Study on the Evaluation Methods of the Vertical Ride Comfort of Railway Vehicle—Mean Comfort Method and Sperling’s Method

Abstract

:1. Introduction

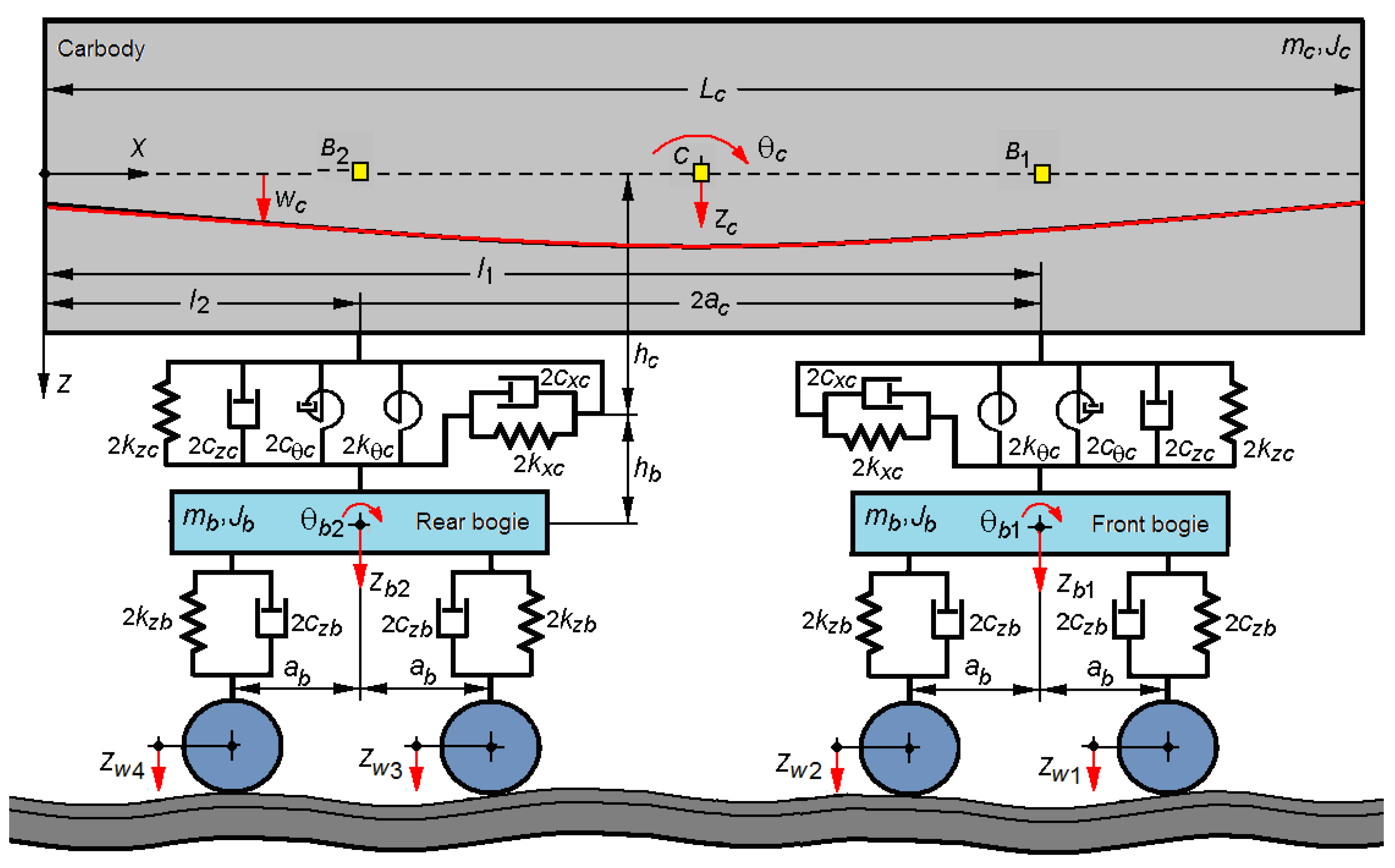

2. Model of the Railway Vehicle for Ride Comfort Assessment at Vertical Vibrations

3. The Dynamic Response of the Railway Vehicle to the Track Vertical Irregularities

4. Ride Comfort Assessment Methods

4.1. Mean Comfort Method

4.2. Sperling’s Method

5. Results and Discussion

5.1. Analysis of the Dynamic Response of the Vehicle Carbody

5.2. Analysis of the Ride Comfort Indices

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Kim, Y.G.; Kwon, H.B.; Kim, S.W.; Park, C.K.; Park, T.W. Correlation of ride comfort evaluation methods for railway vehicles. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2003, 217, 73–88. [Google Scholar] [CrossRef]

- Kim, Y.G.; Choi, S.; Kim, S.W.; Kim, Y.M.; Park, T.W. An experimental study on the ride comfort of the Korean high-speed train. Techniques 2009, 33, 30–37. [Google Scholar] [CrossRef]

- Stănică, D.I.; Dumitriu, M. Critical points numerical analysis of ride comfort of the flexible railway carbody. IOP Conf. Ser. Mater. Sci. Eng. 2019, 682, 012007. [Google Scholar] [CrossRef]

- Kardas-Cinal, E. Ride comfort for various passenger positions in a railwayvehicle—Simulations tudy. Arch. Transp. 2010, 22, 189–199. [Google Scholar] [CrossRef]

- Vincent, J. Etude du Concept de Suspensions Actives. Applications Aux Voitures Ferroviaires. Ph.D. Thesis, Ecole Doctorale de Mécanique de Lyon, Lyon, France, 1999. [Google Scholar]

- Mansfield, N.J. Human Response to Vibration; CRC Press LLC: Boca Raton, FL, USA, 2005. [Google Scholar]

- Griffin, M.J. Handbook of Human Vibration; Academic Press: London, UK, 1990. [Google Scholar]

- Richards, G.L. On the Psychology of Passenger Comfort. In Human Factors in Transport Research; Academic Press: New York, NY, USA, 1980; Volume 2. [Google Scholar]

- Suzuki, H. Effects of the range and frequency of vibrations on the momentary riding comfort evaluation of a railway vehicle. Jpn. Psychol. Res. 1998, 40, 156–165. [Google Scholar] [CrossRef]

- Munawir, T.I.T.; Samah, A.A.A.; Rosle, M.A.A.; Azlis-Sani, J.; Hasnan, K.; Sabri, S.M.; Ismail, S.M.; Yunos, M.N.A.M.; Bin, T.Y. A comparison study on the assessment of ride comfort for LRT passengers. IOP Conf. Ser. Mater. Sci. Eng. 2017, 226, 012039. [Google Scholar] [CrossRef] [Green Version]

- Wei, X.; Liu, Y.; Sun, Q.; Jia, L.; Wang, Y. Rail vehicle ride comfort prediction based on bogie acceleration measurements. In Proceedings of the 2013 25th Chinese Control and Decision Conference (CCDC), Guiyang, China, 25–27 May 2013; pp. 3810–3815. [Google Scholar]

- Iwnicki, S. Handbook of Railway Vehicle Dynamics; Taylor&Francis Group: Milton Park, UK, 2006. [Google Scholar]

- Dumitriu, M.; Leu, M. Correlation between ride comfort index and Sperling’s index for evaluation ride comfort in railway vehicles. Appl. Mech. Mater. 2018, 880, 201–206. [Google Scholar] [CrossRef]

- ISO 2631. Guide for the Evaluation of Human Exposure to Whole-Body Vibration; ISO: Geneva, Switzerland, 1974. [Google Scholar]

- ISO 2631-1. Mechanical Vibration and Shock—Evaluation of Human Exposure to Whole-Body Vibration. Part 1: General Requirements; ISO: Geneva, Switzerland, 1985. [Google Scholar]

- ISO2631-3. Evaluation of Human Exposure to Whole-Body Vibration—Part 3: Evaluation of Exposure to Whole-Body Z-Axis Vertical Vibration in the Frequency Range 0.1 to 0.63 Hz; ISO: Geneva, Switzerland, 1985. [Google Scholar]

- ISO 2631-1. Mechanical Vibration and Shock—Evaluation of Human Exposure to Whole-Body Vibration. Part 1: General Requirements; ISO: Geneva, Switzerland, 1997. [Google Scholar]

- AS 2670-1. Evaluation of Human Exposure to Whole-Body Vibration. General Requirements; Standards Australia: Sydney, Australia, 1983. [Google Scholar]

- BS 6841. Guide to Measurement and Evaluation of Human Exposure to Whole-Body Mechanical Vibration and Repeated Shock; BSI: London, UK, 1987. [Google Scholar]

- Helbig, W.; Sperling, E. Verfahren zur beurteilung der laufeigenschaften von eisenbahnwagen (Process for the evaluation of the running behavior of railway vehicles). Organ Für Die Fortschr. Des Eisenb. 1941, 96, 177–187. [Google Scholar]

- Sperling, E. Beitrag zur beurteilung des fahrkomforts in schienenfahrzeugen (Contribution to the evaluation of ride comfort in rail vehicles). Glas. Ann. 1956, 80, 314–320. [Google Scholar]

- Dumitriu, M.; Gheţi, M.A. Evaluation of the ride quality and ride comfort in railway vehicles based on the index Wz. Ann. Fac. Eng. Hunedoara 2015, 13, 123–132. [Google Scholar]

- B153/RP21. Application of ISO Standard to Railway Vehicles: Comfort Index Nmv—Comparison with the ISO/SNCF Comfort Note and with the Wz; European Rail Research Istitute: Utrecht, The Netherlands, 1993. [Google Scholar]

- B153/RP1-RP20. Application of ISO Standard to Railway Vehicles; European Rail Research Istitute: Utrecht, The Netherlands, 1981. [Google Scholar]

- UIC 513R. Guidelines for Evaluating Passenger Comfort in Relation to Vibration in Railway Vehicles; International Union of Railways: Paris, France, 1994. [Google Scholar]

- EN 12299. Railway Applications. Ride Comfort for Passengers. Measurement and Evaluation; British Standard: London, UK, 1999. [Google Scholar]

- ISO 10056. Mechanical Vibration-Measurement and Analysis of Whole-Body Vibration to Which Passengers and Crew are Exposed in Railway Vehicles; ISO: Geneva, Switzerland, 2001. [Google Scholar]

- Jiang, Y.; Chen, B.K.; Thompson, C. A comparison study of ride comfort indices between Sperling’s method and EN 12299. Int. J. Rail Transp. 2019, 7, 279–296. [Google Scholar] [CrossRef]

- Haladin, I.; Lakušić, S.; Bogut, M. Overview and analysis of methods for assessing ride comfort on tram tracks. Građevinar 2019, 71, 901–921. [Google Scholar]

- Dumitriu, M.; Stănică, D.I. Influence of the primary suspension damping on the ride comfort in the railway vehicles. Mater. Sci. Forum 2019, 957, 53–62. [Google Scholar] [CrossRef]

- Dumitriu, M. Influence of the suspension damping on ride comfort of passenger railway vehicles. Upb Sci. Bull. Ser. D Mech. Eng. 2012, 74, 75–90. [Google Scholar]

- Corradi, R.; Mazzola, L.; Ripamonti, F. Optimisation of secondary suspension dampers to improve the ride comfort of high-speed rail vehicles. In Proceedings of the 23rd International Congress on Sound and Vibration, ICSV 2016, Athens, Greece, 10–14 July 2016. [Google Scholar]

- Johnsson, A.; Berbyuk, V.; Enelund, M. Pareto optimisation of railway bogie suspension damping to enhance safety and comfort. Veh. Syst. Dyn. 2012, 50, 1379–1407. [Google Scholar] [CrossRef]

- Zhou, J.; Goodall, R.; Ren, L.; Zhang, H. Influences of car body vertical flexibility on ride quality of passenger railway vehicles. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2009, 223, 461–471. [Google Scholar] [CrossRef] [Green Version]

- Dumitriu, M.; Cruceanu, C. Influences of carbody vertical flexibility on ride comfort of railway vehicles. Arch. Mech. Eng. 2017, 64, 119–238. [Google Scholar] [CrossRef]

- Shi, H.L.; Luo, R.; Wu, P.B. Application of DVA theory in vibration reduction of carbody with suspended equipment for high-speed EMU. Sci. China Technol. Sci. 2014, 57, 1425–1438. [Google Scholar] [CrossRef]

- Dumitriu, M. Numerical analysis on the influence of suspended equipment on the ride comfort in railway vehicles. Arch. Mech. Eng. 2018, 65, 477–496. [Google Scholar]

- Kargarnovin, M.H.; Younesian, D.; Thompson, D.; Jones, C. Ride comfort of high-speed trains travelling over railway bridges. Veh. Syst. Dyn. 2005, 43, 173–199. [Google Scholar] [CrossRef]

- Sadeghi, J.; Rabiee, S.; Khajehdezfuly, A. Effect of rail irregularities on ride comfort of train moving over ballast-less tracks. Int. J. Struct. Stab. Dyn. 2019, 19, 1950060. [Google Scholar] [CrossRef]

- Lewis, T.D.; Jiang, J.Z.; Neild, S.A.; Gong, C.; Iwnicki, S.D. Using an inerter-based suspension to improve both passenger comfort and track wear in railway vehicles. Veh. Syst. Dyn. 2020, 58, 472–493. [Google Scholar] [CrossRef]

- Ripamonti, F.; Chiarabagliom, A. A smart solution for improving ride comfort in high-speed railway vehicles. J. Vib. Control 2019, 25, 1958–1973. [Google Scholar] [CrossRef]

- Dumitriu, M. Study on improving the ride comfort in railway vehicles using anti-bending dampers. Appl. Mech. Mater. 2018, 880, 207–212. [Google Scholar] [CrossRef]

- Dumitriu, M. Ride comfort enhancement in railway vehicle by the reduction of the carbody structural flexural vibration. IOP Conf. Ser. Mater. Sci. Eng. 2017, 227, 012042. [Google Scholar] [CrossRef] [Green Version]

- Graa, M. Modeling and control for vertical rail vehicle dynamic vibration with comfort evaluation. Int. J. Math. Models Methods Appl. Sci. 2017, 11, 240–245. [Google Scholar]

- Dumitriu, M. A new approach to reducing the carbody vertical bending vibration of railway vehicles. Veh. Syst. Dyn. 2017, 55, 1787–1806. [Google Scholar] [CrossRef]

- Schandl, G.; Lugner, P.; Benatzky, C.; Kozek, M.; Stribersk, M. Comfort enhancement by an active vibration reduction system for a flexible railway car body. Veh. Syst. Dyn. 2007, 45, 835–847. [Google Scholar] [CrossRef]

- Dumitriu, M. On the critical points of vertical vibration in a railway vehicle. Arch. Mech. Eng. 2014, 61, 115–140. [Google Scholar] [CrossRef]

- Dumitriu, M.; Crăciun, C. Modelling of structural flexibility of the carbody railway vehicles. MATEC Web Conf. 2017, 112, 07007. [Google Scholar] [CrossRef] [Green Version]

- C116. Interaction between Vehicles and Track, RP 1, Power Spectral Density of Track Irregularities, Part 1: Definitions, Conventions and Available Data; UIC: Utrecht, The Netherlands, 1971. [Google Scholar]

- Gong, D.; Zhou, J.; Sun, W.J. On the resonant vibration of a flexible railway car body and its suppression with a dynamic vibration absorber. J. Vib. Control 2013, 19, 649–657. [Google Scholar] [CrossRef]

- Dumitriu, M. Analysis of the dynamic response in the railway vehicles to the track vertical irregularities. Part II: The numerical analysis. J. Eng. Sci. Technol. Rev. 2015, 8, 32–39. [Google Scholar] [CrossRef]

- Zhou, J.; Wenjing, S. Analysis on geometric filtering phenomenon and flexible car body resonant vibration of railway vehicles. J. Tongji Univ. 2009, 37, 1653–1657. [Google Scholar]

- Gong, D.; Gu, Y.J.; Song, Y.J.; Zhou, J. Study on geometry filtering phenomenon and flexible car body resonant vibration of articulated trains. Adv. Mater. Res. 2013, 787, 542–547. [Google Scholar] [CrossRef]

- Cheli, F.; Corradi, R. On rail vehicle vibrations induced by track unevenness: Analysis of the excitation mechanism. J. Sound Vib. 2011, 330, 3744–3765. [Google Scholar] [CrossRef]

| The Parameters of the Carbody and Bogie | |||

| Symbol | Definition | Symbol | Definition |

| mc | carbody mass | Lc | carbody length |

| mb | bogie suspended mass | 2ac | carbody wheelbase |

| Jc | carbody inertia moment | 2ab | bogie wheelbase |

| Jb | bogie inertia moment | l1,2 = Lc/2 ± ac | supporting points position of the carbody on the suspension |

| The parameters of the secondary suspension per bogie | |||

| 2czc | vertical damping | 2kzc | vertical stiffness |

| 2cxc | longitudinal damping | 2kxc | longitudinal stiffness |

| 2cθc | angular damping | 2kθc | angular stiffness |

| The parameters of the primary suspension per wheelset | |||

| 2czb | vertical damping | 2kzb | vertical stiffness |

| Ride Comfort Index NMV | Significance |

|---|---|

| NMV < 1 | Very good comfort |

| 1 ≤ NMV < 2 | Good comfort |

| 2 ≤ NMV < 4 | Acceptable comfort |

| 4 ≤ NMV < 5 | Poor comfort |

| NMV ≥ 5 | Very poor comfort |

| Ride Comfort IndexWz | Vibration Sensitivity |

|---|---|

| 1.0 | Just noticeable |

| 2.0 | Clearly noticeable |

| 2.5 | More pronounced, but not unpleasant |

| 3.0 | Strong, irregular, but still tolerable |

| 3.25 | Very irregular |

| 3.5 | Extremely irregular, unpleasant, annoying, prolonged exposure intolerable |

| 4.0 | Extremely unpleasant; prolonged exposure harmful |

| mc = 34,000 kg | 2kzc = 1.2 MN/m |

| mb = 3200 kg | 2kxc = 4MN/m |

| Jc= 1,963,840 kg∙m2 | 2kθc = 256 kN/m |

| Jb= 2048 kg∙m2 | 2czc = 34.28 kNs/m |

| EI = 3.158 × 109 Nm2 | 2cxc = 50 kNs/m |

| mmc = 35224 kg | 2cθc = 2 kNs/m |

| Lc = 26.4 m | 4kzb = 4.4 MN/m |

| 2ac = 19 m | 4czb = 52.21 kNs/m |

| 2ab = 2.56 m | km2 = 88.998 MN/m |

| hc = 1.3 m; hb = 0.2 m | cmc = 53.117 kNs/m |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dumitriu, M.; Stănică, D.I. Study on the Evaluation Methods of the Vertical Ride Comfort of Railway Vehicle—Mean Comfort Method and Sperling’s Method. Appl. Sci. 2021, 11, 3953. https://doi.org/10.3390/app11093953

Dumitriu M, Stănică DI. Study on the Evaluation Methods of the Vertical Ride Comfort of Railway Vehicle—Mean Comfort Method and Sperling’s Method. Applied Sciences. 2021; 11(9):3953. https://doi.org/10.3390/app11093953

Chicago/Turabian StyleDumitriu, Mădălina, and Dragoș Ionuț Stănică. 2021. "Study on the Evaluation Methods of the Vertical Ride Comfort of Railway Vehicle—Mean Comfort Method and Sperling’s Method" Applied Sciences 11, no. 9: 3953. https://doi.org/10.3390/app11093953