Localized Necking Model for Punching Fracture Simulation in Unstiffened and Stiffened Panels

Abstract

1. Introduction

2. Plasticity and Fracture Models

2.1. Stress State Parameters

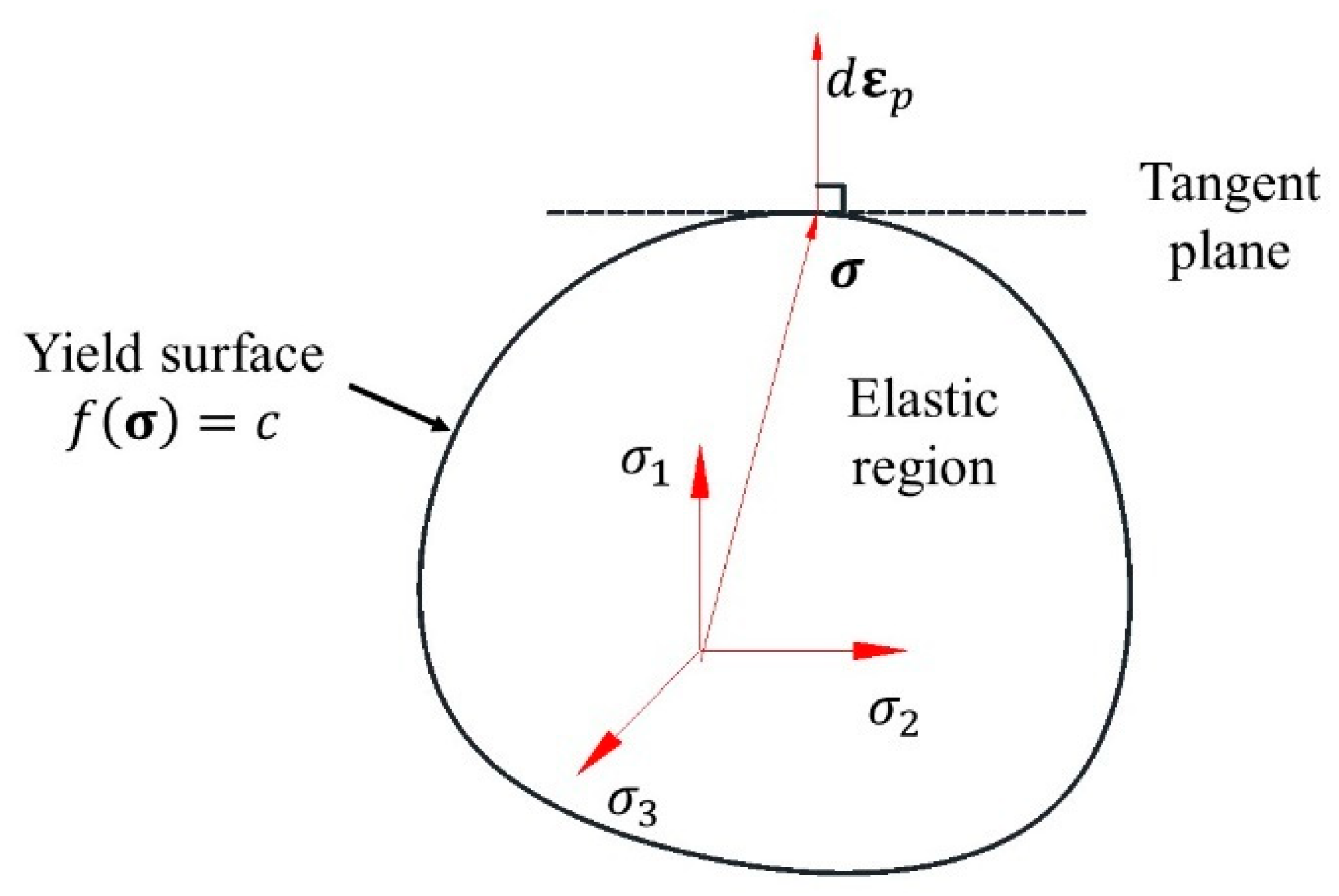

2.2. Plasticity

2.3. Fracture Model

2.3.1. Hosford–Coulomb Fracture Model

2.3.2. Localized Necking Model

3. Fracture Model Formulation

3.1. Material and Experiments

- Standard dog-bone specimen with a 12.5 mm gauge width, denoted as DB [19].

- Central hole specimen with a 6 mm central hole and 20 mm gauge width, denoted as CH.

- A notched tension specimen with a 10 mm gauge width and a notch radius of 20 mm, denoted as NT.

- Plane strain tension specimen with a 16 mm gauge width and a notch radius of 5 mm, denoted as PST.

- Shear specimen, adopted from the design proposed by Park et al. [8], denoted as SH.

3.2. Finite Element Model

3.3. Plasticity Model Parameters Identification

3.4. Fracture Model Parameters Identifications

4. Validation of Fracture Model

4.1. Description of Punch Tests

4.2. Numerical Simulation

4.3. Numerical Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rice, J.R.; Tracey, D.M. On the ductile enlargement of voids in triaxial stress fields*. J. Mech. Phys. Solids 1969, 17, 201–217. [Google Scholar] [CrossRef]

- Oh, S.I.; Chen, C.C.; Kobayashi, S. Ductile Fracture in Axisymmetric Extrusion and Drawing—Part 2: Workability in Extrusion and Drawing. J. Eng. Ind. 1979, 101, 36–44. [Google Scholar] [CrossRef]

- Cerik, B.C.; Choung, J. On the prediction of ductile fracture in ship structures with shell elements at low temperatures. Thin-Walled Struct. 2020, 151, 106721. [Google Scholar] [CrossRef]

- Bai, Y.; Wierzbicki, T. A new model of metal plasticity and fracture with pressure and Lode dependence. Int. J. Plast. 2008, 24, 1071–1096. [Google Scholar] [CrossRef]

- Mohr, D.; Marcadet, S.J. Micromechanically-motivated phenomenological Hosford-Coulomb model for predicting ductile fracture initiation at low stress triaxialities. Int. J. Solids Struct. 2015, 67–68, 40–55. [Google Scholar] [CrossRef]

- Park, S.J.; Cerik, B.C.; Choung, J. Comparative study on ductile fracture prediction of high-tensile strength marine structural steels. Ships Offshore Struct. 2021, 15, S208–S219. [Google Scholar] [CrossRef]

- Cerik, B.C.; Lee, K.; Park, S.-J.; Choung, J. Simulation of ship collision and grounding damage using Hosford-Coulomb fracture model for shell elements. Ocean Eng. 2019, 173, 415–432. [Google Scholar] [CrossRef]

- Park, S.-J.; Lee, K.; Cerik, B.C.; Choung, J. Ductile fracture prediction of EH36 grade steel based on Hosford–Coulomb model. Ships Offshore Struct. 2019, 14, 219–230. [Google Scholar] [CrossRef]

- Cerik, B.C.; Park, B.; Park, S.J.; Choung, J. Modeling, testing and calibration of ductile crack formation in grade DH36 ship plates. Mar. Struct. 2019, 66, 27–43. [Google Scholar] [CrossRef]

- Park, S.-J.; Lee, K.; Cerik, B.C.; Kim, Y.; Choung, J. Ductile Fracture of a Marine Structural Steel based on HC-DSSE Combined Fracture Strain Formulation. J. Soc. Nav. Archit. Korea 2019, 56, 82–93. [Google Scholar] [CrossRef]

- Park, S.-J.; Lee, K.; Cerik, B.C.; Choung, J. Comparative Study on Various Ductile Fracture Models for Marine Structural Steel EH36. J. Ocean Eng. Technol. 2019, 33, 259–271. [Google Scholar] [CrossRef]

- Park, S.-J.; Lee, K.; Choung, J.; Walters, C.L. Ductile fracture prediction of high tensile steel EH36 using new damage functions. Ships Offshore Struct. 2018, 13, 68–78. [Google Scholar] [CrossRef]

- Pack, K.; Mohr, D. Combined necking & fracture model to predict ductile failure with shell finite elements. Eng. Fract. Mech. 2017, 182, 32–51. [Google Scholar] [CrossRef]

- Alsos, H.S.; Amdahl, J.; Hopperstad, O.S. On the resistance to penetration of stiffened plates, Part II: Numerical analysis. Int. J. Impact Eng. 2009, 36, 875–887. [Google Scholar] [CrossRef]

- Cerik, B.C.; Lee, K.; Choung, J. Evaluation of Localized Necking Models for Fracture Prediction in Punch-Loaded Steel Panels. J. Mar. Sci. Eng. 2021, 9, 117. [Google Scholar] [CrossRef]

- Kõrgesaar, M.; Romanoff, J.; Remes, H.; Palokangas, P. Experimental and numerical penetration response of laser-welded stiffened panels. Int. J. Impact Eng. 2018, 114, 78–92. [Google Scholar] [CrossRef]

- Park, S.-J.; Choung, J. Punching Fracture Experiments and Simulations of Unstiffened and Stiffened Panels for Ships and Offshore Structures. J. Ocean Eng. Technol. 2020, 34, 155–166. [Google Scholar] [CrossRef]

- Cerik, B.C.; Park, S.J.; Choung, J. Use of localized necking and fracture as a failure criterion in ship collision analysis. Mar. Struct. 2020, 73, 102787. [Google Scholar] [CrossRef]

- ASTM E08. Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PU, USA, 2004. [Google Scholar]

| Material | C | Si | Mn | P | S |

|---|---|---|---|---|---|

| JIS G3131 SPHC | 0.0509 | 0.02 | 0.24 | 0.014 | 0.0062 |

| 624.2 | 0.0006 | 0.194 | 312.72 | 0.02825 |

| Case | (mm) | Error (%) | Error (%) | |||

|---|---|---|---|---|---|---|

| Unstiffened panel | Test | 72.4 | - | 82.8 | - | |

| Simulation | 65.9 | 9.0 | 81.2 | 1.93 | ||

| 69.1 | 4.6 | 82.6 | 0.24 | |||

| 86.1 | 18.9 | 103.1 | 24.5 | |||

| Stiffened panel | Test | 71.9 | - | 97.6 | - | |

| Simulation | 94.5 | 31.4 | 84.1 | 13.8 | ||

| 74.1 | 3.06 | 98.2 | 0.6 | |||

| 81.3 | 13.07 | 107.6 | 10.25 | |||

| Case | d1 (mm) | d2 (mm) | d3 (mm) | d4 (mm) | |

|---|---|---|---|---|---|

| Unstiffened panel | Test | 7.3 | 5.1 | 7.1 | 8.7 |

| Simulation | 7.32 | 5.2 | 6.63 | 8.04 | |

| Error (%) | 0.27 | 1.96 | 6.62 | 7.59 | |

| Stiffened panel | Test | 12.0 | 9.9 | - | - |

| Simulation | 11.7 | 9.73 | - | - | |

| Error | 2.5 | 1.72 | - | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.-J.; Kim, K. Localized Necking Model for Punching Fracture Simulation in Unstiffened and Stiffened Panels. Appl. Sci. 2021, 11, 3774. https://doi.org/10.3390/app11093774

Park S-J, Kim K. Localized Necking Model for Punching Fracture Simulation in Unstiffened and Stiffened Panels. Applied Sciences. 2021; 11(9):3774. https://doi.org/10.3390/app11093774

Chicago/Turabian StylePark, Sung-Ju, and Kookhyun Kim. 2021. "Localized Necking Model for Punching Fracture Simulation in Unstiffened and Stiffened Panels" Applied Sciences 11, no. 9: 3774. https://doi.org/10.3390/app11093774

APA StylePark, S.-J., & Kim, K. (2021). Localized Necking Model for Punching Fracture Simulation in Unstiffened and Stiffened Panels. Applied Sciences, 11(9), 3774. https://doi.org/10.3390/app11093774