, Italy, 12–15 June 2017; pp. 1–4. [Google Scholar]

- Sokal, N.O. Class-E RF power amplifiers. Qex 2001, 204, 9–20. [Google Scholar]

- Sadeghpour, R.; Nabavi, A. Design Procedure of Quasi-Class-E Power Amplifier for Low-Breakdown-Voltage Devices. IEEE Trans. Circuits Syst. I Reg. Pap. 2014, 61, 1416–1428. [Google Scholar] [CrossRef]

- Fajardo, A.; de Sousa, F.R. Simple expression for estimating the switch peak voltage on the class-E amplifier with finite DC-feed inductance. In Proceedings of the 2016 IEEE 7th Latin American Symposium on Circuits & Systems (LASCAS), Florianopolis, Brazil, 28 February–2 March 2016; pp. 183–186. [Google Scholar] [CrossRef] [Green Version]

- Sokal, N.; Mediano, A. Redefining the optimum RF Class-E switch-voltage waveform, to correct a long-used incorrect waveform. In Proceedings of the 2013 IEEE MTT-S International Microwave Symposium Digest (MTT), Boston, MA, USA, 17–22 June 2013; pp. 1–3. [Google Scholar] [CrossRef]

- Özcelep, Y.; Kuntman, A.; Kuntman, H.; Yarman, S. High voltage stress effects on power MOSFETs in switching DC-DC converters. In Proceedings of the 2011 International Conference Advanced Power System Automation and Protection, Beijing, China, 16–20 October 2011; Volume 2, pp. 1278–1282. [Google Scholar]

- Shilo, G.; Kovalenko, D.; Gaponenko, M. Tolerance design and electronics elements’ selection under external influences. In Proceedings of the 2010 International Conference Modern Problems of Radio Engineering, Telecommunications and Computer Science (TCSET), Lviv, Ukraine, 23–27 February 2010; p. 367. [Google Scholar]

- Surakitbovorn, K.N.; Rivas-Davila, J.M. On the Optimization of a Class-E Power Amplifier with GaN HEMTs at Megahertz Operation. IEEE Trans. Power Electron. 2020, 35, 4009–4023. [Google Scholar] [CrossRef]

- Song, Y.; Lee, S.; Cho, E.; Lee, J.; Nam, S. A CMOS Class-E Power Amplifier with Voltage Stress Relief and Enhanced Efficiency. IEEE Trans. Microw. Theory Tech. 2010, 58, 310–317. [Google Scholar] [CrossRef]

- Jee, S.; Moon, J.; Kim, J.; Son, J.; Kim, B. Switching Behavior of Class-E Power Amplifier and Its Operation Above Maximum Frequency. IEEE Trans. Microw. Theory Tech. 2012, 60, 89–98. [Google Scholar] [CrossRef]

- Suetsugu, T.; Kazimierczuk, M.K. Maximum Operating Frequency of Class-E Amplifier at Any Duty Ratio. IEEE Trans. Circuits Syst. II Exp. Briefs 2008, 55, 768–770. [Google Scholar] [CrossRef]

- Mury, T.; Fusco, V. Exploring figures of merit associated with the suboptimum operation of class-E power amplifiers. IET Circuits Devices Syst. 2007, 1, 401–407. [Google Scholar] [CrossRef]

- Zulinski, R.; Steadman, J. Class E Power Amplifiers and Frequency Multipliers with finite DC-Feed Inductance. IEEE Trans. Circuits Syst. 1987, 34, 1074–1087. [Google Scholar] [CrossRef]

- Smith, G.H.; Zulinski, R.E. An exact analysis of class E amplifiers with finite DC-feed inductance at any output Q. IEEE Trans. Circuits Syst. 1990, 37, 530–534. [Google Scholar] [CrossRef]

- Li, C.; Yam, Y. Maximum frequency and optimum performance of class E power amplifiers. Proc. IEEE Circuits Devices Syst. 1994, 141, 174–184. [Google Scholar] [CrossRef]

- Iwadare, M.; Mori, S.; Ikeda, K. Even Harmonic Resonant Class E Tuned Power Amplifier without RF Choke. Electron. Commun. Jpn. Part 1: Commun. 1996, 79, 23–30. [Google Scholar] [CrossRef]

- Hasani, J.Y.; Kamarei, M. Analysis and Optimum Design of a Class E RF Power Amplifier. IEEE Trans. Circuits Syst. I Reg. Pap. 2008, 55, 1759–1768. [Google Scholar] [CrossRef]

- Du, X.; Nan, J.; Chen, W.; Shao, Z. ’New’ solutions of Class-E power amplifier with finite dc feed inductor at any duty ratio. IET Circuits Devices Syst. 2014, 8, 311–321. [Google Scholar] [CrossRef]

- Fajardo, A.; Páez, C.; Perilla, G.; Casallas, I. Design methodology of Class-E power amplifier using feed inductance tuning for high-efficiency operation in wireless power transfer applications. In Proceedings of the 2020 IEEE Conference ANDESCON, Quito, Ecuador, 13–16 October 2020. [Google Scholar]

- De Venuto, D.; Mezzina, G.; Rabaey, J. Automatic 3D Design for Efficiency Optimization of a Class E Power Amplifier. IEEE Trans. Circuits Syst. II Express Briefs 2018, 65, 201–205. [Google Scholar] [CrossRef]

- Erickson, R.W.; Maksimovic, D. Fundamentals of Power Electronics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007; pp. 483–486. [Google Scholar]

- Mediano, A.; Molina-Gaudo, P.; Bernal, C. Design of Class E Amplifier with Nonlinear and Linear Shunt Capacitances for Any Duty Cycle. IEEE Trans. Microw. Theory Tech. 2007, 55, 484–492. [Google Scholar] [CrossRef]

- Kazimierczuk, M.; Puczko, K. Exact analysis of class E tuned power amplifier at any Q and switch duty cycle. IEEE Trans. Circuits Syst. 1987, 34, 149–159. [Google Scholar] [CrossRef]

| Coefficient Name | ||

|---|---|---|

| 0.4532 | 3.6150 | |

| −1.2590 | −7.4820 | |

| 0.9159 | 3.6860 | |

| 1.2790 | −7.5180 | |

| 1.3440 | 7.6720 | |

| −0.6721 | 19.4100 | |

| 0 | −11.8700 | |

| 0 | −15.7400 | |

| −1.5890 | 9.7070 | |

| −0.1598 | 0.1672 | |

| 0.7299 | −0.06993 | |

| 1.0390 | 0 |

| Coefficient Name | ||

|---|---|---|

| 0.2769 | 0.7978 | |

| −0.6647 | −1.6730 | |

| 0.4641 | 0.8805 | |

| −0.9009 | −2.1030 | |

| 1.1380 | 1.8730 | |

| 2.2670 | 4.9180 | |

| −1.6420 | −2.8230 | |

| −2.3650 | −4.1700 | |

| 1.5920 | 2.4510 |

| ID * | q | D | [V] | [W] | f [MHz] | |

|---|---|---|---|---|---|---|

| 1 | 1.412 | 0.5 | 6 | 2 | 1 | 80 |

| 2 | 1.412 | 0.5 | 6 | 2 | 1 | 20 |

| 3 | 1.412 | 0.5 | 6 | 2 | 1 | 10 |

| 4 | 1.412 | 0.5 | 6 | 2 | 1 | 5 |

| 5 | 1.412 | 0.3 | 6 | 2 | 1 | 20 |

| 6 | 1.412 | 0.4 | 6 | 2 | 1 | 20 |

| 7 | 1.412 | 0.6 | 6 | 2 | 1 | 20 |

| 8 | 1.412 | 0.7 | 6 | 2 | 1 | 20 |

| 9 | 0.4 | 0.5 | 6 | 2 | 1 | 20 |

| 10 | 0.8 | 0.5 | 6 | 2 | 1 | 20 |

| 11 | 1.2 | 0.5 | 6 | 2 | 1 | 20 |

| 12 | 1.6 | 0.5 | 6 | 2 | 1 | 20 |

| ID | |||||

|---|---|---|---|---|---|

| 1 | 0.83 | 1.21 | 0.26 | 15.66 | −12.83 |

| 2 | 0.83 | 1.21 | 0.26 | 15.66 | −12.83 |

| 3 | 0.83 | 1.21 | 0.26 | 15.66 | −12.83 |

| 4 | 0.83 | 1.21 | 1.21 | 15.66 | −12.83 |

| 5 | 0.25 | 0.58 | 2.17 | −0.36 | −4.54 |

| 6 | 0.58 | 0.62 | 1.33 | 3.94 | −8.49 |

| 7 | 0.84 | 3.83 | −0.41 | 47.95 | −14.14 |

| 8 | 0.87 | 14.79 | −0.82 | 156.76 | 11.79 |

| 9 | 0.55 | 34.47 | −0.54 | −52.31 | −24.79 |

| 10 | 0.61 | 7.09 | −0.44 | 57.87 | −46.62 |

| 11 | 0.75 | 2.14 | −0.14 | −9.96 | −46.75 |

| 12 | 0.70 | 0.93 | 0.82 | 12.34 | 3.79 |

| ID | [] | [H] | [nF] | [H] | [pF] |

|---|---|---|---|---|---|

| 1 | 24.54 | 2.86 | 4.44 | 312.43 | 81.07 |

| 2 | 24.54 | 2.86 | 4.44 | 78.11 | 324.30 |

| 3 | 24.54 | 2.86 | 4.44 | 39.05 | 648.58 |

| 4 | 24.54 | 2.86 | 4.44 | 19.53 | 1297.15 |

| 5 | 2.26 | 0.41 | 30.73 | 7.20 | 3115.95 |

| 6 | 12.06 | 1.03 | 12.30 | 38.38 | 632.94 |

| 7 | 25.27 | 9.20 | 1.38 | 80.45 | 320.20 |

| 8 | 27.22 | 36.84 | 0.34 | 86.64 | 298.12 |

| 9 | 11.03 | 54.65 | 2.90 | 35.10 | 763.48 |

| 10 | 13.54 | 12.45 | 3.18 | 43.10 | 615.12 |

| 11 | 20.45 | 4.61 | 3.81 | 65.09 | 397.95 |

| 12 | 17.45 | 1.85 | 5.35 | 55.54 | 441.90 |

| Parameter \ID | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | MAPE | Std. Dev. | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sim. | 0.33 | 0.34 | 0.34 | 0.35 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | |||

| [A] | Cal. | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | ||

| % Er. | 0.01 | 1.00 | 1.87 | 3.98 | 1.84 | 1.74 | 1.69 | 2.63 | 1.66 | 1.55 | 1.14 | 1.45 | 1.72 | 0.95 | |

| Sim. | 0.40 | 0.41 | 0.41 | 0.42 | 1.31 | 0.57 | 0.41 | 0.40 | 0.62 | 0.56 | 0.45 | 0.47 | |||

| [A] | Cal. | 0.40 | 0.40 | 0.40 | 0.40 | 1.33 | 0.58 | 0.40 | 0.38 | 0.60 | 0.54 | 0.44 | 0.48 | ||

| % Er. | 0.08 | 0.90 | 1.94 | 4.84 | 1.69 | 0.92 | 3.02 | 4.84 | 3.21 | 3.06 | 2.28 | 1.48 | 2.35 | 1.50 | |

| Sim. | 9.92 | 10.00 | 10.10 | 10.41 | 2.96 | 6.88 | 10.37 | 10.97 | 6.86 | 7.59 | 9.26 | 8.23 | |||

| [V] | Cal. | 9.91 | 9.91 | 9.91 | 9.91 | 3.01 | 6.94 | 10.05 | 10.43 | 6.64 | 7.36 | 9.04 | 8.35 | ||

| % Er. | 0.08 | 0.91 | 1.95 | 4.85 | 1.76 | 0.89 | 3.00 | 4.85 | 3.25 | 3.07 | 2.29 | 1.46 | 2.36 | 1.51 | |

| Sim. | 21.90 | 22.12 | 22.33 | 22.80 | 16.38 | 18.76 | 27.71 | 37.97 | 21.87 | 21.91 | 22.01 | 22.38 | |||

| [V] | Cal. | 21.98 | 21.98 | 21.98 | 21.98 | 15.70 | 18.32 | 27.48 | 36.64 | 21.38 | 21.62 | 21.86 | 22.10 | ||

| % Er. | 0.38 | 0.61 | 1.54 | 3.57 | 4.12 | 2.34 | 0.82 | 3.51 | 2.27 | 1.34 | 0.69 | 1.27 | 1.87 | 1.28 | |

| Sim. | 0.88 | 0.88 | 0.88 | 0.88 | 2.22 | 1.41 | 0.78 | 0.74 | 0.95 | 0.93 | 0.91 | 0.93 | |||

| [A] | Cal. | 0.88 | 0.88 | 0.88 | 0.88 | 2.20 | 1.39 | 0.78 | 0.73 | 0.95 | 0.94 | 0.91 | 0.92 | ||

| % Er. | 0.33 | 0.14 | 0.49 | 0.73 | 0.60 | 1.25 | 0.30 | 1.10 | 0.44 | 0.26 | 0.16 | 1.28 | 0.59 | 0.41 | |

| Sim. | 0.51 | 0.51 | 0.53 | 0.54 | 0.73 | 0.62 | 0.50 | 0.49 | 0.52 | 0.52 | 0.52 | 0.54 | |||

| [A] | Cal. | 0.51 | 0.51 | 0.51 | 0.51 | 0.68 | 0.59 | 0.48 | 0.44 | 0.52 | 0.51 | 0.52 | 0.50 | ||

| % Er. | 0.20 | 0.39 | 3.66 | 6.71 | 7.00 | 4.18 | 3.40 | 10.20 | 1.01 | 0.72 | 0.05 | 6.83 | 3.70 | 3.37 | |

| Sim. | 784.80 | 191.44 | 92.48 | 43.32 | 63.22 | 139.95 | 191.33 | 198.65 | 137.71 | 150.26 | 176.63 | 167.18 | |||

| [V] | Cal. | 792.58 | 198.14 | 99.07 | 49.54 | 60.15 | 138.89 | 201.09 | 208.68 | 132.82 | 147.19 | 180.88 | 167.08 | ||

| % Er. | 0.99 | 3.51 | 7.13 | 14.36 | 4.85 | 0.76 | 5.10 | 5.05 | 3.55 | 2.05 | 2.40 | 0.06 | 4.15 | 3.83 | |

| Sim. | 800.30 | 206.83 | 107.69 | 58.21 | 74.12 | 152.49 | 206.84 | 214.78 | 132.21 | 147.65 | 184.75 | 180.77 | |||

| [V] | Cal. | 792.58 | 198.15 | 99.07 | 49.54 | 67.93 | 144.84 | 197.74 | 204.66 | 125.56 | 140.63 | 176.89 | 172.45 | ||

| % Er. | 0.96 | 4.20 | 8.00 | 14.89 | 8.35 | 5.01 | 4.40 | 4.71 | 5.03 | 4.75 | 4.26 | 4.60 | 5.76 | 3.43 | |

| Sim. | 15.90 | 16.12 | 16.33 | 16.80 | 10.38 | 12.76 | 21.71 | 31.97 | 15.87 | 15.91 | 16.01 | 16.38 | |||

| [V] | Cal. | 15.98 | 15.98 | 15.98 | 15.98 | 9.70 | 12.32 | 21.48 | 30.64 | 15.38 | 15.62 | 15.86 | 16.10 | ||

| % Er. | 0.53 | 0.84 | 2.10 | 4.84 | 6.50 | 3.44 | 1.05 | 4.17 | 3.13 | 1.85 | 0.95 | 1.73 | 2.59 | 1.85 | |

| Sim. | 0.52 | 0.53 | 0.53 | 0.54 | 2.33 | 1.08 | 0.37 | 0.34 | 0.34 | 0.35 | 0.42 | 0.72 | |||

| [A] | Cal. | 0.53 | 0.53 | 0.53 | 0.53 | 2.36 | 1.10 | 0.36 | 0.34 | 0.33 | 0.35 | 0.42 | 0.72 | ||

| % Er. | 0.34 | 0.42 | 1.06 | 2.57 | 1.00 | 1.60 | 1.14 | 2.67 | 2.77 | 1.37 | 0.36 | 0.78 | 1.34 | 0.89 | |

| Sweep | Amplifier IDs | Max.% Er. | Min. % Er. | MAPE | Std. Dev. |

|---|---|---|---|---|---|

| 1, 2, 3, and 4 | 14.89 | 0.01 | 2.70 | 3.48 | |

| D | 5, 6, 7, and 8 | 10.20 | 0.30 | 3.19 | 2.26 |

| q | 9, 10, 11, and 12 | 6.83 | 0.05 | 2.05 | 1.53 |

| FoMs \ID | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

[W] | Sim. | 2.00 | 2.02 | 2.04 | 2.08 | 2.04 | 2.04 | 2.03 | 2.05 | 2.03 | 2.03 | 2.02 | 2.03 |

| Th. | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | |

[W] | Sim. | 2.00 | 2.02 | 2.04 | 2.08 | 2.04 | 2.04 | 2.03 | 2.05 | 2.03 | 2.03 | 2.02 | 2.03 |

| Th. | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | |

| [%] | Sim. | 99.99 | 99.99 | 99.99 | 99.99 | 99.97 | 99.98 | 99.98 | 99.95 | 99.99 | 99.99 | 99.99 | 99.99 |

| Th. | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | |

[dBc] | Sim. | −47.12 | −34.88 | −28.78 | −22.57 | −31.41 | −34.93 | −32.35 | −30.58 | −31.70 | −32.54 | −34.21 | −33.20 |

| Th. | |||||||||||||

[dBc] | Sim. | −63.42 | −51.12 | −44.76 | −38.03 | −49.95 | −56.12 | −43.50 | −38.43 | −47.84 | −48.72 | −50.44 | −49.25 |

| Th. | |||||||||||||

[%] | Sim. | 0.45 | 1.83 | 3.69 | 7.56 | 2.71 | 1.80 | 2.51 | 3.24 | 2.64 | 2.39 | 1.97 | 2.22 |

| Th. | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casallas, I.; Paez-Rueda, C.-I.; Perilla, G.; Pérez, M.; Fajardo, A. Design of the Class-E Power Amplifier with Finite DC Feed Inductance under Maximum-Rating Constraints. Appl. Sci. 2021, 11, 3727. https://doi.org/10.3390/app11093727

Casallas I, Paez-Rueda C-I, Perilla G, Pérez M, Fajardo A. Design of the Class-E Power Amplifier with Finite DC Feed Inductance under Maximum-Rating Constraints. Applied Sciences. 2021; 11(9):3727. https://doi.org/10.3390/app11093727

Chicago/Turabian StyleCasallas, Ingrid, Carlos-Ivan Paez-Rueda, Gabriel Perilla, Manuel Pérez, and Arturo Fajardo. 2021. "Design of the Class-E Power Amplifier with Finite DC Feed Inductance under Maximum-Rating Constraints" Applied Sciences 11, no. 9: 3727. https://doi.org/10.3390/app11093727

APA StyleCasallas, I., Paez-Rueda, C.-I., Perilla, G., Pérez, M., & Fajardo, A. (2021). Design of the Class-E Power Amplifier with Finite DC Feed Inductance under Maximum-Rating Constraints. Applied Sciences, 11(9), 3727. https://doi.org/10.3390/app11093727