Novel Approach Using Risk Analysis Component to Continuously Update Collaborative Robotics Applications in the Smart, Connected Factory Model

Abstract

:Featured Application

Abstract

1. Introduction

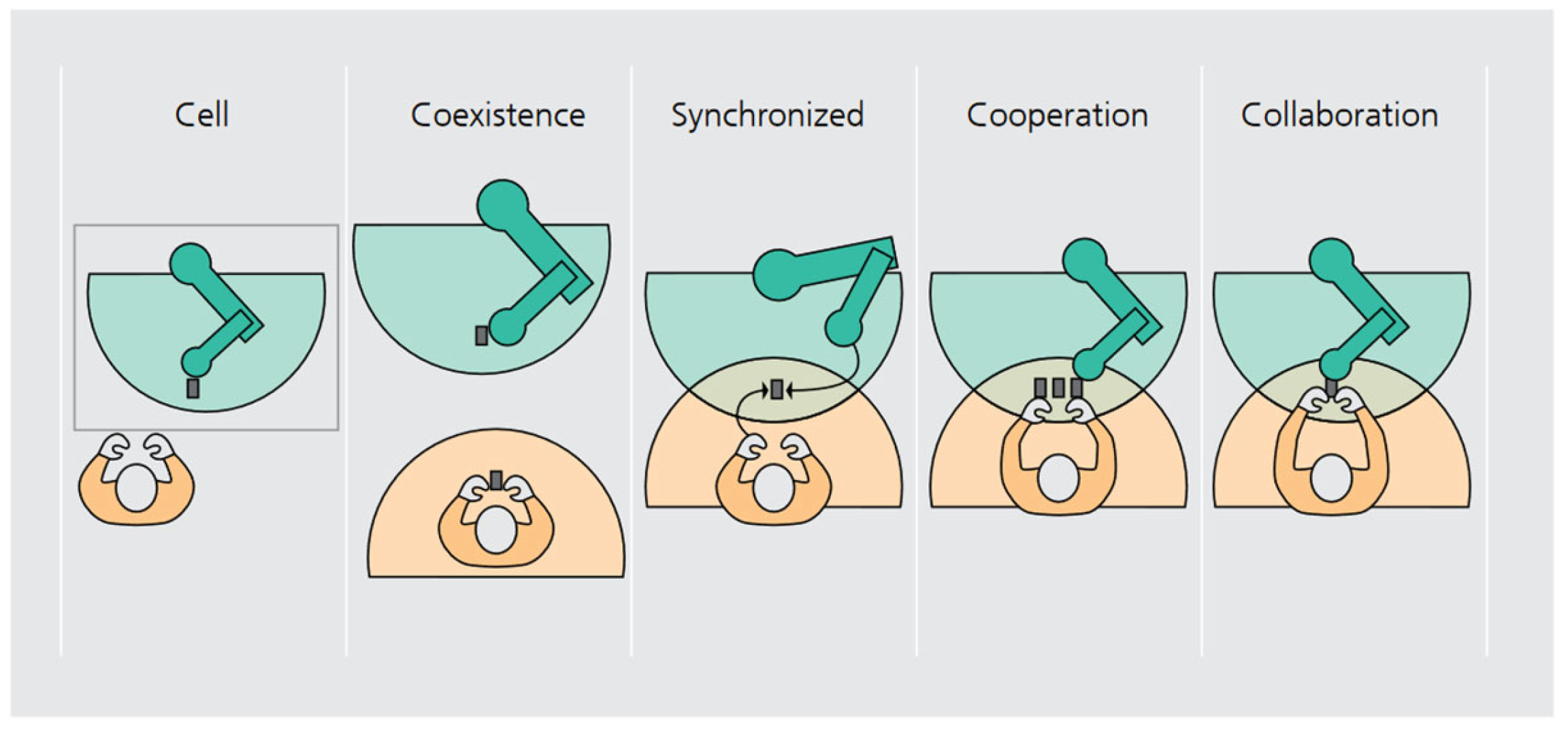

1.1. Smart Factory and Collaborative Robots

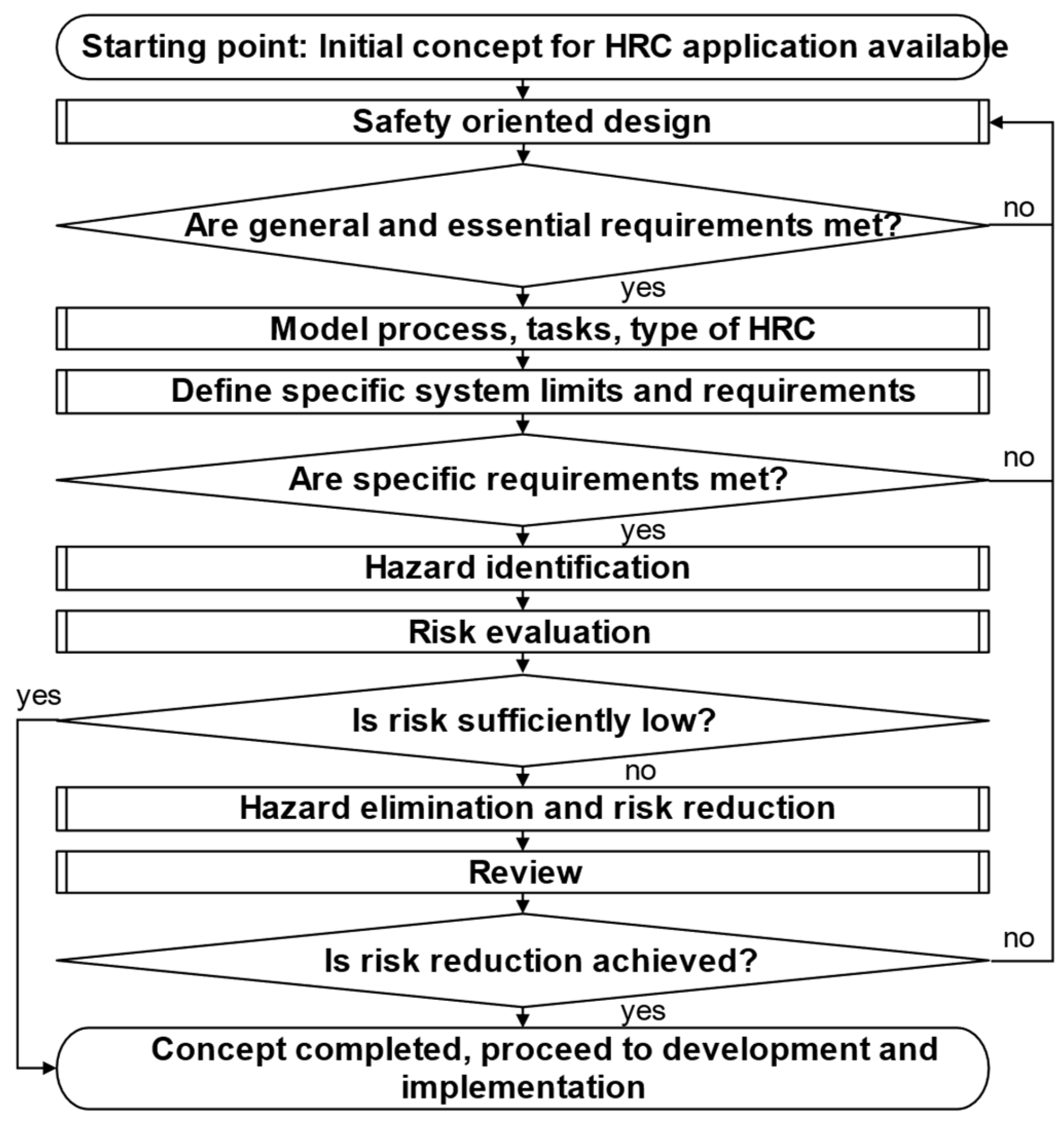

1.2. Risk Analysis and Risk Assessment for Collaborative Robotics Applications

2. Proposed Smart Factory Methods and Methodology

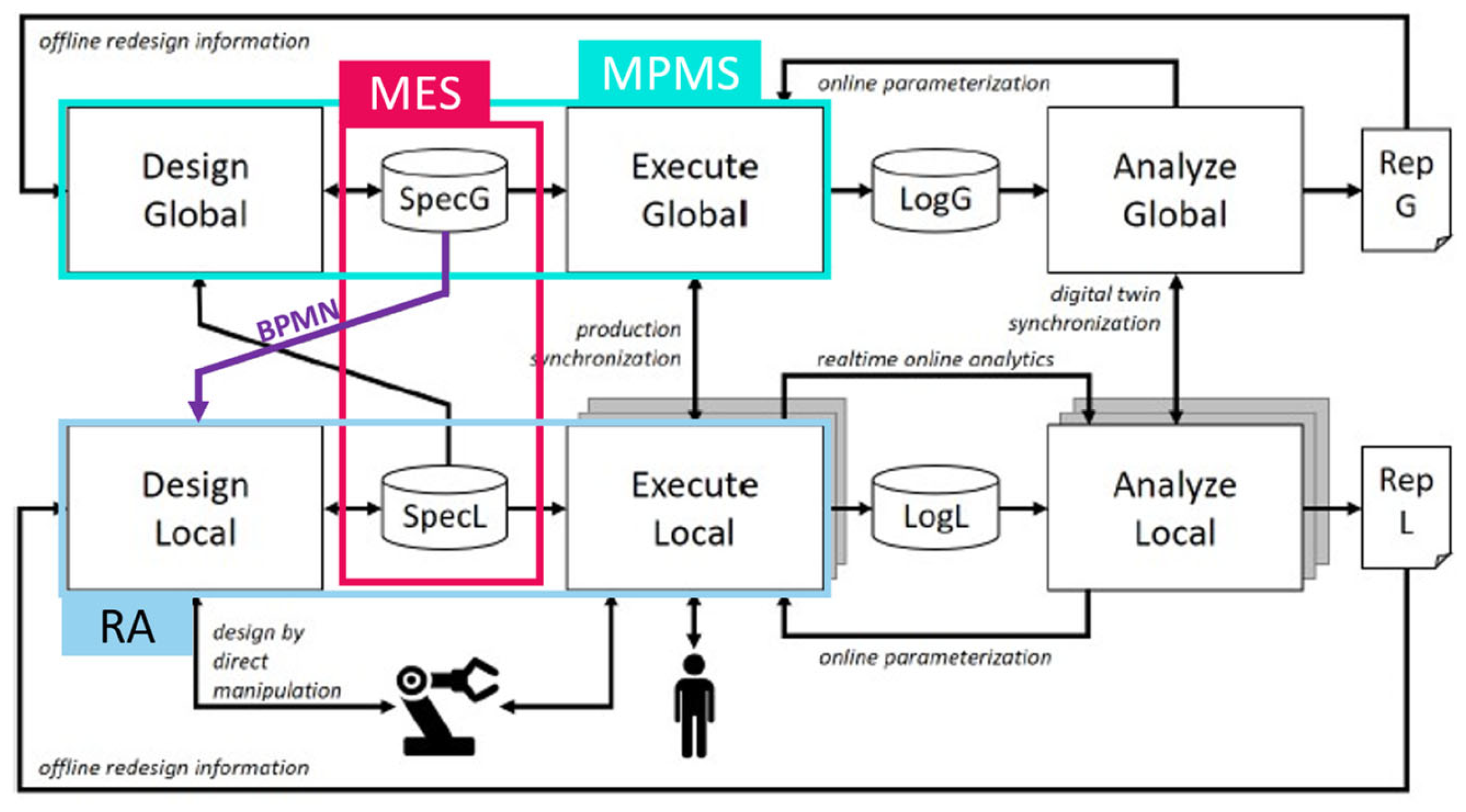

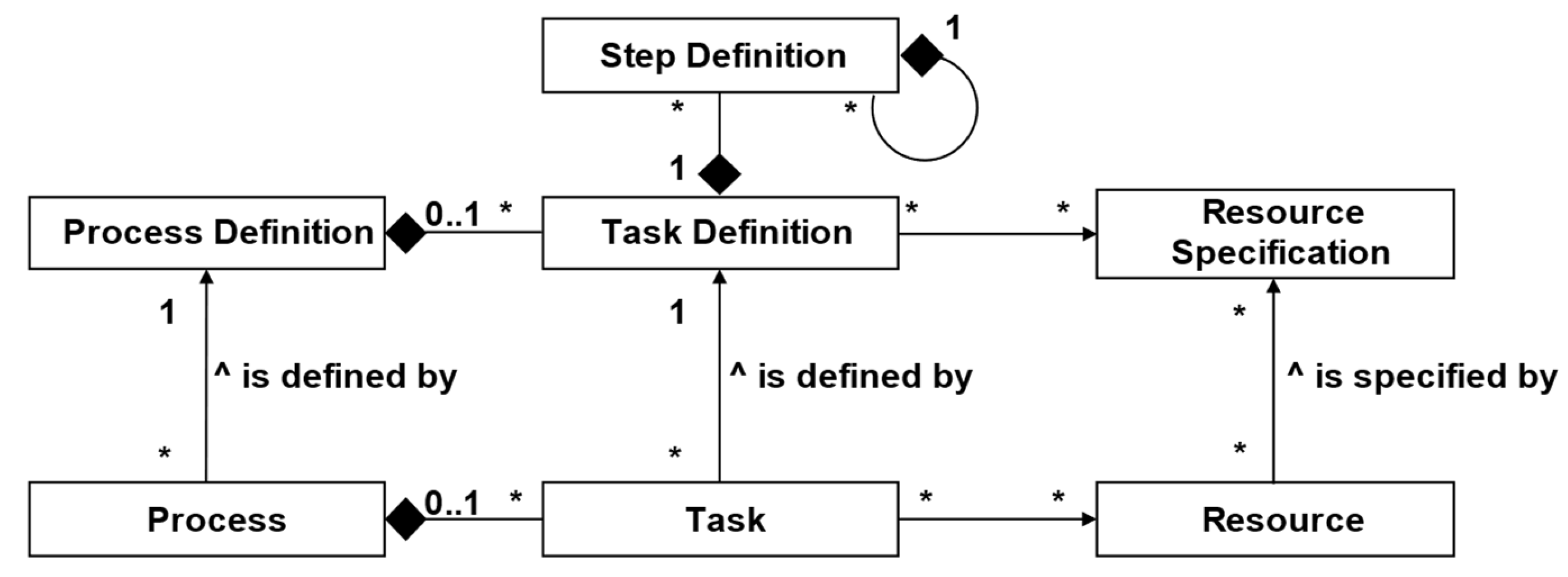

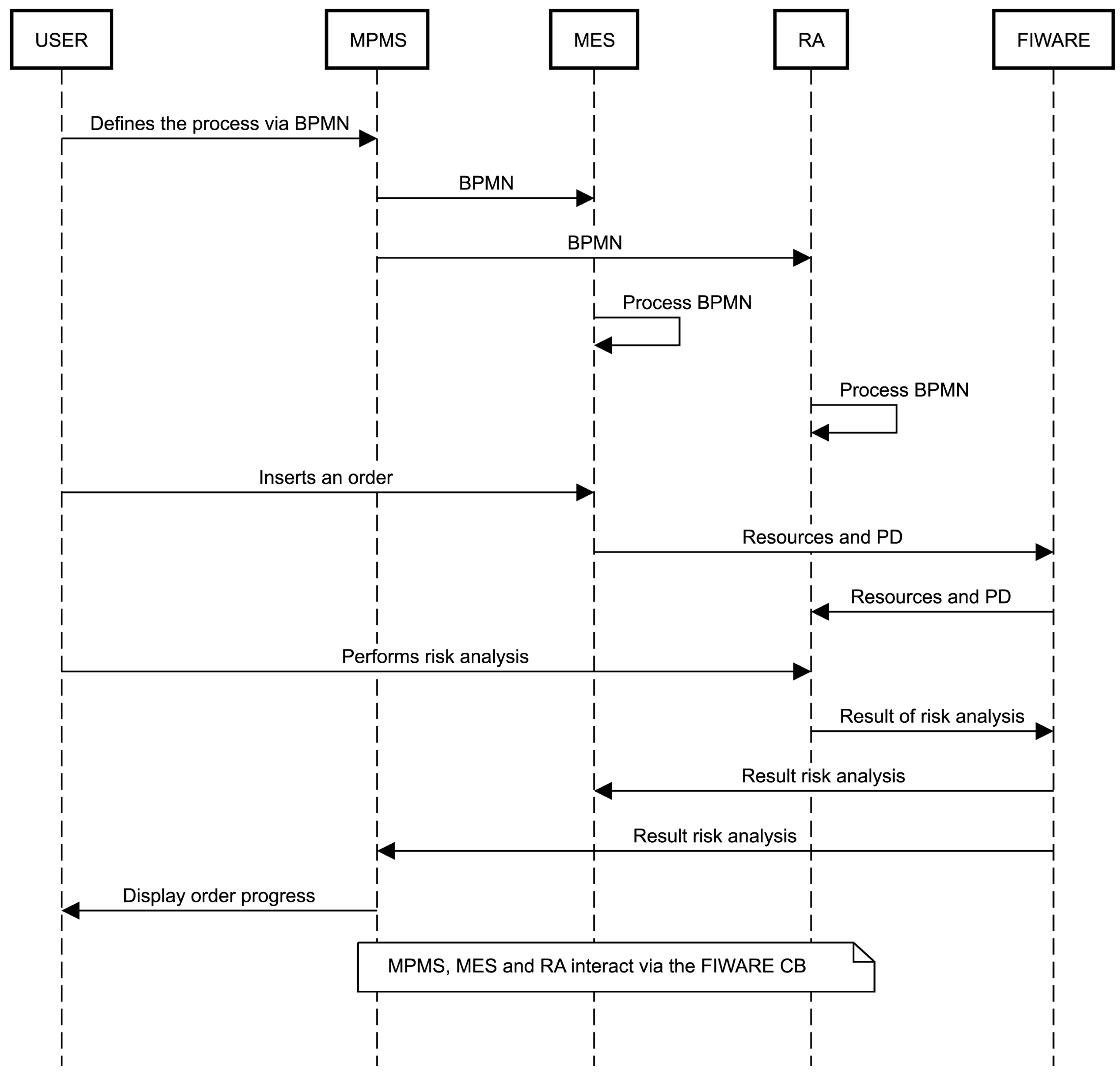

2.1. Overall Architecture and Data Models

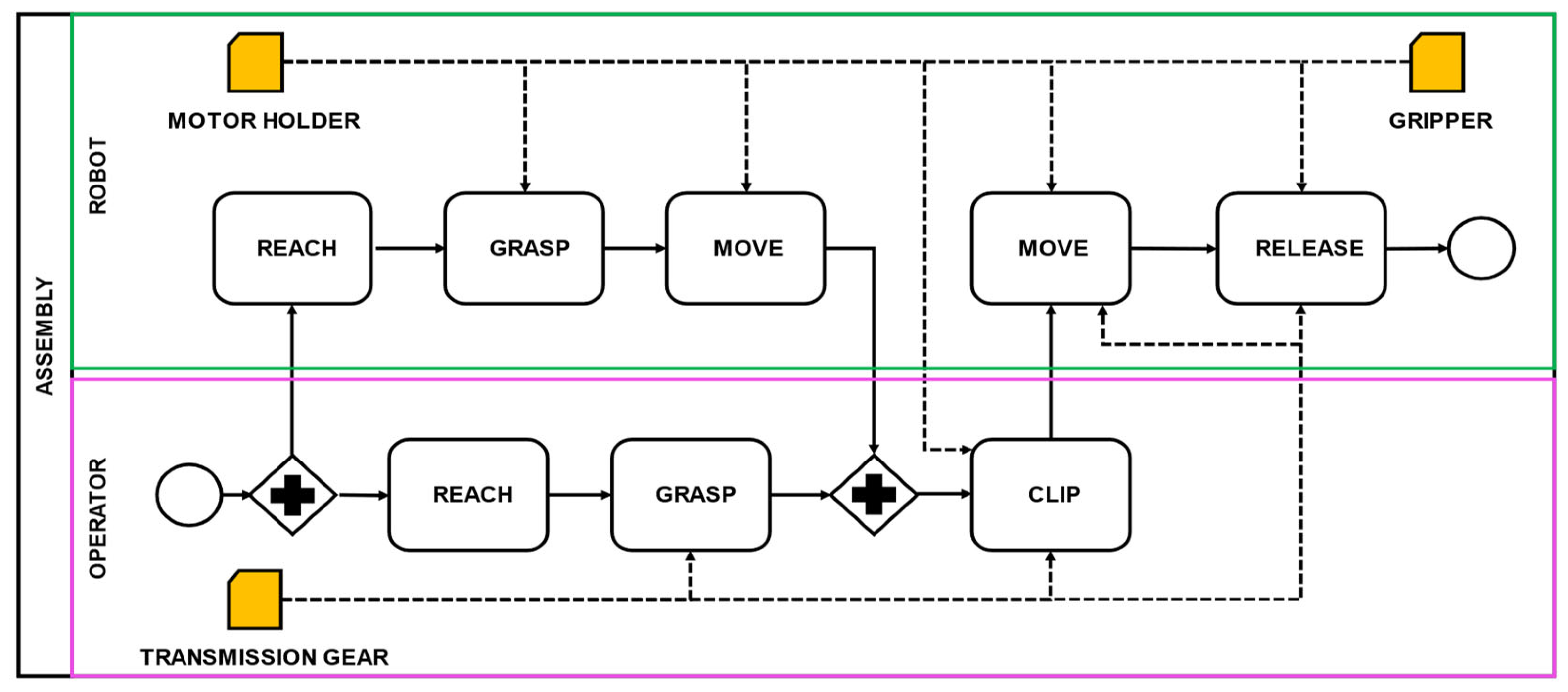

2.2. BPMN Modeling

2.3. Manufacturing Execution System Component

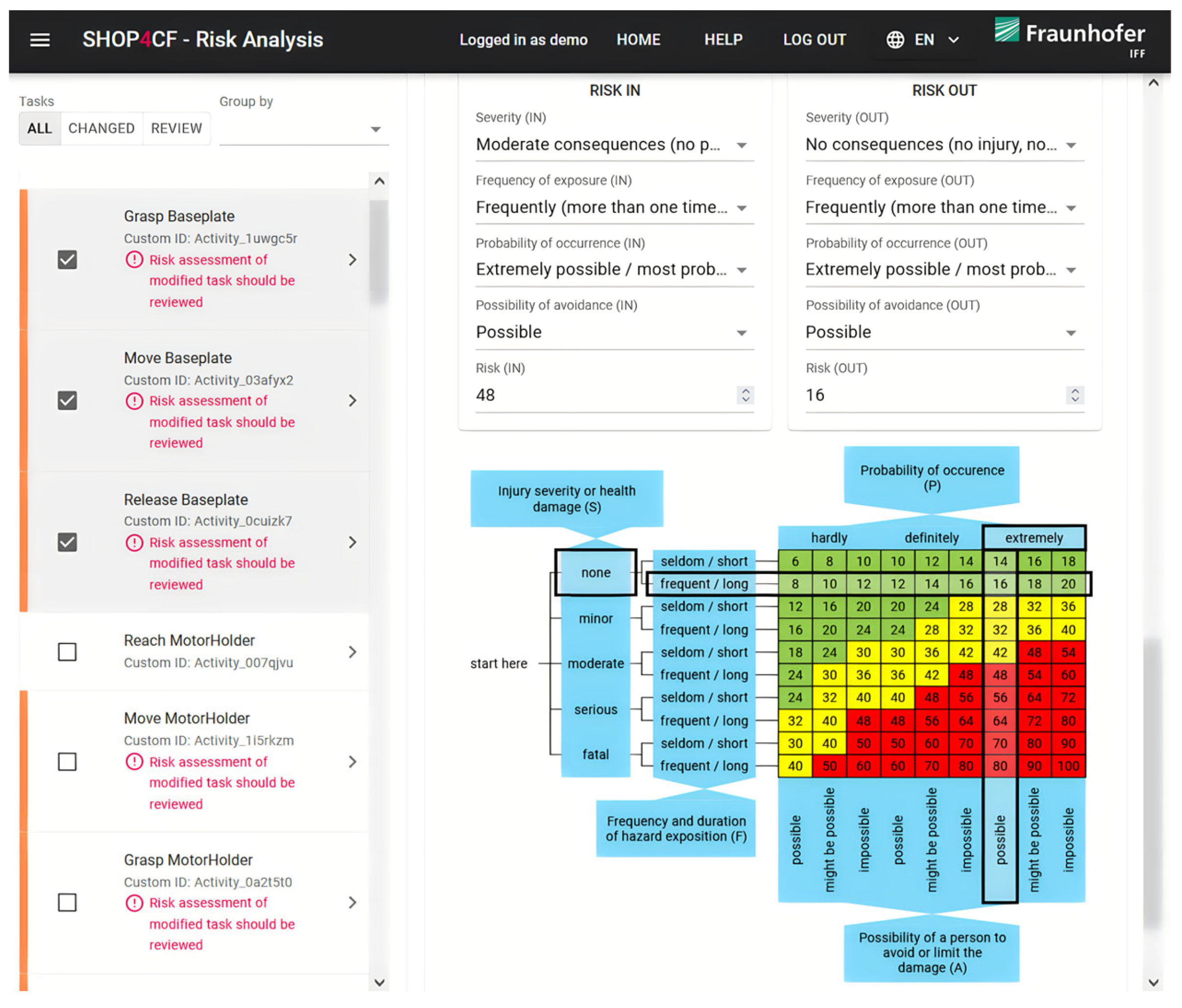

2.4. Risk Analysis Component

3. Smart Factory Use-Case

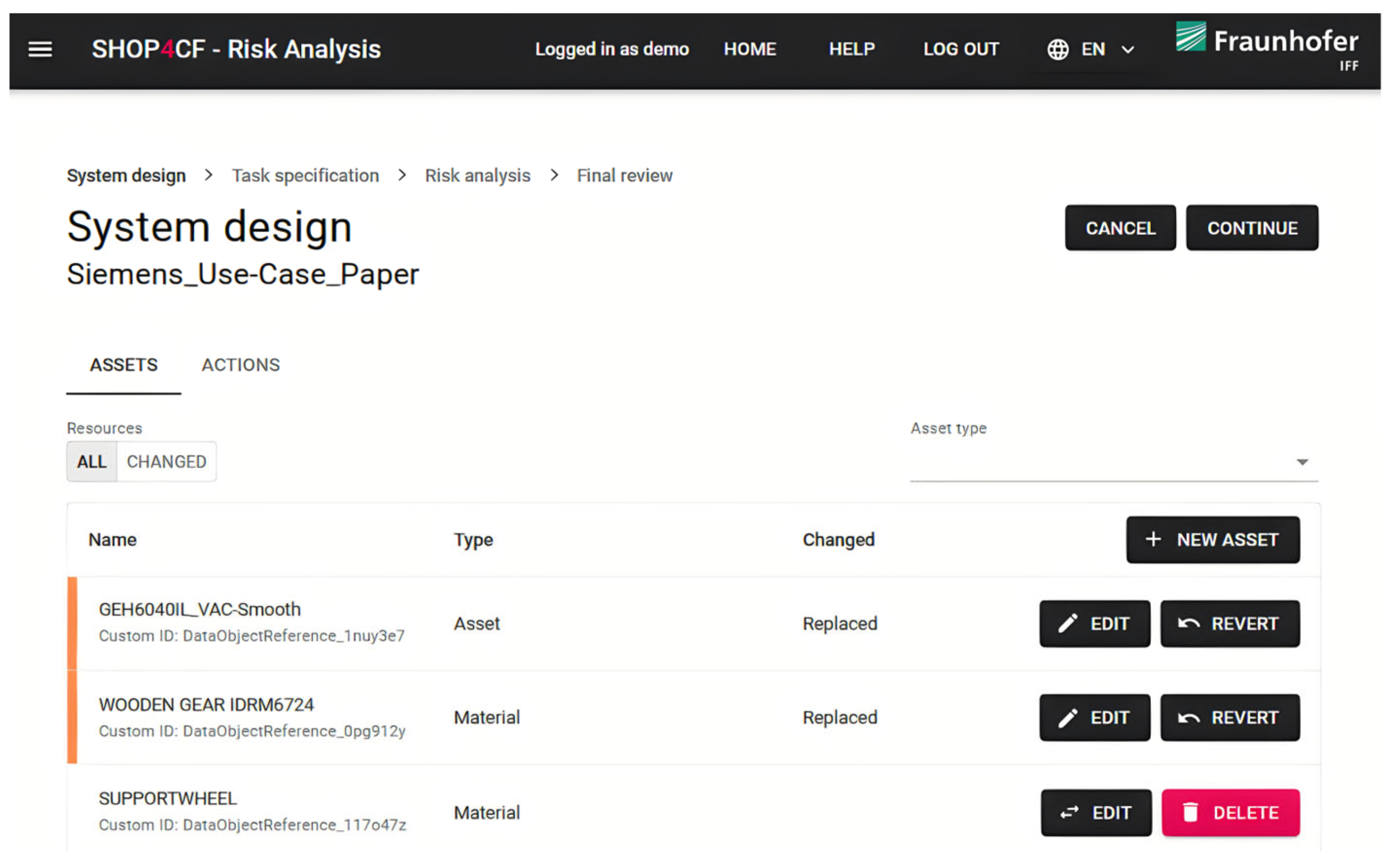

3.1. Workflow for using the Risk Analysis Component

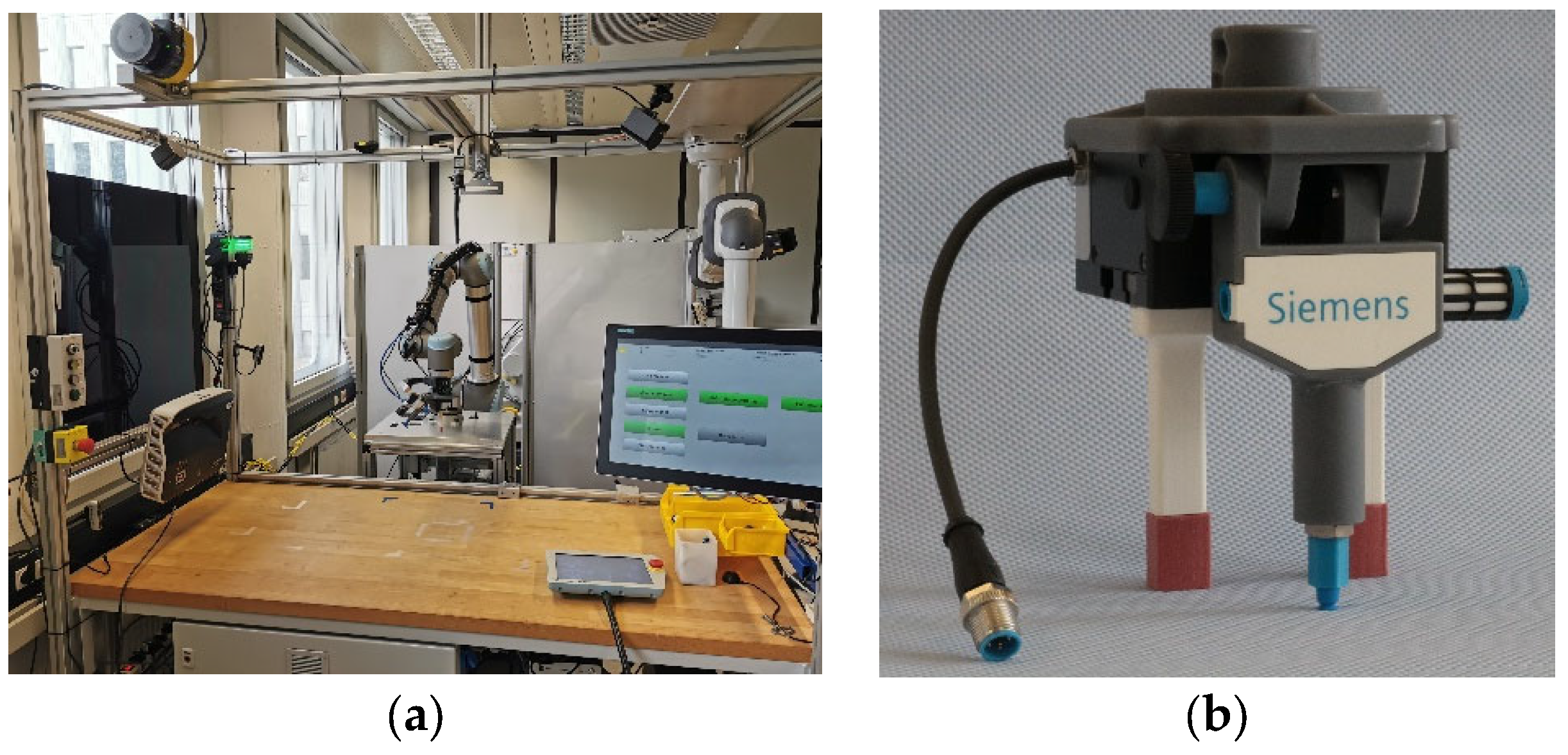

3.2. Hardware Set-Up

3.3. Using Risk Analysis Component for Smart Factory Use-Case

4. Evaluation

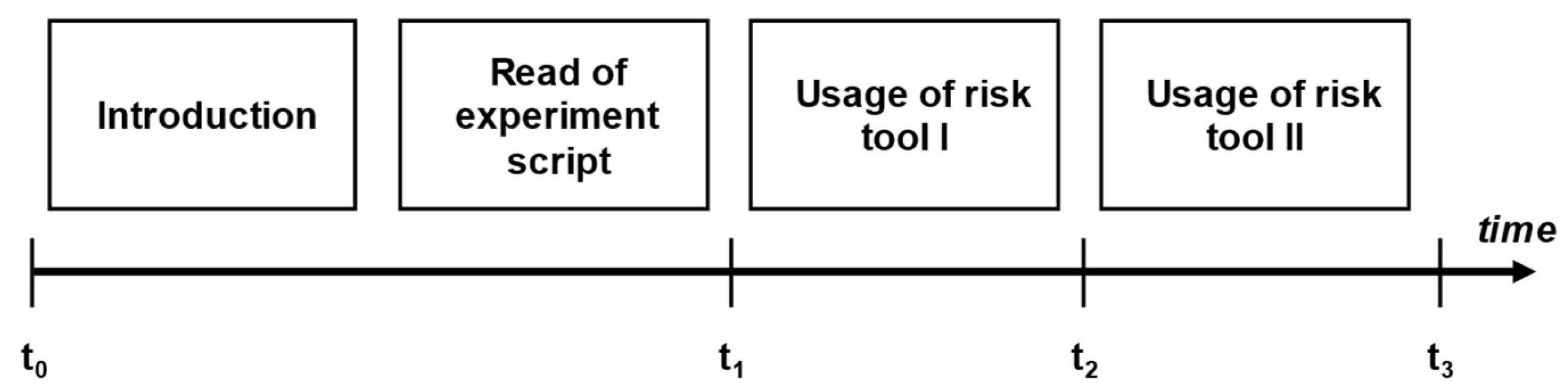

4.1. Usability

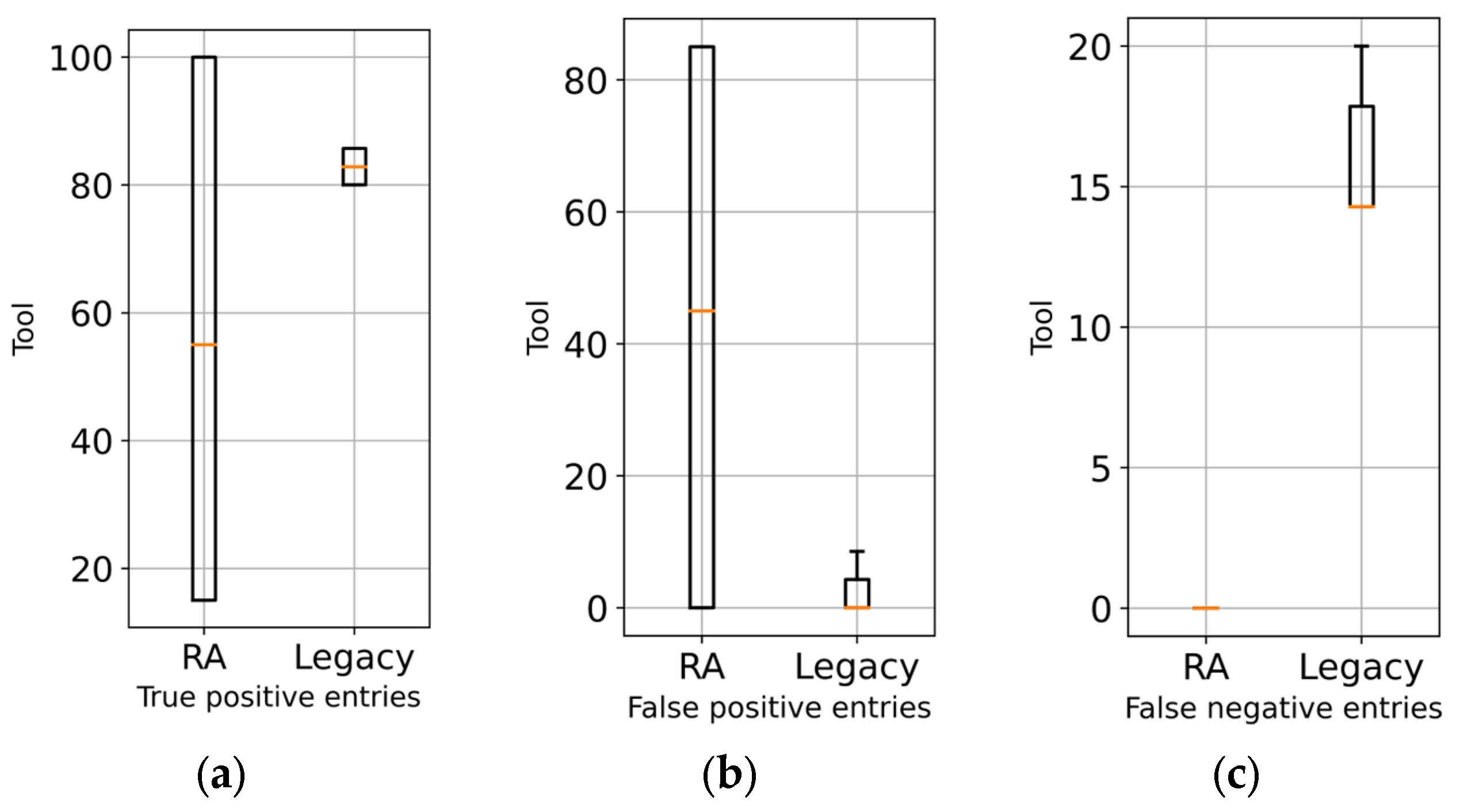

4.2. KPIs on the User Updates to the Risk Assessment

5. Discussion

5.1. Usability

5.2. KPIs on the User Updates to the Risk Analysis

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Anshuk, G.; Magar, C.; Roger, R. How Technology Can Drive the Next Wave of Mass Customization: Seven Technologies Are Making It Easier to Tailor Products and Services to the Wants of Individual Customers—And Still Make a Profit; Business Technology Office, McKinsey & Company: Chicago, IL, USA, 2014. [Google Scholar]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar]

- Forschungsunion; Acatech. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0 Securing the Future of German Manufacturing Industry: Final Report of the Industrie 4.0 Working Group. 2013. Available online: https://www.Gateway-bayern.de/BV041628398 (accessed on 30 August 2021).

- Pozzi, R.; Rossi, T.; Secchi, R. Industry 4.0 technologies: Critical success factors for implementation and improvements in manufacturing companies. Prod. Plan. Control 2021, 1–21. [Google Scholar] [CrossRef]

- European Commission; Executive Agency for Small and Medium-Sized Enterprises; Muller, P.; Cannings, J.; Priem, M.; Unlu Bohn, N.; Lefebvre, V.; Murphy, E.; Aranda, F.; Devnani, S.; et al. Annual Report on European SMEs 2020/2021: Digitalisation of SMEs: Background Document; Hope, K., Ed.; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar]

- Fernández-Macías, E.; Klenert, D.; Antón, J.-I. Not so disruptive yet? Characteristics, distribution and determinants of robots in Europe. Struct. Change Econ. Dyn. 2021, 58, 76–89. [Google Scholar] [CrossRef]

- Aaltonen, I.; Salmi, T. Experiences and expectations of collaborative robots in industry and academia: Barriers and development needs. Procedia Manuf. 2019, 38, 1151–1158. [Google Scholar] [CrossRef]

- Johansen, K.; Rao, S.; Ashourpour, M. The Role of Automation in Complexities of High-Mix in Low-Volume Production—A Literature Review. Procedia CIRP 2021, 104, 1452–1457. [Google Scholar] [CrossRef]

- Karaulova, T.; Andronnikov, K.; Mahmood, K.; Shevtshenko, E. Lean Automation for Low-Volume Manufacturing Environment. In Proceedings of the 30th International DAAAM Symposium 2019, Zadar, Croatia, 20–27 October 2019; Katalinic, B., Ed.; DAAAM International: Vienna, Austria, 2019; pp. 59–68. [Google Scholar]

- Miqueo, A.; Torralba, M.; Yagüe-Fabra, J.A. Lean Manual Assembly 4.0: A Systematic Review. Appl. Sci. 2020, 10, 8555. [Google Scholar] [CrossRef]

- Tomašević, I.; Stojanović, D.; Slović, D.; Simeunović, B.; Jovanović, I. Lean in High-Mix/Low-Volume industry: A systematic literature review. Prod. Plan. Control 2021, 32, 1004–1019. [Google Scholar] [CrossRef]

- Villani, V.; Pini, F.; Leali, F.; Secchi, C. Survey on human–robot collaboration in industrial settings: Safety, intuitive interfaces and applications. Mechatronics 2018, 55, 248–266. [Google Scholar] [CrossRef]

- Jeschke, S.; Brecher, C.; Song, H.; Rawat, D.B. Industrial Internet of Things; Springer International Publishing: Cham, Swizerland, 2017; ISBN 978-3-319-42558-0. [Google Scholar]

- Fujita, M.; Domae, Y.; Noda, A.; Garcia Ricardez, G.A.; Nagatani, T.; Zeng, A.; Song, S.; Rodriguez, A.; Causo, A.; Chen, I.M.; et al. What are the important technologies for bin picking? Technology analysis of robots in competitions based on a set of performance metrics. Adv. Robot. 2020, 34, 560–574. [Google Scholar] [CrossRef]

- Pantano, M.; Blumberg, A.; Regulin, D.; Hauser, T.; Saenz, J.; Lee, D. Design of a collaborative modular end effector considering human values and safety requirements for industrial use cases. In Proceedings of the 14th International Workshop on Human-Friendly Robotics (HFR 2021), Bologna, Italy, 28–29 October 2021. [Google Scholar]

- Eiband, T.; Willibald, C.; Tannert, I.; Weber, B.; Lee, D. Collaborative Programming of Robotic Task Decisions and Recovery Behaviors. Auton. Robot. 2022; in press. [Google Scholar]

- Gualtieri, L.; Rauch, E.; Vidoni, R. Emerging research fields in safety and ergonomics in industrial collaborative robotics: A systematic literature review. Robot. Comput.-Integr. Manuf. 2021, 67, 101998. [Google Scholar] [CrossRef]

- Bauer, W.; Bender, M.; Braun, M.; Rally, P.; Scholtz, O. Lightweight Robots in Manual Assembly—Best to Start Simply: Examining Companies’ Initial Experiences with Lightweight Robots; Frauenhofer-Institut für Arbeitswirtschaft und Organisation IAO: Stuttgart, Germany, 2016. [Google Scholar]

- Saenz, J.; Elkmann, N.; Gibaru, O.; Neto, P. Survey of methods for design of collaborative robotics applications—Why safety is a barrier to more widespread robotics uptake. In Proceedings of the ICMRE 2018: 2018 4th International Conference on Mechatronics and Robotics Engineering, Valenciennes, France, 7–11 February 2018; ACM: New York, NY, USA, 2018; pp. 95–101. [Google Scholar]

- ISO 12100:2010; Safety of Machinery—General Principles for Design—Risk Assessment and Risk Reduction, Version 1. International Organization for Standardization: Geneva, Switzerland, 2010.

- Vicentini, F.; Askarpour, M.; Rossi, M.G.; Mandrioli, D. Safety Assessment of Collaborative Robotics Through Automated Formal Verification. IEEE Trans. Robot. 2020, 36, 42–61. [Google Scholar] [CrossRef]

- Awad, R.; Fechter, M.; van Heerden, J. Integrated risk assessment and safety consideration during design of HRC workplaces. In Proceedings of the 2017 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limassol, Cyprus, 12–15 September 2017; pp. 1–10. [Google Scholar]

- Inam, R.; Raizer, K.; Hata, A.; Souza, R.; Forsman, E.; Cao, E.; Wang, S. Risk Assessment for Human-Robot Collaboration in an automated warehouse scenario. In Proceedings of the 2018 IEEE 23rd International Conference on Emerging Technologies and Factory Automation (ETFA), Turin, Italy, 4–7 September 2018; pp. 743–751. [Google Scholar]

- Liu, Z.; Wang, X.; Cai, Y.; Xu, W.; Liu, Q.; Zhou, Z.; Pham, D.T. Dynamic risk assessment and active response strategy for industrial human-robot collaboration. Comput. Ind. Eng. 2020, 141, 106302. [Google Scholar] [CrossRef]

- Gualtieri, L.; Rauch, E.; Vidoni, R. Development and validation of guidelines for safety in human-robot collaborative assembly systems. Comput. Ind. Eng. 2022, 163, 107801. [Google Scholar] [CrossRef]

- Huck, T.P.; Münch, N.; Hornung, L.; Ledermann, C.; Wurll, C. Risk assessment tools for industrial human-robot collaboration: Novel approaches and practical needs. Saf. Sci. 2021, 141, 105288. [Google Scholar] [CrossRef]

- Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on Machinery and Amending Directive 95/16/EC. Off. J. Eur. Union 2006, L157, 24–86.

- Federal Ministry of Labour and Social Affairs. Interpretation Paper on Substantial Modification to Machinery. 2015. Available online: https://www.bmas.de/SharedDocs/Downloads/DE/Arbeitsschutz/en-interpretation-paper-substantial-modification-to-machinery.pdf?__blob=publicationFile&v=1 (accessed on 3 March 2022).

- Traganos, K.; Grefen, P.; Vanderfeesten, I.; Erasmus, J.; Boultadakis, G.; Bouklis, P. The HORSE framework: A reference architecture for cyber-physical systems in hybrid smart manufacturing. J. Manuf. Syst. 2021, 61, 461–494. [Google Scholar] [CrossRef]

- Grefen, P.W.; Boultadakis, G. Designing an Integrated System for Smart Industry: Designing an Integrated System for Smart Industry; Departmental Office IE&IS, Industrial Engineering and Innovation Sciences: Eindhoven, The Netherlands, 2021; ISBN 979-8667048640. [Google Scholar]

- Zanetti, R. Deliverable 1.2—OPIL Architecture. 2018. Available online: http://www.l4ms.eu/sites/default/files/deliverables/D1.2.pdf (accessed on 28 February 2022).

- Zimniewicz, M. Deliverable 3.2—SHOP4CF Architecture. 2020. Available online: https://elk.adalidda.com/2021/05/SHOP4CF-WP3-D32-DEL-210119-v1.0.pdf (accessed on 28 February 2022).

- Araujo, V.; Mitra, K.; Saguna, S.; Åhlund, C. Performance evaluation of FIWARE: A cloud-based IoT platform for smart cities. J. Parallel Distrib. Comput. 2019, 132, 250–261. [Google Scholar] [CrossRef]

- Vanderfeesten, I.; Erasmus, J.; Traganos, K.; Bouklis, P.; Garbi, A.; Boultadakis, G.; Dijkman, R.; Grefen, P. Developing Process Execution Support for High-Tech Manufacturing Processes. In Empirical Studies on the Development of Executable Business Processes; Lübke, D., Pautasso, C., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 113–142. ISBN 978-3-030-17665-5. [Google Scholar]

- West, M. Developing High Quality Data Models; Morgan Kaufmann: Burlington, MA, USA, 2011; ISBN 978-0-12-375106-5. [Google Scholar]

- IEC-62264; Enterprise-Control System Integration. International Electrotechnical Commission: Geneva, Switzerland, 2013.

- Brunoe, T.D.; Nielsen, K. Complexity Management in Mass Customization SMEs. Procedia CIRP 2016, 51, 38–43. [Google Scholar] [CrossRef] [Green Version]

- Grewal, C. An initiative to implement lean manufacturing using value stream mapping in a small company. Int. J. Manuf. Technol. Manag. 2008, 15, 404. [Google Scholar] [CrossRef]

- Cheng-Leong, A.; Li Pheng, K.; Keng Leng, G.R. IDEF*: A comprehensive modelling methodology for the development of manufacturing enterprise systems. Int. J. Prod. Res. 1999, 37, 3839–3858. [Google Scholar] [CrossRef]

- Kim, C.-H.; Weston, R.H.; Hodgson, A.; Lee, K.-H. The complementary use of IDEF and UML modelling approaches. Comput. Ind. 2003, 50, 35–56. [Google Scholar] [CrossRef]

- OMG. Business Process Model and Notation (BPMN), Version 2.0.2. 2013. Available online: http://www.omg.org/spec/BPMN/2.0.2 (accessed on 8 March 2022).

- García-Domínguez, A.; Marcos, M.; Medina, I. A comparison of BPMN 2.0 with other notations for manufacturing processes. In Proceedings of the 4th Manufacturing Engineering Society International Conference (MESIC 2011), Cadiz, Spain, 21–23 September 2011; AIP: Melville, NY, USA, 2012; pp. 593–600. [Google Scholar]

- Prades, L.; Romero, F.; Estruch, A.; García-Dominguez, A.; Serrano, J. Defining a Methodology to Design and Implement Business Process Models in BPMN According to the Standard ANSI/ISA-95 in a Manufacturing Enterprise. Procedia Eng. 2013, 63, 115–122. [Google Scholar] [CrossRef] [Green Version]

- Erasmus, J.; Vanderfeesten, I.; Traganos, K.; Grefen, P. The Case for Unified Process Management in Smart Manufacturing. In Proceedings of the 2018 IEEE 22nd International Enterprise Distributed Object Computing Conference (EDOC), Stockholm, Sweden, 16–19 October 2018; pp. 218–227. [Google Scholar] [CrossRef]

- Zor, S.; Leymann, F.; Schumm, D. A proposal of BPMN extensions for the manufacturing domain. In Proceedings of the 44th CIRP International Conference on Manufacturing Systems, Madison, WI, USA, 1–3 June 2011. [Google Scholar]

- Meyer, S.; Ruppen, A.; Magerkurth, C. Internet of Things-Aware Process Modeling: Integrating IoT Devices as Business Process Resources. In Active Flow and Combustion Control 2018; King, R., Ed.; Springer International Publishing: Cham, Switzerland, 2019; pp. 84–98. ISBN 978-3-319-98176-5. [Google Scholar]

- Petrasch, R.; Hentschke, R. Process modeling for industry 4.0 applications: Towards an industry 4.0 process modeling language and method. In Proceedings of the 2016 13th International Joint Conference on Computer Science and Software Engineering (JCSSE), Khon Kaen, Thailand, 13–15 July 2016; pp. 1–5. [Google Scholar]

- Abouzid, I.; Saidi, R. Proposal of BPMN extensions for modelling manufacturing processes. In Proceedings of the 2019 5th International Conference on Optimization and Applications (ICOA), Kenitra, Morocco, 25–26 April 2019; pp. 1–6. [Google Scholar]

- Schonberger, D.; Lindorfer, R.; Froschauer, R. Modeling Workflows for Industrial Robots Considering Human-Robot-Collaboration. In Proceedings of the 2018 IEEE 16th International Conference on Industrial Informatics (INDIN), Porto, Portugalt, 18–20 July 2018; pp. 400–405. [Google Scholar]

- Froschauer, R.; Lindorfer, R. Workflow-based programming of human-robot interaction for collaborative assembly stations. In Proceedings of the ARG & OAGM Workshop, Steyr, Austria, 9–10 May 2019. [Google Scholar]

- Lindorfer, R.; Froschauer, R.; Schwarz, G. ADAPT—A decision-model-based Approach for Modeling Collaborative Assembly and Manufacturing Tasks. In Proceedings of the 2018 IEEE 16th International Conference on Industrial Informatics (INDIN), Porto, Portugal, 18–20 July 2018; pp. 559–564. [Google Scholar]

- Schmidbauer, C.; Hader, B.; Schlund, S. Evaluation of a Digital Worker Assistance System to enable Adaptive Task Sharing between Humans and Cobots in Manufacturing. Procedia CIRP 2021, 104, 38–43. [Google Scholar] [CrossRef]

- ISO 10218-2:2011; Robots and Robotic Devices—Safety Requirements for Industrial Robots—Part 2: Robot Systems and Integration, Version 1. International Organization for Standardization: Geneva, Switzerland, 2011.

- ISO 10218-1:2011; Robots and Robotic Devices—Safety Requirements for Industrial Robots—Part 1: Robots, Version 2. International Organization for Standardization: Geneva, Switzerland, 2011.

- Saenz, J.; Fassi, I.; Prange-Lasonder, G.B.; Valori, M.; Bidard, C.; Lassen, A.B.; Bessler-Etten, J. COVR Toolkit—Supporting safety of interactive robotics applications. In Proceedings of the 2021 IEEE 2nd International Conference on Human-Machine Systems (ICHMS), Magdeburg, Germany, 8–10 September 2021; pp. 1–6. [Google Scholar]

- ISO/TS 15066:2016; Robots and Robotic Devices—Collaborative Robots, Version 1. International Organization for Standardization: Geneva, Switzerland, 2016.

- Pantano, M.; Blumberg, A.; Regulin, D.; Hauser, T.; Saenz, J.; Lee, D. Design of a Collaborative Modular End Effector Considering Human Values and Safety Requirements for Industrial Use Cases. In Human-Friendly Robotics 2021; Palli, G., Melchiorri, C., Meattini, R., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 45–60. ISBN 978-3-030-96358-3. [Google Scholar]

- ISO/TR 14121-2:2012; Safety of Machinery—Risk Assessment—Part 2: Practical Guidance and Examples of Methods, Version 2. International Organization for Standardization: Geneva, Switzerland, 2012.

- Brooke, J. SUS—A Quick and Dirty Usability Scale; Usability evaluation in industry; CRC Press: Boca Raton, FL, USA, 1996; ISBN 9780748404605. [Google Scholar]

- Bangor, A.; Kortum, P.T.; Miller, J.T. An Empirical Evaluation of the System Usability Scale. Int. J. Hum.-Comput. Interact. 2008, 24, 574–594. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pantano, M.; Pavlovskyi, Y.; Schulenburg, E.; Traganos, K.; Ahmadi, S.; Regulin, D.; Lee, D.; Saenz, J. Novel Approach Using Risk Analysis Component to Continuously Update Collaborative Robotics Applications in the Smart, Connected Factory Model. Appl. Sci. 2022, 12, 5639. https://doi.org/10.3390/app12115639

Pantano M, Pavlovskyi Y, Schulenburg E, Traganos K, Ahmadi S, Regulin D, Lee D, Saenz J. Novel Approach Using Risk Analysis Component to Continuously Update Collaborative Robotics Applications in the Smart, Connected Factory Model. Applied Sciences. 2022; 12(11):5639. https://doi.org/10.3390/app12115639

Chicago/Turabian StylePantano, Matteo, Yurii Pavlovskyi, Erik Schulenburg, Konstantinos Traganos, Seyedamir Ahmadi, Daniel Regulin, Dongheui Lee, and José Saenz. 2022. "Novel Approach Using Risk Analysis Component to Continuously Update Collaborative Robotics Applications in the Smart, Connected Factory Model" Applied Sciences 12, no. 11: 5639. https://doi.org/10.3390/app12115639

APA StylePantano, M., Pavlovskyi, Y., Schulenburg, E., Traganos, K., Ahmadi, S., Regulin, D., Lee, D., & Saenz, J. (2022). Novel Approach Using Risk Analysis Component to Continuously Update Collaborative Robotics Applications in the Smart, Connected Factory Model. Applied Sciences, 12(11), 5639. https://doi.org/10.3390/app12115639