Application of the Supercapacitor for Energy Storage in China: Role and Strategy

Abstract

:1. Introduction

2. Technology Characterization

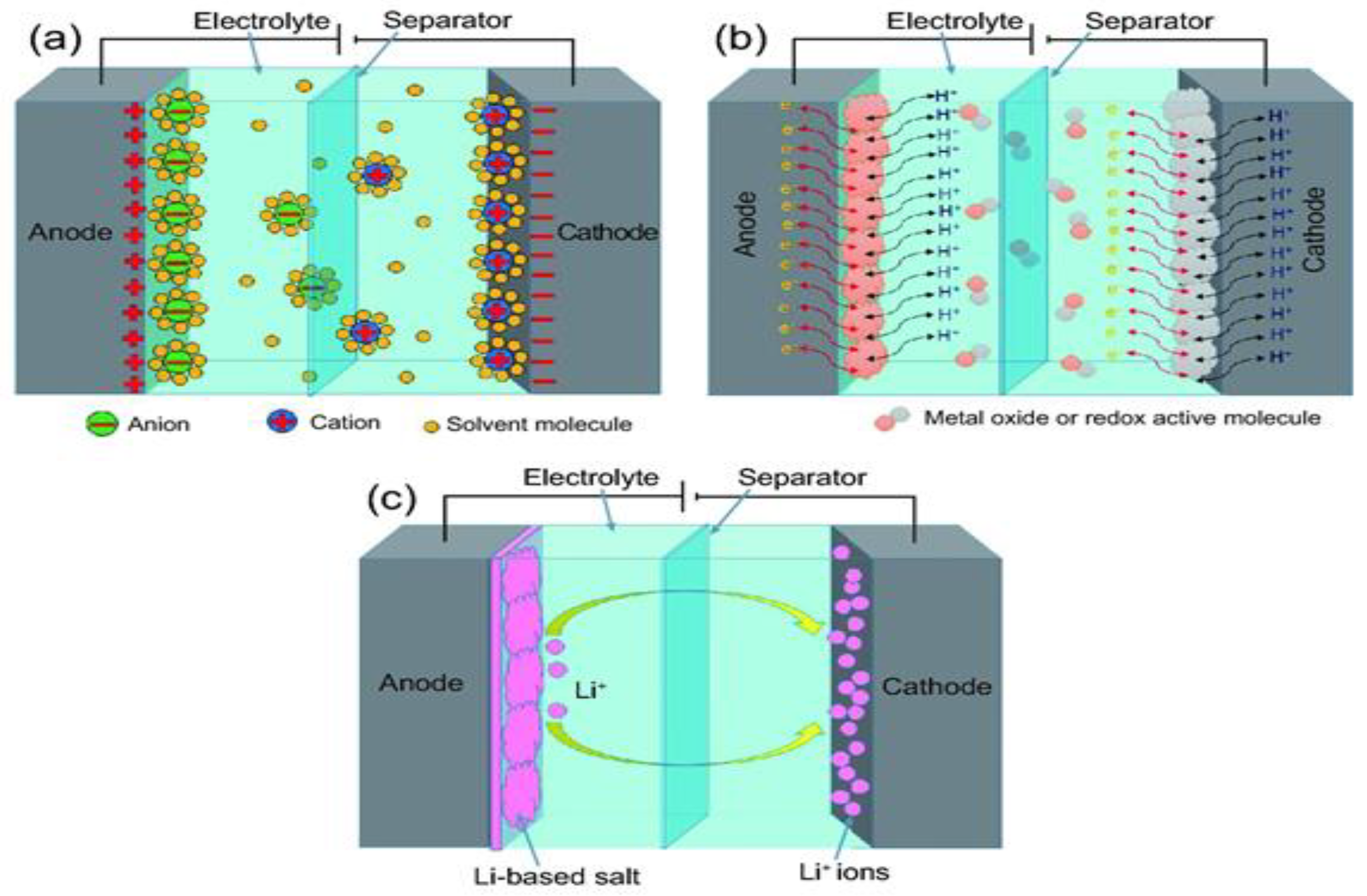

2.1. Double-Layer Supercapacitor

2.2. Faraday Pseudocapacitor

2.3. Hybrid Supercapacitor

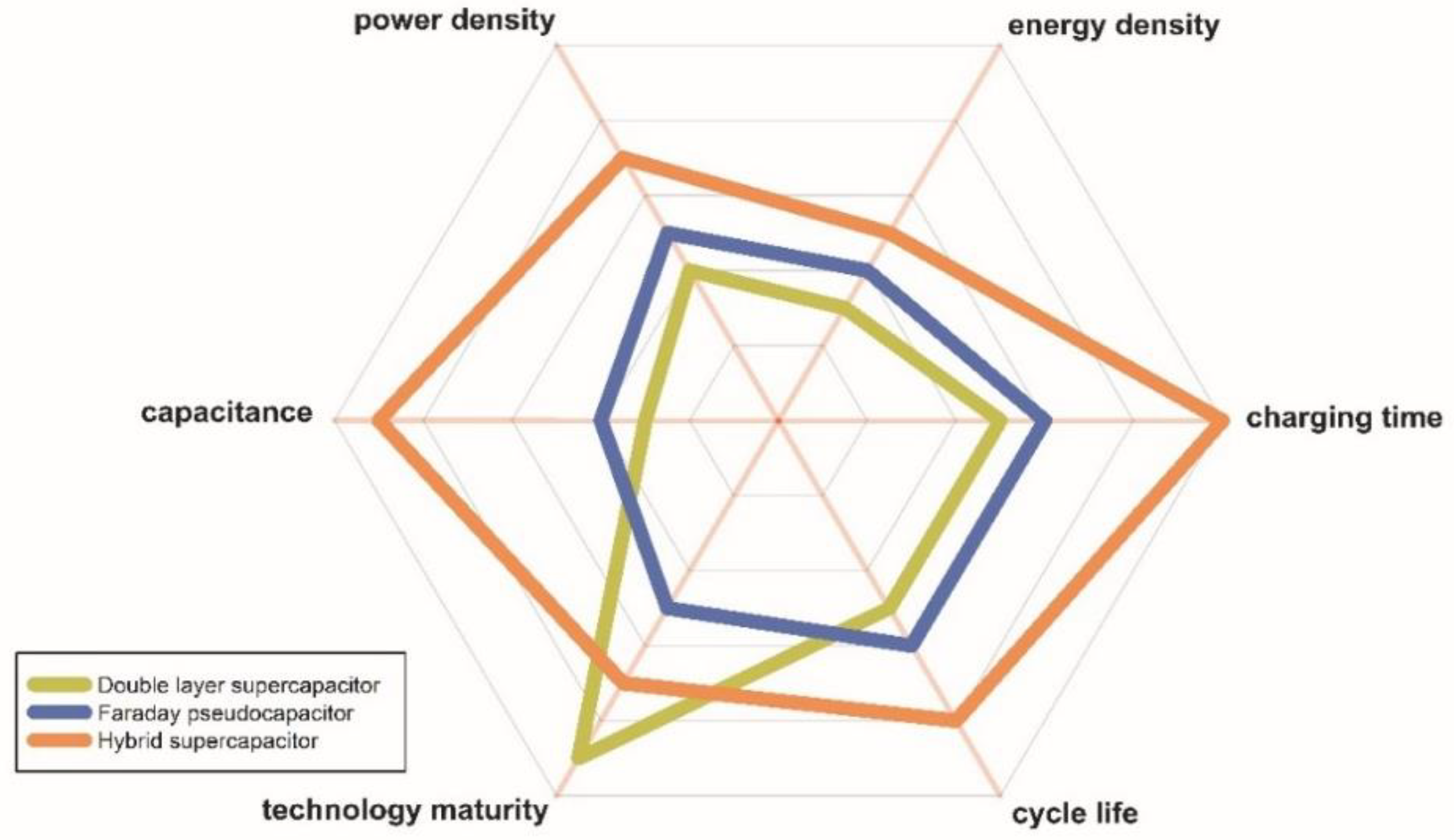

2.4. Comparison

3. Development of China’s Supercapacitor Field

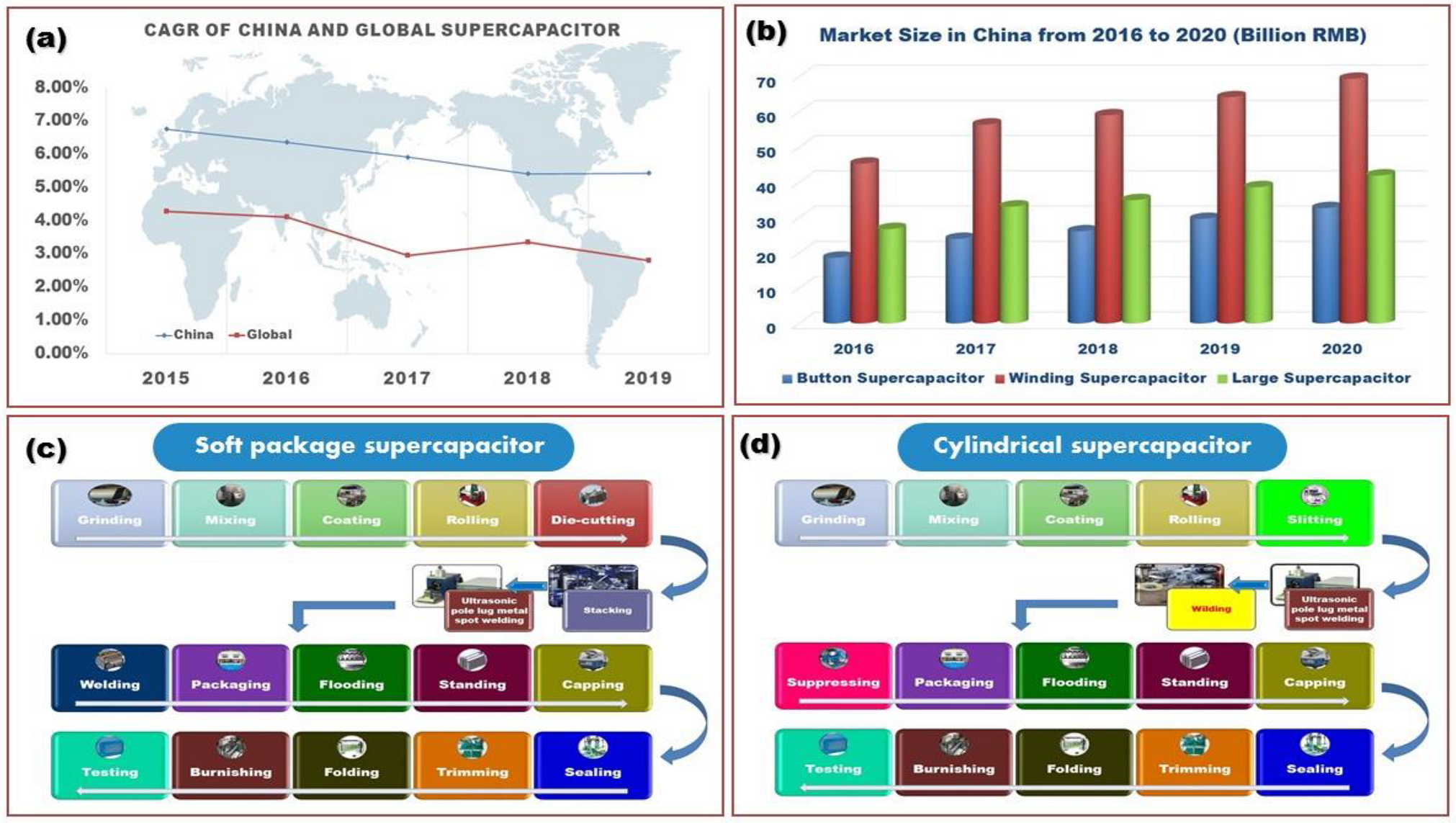

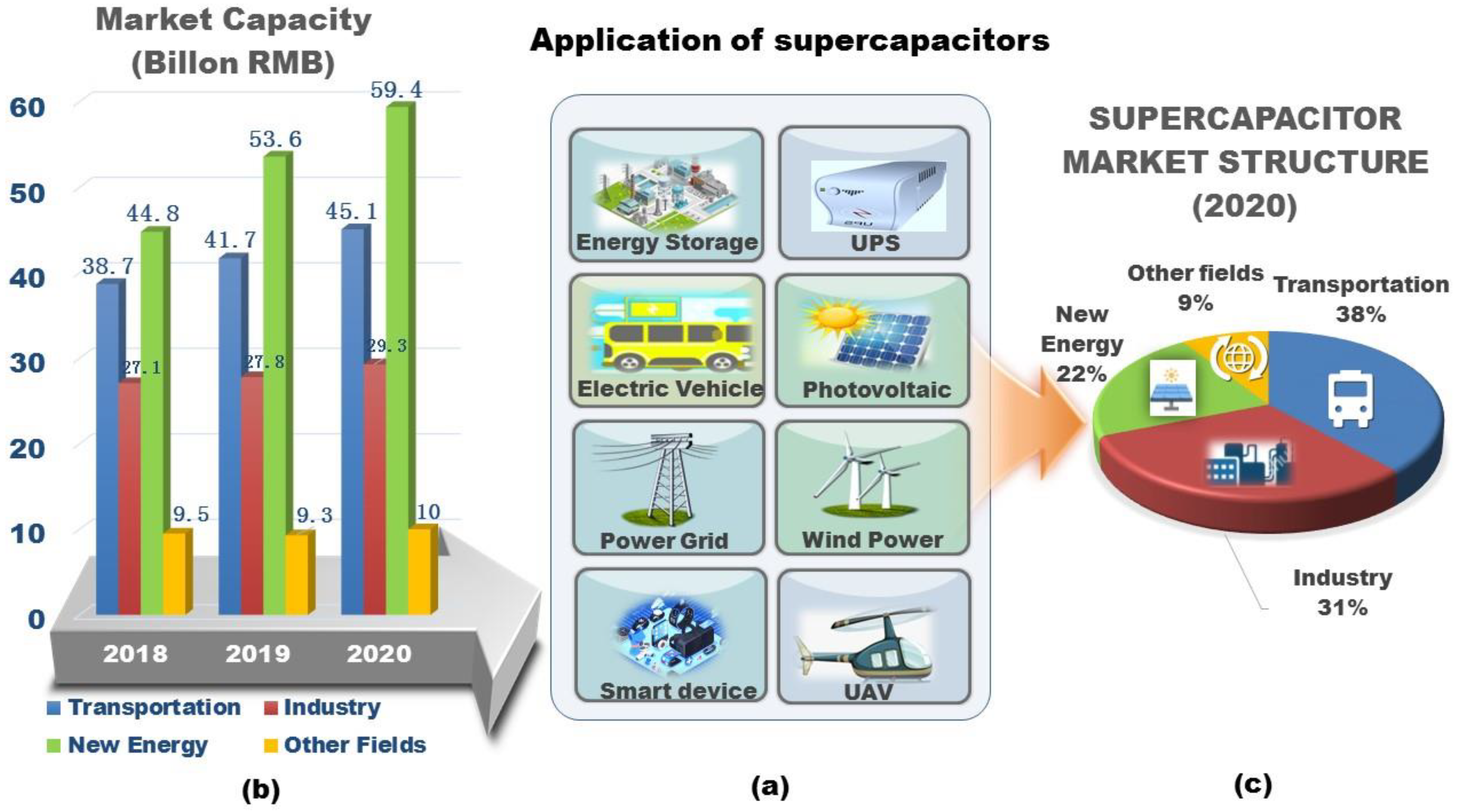

3.1. Market Trends, Upstream Materials, and Preparation Procession

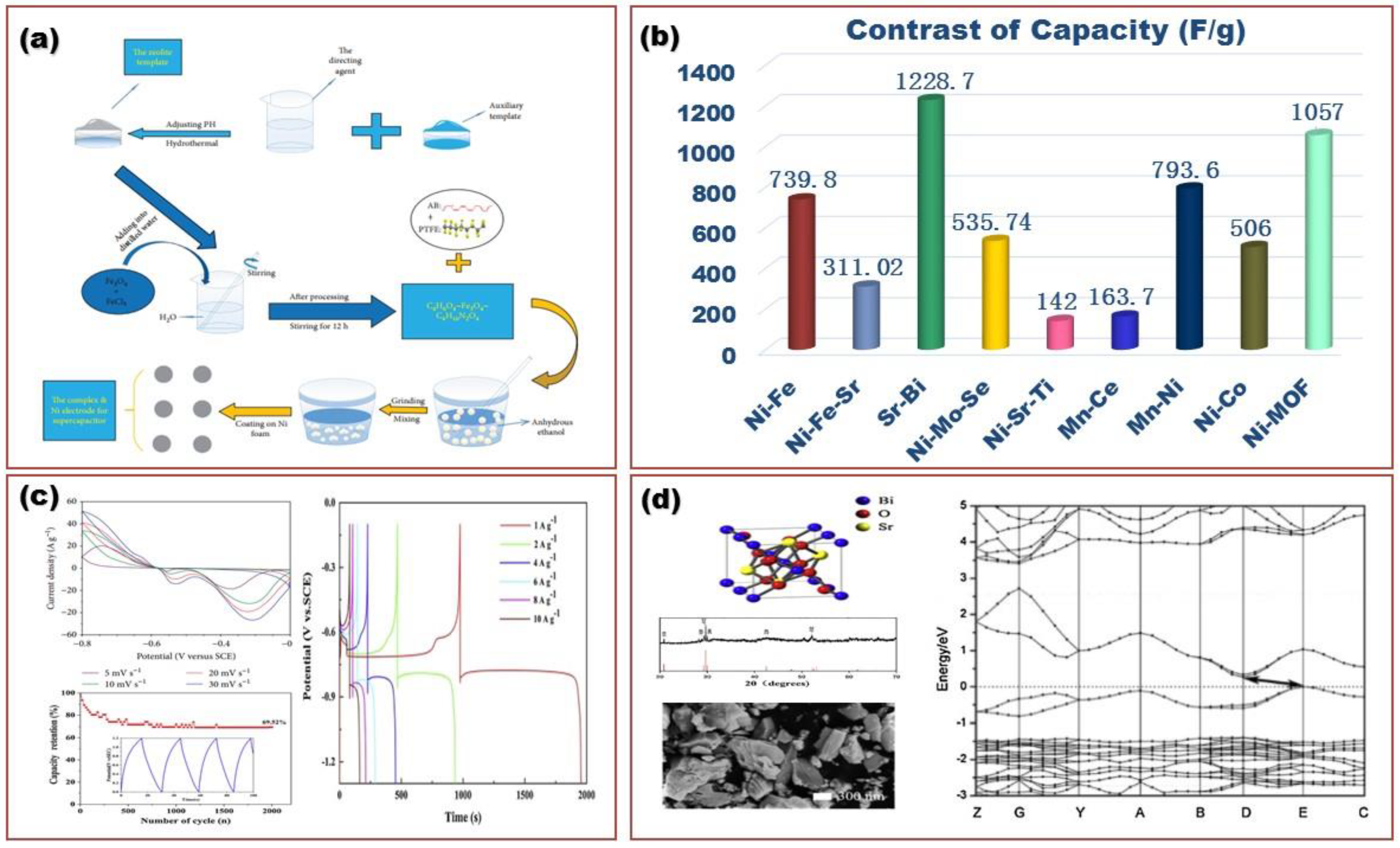

3.1.1. Electrode Materials

3.1.2. Preparation Processes

3.1.3. Electrolytes

3.2. Application Status

3.2.1. Microgrid

3.2.2. Wind Power System

3.2.3. Distribution Automation

3.2.4. Communication and Transportation

4. Strategy and Innovation Status Quo

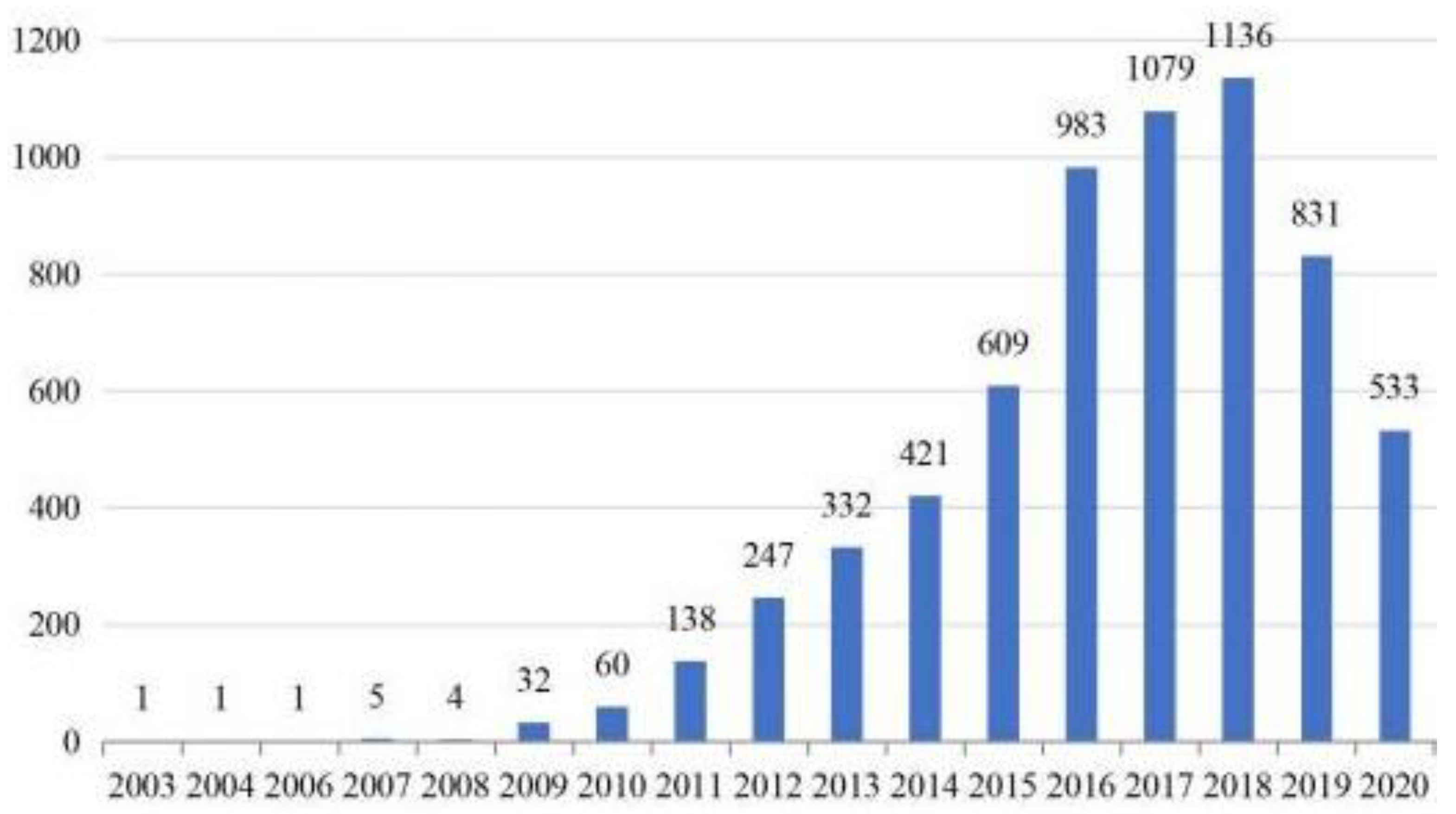

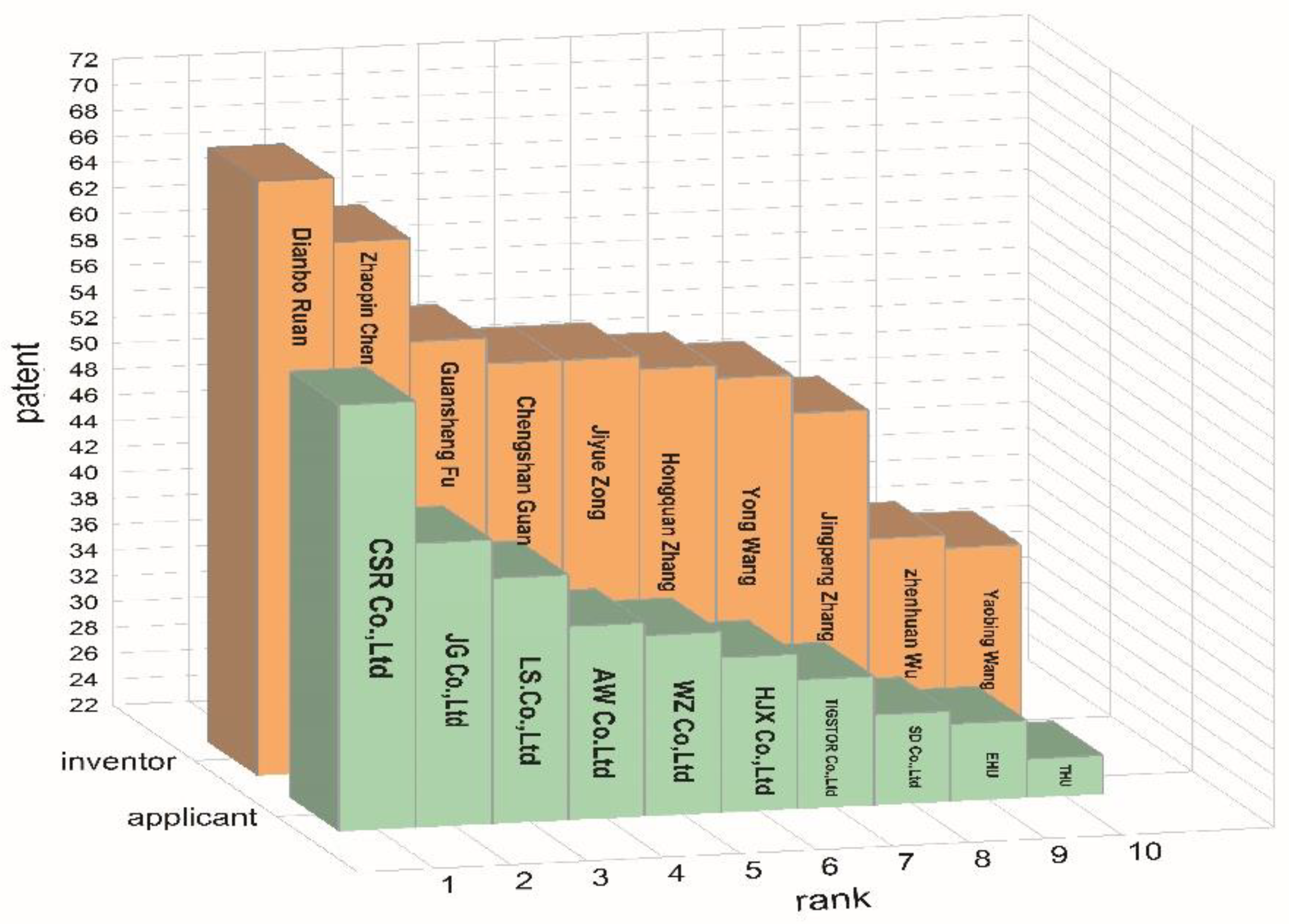

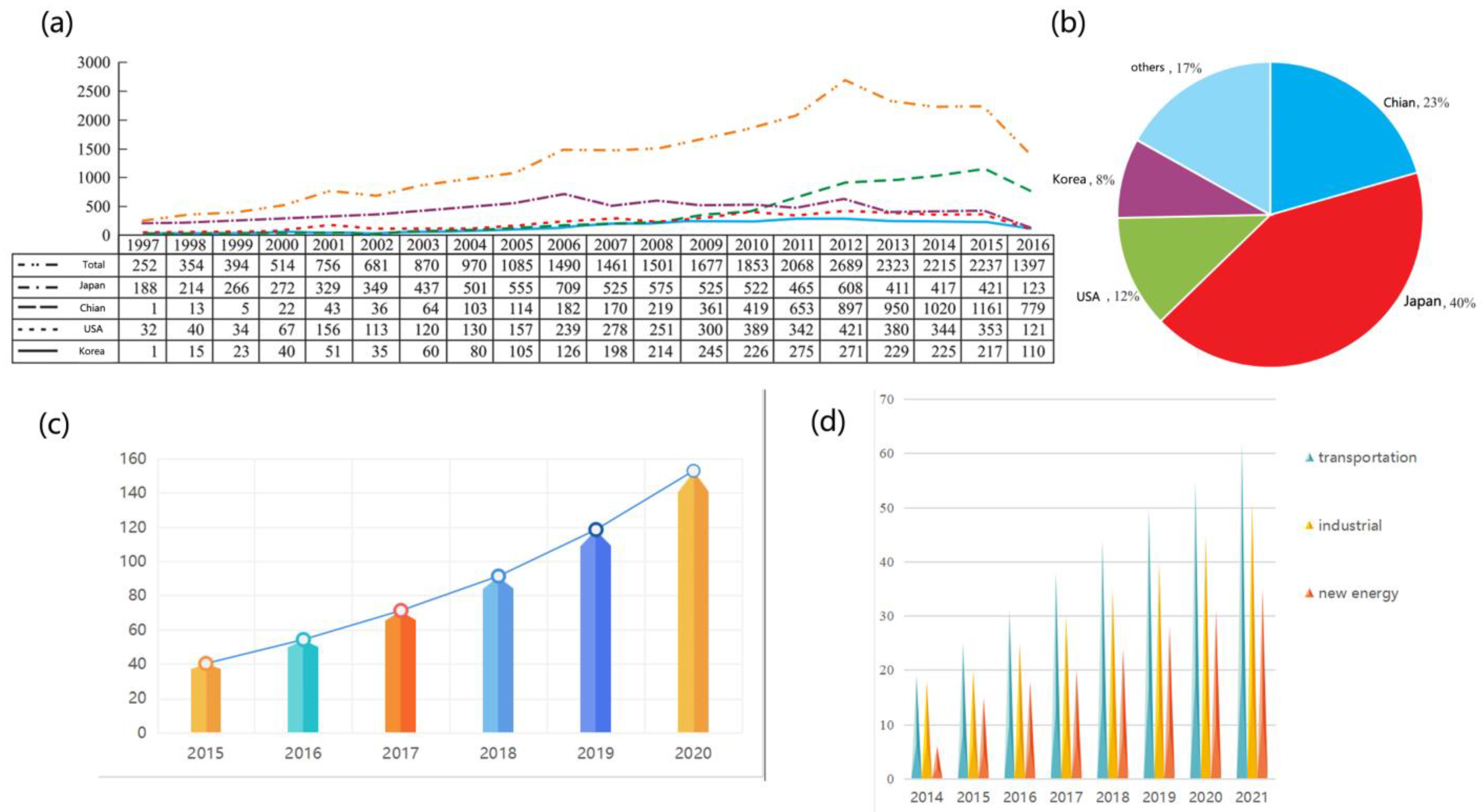

4.1. National Innovative Capacity

4.2. Policy Incentives

4.3. Suggestions

- (1)

- Strengthen research on new technologies for supercapacitors materials.

- (2)

- Develop energy storage technology according to practical demand

- (3)

- Promote the demonstration and commercialization of energy storage technology

- (4)

- Enhance the cooperation in academic and industrial fields

5. Conclusions and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, M.; Patiño-Echeverri, D. Estimating benefits and costs of policies proposed in the 13th FYP to improve energy efficiency and reduce air emissions of China’s electric power sector. Energy Policy 2017, 111, 222–234. [Google Scholar] [CrossRef]

- Zou, C.; Zhang, L.; Hu, X.; Wang, Z.; Wik, T.; Pecht, M. A review of fractional-order techniques applied to lithium-ion batteries, lead-acid batteries, and supercapacitors. J. Power Sources 2018, 390, 286–296. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.; Zhu, X.; Sarkar, S.; Zhao, Y. Challenges and opportunities for supercapacitors. APL Mater. 2019, 7, 100901. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, C. Cost-effective iron-based aqueous redox flow batteries for large-scale energy storage application: A review. J. Power Sources 2021, 493, 229445. [Google Scholar] [CrossRef]

- Simon, P.; Gogotsi, Y. Materials for electrochemical capacitors. Nat. Mater. 2008, 7, 845–854. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, L.; Hu, X.; Wang, Z.; Sun, F.; Dorrell, D. A review of supercapacitor modeling, estimation, and applications: A control/management perspective. Renew Sust. Energ. Rev. 2018, 81, 1868–1878. [Google Scholar] [CrossRef]

- Poudel, M.; Kim, H. Confinement of Zn-Mg-Al-layered double hydroxide and α-Fe2O3 nanorods on hollow porous carbon nanofibers: A free-standing electrode for solid-state symmetric. Chem. Eng. J. 2022, 429, 132345. [Google Scholar] [CrossRef]

- Zhu, L.; Hao, C.; Zhou, S.; Wang, X.; Zhou, T.; Guo, Y. Ternary ZnO/Co3O4/NiO inherited layered core-shell structure from a double template for high performanced supercapacitor. J. Mater. 2021, 7, 708–720. [Google Scholar] [CrossRef]

- Zhu, X.; Li, X.; Tao, H.; Li, M. Preparation of Co2Al layered double hydroxide nanosheet/Co2Mn bimetallic hydroxide nanoneedle nanocomposites on nickel foam for supercapacitors. J. Alloy. Compd. 2021, 851, 156868. [Google Scholar] [CrossRef]

- Wang, W.; Song, X.; Gu, C.; Liu, D.; Liu, J.; Huang, J. A high-capacity NiCo2O4@reduced graphene oxide nanocomposite Li-ion battery anode. J. Alloy. Compd. 2018, 741, 223–230. [Google Scholar] [CrossRef]

- Chavan, H.; Hou, B.; Ahmed, A.; Jo, Y.; Cho, S.; Kim, J.; Pawar, S.; Cha, S.; Inamdar, A.; Im, H.; et al. Nanoflake NiMoO4 based smart supercapacitor for intelligent power balance monitoring. Sol. Energy Mater. Sol. Cells 2018, 185, 166–173. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.; Wu, T.; Han, Y.; Aryana, S. Fabrication of Mn-Ce bimetallic oxides as electrode materials for supercapacitors with high performance. J. Electron. Mater. 2021, 50, 2725–2735. [Google Scholar] [CrossRef]

- Han, Y.; Zhou, J.; Wang, L.; Xing, K.; Xue, Z.; Jiao, Y.; Pang, Y. Redox-active nanostructure electrode of Mn/Ni bimetal organic frameworks anchoring on multi-walled carbon nanotubes for advanced supercapacitor. J. Electroanal. Chem. 2021, 882, 114993. [Google Scholar] [CrossRef]

- Jiao, Y.; Han, Y.; Pang, Y.; Zhou, J.; Qi, X.; Liu, Y. The plate-like hexagonal Ni-Fe-Sr layered double hydroxides as advanced electrodes for electrochemical energy storage. J. Electro. Mater. 2020, 49, 1043–1050. [Google Scholar] [CrossRef]

- Song, L.; Han, Y.; Guo, F.; Jiao, Y.; Li, Y.; Liu, Y.; Gao, F. Mesoporous nickel-based zeolite capsule complex with Fe3O4 as electrode for advanced supercapacitor. J. Nanomater. 2018, 1, 9813203. [Google Scholar] [CrossRef] [Green Version]

- Han, Y.; Li, L.; Liu, Y.; Li, X.; Qi, X.; Song, L. Fabrication of strontium bismuth oxides as novel battery-type electrode materials for high-performance supercapacitors. J. Nanomater. 2018, 1, 5078473. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Wang, Y.; Dai, Z.; Lu, Z.; Gu, X.; Zhao, H.; Sun, G.; Lan, W.; Zhang, Z.; Pan, X.; et al. Nature of improved double-layer capacitance by KOH activation on carbon nanotube-carbon nanofiber hierarchical hybrids. Carbon 2019, 146, 610–617. [Google Scholar] [CrossRef]

- Zhang, S.; Yin, B.; Liu, X.; Gu, D.; Gong, H.; Wang, Z. A high energy density aqueous hybrid supercapacitor with widened potential window through multi approaches. Nano Energy 2019, 59, 41–49. [Google Scholar] [CrossRef]

- González, A.; Goikolea, E.; Barrena, J.; Mysyk, R. Review on supercapacitors: Technologies and materials. Renew. Sust. Energy Rev. 2016, 58, 1189–1206. [Google Scholar] [CrossRef]

- Pandolfo, A.G.; Hollenkamp, A.F. Carbon properties and their role in supercapacitors. J. Power Sources 2006, 157, 11–27. [Google Scholar] [CrossRef]

- Shown, I.; Ganuly, A.; Chen, L.; Chen, K. Conducting polymer-based flexible supercapacitor. Energy Sci. Eng. 2015, 3, 2–26. [Google Scholar] [CrossRef]

- Li, B.; Huang, Y.; Cheng, P.; Liu, B.; Yin, Z.; Lin, Y.; Li, X.; Wang, M.; Cao, H.; Wu, Y. Upgrading comprehensive performances of gel polymer electrolyte based on polyacrylonitrile via copolymerizing acrylonitrile with N-vinylpryrrolidone. Electrochim. Acta 2019, 320, 134572. [Google Scholar] [CrossRef]

- Zhuo, H.; Hu, Y.; Chen, Z.; Zhong, L. Cellulose carbon aerogel/PPy composites for high-performance supercapacitor. Carbohydr. Polym. 2019, 215, 322–329. [Google Scholar] [CrossRef]

- Awang, N.; Nasir, A.; Yajid, M.; Jaafa, J. A review on advancement and future perspective of 3D hierarchical porous aerogels based on electrospun polymer nanofibers for electrochemical energy storage application. J. Environ. Chem. Eng. 2021, 9, 105437. [Google Scholar] [CrossRef]

- Liu, J.; Weng, W.; Xie, H.; Luo, G.; Li, G.; Sun, W.; Ruan, C.; Wang, X. Myoglobin- and hydroxyapatite-doped carbon nanofiber-modified electrodes for electrochemistry and electrocatalysis. ACS Omega 2019, 4, 15653–15659. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Bhat, V.; Gallego, N.; Contescu, C. Thermal treatment effects on charge storage performance of graphene-based materials for supercapacitors. ACS Appl. Mater. Interfaces 2012, 4, 3229–3246. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, Y.; Gao, Z.; Ma, H.; Wang, S.; Peng, J.; Li, J.; Zhai, M. A facile synthesis of platinum nanoparticle decorated graphene by one-step γ-ray induced reduction for high rate supercapacitors. J. Mater. Chem. C 2013, 1, 321–328. [Google Scholar] [CrossRef]

- Zheng, S.; Yang, J.; Yu, S. How renewable energy technological innovation promotes renewable power generation: Evidence from China’s provincial panel data. Renew. Energy 2021, 177, 1394–1407. [Google Scholar] [CrossRef]

- Wang, F.; Wu, X.; Yuan, X.; Liu, Z.; Zhang, Y.; Fu, L.; Zhu, Y.; Zhou, Q.; Wu, Y.; Huang, W. Latest advances in supercapacitors: From new electrode materials to novel device designs. Chem. Soc. Rev. 2017, 46, 6816–6854. [Google Scholar] [CrossRef]

- Gonella, G.; Backus, E.; Nagata, Y.; Bonthuis, D.; Loche, P.; Schlaich, A.; Netz, R.; KÜhnle, A.; McCrum, I.; Koper, M.; et al. Water at charged interfaces. Nat. Rev. Chem. 2021, 5, 466–485. [Google Scholar] [CrossRef]

- Yadav, N.; Yadav, N.; Hashmi, S.A. Ionic liquid incorporated, redox-active blend polymer electrolyte for high energy density quasi-solid-state carbon supercapacitor. J. Power Sources 2020, 451, 227771. [Google Scholar] [CrossRef]

- Fu, C.; Kuang, Y.; Huang, Z.; Huang, Z.; Wang, X.; Yin, Y.; Chen, J.; Zhou, H. Supercapacitor based on graphene and ionic liquid electrolyte. J. Solid State Electrochem. 2011, 15, 2581–2585. [Google Scholar] [CrossRef]

- Gao, Y.; Ai, Q.; Yousif, M.; Wang, X. Source-load-storage consistency collaborative optimization control of flexible DC distribution network considering multi-energy complementarity. Int. J. Electr. Power Energy Syst. 2019, 107, 273–281. [Google Scholar] [CrossRef]

- Cui, W.; Li, J.; Xu, W.; Güneralp, B. Industrial electricity consumption and economic growth: A spatio-temporal analysis across prefecture-level cities in China from 1999 to 2014. Energy 2021, 222, 119932. [Google Scholar] [CrossRef]

- Han, Y.; Pu, Y.; Li, Q.; Fu, W.; Chen, W.; You, Z.; Liu, H. Coordinated power control with virtual inertia for fuel cell-based DC microgrids cluster. Int. J. Hydrogen Energy 2019, 44, 25207–25220. [Google Scholar] [CrossRef]

- Yang, B.; Wang, J.; Wang, J.; Shu, H.; Li, D.; Zeng, C.; Chen, Y.; Zhang, X.; Yu, T. Robust fractional-order PID control of supercapacitor energy storage systems for distribution network applications: A perturbation compensation based approach. J. Clean. Prod. 2021, 279, 123362. [Google Scholar] [CrossRef]

- Nazir, M.S.; Abdalla, A.N.; Wang, Y.; Chu, Z.; Jie, J.; Tian, P.; Jiang, M.; Khan, I.; Sanjeevikumar, P.; Tang, Y. Optimization configuration of energy storage capacity based on the microgrid reliable output power. J. Energy Storage 2020, 32, 101866. [Google Scholar] [CrossRef]

- Yan, Q.; Bo, Q.; Jingjie, Y.; Yunfei, M.; Bingqing, G. Frequency Control Strategy of Hybrid Energy Storage System for Microgrid Based on Frequency Hysteretic Loop. Energy Procedia 2016, 103, 328–332. [Google Scholar] [CrossRef]

- Ma, H.; Zhang, Y.; Shen, M. Application and prospect of supercapacitors in Internet of Energy (IOE). J. Energy Storage 2021, 44, 103299. [Google Scholar] [CrossRef]

- Yang, B.; Wang, J.; Sang, Y.; Yu, L.; Shu, H.; Li, S.; He, T.; Yang, L.; Zhang, X.; Yu, T. Applications of supercapacitor energy storage systems in microgrid with distributed generators via passive fractional-order sliding-mode control. Energy 2019, 187, 115905. [Google Scholar] [CrossRef]

- Tan, Q.; Ding, Y.; Zheng, J.; Dai, M.; Zhang, Y. The effects of carbon emissions trading and renewable portfolio standards on the integrated wind–photovoltaic–thermal power-dispatching system: Real case studies in China. Energy 2021, 222, 119927. [Google Scholar] [CrossRef]

- Chen, H.; Gao, X.-Y.; Liu, J.-Y.; Zhang, Q.; Yu, S.; Kang, J.-N.; Yan, R.; Wei, Y.-M. The grid parity analysis of onshore wind power in China: A system cost perspective. Renew. Energy 2020, 148, 22–30. [Google Scholar] [CrossRef]

- Xie, D.; Liu, M.; Xu, L.; Lu, W. Bi-level programming approach for coordinated configuration of distributed generations and automation devices in distribution networks. Int. J. Electr. Power Energy Syst. 2021, 133, 107210. [Google Scholar] [CrossRef]

- Lin, J.; Niu, J.; Li, H.; Atiquzzaman, M. A Secure and Efficient Location-based Service Scheme for Smart Transportation. Future Gener. Comput. Syst. 2019, 92, 694–704. [Google Scholar] [CrossRef]

| Energy Storage Devices | Advantages | Disadvantages |

|---|---|---|

| Supercapacitor |

|

|

| Lithium-ion battery |

|

|

| Lead-acid battery |

|

|

| Sodium sulfur battery |

|

|

| Types of Supercapacitors | Advantages | Disadvantages |

|---|---|---|

| Double layer supercapacitor |

|

|

| Faraday pseudocapacitor |

|

|

| Hybrid supercapacitor |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Han, Y.; Jiang, W.; Zhang, Y.; Xu, Y.; Ahmed, A.M. Application of the Supercapacitor for Energy Storage in China: Role and Strategy. Appl. Sci. 2022, 12, 354. https://doi.org/10.3390/app12010354

Yang Y, Han Y, Jiang W, Zhang Y, Xu Y, Ahmed AM. Application of the Supercapacitor for Energy Storage in China: Role and Strategy. Applied Sciences. 2022; 12(1):354. https://doi.org/10.3390/app12010354

Chicago/Turabian StyleYang, Yanchun, Yinghui Han, Wenkun Jiang, Yuyang Zhang, Yanmei Xu, and Ayman Mahmoud Ahmed. 2022. "Application of the Supercapacitor for Energy Storage in China: Role and Strategy" Applied Sciences 12, no. 1: 354. https://doi.org/10.3390/app12010354