Numerical Analysis for Ground Subsidence Caused by Extraction Holes of Removed Piles

Abstract

:1. Introduction

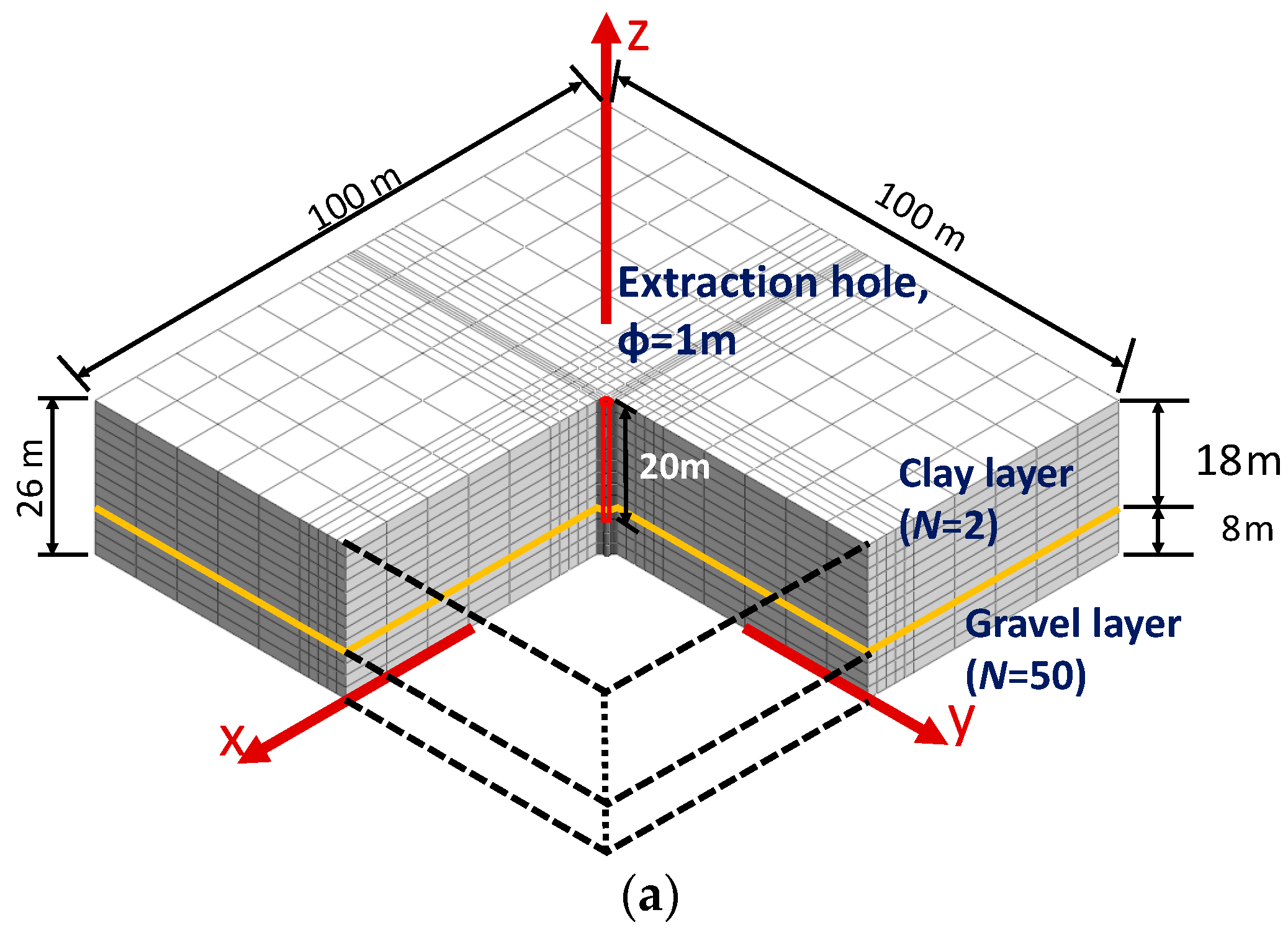

2. Analysis and Target Ground

2.1. Analysis Method

2.2. Cross Section of Target Ground

2.3. Material Parameters of Target Ground

3. Results and Discussion

3.1. Case Where One Extraction Hole of Removed Pile Is Left in a Hollow State

3.2. Case Where Two Extraction Holes of Removed Piles Are Left in a Hollow State

3.3. Case Where Three Extraction Holes of Removed Piles Are Left in a Hollow State

4. Conclusions

- (1)

- If an extraction hole of a removed pile is left as it is, large ground subsidence will occur near the extraction hole of the removed pile, especially at the lower part of the clay layer near the hole.

- (2)

- A cavity grows in the ground around the extraction hole of the removed pile due to the formation of the extraction hole of the removed pile, and the ground subsidence increases with time. In addition, as the number of extraction holes of removed piles increases, the depression phenomenon progresses and countermeasures are required at an early stage. Therefore, it is considered important to inject the filler simultaneously with the formation of each extraction hole of a removed pile.

- (3)

- In the process of pulling out a pile, the suction force acts on the surrounding ground, so the amount of subsidence on the surrounding ground decreases.

- (4)

- The greater the number of extraction holes of removed piles, the greater the compressive stress acting on the extraction holes of removed piles after the pile removal. For this reason, the filler should exhibit strength early as the number of extraction holes of removed piles increases.

- (5)

- When there are two and three extraction holes of removed piles, there is no difference in the compressive stress acting on the extraction holes of removed piles. Therefore, it is thought that the compressive stress acting around each extraction hole of removed pile is caused by the surrounding ground conditions.

- (6)

- When there is only one extraction hole of a removed pile, there is a difference between the compressive stress concentrated in the extraction hole of a removed pile on the ground’s surface and the compressive stress acting near the lower part of the clay layer. On the other hand, when there are two or three extraction holes of removed piles, the difference in compressive stress acting on the extraction holes of removed piles due to the depth is small. From this, it can be said that as the number of extraction holes of removed piles increases, the necessity to inject a filler that exhibits uniform strength up to the deepest part increases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yoshioka, S.; Kawasaki, H. Japan’s High-Growth Postwar Period (The Role of Economic Plans); ESRI Research Note 2016; Cabinet Office: Tokyo, Japan, 2016; Volume 27, pp. 1–82. [Google Scholar]

- Ministry of Land, Infrastructure, Transport and Tourism (MLIT). Public Building Construction Standard Specification (Building Work), 2013th ed.; Ministry of Land, Infrastructure, Transport and Tourism: Tokyo, Japan, 2016. [Google Scholar]

- Inazumi, S.; Tanaka, S.; Komaki, T.; Kuwahara, S. Effect of insertion of casing by rotation on existing piles in removal of existing pile. Geotech. Res. 2021, 8, 25–37. [Google Scholar] [CrossRef]

- Takao, M. Leaving the foundation pile, backfilling denied the defects of ground support force of the part, agent of accountability violation was also negative case. RETIO 2011, 82, 166–167. [Google Scholar]

- Kuwahara, S.; Inazumi, S.; Jotisankasa, A.; Chaiprakaikeow, S. Influence of the condition of pullout holes on the surrounding ground. Int. J. Geo-Eng. 2020, 11, 10. [Google Scholar] [CrossRef]

- Inazumi, S.; Kuwahara, S.; Jotisankasa, A.; Chaiprakaikeow, S. Construction method for pulling out existing piles and influence of pulling-out holes on the surrounding ground. Geotech. Geol. Eng. 2020, 38, 6107–6123. [Google Scholar] [CrossRef]

- Kuwahara, S.; Inazumi, S. Settlement of surrounding grounds due to existence of pile pulling-out holes. Int. J. Geomate Geotech. Constr. Mater. Environ. 2019, 16, 81–85. [Google Scholar] [CrossRef]

- Inazumi, S.; Kuwahara, S.; Jotisankasa, A.; Chaiprakaikeow, S. MPS-CAE simulation on dynamic interaction between steel casing and existing pile when pulling out existing piles. Int. J. Geomate: Geotech. Constr. Mater. Environ. 2020, 18, 68–73. [Google Scholar] [CrossRef]

- Nakao, K.; Inazumi, S.; Takaue, T.; Tanaka, S.; Shinoi, T. Evaluation of Discharging Surplus Soils for Relative Stirred Deep Mixing Methods by MPS-CAE Analysis. Sustainability 2022, 14, 58. [Google Scholar] [CrossRef]

- Inazumi, S.; Kuwahara, S.; Jotisankasa, A.; Chaiprakaikeow, S. Improvement mechanism of sodium carbonate on traditional composite filler. Ground Improv. 2021, 174, 132–139. [Google Scholar] [CrossRef]

- Hang, C.; Gao, X.; Yuan, M.; Huang, Y.; Zhu, R. Discrete element simulations and experiments of soil disturbance as affected by the tine spacing of subsoiler. Biosyst. Engineering. 2018, 168, 73–82. [Google Scholar] [CrossRef]

- Cundall, P.A.; Hart, R.D. Numerical modeling of discontinua. Anal. Des. Methods 1993, 231–243. [Google Scholar] [CrossRef]

- Antoniou, A.; Daudeville, L.; Marin, P.; Omar, A.; Potapov, S. Discrete element modelling of concrete structures under hard impact by ogive-nose steel projectiles. Eur. Phys. J. Spec. Top. 2018, 227, 143–154. [Google Scholar] [CrossRef]

- Inazumi, S.; Hamaguchi, S.; Kuwahara, S. Performance evaluation of backfilling methods by improved air-lift on pulling-out holes of existing piles. J. Jpn. Constr. Mach. Constr. Assoc. 2018, 70, 91–101. [Google Scholar]

- Inazumi, S.; Shakya, S.; Komaki, T.; Nakanishi, Y. Numerical analysis on performance of middle-pressure jet grouting method for ground improvement. Geosciences 2021, 11, 313. [Google Scholar] [CrossRef]

- Inazumi, S.; Hashimoto, R.; Shinsaka, T.; Nontananandh, S.; Chaiprakaikeow, S. Applicability of Additives for Ground Improvement Utilizing Fine Powder of Waste Glass. Materials 2021, 14, 5169. [Google Scholar] [CrossRef]

- Inazumi, S.; Shishido, K.; Soralump, S. Possibility of impervious coating for the geotechnical reuse of soil and solid waste. Environ. Geotech. 2021, 8, 324–333. [Google Scholar] [CrossRef]

- Kumar, N.; Dey, A. Finite element analysis of flexible anchored sheet pile walls: Effect of mode of construction and dewatering. In Proceeding of Golden Jubilee Conference of the IGS Bangalore Chapter, Geo-Innovations, Bangalore, India, 30–31 October 2014; pp. 1–8. [Google Scholar]

- Mroueh, H.; Shahrour, I. Numerical analysis of the response of battered piles to inclined pullout loads. Int. J. Numer. Anal. Meth. Geomech. 2018, 33, 1277–1288. [Google Scholar] [CrossRef]

- Zheng, G.; Yang, X.; Zhou, H.; Du, Y.; Sun, J.; Yu, X. A simplified prediction method for evaluating tunnel displacement induced by laterally adjacent excavations. Comput. Geotech. 2018, 95, 119–128. [Google Scholar] [CrossRef]

- Small, J.C.; Booker, J.R.; Davis, E.H. Elasto-plastic consolidation of soil. Int. J. Solids Struct. 1976, 12, 431–448. [Google Scholar] [CrossRef]

- Saini, S.; Goyal, E.T. Analysis of piled raft foundation using MIDAS GTS NX. Int. Res. J. Eng. Technol. 2019, 6, 5491–5499. [Google Scholar]

- Cao, Q.; Hang, Y. Settlement simulation of soft clay in the subway under dynamic load based on Midas GTS NX. E3S Web Conf. 2021, 237, 03011. [Google Scholar] [CrossRef]

- Wang, Z. Comparative analysis of Midas GTS NX and SLOPE/W numerical simulation softwares. Int. Core J. Eng. 2020, 6, 83–85. [Google Scholar] [CrossRef]

- Bałachowski, L. Physical modelling of geotechnical structures in ports and offshore. Pol. Marit. Res. 2017, 24, 4–9. [Google Scholar] [CrossRef] [Green Version]

- Nakazawa, F.; Furugaichi, Y. Evaluation of Young’s modulus of liquidity stabilized soil. Tokyu Constr. Tech. Rep. 2015, 40, 49–52. [Google Scholar]

- Furugaichi, Y. Deformation properties of the backfill material which has a fluidity and self-hardening. Town Value-Up Manag. Rep. 2011, 37, 41–44. [Google Scholar]

- Li, S.Z.; Ren, F.; Sheng, G.L.; Zhao, W.P. Three-dimensional numerical analysis of deformation of various combined support forms. IOP Conf. Ser. Mater. Sci. Eng. 2018, 423, 012025. [Google Scholar] [CrossRef]

- Ambrosini, D.; Luccioni, B. Effects of underground explosions on soil and structures. Undergr. Space 2020, 5, 324–338. [Google Scholar] [CrossRef]

- Cho, H.; Bang, E.S.; Yi, M.J.; Kim, D.S. Physical modeling of ground subsidence due to underground cavity and its monitoring by electrical resistivity survey in geotechnical centrifuge. In Proceedings of the 15th Asian Regional Conference on Soil Mechanics and Geotechnical Engineering, Kyushu, Japan, 9–13 November 2014. [Google Scholar] [CrossRef] [Green Version]

- Heib, M.A.; Emeriault, F.; Ngjiem, H.L. On the use of 1g physical models for ground movements and soil-structure interaction problems. J. Rock Mech. Geotech. Eng. 2020, 12, 197–211. [Google Scholar] [CrossRef]

- Goldstein, R.V.; Dudchenko, A.V.; Kuznetsov, S.V. The modified Cam-Clay (MCC) model: Cyclic kinematic deviatoric loading. Arch. Appl. Mech. 2016, 86, 2021–2031. [Google Scholar] [CrossRef]

- Akishige, H.; Tamura, M.; Watanabe, K.; Kimura, T.; Nemoto, H.; Kaneko, O.; Mizutani, Y.; Abe, A. Performance evaluation method of foundation in building regulations of Japan and oversea (Part 1: Limitations of settlement). In Proceedings of the Summaries of Technical Papers of Annual Meeting, Stockholm, Switzerland, 12–16 January 2004; pp. 621–622. [Google Scholar]

- Aydin, A.; Johnson, A. Development of faults as zones of deformation bands and as slip surfaces in sandstone. Pure Appl. Geophys. 1978, 116, 931–942. [Google Scholar] [CrossRef]

- Resare, F. Analysis of an Inclined Pile in Settling Soil. Master’s Thesis, Royal Institute of Technology, Stockholm, Switzerland, 2015; pp. 1–34. [Google Scholar]

- Inazumi, S.; Intui, S.; Jotisankasa, A.; Chaiprakaikeow, S.; Shinsaka, T. Applicability of mixed solidification material based on inorganic waste as soil stabilizer. Case Stud. Constr. Mater. 2020, 12, e00305. [Google Scholar] [CrossRef]

- Nakao, K.; Inazumi, S.; Takaue, T.; Tanaka, S.; Shinoi, T. Visual evaluation of relative deep mixing method type of ground-improvement method. Results Eng. 2021, 10, 100233. [Google Scholar] [CrossRef]

| Clay Layer | Gravel Layer | ||

|---|---|---|---|

| γt | (kN/m3) | 15 | 21 |

| γsat | (kN/m3) | 16 | 21 |

| E | (kN/m3) | 7.9 × 103 | 1.4 × 105 |

| ν | (-) | 0.45 | 0.3 |

| c | (kN/m2) | 25.0 | 0 |

| φ | (°) | 0 | 47 |

| N-value | (-) | 2 | 50 |

| qu | (kN/m2) | 50 | 2.5 × 103 |

| k | (m/s) | 1.0 × 10−8 | 1.0 × 10−5 |

| γt (kN/m3) | E (kN/m2) | ν (-) | |

|---|---|---|---|

| Pile foundation | 24 | 2.1 × 107 | 0.18 |

| Kn (kN/m3) | Kt (kN/m3) | |

|---|---|---|

| Joint element | 3.0 × 104 | 3.0 × 105 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Inazumi, S.; Kuwahara, S.; Nontananandh, S.; Jotisankasa, A.; Chaiprakaikeow, S. Numerical Analysis for Ground Subsidence Caused by Extraction Holes of Removed Piles. Appl. Sci. 2022, 12, 5481. https://doi.org/10.3390/app12115481

Inazumi S, Kuwahara S, Nontananandh S, Jotisankasa A, Chaiprakaikeow S. Numerical Analysis for Ground Subsidence Caused by Extraction Holes of Removed Piles. Applied Sciences. 2022; 12(11):5481. https://doi.org/10.3390/app12115481

Chicago/Turabian StyleInazumi, Shinya, Shuichi Kuwahara, Supakij Nontananandh, Apiniti Jotisankasa, and Susit Chaiprakaikeow. 2022. "Numerical Analysis for Ground Subsidence Caused by Extraction Holes of Removed Piles" Applied Sciences 12, no. 11: 5481. https://doi.org/10.3390/app12115481