CFD Analysis and Shape Optimization of Airfoils Using Class Shape Transformation and Genetic Algorithm—Part I

Abstract

:1. Introduction

2. Mathematical Model

2.1. CST Parametrization of Airfoil

2.2. Optimization Scheme

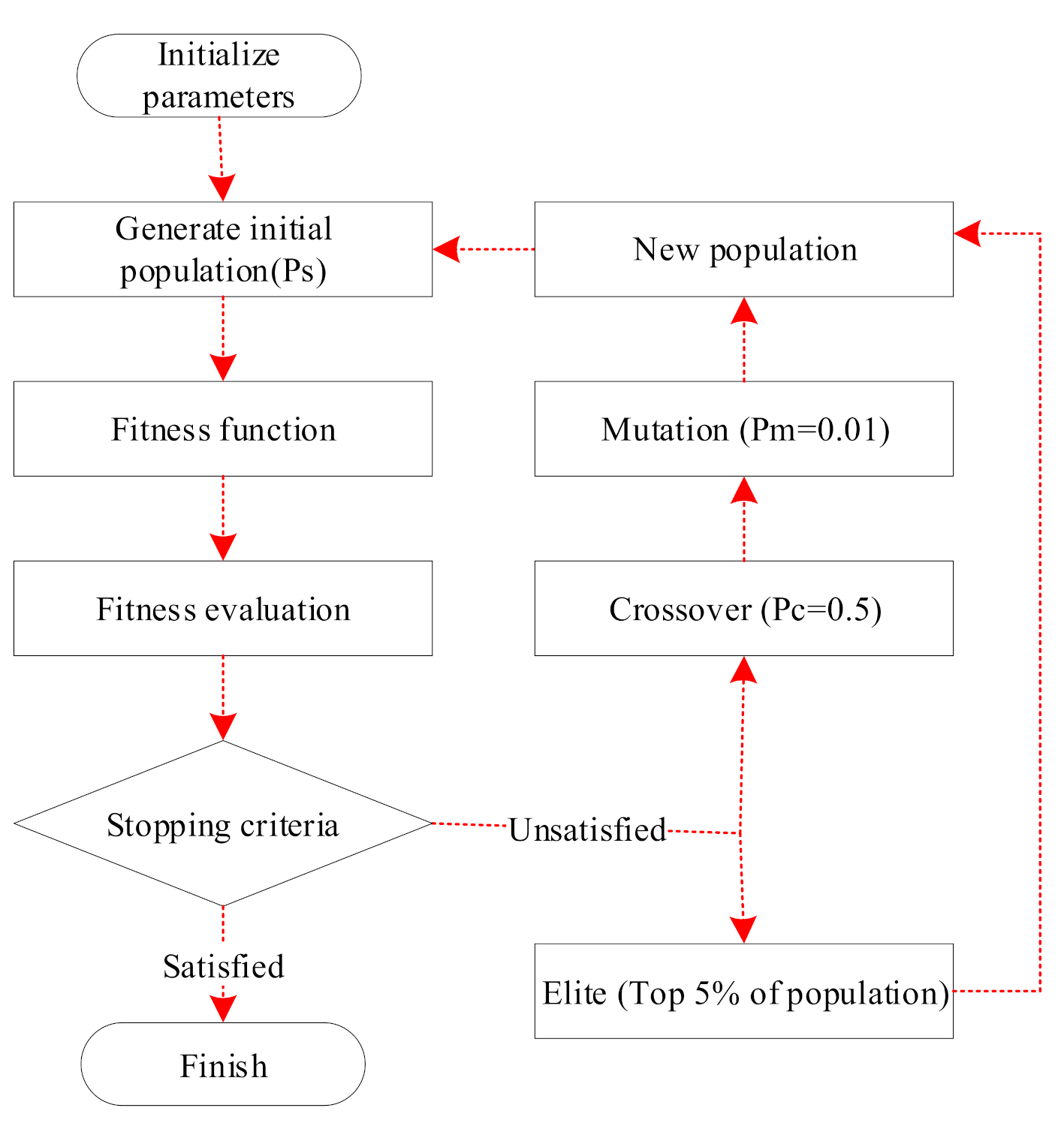

2.3. Genetic Algorithm

2.3.1. Initialization

2.3.2. Selection

2.3.3. Crossover

2.3.4. Mutation

2.3.5. Fitness Evaluation

2.3.6. XFOIL

3. Methodology

3.1. Computational Model

3.2. Numerical Simulation and Boundary Conditions

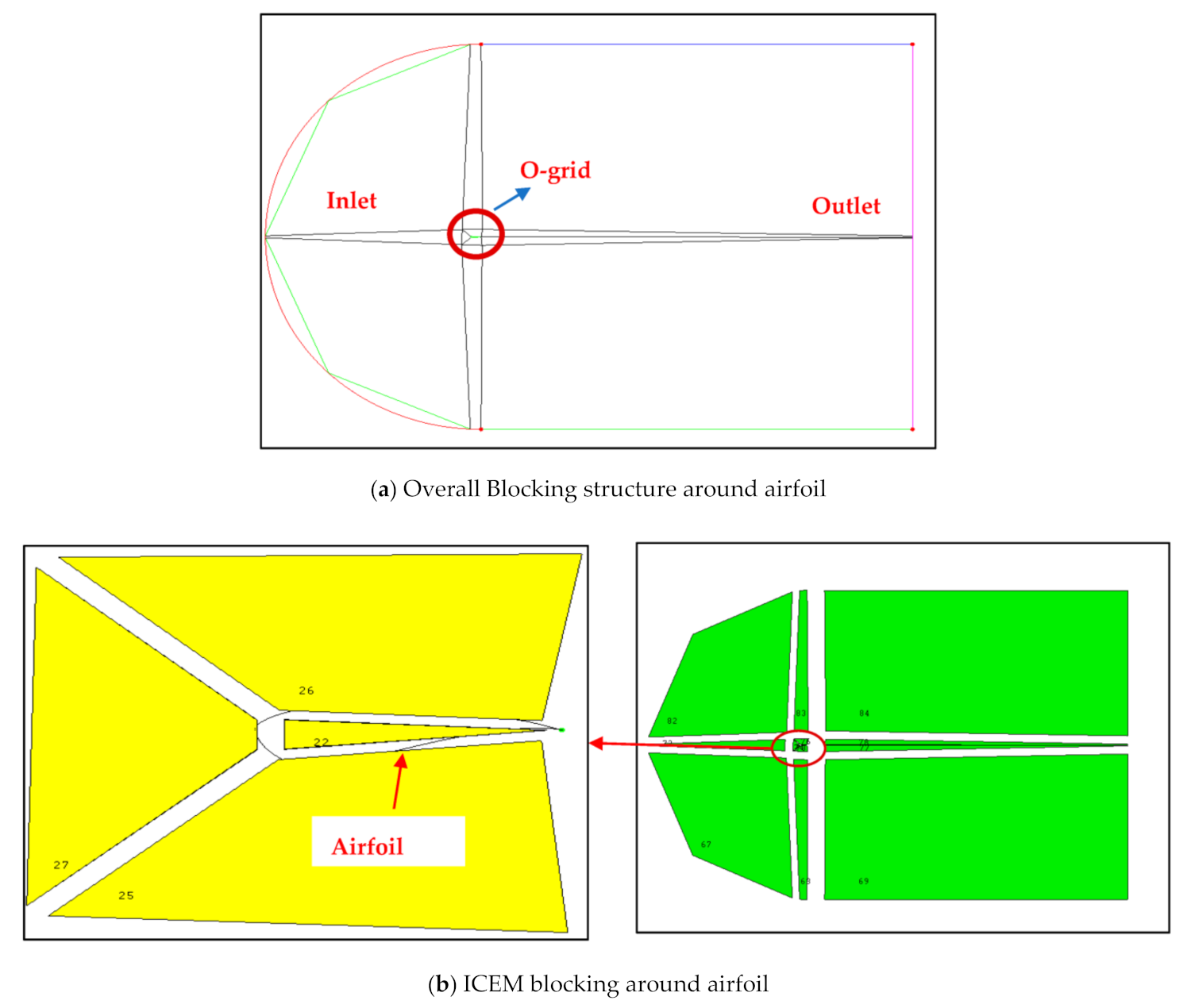

3.3. Mesh Generation

3.4. Mesh Independence Study

4. Results and Discussion

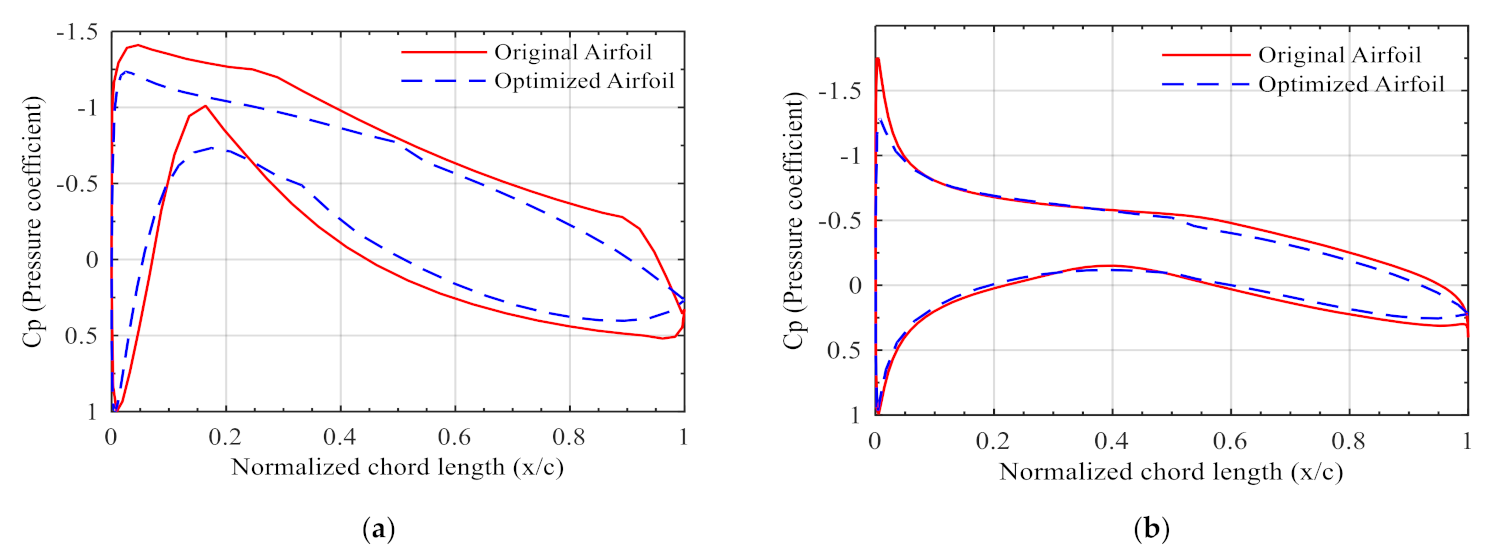

4.1. Subsonic (NREL S-821) and Transonic (RAE-2822) Airfoil Design

4.2. Numerical Validation

5. Conclusions

- The drag coefficients by XFOIL for optimized NREL S-821 subsonic airfoil and RAE 2822 transonic airfoil are decreased by 10% and 12%, respectively, while the lift to drag ratios are improved by 7.4% and 15.9% at fixed 3° angle of attack.

- The proposed methodology in terms of lift to drag ratio, which is the crucial deciding factor in the wind turbine design, exhibits superior characteristics (3.5%) in aerodynamic optimization for subsonic airfoil as compared to the transonic airfoil.

- The CFD analysis of the baseline airfoil shows the improvements of 2.1% for the lift to drag ratio while comparing the airfoil with the NREL experimental results of the subsonic airfoil (NREL S-821).

- The CFD result for the lift to drag ratio for an optimized airfoil is about 2.2% higher than the baseline airfoil NREL S-821.

- The present aerodynamic shape optimization scheme is in close agreement with previous results and further applicability of the CST approach could be deployed alongside other competing optimization techniques with reasonable flexibility.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| ASO | Aerodynamic shape optimization |

| C | Class function |

| c | Chord length [m] |

| Cd | Drag coefficient |

| Cl | Lift coefficient |

| CP | Pressure coefficient |

| CST | Class shape transformation |

| DNO | Direct Numerical Optimization |

| DNS | Direct Numerical Simulation |

| D | Drag force [N] |

| GA | Genetic algorithm |

| ID | Inverse design |

| K | Binomial coefficient |

| L | Lift force [N] |

| L/D | Lift to drag ratio |

| M | Viscosity [Pa-S] |

| Ma | Mach number |

| N | Order of Bernstein polynomial |

| n | Number of design variable |

| N1 | First-class function exponent |

| N2 | Second class function exponent |

| NREL | National Renewable Energy Laboratory |

| Pc | Crossover Probability |

| Pm | Mutation Probability |

| PS | Population size |

| RANS | Reynolds Averaged Navier-Stokes’s equation |

| Re | Reynolds number |

| S | Shape function |

| S1 | Lower shape function |

| SU | Upper shape function |

| TTE | Trailing edge thickness |

| Greek Symbols | |

| α | Angle of attack |

| β | Turbulence modeling constant |

| τ | Airfoil thickness |

| ρ | density [kg/m3] |

| μk | Effective viscosity [Pa-S] |

| μt | Turbulence viscosity [Pa-S] |

| Δ | Boundary layer thickness |

| ω | angular speed [rad/s |

References

- Chehouri, A.; Younes, R.; Ilinca, A.; Perron, J. Review of performance optimization techniques applied to wind turbines. Appl. Energy 2015, 142, 361–388. [Google Scholar] [CrossRef]

- Saenz-Aguirre, A.; Fernandez-Gamiz, U.; Zulueta, E.; Ulazia, A.; Martinez-Rico, J. Optimal wind turbine operation by artificial neural network-based active gurney flap flow control. Sustainability 2019, 11, 2809. [Google Scholar] [CrossRef] [Green Version]

- Rodriguez-Eguia, I.; Errasti, I.; Fernandez-Gamiz, U.; Blanco, J.M.; Zulueta, E.; Saenz-Aguirre, A. A parametric study of trailing edge flap implementation on three different airfoils through an artificial neuronal network. Symmetry 2020, 12, 828. [Google Scholar] [CrossRef]

- Shahrokhi, A.; Jahangirian, A. Airfoil shape parameterization for optimum navier—stokes design with genetic algorithm. Aerosp. Sci. Technol. 2007, 11, 443–450. [Google Scholar] [CrossRef]

- Zhu, W.J.; Shen, W.Z.; Sørensen, J.N. Integrated airfoil and blade design method for large wind turbines. Renew. Energy 2014, 70, 172–183. [Google Scholar] [CrossRef] [Green Version]

- Song, W.; Keane, A.J. A Study of shape parameterisation methods for airfoil optimization. In Proceedings of the 10th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Albany, NY, USA, 30 August–1 September 2004; pp. 1–8. [Google Scholar]

- Della, P.; Daniele, E.; Amato, E.D. An airfoil shape optimization technique coupling PARSEC parameterization and evolutionary algorithm. Aerosp. Sci. Technol. 2014, 32, 103–110. [Google Scholar] [CrossRef]

- Khurana, M.; Winarto, H.; Sinha, A. Airfoil geometry parameterization through shape optimizer and computational fluid dynamics. In Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 7–10 January 2008; pp. 1–18. [Google Scholar]

- Safari, M.; Ahmadabadi, M.N.; Ghaei, A.; Shirani, E. Inverse design in subsonic and transonic external flow regimes using Elastic Surface Algorithm. Comput. Fluids 2014, 102, 41–51. [Google Scholar] [CrossRef]

- Ahmadabadi, M.N.; Ghadak, F.; Mohammadi, M. Subsonic and transonic airfoil inverse design via ball-spine algorithm. Comput. Fluids 2013, 84, 87–96. [Google Scholar] [CrossRef]

- Saleem, A.; Kim, M.H. Effect of rotor axial position on the aerodynamic performance of an airborne wind turbine system in shell configuration. Energy Convers. Manag. 2017, 151, 587–600. [Google Scholar] [CrossRef]

- Sripawadkul, V.; Padulo, M.; Guenov, M. A comparison of airfoil shape parameterization techniques for early design optimization. In Proceedings of the 13th AIAA/ISSMO Multidisciplinary Analysis Optimization Conference, Fort Worth, TX, USA, 13–15 September 2010; pp. 1–9. [Google Scholar]

- Derksen, R.W.; Rogalsky, T. Advances in engineering software Bezier-PARSEC: An optimized aerofoil parameterization for design. Adv. Eng. Softw. 2010, 41, 923–930. [Google Scholar] [CrossRef]

- Han, X.; Zingg, D.W. An adaptive geometry parametrization for aerodynamic shape optimization. Optim. Eng. 2014, 15, 69–91. [Google Scholar] [CrossRef]

- Yang, F.; Yue, Z.; Li, L.; Yang, W. Aerodynamic optimization method based on Bezier curve and radial basis function. Proc. Inst. Mech. Eng. Part G J. Aeros Eng. 2018, 232, 459–471. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, W.; Peng, X.; Wang, Z. Benchmark aerodynamic shape optimization with the POD-based CST airfoil parametric method. Aerosp. Sci. Technol. 2019, 84, 632–640. [Google Scholar] [CrossRef]

- Ullah, Z.; Wang, X.; Chen, Y.; Zhang, T.; Ju, H.; Zhao, Y. Time-domain output data identification model for pipeline flaw detection using blind source separation technique complexity pursuit. Acoustics 2019, 1, 13. [Google Scholar] [CrossRef] [Green Version]

- Saleem, A.; Kim, M.H. Aerodynamic performance optimization of an airfoil-based airborne wind turbine using genetic algorithm. Energy 2020, 203. [Google Scholar] [CrossRef]

- Samareh, J.A. Survey of shape parameterization techniques for high-fidelity multidiscplinary shape optimization. AIAA J. 2001, 39, 877–884. [Google Scholar] [CrossRef]

- Ulaganathan, S.; Balu, R. Optimum hierarchical bezier parameterisation of arbitrary curves and surfaces. In Proceedings of the 11th Annual CFD Symposium, Bangalore, India, 11–12 August 2009; pp. 46–48. [Google Scholar]

- Kulfan, B.M. Universal parametric geometry representation method-CST. J. Aircr. 2008, 45, 142–158. [Google Scholar] [CrossRef]

- Kulfan, B.M.; Bussoletti, J.E. “Fundamental” parametric geometry representations for aircraft component shapes. In Proceedings of the 11th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Portsmouth, VA, USA, 6–8 September 2006; p. 6948. [Google Scholar]

- Sobieczky, H. Geometry generator for CFD and applied aerodynamics. In New Design Concepts for High Speed Air Transport; Springer: Vienna, Austria, 1997; pp. 137–158. [Google Scholar]

- Lane, K.; Marshall, D. A surface parameterization method for airfoil optimization and high lift 2D geometries utilizing the CST methodology. In Proceedings of the 47th AIAA Aerospace Sciences Meeting including The New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009. [Google Scholar] [CrossRef] [Green Version]

- Akram, M.T.; Kim, M.-H. Aerodynamic shape optimization of NREL S809 airfoil for wind turbine blades using reynolds-averaged navier stokes model—Part II. Appl. Sci. 2021, 11, 2211. [Google Scholar] [CrossRef]

- Lane, K.; Marshall, D. Inverse airfoil design utilizing CST parameterization. In Proceedings of the 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, Fl, USA, 4–7 January 2010. [Google Scholar] [CrossRef] [Green Version]

- Mukesh, R.; Lingadurai, K.; Selvakumar, U. Airfoil shape optimization using non-traditional optimization technique and its validation. J. King Saud Univ. Eng. Sci. 2014, 26, 191–197. [Google Scholar] [CrossRef] [Green Version]

- Orman, E.; Durmus, G. Comparison of shape optimization techniques coupled with genetic algorithm for a wind turbine airfoil. In Proceedings of the 2016 IEEE Aerospace Conference, Big Sky, MT, USA, 3 May–3 December 2016; pp. 1–7. [Google Scholar] [CrossRef]

- Goldberg, D.E. Genetic Algorithms in Search, Optimization, and Machine Learning; Addison-Wesley Publishing Company: Boston, MA, USA, 1989; p. 432. [Google Scholar]

- Chapman, S.J. MATLAB Programming for Engineers, 4th ed.; James, H., Ed.; Thomson Learning: Toronto, ON, Canada, 2008; pp. 3–251. [Google Scholar]

- Patankar, S. Numerical Heat Transfer and Fluid Flow; Taylor: London, UK, 1980; pp. 1–197. [Google Scholar]

- Markatos, N.C. Modelling of two-phase transient flow and combustion of granular propellants. Int. J. Multiph. Flow 1986, 12, 913–933. [Google Scholar] [CrossRef]

- Karabelas, S.J.; Markatos, N.C. Unsteady transition from a Mach to a regular shockwave intersection. In Proceedings of the IASME/WSEAS International Conference on Fluid Dynamics and Aerodynamics, Corfu, Greece, 20–22 August 2005; pp. 168–173. [Google Scholar]

- Karabelas, S.J.; Markatos, N.C. Water vapor condensation in forced convection flow over an airfoil. Aerosp. Sci. Technol. 2008, 12, 150–158. [Google Scholar] [CrossRef]

- Menter, F.R. Zonal two equation k—ω turbulence models for aerodynamic flows. In Proceedings of the 24th Fluid Dynamics Conference for Aerodynamic Flows-AIAA, Orlando, FL, USA, 6–9 July 1993. [Google Scholar] [CrossRef]

- Date, A.W. Introduction to Computational Fluid Dynamics; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Saeed, M.; Kim, M.H. Aerodynamic performance analysis of an airborne wind turbine system with NREL Phase IV rotor. Energy Convers. Manag. 2017, 134, 278–289. [Google Scholar] [CrossRef]

- Somers, D.M. The S819, S820, and S821 airfoils. Nat. Renew. Energy Lab. 2005. [Google Scholar] [CrossRef] [Green Version]

| Boundary Condition | Velocity of Flow (u) | Mach Number (M) | Reynolds Number (Re) | Angle of Attack (deg.) | Dynamic Viscosity (μ) | Density (ρ) | Chord Length (c) | Temperature (T) | Gas Constant (R) | Working Fluid | Pressure (P) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Units | m/s | − | − | − | kg/ms | kg/m3 | m | k | j/kg | − | |

| NREL S-821 | 34 | 0.1 | 3 | 1.258 | 0.34 | 288 | 287 | Air | |||

| RAE-2822 | 238 | 0.7 | 3 | 0.179 | 0.34 | 288 | 287 | Air |

| Mesh | Nodes along Upstream | Nodes along the Leading Edge of Airfoil | Nodes along Downstream | Number of Nodes around Airfoil Length | Face Diagonal Nodes | Nodes along Trailing Edge | Nodes along the Leading Edge | Maximum Value of y+ | Coefficient of Drag (Cd) | Coefficient of Lift (Cl) | Total Number of Nodes (million) | Memory Allocated by the Solver | Total CPU Time | Total Iterations at Convergence |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M-i | NU | FLE | ND | NCL | FD | NT | NLE | y+ | Cd | Cl | Nt | [MB] | [s] | |

| M1 | 100 | 75 | 100 | 150 | 100 | 100 | 150 | 0.7 | 0.018 | 0.591 | 0.34 | 638 | 1320 | 300 |

| M2 | 100 | 100 | 100 | 150 | 150 | 250 | 200 | 0.7 | 0.0179 | 0.593 | 0.54 | 989 | 1860 | 274 |

| M3 | 100 | 125 | 100 | 150 | 200 | 300 | 250 | 0.7 | 0.0178 | 0.595 | 0.7 | 1065 | 2280 | 226 |

| M4 | 100 | 150 | 100 | 150 | 250 | 350 | 300 | 0.7 | 0.0178 | 0.595 | 0.97 | 1203 | 2700 | 205 |

| Angle of Attack (AOA) | 3° |

| Geometric constraints | Thickness ≈22% of chord length for NREL S-821. Thickness ≈12.5% of chord length for RAE-2822 Minimum thickness ≥1% of chord length. and |

| Aerodynamic constraint | Coefficient of drag () < original airfoil S-821 & RAE-2822. Lift to drag ratio > original airfoil S-821 & RAE-2822 |

| Objective | Minimize the coefficient of drag () |

| Termination Condition | GA stopped based on bit string affinity value |

| Variables | RAE-2822 | S-821 |

|---|---|---|

| −0.1232 | −0.4750 | |

| −0.1734 | −0.3828 | |

| −0.1791 | −0.0710 | |

| 0.0586 | 0.1254 | |

| 0.1261 | 0.2283 | |

| 0.152 | 0.3335 | |

| 0.2066 | 0.2181 | |

| 0.1961 | 0.3586 |

| NREL S-821 | RAE-2822 | |||

|---|---|---|---|---|

| Original Airfoil | Optimized Airfoil | Original Airfoil | Optimized Airfoil | |

| Cl | 0.637 | 0.616 | 0.539 | 0.547 |

| Cd | 0.010 | 0.009 | 0.008 | 0.007 |

| L/D | 63.7 | 68.4 | 67.4 | 78.1 |

| AOA (degree) | 3° | 3° | 3° | 3° |

| NREL S-821 | Relative Variation | ||||

|---|---|---|---|---|---|

| Experimental Data [32] | Baseline Airfoil (CFD) | Optimized Airfoil (CFD) | Baseline with Exp. | Optimized with Baseline | |

| Cl | 0.61 | 0.59 | 0.56 | −3.4% | −5.08% |

| Cd | 0.019 | 0.018 | 0.0167 | +5.50% | +7.22% |

| L/D | 32.1 | 32.77 | 33.53 | +2.1% | +2.2% |

| AOA | 3° | 3° | 3° | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akram, M.T.; Kim, M.-H. CFD Analysis and Shape Optimization of Airfoils Using Class Shape Transformation and Genetic Algorithm—Part I. Appl. Sci. 2021, 11, 3791. https://doi.org/10.3390/app11093791

Akram MT, Kim M-H. CFD Analysis and Shape Optimization of Airfoils Using Class Shape Transformation and Genetic Algorithm—Part I. Applied Sciences. 2021; 11(9):3791. https://doi.org/10.3390/app11093791

Chicago/Turabian StyleAkram, Md Tausif, and Man-Hoe Kim. 2021. "CFD Analysis and Shape Optimization of Airfoils Using Class Shape Transformation and Genetic Algorithm—Part I" Applied Sciences 11, no. 9: 3791. https://doi.org/10.3390/app11093791