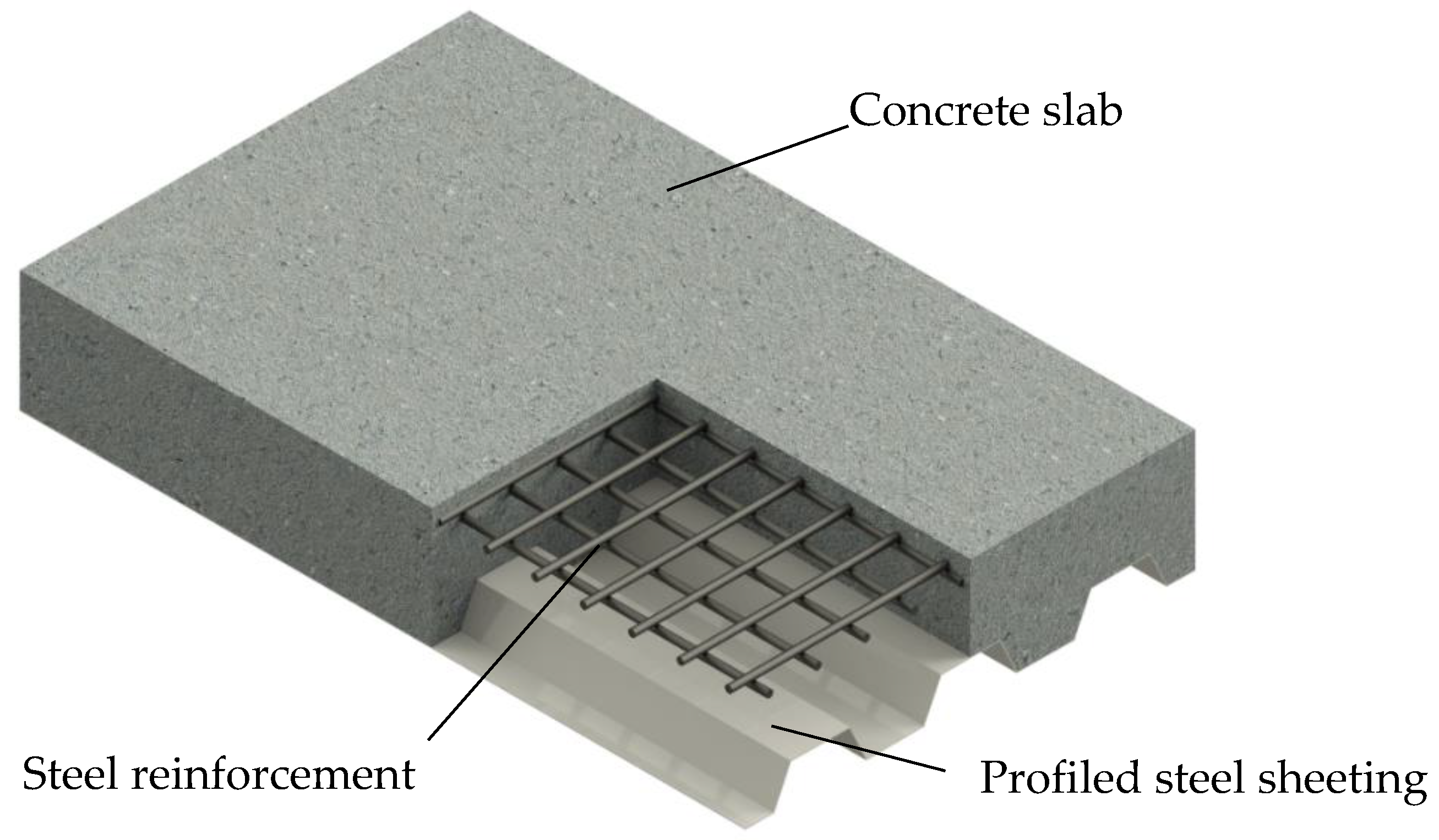

Shrinkage-Induced Response of Composite Steel–Concrete Slabs: A State-of-the-Art Review

Abstract

:1. Introduction

2. Time-Dependent Concrete Response in Composite Steel–Concrete Slabs

3. Time-Dependent Responses of Composite Slabs

3.1. Simply-Supported Composite Slabs

| Ref. | Sample ID | 1 | 1 | 1 | 1 | 1 | b 1 | D 1 | Profiled Steel Sheeting | Remarks |

|---|---|---|---|---|---|---|---|---|---|---|

| [MPa] | [kN/m] | [Days] | [Days] | [mm] | [mm] | [mm] | ||||

| [16] | CS1 | 27.3 | 0 | 15 | 119 | 3300 (3000) | 900 | 180 | Condeck HP® [21] | |

| CS2 | ||||||||||

| SS1 | 27.3 | 0 | 15 | 119 | 3300 (3000) | 900 | 180 | No | Solid slab 2 | |

| SS2 | ||||||||||

| [18] | CS-120 | 29 | 4.5 | 28 | 268 | 3300 (3000) | 510 | 120 | DW-65-510-170 | |

| CS-180 | 9.0 | 180 | ||||||||

| CS-120-SH | 29 | 0 | 28 | 268 | 3300 (3000) | 510 | 120 | DW-65-510-170 | ||

| CS-180-SH | 180 | |||||||||

| [50] | 1LT-70-0 | 28 | 0 | 64 | 242 | 3300 (3100) | 1200 | 150 | KF70® [23] | |

| 2LT-70-3 | 4.1 | 242 | ||||||||

| 3LT-70-3 | 4.1 | 242 | ||||||||

| 4LT-70-6 | 7.2 | 242 | ||||||||

| 5LT-70-8 | 7.3 | 196 | ||||||||

| 9.5 | 242 | |||||||||

| 6LT-40-0 | 35.5 | 0 | 64 | 205 | 3300 (3100) | 1200 | 150 | KF40® [23] | ||

| 7LT-40-3 | 4.1 | |||||||||

| 8LT-40-3 | 4.1 | |||||||||

| 9LT-40-6 | 7.7 | |||||||||

| 10LT-40-6 | 7.7 | |||||||||

| [52] | S1 | 31.1 | 2.1 | 8 | 134 | 3200 (3000) | 918 | 125 | MD55 | |

| [14] | SS | 33.7 | 0 | 8 | 239 | 7200 (6000) | 900 | 180 | No Condeck HP® [21] PrimeForm® [22] | Solid slab 2 |

| CK | ||||||||||

| PF | ||||||||||

| [54] | CK1 | 41.5 | 0 | 7 | 90 | 7200 (6000) | -- | 180 | Condeck HP® [21] | |

| CK2 | ||||||||||

| CK3 | ||||||||||

| CK4 | ||||||||||

| CK5 | 41.5 | 0 | 7 | 90 | 8650 (7450) | -- | 225 | Condeck HP® [21] | ||

| CK6 | ||||||||||

| [53] | SS1 | 32 | 0 | 14 | 267 | 3200 (3000) | 634 | 120 | Condeck HP® [21] | |

| SS2 | ||||||||||

| SS3 |

| Ref. | Sample ID | 1 | 1 | 1 | 1 | 1 | b 1 | D 1 | Steel Sheeting |

|---|---|---|---|---|---|---|---|---|---|

| [MPa] | [kN/m] | [Days] | [Days] | [mm] | [mm] | [mm] | |||

| [19] | CCS-NAC-L | 57.5 | 4.5 | 28 | 500 | 6300 (6000) | 510 | 120 | DW-65 |

| CCS-RAC-L | 47.4 | 4.5 | |||||||

| CCS-RAC-SH | 47.4 | 0 | |||||||

| [53] | CS1 | 32 | 0 | 14 | 267 | 6200 (6000) | 634 | 120 | Condeck HP® [21] |

| CS2 | |||||||||

| CS3 | |||||||||

| [55] | CLT-70-0 | 36.7 | 0 | 28 | 376 | 6900 (6700) | 1200 | 150 | KF70® [23] |

| CLT-70-3 | 3.72 | ||||||||

| CLT-70-6 | 6.72 | ||||||||

| [56] | L1 | 34.8 | 0 | 7 | 97 | 6300 (6000) | 1200 | 150 | ComFlor® 80 [57] |

| L2 | 34.8 | ||||||||

| L3 | 34.8 | ||||||||

| L4 | 34.8 | ||||||||

| L5 | 36.2 | ||||||||

| L6 | 35.8 | ||||||||

| L7 | 33.8 | ||||||||

| L8 | 34.6 | ||||||||

| L9 | 34.6 | ||||||||

| L10 | 34.6 | ||||||||

| L11 | 34.6 | ||||||||

| L12 | 37.1 | ||||||||

| L13 | 37.1 | ||||||||

| L14 | 37.1 | ||||||||

| L15 | 35.8 | ||||||||

| L16 | 36.2 | ||||||||

| [58] | Slab 1 | 20 | 11.8 | 7 | 228 | 4600 | 914 | 150 | Corrugated steel sheeting |

| Slab 2 | 11.8 | 228 | 150 | ||||||

| Slab 3 | 9.5 | 903 | 125 | ||||||

| Slab 4 | 9.5 | 903 | 125 |

3.2. Continuous Composite Slabs

4. Time-Dependent Modelling of Composite Slabs

4.1. Numerical Model

4.2. Design Model

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oehlers, D.J.; Bradford, M.A. Composite Steel and Concrete Structural Members: Fundamental Behaviour; Elsevier: Amsterdam, The Netherlands, 1995. [Google Scholar] [CrossRef]

- Oehlers, D.J.; Bradford, M.A. Elementary Behaviour of Composite Steel and Concrete Structural Members; Butterworth-Heinemann: Oxford, UK, 1999. [Google Scholar]

- Nethercot, D. (Ed.) Composite Construction; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar] [CrossRef]

- Johnson, R.P. Composite Structures of Steel and Concrete, 4th ed.; Wiley Blackwell: Hoboken, NJ, USA, 2018. [Google Scholar]

- Collings, D. Steel—Concrete Composite Buildings: Designing with Eurocodes; Thomas Telford Ltd.: London, UK, 2010. [Google Scholar]

- Taranath, B.S. Structural Analysis and Design of Tall Buildings: Steel and Composite Construction; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Ghali, A.; Favre, R.; Elbadry, M. Concrete Structures: Stresses and Deformations, 3rd ed.; CRC Press: London, UK; New York, NY, USA, 2002. [Google Scholar] [CrossRef]

- Gilbert, R.I.; Ranzi, G. Time-Dependent Behaviour of Concrete Structures, 1st ed.; Spon Press: London, UK, 2011. [Google Scholar] [CrossRef]

- Ranzi, G.; Leoni, G.; Zandonini, R. State of the Art on the Time-Dependent Behaviour of Composite Steel–Concrete Structures. J. Constr. Steel Res. 2013, 80, 252–263. [Google Scholar] [CrossRef]

- Bocciarelli, M.; Caldentey, A.P.; Cusatis, G.; Dezi, L.; Dönmez, A.A.; Di Luzi, G.; Geng, Y.; Gilbert, R.; Hewitt, J.; Jordán, J.; et al. Time-Dependent Behaviour and Design of Composite Steel-Concrete Structures; Ranzi, G., Ed.; International Association for Bridge and Structural Engineering (IABSE): Zurich, Switzerland, 2021. [Google Scholar] [CrossRef]

- Standards Australia. Australian Standard for Concrete Structures. AS 3600-2009; Standards Australia: Sydney, Australia, 2009. [Google Scholar]

- Ranzi, G. Service Design Approach for Composite Steel–Concrete Floors. Proc. Inst. Civ. Eng. Struct. Build. 2018, 171, 38–49. [Google Scholar] [CrossRef] [Green Version]

- Australian/New Zealand Standard. Composite Structures—Composite Steel-Concrete Construction in Buildings. AS/NZS 2327:2017; Standards Australia: Sydney, Australia, 2017. [Google Scholar]

- Ranzi, G.; Al-Deen, S.; Ambrogi, L.; Uy, B. Long-Term Behaviour of Simply-Supported Post-Tensioned Composite Slabs. J. Constr. Steel Res. 2013, 88, 172–180. [Google Scholar] [CrossRef]

- Al-deen, S.; Ranzi, G. Effects of Non-Uniform Shrinkage on the Long-Term Behaviour of Composite Steel-Concrete Slabs. Int. J. Steel Struct. 2015, 15, 415–432. [Google Scholar] [CrossRef]

- Al-Deen, S.; Ranzi, G.; Uy, B. Non-Uniform Shrinkage in Simply-Supported Composite Steel-Concrete Slabs. Steel Compos. Struct. 2015, 18, 375–394. [Google Scholar] [CrossRef]

- Gilbert, R.I.; Bradford, M.A.; Gholamhoseini, A.; Chang, Z.-T. Effects of Shrinkage on the Long-Term Stresses and Deformations of Composite Concrete Slabs. Eng. Struct. 2012, 40, 9–19. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Q.; Geng, Y.; Ranzi, G. Long-Term Behaviour of Simply Supported Composite Slabs with Recycled Coarse Aggregate. Mag. Concr. Res. 2016, 68, 1278–1293. [Google Scholar] [CrossRef]

- Zhang, H.; Geng, Y.; Wang, Y.Y.; Wang, Q. Long-Term Behavior of Continuous Composite Slabs Made with 100% Fine and Coarse Recycled Aggregate. Eng. Struct. 2020, 212, 110464. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, J.; Patrick, B.; Zheng, A.; Shi, Y. Long-Term Shrinkage Behaviour of Steel-Concrete Composite Slabs with Recycled Coarse Aggregate. IOP Conf. Ser. Earth Environ. Sci. 2020, 510, 052028. [Google Scholar] [CrossRef]

- Stramit. Stramit Condeck HP, Composite Slab System, Product Technical Manual; Stramit Corporation Property Limited: Queensland, Australia, 2012. [Google Scholar]

- Stramit. Stramit PrimeForm Left-Iniplace Formwork System, Product Technical Manual; Stramit Corporation Property Limited: Banyo, Australia, 2011. [Google Scholar]

- Fielders Australia. Specifying Fielders–Kingflor–Composite Steel Formwork System Design Manual; Fielders Australia Pty Ltd.: Marleston, Australia, 2008. [Google Scholar]

- Bažant, Z.P.; Jirásek, M. Solid Mechanics and Its Applications. In Creep and Hygrothermal Effects in Concrete Structures; Springer: Dordrecht, The Netherlands, 2018; Volume 225. [Google Scholar] [CrossRef]

- Jiang, Z.; Sun, Z.; Wang, P. Autogenous Relative Humidity Change and Autogenous Shrinkage of High-Performance Cement Pastes. Cem. Concr. Res. 2005, 35, 1539–1545. [Google Scholar] [CrossRef]

- Hu, S.; Wu, J.; Yang, W.; Lu, L.; He, Y. Relationship between Autogenous Deformation and Internal Relative Humidity of High-Strength Expansive Concrete. J. Wuhan Univ. Technol. Sci. Ed. 2010, 25, 504–508. [Google Scholar] [CrossRef]

- Zhang, J.; Dongwei, H.; Wei, S. Experimental Study on the Relationship between Shrinkage and Interior Humidity of Concrete at Early Age. Mag. Concr. Res. 2010, 62, 191–199. [Google Scholar] [CrossRef]

- Jun, Z.; Dongwei, H.; Haoyu, C. Experimental and Theoretical Studies on Autogenous Shrinkage of Concrete at Early Ages. J. Mater. Civ. Eng. 2011, 23, 312–320. [Google Scholar] [CrossRef]

- Wei, Y.; Huang, J.; Liang, S. Measurement and Modeling Concrete Creep Considering Relative Humidity Effect. Mech. Time-Dependent Mater. 2020, 24, 161–177. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, Y.; Han, Y.; Sun, W. Shrinkage and Interior Humidity of Concrete under Dry–Wet Cycles. Dry. Technol. 2012, 30, 583–596. [Google Scholar] [CrossRef]

- Parrott, L.J. Moisture Profiles in Drying Concrete. Adv. Cem. Res. 1988, 1, 164–170. [Google Scholar] [CrossRef]

- Parrott, L.J. Factors Influencing Relative Humidity in Concrete. Mag. Concr. Res. 1991, 43, 45–52. [Google Scholar] [CrossRef]

- Kim, J.-K.; Lee, C.-S. Moisture Diffusion of Concrete Considering Self-Desiccation at Early Ages. Cem. Concr. Res. 1999, 29, 1921–1927. [Google Scholar] [CrossRef]

- Grasley, Z.C.; Lange, D.A.; D’Ambrosia, M.D. Internal Relative Humidity and Drying Stress Gradients in Concrete. Mater. Struct. 2006, 39, 901–909. [Google Scholar] [CrossRef]

- Jiang, Z.; Sun, Z.; Wang, P. Internal Relative Humidity Distribution in High-Performance Cement Paste Due to Moisture Diffusion and Self-Desiccation. Cem. Concr. Res. 2006, 36, 320–325. [Google Scholar] [CrossRef]

- Amba, J.C.; Balayssac, J.P.; Détriché, C.H. Characterisation of Differential Shrinkage of Bonded Mortar Overlays Subjected to Drying. Mater. Struct. 2010, 43, 297–308. [Google Scholar] [CrossRef]

- Holmes, N.; West, R.P. Enhanced Accelerated Drying of Concrete Floor Slabs. Mag. Concr. Res. 2013, 65, 1187–1198. [Google Scholar] [CrossRef] [Green Version]

- Holmes, N. Moisture Movement in Concrete During Drying; University of Dublin: Dublin, Ireland, 2009. [Google Scholar]

- Ramseyer, C.; Shadravan, S.; Gorman, P.; Santamaria, C.R. Dimensional Stability of Concrete Slabs on Grade; Oklahoma Transportation Center: Midwest City, OK, USA, 2012. [Google Scholar]

- Bocciarelli, M.; Ranzi, G.; Rahman, M. A Hygro-Thermo-Chemical-Mechanical Model for the Shrinkage Prediction in Composite Steel-Concrete Floors. In Proceedings of the 28th Biennial National Conference of the Concrete Institute of Australia, Adelaide, Australia, 22–25 October 2017; pp. 1–10. [Google Scholar]

- Azenha, M.; Leitão, L.; Granja, J.L.; de Sousa, C.; Faria, R.; Barros, J.A.O. Experimental Validation of a Framework for Hygro-Mechanical Simulation of Self-Induced Stresses in Concrete. Cem. Concr. Compos. 2017, 80, 41–54. [Google Scholar] [CrossRef]

- Azenha, M.; Granja, J.L. Monitoring and Simulating Humidity Profiles in Concrete Elements during Drying. In Proceedings of the International RILEM Conference on Materials, Systems and Structures in Civil Engineering Conference segment on Moisture in Materials and Structures, Lyngby, Denmark, 22–24 August 2016; pp. 115–124. [Google Scholar]

- Choi, S.; Won, M.C. Thermal Strain and Drying Shrinkage of Concrete Structures in the Field. ACI Mater. J. 2010, 107, 498–507. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, Y.; Qi, K.; Gao, Y. Interior Relative Humidity of Normal- and High-Strength Concrete at Early Age. J. Mater. Civ. Eng. 2012, 24, 615–622. [Google Scholar] [CrossRef]

- Pour-ghaz, M.; Spragg, R.; Weiss, J. Moisture Profiles and Diffusion Coefficients in Mortars Containing Shrinkage Reducing Admixtures. In Proceedings of the International RILEM Conference on Use of Superabsorbent Polymers and Other New Additives in Concrete, Lyngby, Denmark, 15–18 August 2010; pp. 197–206. [Google Scholar]

- Zhou, J.; Chen, X.; Zhang, J.; Wang, Y. Internal Relative Humidity Distribution in Concrete Considering Self-Desiccation at Early Ages. Int. J. Phys. Sci. 2011, 6, 1604–1610. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, Y.; Han, Y. Interior Humidity of Concrete under Dry-Wet Cycles. J. Mater. Civ. Eng. 2012, 24, 289–298. [Google Scholar] [CrossRef]

- Wei, Y.; Liang, S.; Gao, X. Numerical Evaluation of Moisture Warping and Stress in Concrete Pavement Slabs with Different Water-to-Cement Ratio and Thickness. J. Eng. Mech. 2017, 143, 04016111. [Google Scholar] [CrossRef]

- Wei, Y.; Gao, X.; Hansen, W. Influential Depth by Water Absorption and Surface Drying in Concrete Slabs. Transp. Res. Rec. J. Transp. Res. Board 2013, 2342, 76–82. [Google Scholar] [CrossRef]

- Gholamhoseini, A.; Gilbert, R.I.; Bradford, M.A.; Chang, Z.T. Long-Term Deformation of Composite Concrete Slabs under Sustained Loading. In Proceedings of the From Materials to Structures: Advancement Through Innovation—Proceedings of the 22nd Australasian Conference on the Mechanics of Structures and Materials, ACMSM, Sydney, Australia, 11–14 December 2012; pp. 67–72. [Google Scholar]

- Gholamhoseini, A. Modified Creep and Shrinkage Prediction Model B3 for Serviceability Limit State Analysis of Composite Slabs. Int. J. Adv. Struct. Eng. 2016, 8, 87–101. [Google Scholar] [CrossRef] [Green Version]

- Oliveira, L.A.M.; Borghi, T.M.; Rodrigues, Y.O.; El Debs, A.L.H.D.C. Assessment of Design Codes for the In-Service Behaviour of Steel-Concrete Composite Slabs. IBRACON Struct. Mater. J. 2021, 14, 1–22. [Google Scholar] [CrossRef]

- Ranzi, G.; Frigerio, G.; Vallati, O. Long-Term Experiments on Composite Slabs Exposed to Different Surface Drying Conditions. In Proceedings of the 16th East Asian-Pacific Conference on Structural Engineering and Construction, Brisbane, Australia, 3–6 December 2019; Springer Science+Business Media: Brisbane, Australia, 2019. [Google Scholar] [CrossRef]

- Ranzi, G.; Ostinelli, A.; Uy, B. An Experimental Study on the Shrinkage and Ultimate Behaviour of Post-Tensioned Composite Slabs. In Proceedings of the 22nd Australasian Conference on the Mechanics of Structures and Materials (ACMSM22), Sydney, Australia, 11–14 December 2012; Samali, A.S., Ed.; CRC Press: Boca Raton, FL, USA; Sydney, Australia, 2013; pp. 339–344. [Google Scholar]

- Gholamhoseini, A.; Gilbert, R.I.; Bradford, M.A. Long-Term Deformations in Continuous Composite Concrete Slabs. Aust. J. Struct. Eng. 2016, 17, 197–212. [Google Scholar] [CrossRef]

- Gholamhoseini, A.; Khanlou, A.; MacRae, G.; Scott, A.; Hicks, S.; Leon, R. An Experimental Study on Strength and Serviceability of Reinforced and Steel Fibre Reinforced Concrete (SFRC) Continuous Composite Slabs. Eng. Struct. 2016, 114, 171–180. [Google Scholar] [CrossRef]

- Steel & Tube Holdings Ltd. Product Guide, ComFlor 80, Composite Floor Decking; Steel & Tube Holdings Ltd.: Auckland, New Zealand, 2016. [Google Scholar]

- Altoubat, S.; Rieder, K.A.; Junaid, M.T. Short- and Long-Term Restrained Shrinkage Cracking of Fiber Reinforced Concrete Composite Metal Decks: An Experimental Study. Mater. Struct. Constr. 2017, 50, 1–15. [Google Scholar] [CrossRef]

- Gholamhoseini, A.; Gilbert, R.I.; Bradford, M. Long-Term Behavior of Continuous Composite Concrete Slabs with Steel Decking. ACI Struct. J. 2018, 115, 439–449. [Google Scholar] [CrossRef]

- Gilbert, R.I. Time Effects in Concrete Structures; Elsevier Science Publishers: Amsterdam, The Netherlands, 1988. [Google Scholar]

- Gilbert, R.I. Time-Dependent Analysis of Composite Steel-Concrete Sections. J. Struct. Eng. 1989, 115, 2687–2705. [Google Scholar] [CrossRef]

- Uy, B. Long-Term Service-Load Behaviour of Simply Supported Profiled Composite Slabs. Proc. Inst. Civ. Eng. Struct. Build. 1997, 122, 193–208. [Google Scholar] [CrossRef]

- Bradford, M.A. Generic Modelling of Composite Steel–Concrete Slabs Subjected to Shrinkage, Creep and Thermal Strains Including Partial Interaction. Eng. Struct. 2010, 32, 1459–1465. [Google Scholar] [CrossRef]

- Bradford, M.A.; Gilbert, R.I.; Zeuner, R.; Brock, G. Shrinkage Deformations of Composite Slabs with Open Trapezoidal Sheeting. Procedia Eng. 2011, 14, 52–61. [Google Scholar] [CrossRef] [Green Version]

- Gilbert, R.I. Time-Dependent Stiffness of Cracked Reinforced and Composite Concrete Slabs. Procedia Eng. 2013, 57, 19–34. [Google Scholar] [CrossRef] [Green Version]

- Gholamhoseini, A.; Gilbert, R.I.; Bradford, M.; Chang, Z.-T. Time-Dependent Deflection of Composite Concrete Slabs. ACI Struct. J. 2014, 111, 765–775. [Google Scholar] [CrossRef]

- Ranzi, G.; Gilbert, R.I. Structural Analysis: Principles, Methods and Modelling; CRC Press: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Bocciarelli, M.; Ranzi, G. Evaluation of Shrinkage-Induced Deflections of Composite Slabs with a Simplified Design Approach and a Hygro-Thermo-Chemical-Mechanical Model. In Proceedings of the 25th Australasian Conference on the Mechanics of Structures and Materials (ACMSM25), Brisbane, Australia, 4−7 December 2018; Wang, C.M., Ho, J.C.M., Kitipornchai, S., Eds.; Springer: Singapore; Brisbane, Australia, 2018. [Google Scholar] [CrossRef]

- Bocciarelli, M.; Ranzi, G. Identification of the Hygro-Thermo-Chemical-Mechanical Model Parameters of Concrete through Inverse Analysis. Constr. Build. Mater. 2018, 162, 202–214. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, J.; Liang, Y.; Zhang, H.; Zhao, Y.; Ren, Q. Prediction of Time-Dependent Behaviour of Steel–Recycled Aggregate Concrete (RAC) Composite Slabs via Thermo-Mechanical Finite Element Modelling. J. Build. Eng. 2020, 29, 101191. [Google Scholar] [CrossRef]

| Ref. | Sample ID | 1 | 1 | 1 | L 1 | b 1 | D 1 | Profiled Steel Sheeting | Remarks |

|---|---|---|---|---|---|---|---|---|---|

| [MPa] | [Days] | [Days] | [mm] | [mm] | [mm] | ||||

| [14] | S1 | 33.7 | 8 | 239 | 900 | 900 | 180 | None | Solid slab 2 |

| S2 | None | Solid slab 3 | |||||||

| S3 | Condeck HP® [21] | ||||||||

| S4 | PrimeForm® [22] | ||||||||

| [15] | SS120 | 27.3 | 15 | 210 | 900 | 900 | 120 | None | |

| SS180 | 120 | 180 | Solid slab 2 | ||||||

| SS250 | 210 | 250 | |||||||

| SP120 | 27.3 | 15 | 210 | 900 | 900 | 120 | None | Solid slab 3 | |

| SP180 | 120 | 180 | |||||||

| SP250 | 210 | 250 | |||||||

| PF120 | 27.3 | 15 | 120 | 900 | 900 | 120 | PrimeForm® [22] | ||

| PF180 | 120 | 180 | |||||||

| PF250 | 120 | 250 | |||||||

| CK120 | 27.3 | 15 | 120 | 900 | 900 | 120 | Condeck HP® [21] | ||

| CK180 | 120 | 180 | |||||||

| CK250 | 120 | 250 | |||||||

| [16] | SH1 | 27.3 | 15 | 119 | 900 | 900 | 180 | None | Solid slab 2 |

| SH2 | None | Solid slab 3 | |||||||

| SH3 | Condeck HP® [21] | ||||||||

| [17] | 1A | 34.5 | 21 | 322 | 750 | 750 | 150 | KF40® [23] | |

| 1B | 150 | None | KF40-shaped void 4 | ||||||

| 2A | 150 | KF70® [23] | |||||||

| 2B | 150 | None | KF70-shaped void 4 | ||||||

| 3A | 200 | KF70® [23] | |||||||

| 3B | 200 | None | KF70-shaped void 4 | ||||||

| 4A | 300 | KF70® [23] | |||||||

| 4B | 300 | None | KF70-shaped void 4 | ||||||

| 5A | 150 | RF55® [23] | |||||||

| 5B | 150 | None | RF55-shaped void 4 | ||||||

| [18,20] | ES 120 | 29.0 | 28 | 268 | 600 | 600 | 120 | None | Solid slab 5 |

| ES 180 | 180 | ||||||||

| [19] | NAC | 57.5 | 28 | 500 | 600 | 510 | 120 | None | Solid slab 5 |

| RAC | 47.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, M.M.; Ranzi, G. Shrinkage-Induced Response of Composite Steel–Concrete Slabs: A State-of-the-Art Review. Appl. Sci. 2022, 12, 223. https://doi.org/10.3390/app12010223

Rahman MM, Ranzi G. Shrinkage-Induced Response of Composite Steel–Concrete Slabs: A State-of-the-Art Review. Applied Sciences. 2022; 12(1):223. https://doi.org/10.3390/app12010223

Chicago/Turabian StyleRahman, Md Mahfuzur, and Gianluca Ranzi. 2022. "Shrinkage-Induced Response of Composite Steel–Concrete Slabs: A State-of-the-Art Review" Applied Sciences 12, no. 1: 223. https://doi.org/10.3390/app12010223

APA StyleRahman, M. M., & Ranzi, G. (2022). Shrinkage-Induced Response of Composite Steel–Concrete Slabs: A State-of-the-Art Review. Applied Sciences, 12(1), 223. https://doi.org/10.3390/app12010223