Analysis of the Propulsion Performance and Internal Flow Field of an Underwater Launcher

Abstract

:1. Introduction

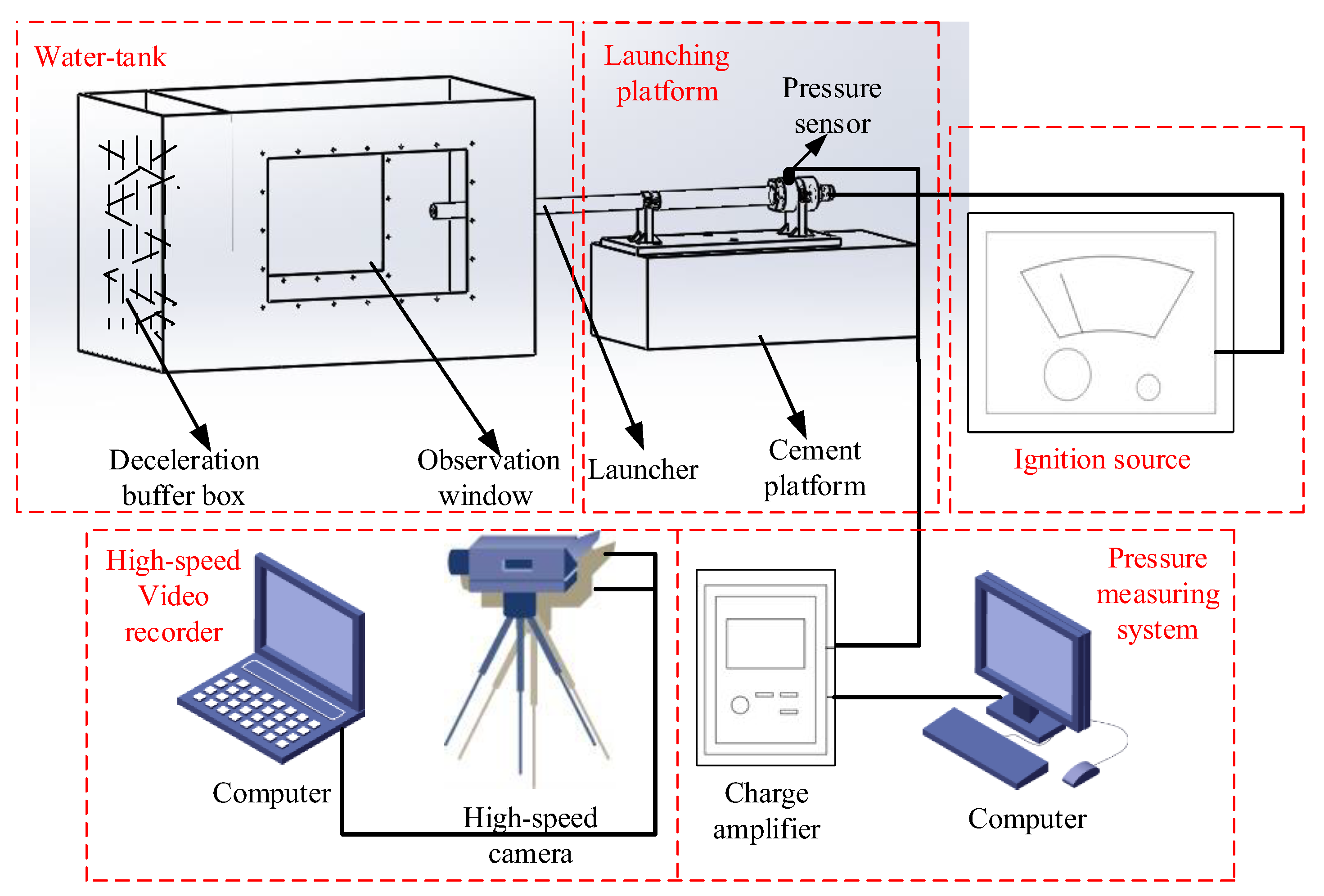

2. Experimental Research

2.1. Experimental Device

2.2. Experimental Results and Discussions

3. Numerical Analysis

3.1. The Modeling and Verification

3.1.1. Physical Model

- (1)

- The burning of propellant satisfies the law of exponential burning rate.

- (2)

- The impetus f, residual capacity α, and specific heat ratio k are considered to be constant; ϕ is taken as the coefficient of other minor work.

- (3)

- The composition of the gas jet is not taken into account, and its volumetric force is neglected.

- (4)

- Ignoring the influence of liquid water evaporation due to heat absorption.

3.1.2. Mathematical Model

- (1)

- Form function of the propellant:where ψ is the mass fraction of burnt propellant, Z is the relative thickness of burnt propellant, and χ0, λ0, μ0, χs, and λs are form characteristic quantities of the propellant.

- (2)

- Burning law of the propellant:where e1 is half of the web thickness of the propellant, u1 is the burning coefficient, n is the burning exponent, and p is the mean pressure in the chamber.

- (3)

- Momentum equation of projectile:where A is the sectional area of the projectile, pd is the pressure at the projectile base, ph is the pressure at the projectile head, m is the mass of the projectile, v is the velocity of the projectile, and φ is the minor work coefficient.

- (4)

- Orifice flow equation:where

- (5)

- Energy equation of interior ballistics:where ω is the charge weight, θ = k0–1, l is the projectile displacement, vg is the average velocity of the propellant gas flowing through the center nozzle inside the projectile, Cp is the constant-pressure specific heat capacity, and T is the gas temperature. lψ is the diameter-shrunk length of the free volume and is given bywhere l0 is the diameter-shrunk length of the chamber, Δ is the charge density, ρp is the solid propellant density, and αp is the covolume.

- (6)

- State equation of the gas inside the chamber:where R is the gas constant and T is the temperature.

- (7)

- Motion equation:

- (8)

- Mass conservation equations:

- (9)

- Mixture momentum conservation equation:

- (10)

- Mixture energy conservation equation:

- (11)

- Turbulence equation:where k and ε are the kinetic energy and dissipation rate, respectively. The constants and are the Prandtl numbers corresponding to the turbulent kinetic energy and the dissipation rate, respectively. is the turbulent viscosity. The constants , , and are empirical coefficients.

3.1.3. Numerical Verification

3.2. Analysis of Propulsion Performance

3.3. Gas-Curtain Evolution Characteristics

3.4. Analysis of Pressure Distribution

4. Conclusions

- (1)

- The experimental results show that under the same charge condition, the maximum pressure and muzzle velocity of projectile A are 53.4 MPa and 159.8 m·s−1, respectively. For projectiles B and C, the maximum pressure and muzzle velocity are 41.8 MPa/177.5 m·s−1 and 70.9 MPa/150.1 m·s−1, respectively. This demonstrates that the interior ballistics characteristics of a gas-curtain launcher are heavily influenced by jet structures.

- (2)

- The calculation results reveal that the three jet structures have good drag reduction effects and interior ballistics performance, but there are still some variances in the propulsion performance and flow field. In general, the central nozzle is more conductive to drag reduction than the sidewall grooves, but it also loses the effective cross-sectional area of the projectile. However, the effective cross-sectional area has a higher impact on the propulsion performance of an underwater gas-curtain launcher.

- (3)

- The nozzle construction of projectiles A and B is identical, as are the gas-curtain evolution and pressure distribution characteristics. While projectile C has a more complicated sidewall groove jet structure than the first two, its gas-curtain evolution and flow field pressure distribution characteristics are more complicated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Nouri, N.M.; Riahi, M.; Valipour, A.; Raeyatpishe, M.M.; Molavi, E. Analytical and Experimental Study of Hydrodynamic and Hydroacoustic Effects of Air Injection Flow Rate in Ventilated Supercavitation. Ocean Eng. 2015, 95, 94–105. [Google Scholar] [CrossRef]

- Jiang, Y.; Jeong, S.W.; Ahn, B.K.; Kim, H.T.; Jung, Y.R. Experimental investigation of drag characteristics of ventilated supercavitating vehicles with different body shapes. Phys. Fluids 2019, 31, 052106. [Google Scholar] [CrossRef]

- Erfanian, M.R.; Moghiman, M. Experimental investigation of critical air entrainment in ventilated cavitating flow for a forward facing model. Appl. Ocean Res. 2020, 97, 102089. [Google Scholar] [CrossRef]

- Wang, K.; Rong, G.; Yin, H.; Yi, W. Dynamic features of kinetic energy supercavitating vehicles. Appl. Ocean Res. 2020, 102, 102304. [Google Scholar] [CrossRef]

- Kim, M.J.; Kim, S.H.; Lee, K.C.; Paik, B.G.; Kim, M.C. Cavitator Design for Straight-Running Supercavitating Torpedoes. Appl. Sci. 2021, 11, 6247. [Google Scholar] [CrossRef]

- Stace, J.J.; Dean, L.M.; Kirschner, I.N. Sealing Apparatus for Exclusion of Water from Underwater Launcher Barrels. U.S. Patent 5687501, 18 November 1997. [Google Scholar]

- Kirschner, I.N.; Dean, L.M.; Bonin, R.L.; Mulherin, J.E. Regulated Gas Source for Underwater Launcher Operation. U.S. Patent 5911568, 15 June 1999. [Google Scholar]

- Kirschner, I.N.; Berlam, G.R. Muzzle Brake for an Underwater Launcher. U.S. Patent 5746018, 5 May 1998. [Google Scholar]

- Fu, J.H.; Howard, R.J.; Rapp, J.W.; Paulic, A. Underwater Launcher Comprising a Plate-Type Barrel Seal. U.S. Patent 7874091, 25 January 2011. [Google Scholar]

- Cipolla, J.L.; Ri, N. Means to Fire a Fully Automatic Launcher Underwater Using a Special Barrel Clearance Blank Round. U.S. Patent 5639982, 17 June 1997. [Google Scholar]

- Chen, Z.; Wang, C.M.; Di, C.A.; Liu, G. Interior ballistics calculations of an under water launcher at various depths. Acta Armamentarii 2002, 23, 462–464. [Google Scholar]

- Hu, Z.T.; Yu, Y.G. Study on three-dimensional expansion characteristics of four wall combustion-gas jets in confined liquid space. Acta Mech. Sin. 2017, 33, 341–355. [Google Scholar] [CrossRef]

- Zhou, L.L.; Yu, Y.G. Experimental study on gas-curtain generation characteristics by multicombustion-gas jets in the cylindrical liquid chamber. Ocean Eng. 2015, 109, 410–417. [Google Scholar] [CrossRef]

- Xue, X.C.; Yu, Y.G.; Zhao, J.J. Study on draining off water mechanism and interaction characteristic of high-temperature and high-pressure combustion-gas jets with the water. Appl. Therm. Eng. 2018, 143, 570–581. [Google Scholar] [CrossRef]

- Hu, Z.T.; Yu, Y.G. Expansion Characteristics of Multiple Wall Jets in Cylindrical Observation Chamber. Appl. Therm. Eng. 2017, 113, 1396–1409. [Google Scholar] [CrossRef]

- Zhao, J.J.; Yu, Y.G. The Interaction between Multiple High Pressure Combustion Gas Jets and Water in a Water-Filled Vessel. Appl. Ocean Res. 2016, 61, 175–182. [Google Scholar] [CrossRef]

- Hu, Y.B.; Yu, Y.G.; Zhang, X.W. Groove structure on the drainage characteristics of the gas curtain. Ocean Eng. 2022, 243, 110280. [Google Scholar] [CrossRef]

- Zhou, L.L.; Yu, Y.G. Study on Interaction Characteristics between Multi Gas Jets and Water during the Underwater Launching Process. Exp. Therm. Fluid Sci. 2017, 83, 200–206. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.W.; Yu, Y.G. Experimental and numerical research on a novel underwater launching method with high efficiency and low resistance. AIP Adv. 2021, 11, 025212. [Google Scholar] [CrossRef]

| No. | Type | Characteristics | Jet Structure and Size/mm | Mass m/g |

|---|---|---|---|---|

| 1 | A | Central nozzle | Φ3 | 45 |

| 2 | B | Central nozzle | Φ4 | 45 |

| 3 | C | Sidewall groove | 4 × Φ2 | 45 |

| No. | Projectile Type | Barrel Length x/m | Projectile Weight m/g | Charge Weight ω/g | Maximum Pressure pm/MPa | Muzzle Velocity v0/m·s−1 |

|---|---|---|---|---|---|---|

| 1 | A | 1.028 | 45 | 8.5 | 53.4 | 159.8 |

| 2 | B | 1.028 | 45 | 8.5 | 41.8 | 177.5 |

| 3 | C | 1.028 | 45 | 8.5 | 70.9 | 150.1 |

| Parameters | Values | Units |

|---|---|---|

| ω | 17 | g |

| m | 45 | g |

| ρp | 1600 | kg·m−3 |

| fp | 950 | kJ·kg−1 |

| θp | 0.25 | |

| lg | 1.028 | m |

| V0 | 2.175 × 10−5 | m3 |

| pb0 | 1.0 | MPa |

| ps | 45.0 | MPa |

| Condition | Projectile Type | x/m | ω/g | pm/MPa | v/m·s−1 | t/ms |

|---|---|---|---|---|---|---|

| 1 | A | 1.028 | 17 | 338.9 | 729.6 | 2.37 |

| 2 | B | 1.028 | 17 | 325.0 | 688.2 | 2.42 |

| 3 | C | 1.028 | 17 | 353.2 | 775.1 | 2.28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Yu, Y. Analysis of the Propulsion Performance and Internal Flow Field of an Underwater Launcher. Appl. Sci. 2022, 12, 5443. https://doi.org/10.3390/app12115443

Zhang X, Yu Y. Analysis of the Propulsion Performance and Internal Flow Field of an Underwater Launcher. Applied Sciences. 2022; 12(11):5443. https://doi.org/10.3390/app12115443

Chicago/Turabian StyleZhang, Xinwei, and Yonggang Yu. 2022. "Analysis of the Propulsion Performance and Internal Flow Field of an Underwater Launcher" Applied Sciences 12, no. 11: 5443. https://doi.org/10.3390/app12115443