Investigation of Seal Cavity Leakage Flow Effect on Multistage Axial Compressor Aerodynamic Performance with a Circumferentially Averaged Method

Abstract

Featured Application

Abstract

1. Introduction

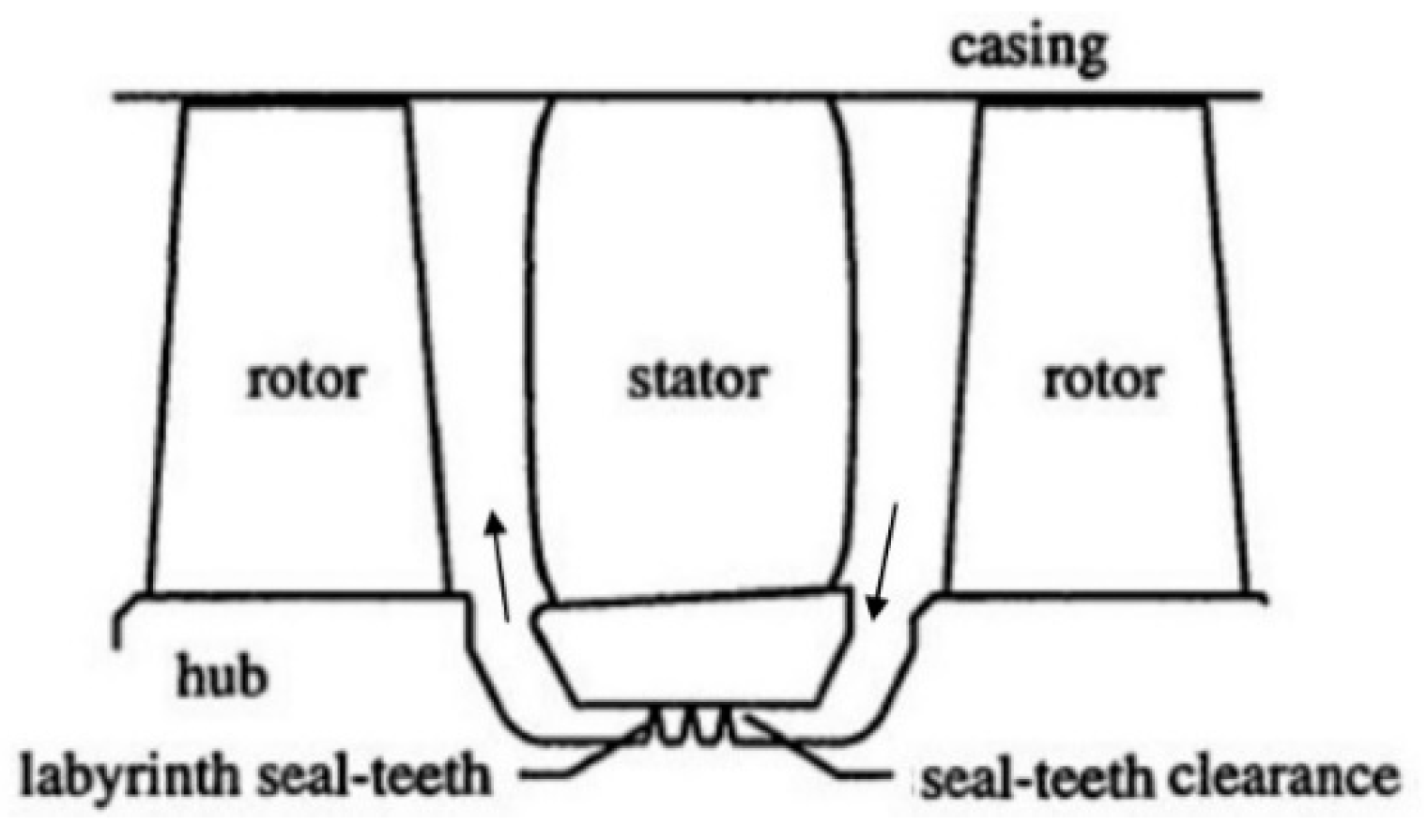

2. Numerical Model and Research Object

3. Results and Discussion

3.1. Compressor Performance

3.2. Stage Performance

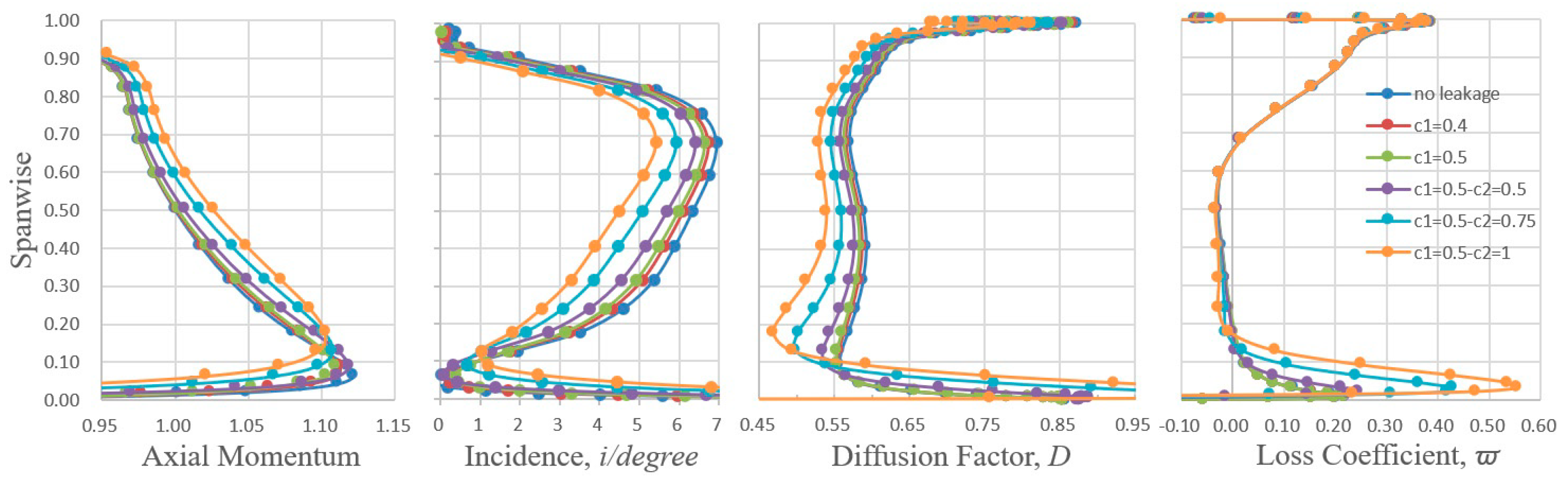

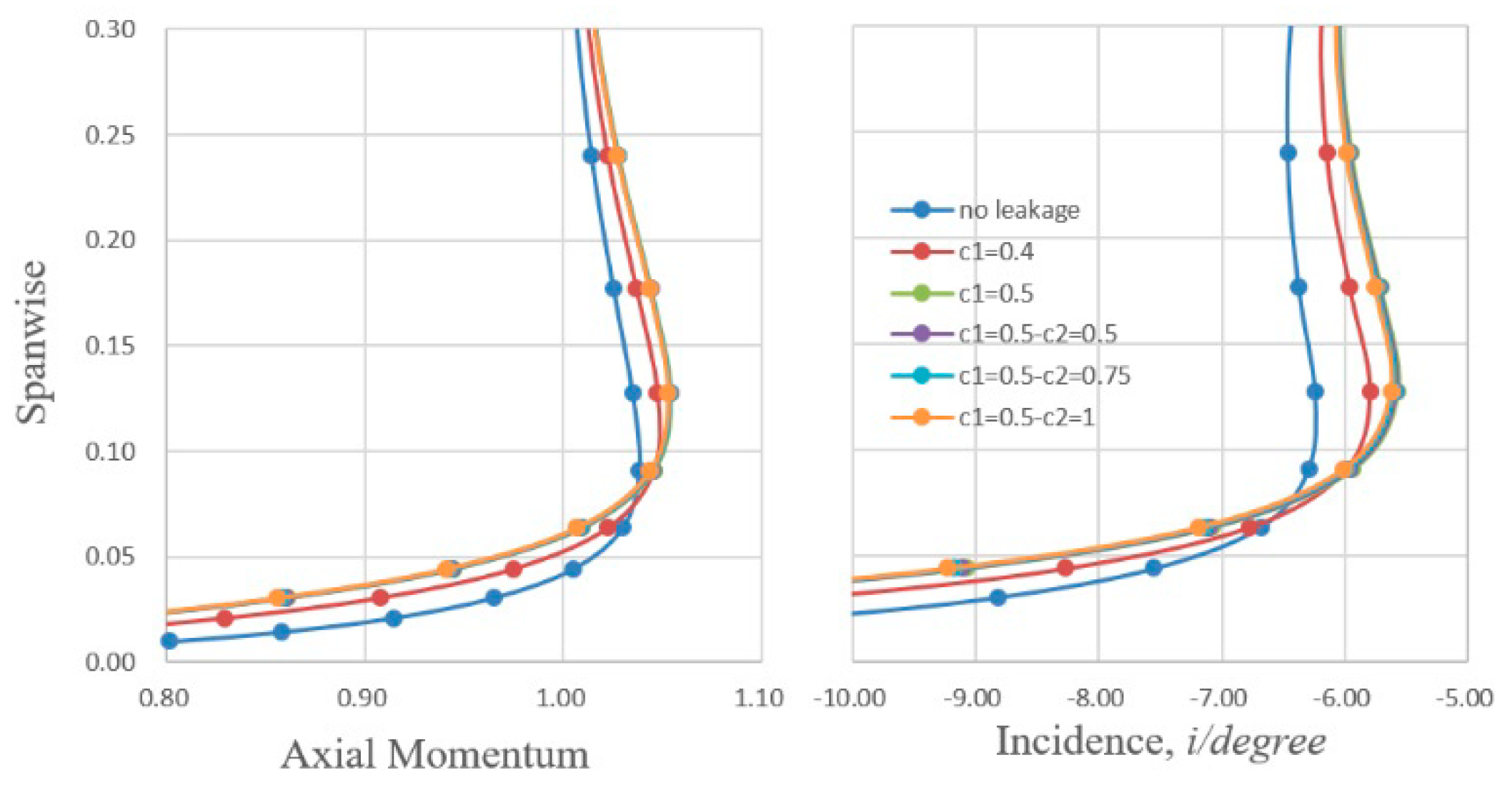

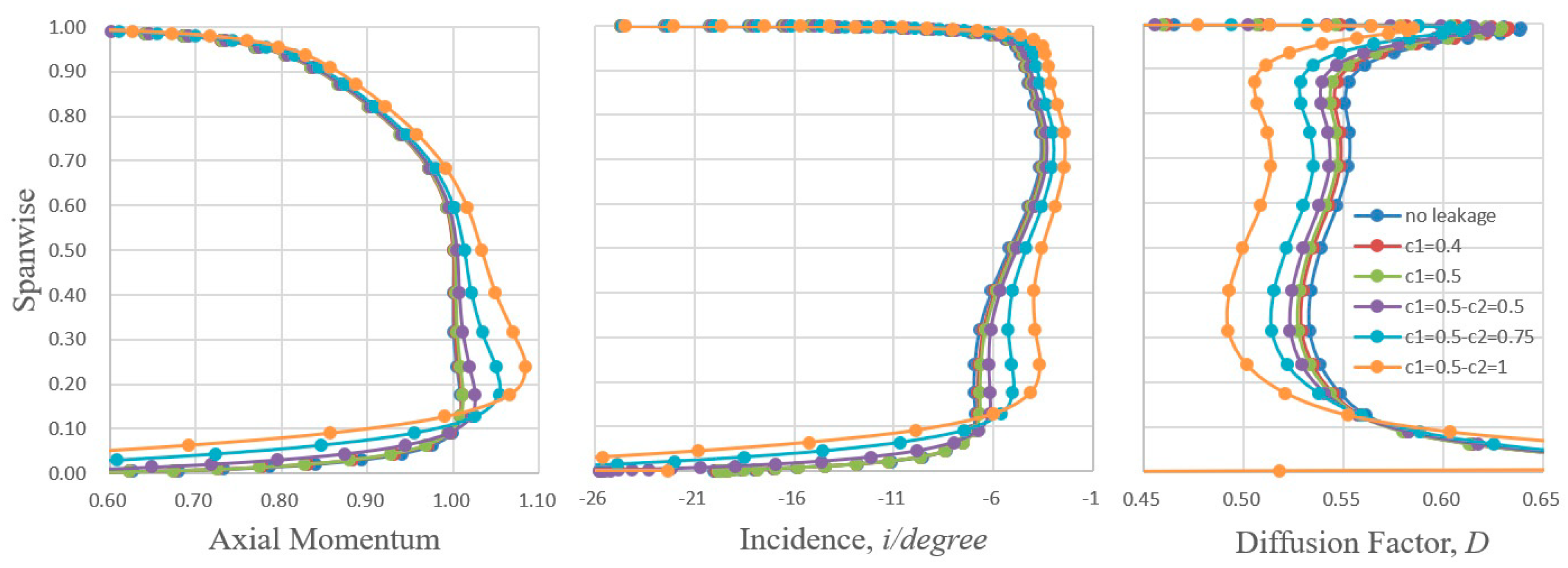

3.3. Spanwise Parameters

4. Conclusions

- (1)

- With the increase of leakage flow, the total pressure ratio and efficiency of the compressor decrease to some extent. The labyrinth clearance-to-span ratio of cavity 1 increases by 1%, and the compressor efficiency decreases by 0.4%. For cavity 2, the decrease in efficiency is 0.6% when labyrinth clearance-to-span ratio increases by 1%. Therefore, in order to predict the performance of the compressor correctly, the effect of leakage flow in the seal cavity should not be ignored.

- (2)

- The leakage flow in the seal cavity has little effect on the performance of the upstream blade row, but will deteriorate the flow field and performance of the stator and the downstream rotor where the leakage occurs. Reflected in the stage characteristics, it has no effect on the front stage, but has a little influence on the work capacity of the current stage, while the work capacity of the later stage and the pressurizing capacity of the current stage and the rear stage reduces significantly. This is reflected in the performance of blade row that the total pressure loss at the root of stator increases obviously, and the load of stator and downstream rotor decreases in most of the span ranges.

- (3)

- The seal cavity leakage flow causes the blockage of the flow at the root of the blade, which leads to the spanwise migration of the flow. The blockage and spanwise migration further change the incidence angle characteristics of the blade row. As a consequence, the incidence angle increases at the hub, which induces an increase of total pressure loss. At midspan, on the other hand, the incidence angle decreases, resulting in a decrease of blade load.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Nomenclature | |

| b | throttle clearance length (tooth tip thickness) |

| c | labyrinth clearance |

| d | diameter of labyrinth tooth tip |

| D | diffusion factor |

| h | blade height |

| labyrinth tooth height | |

| total enthalpy | |

| i | incidence |

| total pressure | |

| S | labyrinth pitch |

| total temperature | |

| Um | tangential speed of the rotor at 50% of the span at the leading edge of the stage |

| relative velocity | |

| tangential component of relative velocity | |

| torsional velocity | |

| Greek letters | |

| adiabatic efficiency | |

| pressure coefficient | |

| work coefficient | |

| total pressure loss coefficient | |

| blade solidity | |

| Subscripts | |

| in | the inlet of stage |

| out | the outlet of stage |

| isen | isentropic |

References

- Marx, J.; Städing, J.; Reitz, G.; Friedrichs, J. Investigation and analysis of deterioration in high pressure compressors due to operation. CEAS Aeronaut. J. 2014, 5, 515–525. [Google Scholar] [CrossRef]

- Reitz, G.; Friedrichs, J. Impact of Front- and Rear-Stage High Pressure Compressor Deterioration on Jet Engine Performance. Int. J. Turbomach. Propuls. Power 2018, 3, 15. [Google Scholar]

- Reitz, G.; Kellersmann, A.; Friedrichs, J. Full High Pressure Compressor Investigations to Determine Aerodynamic Changes due to Deterioration. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018; ASME: New York, NY, USA, 2018. [Google Scholar]

- Yao, J.; Jameson, A.; Alonso, J.J.; Liu, F. Development and Validation of a Massively Parallel Flow Solver for Turbomachinery Flows. J. Propul. Power 2001, 17, 659–668. [Google Scholar] [CrossRef]

- Mahesh, K.; Constantinescu, G.; Apte, S.; Iaccarino, G.; Ham, F.; Moin, P. Large-Eddy Simulation of Reacting Turbulent Flows in Complex Geometries. J. Appl. Mech. Trans. ASME 2006, 73, 374–381. [Google Scholar] [CrossRef]

- Medic, G.; You, D.; Kalitzin, G.; Herrmann, M.; Ham, F.; Pitsch, H.; van der Weide, E.; Alonso, J. Intergrated Computations of an Entire Jet Engine. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007; ASME: New York, NY, USA, 2007. ASME Paper No. GT2007-27094. [Google Scholar]

- Schlüter, J.U.; Pitsch, H.; Moin, P.; Shankaran, S.; Kim, S.; Alonso, J. Towards Multi-Component Analysis of Gas Turbines by CFD: Integration of RANS and LES Flow Solvers. In Proceedings of the ASME Turbo Expo 2003, Collocated with the 2003 International Joint Power Generation Conference, Atlanta, GA, USA, 16–19 June 2003; ASME: New York, NY, USA, 2003. ASME Paper No. GT2003-38350. [Google Scholar]

- Schlüter, J.U.; Pitsch, H.; Moin, P. Large-eddy Simulation Inflow Conditions for Coupling with Reynolds-averaged Flow Solvers. AIAA J. 2004, 42, 478–484. [Google Scholar] [CrossRef][Green Version]

- Medic, G.; Kalitzin, G.; You, D.; Herrmann, M.; Ham, F.; van der Weide, E.; Pitsch, H.; Alonso, J. Integrated RANS/LES Computations of Turbulent Flow through a Turbofan Jet Engine. Center for Turbulence Research. Annu. Res. Briefs 2006, 275–285. [Google Scholar]

- Schlüter, J.U.; Wu, X.; Kim, S.; Shankaran, S.; Alonso, J.J.; Pitsch, H. A Framework for Coupling Reynolds-Averaged with Large-Eddy Simulations for Gas Turbine Applications. J. Fluids Eng. Trans. ASME 2005, 127, 806–815. [Google Scholar] [CrossRef]

- Lytle, J.K. The Numerical Propulsion System Simulation: An Overview; NASA/TM-2000-209915; NASA: Washington, DC, USA, 2000.

- Wang, Z.X.; Song, F.; Zhou, L.; Zhang, X.B.; Zhang, C.Y. Research Progress in Numerical Zooming Technology of Aeroengine. J. Propul. Technol. 2018, 39, 1441–1454. [Google Scholar]

- Denton, J.D.; Dawes, W.N. Computational Fluid Dynamics for Turbomachinery Design. Proc. Inst. Mech. Eng. Part C J. Eng. Mech. Eng. Sci. 1998, 213, 107–124. [Google Scholar] [CrossRef]

- Wellborn, S.R. Effects of Shrouded Stator Cavity Flows on Multistage Axial Compressor Aerodynamic Performance. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 1996. [Google Scholar]

- Ludwig, L.P.; Bill, R.C. Gas Path Sealing in Turbine Engines. J. ASLE Trans. 1980, 23, 1–22. [Google Scholar] [CrossRef][Green Version]

- Wisler, D.C. Advanced Compressor and Fan Systems, GE Aircraft Engines, Cincinnati, Ohio, 1988; (Also 1986 Lecture to ASME Turbomachinery Institute, Ames, Iowa); ASME Turbomachinery Institute: Ames, IA, USA, 1986. [Google Scholar]

- Mahler, F.H. Advanced Seal Technology; Pratt and Whitney Aircraft Division Tech. Rep. PWA-4372; Pratt and Whitney Aircraft Division: Hartford, CO, USA, 1972. [Google Scholar]

- Cumpsty, N.A. Compressor Aerodynamics; Longman Scientific & Technical, Longman Group: Harlow, UK, 1989. [Google Scholar]

- Freeman, C. Effect of Tip Clearance Flow on Compressor Stability and Performance. VKM Lecture Ser. 1985, 5, 5. [Google Scholar]

- Mahmood, S.M.H.; Turner, M.G. Modeling Capability for Cavity Flows in an Axial Compressor. In Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, Charlotte, NC, USA, 26–30 June 2017; ASME: New York, NY, USA, 2017. ASME Paper, GT2017-64040. [Google Scholar]

- Kato, D.; Yamagami, M.; Tsuchiya, N.; Kodama, H. The Influence of Shrouded Stator Cavity Flows on the Aerodynamic Performance of a High-Speed Multistage Axial-Flow Compressor. In Proceedings of the ASME Turbo Expo 2011: Turbine Technical Conference and Exposition, Vancouver, BC, Canada, 6–10 June 2011; ASME: New York, NY, USA, 2011. ASME Paper, GT2011-46300. [Google Scholar]

- Gier, J.; Stubert, B.; Brouillet, B.; Vito, L.D. Interaction of Shroud Leakage Flow and Main Flow in a Three-Stage LP Turbine. J. Turbomach. 2005, 127, 649–658. [Google Scholar] [CrossRef]

- Rosic, B.; Denton, J.D.; Pullan, G. The Importance of Shroud Leakage Modeling in Multistage Turbine Flow Calculations. J. Turbomach. 2006, 128, 699–707. [Google Scholar] [CrossRef]

- Kuerner, M.; Reichstein, G.A.; Schrack, D.; Rose, M.G.; Staudacher, S.; Gier, J.; Engel, K. Low Pressure Turbine Secondary Vortices Reynolds Lapse. J. Turbomach. 2012, 134, 061022. [Google Scholar] [CrossRef]

- Morris, A.W.H.; Hoare, R.G. Secondary Loss Measurements in a Cascade of Turbine Blades with Meridional Wall Profiling. In Proceedings of the ASME, Winter Annual Meeting, Houston, TX, USA, 30 November–5 December 1975; ASME: New York, NY, USA, 1975. ASME Paper No. 75-WA/GT-13. [Google Scholar]

- Roberts, W.B.; Serovy, G.K.; Sandercock, D.M. Modeling the 3-D Flow Effects on Deviation Angle for Axial Compressor Middle Stages. J. Eng. Gas Turbines Power 1986, 108, 131–137. [Google Scholar] [CrossRef]

- Banjac, M.; Petrovic, M.V. Secondary flows, endwall effects, and stall detection in axial compressor design, In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014; ASME: New York, NY, USA, 2014; ASME Paper, GT2014-25115.

- Ricci, M.; Pacciani, R.; Marconcini, M.; Macelloni, P.; Cecchi, S.; Bettini, C. CFD-Based Throughflow Analysis of Transonic Flows in Steam Turbines. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, Arizona, USA, 17–21 June 2019; ASME: New York, NY, USA, 2019. ASME Paper, GT2019-90851. [Google Scholar]

- Liang, D.; Gui, X.M.; Jin, D.H. Influence of Seal Cavity Leakage Flow on Compressor Performance Investigated with a Circumferentially Averaged Method. Appl. Sci. 2021, 11, 780. [Google Scholar] [CrossRef]

- Merkle, C.L.; Choi, Y.H. Computation of Low-Speed Compressible Flows with time Marching Procedures. Int. J. Numer. Methods Eng. 1988, 25, 293–311. [Google Scholar] [CrossRef]

- Jin, H.L.; Jin, D.H.; Li, X.J.; Gui, X.M. A Time-Marching Throughflow Model and its Application in Transonic Axial Compressor. J. Therm. Sci. 2010, 19, 519–525. [Google Scholar]

- Liu, X.H.; Wan, K.; Jin, D.H.; Gui, X.M. Development of a Throughflow-Based Simulation Tool for Preliminary Compressor Design Considering Blade Geometry in Gas Turbine Engine. Appl. Sci. 2021, 11, 422. [Google Scholar] [CrossRef]

- Tang, M.Z.; Jin, D.H.; Gui, X.M. Modeling and numerical investigation of the inlet circumferential fluctuations of swept and bowed blades. J. Therm. Sci. 2017, 26, 1–10. [Google Scholar] [CrossRef]

- Liu, X.H.; Jin, D.H.; Gui, X.M. Throughflow Method for a Combustion Chamber with Effusion Cooling Modelling. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018; ASME: New York, NY, USA, 2018. [Google Scholar]

- Prasad, B.V.S.S.S.; Manavalan, V.S.; Rao, N.N. Computational and Experimental Investigations of Straight-Through Labyrinth Seals. In Proceedings of the ASME 1997 International Gas Turbine and Aeroengine Congress and Exhibition, Orlando, FL, USA, 2–5 June 1997; ASME: New York, NY, USA, 1997. ASME Paper No. 97-GT-326. [Google Scholar]

| Parameters | S0 | R1 | S1 | R2 | S2 | R3 | S3 |

|---|---|---|---|---|---|---|---|

| No. of Airfoils | 32 | 28 | 50 | 38 | 68 | 50 | 82 |

| Chord/mm | 51.65 | 103.26 | 46.27 | 68.51 | 33.37 | 50.42 | 28.38 |

| Solidity | 0.86 | 1.74 | 1.35 | 1.49 | 1.27 | 1.39 | 1.27 |

| Aspect ratio | 3.65 | 1.67 | 2.91 | 1.68 | 2.78 | 1.59 | 2.39 |

| Inlet metal angle/(°) | 0.47 | −51.22 | 44.76 | −54.12 | 44.37 | −55.21 | 45.89 |

| Outlet metal angle/(°) | 8.16 | −40.49 | 9.60 | −42.96 | 11.51 | −43.28 | 14.21 |

| Configuration | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| c1/mm | 0 | 0.4 | 0.5 | 0.5 | 0.5 | 0.5 |

| c2/mm | 0 | 0 | 0 | 0.5 | 0.75 | 1 |

| c1/h1 × 100 | 0 | 0.30 | 0.37 | 0.37 | 0.37 | 0.37 |

| c2/h2 × 100 | 0 | 0 | 0 | 0.54 | 0.81 | 1.08 |

| Position | S0 with Inlet | R1 | S1 | R2 | S2 | R3 | S3 with Outlet | Cavity 1 | Cavity 2 | Sum |

|---|---|---|---|---|---|---|---|---|---|---|

| No. of grid points | 67 × 49 | 29 × 49 | 29 × 49 | 36 × 49 | 39 × 49 | 32 × 49 | 51 × 49 | 6975 | 8753 | 29,595 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, D.; Jin, D.; Gui, X. Investigation of Seal Cavity Leakage Flow Effect on Multistage Axial Compressor Aerodynamic Performance with a Circumferentially Averaged Method. Appl. Sci. 2021, 11, 3937. https://doi.org/10.3390/app11093937

Liang D, Jin D, Gui X. Investigation of Seal Cavity Leakage Flow Effect on Multistage Axial Compressor Aerodynamic Performance with a Circumferentially Averaged Method. Applied Sciences. 2021; 11(9):3937. https://doi.org/10.3390/app11093937

Chicago/Turabian StyleLiang, Dong, Donghai Jin, and Xingmin Gui. 2021. "Investigation of Seal Cavity Leakage Flow Effect on Multistage Axial Compressor Aerodynamic Performance with a Circumferentially Averaged Method" Applied Sciences 11, no. 9: 3937. https://doi.org/10.3390/app11093937

APA StyleLiang, D., Jin, D., & Gui, X. (2021). Investigation of Seal Cavity Leakage Flow Effect on Multistage Axial Compressor Aerodynamic Performance with a Circumferentially Averaged Method. Applied Sciences, 11(9), 3937. https://doi.org/10.3390/app11093937