Use of Carbon and Basalt Fibers with Adhesives to Improve Physical and Mechanical Properties of Plywood

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Plywood Panels

2.1.2. Reinforcement Fibers

2.1.3. Adhesives

2.2. Methods

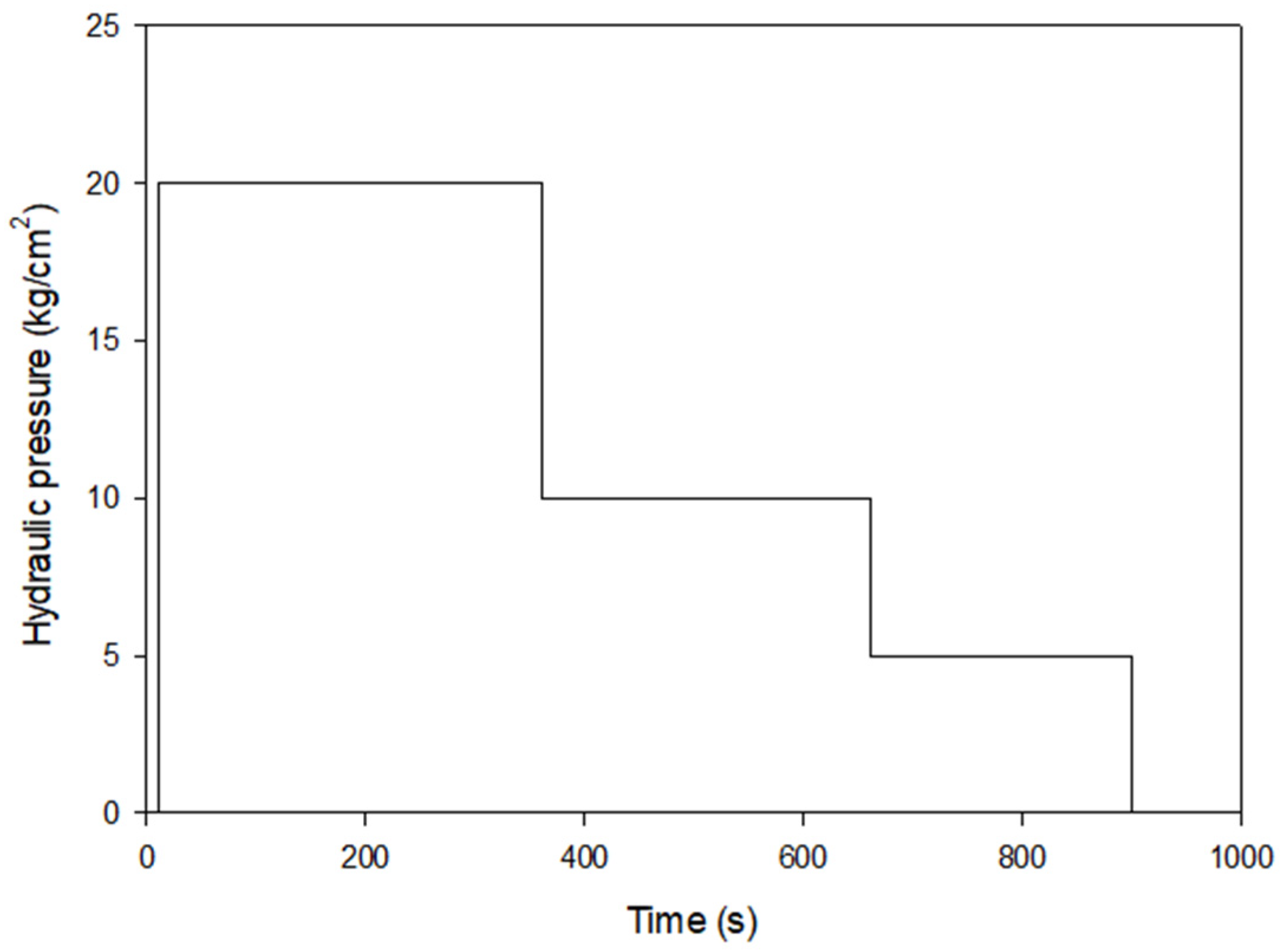

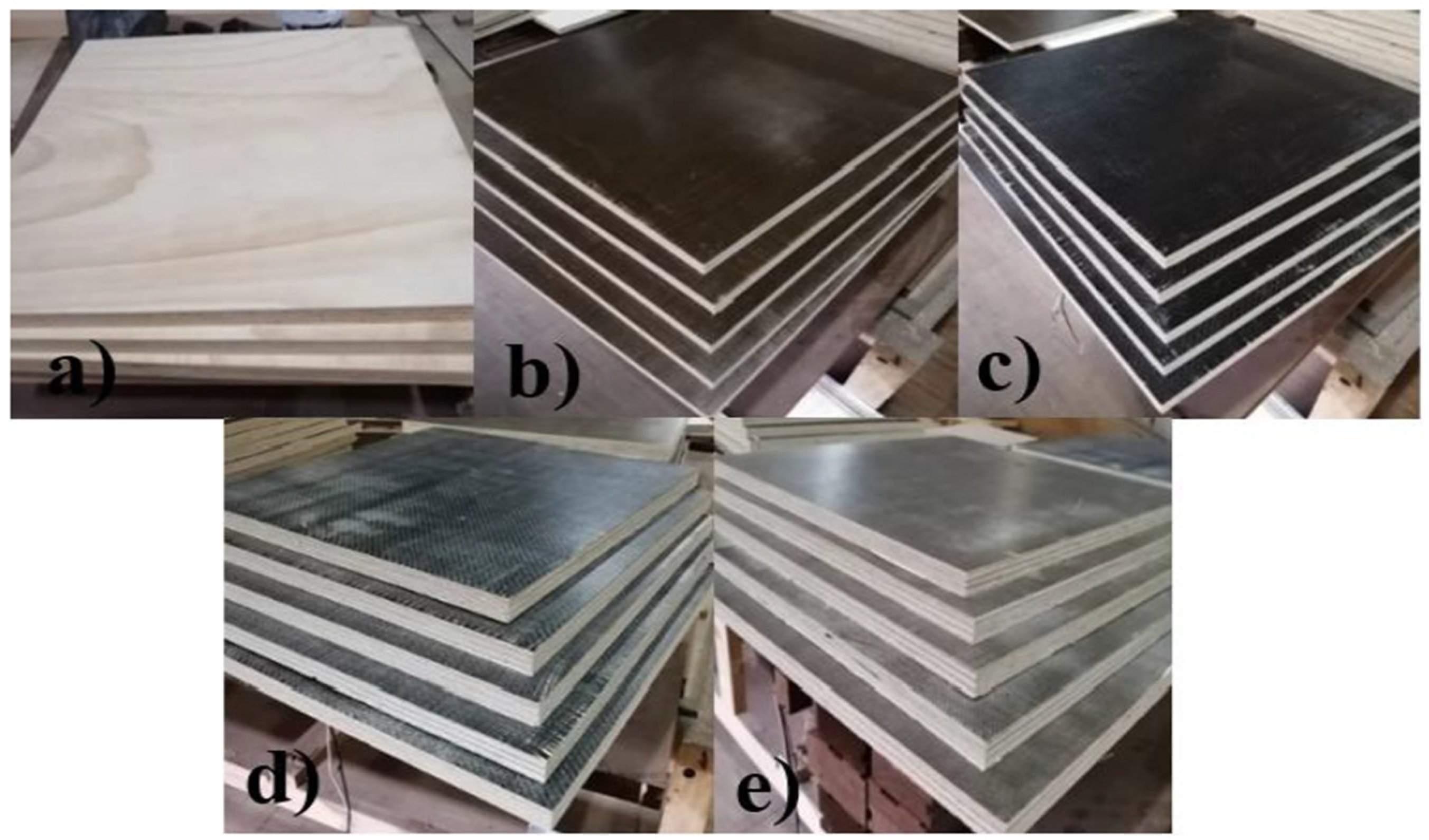

2.2.1. Reinforcement of Plywood Panels

2.2.2. Physical Properties

2.2.3. Mechanical Properties

2.2.4. Analysis of Data

3. Results

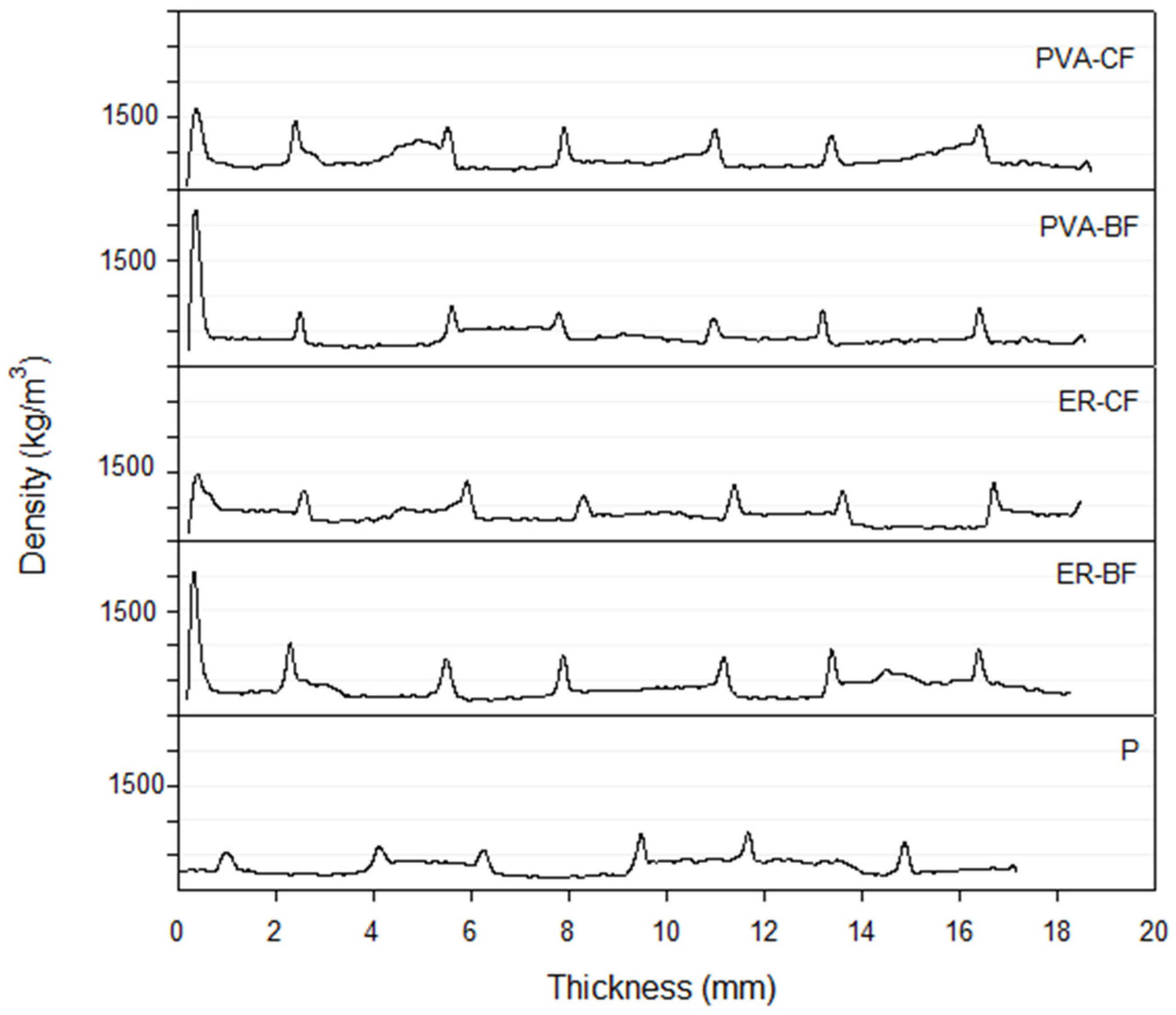

3.1. Physical Properties

3.2. Mechanical Properties

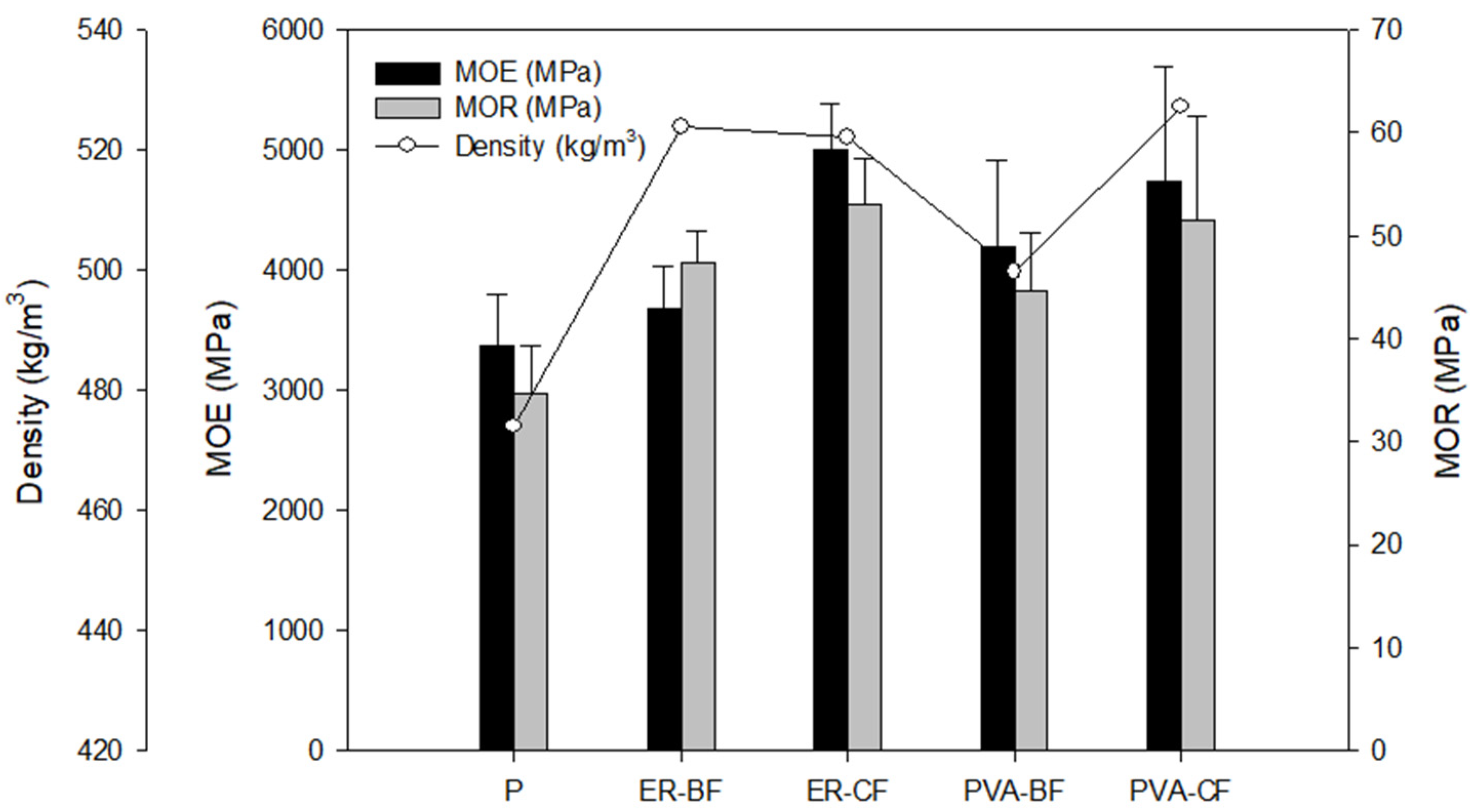

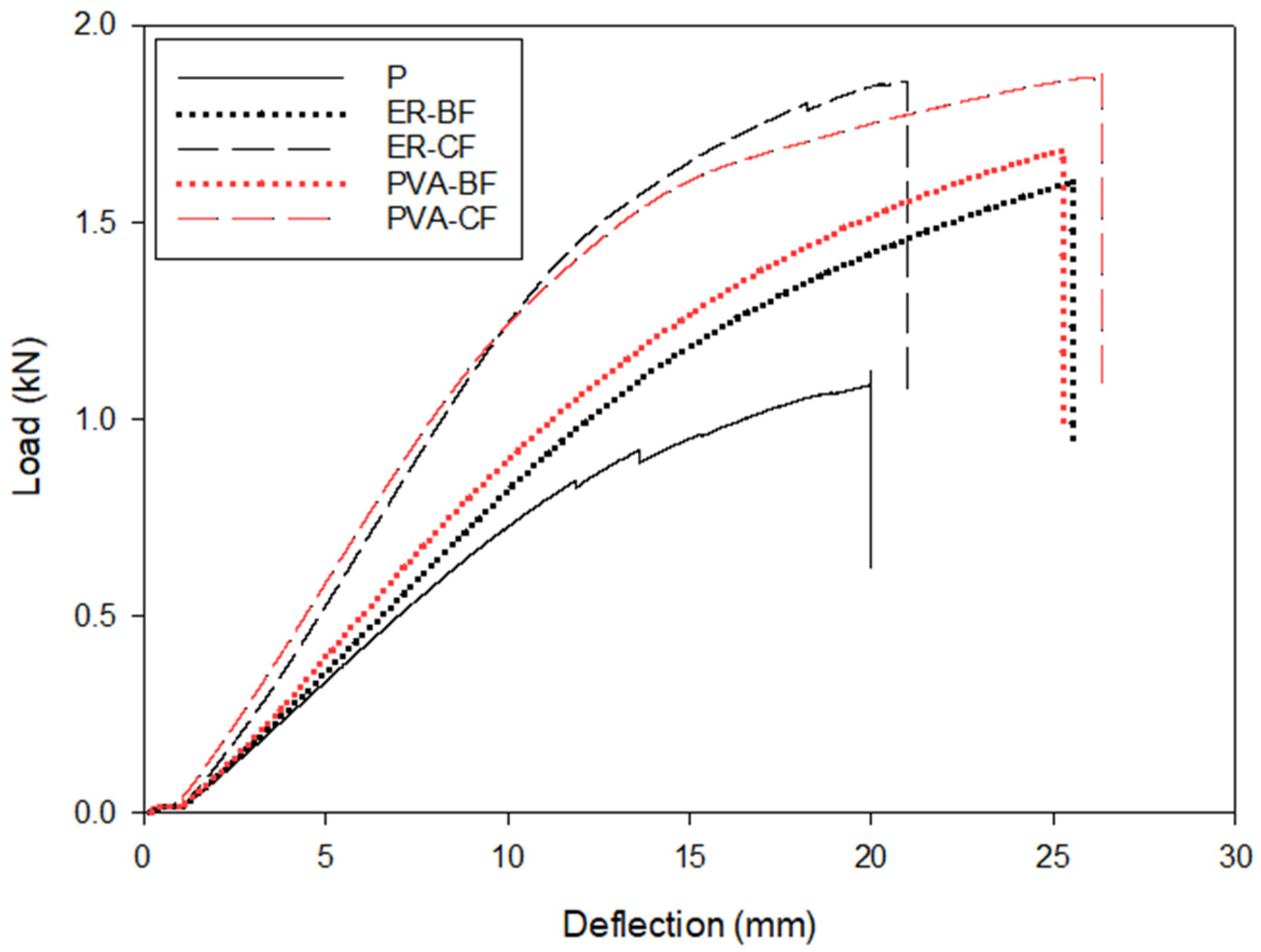

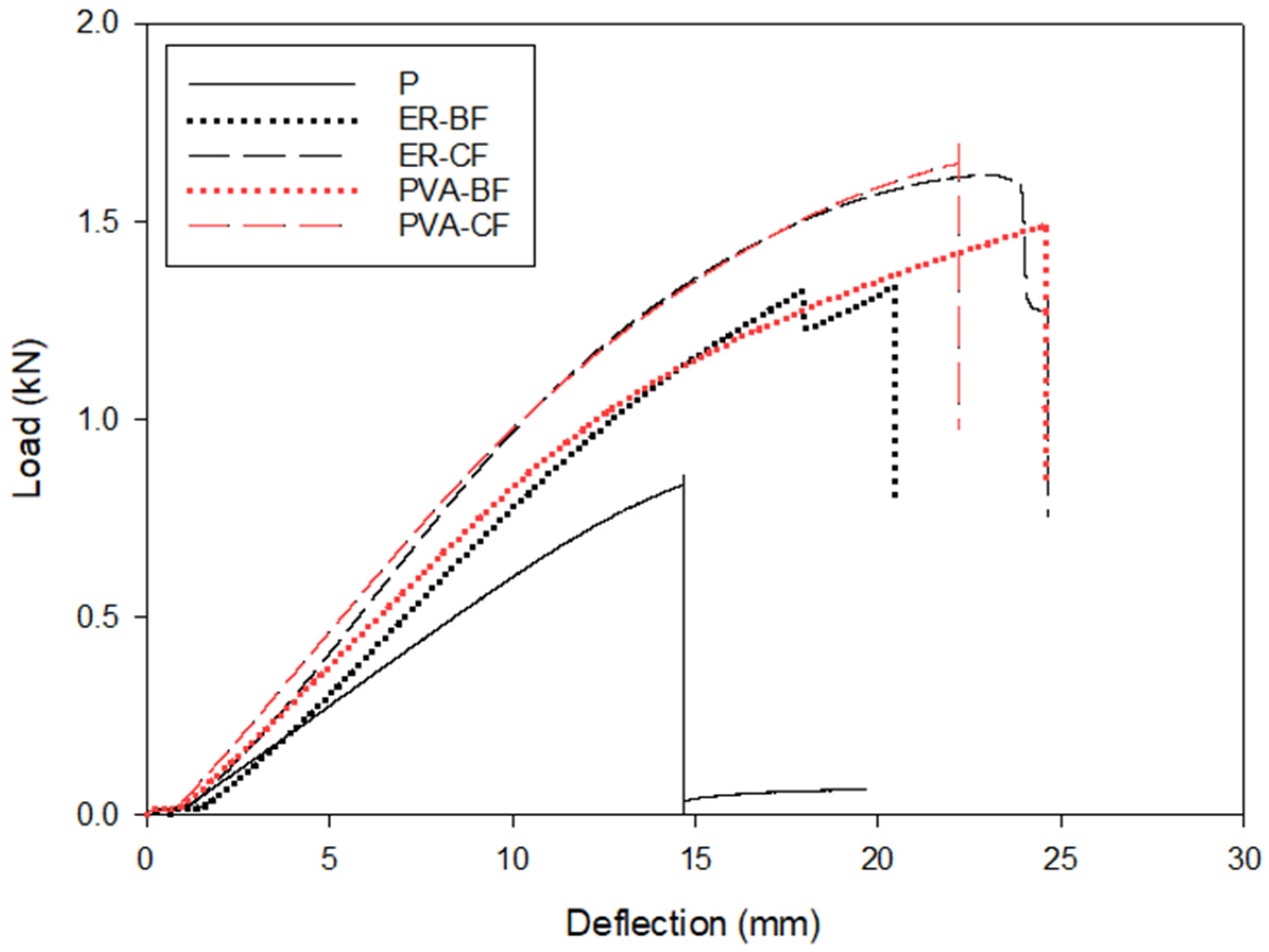

3.2.1. Strength and Stiffness Bending Properties

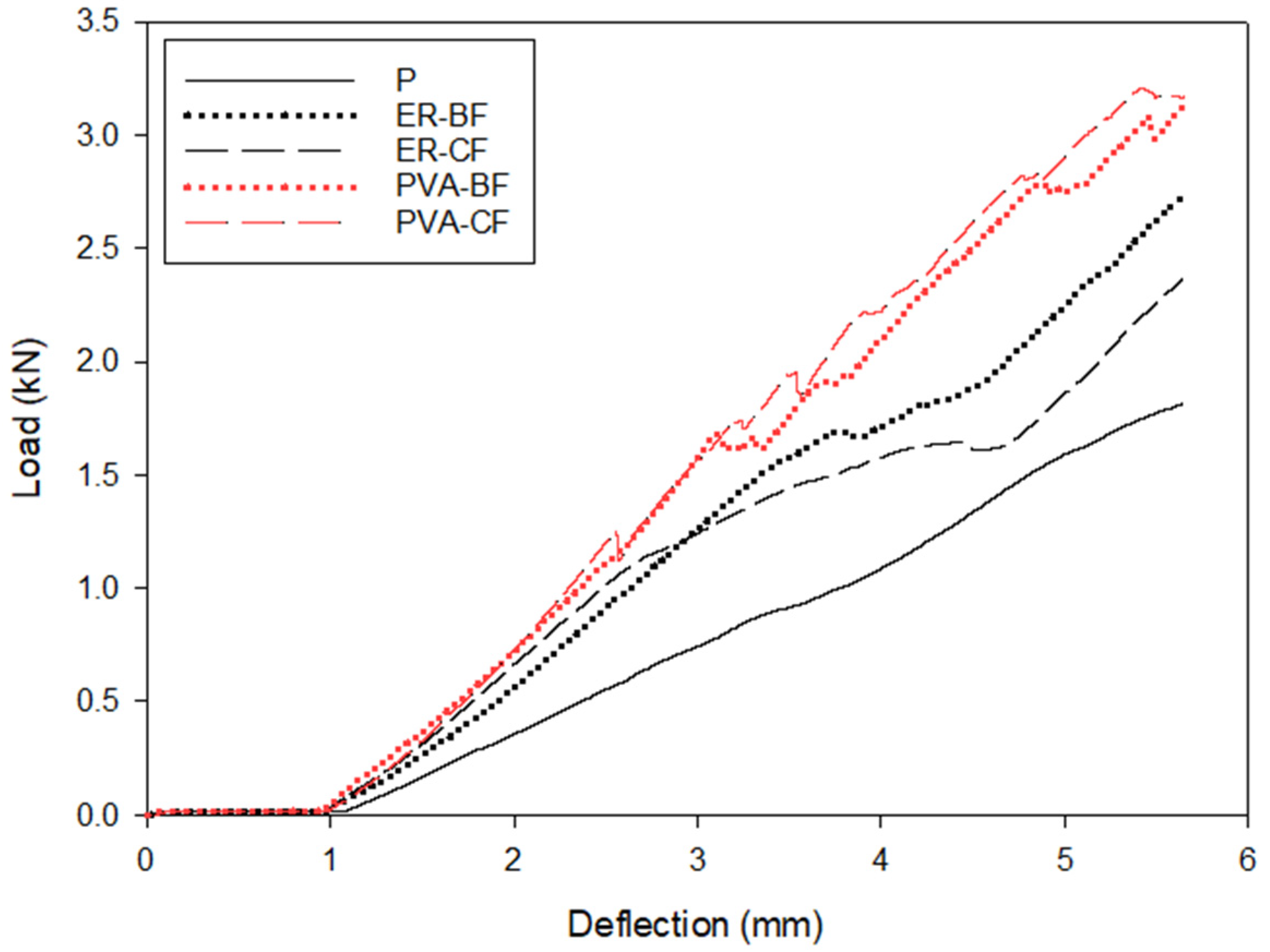

3.2.2. Results of the Janka Hardness Test

4. Discussion

4.1. Physical Properties

4.2. Mechanical Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramage, M.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.; Wu, G.; Tu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Sandberg, D. Additives in Wood Products—Today and Future Development. In Environmental Impacts of Traditional and Innovative Forest-based Bioproducts, 1st ed.; Kutnar, A., Muthu, S., Eds.; Springer: Singapore, 2016; Volume 1, pp. 105–172. ISBN 978-981-10-0655-5. [Google Scholar]

- Falk, R.H. Wood-Based composite Materials. In Wood Handbook: Wood as an Engineering Material. Forest Products Laboratory; Ross, R.J., Ed.; Department of Agriculture Forest Service: Madison, WI, USA, 2010; pp. 11–15. [Google Scholar] [CrossRef]

- Rogovina, S.Z.; Prut, E.V.; Berlin, A.A. Composite Materials Based on Synthetic Polymers Reinforced with Natural Fibers. Polym. Sci. Ser. A 2019, 64, 417–438. [Google Scholar] [CrossRef]

- Yang, G.; Park, M.; Park, S. Recent progresses of fabrication and characterization of fibers-reinforced composited: A review. Compos. Commun. 2019, 14, 34–42. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, T.; Jiang, B.; Zhao, L.; Liu, H.; Zhang, J.; Fan, J.; Guo, Z.; Huang, Y. Interfacially reinforced carbon fiber silicone resin via constructing functional nano-structural silver. Compos. Sci. Technol. 2019, 181, 1–6. [Google Scholar] [CrossRef]

- Newcomb, B. Processing, structure, and properties of carbon fibers. Compos. Part A 2016, 91, 262–282. [Google Scholar] [CrossRef]

- Das, T.; Ghosh, P.; Das, N. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: A review. Adv. Compos. Hybrid Mater. 2019, 2, 214–233. [Google Scholar] [CrossRef]

- Li, Q.; Xie, S.; Serem, W.; Naik, M.; Liu, L.; Yuan, J. Quality Carbon Fiber from Fractionated Lignin. Green Chem. 2017, 19, 1628–1634. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.; Park, S.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Part B 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Rafique, I.; Kausar, A.; Muhammad, B. Epoxy Resin Composite reinforced with Carbon Fiber and Inorganic Filler: Overview on Preparation and Properties. Polym. Plast. Technol. Eng. 2016, 55, 1653–1672. [Google Scholar] [CrossRef]

- Úlker, O. Wood Adhesives and Bonding Theory. In Adhesives—Applications and Properties, 1st ed.; Rudawska, A., Ed.; InTech: Rijeka, Croatia, 2016; Volume 1, pp. 271–288. [Google Scholar] [CrossRef]

- Tout, R. A review of adhesives for furniture. Int. J. Adhes. Adhes. 2000, 20, 269–272. [Google Scholar] [CrossRef]

- Kramár, S.; Trcala, M.; Chitbanyong, K.; Král, P.; Puangsin, B. Basalt-Fiber-Reinforced Polyvinyl Acetate Resin: A coating for Ductile Plywood Panels. Materials 2020, 13, 49. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bal, B.; Bektas, Í.; Mengeloglu, F.; Karakus, K.; Demir, H. Some technological properties of poplar plywood panels reinforced with glass fiber fabric. Constr. Build. Mater. 2015, 101, 952–957. [Google Scholar] [CrossRef]

- Ashori, A.; Ghofrani, M.; Rezvani, M.; Ayrilmis, N. Development and Material Properties of Reinforced Plywood Using Carbon Fiber and Waste Rubber Powder. Polym. Compos. 2016, 39, 675–680. [Google Scholar] [CrossRef]

- Zhang, W.; Cao, Y.; Yang, P.; Chen, M.; Zhou, X. Manufacturing and interfacial bonding behavior of plasma-treated-carbon fiber reinforced veneer-based composites. Compos. Struct. 2019, 226, 111203. [Google Scholar] [CrossRef]

- Auriga, R.; Gumowska, A.; Szymanowski, K.; Wronka, A.; Robles, E.; Ocipka, P.; Kowaluk, G. Performance properties of plywood composites reinforced with carbon fibers. Compos. Struct. 2020, 248, 112533. [Google Scholar] [CrossRef]

- Kramár, S.; Král, P. Reinforcing Effect of a Thin Basalt Fiber-reinforced Polymer Plywood Coating. Bioresources 2019, 14, 2062–2078. [Google Scholar] [CrossRef]

- Lohmus, R.; Kallakas, H.; Tuhkanen, E.; Gulik, V.; Kiisk, M.; Saal, K.; Kalamees, T. The Effect of Prestressing and Temperature on Tensile Strength of Basalt Fiber-Reinforced Plywood. Materials 2021, 14, 4701. [Google Scholar] [CrossRef]

- NCh 176/2; Wood—Part 2: Determination of Density. Instituto Nacional de Normalización: Santiago, Chile, 1988.

- NCh 176/1; Wood—Part 1: Determination of Moisture. Instituto Nacional de Normalización: Santiago, Chile, 2019.

- EN 317; Particleboards and Fibreboards. Determination of Swelling in Thickness after Immersion in Water. European Committee for Standardization: Madrid, Spain, 1994.

- EN 310; Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Madrid, Spain, 1994.

- ASTM D1037-12; Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- Kollmann, F.F.P.; Kuenzi, E.W.; Stamm, A.J. Principles of Wood Science and Technology, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 1975; Volume 2, ISBN 3642879330. [Google Scholar]

- Thorhallsson, E.R.; Hinriksson, G.I.; Snaebjörnsson, J.T. Strength and stiffness of glulam beams reinforced with glass and basalt fibres. Compos. Part B 2017, 115, 300–307. [Google Scholar] [CrossRef]

- Bal, B.C.; Bektas, I. Some mechanical properties of plywood produced from eucalyptus, beech, and poplar veneer. Maderas—Cienc. Tecnol. 2014, 16, 99–108. [Google Scholar] [CrossRef] [Green Version]

- Chanda, A.; Kim, N.K.; Bhattacharyya, D. Effects of adhesive systems on the mechanical and fire-reaction properties of wood veneer laminates. Compos. Sci. Technol. 2022, 225, 109331. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef] [Green Version]

- Konnerth, J.; Gindl, W.; Müller, U. Elastic Properties of Adhesive Polymers. I. Polymer Films by Means of Electronic Speckle Pattern Interferometry. J. Appl. Polym. Sci. 2007, 103, 3936–3939. [Google Scholar] [CrossRef]

- de Souza, J.B.; de Azevêdo, T.B.; Souza, T.B.; da Silva, G.C.; Guimarães, J., Jr.; Pimenta, A.S. Plywood bonding with an adhesive based on tannins from Acacia mangium Wild. bark from trees grown in Northeastern Brazil. Rev. Bras. Cienc. Agrar. 2020, 15, 1–7. [Google Scholar] [CrossRef]

- Ulker, O. Surface roughness of Composite Panels as a Quality Control Tool. Materials 2018, 11, 407. [Google Scholar] [CrossRef] [Green Version]

| Properties | Basalt Fiber | Carbon Fiber |

|---|---|---|

| Fabric | Bidirectional weaving | Bidirectional weaving |

| Thickness (mm) | 0.12 | 0.29 |

| Grammage (g/m²) | 200 | 200 |

| Tensile Strength (MPa) | ≥1000 | ≥3500 |

| Properties | Polyvinyl Acetate | Epoxy Resin | Epoxy Resin Hardener |

|---|---|---|---|

| Viscosity (mPa s) | 4500–5500 | 800–1500 | 30–70 |

| pH | 3.0–4.0 | 4.0–5.0 | 6.0–7.0 |

| Solid content (%) | 45–48 | 100 | |

| ID | N° Plywood | Adhesive Grammage (g/m²) |

|---|---|---|

| P | 5 | 0 |

| ER–BF | 5 | 220 |

| ER–CF | 5 | 220 |

| PVA–BF | 5 | 400 |

| PVA–CF | 5 | 400 |

| ID | Density (kg/m³) | Moisture Content (%) | Thickness Swelling (%) | Water Absorption (g) | ||||

|---|---|---|---|---|---|---|---|---|

| Mean | St. Dev. | Mean | St. Dev. | Mean | St. Dev. | Mean | St. Dev. | |

| P | 435.96 a | 17.26 | 8.55 a | 0.29 | 5.08 a | 0.82 | 0.69 a | 0.13 |

| ER–BF | 511.31 b | 9.74 | 9.23 a | 0.13 | 5.03 a | 0.85 | 0.50 b | 0.02 |

| ER–CF | 553.89 c | 30.27 | 11.29 b | 2.24 | 5.15 a | 0.70 | 0.51 b | 0.03 |

| PVA–BF | 537.38 c | 11.23 | 9.54 a | 0.29 | 5.48 a | 0.54 | 0.50 b | 0.03 |

| PVA–CF | 514.66 b | 11.53 | 9.01 a | 0.14 | 5.02 a | 0.69 | 0.59 c | 0.05 |

| ID | MOE (MPa) | MOR(MPa) | Density (kg/m³) | Moisture Content (%) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | St. Dev. | Mean | St. Dev. | Mean | St. Dev. | Mean | St. Dev. | ||

| Parallel direction | P | 3371.75 a | 421.5 | 34.65 a | 4.7 | 473.98 a | 28.19 | 6.97 ab | 0.22 |

| ER–BF | 3680.43 a | 350.5 | 47.40 ab | 3.0 | 523.84 a | 5.87 | 7.23 ab | 0.66 | |

| ER–CF | 4997.87 b | 381.3 | 52.95 b | 4.5 | 521.96 a | 22.10 | 7.35 a | 0.54 | |

| PVA–BF | 4192.37 ab | 724.3 | 44.65 ab | 5.6 | 499.77 a | 17.78 | 7.03 ab | 0.32 | |

| PVA–CF | 4739.29 b | 947.7 | 51.47 b | 10.2 | 527.17 a | 11.32 | 6.85 b | 0.45 | |

| Perpendicular direction | P | 2675.13 a | 189.8 | 25.08 a | 1.5 | 432.10 a | 7.49 | 6.93 a | 0.21 |

| ER–BF | 3453.16 b | 530.9 | 39.52 b | 6.0 | 487.21 b | 21.82 | 6.94 a | 0.24 | |

| ER–CF | 4065.61 c | 304.6 | 42.89 b | 7.7 | 501.05 bc | 18.97 | 6.96 a | 0.17 | |

| PVA–BF | 3188.00 b | 528.6 | 43.81 b | 3.7 | 529.53 d | 14.37 | 6.43 b | 0.30 | |

| PVA–CF | 3899.68 c | 322.3 | 50.89 c | 2.2 | 516.35 cd | 27.65 | 6.59 b | 0.31 | |

| ID | Janka Hardness (kN) | MOE (MPa) | Density (kg/m3) | Moisture Content (%) | ||||

|---|---|---|---|---|---|---|---|---|

| Mean | St. Dev. | Mean | St. Dev. | Mean | St. Dev. | Mean | St. Dev. | |

| P | 1.87 a | 0.18 | 2.52 a | 0.34 | 431.83 a | 10.64 | 7.32 a | 0.86 |

| ER–BF | 2.62 bc | 0.32 | 3.36 b | 0.34 | 459.05 b | 18.22 | 7.47 a | 0.69 |

| ER–CF | 2.57 b | 0.22 | 3.63 b | 0.46 | 466.34 b | 11.80 | 7.21 a | 0.61 |

| PVA–BF | 2.97 c | 0.41 | 4.17 c | 0.44 | 530.82 c | 8.19 | 6.94 a | 0.55 |

| PVA–CF | 3.35 d | 0.38 | 4.61 c | 0.50 | 500.92 d | 12.70 | 7.59 a | 1.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Núñez-Decap, M.; Barra-Rodríguez, Y.; Opazo-Carlsson, C.; Moya-Rojas, B.; Vidal-Vega, M.; Opazo-Vega, A. Use of Carbon and Basalt Fibers with Adhesives to Improve Physical and Mechanical Properties of Plywood. Appl. Sci. 2022, 12, 5114. https://doi.org/10.3390/app12105114

Núñez-Decap M, Barra-Rodríguez Y, Opazo-Carlsson C, Moya-Rojas B, Vidal-Vega M, Opazo-Vega A. Use of Carbon and Basalt Fibers with Adhesives to Improve Physical and Mechanical Properties of Plywood. Applied Sciences. 2022; 12(10):5114. https://doi.org/10.3390/app12105114

Chicago/Turabian StyleNúñez-Decap, Mario, Yasna Barra-Rodríguez, Camila Opazo-Carlsson, Boris Moya-Rojas, Marcela Vidal-Vega, and Alexander Opazo-Vega. 2022. "Use of Carbon and Basalt Fibers with Adhesives to Improve Physical and Mechanical Properties of Plywood" Applied Sciences 12, no. 10: 5114. https://doi.org/10.3390/app12105114

APA StyleNúñez-Decap, M., Barra-Rodríguez, Y., Opazo-Carlsson, C., Moya-Rojas, B., Vidal-Vega, M., & Opazo-Vega, A. (2022). Use of Carbon and Basalt Fibers with Adhesives to Improve Physical and Mechanical Properties of Plywood. Applied Sciences, 12(10), 5114. https://doi.org/10.3390/app12105114