Efficiency of Different Cage Armour Systems

Abstract

:Featured Application

Abstract

1. Introduction

2. Cage Armour Working Principle

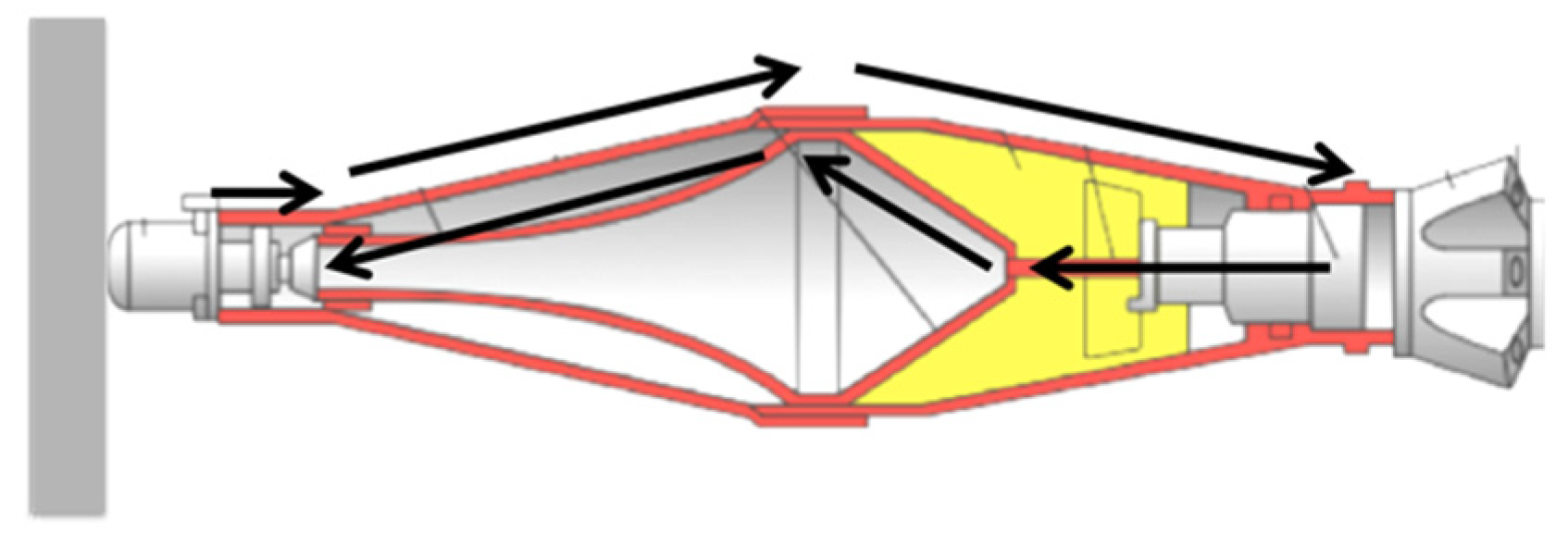

2.1. PG-7(M) Detonation Chain

2.2. Cage Armour Working Principle

2.3. Cage Armour Design Principle

3. Technical Solutions for a Cage Armour System

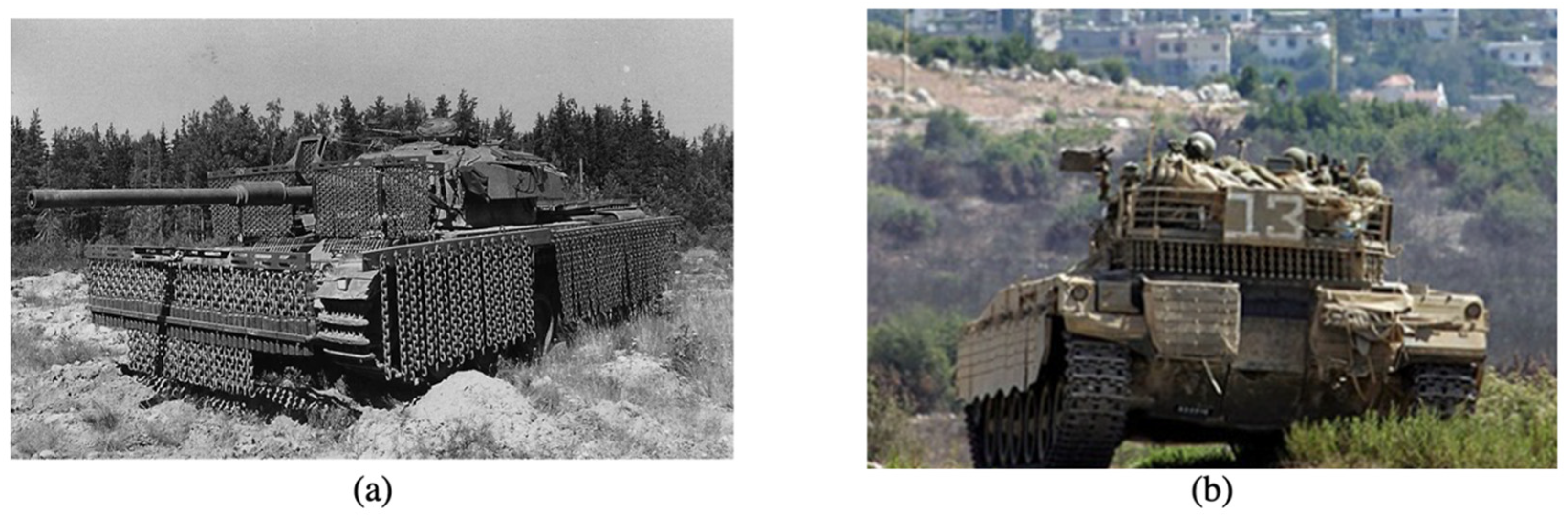

3.1. Bar Armour

3.2. Slat Armour

3.3. Net/Mesh Armour

3.4. Inertial Distributed Weight Armour

3.5. Special Versions

3.5.1. Spike Armour

3.5.2. Steel Cable Armour

3.5.3. Chain/Ball Armour

4. Experimental Validation of the Geometrical Efficiency Calculation

4.1. Metal-Based Cage Armour Systems

4.1.1. Geometrical Analysis

4.1.2. Experimental Validation

Case A: Lamellar Slat Armour

Case B: Steel Fibre-Based Net Armour System

4.2. Polymer Fibre-Based Net Armour System

4.3. Final Comparison Experiment vs. Modeling

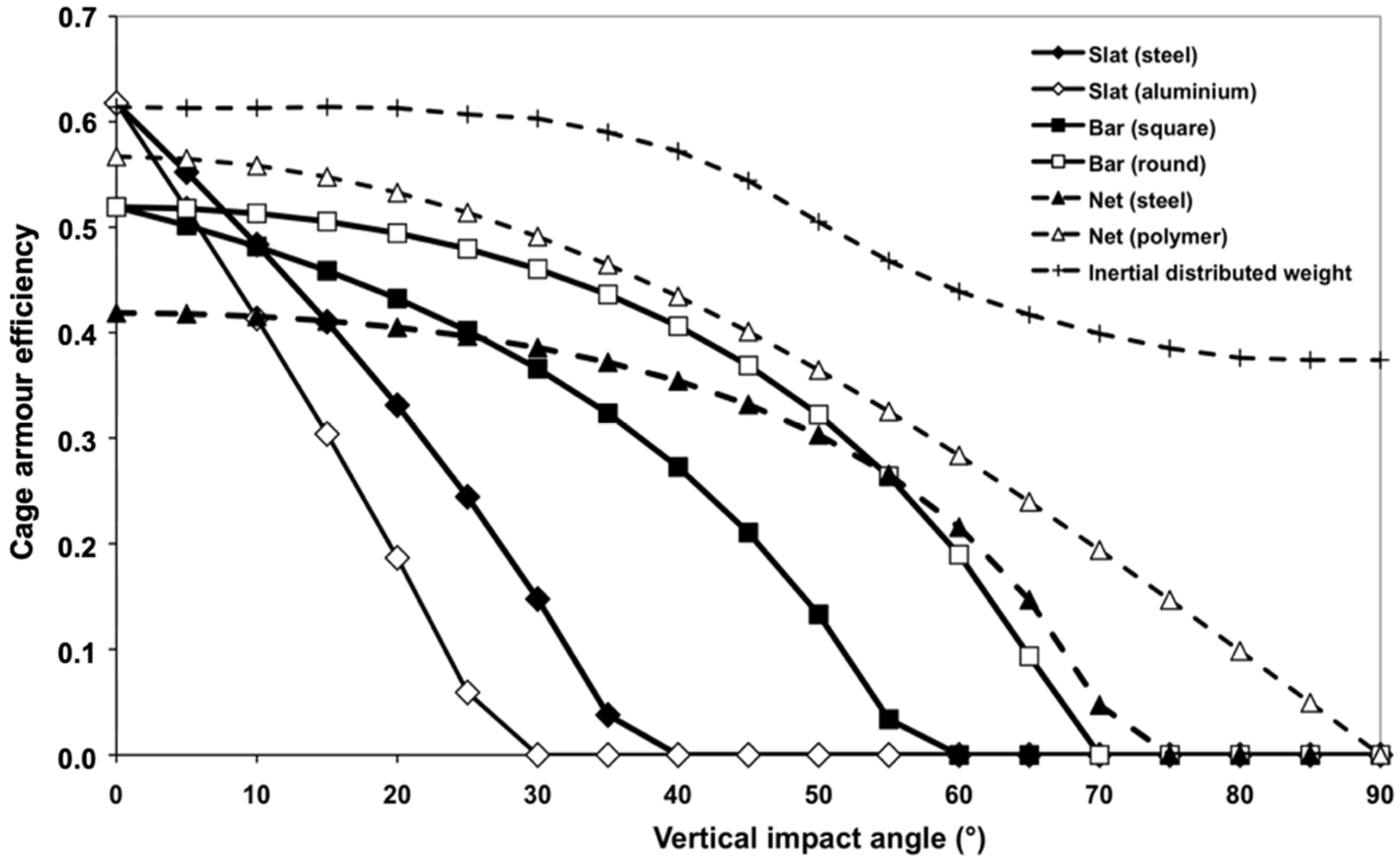

5. Comparison of Different Cage Armour Systems

5.1. Description of the Considered Cage Armour Systems

5.2. Ballistic Efficiency Comparison

5.2.1. Influence of the Vertical Impact Angle

5.2.2. Combined Influence of the Horizontal and Vertical Impact Angle

5.3. Mass Efficiency Comparison

6. Determining the Likely Range of Vertical Impact Angles

6.1. PG-7 Trajectory Model

- Booster phase: the tail part of the projectile (with the fins still folded), containing a booster charge, accelerates the projectile out of the RPG-7 launcher, giving the projectile an initial velocity of ±117 m/s at a distance of ±11 m. This phase starts with the ignition of the booster charge due to the firing of the weapon and ends with the ignition of the rocket engine. A constant accelerating force for the booster was assumed for this phase of the trajectory model, next to the gravity and drag forces.

- Sustained flight phase: the rocket engine is ignited and further accelerates the projectile from its initial velocity of ±117 m/s up to its maximum velocity of ±300 m/s. The rocket engine is burned out after a flight distance of ±100 m (corresponding to the bending point in the curve in Figure 26). A constant accelerating force was again assumed for this phase of the trajectory model next to the gravity and drag forces.

- Ballistic phase: on this part of its trajectory, the PG-7 projectile is no longer propelled by the rocket engine but continues following a purely ballistic trajectory only subjected to the gravity and drag forces.

- ap [m/s2] = acceleration of the projectile

- mp [kg] = mass of the projectile

- Dp [m] = maximum diameter of the projectile

- vp [m/s] = instantaneous velocity of the projectile

- CD0,p [/] = drag coefficient of the projectile

- δ [rad] = angle between the projectile axis/velocity vector and the horizontal plane

- Fbooster [N] = accelerating force acting on the projectile generated by the booster

- Frocket engine [N] = accelerating force acting on the projectile generated by the rocket engine

- ρair [kg/m3] = specific density of the air

- g [m/s2] = gravitational constant

6.2. PG-7 Trajectory Characteristics

6.3. Consequences for the Considered Cage Armour Systems

6.3.1. Ballistic Efficiency Comparison

6.3.2. Mass Efficiency Comparison

7. Conclusions

Funding

Conflicts of Interest

Appendix A

Appendix A.1. Projectile Dimensional Properties Affecting the Efficiency

Appendix A.2. Lamellar Slat Armour Efficiency

Appendix A.3. Square Bar Armour Efficiency

Appendix A.4. Round Bar Armour Efficiency

Appendix A.5. Net/Mesh, Non-Rotated Square, Armour Efficiency

Appendix A.6. Net/Mesh, Rotated, Diamond-Shaped, Armour Efficiency

Appendix A.7. Inertial Distributed Weight Armour Efficiency

References

- Coghe, F. Ballistic efficiency of lightweight cage armor systems. In Proceedings of the 31st International Symposium on Ballistics, (IBS 31), Hyderabad, India, 4–8 November 2019; pp. 2339–2349. [Google Scholar]

- Hogg, I. (Ed.) Jane’s Infantry Weapons; Jane’s Publishing Company Ltd.: London, UK, 1986; pp. 721–722. [Google Scholar]

- Rottman, G. The Rocket Propelled Grenade; Osprey Publishing Ltd.: Oxford, UK, 2010. [Google Scholar]

- US Army. Tradoc Bulletin No. 3: Soviet Rpg-7 Antitank Grenade Launcher: Capabilities and Countermeasures; US Army: Arlington County, VA, USA, 1976. [Google Scholar]

- Hasik, J. A Working Paper on Recent Fatalities in Military Vehicles in Iraq and Afghanistan (Version 3.1). Available online: http://img.bemil.chosun.com/nbrd/data/10040/upfile/200911/20091111165052.pdf (accessed on 5 May 2022).

- Hawkes, J. Russian Turret Cages. Available online: https://www.tanknology.co.uk/post/russian-turret-cages (accessed on 27 April 2022).

- Tollast, R. How Javelin Missiles Penetrate Russian Tank Cage Armour. Available online: https://www.thenationalnews.com/world/2022/04/07/how-javelin-missiles-penetrate-russian-tank-cage-armour/ (accessed on 27 April 2022).

- Shoaib, A. Russian Soldiers Appear to be Fixing Makeshift Cages to the Turrets of Their Tanks in a Crude Effort to Protect Themselves Against Ukraine’s Anti-Tank Missiles. Available online: https://www.businessinsider.com/russian-forces-are-attaching-cages-to-their-tanks-experts-say-they-demon?international=true&r=US&IR=T (accessed on 27 April 2022).

- Parker, C. Fearful Russian Crews Attach Cages to Tanks. Available online: https://www.thetimes.co.uk/article/fearful-russian-crews-attach-cages-to-tanks-rkr3dbjfz (accessed on 27 April 2022).

- Chevalier, T.; Lapotre, C.; Simoneti, J.; Guichard, G. Assessment of rate dysfunction of statistical armour against rpg-7 family threat. In Proceedings of the 30th 31st International Symposium on Ballistics (IBS 30), Long Beach, CA, USA, 11–15 September 2017; pp. 1226–1234. [Google Scholar]

- Malciu, A.; Puica, C.; Pupaza, C.; Pintilie, D.; Iancu, F. Research on the mitigation of shaped charge effect. Proc. Rom. Acad. Ser. A 2020, 21, 273–282. [Google Scholar]

- Fayed, A.; El Amaim, Y.A.; Elgohary, D. Investigating the Behavior of Manufactured Rocket Propelled Grenade (RPG) Armour Net Screens from Different Types of High Performance Fibers. Int. J. Sci. Res. 2018, 8, 2088. [Google Scholar]

- Soukos, K.N. Apparatus for Protecting at Arget from an Explosive Warhead. U.S. Patent US2010/0288114A1, 18 November 2010. [Google Scholar]

- Farinella, M.D.; Cardenas, R.L.; Lawson, W.R.; La, B.; Frances, B.; David, R.; Michael, H.; Michael, W.; Thomas, A.; Kanaan, M.A.; et al. Vehicle and Structure Shield. U.S. Patent US2009/0266227A1, 29 October 2009. [Google Scholar]

- Radstake, M.; Kaufmann, H. Protection of an Object from Hollow Charges. European Patent EP 2 455 702 B1, 12 December 2014. [Google Scholar]

- Shoshan, A.B.; Laor, A.; Eyal, S.; Showken, T. Hybrid Slat Armor. U.S. Patent US2015/0226526A1, 20 September 2017. [Google Scholar]

- Zochowski, P. Effectiveness of PG-7 grenade after passing through the net-armor—Numerical analysis. In Proceedings of the 24th International Symposium on Ballistics (IBS 24), New Orleans, LA, USA, 22–26 September 2008; pp. 67–76. [Google Scholar]

- Szudrowicz, M. Analysis of bar and net screens structure protecting vehicles against anti-tank grenades fired from rpg-7. J. KONES Powertrain Transp. 2011, 18, 639–644. [Google Scholar]

- Zochowski, P.; Podgorzaknu, P. Numerical analysis of effectiveness for vehicle net systems protecting against shaped charge projectiles. J. Probl. Mechatron. Armament Aviat. Saf. Eng. 2016, 139, 23–27. [Google Scholar] [CrossRef]

| Case | Slat Armour Properties | Projectile Properties | ||

|---|---|---|---|---|

| D (mm) | I (mm) | P (mm) | Impact Angle (°) | |

| A | 6 | 55 | 21.5 | 0 |

| B | 8 | 47 | 21.5 | 0 |

| Case | Number of Shots | Short-Circuited Fuzes | Experimental Probability (%) | Theoretical Probability (%) |

|---|---|---|---|---|

| A | 26 | 14 | 54 | 55 |

| B | 25 | 11 | 44 | 46 |

| Case | Net Armour Properties | Projectile Properties | |||||

|---|---|---|---|---|---|---|---|

| D (mm) | Dmin (mm) | Dmax (mm) | Type | Ceff (mm) | P (mm) | Impact Angle (°) | |

| C | 4 | 110 | 192 | PG-7 | 75 | 21.5 | 0 |

| D | 4 | 110 | 192 | PG-7L | 84 | 21.5 | 0 |

| E | 4 | 110 | 192 | PG-7 | 75 | 21.5 | 45 |

| F | 4 | 110 | 192 | PG-7L | 84 | 21.5 | 45 |

| Case | Number of Shots | Short-Circuited Fuzes | Experimental Probability (%) | Theoretical Probability (%) |

|---|---|---|---|---|

| C | 51 | 25 | 49 | 55 |

| D | 52 | 27 | 52 | 59 |

| E | 4 | 2 | (50) | (46) |

| F | 3 | 2 | (67) | (57) |

| Case | Impact Angle (°) | Number of Shots | Short-Circuited Fuzes | Experimental Probability (%) | Theoretical Probability (%) |

|---|---|---|---|---|---|

| Benchmark | 0 | 30 | 17 | 57 | N/A |

| G | 45 | 28 | 11 | 39 | 40 |

| System | Type | Material | Dimensions |

|---|---|---|---|

| 1 | Slat | Steel | Slat 6 mm × 50 mm 68 mm centre slat to centre slat |

| 2 | Slat | Aluminium | Slat 6 mm × 77 mm 68 mm centre slat to centre slat |

| 3 | Square bar | Steel | Round bar 12.7 mm diameter 68 mm centre bar to centre bar |

| 4 | Round bar | Steel | Square 12.7 mm sides 68 mm centre bar to centre bar |

| 5 | Net | Steel | Wire 4 mm diameter, mesh size 192 mm × 110 mm (horizontal × vertical) |

| 6 | Net | Polymer | N/A |

| 7 | Inertial distributed mass | Steel | Spherical nodule 20 mm diameter, square grid 65 mm centre nodule to centre nodule |

| Projectile Properties | ||

|---|---|---|

| Type | Ceff (mm) | P (mm) |

| PG-7 | 75 | 21.5 |

| Trajectory Model Parameters | ||

|---|---|---|

| mp | [kg] | 2.25 |

| Dp | [m] | 0.085 |

| CD0,p | [/] | 1.041 |

| Fbooster | [N] | 1225 |

| Frocket engine | [N] | 1419 |

| ρair | kg/m3 | 1.225 |

| g | m/s2 | 9.81 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coghe, F. Efficiency of Different Cage Armour Systems. Appl. Sci. 2022, 12, 5064. https://doi.org/10.3390/app12105064

Coghe F. Efficiency of Different Cage Armour Systems. Applied Sciences. 2022; 12(10):5064. https://doi.org/10.3390/app12105064

Chicago/Turabian StyleCoghe, Frederik. 2022. "Efficiency of Different Cage Armour Systems" Applied Sciences 12, no. 10: 5064. https://doi.org/10.3390/app12105064

APA StyleCoghe, F. (2022). Efficiency of Different Cage Armour Systems. Applied Sciences, 12(10), 5064. https://doi.org/10.3390/app12105064