Research on Permanent Magnet Synchronous Motor Control System Based on Adaptive Kalman Filter

Abstract

:1. Introduction

2. Theoretical Analysis of the EKF

2.1. The EKF Model of the PMSM

2.2. The PAEKF Model of the PMSM

2.3. Practical Implementation Considerations

3. Simulation Results and Discussions

3.1. Simulation of PMSM Control System Based on EKF and PAEKF

3.2. Simulation of PMSM Control System Based on PAEKF and Existing Parameter Adaptive Methods

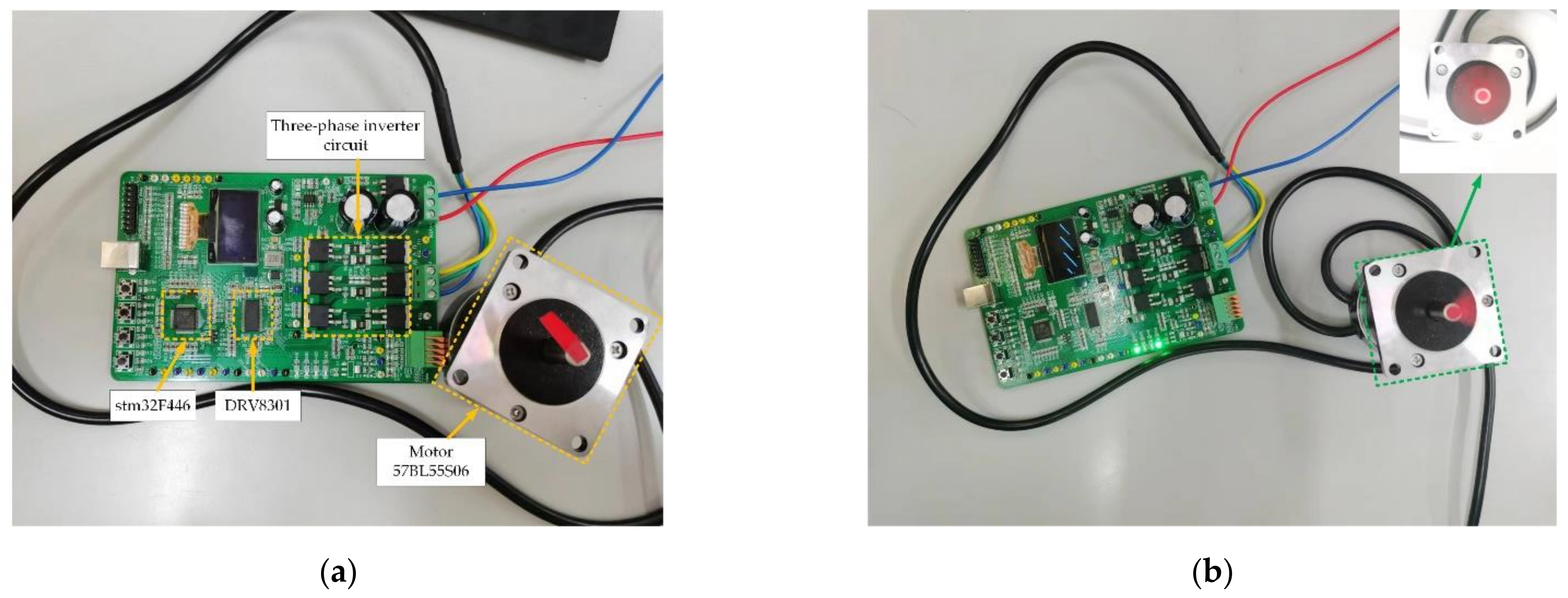

3.3. Experiment of PMSM Control System Based on PAEKF

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Xu, D.; Zhang, S.; Liu, J. Very-low speed control of PMSM based on EKF estimation with closed loop optimized parameters. ISA Trans. 2013, 52, 835–843. [Google Scholar] [CrossRef] [PubMed]

- Aguilar-Mejía, O.; Minor-Popocatl, H.; Pacheco-García, P.F.; Tapia-Olvera, R. Neuroadaptive Robust Speed Control for PMSM Servo Drives with Rotor Failure. Appl. Sci. 2021, 11, 11090. [Google Scholar] [CrossRef]

- Tian, Y.; Chai, Y.; Feng, L. Simultaneous Load Disturbance Estimation and Speed Control for Permanent Magnet Synchronous Motors in Full Speed Range. Appl. Sci. 2020, 10, 9006. [Google Scholar] [CrossRef]

- Grouz, F.; Sbita, L.; Boussak, M. Current sensors faults detection, isolation and control reconfiguration for PMSM drives. In Proceedings of the 2013 International Conference on Electrical Engineering and Software Applications, Hammamet, Tunisia, 21–23 March 2013; pp. 1–6. [Google Scholar]

- Gopinath, G.R.; Das, S.P. An extended kalman filter based sensorless permanent magnet synchronous motor drive with improved dynamic performance. In Proceedings of the 2018 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Madras, India, 18–21 December 2018; pp. 1–6. [Google Scholar]

- Acarnley, P.P.; Watson, J.F. Review of position-sensorless operation of brushless permanent-magnet machines. IEEE Trans. Ind. Electron. 2006, 53, 352–362. [Google Scholar] [CrossRef]

- Walambe, R.A.; Joshi, V.A.; Apte, A.A.; Kolhe, J.P.; Deshpande, A. Study of sensorless control algorithms for a permanent magnet synchronous motor vector control drive. In Proceedings of the 2015 International Conference on Industrial Instrumentation and Control (ICIC), Maharashtra, India, 28–30 May 2015; pp. 423–428. [Google Scholar]

- Kung, Y.S. ModelSim/Simulink co-simulation of a sensorless control for PMSM drives based on I-F startup and EKF. In Proceedings of the 2016 International Conference on Applied System Innovation (ICASI), Osaka, Japan, 22–27 May 2016; pp. 1–4. [Google Scholar]

- Walambe, R.A.; Joshi, V.A. Survey of EKF based sensorless vector control methodologies for a permanent magnet synchronous motor. In Proceedings of the 2016 Indian Control Conference (ICC), Hyderabad, India, 4–6 January 2016; pp. 93–98. [Google Scholar]

- Liu, J.M.; Zhu, Z.Q. Sensorless Control Strategy by Square-Waveform High-Frequency Pulsating Signal Injection into Stationary Reference Frame. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 171–180. [Google Scholar] [CrossRef]

- Tuovinen, T.; Hinkkanen, M. Adaptive Full-Order Observer with High-Frequency Signal Injection for Synchronous Reluctance Motor Drives. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 181–189. [Google Scholar] [CrossRef] [Green Version]

- Carbone, L.; Cosso, S.; Marchesoni, M.; Passalacqua, M.; Vaccaro, L. State-Space Approach for SPMSM Sensorless Passive Algorithm Tuning. Energies 2021, 14, 7180. [Google Scholar] [CrossRef]

- Wu, J.; Wei, H.; Zhang, Y.; Wei, H. Sensorless vector control of permanent magnet synchronous motor based on model reference adaptive system. In Proceedings of the 2017 3rd IEEE International Conference on Computer and Communications (ICCC), Chengdu, China, 13–16 December 2017; pp. 2879–2883. [Google Scholar]

- Liang, D.; Li, J.; Qu, R.; Kong, W. Adaptive Second-Order Sliding-Mode Observer for PMSM Sensorless Control Considering VSI Nonlinearity. IEEE Trans. Power Electr. 2018, 33, 8994–9004. [Google Scholar] [CrossRef]

- Kang, K.; Kim, J.; Hwang, K.; Kim, K. Sensorless control of PMSM in high speed range with iterative sliding mode observer. In Proceedings of the Nineteenth Annual IEEE Applied Power Electronics Conference and Exposition, Anaheim, CA, USA, 27 September 2004; pp. 1111–1116. [Google Scholar]

- Tety, P.; Konate, A.; Asseu, O.; Soro, E.; Yoboue, P.; Kouadjo, A.R. Others A robust extended Kalman filter for speed-sensorless control of a linearized and decoupled PMSM drive. Engineering 2015, 7, 691. [Google Scholar] [CrossRef] [Green Version]

- Krim, S.; Gdaim, S.; Mtibaa, A.; Mimouni, M.F. Contribution of the FPGAs for Complex Control Algorithms: Sensorless DTFC with an EKF of an Induction Motor. Int. J. Autom. Comput. 2019, 16, 226–237. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, J.; Chen, D.; Qi, J. Model Reference Adaptive Control of Marine Permanent Magnet Propulsion Motor Based on Parameter Identification. Electronics 2022, 11, 1012. [Google Scholar] [CrossRef]

- Termizi, M.S.; Lazi, J.M.; Ibrahim, Z.; Talib, M.H.N.; Aziz, M.J.A.; Ayob, S.M. Sensorless PMSM drives using Extended Kalman Filter (EKF). In Proceedings of the 2017 IEEE Conference on Energy Conversion (CENCON), Kuala Lumpur, Malaysia, 30–31 October 2017; pp. 145–150. [Google Scholar]

- Walambe, R.A.; Joshi, V.A. Closed Loop Stability of a PMSM-EKF Controller-Observer Structure. IFAC-Paper 2018, 51, 249–254. [Google Scholar] [CrossRef]

- Zerdali, E. A Comparative Study on Adaptive EKF Observers for State and Parameter Estimation of Induction Motor. IEEE Trans. Energy Conver. 2020, 35, 1443–1452. [Google Scholar] [CrossRef]

- Chen, Q.; Huang, Y. Speed Estimation by EKF with Parameter Adaption. In Proceedings of the 2020 Chinese Automation Congress (CAC), Shanghai, China, 6–8 November 2020; pp. 2458–2462. [Google Scholar]

- Wang, A.; Wang, Q.; Hu, C.; Qian, Z.; Ju, L.; Liu, J. An EKF for PMSM sensorless control based on noise model identification using Ant Colony Algorithm. In Proceedings of the 2009 International Conference on Electrical Machines and Systems, Tokyo, Japan, 15–18 November 2009; pp. 1–4. [Google Scholar]

- Bolognani, S.; Tubiana, L.; Zigliotto, M. Extended Kalman filter tuning in sensorless PMSM drives. IEEE Trans. Ind. Appl. 2003, 39, 1741–1747. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, X. Sensorless control of permanent magnet synchronous motors and EKF parameter tuning research. Math. Probl. Eng. 2016, 2016, 3916231. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Wang, J.; Zhang, D.; Shao, X.; Chen, G. Kalman Filtering Through the Feedback Adaption of Prior Error Covariance. Signal Process. 2018, 152, 47–53. [Google Scholar] [CrossRef]

| Parameter | Values |

|---|---|

| Voltage (V) | 24 |

| Rated speed (r/min) | 3000 |

| Inductance L (mH) | 1.4 |

| Resistance R (Ω) | 0.6 |

| viscous damping F (N·m·s) | 1 × 10−4 |

| Pole pairs p | 1 |

| Rotor moment of inertia J (kg⋅m2) | 1.1 × 10−5 |

| Numbers | Values |

|---|---|

| ① | Q = diag(0.1,0.1,0.1,0.1) |

| ② | Q = diag(0.1,0.1,0.5,0.1) |

| ③ | Q = diag(0.1,0.1,5.0,0.1) |

| ④ | Q = diag(0.1,0.1,50,0.1) |

| ⑤ | Q = diag(0.1,0.1,500,0.1) |

| ⑥ | Q = diag(0.1,0.1,0.5,1.0) |

| ⑦ | Q = diag(0.1,0.1,5.0,1.0) |

| ⑧ | Q = diag(0.1,0.1,50,1.0) |

| ⑨ | Q = diag(0.1,0.1,500,1.0) |

| Parameter | Values |

|---|---|

| Voltage (V) | 24 |

| Rated speed (r/min) | 3000 |

| Inductance L (mH) | 1.4 |

| Resistance R (Ω) | 0.59 |

| viscous damping F (N·m·s) | 6.12 × 10−6 |

| Pole pairs p | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, J.; Xing, W.; Qin, H.; Hua, Y.; Zhang, X.; Liu, X. Research on Permanent Magnet Synchronous Motor Control System Based on Adaptive Kalman Filter. Appl. Sci. 2022, 12, 4944. https://doi.org/10.3390/app12104944

Cui J, Xing W, Qin H, Hua Y, Zhang X, Liu X. Research on Permanent Magnet Synchronous Motor Control System Based on Adaptive Kalman Filter. Applied Sciences. 2022; 12(10):4944. https://doi.org/10.3390/app12104944

Chicago/Turabian StyleCui, Jiadong, Wenhao Xing, Huibin Qin, Yongzhu Hua, Xin Zhang, and Xinran Liu. 2022. "Research on Permanent Magnet Synchronous Motor Control System Based on Adaptive Kalman Filter" Applied Sciences 12, no. 10: 4944. https://doi.org/10.3390/app12104944

APA StyleCui, J., Xing, W., Qin, H., Hua, Y., Zhang, X., & Liu, X. (2022). Research on Permanent Magnet Synchronous Motor Control System Based on Adaptive Kalman Filter. Applied Sciences, 12(10), 4944. https://doi.org/10.3390/app12104944