Featured Application

The reduction of toxic acrylamide content in fried potato products, i.e., French fries and potato chips, is possible due to the existing knowledge on the selection of appropriate raw materials and various technological processes applied during the production of potato snacks. However, the formation of this compound in ready products has not been completely eliminated; therefore, the search for new methods and solutions is still current and necessary.

Abstract

The reduction of toxic acrylamide content in potato snacks, i.e., French fries and potato chips, is necessary due to the adverse effects of this compound on the human body. Therefore, in the presented review paper, a detailed characterization of French fries and chips in terms of AA content and their organoleptic quality is included. Detailed information was also collected on the raw material and technological factors that affect the formation of acrylamide content, including methods and techniques affecting the reduction of the amount of this compound in potato snacks. The obligation to control the level of acrylamide in various food products (including fried potato snacks with a higher content of this compound), introduced in 2018, has mobilized manufacturers to seek solutions, while scientists conduct further intensive research on the possibility of reducing the level of AA or even eliminating its presence from products. Therefore, it is necessary to conduct such activities, especially, because potato French fries and potato chips are willingly consumed by younger and younger consumers.

1. Introduction

Considering the health and safety of consumers and their expectations concerning potato snacks, which should be characterized by appropriate organoleptic features, including a reduced amount of fat [1,2,3,4,5,6,7], special attention should be paid to the presence of acrylamide (AA) in French fries and potato chips [8,9,10,11,12,13]. Because these snacks are constantly growing in popularity, due to their interesting aroma and taste and more and more “attractive” assortments in terms of shape and color, associated with the use of various spices, and the possibility of using potatoes with colored skin (e.g., red and purple) [14,15,16,17,18].

These snacks also owe their popularity to a certain type of “fashion” for eating them in the company of friends, especially among children and adolescents. Therefore, the producers of fried potato snacks, and, especially, scientists, are faced with the task of conducting further intensive research and searching for an effective method to reduce the amount of acrylamide in French fries and potato chips. This is also important because the amount of AA in ready products may vary depending on the way it is prepared: in production plants, prepared in a restaurant, in a fast-food, or independently at home [11,13,19,20,21,22,23,24]. This review article presents, for the first time, a detailed description of the quality characteristics of French fries and potato chips in terms of (AA) content in the ready product, as well as detailed information on traditional and new research directions concerning toxic compound content in fried potato snacks.

2. Fried Potato Products in the Form of French Fries and Potato Chips

With the progress of civilization, there is a continuous increase in the consumption of processed potatoes, in the form of fried products, which include various types of snacks, including French fries and potato chips, which enjoy constant interest from consumers around the world [2,25].

French fries (chips) are a semi-finished product and ready product that is sold frozen in a wide variety of assortments, usually in the form of strips of various thicknesses, but also in the form of slices, half-moons, and quarters, with or without skin, or even as whole small tubers. Traditional French fries are the most popular variant, defined as deep-fried potato pieces in the shape of strips with a cross-section of 10 × 10 mm and a length exceeding 6–7 cm, which contain about 4% fat when pre-fried, while ready-to-eat fries may contain about 7% fat [2]. In the United Kingdom, this product is referred to as “chips” and in Germany and France it is called “pommes frites”; however, the most popular term used in most countries is French fries [2,26].

The technological process of the production of French fries consists of the following stages: cleaning, washing and peeling the potatoes (in factories, steam peeling is used), cutting, blanching potato strips in water, pre-drying, and frying in a frying medium (industrially manufactured French fries are pre-fried—I0 frying stage), after which they have to undergo thermal processing before consumption [2]. It is also possible to obtain French fries using a two-stage frying method, first in oil at a temperature of 175 °C for 1 min (I0 frying stage), and then in oil at a temperature of 175 °C for 5 min (II0 frying stage). Potato pieces fried in this way constitute the ready product [15,27].

Potato chips (crisps) are another extremely popular potato snack that are obtained by frying thin slices of potato in fat or oil. The thickness of the slices may range from 1.27 to 2 mm [3,28,29]. After frying, the moisture content of chips varies between 1.7–1.8% (less than 2%), and the fat content may be approximately 35% (33–38%) in total [2,3,29,30]. The fat content of a traditional ready product can be about 1/3 of its weight [29,31]. There are also “light” chips, with reduced fat content, which contain approximately 25% of this ingredient [3,32]. The process of obtaining potato chips consists of several technological stages, which include cleaning, washing and peeling the raw material (industrial potato chip production uses mechanical peeling with carborundum), slicing tubers, optional blanching, drying, and frying in oil, and, while in the production plant, the potato chips are additionally seasoned with a blend of spices [2].

The technological process of the production of French fries and potato chips (including the selection of various types of parameters) has an impact on both the organoleptic properties of ready potato snacks and the content of the formed acrylamide (AA).

3. Frying Process of French Fries and Potato Chips and Organoleptic Features of Ready Potato Snacks

Both French fries and potato chips are obtained through the frying process, which is one of the most popular food processing methods alongside cooking, baking, and drying [2,26,30,33]. Traditionally obtained snacks are deep-fried in oil, which is heated to high temperatures (French fries—175–180 °C; chips—175–185 °C) [2,3,18,26,27,34,35]. During the course of this process (deep-fat frying), many transformations take place, such as simultaneous heat and mass transfer, which is connected with the flow of water vapor in opposite directions (in the form of bubbles) and oil on the surface of the fried potato pieces. As a result of this phenomenon, pores are formed on the surface of the fried product [36,37,38,39,40]. It also shapes the consistency of the ready product by creating a crispy and crunchy outer layer, while French fries are also floury inside [2,3,26,41]. The fat content of the fried potato pieces is also ultimately formed [33,39,40,42].

There are also other specific organoleptic features typical of ready-made potato products, i.e., color, characteristic taste, and smell, which are related to the course of the processes accompanying the Maillard reaction [29,43,44,45,46].

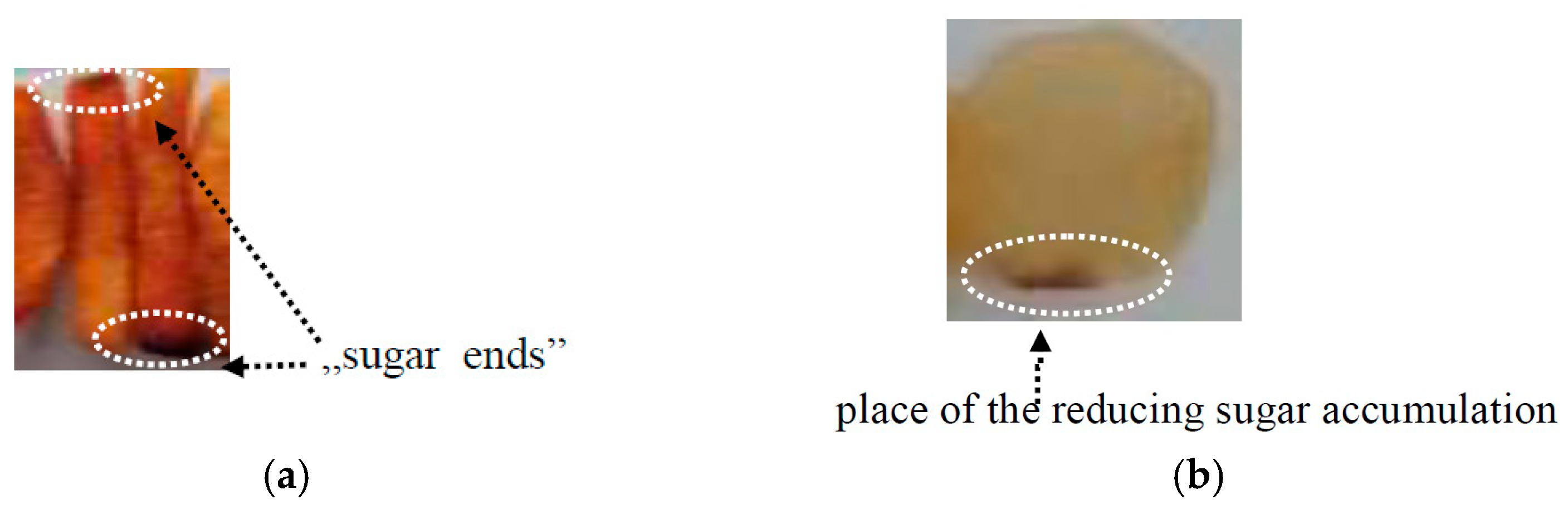

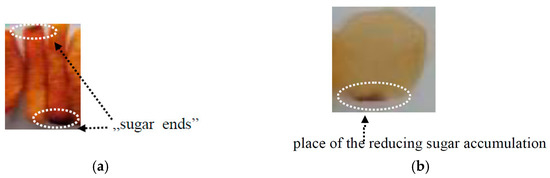

The color of French fries and potato chips is the first priority for consumers. Regardless of the method of preparing the ready potato snacks, they should be light and golden, without brown discoloration, black streaks, or stains [2,26,27,43]. The color of French fries and potato chips is related to the content of reducing sugars in potatoes and their distribution over the tuber cross-section [3,7,26,27]. The uneven distribution of sugars in the tuber—Figure 1 (higher sugar content in the top and stolon parts) may affect the browning of the ends of the French fries—the so-called “sugar end”, as can be seen in Figure 1a, while in the potato chips, brown-tinged edges of the snack may appear, as demonstrated in Figure 1b [2,26,47].

Figure 1.

Accumulation place of reducing sugars in the fried potato snacks (a) the “sugar end” in French fries (b) accumulation of reducing sugars on the edges of a fried potato chip (visible as a brown stain).

This effect in the fried product is the result of the Maillard reaction taking place with the participation of reducing sugars and free amino acids [8,10,11,45,48,49], where a bitter taste may be produced if the brown color is too intense [8,26,45,48,49]. As a result of this reaction, melanoidin compounds are formed, which not only affect the color of the ready product, but also its taste [45,46]. The taste and smell of potato snacks (French fries and potato chips) should be typical potato and oil, with no noticeable aftertaste or smell of bitterness, burning, or rancid fat [2,26,50]. During the frying process of snack products, many favorable visual and taste characteristics are formed, but high-temperature processing and the accompanying Maillard reaction also contribute to the formation of a harmful compound—acrylamide [8,10,45,49,51,52].

4. Acrylamide in Potato Snacks

Acrylamide (CH2=CH-CONH2) has been classified as “potentially carcinogenic for humans” and is classified in group 2A by the International Agency for Research on Cancer [53], and eating foods with high levels of this compound clearly increases the likelihood of developing cancer [8,10,48,52,54,55]. Acrylamide is formed as a result of the complex Maillard reaction, and the main precursors leading to its formation are reducing sugars (i.e., glucose and fructose) and amino acids—especially asparagine [8,54,56,57,58,59]. Generally, acrylamide is formed during the heating processes of raw materials (high-starch, high-carbohydrate) at a temperature above 120 °C [8,57,58,60,61], and the course of its formation has been described by many authors [57,58,60,61,62]. The rate of acrylamide formation in the fried product is not uniform and depends primarily on the water content in the raw material and the course of the process temperature [8,10,49,51,61,63]. The temperature inside the fried product (closer to its center) does not exceed 100 °C, even when the product is fried in oil at a temperature of 190 °C for a long time [31,39,40,43]. On the other hand, the temperature in the outer layer of the product is clearly higher, which explains the distribution of (AA) in the ready product. This compound is formed on the surface of the fried product (at the end of this process) when the temperature of the fried potato reaches about 120 °C–130 °C. As a result, the amount of the compound produced depends not only on the initial temperature of the oil, but also on the need to maintain a constant frying temperature throughout the course of the process [49,51,64].

The acrylamide content in French fries and potato chips may vary depending on the raw material used (its variety), cultivation and climatic factors affecting the chemical composition of potato tubers, and storage conditions [8,59,65,66,67], as well as on the application of diversified process parameters during the technological production of potato snacks [19,48,49,51,64,68,69].

The determination of the content of this compound in snack products is also affected by the method of determination. The most common methods of analyzing the amount of acrylamide in a product are measurement techniques involving gas chromatography (GC) or liquid chromatography (HPLC) using a mass spectrometer (MS) or a tandem mass spectrometer (MS-MS) [8,59,60,70,71]. Various newer measurement techniques are also used more and more often: for example, HPLC-DAD (diode array detector), HPLC (UV-detection), GC (ECD-electron capture detection), zonal capillary electrophoresis (CZE), capillary electrophoresis (CE), electrochemical biosensors, enzyme-linked immunosorbent assays (ELISA) and ultra-performance liquid chromatography (UHPLC-MS), UHPLC/MS-MS, and UHPLC-ESI-MS/MS [72,73].

Various authors report that, depending on many factors, the acrylamide content in French fries may range from ˂50 to 5312 (µg·kg−1), and in the potato chips from 59 to 12,000 (µg·kg−1) (Table 1).

Table 1.

Acrylamide content in potato snacks (French fries and potato chips).

In 2013, the European Commission [81] provided indicative values for potato snacks, for French fries at the level of 600 [µg·kg−1] and for potato chips—1000 [µg·kg−1]. In 2017, the Commission [82] decided to lower the benchmark level for French fries to 500 [μg/kg] and for potato chips to 750 [μg/kg] in order to analyze the performance of existing strategies to reduce acrylamide in ready products. These regulations have been in force since April 2018 and apply to all food producers. On the other hand, in 2020, the EFSA [20] provided recommendations on how to proceed and include additional information in the product description: for French fries, e.g., prepared at home or fried in a factory, made from potatoes or dough; for potato chips, e.g., indicate whether continuously fried or batch fried. Research on the content of acrylamide in ready-made snack products, carried out for years, has already produced results in terms of a partial reduction of its amount. However, there is still a need to find a way to reduce the toxic AA content in French fries and potato chips, due to their constantly increasing consumption.

5. Possibilities of Reducing the Acrylamide Content in French Fries and Potato Chips

Factors that influence the shaping and lower the acrylamide content in French fries and potato chips are divided into two basic groups: raw materials and technological factors. The raw material factors include the aforementioned potato variety, climatic and cultivation conditions, and potato storage (including the length of the storage period, humidity, and temperature of the process) [65,66,67]. Storage of potatoes intended for the production of French fries should be carried out at a temperature of 6–8 °C, and at 8–10 °C for potato chips, not lower, so that the tubers do not accumulate more reducing sugars [83].

5.1. Varietal Factors

Potato varieties may differ in the amount of reducing sugars and asparagine in the tuber, the content of which may be shaped depending on the climatic and cultivation (fertilization) conditions and the type of soil [65,66,84]. Climatic conditions during the growing season of potatoes may have a significant impact on the amount of accumulated reducing sugars. Water shortages in the period of tuber setting may significantly deteriorate the chemical composition of the raw material, and, therefore, proper irrigation is important. However, in the final period of potato vegetation, a large amount of rainfall and low air temperature are particularly unfavorable, because there is then an increased accumulation of reducing sugars in the tuber [84]. Under such unfavorable conditions, reducing sugars may be unevenly distributed in the potato tuber [26].

Cultivation factors in addition to potato variety and climatic conditions can affect the formation of reducing sugar and asparagine content in the tuber. Fertilizing potatoes with nitrogen in lower doses increases the content of reducing sugars both after harvest and during its storage, and, as a result, increases the amount of acrylamide in the ready product [85]. However, the application of higher nitrogen doses causes an increase in the amount of amino acids in potato tubers [86]. A higher phosphorus and lower potassium rate may increase the free asparagine and reducing sugars in potatoes, while a moderate nitrogen fertilization level together with a good potassium supply reduces the amount of both [86,87,88]. Therefore, fertilization of potatoes should be associated with the application of the appropriate rate and type of fertilizer so that, as far as possible, the amount of reactants affecting the level of AA formed is as low as possible.

The chemical composition of potato tubers, including the content of reducing sugars and asparagine, may also be influenced by soil type (sandy-loam or loamy), the content of mineral components, the degree of irrigation and aeration, and soil temperature [66,67,85,89]. Therefore, taking into account all the previously described factors, one should consider their impact on the content of two reagents (reducing sugars and asparagine) in potato tubers and their impact on the possibility of creating a toxic compound in the ready product, and, on this basis, select the appropriate variety for the production of potato snacks.

The selection of the potato variety (genotype) for the production of French fries and potato chips, and, above all, the content of reducing sugars in the tuber related to them, determines the amount of acrylamide formed in snacks [8,16,59,83,86]. There is a clear correlation between the color of French fries and potato chips and their acrylamide content: with increasing reducing sugar content in potato tubers, the acrylamide content in prepared snacks also increases and the color of the ready product deteriorates (towards brown) [8,9,48,49,52,78]. Therefore, the selection of a potato variety with the lowest content of this component determines the formation of a lower amount of the toxic compound in the ready product [48,52,59,83,86,87]. It is also advisable to use potato varieties with a low ability to create reducing sugars during the growing season, as well as accumulating a small amount during the storage of the raw material, the so-called “cold storage variety” [90].

In order to reduce the amount of acrylamide in the ready product, it is also possible to prepare French fries and potato chips, not only from potatoes with traditional (light) flesh, commonly used in processing, but also from potatoes with colored flesh, still little known. Within the group of potatoes of these varieties, there is a large variation in the intensity and uniformity of flesh and skin color, but they are generally divided into varieties with red and purple flesh [15,16,35,91,92]. Potato tubers of these varieties contain various biologically active compounds, including phenolic acids and natural anthocyanin pigments, absent in potatoes with light flesh [17,91]. The content of phenolic acids in potatoes with colored flesh can be several times higher than in potatoes with traditional flesh and they also exhibit higher antioxidant activity [93,94]. New research on the relationship between the content of biologically active compounds in potatoes and the amount of acrylamide formed in the ready product has shown a lower ability to form a toxic compound in snacks made from potatoes with colored flesh [16,95]. This is associated with the presence of antioxidant compounds, partially blocking the formation of intermediate products of the Maillard reaction, and, as a result, acrylamide in the ready product [95].

Research has also been undertaken in the field of genetic modification of potatoes, aimed at reducing the amount of asparagine in tubers. For this purpose, the asparagine synthetase gene was modified, as a result of which the amount of free asparagine decreased by almost 20 times, and the acrylamide content in the ready product also significantly decreased (only 5% of the original AA amount was left in the French fries, and 8% in the potato chips) compared to snacks obtained from potatoes without transgenic modification [96]. As a result, reducing the amount of acrylamide in potato snacks is related to the possibility of selecting a potato variety characterized by a low content of reducing sugars and asparagine in the tuber, or using solutions to reduce the level of both reagents in potatoes.

5.2. Technological Factors

Further possibilities to reduce AA are related to the course of the technological process, which may shape the final amount of this compound in the product.

5.2.1. Cutting of Potatoes

At the initial stage of the potato snack production process, the steam peeling of tubers intended for the production of French fries and the mechanical peeling of raw material intended for the preparation of potato chips are followed by the cutting of the potatoes [2,26]. As a result of the process of cutting potatoes into slices, strips, or particles, the starch granules are partially damaged and the starch is washed out when the potato pieces are rinsed in water, and there is also a slight reduction in the amount of reducing sugars and asparagine [2,26,89]. Acrylamide is formed in the outer layer of the potato product, and, therefore, the size and shape of the cross-section of the product (surface area to volume ratio) also affect the acrylamide content of the fried snacks. In studies of product size (surface to volume ratio), French fries with a smaller cross-section were found to contain more acrylamide than those with a larger cross-section [68]. Tepe et al. [80] showed that the acrylamide content of potato chips is also related to the thickness of potato slices: the thicker the chips were the less acrylamide the product had. Therefore, among the prepared slices of 3, 6, and 9 mm thickness, the thickest ones contained the least amount of this compound.

The production of French fries and potato chips is carried out using various parameters of the technological process, adapted to the type of raw material processed, so as to obtain a ready product with appropriate organoleptic features [7,10,52,68,73]. The selection of these parameters is also aimed at reducing the content of acrylamide formed in French fries and potato chips [10,19,52,97].

The thermal processes used in the production of snacks have an influence on the content of the toxic compound in the ready product [8,48,62,98]. In the production of French fries, thermal processes include blanching, pre-drying, pre-frying, and frying, while in the production of potato chips, they include blanching (optional), pre-drying, and frying or possibly drying after frying [2]. The above technological processes can be subjected to some modifications.

5.2.2. Blanching of Potato Pieces

Blanching is one of the most frequently modified stages, in which the temperature and time of the process can be appropriately selected [2,11,98,99], leading to a favorable extraction of reducing sugars and asparagine from the surface of potato pieces [98,100].

Asparagine (the most abundant of the group of free amino acids contained in potatoes), is the second most important reagent responsible for AA formation [101]. Its content in the tubers is relatively high, but it is not the main factor limiting the amount of acrylamide formed, as it is in cereals [63]. Despite this, various studies have been conducted on the possibility of reducing the amount of asparagine in potatoes. These involved the use of the enzyme asparaginase (E.C 3.5.1.1) obtained from Aspergillus oryzae, which catalyzes the breakdown of the amino acid asparagine to ammonia and aspartic acid, as a result of which asparagine does not participate in the formation of AA [29,48,52,78,102]. Blanched potato strips were dipped in a solution of 10,000 ASNU/l asparaginase (at 40 °C for 20 min), which contributed to the reduction of acrylamide in ready French fries by about 60%, by reducing the amount of asparagine in potato pieces [78]. Mogol et al. [52] emphasize that using the asparaginase enzyme has the advantage of reducing the amount of acrylamide and it also does not degrade the quality of the ready product, including its color and taste. Based on the possibility of using the enzyme asparaginase (E.C 3.5.1.1 obtained from Aspergillus oryzae) to reduce the amount of AA in snack products (French fries and potato chips), further research was conducted in this area. Dias et al. [103] used the L-asparaginase enzyme CCT 3940 (from Aspergillus oryzae) to reduce AA and found that the amount of the toxic compound in French fries was reduced by about 72%. The use of the enzyme L-asparaginase (E.C 3.5.1.1) as a solution for reducing the amount of the toxic compound in ready products was also observed by da Cunha et al. [104]. Whereas the authors Farahat et al. [105] used a novel L-asparaginase gene (CobAsnase) from halotolerant Cobetia amphilecti AMI6, cloned and over-expressed in Escherichia coli, in which potato slices were dipped before frying. After the use of this enzyme, a reduction of approximately 81% in AA content was observed in the potato chips compared to the control sample (without enzyme). A study was also conducted using a novel bacterial type II l-asparaginase, abASNase2, from Aquabac-terium sp. A7-Y, in the production of French fries and found that the enzyme had the effect of reducing the amount of acrylamide in the ready snacks by approximately 88%, compared to samples obtained without the enzyme [106]. In the study, the authors Bhagat et al. [107] showed that the use of the purified asparaginase enzyme from endophytic P. oryzihabitans bacteria, isolated from H. rosa-sinensis, in the production of fried potato pieces had the effect of reducing the amount of toxic AA by about 90% compared to the control sample.

Various types of additives for blanching solutions may also be used, e.g., the addition of monovalent and divalent ions (Na+, Ca++, Mg++). The addition of calcium and sodium chloride to the blanching solution reduced the amount of AA in French fries, by about 95% and 57%, respectively, compared to the control sample [108], and in chips by about 85% and even 90%, without compromising the texture and color of the product [78]. Research was also conducted on the possibility of using an amino acid other than asparagine for blanching. In a study by the authors Mestdagh et al. [99], the addition of glycine and lysine reduced the amount of acrylamide in snacks by about 85% on average. On the other hand, the addition of glycine and glutamine resulted in an approximately 30% reduction in AA content in model tests, but no effect of the addition of these amino acids on the reduction of the compound in French fries was found [109].

One of the new possibilities for reducing the AA content in the ready product in terms of modifying the blanching process is the use of a pulsed electric field (PEF) along with traditional blanching, preceding the frying process. The use of PEF reduced the content of the toxic compound in the potato chips by about 30% compared to the control sample blanched in water [110]. A study was also conducted using PEF in the production of French fries. It was found that this process had a significant effect on improving the shape of the cut strips (80% less damaged edges of potato pieces) and reducing the amount of fat in the ready product from 7.5% to 6.8% [111].

The amount of acrylamide formed in ready products also depends on the pH of the blanching solution, and the amount of the compound decreases with a lower pH of the solution [112,113]. In acidic media, the acrylamide formation reaction is blocked as a result of the conversion of free amino groups (-NH2) to groups (-NH3), which inhibit the formation of Schiff’s base and, as a result, a toxic compound in the ready product [52,114]. The authors used various acids to lower the pH of the blanching solutions: citric, acetic, and sodium pyrophosphate solution [98,113,114,115]. Dipping potato strips in 1% and 2% citric acid solution for 1 h reduced the amount of acrylamide in French fries by about 73% and about 80% respectively. However, a slight sour taste was detected with the 2% citric acid dipping, but no aftertaste was found in the French fries with the use of a 1% solution of this acid [114]. Blanching in a citric acid solution had a greater effect on reducing the amount of AA in French fries than in a sodium pyrophosphate solution, and its efficiency increased with the reduction of the frying temperature from 190 °C to 150 °C [98]. Dipping potato slices in an acetic acid solution at 20 °C for 60 min reduced the toxic compound content by about 90% in ready snacks [113]. Lowering the pH of the solution from 7 to 4 can reduce the acrylamide content by up to about 99%, given the lower frying temperature of the samples [114]. The advantage of choosing the right concentration of the acid used for blanching the samples is not only reducing the amount of AA in ready snacks, but also ensuring the proper color and taste of the product [114,115]. The expected lowering of the pH of the blanching solution (to about 4) can be achieved through lactic fermentation, which can have the effect of both reducing the amount of reducing sugars and amino acids (i.e., alanine, arginine, phenylalanine, serine) in the potato strips and thus the amount of AA in the ready French fries [116]. On the other hand, blanching the solution after lactic acid fermentation with the addition of glycine resulted in a 70% reduction in the amount of AA in fried potatoes (compared to those immersed only in water) and did not deteriorate the organoleptic quality of the ready product [97].

The addition of other compounds was also tested, analyzing their influence on the acrylamide content. In the studies for the asparagine and glucose model system, vitamins C, B2, and B5 were used. It was found that the addition of 1% of vitamins C, B2, and B5 reduced the amount of the toxic compound by about 60%, 20%, and 30%, respectively [117].

An interesting direction that provides a wide range of possibilities is the use of various types of plant additives for blanching or dipping samples, most often in the form of plant extracts. Herbs and spice plants are readily available and interest in them is increasing due to their content of valuable phenolic compounds [118]. These compounds in plants can reduce the amount of acrylamide in ready products by partially blocking the formation of intermediate Maillard reaction products and thus reducing the amount of the toxic compound [119]. Dipping potato pieces after blanching in a solution with bamboo leaf antioxidants had the effect of reducing the amount of AA by about 75% in both the French fries (antioxidant concentration 0.1%) and the potato chips (concentration 0.01%). On the other hand, the simultaneous application of bamboo leaf antioxidant (AOB) and green tea extract (EGT) independently reduced the amount of acrylamide in the samples by about 74%, and the presence of both antioxidants had the effect of lowering the solution pH to 6.8 [120]. Model studies (in the asparagine-glucose system) with the use of various types of plant extracts and the addition of phenolic acids showed that all aqueous extracts (except one) and almost all phenolic acids from the 11 taken for the study had an effect on reducing the amount of acrylamide [121]. In a more recent study, the addition of green tea extract, cinnamon, and oregano to potato slice dipping was used to produce French fries, which had the effect of reducing the amount of acrylamide in the snacks by approximately 62%, 39%, and 17%, respectively, compared to the control sample [95]. The addition of grape polyphenols to potato slice dipping was also used, which reduced the amount of acrylamide by about 60%, using a polyphenol concentration of 0.1% [122]. In model tests, the addition of epicatechin was used and it was found that it reduced the amount of acrylamide by blocking the course of the condensation reaction, thus inhibiting the course of the initial stages of the Maillard reaction [123].

The new direction of research was based on the use of proanthocyanidins in the production of potato chips, where soaking potato slices in 0.1 mg/ml of this additive had an effect on reducing the AA content in the ready product by about 44% [124]. On the other hand, Yu et al. [125] used the addition of lipophilic grape seed proanthocyanidin (LGSP) in the production of French fries and potato chips and found a significant reduction in the amount of acrylamide in the ready product, by about 85% and 81%, respectively. There were also studies on the addition of herbs (rosemary) to soybean oil [126] or olive oil and corn oil in which the samples were fried [75]. This addition had the effect of reducing the amount of toxic acrylamide in the ready product by approximately 25% [75]. The addition of rosemary extract was also used in the production of potato snacks, and a significant reduction in the amount of the toxic compound in fried potatoes was found, as well as a lower fat content in the ready product [127]. However, the addition of flavonoids in the spice mixture reduced the content of this compound in the product by about 50% [128].

5.2.3. Pre-Drying Process

Another thermal stage used in the technological production of French fries (and potato chips after frying) is pre-drying. The main purpose of this process is to remove excess water from the surface of the semi-finished product before frying. A lower moisture content in the cuttings allows for shorter frying times and, as a result, less fat in the French fries [3,4,12,26,27,129], and, most importantly, reduces the acrylamide content in the ready product [49]. There is a relationship between water content and water activity (aw) in the product and the aspect of acrylamide formation. It was found that acrylamide is formed with a water activity ranging between 0.4 and 0.8, while the amount of acrylamide in the ready product increases when the moisture content is below 5% [49]. Pre-drying can be carried out at different times and temperatures, along with the possibility of using the convection, microwave, and microwave-vacuum methods [129,130].

5.2.4. Frying of Potato Pieces

In the production of potato snacks, the main stage of thermal processing is frying, where the applied parameters, i.e., time and temperature, have the greatest influence on the amount of acrylamide in ready snacks [7,8,9,10,49,52,58,64,68,75]. The higher the temperature of this process and the longer its duration, the more acrylamide can be formed in the ready product [10,49,52,131]. There are many different factors associated with the frying process that shape the amount of the toxic compound in potato snacks, among which the type of oil used in the process is particularly important [32,68,79]. French fries fried in different oils had varying amounts of acrylamide. It was most abundant in samples fried in palm oil compared to rapeseed and sunflower oils [44,132]. Diversified content of the toxic compound was also characteristic for the potato chips obtained after frying potato slices in the following oils: palm olein, coconut oil, canola oil, and soybean oil. The highest amount of AA was found after using palm olein—2019 µg·kg−1 [133]. Heating different types of oil at 180 °C, resulted in a clear variation in the amount of acrylamide, the highest amount of this compound was in soybean oil (2447 µg·kg−1), followed by palm olein ˃ sunflower ˃ sesame ˃ olive ˃ corn (430 µg·kg−1) [134].

Other factors related to the frying process also include the type of fryer used (traditional or vacuum) [32,135,136], degree of oil degradation [3,137], the percentage ratio of oil used to sample [49,138], and the size of the French fries and the thickness of the potato chips [68,80,131].

5.2.5. Drying of Potato Chips after Frying

In the production process of potato chips, there is one more solution to reduce acrylamide content in the ready product. It consists of shortening the frying time of the slices and then drying them to the required humidity. As a result of the drying of potato chips after frying at 185 °C, the amount of acrylamide in the ready snacks decreased by about 70%, and after treatment at 160 °C by about 80% [113]. Koklamaz et al. [139] conducted a new study on the possibility of reducing the frying time of potato slices in oil using a conventional fryer and drying the samples to a suitable moisture content using radio-frequency (RF) drying. It was found that in potato chips dried using RF after frying the amount of acrylamide decreased by about 26% in comparison with the control sample (without drying). All the processes used in the production of French fries and potato chips may, to a greater or lesser extent, reduce the amount of acrylamide in potato snacks. However, the fundamental problem with strategies to prevent the formation of AA in ready products lies in the fact that this compound is formed through the same Maillard reactions as the compounds responsible for shaping the pleasant and desirable taste, smell, and color [1,2,7,45] quality features expected by the consumer. Therefore, these actions must be balanced in terms of maintaining the required organoleptic features of potato snacks, with the lowest possible level of acrylamide.

The harmfulness of this toxic compound for human health and life has been confirmed by many scientific studies and the consumption of potato snacks is constantly increasing. Therefore, it would be extremely important to conduct a campaign aimed at making consumers (especially children and young people) aware of the risks that acrylamide poses to their health.

6. Conclusions

Studies on the presence of toxic acrylamide (AA) in food and attempts to reduce its amount or even eliminate it from products have been carried out for some time, but this problem still has not been solved. The obligation to control the level of acrylamide in various product groups (including traditional potato snacks with an increased amount of this compound), which was introduced in April 2018, mobilized food producers to look for solutions and scientists to conduct further research on the possibility of reducing the AA level. Therefore, such actions are necessary, especially when they concern French fries and potato chips, which are more and more eagerly eaten by consumers, especially younger ones (children and teenagers).

Author Contributions

CONCEPTUALIZATION, writing—original draft preparation, Supervision, writing review, and editing—A.T.-C.; supervision—A.K. and E.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Romani, S.; Bacchiocca, M.; Rocculi, P.; Rosa, M.D. Effect of frying time on acrylamide content and quality aspects of French fries. Eur. Food Res. Technol. 2008, 226, 555–560. [Google Scholar] [CrossRef]

- Kita, A.; Lisińska, G.; Tajner-Czopek, A.; Pęksa, A.; Rytel, E. The properties of Potato Snacks Influenced by the Frying Medium. In Potato IV. Food, Global Science Books; Yee, N., Bussel, W.T., Eds.; Unitec: Auckland, New Zeland, 2009; pp. 93–98. [Google Scholar]

- Kita, A. The effect of frying on fat uptake and texture of fried potato products. Eur. J. Lipid Sci. Technol. 2014, 116, 735–740. [Google Scholar] [CrossRef]

- Teruel, M.R.; Gordon, M.B.; Linares, M.B.; Garrido, M.D.; Ahromrit, A.; Niranjan, K.A. Comparative Study of the Charac-teristics of French Fries Produced by Deep Fat Frying and Air Frying. J. Food Sci. 2015, 80, E349–E358. [Google Scholar] [CrossRef] [PubMed]

- Arslan, M.; Xiabo, Z.; Shi, J.; Rakha, A.; Hu, X.; Zareef, M.; Zhai, X.; Barsheer, S. Oil uptake by potato chips or french fries: A review. Eur. J. Lipid Sci. Technol. 2018, 120, 1800058. [Google Scholar] [CrossRef]

- Lumanlan, J.C.; Fermando, W.; Jayasena, V. Mechanisms of oil uptake during deep frying and applications of predrying and hydrocolloids in reducing fat content of chips. Int. J. Food Sci. Technol. 2020, 55, 1661–1670. [Google Scholar] [CrossRef]

- Su, Y.; Gao, J.; Tang, S.; Feng, L.; Azam, S.R.; Zheng, T. Recent advances in physical fields-based frying techniques for enhanced efficiency and quality attributes. Crit. Rev. Food Sci. Nutr. 2021. [Google Scholar] [CrossRef]

- Friedman, M. Chemistry, Biochemistry, and Safety of Acrylamide. A Review. J. Agric. Food Chem. 2003, 51, 4504–4526. [Google Scholar] [CrossRef]

- Romani, S.; Bacchiocca, M.; Rocculi, P.; Rosa, M.D. Influence of frying conditions on acrylamide content and other quality characteristics of French fries. J. Food Compos. Anal. 2009, 22, 582–588. [Google Scholar] [CrossRef]

- Friedman, M. Acrylamide: Inhibition of formation in processed food and mitigation of toxicity in cells, animals, and humans. Food Funct. 2015, 6, 1752–1772. [Google Scholar] [CrossRef]

- Paul, V.; Ezekiel, R.; Pandey, R. Acrylamide in processed potato products: Progress made and present status. Acta Physiol. Plant. 2016, 38, 276. [Google Scholar] [CrossRef]

- Dourado, C.; Pinto, C.; Barba, F.J.; Lorenzo, J.M.; Delgadillo, I.; Saraiva, J.A. Innovative non-thermal technologies affecting potato tuber and fried potato quality. Trends Food Sci. Technol. 2019, 88, 274–289. [Google Scholar] [CrossRef]

- Ledbetter, M.; Bartlett, L.; Fiore, A.; Montague, G.; Sturrock, K.; McNamara, G. Acrylamide in industrial potato crisp manufacturing: A potential tool for its reduction. LWT 2020, 123, 109111. [Google Scholar] [CrossRef]

- Kita, A.; Bąkowska-Barczak, A.; Hamouz, K.; Kułakowska, K.; Lisińska, G. The effect of frying on anthocyanin stability and antioxidant activity of crisps from red- and purple-fleshed potatoes (Solanum tuberosum L.). J. Food Compos. Anal. 2013, 32, 169–175. [Google Scholar] [CrossRef]

- Tajner-Czopek, A.; Rytel, E.; Aniołowska, M.; Hamouz, K. The influence of French fries processing on the glycoalkaloid content in coloured-fleshed potatoes. Eur. Food Res. Technol. 2014, 238, 895–904. [Google Scholar] [CrossRef]

- Furrer, A.; Cladis, D.P.; Kurilich, A.; Manoharan, R.; Ferruzzi, M.G. Changes in phenolic content of commercial potato va-rieties through industrial processing and fresh preparation. Food Chem. 2017, 218, 47–55. [Google Scholar] [CrossRef] [PubMed]

- Rytel, E.; Tajner-Czopek, A.; Kita, A.; Kucharska, A.Z.; Sokół-Łętowska, A.; Hamouz, K. Content of anthocyanins and gly-coalkaloids in blue-fleshed potatoes and changes in the content of α-solanine and α-chaconine during manufacture of fried and dried products. Int. J. Food Sci Technol. 2017, 53, 719–727. [Google Scholar] [CrossRef]

- Rytel, E.; Tajner-Czopek, A.; Kita, A.; Tkaczyńska, A.; Kucharska, A.Z.; Sokół-Łętowska, A. The Influence of the Production Process on the Anthocyanin Content and Composition in Dried Potato Cubes, Chips, and French Fries Made from Red-Fleshed Potatoes. Appl. Sci. 2021, 11, 1104. [Google Scholar] [CrossRef]

- Anese, M.; Manzocco, L.; Calligaris, S.; Nicoli, M.C. Industrially Applicable Strategies for Mitigating Acrylamide, Furan, and 5-Hydroxymethylfurfural in Food. J. Agric. Food Chem. 2013, 61, 10209–10214. [Google Scholar] [CrossRef]

- EFSA (European Food Safety Authority). Chemical Monitoring Reporting Guidance: 2020 Data Collection; European Food Safety Authority: Ej EFSA on the Wiley Online Library. 2020, Volume 17. Available online: https://doi.org/10.2903/sp.efsa.2020.EN-1796 (accessed on 12 January 2020).

- Mesias, M.; Delgado-Andrade, C.; Morales, F.J. Are Household Potato Frying Habits Suitable for Preventing Acrylamide Exposure? Foods 2020, 9, 799. [Google Scholar] [CrossRef]

- Michalak, J.; Gujska, E.; Klepacka, J. The Effect of Domestic Preparation of Some Potato Products on Acrylamide Content. Plant Foods Hum. Nutr. 2011, 66, 307–312. [Google Scholar] [CrossRef]

- Mojska, H.; Gielecińska, I. Change trends in acrylamide level in potato products in Poland in 2004–2016. Food Sci. Technol. Qual. 2018, 2, 93–107. (In Polish) [Google Scholar] [CrossRef]

- Mojska, H. Secular Trends in Food Acrylamide. In Acrylamide in Food Analysis, Content and Potential Health Effects, 1st ed.; Gökmen, V., Ed.; Academic Press: London, UK, 2016; Volume 3, pp. 39–59. [Google Scholar]

- Pedreschi, F.; Mery, D.; Marique, T. Quality Evaluation and Control of Potato Chips. In Computer Vision Technology for Food Quality Evaluation; Academic Press, Elsevier Inc.: New York, NY, USA, 2016; pp. 591–613. [Google Scholar]

- Lisińska, G.; Leszczyński, W. Potato Science and Technology; Elsevier Applied Science Publishers Ltd.: London, UK, 1989; pp. 1–391. [Google Scholar]

- Tajner-Czopek, A.; Figiel, A.; Carbonell-Barrachina, Ángel, A. Effects of potato strip size and pre-drying method on french fries quality. Eur. Food Res. Technol. 2007, 227, 757–766. [Google Scholar] [CrossRef]

- Moreira, R.G.; Sun, X.; Chen, Y. Factors affecting oil uptake in tortilla chips in deep-fat frying. J. Food Eng. 1997, 31, 485–498. [Google Scholar] [CrossRef]

- Pedreschi, F. Fried and Dehydrated Potato Products. In Advances in Potato Chemistry and Technology, 1st ed.; Singh, J., Kaur, L., Eds.; Academic Press, Elsevier Inc.: New York, NY, USA, 2009; Volume 11, pp. 319–337. [Google Scholar]

- Pedreshi, F.; Mariotti, M.S.; Cortés, P. Fried and Dehydrated Potato Products. In Advances in Potato Chemistry and Technology, 2nd ed.; Singh, J., Kaur, L., Eds.; Academic Press, Elsevier Inc.: New York, NY, USA, 2016; Volume 15, pp. 459–474. [Google Scholar]

- Mellema, M. Mechanism and reduction of fat uptake in deep-fat fried products. Trends Food Sci. Technol. 2003, 14, 364–373. [Google Scholar] [CrossRef]

- Kita, A. Reducing Saturated Fat in Savory Snacks and Fried Foods. In Reducing Saturated Fats in Foods, 1st ed.; Talbot, G., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2011; Volume 221, pp. 266–282. [Google Scholar]

- Tarmizi, A.H.A.; Niranjan, K. Post-Frying Oil Drainage from Potato Chips and French Fries: A Comparative Study of Atmospheric and Vacuum Drainage. Food Bioprocess Technol. 2011, 6, 489–497. [Google Scholar] [CrossRef]

- Lisińska, G.; Tajner-Czopek, A.; Kalum, L. The effects of enzymes on fat content and texture of French fries. Food Chem. 2007, 102, 1055–1060. [Google Scholar] [CrossRef]

- Tajner-Czopek, A.; Rytel, E.; Kita, A.; Pęksa, A.; Hamouz, K. The influence of thermal process of coloured potatoes on the content of glycoalkaloids in the potato products. Food Chem. 2012, 133, 1117–1122. [Google Scholar] [CrossRef]

- Bouchon, B.; Aquilera, J.M.; Pyle, D.L. Structure Oil-Absorption Relationships During Deep-Fat Frying. J. Food Sci. 2003, 68, 2711–2716. [Google Scholar] [CrossRef]

- Achir, N.; Vitrac, O.; Trystram, G. Simulation and ability to control the surface thermal history and reactions during deep fat frying. Chem. Eng. Process. Process. Intensif. 2008, 47, 1953–1967. [Google Scholar] [CrossRef]

- Kalogianni, E.P.; Papastergiadis, E. Crust pore characteristics and their development during frying of French-fries. J. Food Eng. 2014, 120, 175–182. [Google Scholar] [CrossRef]

- Patsioura, A.; Vauvre, J.-M.; Kesteloot, R.; Smith, P.; Trystram, G.; Vitrac, O. Mechanisms of Oil Uptake in French Fries. In Advances in Potato Chemistry and Technology, 2nd ed.; Singh, J., Kaur, L., Eds.; Academic Press, Elsevier Inc.: New York, NY, USA, 2016; Volume 17, pp. 503–526. [Google Scholar]

- Zhang, J.; Liu, Y.; Fan, L. Effect of pore characteristics on oil absorption behavior during frying of potato chips. Innov. Food Sci. Emerg. Technol. 2020, 66, 102508. [Google Scholar] [CrossRef]

- Tajner-Czopek, A. Changes of pectic substances concentration in potatoes and French fries and the effect of these substances on the texture of the final product. Food/Nahrung 2003, 47, 228–231. [Google Scholar] [CrossRef]

- Miranda, M.L.; Aguilera, J.M. Structure and Texture Properties of Fried Potato Products. Food Rev. Int. 2006, 22, 173–201. [Google Scholar] [CrossRef]

- Pedreschi, F. Frying of Potatoes: Physical, Chemical, and Microstructural Changes. Dry. Technol. 2012, 30, 707–725. [Google Scholar] [CrossRef]

- Gertz, C. Fundamentals of the frying process*. Eur. J. Lipid Sci. Technol. 2014, 116, 669–674. [Google Scholar] [CrossRef]

- Liska, D.A.J.; Cook, C.M.; Wang, D.D.; Szpylka, J. Maillard reaction products and potatoes: Have the benefits been clearly assessed? Food Sci. Nutr. 2016, 4, 234–249. Available online: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4779479/pdf/FSN3-4-234.pdf (accessed on 21 March 2021). [CrossRef]

- Mesías, M.; Delgado-Andrade, C. Melanoidins as a potential functional food ingredient. Curr. Opin. Food Sci. 2017, 14, 37–42. [Google Scholar] [CrossRef]

- Lisińska, G.; Pęksa, A.; Kita, A.; Rytel, E.; Tajner-Czopek, A. The quality of potato for processing and con-sumption. In Global Science Books; Potato III. Food; Yee, N., Bussel, W.T., Eds.; Unitec: Auckland, New Zeland, 2009; pp. 99–104. [Google Scholar]

- Pedreschi, F.; Mariotti, M.S.; Granby, K. Current issues in dietary acrylamide: Formation, mitigation and risk assessment. J. Sci. Food Agric. 2013, 94, 9–20. [Google Scholar] [CrossRef]

- Gökmen, V.; Pazaloğlu, T.K. Acrylamide formation in foods during thermal processing with a focus on frying. Food Bioprocess Tech. 2008, 1, 35–42. [Google Scholar] [CrossRef]

- Kitizo, K.F.; Abdel-Aal, M.H.; Ragab, M.H.; Youssef, M.M. Quality attributes of French fries as affected by different coatings, frozen storage and frying conditions. J. Agric. Sci. Bot. 2017, 1, 18–24. [Google Scholar] [CrossRef]

- Vinci, R.M.; Mestdagh, F.; De Meulenaer, B. Acrylamide formation in fried potato products—Present and future, a critical review on mitigation strategies. Food Chem. 2012, 133, 1138–1154. [Google Scholar] [CrossRef]

- Mogol, B.A.; Hamzalıoğlu, A.; Gökmen, V. Mitigation of Acrylamide in Thermally Processed Foods. In Comprehensive Foodomics, 1st ed.; Cifuentes, A., Ed.; Elsevier Inc.: New York, NY, USA, 2021; Volume 3, pp. 32–43. [Google Scholar]

- IARC (International Agency for Research on Cancer). Acrylamide. Monographs on the Evaluation of the Carcinogenic Risk of Chemical to Humans; IARC: Lyon, France, 1994; pp. 389–433. [Google Scholar]

- Friedman, M.; Levin, C.E. Review of methods for the reduction of dietary content and toxicity of acrylamide. J. Agric. Food Chem. 2008, 56, 6113–6140. [Google Scholar] [CrossRef] [PubMed]

- Rafai, L.; Saleh, F.A. A Review on Acrylamide in Food: Occurrence, Toxicity, and Mitigation Strategies. Int. J. Toxic. 2020, 39, 93–102. [Google Scholar] [CrossRef] [PubMed]

- Yaylayan, V.A.; Wronowski, A.; Locas, C.P. Why asparagine needs carbohydrates to generate acrylamide. J. Agric. Food Chem. 2003, 51, 1753–1757. [Google Scholar] [CrossRef] [PubMed]

- Stadler, R.H.; Blank, I.; Varga, N.; Robert, F.; Hau, J.; Guy, P.A.; Robert, M.-C.; Riediker, S. Acrylamide from Maillard reaction products. Nat. Cell Biol. 2002, 419, 449–450. [Google Scholar] [CrossRef]

- Tareke, E.; Rydberg, P.; Karlsson, P.; Eriksson, S.; Törnqvist, M. Analysis of Acrylamide, a Carcinogen Formed in Heated Foodstuffs. J. Agric. Food Chem. 2002, 50, 4998–5006. [Google Scholar] [CrossRef]

- Lineback, D.R.; Coughlin, J.R.; Stadler, R.H. Acrylamide in Foods: A Review of the Science and Future Considerations. Annu. Rev. Food Sci. Technol. 2012, 3, 15–35. [Google Scholar] [CrossRef]

- Rosén, J.; Hellenäs, K.-E. Analysis of acrylamide in cooked foods by liquid chromatography tandem mass spectrometry. Analyst 2002, 127, 880–882. [Google Scholar] [CrossRef]

- Maan, A.A.; Anjum, M.A.; Khan, M.K.I.; Nazir, A.; Saeed, F.; Afzaal, M.; Aadil, R.M. Acrylamide Formation and Different Mitigation Strategies during Food Processing—A Review. Food Rev. Int. 2020, 5, 1–18. [Google Scholar] [CrossRef]

- Zyzak, D.V.; Sanders, R.A.; Stojanovic, M.; Tallmadge, D.H.; Eberhart, B.L.; Ewald, D.K.; Gruber, D.C.; Morsch, T.R.; Strothers, M.A.; Rizzi, G.P.; et al. Acrylamide Formation Mechanism in Heated Foods. J. Agric. Food Chem. 2003, 51, 4782–4787. [Google Scholar] [CrossRef]

- Claeys, W.L.; De Vleeschouwer, K.; Hendrickx, M.E. Quantifying the formation of carcinogens during food processing: Acrylamide. Trends Food Sci. Technol. 2005, 16, 181–193. [Google Scholar] [CrossRef]

- Gökmen, V.; Palazoğlu, T.K.; Şenyuva, H.Z. Relation between the acrylamide formation and time–temperature history of surface and core regions of French fries. J. Food Eng. 2006, 77, 972–976. [Google Scholar] [CrossRef]

- Muttucumaru, N.; Powers, S.J.; Elmore, J.S.; Mottram, D.S.; Halford, N.G. Effects of Nitrogen and Sulfur Fertilization on Free Amino Acids, Sugars, and Acrylamide-Forming Potential in Potato. J. Agric. Food Chem. 2013, 61, 6734–6742. [Google Scholar] [CrossRef]

- Muttucumaru, N.; Powers, S.J.; Elmore, J.S.; Dodson, A.; Briddon, A.; Mottram, D.S.; Halford, N.G. Acrylamide-forming potential of potatoes grown at different locations, and the ratio of free asparagine to reducing sugars at which free asparagine becomes a limiting factor for acrylamide formation. Food Chem. 2017, 220, 76–86. [Google Scholar] [CrossRef]

- Krishnakumar, T.; Visvanathan, R. Acrylamide in Food Products: A Review. J. Food Process Technol. 2014, 5, 1000344. [Google Scholar] [CrossRef]

- Matthäus, B.; Haase, N.U.; Vosmann, K. Factors affecting the concentration of acrylamide during deep-fat frying of potatoes. Eur. J. Lipid Sci. Technol. 2004, 106, 793–801. [Google Scholar] [CrossRef]

- Wicklund, T.; Østlie, H.; Lothe, O.; Knutsen, S.H.; Bråthen, E.; Kita, A. Acrylamide in potato crisp—the effect of raw material and processing. LWT-Food Sci. Technol. 2006, 39, 571–575. [Google Scholar] [CrossRef]

- Oracz, J.; Nebesny, E.; Żyżelewicz, D. New trends in quantification of acrylamide in food products. Talanta 2011, 86, 23–34. [Google Scholar] [CrossRef]

- Mojska, H.; Gielecińska, I.; Małecka, K. Determination of acrylamide content in potato products using GC-MS/MS and LC-MS/MS methods. Roczniki Panstwowego Zakladu Higieny 2010, 61, 237–242. (In Polish) [Google Scholar]

- Cantrell, M.S.; McDougal, O.M. Biomedical rationale for acrylamide regulation and methods of detection. Compr. Rev. Food Sci. Food Saf. 2021, 20, 2176–2205. [Google Scholar] [CrossRef]

- Pan, M.; Liu, K.; Yang, J.; Hong, L.; Xie, X.; Wang, S. Review of Research into the Determination of Acrylamide in Foods. Foods 2020, 9, 524. [Google Scholar] [CrossRef]

- FAO/WHO. Report of a Joint FAO/WHO Consultation on the Health Implications of Acrylamide in Food. In Collaboration with the Food and Agriculture Organization of the United Nations; World Health Organization: Geneva, Switzerland, 2002; Available online: http://www.who.int/fsf (accessed on 11 January 2020).

- Becalski, A.; Lau, B.P.-Y.; Lewis, A.D.; Seaman, S.W. Acrylamide in Foods: Occurrence, Sources, and Modeling. J. Agric. Food Chem. 2003, 51, 802–808. [Google Scholar] [CrossRef]

- JECFA—Joint Expert Committee on Food Additives. Report of the 64th Meeting; Acrylamide: Rome, Italy, 2005. [Google Scholar]

- Ölmez, H.; Tuncay, F.; Özcan, N.; Demirel, S. A survey of acrylamide levels in foods from the Turkish market. J. Food Compos. Anal. 2008, 21, 564–568. [Google Scholar] [CrossRef]

- Pedreschi, F.; Kaack, K.; Granby, K. The effect of asparaginase on acrylamide formation in French fries. Food Chem. 2008, 109, 386–392. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, H.; Cheng, L.; Wang, L.; Qian, H. Influence of deep-frying using various commercial oils on acrylamide formation in French fries. Food Addit. Contam. Part A 2015, 32, 1083–1088. [Google Scholar] [CrossRef] [PubMed]

- Tepe, T.K.; Kadakal, Ç. Temperature and slice size dependences of acrylamide in potato fries. J. Food Process. Preserv. 2019, 43, 2–11. [Google Scholar] [CrossRef]

- European Commision. On Investigations into the Levels of Acrylamide in Food; EC: Brussels, Belgium, 2013; Available online: https://eurlex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2013:301:0015:0017:EN:PDF (accessed on 10 January 2020).

- European Commision. Establishing Mitigation Measures and Benchmark Levels for the Reduction of the Presence of Acrylamide in Food; EC: Brussels, Belgium, 2017; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32017R2158 (accessed on 12 January 2020).

- De Wilde, T.; De Meulenaer, B.; Mestdagh, F.; Govaert, Y.; Vandeburie, S.; Ooghe, W.; Fraselle, S.; Demeulemeester, K.; Van Peteghem, C.; Calus, A.; et al. Influence of Storage Practices on Acrylamide Formation during Potato Frying. J. Agric. Food Chem. 2005, 53, 6550–6557. [Google Scholar] [CrossRef]

- Kumar, D.; Singh, B.P.; Kumar, P. An overview of the factors affecting sugar content of potatoes. Ann. Appl. Biol. 2004, 145, 247–256. [Google Scholar] [CrossRef]

- De Wilde, T.; De Meulenaer, B.; Mestdagh, F.; Govaert, Y.; Vandeburie, S.; Ooghe, W.; Fraselle, S.; Demeulemeester, K.; Van Peteghem, C.; Calus, A.; et al. Influence of Fertilization on Acrylamide Formation during Frying of Potatoes Harvested in 2003. J. Agric. Food Chem. 2006, 54, 404–408. [Google Scholar] [CrossRef] [PubMed]

- Silva, E.M.; Simon, P.W. Genetic, Physiological and Environmental Factors Affecting Acrylamide Concentration in Fried Products. In Chemistry and Safety of Acrylamide in Food, 1st ed.; Friedman, M., Mottram, D., Eds.; Springer: New York, NY, USA, 2005; Volume 561, pp. 371–386. [Google Scholar]

- Amrein, T.M.; Bachmann, S.; Noti, A.; Biedermann, M.; Barbosa, M.F.; Biedermann-Brem, S.; Grob, K.; Keiser, A.; Realini, P.; Escher, F.; et al. Potential of Acrylamide Formation, Sugars, and Free Asparagine in Potatoes: A Comparison of Cultivars and Farming Systems. J. Agric. Food Chem. 2003, 51, 5556–5560. [Google Scholar] [CrossRef] [PubMed]

- Gerendas, J.; Heuser, F.; Sattelmacher, B. Influence of nitrogen and potassium supply on contents of acrylamide precursors in potato trubers and on acrylamide accumulation in french fries. J. Plant Nutr. 2007, 30, 1499–1516. [Google Scholar] [CrossRef]

- Torres, M.D.A.; Parreńo, W.C. Thermal Processing of Potatoes. In Advances in Potato Chemistry and Technology, 2nd ed.; Singh, J., Kaur, L., Eds.; Academic Press, Elsevier Inc.: New York, NY, USA, 2016; Volume 14, pp. 403–457. [Google Scholar]

- Edwards, C.G.; Englar, J.W.; Brown, C.R.; Peterson, J.C.; Sorensen, E.J. Changes in color and sugar content of yellow—fleshed potatoes stored at three different temperatures. Am. J. Potato Res. 2002, 79, 49–53. [Google Scholar] [CrossRef]

- Rytel, E.; Nemś, A.; Peksa, A.; Kita, A.; Miedzianka, J.; Tajner-Czopek, A.; Kucharska, A.Z.; Sokół-Łętowska, A.; Hamouz, K. Discolouration of raw and cooked coloured fleshed potatoes differing in anthocyanins and polyphenols content. Int. J. Food Sci. Technol. 2019, 54, 92–101. [Google Scholar] [CrossRef]

- Ru, W.; Pang, Y.; Gan, Y.; Liu, Q.; Bao, J. Phenolic Compounds and Antioxidant Activities of Potato Cultivars with White, Yellow, Red and Purple Flesh. Antioxidants 2019, 8, 419. [Google Scholar] [CrossRef] [PubMed]

- Bellumori, M.; Innocenti, M.; Michelozzi, M.; Cerretani, L.; Mulinacci, N. Coloured-fleshed potatoes after boiling: Promising sources of known antioxidant compounds. J. Food Compos. Anal. 2017, 59, 1–7. [Google Scholar] [CrossRef]

- Rytel, E.; Tajner-Czopek, A.; Kita, A.; Aniołowska, M.; Kucharska, A.; Sokół-Łętowska, A.; Hamouz, K. Content of polyphenols in coloured and yellow fleshed potatoes during dices processing. Food Chem. 2014, 161, 224–229. [Google Scholar] [CrossRef] [PubMed]

- Morales, G.; Jimenez, M.; Garcia, O.; Mendoza, M.R.; Beristain, C.I. Effect of natural extracts on the formation of acrylamide in fried potatoes. LWT-Food Sci. Technol. 2014, 58, 587–593. [Google Scholar] [CrossRef]

- Rommens, C.M.; Yan, H.; Swords, K.; Richael, C.; Ye, J. Low-acrylamide French fries and potato chips. Plant Biotechnol. J. 2008, 6, 843–853. [Google Scholar] [CrossRef]

- Anese, M.; Suman, M.; Nicoli, M.C. Technological Strategies to Reduce Acrylamide Levels in Heated Foods. Food Eng. Rev. 2009, 1, 169–179. [Google Scholar] [CrossRef]

- Pedreschi, F.; Kaack, K.; Granby, K.; Troncoso, E. Acrylamide reduction under different pre-treatments in French fries. J. Food Eng. 2007, 79, 1287–1294. [Google Scholar] [CrossRef]

- Mestdagh, F.; Maertens, J.; Cucu, T.; Delporte, K.; Van Peteghem, C.; De Meulenaer, B. Impact of additives to lower the formation of acrylamide in a potato model system through pH reduction and other mechanisms. Food Chem. 2008, 107, 26–31. [Google Scholar] [CrossRef]

- Mestdagh, F.; De Wilde, T.; Fraselle, S.; Govaert, Y.; Ooghe, W.; Degroodt, J.M.; Vehre, R.; Van Peteghem, C.; De Meulenaer, B. Optimization of the blanching proces to reduce acrylamide in fried potatoes. Food Sci. Technol. 2008, 41, 1648–1654. [Google Scholar] [CrossRef]

- Amrein, T.M.; Schönbächler, B.; Rohner, F.; Lukac, H.; Schneider, H.; Keiser, A.; Escher, F.; Amadò, R. 2004b. Potential for acrylamide formation in potatoes: Data from the 2003 harvest. Eur. Food Res. Technol. 2004, 219, 572–578. [Google Scholar] [CrossRef]

- Hendriksen, H.V.; Kornbrust, B.A.; Østergaard, P.R.; Stringer, M.A. Evaluating the Potential for Enzymatic Acrylamide Mitigation in a Range of Food Products Using an Asparaginase from Aspergillus oryzae. J. Agric. Food Chem. 2009, 57, 4168–4176. [Google Scholar] [CrossRef] [PubMed]

- Dias, F.F.G.; Junior, S.B.; Hantao, L.W.; Augusto, F.; Sato, H.H. Acrylamide mitigation in French fries using native l-asparaginase from Aspergillus oryzae CCT 3940. LWT-Food Sci. Technol. 2017, 76, 222–229. [Google Scholar] [CrossRef]

- Da Cunha, M.C.; Aguilar, J.G.D.; de Melo, R.R.; Nagamatsu, S.T.; Ali, F.; de Castro, R.J.S.; Sato, H.H. Fungal L-asparaginase: Strategies for production and food applications. Food Res. Inter. 2019, 126, 108658. [Google Scholar] [CrossRef]

- Farahat, M.G.; Amr, D.; Galal, A. Molecular cloning, structural modeling and characterization of a novel glutaminase-free L-asparaginase from Cobetia amphilecti AMI6. Int. J. Biol. Macromol. 2020, 143, 685–695. [Google Scholar] [CrossRef]

- Sun, Z.; Qin, R.; Li, D.; Ji, K.; Wang, T.; Cui, Z.; Huang, Z. A novel bacterial type II l-asparaginase and evaluation of itsenzymatic acrylamide reduction in French fries. Int. J. Biol. Macromol. 2016, 92, 232–239. [Google Scholar] [CrossRef]

- Bhagat, J.; Kaur, A.; Chadha, B.S. Single step purification of asparaginase from endophytic bacteria Pseudomonas oryzihabitans exhibiting high potential to reduce acrylamide in processed potato chips. Food Bioprod. Process. 2016, 99, 222–230. [Google Scholar] [CrossRef]

- Gökmen, V.; Şenyuva, H.Z. Acrylamide formation is prevented by divalent cations during the Maillard reaction. Food Chem. 2007, 103, 196–203. [Google Scholar] [CrossRef]

- Bråthen, E.; Kita, A.; Knutsen, S.H.; Wicklund, T. Addition of glycine reduces the content of acrylamide in ce-real and potato products. J. Agric. Food Chem. 2005, 53, 3259–3264. [Google Scholar] [CrossRef]

- Genovese, J.; Tappi, S.; Luo, W.; Tylewicz, U.; Marzocchi, S.; Marziali, S.; Romani, S.; Ragni, L.; Rocculi, P. Important factors to consider for acrylamide mitigation in potato crisps using pulsed electric fields. Innov. Food Sci. Emerg. Technol. 2019, 55, 18–26. [Google Scholar] [CrossRef]

- Fauster, T.; Schlossiki, D.; Rath, F.; Ostermeier, R.; Teufel, F.; Toepfl, S.; Jaeger, H. Impact of pulsed electric field (PEF) pretreatment on process performance of industrial French fries production. J. food Eng. 2018, 235, 16–22. [Google Scholar] [CrossRef]

- Rydberg, P.; Eriksson, S.; Tareke, E.; Karlsson, P.; Ehrenberg, A.L.; Törnqvist, M. Investigations of Factors That Influence the Acrylamide Content of Heated Foodstuffs. J. Agric. Food Chem. 2003, 51, 7012–7018. [Google Scholar] [CrossRef] [PubMed]

- Kita, A.; Bråthen, E.; Knutsen, S.H.; Wicklund, T. Effective ways of decreasing acrylamide content in potato crisps during processing. J. Agric. Food Chem. 2004, 52, 7011–7016. [Google Scholar] [CrossRef] [PubMed]

- Jung, M.; Choi, D.; Ju, J. A Novel Technique for Limitation of Acrylamide Formation in Fried and Baked Corn Chips and in French Fries. J. Food Sci. 2003, 68, 1287–1290. [Google Scholar] [CrossRef]

- Sansano, M.; Juan-Borrás, M.; Escriche, I.; Andrés, A.; Heredia, A. Effect of Pretreatments and Air-Frying, a Novel Technology, on Acrylamide Generation in Fried Potatoes. J. Food Sci. 2015, 80, T1120–T1128. [Google Scholar] [CrossRef]

- Baardseth, P.; Blom, H.; Skrede, G.; Mydland, L.T.; Skrede, A.; Slinde, E. Lactic Acid Fermentation Reduces Acrylamide Formation and Other Maillard Reactions in French Fries. J. Food Sci. 2006, 71, C28–C33. [Google Scholar] [CrossRef]

- Wang, X.; Xu, L. Influence Factors on the Formation of Acrylamide in the Amino Acid/Sugar Chemical Model System. J. Food Nutr. Res. 2014, 2, 344–348. [Google Scholar] [CrossRef][Green Version]

- Tajner-Czopek, A.; Gertchen, M.; Rytel, E.; Kita, A.; Kucharska, A.Z.; Sokół-Łętowska, A. Study of Antioxidant Activity of Some Medicinal Plants Having High Content of Caffeic Acid Derivatives. Antioxidants 2020, 9, 412. [Google Scholar] [CrossRef]

- Kahkeshani, N.; Saeidnia, S.; Abdollahi, M. Role of antioxidants and phytochemicals on acrylamide mitigation from food and reducing its toxicity. J. Food Sci. Technol. 2014, 52, 1–18. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, J.; Zhang, X.; Wu, X.; Zhang, Y. Addition of antioxidant of bamboo leaves (AOB) effectively reduces acrylamide formation in potato crips and French fries. J. Agric. Food Chem. 2007, 55, 523–528. [Google Scholar] [CrossRef]

- Zhu, F.; Cai, Y.-Z.; Ke, J.; Corke, H. Evaluation of the effect of plant extracts and phenolic compounds on reduction of acrylamide in an asparagine/glucose model system by RP-HPLC-DAD. J. Sci. Food Agric. 2009, 89, 1674–1681. [Google Scholar] [CrossRef]

- Xu, C.; Yagiz, Y.; Marshall, S.; Li, Z.; Simmone, A.; Lu, J.; Marshall, M.R. Application of muscadine grape (Vitis rotundifolia Michx.) pomace extract to reduce carcinogenic acrylamide. Food Chem. 2015, 182, 200–208. [Google Scholar] [CrossRef] [PubMed]

- Qi, Y.; Zhang, H.; Zhang, H.; Wu, G.; Wang, L.; Qian, H.; Qi, X. Epicatechin Adducting with 5-Hydroxymethylfurfural as an Inhibitory Mechanism against Acrylamide Formation in Maillard Reactions. J. Agric. Food Chem. 2018, 66, 12536–12543. [Google Scholar] [CrossRef]

- Qi, Y.; Zhang, H.; Wu, G.; Zhang, H.; Gu, L.; Wang, L.; Qian, H.; Qi, X. Mitigation effects of proanthocyanidins with different structures on acrylamide formation in chemical and fried potato crisp models. Food Chem. 2018, 250, 98–104. [Google Scholar] [CrossRef]

- Yu, S.; Chen, Z.; Meng, H.; Chen, M. Addition of lipophilic grape seed proanthocyanidin effectively reduces acrylamide formation. J. Sci. Food Agric. 2019, 100, 1213–1219. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Yang, X.; Lee, W.J.; Huang, F.; Wang, Y.; Li, Y. Comparison between synthetic and rosemary-based antioxidants for the deep frying of French fries in refined soybean oils evaluated by chemical and non-destructive rapid methods. Food Chem. 2021, 335, 127638. [Google Scholar] [CrossRef] [PubMed]

- Urbančič, S.; Kolar, M.H.; Dimitrijević, D.; Demšar, L.; Vidrih, R. Stabilisation of sunflower oil and reduction of acrylamide formation of potato with rosemary extract during deep-fat frying. LWT-Food Sci. Technol. 2014, 57, 671–678. [Google Scholar] [CrossRef]

- Fernández, S.; Kurppa, L.; Hyvönen, L. Content of acrylamide decreases in potato chips with addition of a proprietary flavonoid spice mix (Flavomare) in frying. Innov. Food Technol. 2003, 18, 24–26. [Google Scholar]

- Tajner-Czopek, A.; Figiel, A.; Rytel, E. Effect of potato strips pre-drying method on French fries quality. Polish J. Food Nutr. Sci. 2007, 57, 175–181. [Google Scholar] [CrossRef]

- Michalak, J.; Czarnowska-Kujawska, M.; Klepacka, J.; Gujska, E. Effect of Microwave Heating on the Acrylamide Formationin Foods. Molecules 2020, 25, 4140. [Google Scholar] [CrossRef] [PubMed]

- Martinez, E.; Rodriguez, J.A.; Mondragon, A.C.; Lorenzo, J.M.; Santos, E.M. Influence of Potato Crisps Processing Parameters on Acrylamide Formation and Bioaccesibility. Molecules 2019, 24, 3827. [Google Scholar] [CrossRef]

- Gertz, C.; Klostermann, S. Analysis of acrylamide and mechanisms of its formation in deep-fried products. Eur. J. Lipid Sci. Technol. 2002, 104, 762–771. [Google Scholar] [CrossRef]

- Lim, P.; Jinap, S.; Sanny, M.; Tan, C.; Khatib, A. The Influence of Deep Frying Using Various Vegetable Oils on Acrylamide Formation in Sweet Potato (Ipomoea batatasL. Lam) Chips. J. Food Sci. 2014, 79, T115–T121. [Google Scholar] [CrossRef]

- Daniali, G.; Jinap, S.; Hajeb, P.; Sanny, M.; Tan, C. Acrylamide formation in vegetable oils and animal fats during heat treatment. Food Chem. 2016, 212, 244–249. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, M.; Zhang, W. Effect of low temperature on the microwave-assisted vacuum frying of potato chips. Dry. Technol. 2015, 34, 227–234. [Google Scholar] [CrossRef]

- Yagua, C.V.; Moreira, R.G. Physical and thermal properties of potato chips during vacuum frying. J. Food Eng. 2011, 104, 272–283. [Google Scholar] [CrossRef]

- Mestdagh, F.; De Meulenaer, B.; Van Peteghem, C. Influence of oil degradation on the amounts of acrylamide generated in a model system and in French fries. Food Chem. 2007, 100, 1153–1159. [Google Scholar] [CrossRef]

- Taubert, D.; Harlfinger, S.; Henkes, L.; Berkels, R.; Schömig, E. Influence of Processing Parameters on Acrylamide Formation during Frying of Potatoes. J. Agric. Food Chem. 2004, 52, 2735–2739. [Google Scholar] [CrossRef] [PubMed]

- Koklamaz, E.; Palazoğlu, T.K.; Kocadağlı, T.; Gökmen, V. Effect of combining conventional frying with radio-frequency post-drying on acrylamide level and quality attributes of potato chips. J. Sci. Food Agric. 2014, 94, 2002–2008. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).