Characteristics of Dynamic Safety Factors during the Construction Process for a Tunnel-Group Metro Station

Abstract

:1. Introduction

2. Analysis Method

2.1. Calculation Process of Strength-Reduction Finite Element Method

2.2. Judgment of Tunnel Instability in Calculation

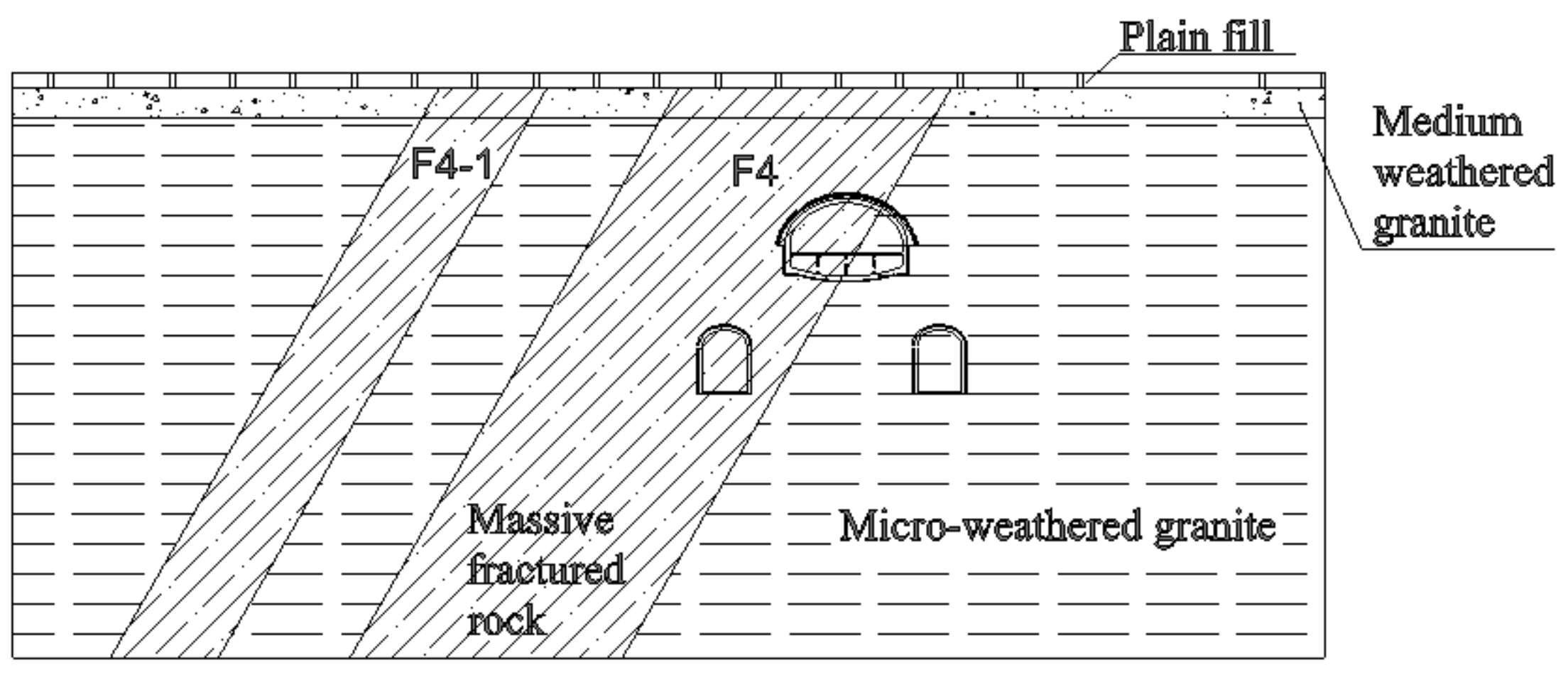

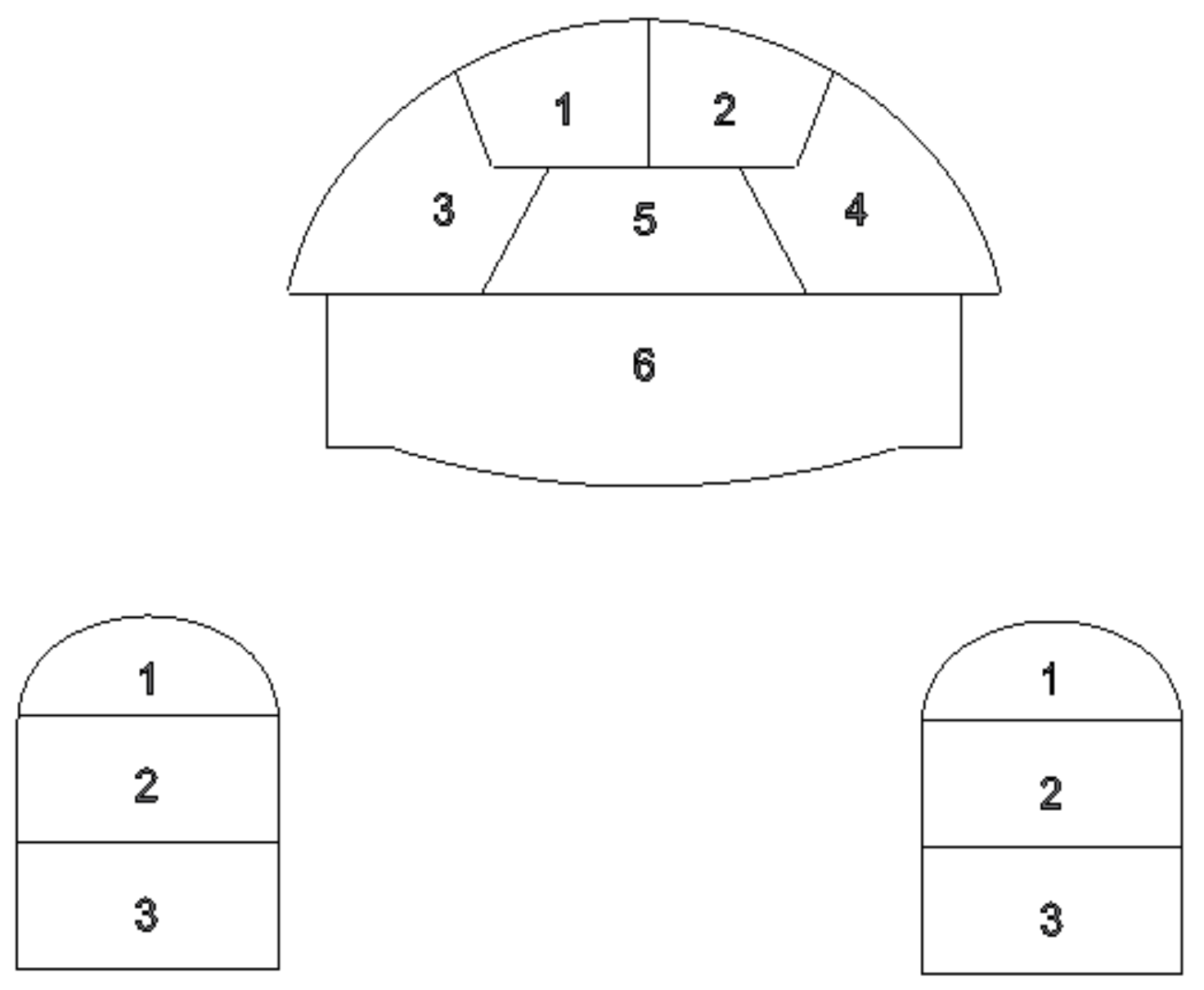

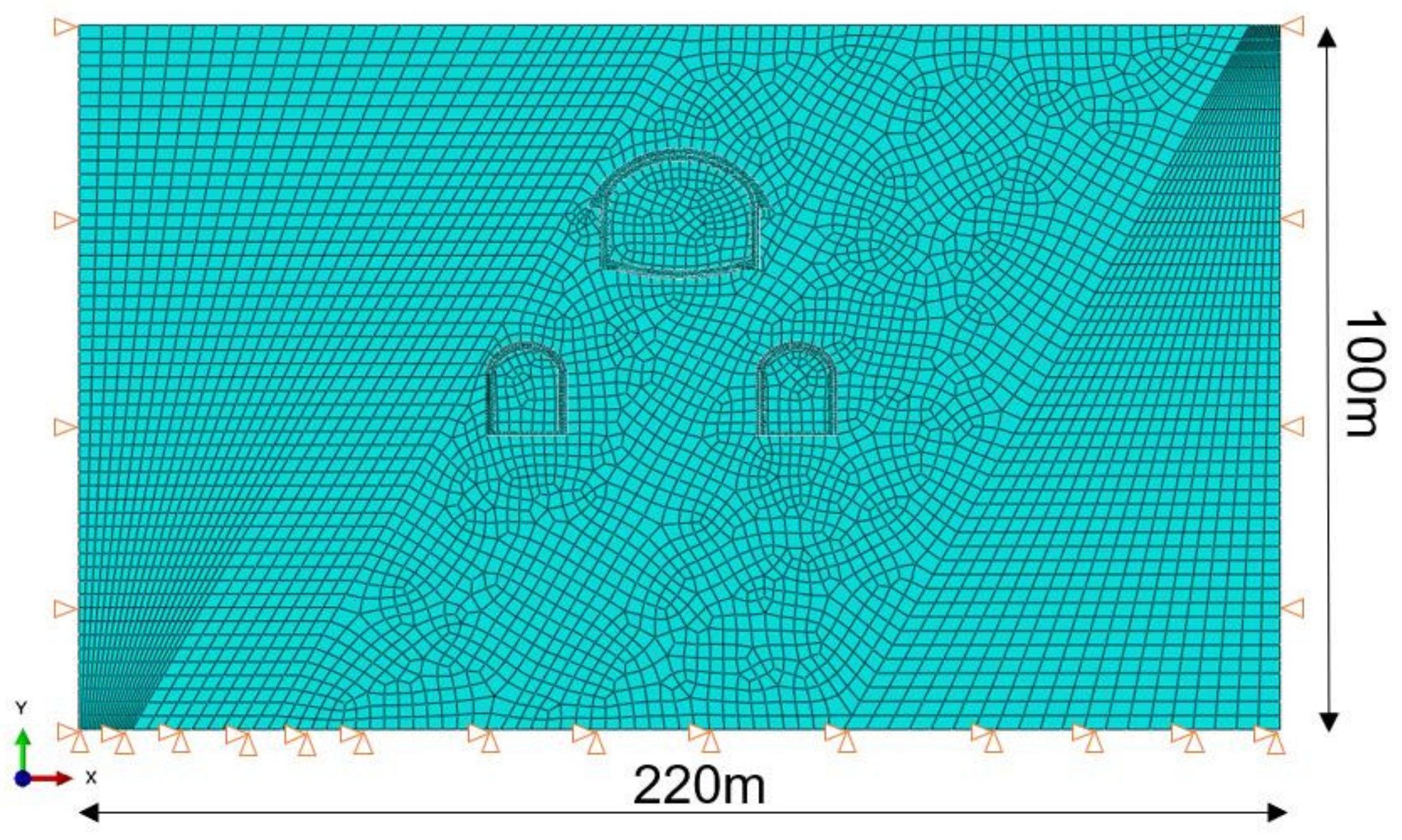

2.3. Numerical Model and Parameters

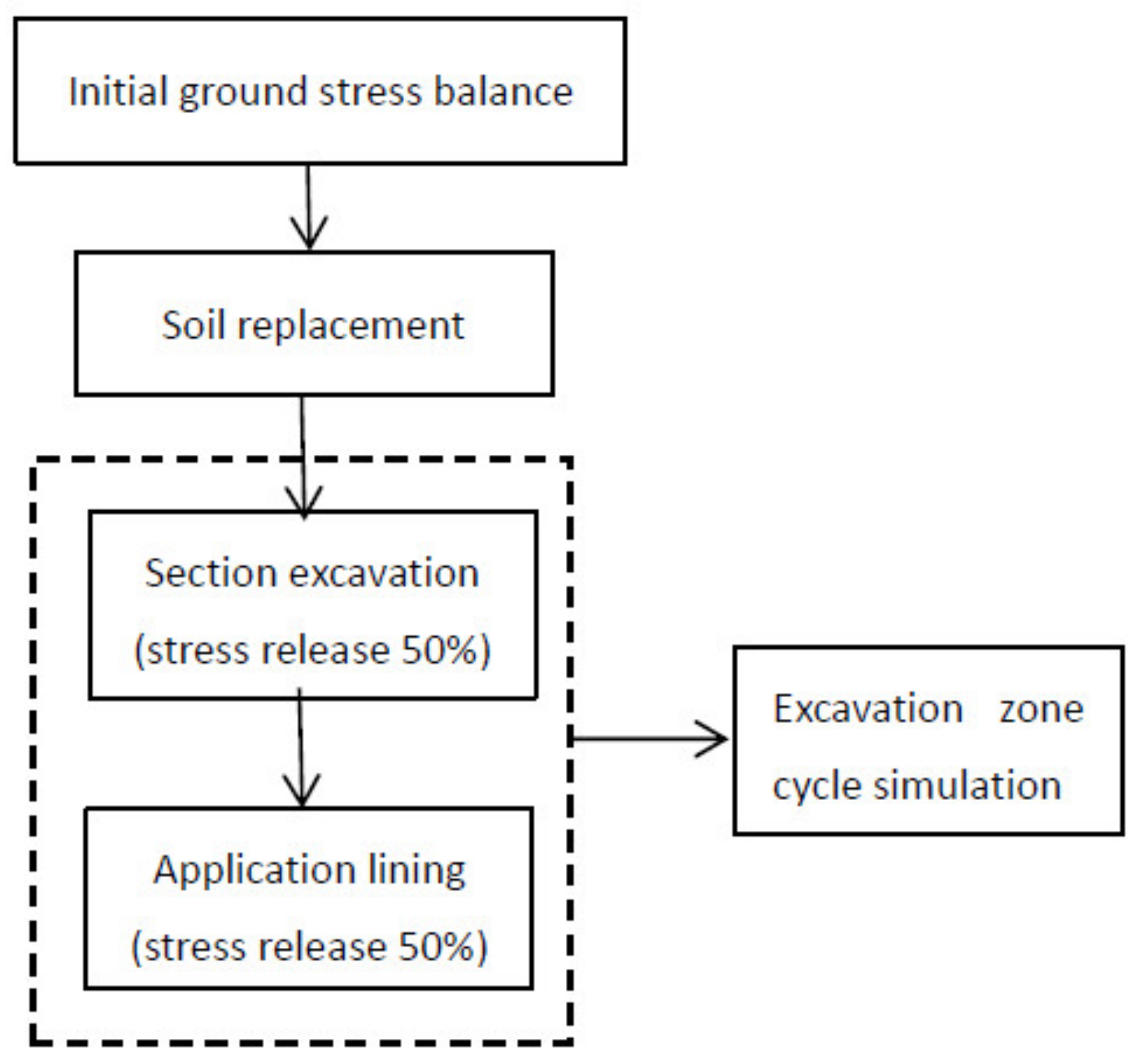

2.4. Analysis Steps

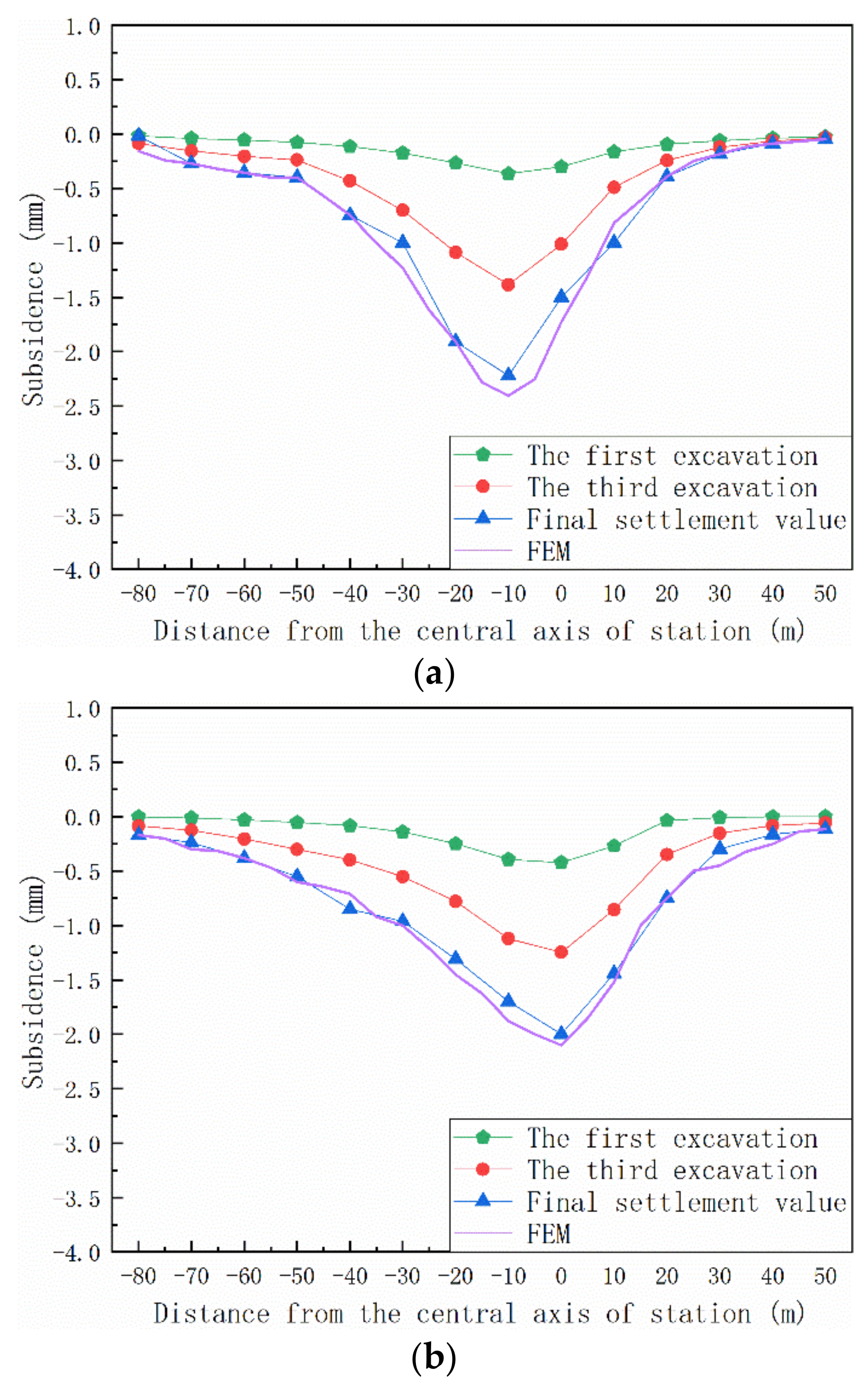

2.5. Comparison of On-Site Monitoring Results

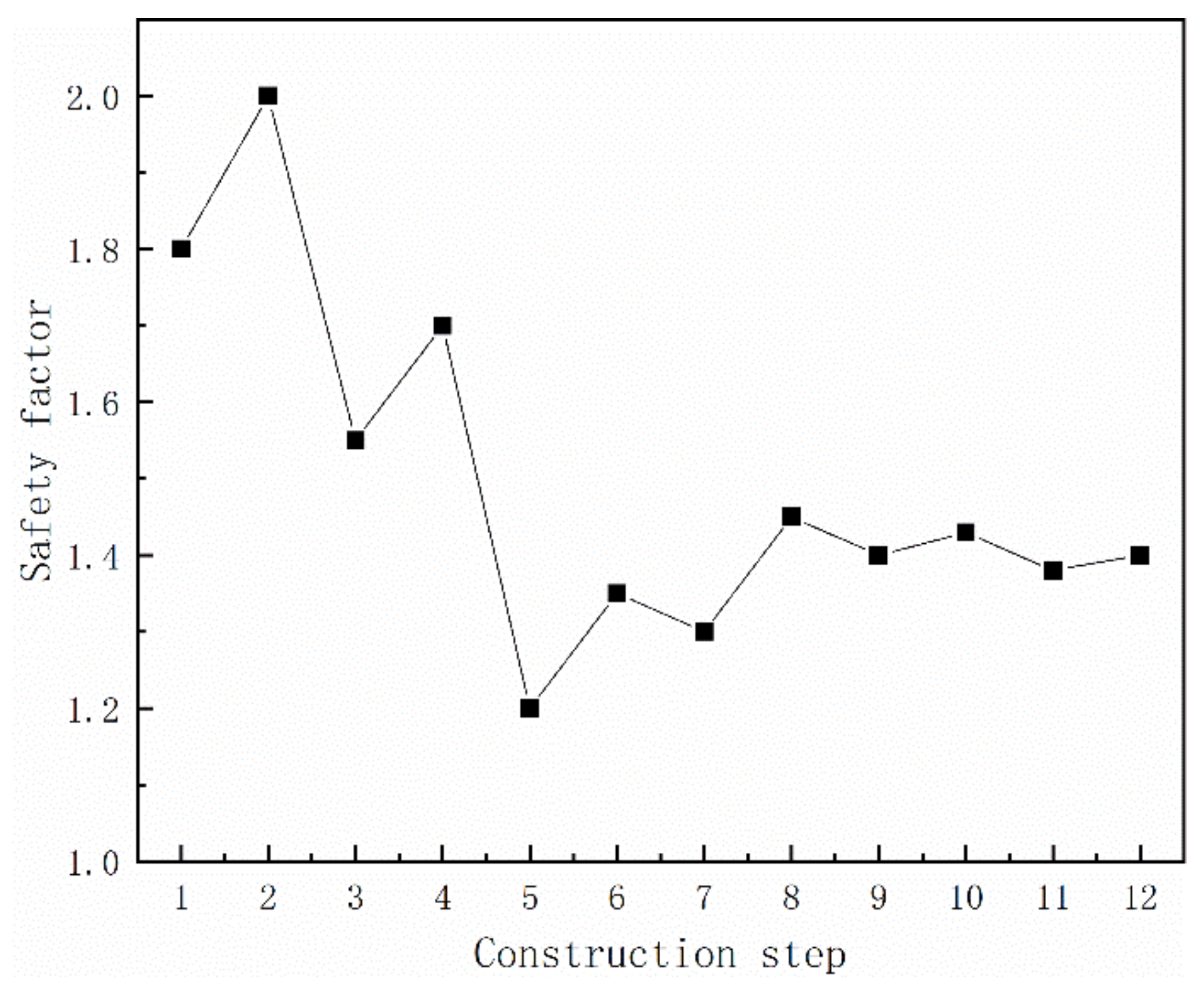

3. Dynamic Change of Safety Factor

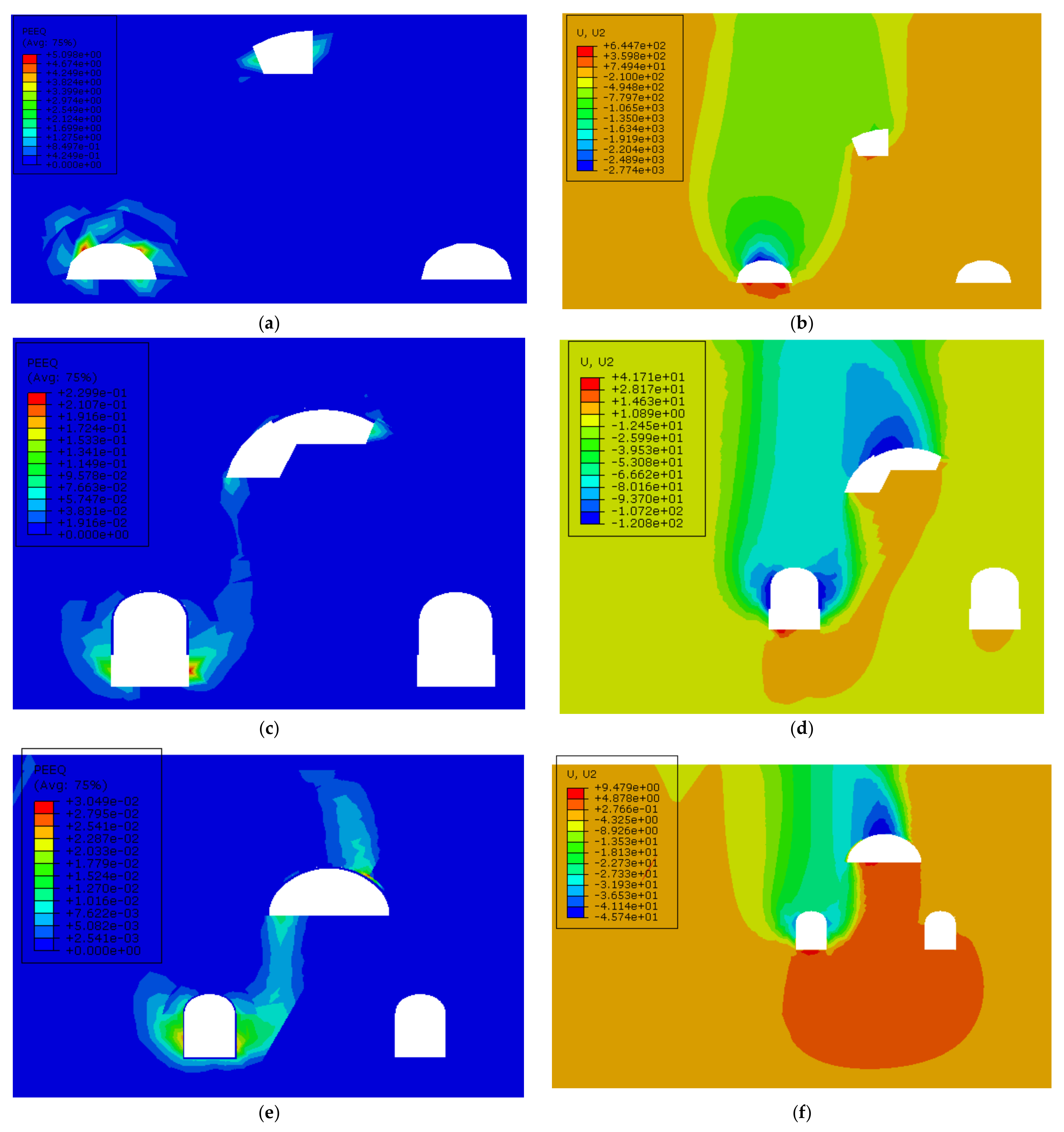

3.1. Equivalent Plastic Strain and Displacement

3.2. Safety Factor of the Construction Step and Key Working Conditions

4. Conclusions

- (1)

- When the finite element strength-reduction method was used for the analysis of the stability of the surrounding rock, a judgment method based on the convergence of the finite element calculation could be adopted, since the non-convergence is associated with either local instability of the rock surrounding the excavation area or overall instability of the rock of the connected plastic zones.

- (2)

- For the form of instability under each working condition, designers should carefully select the crossing stratum of the tunnel vault and pay attention to the pre-reinforcement of the surrounding rock of the vault before construction. Pre-reinforcement approaches may include expanding the scope of the reinforcement area or increasing the reinforcement strength.

- (3)

- For a large-span concealed tunnel, the initial support should be implemented in time. After the arch is excavated, the initial support of the section should be closed early.

- (4)

- For this tunnel-group metro station, excavating in area 3 was the most dangerous construction step. The application of initial support in each excavation step will increase the safety factor of the surrounding rock to different degrees.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maleska, T.; Beben, D. Numerical analysis of a soil-steel bridge during backfilling using various shell models. Eng. Struct. 2019, 196, 109358. [Google Scholar] [CrossRef]

- Ramadan, S.H.; El Naggar, M.H. Effect of large-span three-sided culvert configuration on its performance at service and ultimate loading conditions. Tunn. Undergr. Space Technol. 2022, 122, 104346. [Google Scholar] [CrossRef]

- Wadi, A.; Pettersson, L.; Karoumi, R. On Predicting the Ultimate Capacity of a Large-Span Soil–Steel Composite Bridge. Int. J. Geosynth. Ground Eng. 2020, 6, 48. [Google Scholar] [CrossRef]

- Bhasin, R.; Grimstad, E. The use of stress-strength relationships in the assessment of tunnel stability. Tunn. Undergr. Space Technol. 1996, 11, 93–98. [Google Scholar] [CrossRef]

- Meng, L.; Li, T.; Jiang, Y. Characteristics and Mechanisms of Large Deformation in the Zhegu Mountain Tunnel on the Sichuan-Tibet Highway. Tunn. Undergr. Space Technol. 2013, 37, 157–164. [Google Scholar] [CrossRef]

- AASHTO. Technical Manual for Design and Construction of Road Tunnels-Civil Element; U.S. Department of Transportation: Chipley, FL, USA, 2010.

- Panji, M.; Asgari, M.J.; Tavousi, T.S. Evaluation of effective parameters on the underground tunnel stability using BEM. J. Struct. Eng. Geotech. 2011, 1, 29–37. [Google Scholar]

- Chapman, D.; Metje, N.; Stärk, A. Introduction to Tunnel Construction; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Kuesel, T.R.; King, E.H.; Bickel, J.O. Tunnel Engineering Handbook; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Sun, H.; Liu, S.; Zhong, R.; Du, L. Cross-section deformation analysis and visualization of shield tunnel based on mobile tunnel monitoring system. Sensors 2020, 20, 1006. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, T.T.; Jaw, J.J.; Chang, Y.H.; Jeng, F.S. Application and validation of profile–image method for measuring deformation of tunnel wall. Tunn. Undergr. Space Technol. 2009, 24, 136–147. [Google Scholar] [CrossRef]

- Nuttens, T.; Stal, C.; De Backer, H.; Schotte, K.; Van Bogaert, P.; De Wulf, A. Methodology for the ovalization monitoring of newly built circular train tunnels based on laser scanning: Liefkenshoek Rail Link (Belgium). Autom. Constr. 2014, 43, 1–9. [Google Scholar] [CrossRef]

- Zeinkiewicz, O.; Humpheson, C.; Lewis, R. Associated and non-associated visco-plasticity in soils mechanics. J. Geotech. 1975, 25, 671–689. [Google Scholar] [CrossRef]

- Mateui, T.; San, K.C. Finite element slope stability analysis by shear strength reduction. Soils Found. 1992, 32, 59–70. [Google Scholar] [CrossRef] [Green Version]

- Ugai, K. A method of calculation of total factor of safety of slopes by elastic-plastic FEM. Soils Found. 1989, 29, 190–195. [Google Scholar] [CrossRef] [Green Version]

- Ugai, K.; Leshchinaky, D. Three-dimensional limit equilibrium method and finite element analysis: A comparison of results. Soils Found. 1995, 35, 1–7. [Google Scholar] [CrossRef]

- Cai, F.; Ugai, K. Numerical analysis of the stability of a slope reinforced with piles. J. Jpn. Geotech. Soc. Soils Found. 2008, 40, 73–84. [Google Scholar] [CrossRef] [Green Version]

- Griffiths, D.V.; Lane, P.A. Slope stability analysis by finite elements. Geotechnique 1999, 49, 387–403. [Google Scholar] [CrossRef]

- Hammah, R.E.; Yacoub, T.E.; Corkum, B.C.; Curran, J.H. The Shear Strength Reduction Method for the Generalized Hoek-Brown Criterion. In Proceedings of the 40th U.S. Symposium on Rock Mechanics (USRMS), Anchorage, AK, USA, 25–29 June 2005; Volume 5, p. 810. [Google Scholar]

- Cheng, Y.M.; Lansivaara, T.; Wei, W.B. Two-dimensional slope stability analysis by limit equilibrium and strength reduction methods. Comput. Geotech. 2007, 34, 137–150. [Google Scholar] [CrossRef]

- Yuan, W.; Bai, B.; Li, X.-c.; Wang, H.-b. A strength reduction method based on double reduction parameters and its application. J. Cent. South Univ. 2013, 20, 2555–2562. [Google Scholar] [CrossRef]

- Bai, B.; Yuan, W.; Li, X. A new double reduction method for slope stability analysis. J. Cent. South Univ. 2014, 21, 1158–1164. [Google Scholar] [CrossRef]

- Zhang, Z.; Tang, C.A.; Li, L.C.; Ma, T.H.; Tang, S.B. Strength Reduction Method on Stability Analysis of Tunnel. In Computational Mechanics; Springer: Berlin/Heidelberg, Germany, 2007; pp. 296–298. [Google Scholar]

- Jong, D.Y.; Han, U.C.; Jang, U.J. Determination of Safety Factor for Rock Mass Surrounding Tunnel by Sudden Change of Equivalent Plastic Strain in Strength Reduction Method. Geotech. Geol. Eng. 2022, 1–17. [Google Scholar] [CrossRef]

- Sun, J.; Wang, F.; Wang, X.; Wu, X. A Quantitative Evaluation Method Based on Back Analysis and the Double-Strength Reduction Optimization Method for Tunnel Stability. Adv. Civ. Eng. 2021, 34, 137–150. [Google Scholar] [CrossRef]

- Huang, F.; Yang, X.; Zhao, L.; Ling, T. Upper Bound Solutions of Safety Factor for Shallow Tunnels Subjected to Nonlinear Failure Criterion and Strength Reduction Method. Eng. Mech. 2013, 30, 160–166. [Google Scholar]

- Wang, W.; Zhang, J.; Li, A. The Application of the Strength Reduction Shortest Path Method to the Stability Analysis of Shallow Buried Tunnel. Geotech. Geol. Eng. 2022, 40, 1091–1101. [Google Scholar] [CrossRef]

- Zheng, Y.R.; Zhao, S.Y.; Kong, W.X.; Deng, C.J. Geotechnical engineering limit analysis using finite element method. Rock Soil Mech. 2005, 26, 163–168. (In Chinese) [Google Scholar]

- Shiau, J.; Al-Asadi, F. Stability analysis of twin circular tunnels using shear strength reduction method. Géotech. Lett. 2020, 10, 311–319. [Google Scholar] [CrossRef]

- Liang, Z.; Gong, B.; Li, W. Instability analysis of a deep tunnel under triaxial loads using a three-dimensional numerical method with strength reduction method. Tunn. Undergr. Space Technol. 2019, 86, 51–62. [Google Scholar] [CrossRef]

- Xia, C.; Xu, C.; Zhao, X. Study of The Strength Reduction DDA Method and Its Application to Mountain Tunnel. Int. J. Comput. Methods 2012, 9, 1250041. [Google Scholar] [CrossRef]

- Xia, C.; Zhao, X.; Zhang, G.; Wang, C. Stability Analysis by Strength Reduction Method in Shallow Buried Tunnels. In Tunneling and Underground Construction, Proceedings of the Geo-Shanghai 2014, Shanghai, China, 26–28 May 2014; American Society of Civil Engineers: Reston, VA, USA, 2014; p. 242. [Google Scholar]

- Pan, Q.; Dias, D. Upper-bound analysis on the face stability of a non-circular tunnel. Tunn. Undergr. Space Technol. 2017, 62, 96–102. [Google Scholar] [CrossRef]

- He, P. Research on the Orthogonal Test of Tunnel Supporting Parameters Based on the Finite Element Strength Reduction Method. Appl. Mech. Mater. 2012, 170–173, 1533–1537. [Google Scholar] [CrossRef]

- Chen, B.; Gong, B.; Wang, S.; Tang, C.A. Research on Zonal Disintegration Characteristics and Failure Mechanisms of Deep Tunnel in Jointed Rock Mass with Strength Reduction Method. Mathematics 2022, 10, 922. [Google Scholar] [CrossRef]

- Dawson, E.M.; Roth, W.H.; Drescher, A. Slope stability analysis by strength reduction. Geotechnique 1999, 49, 835–840. [Google Scholar] [CrossRef]

- Feng, X.T.; Hudson, J.A. Rock Engineering Design; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Heng, C.; Sun, S.; Zhang, J.; Zhou, Z. Calculation Method of Underground Passage Excavation on Interactive Effects among Pipe-Roof, Steel Bracing and Foundation Soil. KSCE J. Civ. Eng. 2022, 26, 448–459. [Google Scholar] [CrossRef]

- Xu, Z.; Luo, Y.; Chen, J.; Su, Z.; Zhu, T.; Yuan, J. Mechanical properties and reasonable proportioning of similar materials in physical model test of tunnel lining cracking. Constr. Build. Mater. 2021, 300, 123960. [Google Scholar] [CrossRef]

- Brady, B.H.; Brown, E.T. Rock Mechanics: For Underground Mining; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Su, Y.; Su, Y.; Zhao, M.; Vlachopoulos, N. Tunnel stability analysis in weak rocks using the convergence confinement method. Rock Mech. Rock Eng. 2021, 54, 559–582. [Google Scholar] [CrossRef]

| Type | E (MPa) | c (kPa) | φ (°) | υ |

|---|---|---|---|---|

| Plain fill | 2 | 10 | 8 | 0.42 |

| Medium weathered granite | 5000 | 700 | 35 | 0.3 |

| Massive fractured rock | 3000 | 300 | 27 | 0.35 |

| Micro-weathered granite | 11,000 | 1100 | 40 | 0.28 |

| Initial support | 28,000 | 2000 | 45 | 0.2 |

| Working Condition | Safety Factor | Instability Form | Increase Value |

|---|---|---|---|

| Excavation area 1 | 1.83 | Partial collapse of the roof | 9.80% |

| Support area 1 | 2.01 | / | |

| Excavation area 3 | 1.20 | Side wall collapse | 12.50% |

| Support area 3 | 1.35 | / | |

| Excavation area 5 | 1.41 | Partial collapse of the roof | 1.40% |

| Support area 5 | 1.43 | / |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Li, R.; He, W.; Gao, X.; Yao, X.; Yuan, Y.; Zhang, J. Characteristics of Dynamic Safety Factors during the Construction Process for a Tunnel-Group Metro Station. Appl. Sci. 2022, 12, 4900. https://doi.org/10.3390/app12104900

Li Q, Li R, He W, Gao X, Yao X, Yuan Y, Zhang J. Characteristics of Dynamic Safety Factors during the Construction Process for a Tunnel-Group Metro Station. Applied Sciences. 2022; 12(10):4900. https://doi.org/10.3390/app12104900

Chicago/Turabian StyleLi, Qingfei, Ruozhou Li, Weiguo He, Xin Gao, Xupeng Yao, Yong Yuan, and Jiaolong Zhang. 2022. "Characteristics of Dynamic Safety Factors during the Construction Process for a Tunnel-Group Metro Station" Applied Sciences 12, no. 10: 4900. https://doi.org/10.3390/app12104900