Investigation into the Effects of Roller Pressing on Hardness, Roughness and Elastic Modulus of Wooden Workpieces

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Porankiewicz, B. Wood machining investigations: Parameters to consider for thorough experimentation. BioRes 2014, 9, 4–6. [Google Scholar] [CrossRef] [Green Version]

- Guitard, D. Méchanique du Matériau Bois et Composites; Cepadues-Editions; Collection Nabla: Toulouse, France, 2008. [Google Scholar]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. iForest 2017, 10, 895–908. [Google Scholar] [CrossRef] [Green Version]

- Fernandes, C.; Gaspar, M.J.; Pires, J.; Alves, A.; Simões, R.; Rodrigues, J.C.; Silva, M.E.; Carvalho, A.; Brito, J.E.; Lousada, J.L. Physical, chemical and mechanical properties of Pinus sylvestris wood at five sites in Portugal. iForest 2017, 10, 669–679. [Google Scholar] [CrossRef] [Green Version]

- Dias, A.; Carvalho, A.; Silva, M.E.; Lima-Brito, J.; Gaspar, M.J.; Alves, A.; Lousada, J.L. Physical, chemical and mechanical wood properties of Pinus nigra growing in Portugal. Ann. For. Sci. 2020, 77, 72. [Google Scholar] [CrossRef]

- Marini, F.; Manetti, M.C.; Corona, P.; Portoghesi, L.; Vinciguerra, V.; Tamantini, S.; Romagnoli, M. Influence of forest stand characteristics on physical, mechanical properties and chemistry of chestnut wood. Sci. Rep. 2021, 11, 1549. [Google Scholar] [CrossRef]

- Zhang, S.Y. Effect of growth rate on wood specific gravity and selected mechanical properties in individual species from distinct wood categories. Wood Sci. Technol. 1995, 29, 451–465. [Google Scholar] [CrossRef]

- Roman, K.; Roman, M.; Szadkowska, D.; Szadkowski, J.; Grzegorzewska, E. Evaluation of Physical and Chemical Parameters According to EnergeticWillow (Salix viminalis L.) Cultivation. Energies 2021, 14, 2968. [Google Scholar] [CrossRef]

- Navi, P.; Pizzi, A. Property changes in thermo-hydro-mechanical processing: COST Action FP0904 2010–2014: Thermo-hydro-mechanical wood behavior and processing. Holzforschung 2015, 69, 863–873. [Google Scholar] [CrossRef]

- Cruz, N.; Bustos, C.A.; Aguayo, M.G.; Cloutier, A.; Castillo, R. Impact of the chemical composition of Pinus radiata wood on its physical and mechanical properties following thermo-hygromechanical densification. BioResources 2018, 13, 2268–2282. [Google Scholar] [CrossRef]

- Adachi, K.; Inoue, M.; Kanayama, K.; Rowell, R.M.; Kawai, S. Water removal of wet veneer by roller pressing. J. Wood Sci. 2004, 50, 479–483. [Google Scholar] [CrossRef] [Green Version]

- Inoue, M.; Adachi, K.; Tsunoda, K.; Rowell, R.M.; Kawai, S. A new procedure for treating wood. Wood Mater. Sci. Eng. 2008, 3, 46–54. [Google Scholar] [CrossRef]

- Laine, K. Improving the Properties of Wood by Surface Densification; Aalto University: Helsinki, Finland, 2014. [Google Scholar]

- Neyses, B.; Hagman, O.; Sandberg, D.; Nilsson, A. Development of a Continuous Wood Surface Densification Process—The Roller Pressing Technique. In Proceedings of the 59th International Convention of Society of Wood Science and Technology, Curitiba, Brazil, 6–10 March 2016. [Google Scholar]

- Rautkari, L.; Properzi, M.; Pichelin, F.; Hughes, M. Surface modification of wood using friction. Wood Sci. Technol. 2009, 43, 291–299. [Google Scholar] [CrossRef] [Green Version]

- Rautkari, L.; Laine, K.; Laflin, N.; Hughes, M. Surface modification of Scots pine: The effect of process parameters on the through thickness density profile. J. Mater. Sci. 2011, 46, 4780–4786. [Google Scholar] [CrossRef]

- Sadatnezhad, S.H.; Khazaeian, A.; Sandberg, D.; Tabarsa, T. Continuous Surface Densification of Wood: A New Concept for Large-scale Industrial Processing. BioRes 2017, 12, 3122–3132. [Google Scholar] [CrossRef] [Green Version]

- Nairn, J.A. Numerical Simulations of Transverse Compression and densification in Wood. Wood Fiber. Sci. 2006, 38, 576–591. [Google Scholar]

- Samson, M.; Sotomayor-Castellanos, J.R. Bending Method for Determining Modulus of Elasticity of Lumber in Structural Size. Wood Fiber. Sci. 1991, 23, 520–532. [Google Scholar]

- Rocha, M.F.V.; Costa, L.R.; Costa, L.J.; Araujo, A.C.C.; de Soares, B.C.D.; Hein, P.R.G. Wood Knots Influence the Modulus of Elasticity and Resistance to Compression. Floresta Ambient 2018, 25, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Babiak, M.; Gaff, M.; Sikora, A.; Hysek, S. Modulus of elasticity in three- and four-point bending of wood. Compos. Struct. 2018, 204, 454–465. [Google Scholar] [CrossRef]

- Christoforo, A.L.; Panzera, T.H.; Silva, D.A.L.; Fiorelli, J.; Lahr, F.A.R. Shear and Longitudinal Modulus of Elasticity in Structural Lumber Beams. Int. J. Mater. Eng. 2014, 4, 31–36. [Google Scholar] [CrossRef] [Green Version]

- Lahr, F.A.R.; Christoforo, A.L.; Varanda, L.D.; Chahud, E.; Araújo, V.A.; Branco, L.A. Shear and longitudinal modulus of elasticity in wood: Relations based on static bending tests. Acta Sci. Technol. 2017, 39, 433–437. [Google Scholar] [CrossRef] [Green Version]

- Lopes, D.A.; Bertolini, M.S.; Christoforo, A.L.; Lahr, F.A.R. Influence of Testing Methods to Determine the Bending Modulus of Elasticity of Wood. Revista Vértices 2015, 17, 127–137. [Google Scholar] [CrossRef]

- Malaga-Tobola, U.; Lapka, M.; Tabor, S.; Niesłony, A.; Findura, P. Influence of wood anisotropy on its mechanical properties in relation to the scale effect. Int. Agrophys. 2019, 33, 337–345. [Google Scholar] [CrossRef]

- Segundinho, P.G.A.; Lahr, F.A.R.; Bertolini, M.S.; Regazzi, A.J.; Carreira, M.R. Variation of Modulus of Elasticity Obtained Through the Static Bending Method Considering the S/h Ratio. Wood Res. 2015, 60, 189–200. [Google Scholar]

- Togay, A.; Dongel, N.; Sogutlu, C.; Ergin, E.; Uzel, M.; Gunes, S. Determination of the Modulus of Elasticity of Wooden Construction Elements Reinforced with Fiberglass Wire Mesh and Aluminum Wire Mesh. BioRes 2017, 12, 2466–2478. [Google Scholar] [CrossRef] [Green Version]

- Faria, O.B.; Silva, D.A.L.; Lahr, F.A.R.; Chahud, E.; Varanda, L.D. Influence of wood moisture content on modulus of elasticity on tension parallel to the grain of Brazilian species. Eur. Int. J. Sci. Technol. 2012, 1, 11–22. [Google Scholar]

- Baar, J.; Tippner, J.; Rademacher, P. Prediction of mechanical properties—Modulus of rupture and modulus of elasticity—Of five tropical species by non-destructive methods. Maderas-Cienc. Tecnol. 2015, 17, 239–252. [Google Scholar] [CrossRef] [Green Version]

- Haines, D.W.; Leban, J.M.; Herbe, C. Determination of Young’s modulus for spruce, fir and isotropic materials by the resonance flexure method with comparisons to static flexure and other dynamic methods. Wood Sci. Technol. 1996, 30, 253–263. [Google Scholar] [CrossRef]

- Yoshihara, H.; Yoshinobu, M. Young’s modulus and shear modulus of solid wood measured by the flexural vibration test of specimens with large height/length ratios. Holzforschung 2015, 69, 493–499. [Google Scholar] [CrossRef]

- Fedyukov, V.I.; Saldaeva, E.Y.; Tsvetkova, E.M. Resonance wood microstructure peculiarities. Wood Res. 2016, 61, 413–422. [Google Scholar]

- Fedyukov, V.I.; Chernova, M.S. Method for Express Diagnostics of Resonant Properties of Wood Aged in Buildings. J. Appl. Eng. Sci. 2020, 18, 510–514. [Google Scholar] [CrossRef]

- Hassan, K.T.S.; Horacek, P.; Tippner, J. Evaluation of stiffness and strength of Scots pine wood using resonance frequency and ultrasonic techniques. BioRes 2013, 8, 1634–1645. [Google Scholar] [CrossRef] [Green Version]

- Krauss, A.; Kudela, J. Ultrasonic wave propagation and Young’s modulus of elasticity along the grain of Scots pine wood (Pinus sylvestris L.) varying with distance from the pith. Wood Res. 2011, 56, 479–488. [Google Scholar]

- Cavalheiro, R.; Almeida, D.; Almeida, T.; Christoforo, A.; Lahr, F. Estimation of Modulus of Elasticity in Static Bending of Wood in Structural Dimensions as a Function of Longitudinal Vibration and Density. Curr. J. Appl. Sci. Technol. 2018, 26, CJAST.39531. [Google Scholar] [CrossRef]

- Forest Products Laboratory. Mechanical Properties of Wood. In Wood Handbook: Wood as an Engineering Material; United States Department of Agriculture Forest Service: Madison, WI, USA, 1999. [Google Scholar] [CrossRef]

- Olorunnisola, A.O. (Ed.) Mechanical Properties of Wood. In Design of Structural Elements with Tropical Hardwoods; Springer: Berlin/Heidelberg, Germany, 2017; pp. 31–47. [Google Scholar] [CrossRef]

- Miljojkovic, J.; Bijelic, I.; Vranic, N.; Radovanovic, N.; Zivkovic, M. Determining Elastic Modulus of the Material by Measuring the Deflection of the Beam Loaded in Bending. Teh. Vjesn. 2017, 24, 1227–1234. [Google Scholar] [CrossRef] [Green Version]

- Riggio, M.; Piazza, M. Hardness Test, In Situ Assessment of Structural Timber; RILEM State of the Art Reports; Kasal, B., Tannert, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; Volume 7. [Google Scholar] [CrossRef]

- Lykidis, C.; Nikolakakos, M.; Sakellariou, E.; Birbilis, D. Assessment of a modification to the Brinell method for determining solid wood hardness. Mater. Struct. 2015, 49, 961–967. [Google Scholar] [CrossRef]

- Koczan, G.; Karwat, Z.; Kozakiewicz, P. An attempt to unify the Brinell, Janka and Monnin hardness of wood on the basis of Meyer law. J. Wood Sci. 2021, 67, 7. [Google Scholar] [CrossRef]

- Gurau, L.; Irle, M. Surface Roughness Evaluation Methods for Wood Products: A Review. Curr. Forestry Rep. 2017, 3, 119–131. [Google Scholar] [CrossRef]

- Tiryaki, S.; Malkocoglu, A.; Ozsahin, S. Using artificial neural networks for modeling surface roughness of wood in machining process. Constr. Build. Mater. 2014, 66, 329–335. [Google Scholar] [CrossRef]

- Tiryaki, S.; Hamzacebi, C.; Malkocoglu, A. Evaluation of process parameters for lower surface roughness in wood machining by using Taguchi design methodology. Eur. J. Wood Wood Prod. 2015, 73, 537–545. [Google Scholar] [CrossRef]

- Kowalik, M.; Trzepiecinski, T.; Kukielka, L.; Paszta, P.; Maciąg, P.; Legutko, S. Experimental and Numerical Analysis of the Depth of the Strengthened Layer on Shafts Resulting from Roller Burnishing with Roller Braking Moment. Materials 2021, 14, 5844. [Google Scholar] [CrossRef]

- Rotella, G.; Caruso, S.; Del Prete, A.; Filice, L. Prediction of Surface Integrity Parameters in Roller Burnishing of Ti6Al4V. Metals 2020, 10, 1671. [Google Scholar] [CrossRef]

- Babic, M.; Kocovic, V.; Vukelic, D.; Mihajlovic, G.; Eric, M.; Tadic, B. Investigation of ball burnishing processing on mechanical characteristics of wooden elements. Proc. Inst. Mech. Eng. Part. C J. Mech. Eng. Sci. 2017, 231, 120–127. [Google Scholar] [CrossRef]

- Vukelic, D.; Tadic, B.; Dzunic, D.; Kocovic, V.; Brzakovic, L.; Zivkovic, M.; Simunovic, G. Analysis of ball-burnishing impact on barrier properties of wood workpieces. Int. J. Adv. Manuf. Technol. 2017, 92, 129–138. [Google Scholar] [CrossRef]

- Akkurt, A. Comparison of Roller Burnishing Method with Other Hole Surface Finishing Processes Applied on AISI 304 Austenitic Stainless Steel. J. Mater. Eng. Perform. 2010, 20, 960–968. [Google Scholar] [CrossRef]

- Dobrzynski, M.; Javorek, L.; Orlowski, K.A.; Przybylski, W. The Effect of an Active Force While Slide Diamond Burnishing of Wooden Shafts Upon Process Quality. J. Mach. Constr. Maint. 2019, 1, 7–15. [Google Scholar]

- Roman, K.; Barwicki, J.; Rzodkiewicz, W.; Dawidowski, M. Evaluation of Mechanical and Energetic Properties of the Forest Residues Shredded Chips during Briquetting Process. Energies 2021, 14, 3270. [Google Scholar] [CrossRef]

- Korkut, D.S.; Hiziroglu, S.; Aytin, A. Effect of Heat Treatment on Surface Characteristics of Wild Cherry Wood. BioRes 2013, 8, 1582–1590. [Google Scholar] [CrossRef]

- Martinsson, O. Wild Cherry (Prunus avium L.) for Timber Production: Consequences for Early Growth from Selection of Open-pollinated Single-tree Progenies in Sweden. Scand. J. For. Res. 2001, 16, 117–126. [Google Scholar] [CrossRef]

- Salca, E.A. Black Alder (Alnus glutinosa L.)—A Resource for Value-Added Products in Furniture Industry Under European Screening. Curr. Forestry. Rep. 2019, 5, 41–54. [Google Scholar] [CrossRef]

- Bekhta, P.; Proszyk, S.; Lis, B.; Krystofiak, T. Gloss of thermally densified alder (Alnus glutinosa Goertn.), beech (Fagus sylvatica L.), birch (Betula verrucosa Ehrh.), and pine (Pinus sylvestris L.) wood veneers. Eur. J. Wood Wood Prod. 2014, 72, 799–808. [Google Scholar] [CrossRef] [Green Version]

- İmirzi, H.Ö.; Ülker, O.; Burdurlu, E. Effect of densification temperature and some surfacing techniques on the surface roughness of densified Scots pine (Pinus sylvestris L.). BioResources 2014, 9, 191–209. [Google Scholar] [CrossRef]

- Nurek, T.; Gendek, A.; Roman, K.; Dąbrowska, M. The effect of temperature and moisture on the chosen parameters of briquettes made of shredded logging residues. Biomass Bioenergy 2019, 130, 105368. [Google Scholar] [CrossRef]

| Wood Type | HB | E (MPa) | Ra (μm) |

|---|---|---|---|

| Cherry | 2.007 | 7997.82 | 6.731 |

| Fir | 2.102 | 10,227.18 | 5.774 |

| Alder | 2.188 | 8797.24 | 9.064 |

| Linden | 2.36 | 13,752.09 | 5.936 |

| Beech | 3.107 | 11,823.74 | 7.399 |

| Walnut | 3.372 | 8594.25 | 7.214 |

| Oak | 3.078 | 13,386.74 | 9.344 |

| Ash | 2.788 | 10,779.82 | 11.086 |

| Wood Type | Pressing Force F (N) | |||

|---|---|---|---|---|

| 392 | 785 | 1177 | 1570 | |

| Cherry | 2.095 | 3.225 | 3.365 | 3.954 |

| Fir | 2.603 | 2.739 | 2.823 | 2.36 |

| Alder | 3.084 | 3.439 | 3.517 | 3.512 |

| Linden | 2.46 | 2.579 | 2.955 | 2.516 |

| Beech | 3.587 | 4.146 | 4.394 | 4.686 |

| Walnut | 3.68 | 4.379 | 5.157 | 5.505 |

| Oak | 3.096 | 3.495 | 3.626 | 5.411 |

| Ash | 3.679 | 5.127 | 5.718 | 7.693 |

| Wood Type | Pressing Force F (N) | |||

|---|---|---|---|---|

| 392 | 785 | 1177 | 1570 | |

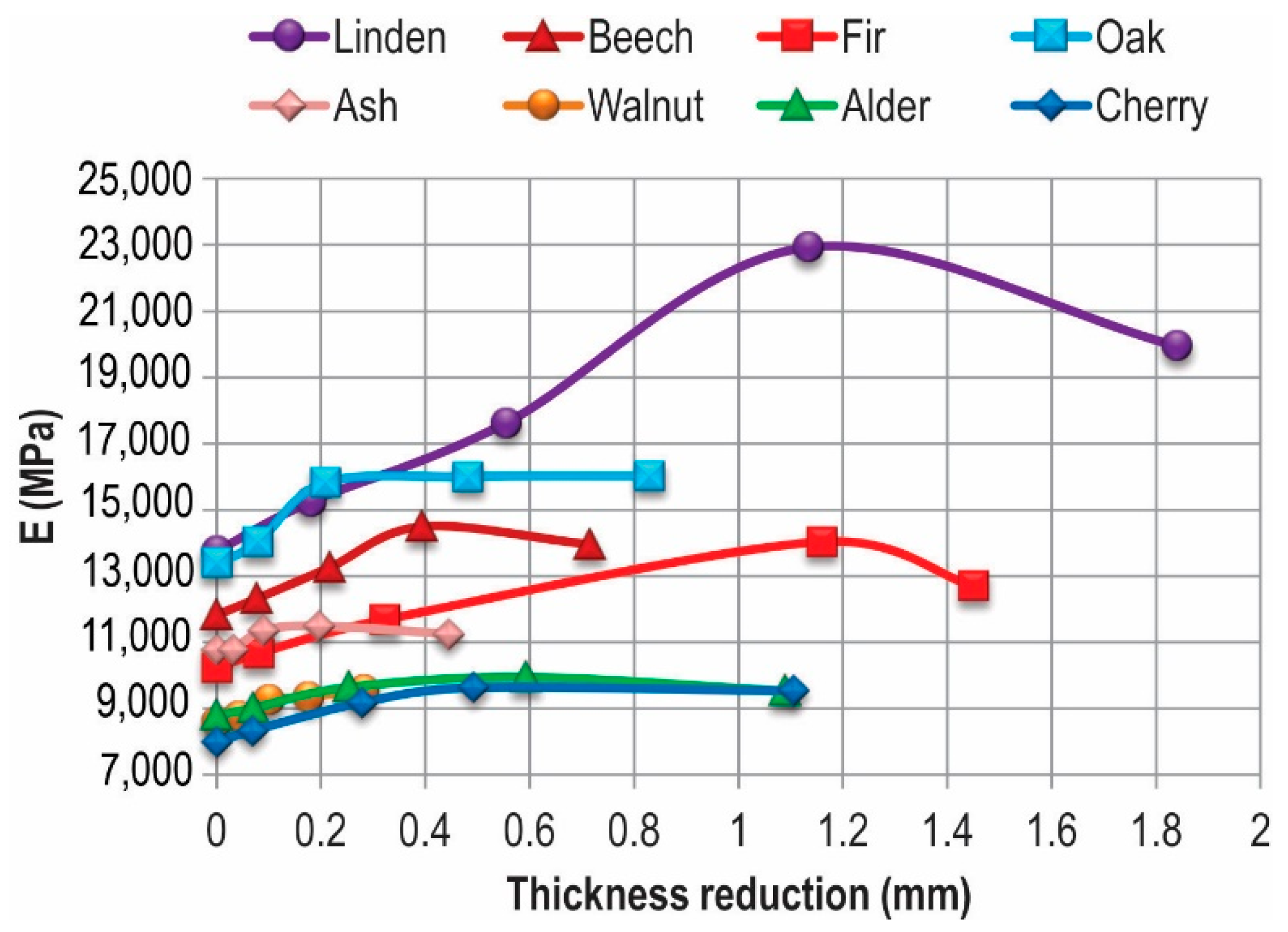

| Cherry | 8319.65 | 9179.55 | 9633.2 | 9534.54 |

| Fir | 10,660.3 | 11,683.07 | 14,036.21 | 12,696.9 |

| Alder | 9014.75 | 9637.57 | 9942.77 | 9523.9 |

| Linden | 15,239.1 | 17,625.72 | 22,928.77 | 19,946.6 |

| Beech | 12,316 | 13,249.53 | 14,486.93 | 13,947.6 |

| Walnut | 8751.26 | 9249.76 | 9333.5 | 9569.54 |

| Oak | 14,018.2 | 15,821.92 | 15,999.43 | 16,020.3 |

| Ash | 10,785.1 | 11,362.02 | 11,485.04 | 11,250 |

| Wood Type | Pressing Force F (N) | |||

|---|---|---|---|---|

| 392 | 785 | 1177 | 1570 | |

| Cherry | 4.771 | 3.37 | 3.635 | 4.291 |

| Fir | 5.106 | 7.255 | 10.768 | 11.525 |

| Alder | 5.261 | 4.37 | 4.101 | 4.301 |

| Linden | 4.229 | 3.524 | 3.536 | 3.711 |

| Beech | 6.082 | 5.593 | 5.485 | 5.6 |

| Walnut | 5.078 | 4.122 | 4.015 | 3.348 |

| Oak | 7.359 | 6.6 | 7.456 | 8.27 |

| Ash | 8.613 | 7.177 | 6.961 | 7.504 |

| Wood Type | Hardness | Elastic Modulus | Roughness |

|---|---|---|---|

| Cherry | 0.93 | 0.96 | −0.90 |

| Fir | 0.92 | 0.94 | 0.88 |

| Alder | 0.92 | 0.98 | −0.89 |

| Linden | 0.94 | 0.99 | −0.90 |

| Beech | 0.98 | 0.98 | −0.92 |

| Walnut | 0.98 | 0.96 | −0.92 |

| Oak | 0.95 | 0.96 | −0.71 |

| Ash | 0.99 | 0.93 | −0.94 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kocovic, V.; Dzunic, D.; Kostic, S.; Brzakovic, L.; Tadic, B.; Prica, M.; Vukelic, D. Investigation into the Effects of Roller Pressing on Hardness, Roughness and Elastic Modulus of Wooden Workpieces. Appl. Sci. 2022, 12, 5575. https://doi.org/10.3390/app12115575

Kocovic V, Dzunic D, Kostic S, Brzakovic L, Tadic B, Prica M, Vukelic D. Investigation into the Effects of Roller Pressing on Hardness, Roughness and Elastic Modulus of Wooden Workpieces. Applied Sciences. 2022; 12(11):5575. https://doi.org/10.3390/app12115575

Chicago/Turabian StyleKocovic, Vladimir, Dragan Dzunic, Sonja Kostic, Ljiljana Brzakovic, Branko Tadic, Miljana Prica, and Djordje Vukelic. 2022. "Investigation into the Effects of Roller Pressing on Hardness, Roughness and Elastic Modulus of Wooden Workpieces" Applied Sciences 12, no. 11: 5575. https://doi.org/10.3390/app12115575

APA StyleKocovic, V., Dzunic, D., Kostic, S., Brzakovic, L., Tadic, B., Prica, M., & Vukelic, D. (2022). Investigation into the Effects of Roller Pressing on Hardness, Roughness and Elastic Modulus of Wooden Workpieces. Applied Sciences, 12(11), 5575. https://doi.org/10.3390/app12115575